Polysaccharides as Effective and Environmentally Friendly Inhibitors of Scale Deposition from Aqueous Solutions in Technological Processes

Abstract

:1. Introduction

2. Composition and Saturation of Formation and Industrial Waters

| >10,000 mg/L | Na+, Cl− |

| 100–10,000 mg/L | Ca2+, Mg2+, K+, Sr2+, Ba2+, SO42− |

| 1–100 mg/L | Al3+, Fe2+, Li+, borates, silicates, NH4+, HCO3−/CO32− |

| <1 mg/L | Zn2+, Hg°, Be2+, Co2+, Pb2+ |

3. The Main Causes of Scale Deposits Formed in Technological Processes, Their Compositions, and Their Structures

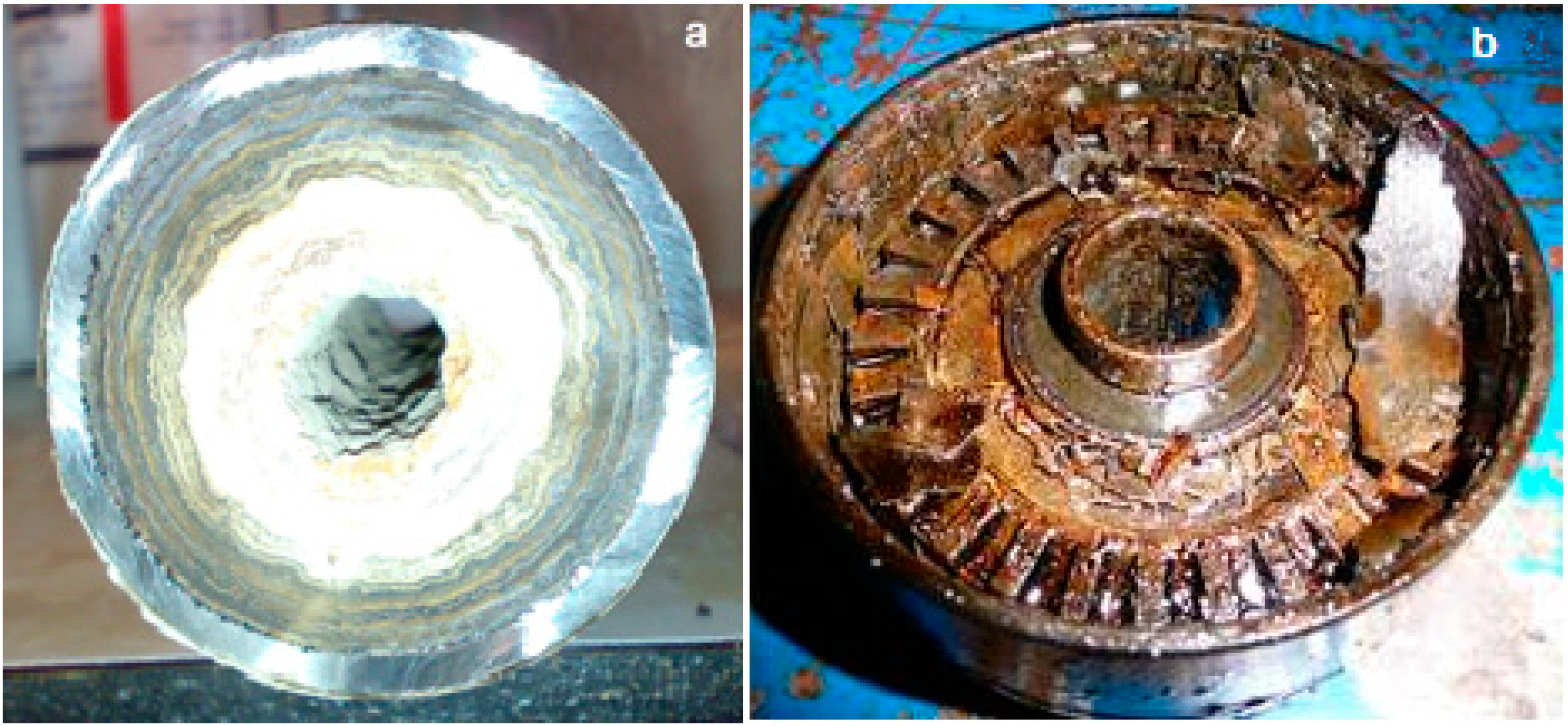

- Calcite precipitation occurs when thermobaric conditions change, mainly with a decrease in pressure and an increase in temperature. When the pressure decreases, carbon dioxide is released from the water, which leads to calcite precipitation. As a result, carbonates are deposited on the surface of pumping equipment and inside pumping and compressor pipes.

- The mixing of incompatible waters leads to scale formation. When water containing calcium, barium, and strontium cations is mixed with water (for example, with sea water) containing sulfate ions, the poorly soluble minerals barite, celestine, gypsum, and anhydrite are formed.

- 3.

- A significant factor affecting scale deposition in low-watered wells is the partial evaporation of water into the gas phase during the degassing of borehole products. In the process of water evaporation, there is a general decrease in the solubility of salts, and even salts that are well soluble under normal conditions can enter the precipitate [55,56,57].

- 4.

- One of the reasons for the intensive deposition of calcium carbonate and gypsum in pumping equipment is the increase in the temperature of the flow of extracted products due to the friction of the pump impellers and heat transfer from a working submersible electric motor. An increase in the temperature due to the flow of the extracted products, depending on the flow rate of the well, occurs by 4–15 °C, which creates conditions for scale deposition on the wheels of the ESP [58].

- 5.

- When the well is put into operation after its silencing with scale solutions, intense scale formation is also possible. The reason for scale formation in this case is the increase in the concentration of scale-forming ions, decrease in the concentration of dissolved CO2, and change in the ionic strength of the extracted aqueous solutions. Favorable conditions for sedimentation can be realized when silencing with solutions of calcium chloride or other calcium-containing solutions. Sedimentation also occurs when wells are silenced with a sodium chloride solution, although less intensely [58].

4. Scale Inhibitors

5. Mechanisms of Inhibition of Scale Formation in the Presence of Polysaccharides

6. Polysaccharides as the Basis of Scale Inhibitors

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Amjad, Z.; Koutsoukos, P.G. The Science and Technology of Industrial Water Treatment. In Mineral Scales and Deposits, 1st ed.; CRC Press: Boca Rator, FL, USA, 2010; pp. 1–20. [Google Scholar] [CrossRef]

- Jordan, M.M.; Mackey, E.J. Scale control in deepwater fields: Use interdisciplinary approach to control scale. World Oil 2005, 226, 75–80. [Google Scholar]

- Graham, G.M.; Mackay, E.J.; Dyer, S.J.; Bourne, H.M. The Challenges for Scale Control in Deepwater Production Systems: Chemical Inhibition and Placement. In Proceedings of the CORROSION 2002, Denver, CO, USA, 7–11 April 2002. NACE-02316. [Google Scholar]

- Olajire, A.A. A review of oilfield scale management technology for oil and gas production. J. Pet. Sci. Eng. 2015, 135, 723–737. [Google Scholar] [CrossRef]

- MacAdam, J.; Jarvis, P. Water-Formed Scales and Deposits: Types, Characteristics, and Relevant Industries. In Mineral Scales and Deposits; Elsevier: Amsterdam, The Netherlands, 2015; pp. 3–23. [Google Scholar] [CrossRef]

- Fink, J.K. Scale Inhibitors. In Petroleum Engineer’s Guide to Oil Field Chemicals and Fluids, 3rd ed.; Gulf Professional Publishing: Oxford, UK, 2021; pp. 351–391. [Google Scholar] [CrossRef]

- Zuhl, R.W.; Amjad, Z. Scale and Deposit Control Polymers for Industrial Water Treatment. In The Science and Technology of Industrial Water Treatment; CRC Press: Boca Rator, FL, USA, 2010; pp. 81–103. [Google Scholar] [CrossRef]

- Vazquez, O.; Herrero, P.; Mackay, E.; Jordan, M. Nonaqueous vs. aqueous overflush scale inhibitor squeeze treatment in an oilfield offshore Norway. J. Pet. Sci. Eng. 2016, 138, 1–10. [Google Scholar] [CrossRef]

- Yan, F.; Zhang, F.; Bhandari, N.; Wang, L.; Dai, Z.; Zhang, Z. Adsorption and precipitation of scale inhibitors on shale formations. J. Pet. Sci. Eng. 2015, 136, 32–40. [Google Scholar] [CrossRef]

- Heng, L.; Ming-Kai, H.; Shih-Hsiang, C.; Monnell, J.D.; Dzombak, D.A.; Vidic, R.D. Control of mineral scale deposition in cooling systems using secondary-treated municipal wastewater. Water Res. 2011, 45, 748–760. [Google Scholar] [CrossRef]

- Gabrielli, C.; Keddam, M.; Perrot, H.; Khalil, A.; Rosset, R.; Zidoune, M. Characterization of the efficiency of antiscale treatments of water. Part I: Chemical processes. J. Appl. Electrochem. 1996, 26, 1125–1132. [Google Scholar] [CrossRef]

- Hoang, T.A. Mechanisms of Scale Formation and Inhibition. In Mineral Scales and Deposits; Elsevier: Amsterdam, The Netherlands, 2015; pp. 48–83. [Google Scholar] [CrossRef]

- Ishmuratov, F.G.; Koptyaeva, E.I.; Voloshin, A.I.; Telin, A.G.; Tomilov, Y.V.; Nifant’ev, N.E.; Dokichev, V.A. Arabinogalactan as Effective Inhibitor of Calcium Carbonate Scaling. Russ. J. Appl. Chem. 2015, 88, 1920–1922. [Google Scholar] [CrossRef]

- Ismail, N.; Alshami, A.S.; Hussein, I.A. Synthesis and evaluation of a novel polyacrylamide functionalized nano-silica as a calcium carbonate inhibitor in upstream applications. J. Pet. Sci. Eng. 2022, 209, 109864. [Google Scholar] [CrossRef]

- Li, J.; Tang, M.-J.; Ye, Z.; Cheng, L.; Zhou, Y. Scale formation and control in oil and gas fields: A review. J. Dispers. Sci. Technol. 2017, 38, 661–670. [Google Scholar] [CrossRef]

- Fakhreeva, A.V.; Voloshin, A.I.; Telin, A.G.; Magadova, L.A.; Spirikhin, L.V.; Dokichev, V.A. Inhibitors based on new polysaccharides in technological processes of oil production. Efficiency of inhibition of scale formation and influence on stability of water-oil emulsion. IOP Conf. Ser. Mater. Sci. Eng. 2020, 848, 012018. [Google Scholar] [CrossRef]

- Kelland, M.A. Scale Controle. In Production Chemicals for the Oil and Gas Industry, 2nd ed.; CRC Press: Boca Rator, FL, USA, 2014; pp. 51–110. [Google Scholar] [CrossRef]

- Woods, H.A.; Moran, A.L.; Atkinson, D.; Audzijonyte, A.; Berenbrink, M.; Borges, F.O.; Burnett, K.G.; Burnett, L.E.; Coates, C.J.; Collin, R.; et al. Integrative Approaches to Understanding Organismal Responses to Aquatic Deoxygenation. Biol. Bull. 2022, 243, 85–103. [Google Scholar] [CrossRef]

- Grillo, C.A.; Mirífico, M.V.; Morales, M.L.; Reigosa, M.A.; de Mele, M.F.L. Assessment of Cytotoxic and Cytogenetic Effects of a 1,2,5-Thiadiazole Derivative on CHO-K1 Cells. Its Application as Corrosion Inhibitor. J. Hazard. Mater. 2009, 170, 1173–1178. [Google Scholar] [CrossRef]

- Darling, D.; Rakshpal, R. Green chemistry applied to corrosion and scale inhibitors. Mater. Perform. 1998, 37, 42–45. [Google Scholar]

- Mazumder, M.A.J. A Review of Green Scale Inhibitors: Process, Types, Mechanism and Properties. Coatings 2020, 10, 928. [Google Scholar] [CrossRef]

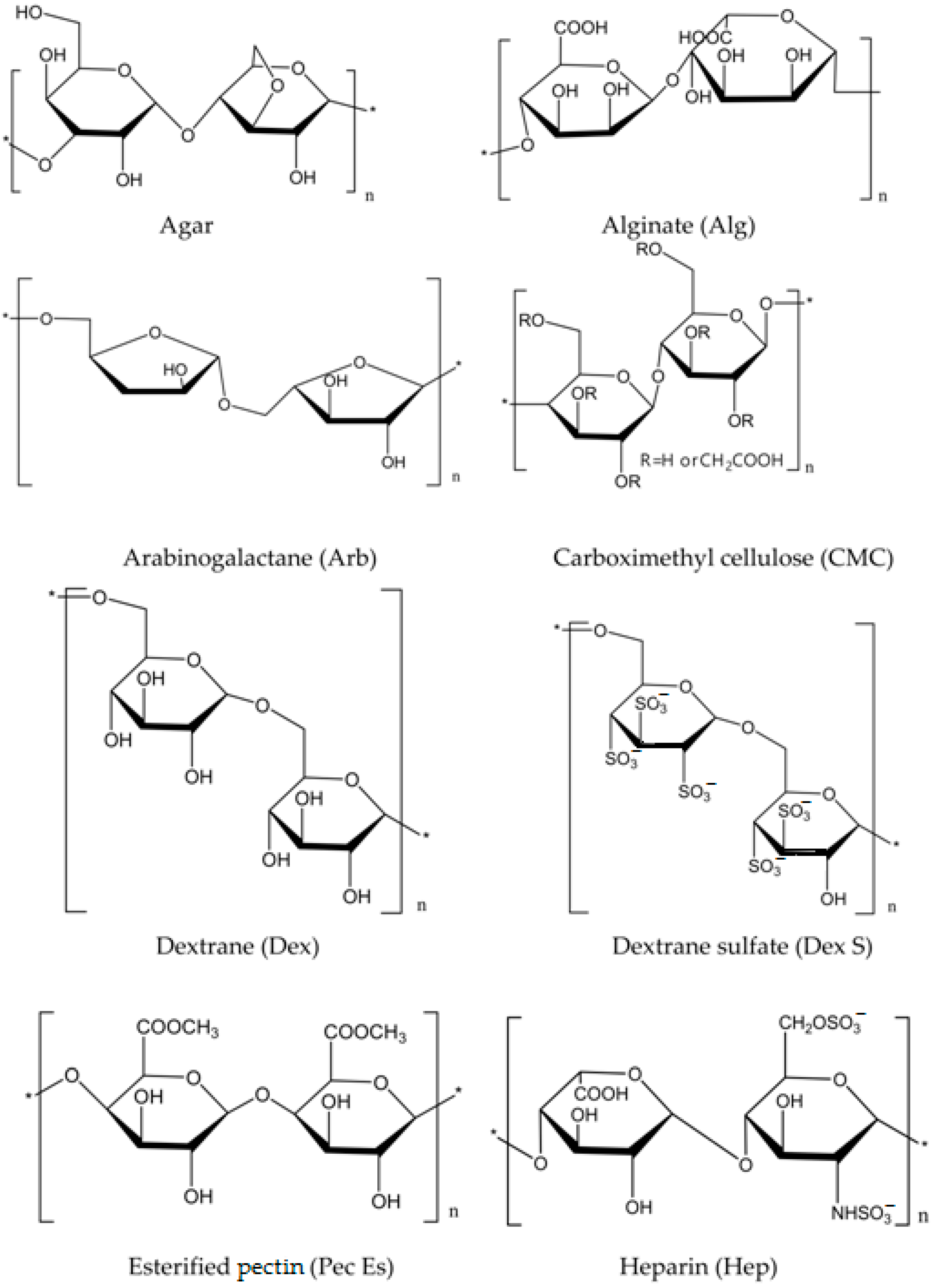

- Arias, J.L.; Fernandez, M.S. Polysaccharides and proteoglycans in calcium carbonate based biomineralization. Chem. Rev. 2008, 108, 4475–4482. [Google Scholar] [CrossRef]

- Rao, A.; Berg, J.K.; Kellermeier, M.; Gebauer, D. Sweet on biomineralization effects of carbohydrates on the early stages of calcium carbonate crystallization. Eur. J. Mineral. 2014, 26, 537–552. [Google Scholar] [CrossRef]

- Kontrec, J.; Kralj, D.; Breþeviü, L.; Falini, G. Influence of some polysaccharides on the production of calcium carbonate filler particles. J. Cryst. Growth 2008, 310, 4554–4560. [Google Scholar] [CrossRef]

- Derakhshanian, V.; Banerjee, S. Cyclodextrin inhibits calcium carbonate crystallization and scaling. Ind. Eng. Chem. Res. 2012, 51, 4463–4465. [Google Scholar] [CrossRef]

- Kirboga, S.; Öner, M. The inhibitory effects of carboxymethyl inulin on the seeded growth of calcium carbonate. Colloids Surf. B Biointerfaces 2012, 91, 18–25. [Google Scholar] [CrossRef] [PubMed]

- Fakhreeva, A.V.; Voloshin, A.I.; Musin, F.F.; Telin, A.G.; Dokichev, V.A. Carboxymethylcellulose sodium salt—Effective “green” regent for management of calcium carbonate crystallization and natural gas hydrate formation. IOP Conf. Ser. Mater. Sci. Eng. 2019, 525, 012050. [Google Scholar] [CrossRef] [Green Version]

- Dokichev, V.A.; Koptyaeva, E.I.; Ishmuratov, F.G.; Alimbekova, S.R.; Tomilov, Y.V.; Nifant’yev, N.E. Carbohydrates—A new class of ‘‘green’’ scale inhibitors. Oil Ind. 2016, 5, 92–94. [Google Scholar]

- Gill, J.S. Development of scale inhibitors. In Proceedings of the CORROSION 96, Denver, CO, USA, 25–29 March 1996. NACE 96229. [Google Scholar]

- McCafferty, R. Improvement to Prevent Incrustations in Stream-Boilers. U.S. Patent 17046, 14 April 1857. [Google Scholar]

- Belarbi, Z.; Gamby, J.; Makhloufi, L.; Sotta, B.; Tribollet, B. Inhibition of calcium carbonate precipitation by aqueous extract of Paronychia argentea. J. Cryst. Growth 2014, 386, 208–214. [Google Scholar] [CrossRef] [Green Version]

- Horner, O.; Cheap-Charpentier, H.; Cachet, X.; Perrot, H.; Lédion, J.; Gelus, D.; Pécoul, N.; Litaudon, M.; Roussi, F. Antiscalant properties of Herniaria glabra aqueous solution. Desalination 2017, 409, 157–162. [Google Scholar] [CrossRef]

- Chaussemier, M.; Pourmohtasham, E.; Gelus, D.; Pécoul, N.; Perrot, H.; Lédion, J.; Cheap-Charpentier, H.; Horner, O. State of art of natural inhibitors of calcium carbonate scaling. A review article. Desalination 2015, 356, 47–55. [Google Scholar] [CrossRef]

- Akstinat, M. Chemical and physicochemical properties of formation waters of the oil and gas industry. J. Hydrol. 2019, 578, 124011. [Google Scholar] [CrossRef]

- Hannigan, R.E.; Genest, D.M.; Robinson, W.E. Chemistry of Natural Waters. In Green Chemistry an Inclusive Approach; University of Massachusetts Boston: Boston, MA, USA, 2018. [Google Scholar] [CrossRef]

- Kraynov, S.R.; Ryzhenko, B.N.; Shvets, V.M. Geochemistry of Ground Water. In Theoretical, Applied and Environmental Aspects; Nauka: Moskow, Russia, 2004. [Google Scholar]

- Barthel, J.; Krienke, H.; Neueder, R.; Holovko, M. The role of ion-aggregate formation in the calculation of physical properties of electrolyte solutions. Fluid Phase Equilibria 2002, 194, 107–122. [Google Scholar] [CrossRef]

- Sverjensky, D.A.; Shock, E.L.; Helgeson, H.C. Prediction of the thermodynamic properties of aqueous metal complexes to 1000 °C and 5 kb. Geochim. Cosmochim. Acta 1997, 61, 1359–1412. [Google Scholar] [CrossRef]

- Ni, Y.; Liao, F.; Chen, J.; Yao, L.; Wei, J.; Sui, J.; Gao, J.; Coyte, R.M.; Lauer, N.; Vengosh, A. Multiple geochemical and isotopic (Boron, Strontium, Carbon) indicators for reconstruction of the origin and evolution of oilfield water from Jiuquan Basin, Northwestern China. Appl. Geochem. 2021, 130, 104962. [Google Scholar] [CrossRef]

- Lummer, N.R.; Willert, T. Innovative Fluid System for Dissolving Lead Scales—Fluid Development and Field Trial in a Geothermal Well. In Proceedings of the European Geothermal Congress, Den Haag, The Netherlands, 11–14 June 2019. [Google Scholar]

- Israelachvili, J.N. Intermolecular and Surface Forces; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar] [CrossRef]

- Wallace, A.F.; Hedges, L.O.; Fernandez-Martinez, A.; Raiteri, P.; Gale, J.D.; Waychunas, G.A.; Whitelam, S.; Banfield, J.F.; de Yoreo, J.J. Microscopic Evidence for Liquid-Liquid Separation in Supersaturated CaCO3 Solutions. Science 2013, 341, 885–889. [Google Scholar] [CrossRef] [Green Version]

- Bin Merdhah, A.B.; Yassin, A.M. Formation damage due to scale formation in porous media resulting water injection. Emir. J. Eng. Res. 2008, 13, 69–79. [Google Scholar]

- Jing, G.; Tang, S.; Li, X.; Wang, H. The analysis of scaling mechanism for water-injection pipe columns in the Daqing Oilfield. Arab. J. Chem. 2017, 10, S1235–S1239. [Google Scholar] [CrossRef] [Green Version]

- El-Said, M.; Ramzi, M.; Abdel-Moghny, T. Analysis of oilfield waters by ion chromatography to determine the composition of scale deposition. Desalination 2009, 249, 748–756. [Google Scholar] [CrossRef]

- Bazin, B.; Brosse, E.; Sommer, F. Chemistry of oil-field brines in relation to diagenesis of reservoirs 1. Use of mineral stability fields to reconstruct in situ water composition, Example of the Mahakam basin. Mar. Pet. Geol. 1997, 14, 481–495. [Google Scholar] [CrossRef]

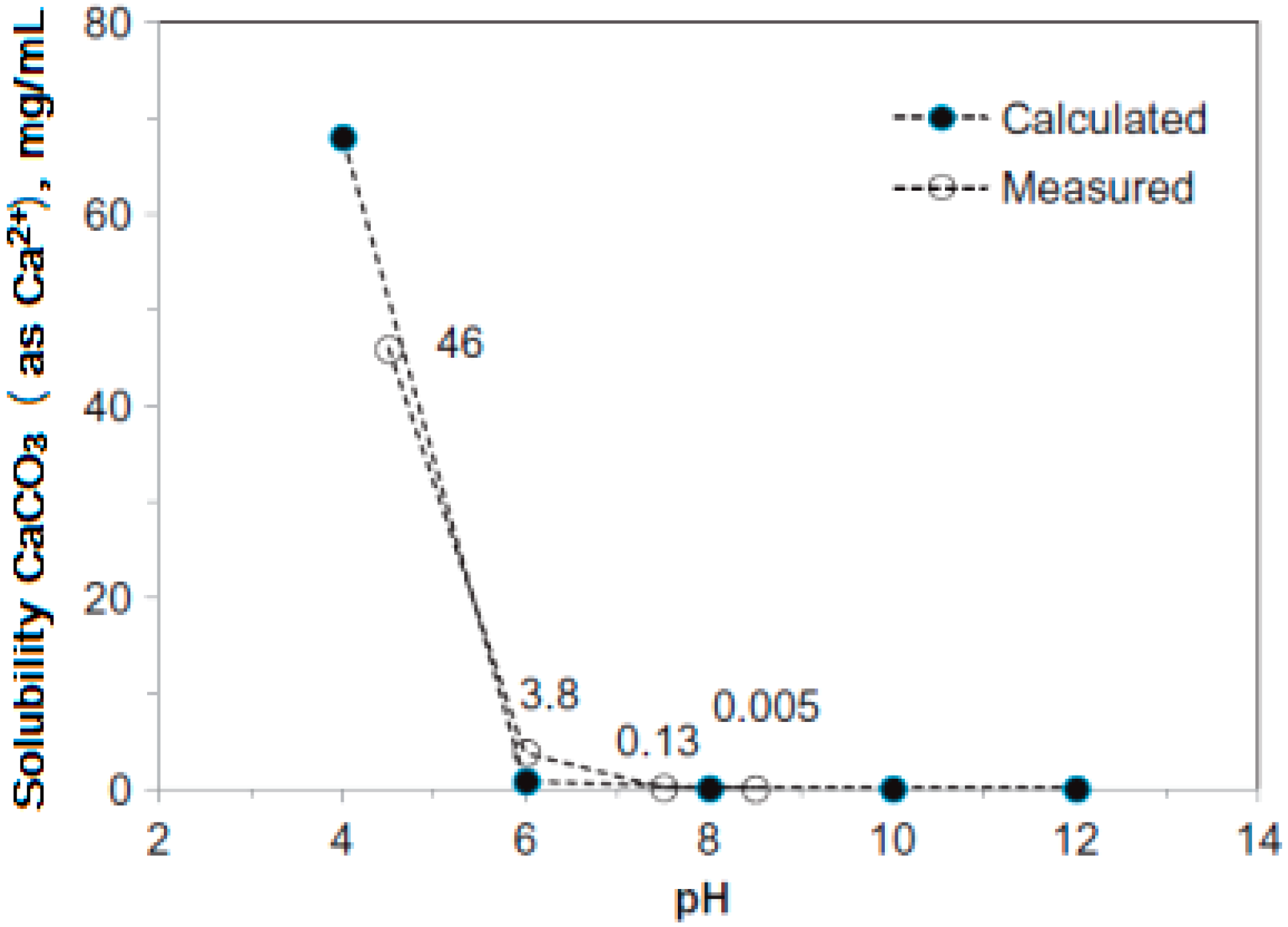

- Plummer, L.; Busenberg, N.E. The solubilities of calcite, aragonite and vaterite in CO2–H2O solutions between 0 and 90 °C, and an evaluation of the aqueous model for the system CaCO3–CO2–H2O. Geochim. Cosmochim. Acta 1982, 46, 1011–1040. [Google Scholar] [CrossRef]

- Sincero, A.P.; Sincero, G.A. Water stabilization. In Physical–Chemical Treatment of Water and Wastewater; IWA Publisher and CRC Press: London, UK, 2002. [Google Scholar] [CrossRef]

- Gal, J.-Y.; Bollinger, J.-C.; Tolosa, H.; Gache, N. Calcium carbonate solubility: A reappraisal of scale formation and inhibition. Talanta 1996, 43, 1497–1509. [Google Scholar] [CrossRef]

- Coto, B.; Martos, C.; Peña Díez, J.L.; Rodríguez, R.; Pastor, G. Effects in the solubility of CaCO3: Experimental study and model description. Fluid Phase Equilibria 2012, 324, 1–7. [Google Scholar] [CrossRef]

- Al Omari, M.M.H.; Rashid, I.S.; Qinna, N.A.; Jaber, A.M.; Badwan, A.A. Calcium Carbonate. In Profiles of Drug Substances, Excipients and Related Methodology; Brittain, H.G., Ed.; Academic Press: Burlington, VT, USA, 2016; Volume 41, pp. 31–132. [Google Scholar] [CrossRef]

- Mohamed, A.S.; Alian, S.S.; Singh, J.; Singh, R.; Goyal, A.; Munainni, G. Remediation of Well Impaired by Complex Organic Deposits Embedded with Naphthenate and Contaminated with Inorganics. In Proceedings of the Offshore Technology Conference Asia, Kuala Lumpur, Malaysia, 22–25 March 2016. OTC-26524. [Google Scholar] [CrossRef]

- Mann, S.; Cőlten, H. Higher-Order Organization by Mesoscale Self-Assembly and Transformation of Hybrid Nanostructures. Angew. Chem. Int. Ed. 2003, 42, 2350–2365. [Google Scholar] [CrossRef] [Green Version]

- Kleinitz, W.; Dietzsch, G.; Köhler, M. Halite Scale Formation in Gas-Producing Wells. Chem. Eng. Res. Des. 2003, 81, 352–358. [Google Scholar] [CrossRef]

- Ruan, G.; Liu, Y.; Kan, A.T.; Tomson, M.B.; Zhang, P. Sodium chloride (halite) mineral scale threat assessment and scale inhibitor evaluation by two common jar test based methods. J. Water Process Eng. 2021, 43, 102241. [Google Scholar] [CrossRef]

- Wylde, J.J.; Slayer, J.L. Halite Scale Formation Mechanisms, Removal and Control: A Global Overview of Mechanical, Process and Chemical Strategies. In Proceedings of the SPE International Symposium on Oilfield Chemistry, The Woodlands, TX, USA, 8–10 April 2013. SPE-164081. [Google Scholar] [CrossRef]

- Zhang, Y.; Isaj, E. Halite Envelope for Downhole Salt Deposition Prediction and Management. In Proceedings of the SPE European Formation Damage Conference and Exhibition, Budapest, Hungary, 3–5 June 2015. [Google Scholar] [CrossRef]

- Voloshin, A.; Ragulin, V.; Neviadovskyi, E.; Ganiev, I. Technical and Economic Strategy in the Scale Deposition Management is an Important Factor in Enhancement the Efficiency of Oil Production. In Proceedings of the SPE Russian Oil and Gas Conference and Exhibition, Moscow, Russia, 26–28 October 2010. SPE-138066. [Google Scholar] [CrossRef]

- Barker, R.; Burkle, D.; Charpentier, T.; Thompson, H.; Nevill, A. A review of iron carbonate (FeCO3) formation in the oil and gas industry. Corros. Sci. 2018, 58, 226–234. [Google Scholar] [CrossRef]

- Morse, J.W.; Arvidson, R.S.; Lüttge, A. Calcium carbonate formation and dissolution. Chem. Rev. 2007, 107, 342–381. [Google Scholar] [CrossRef]

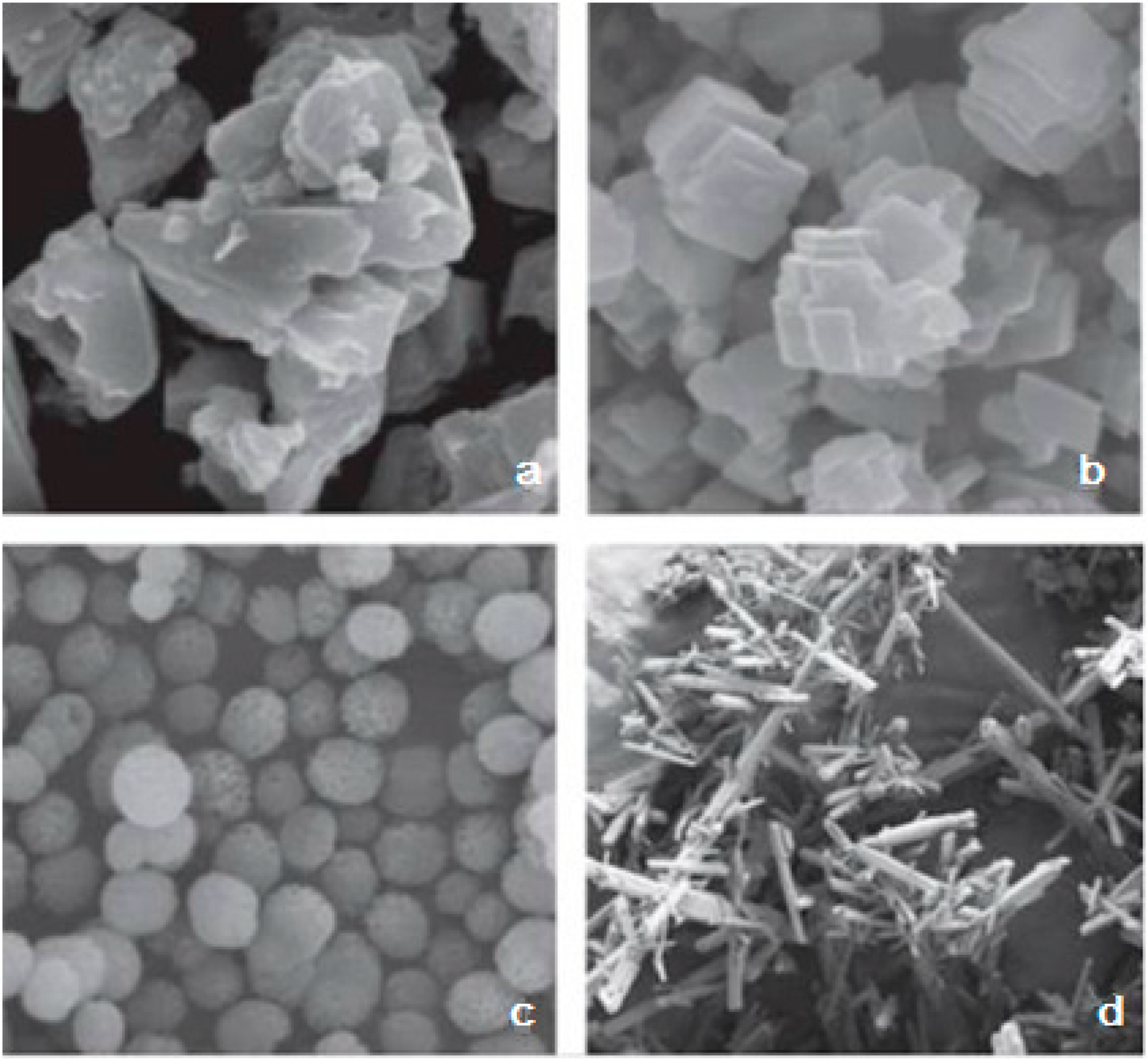

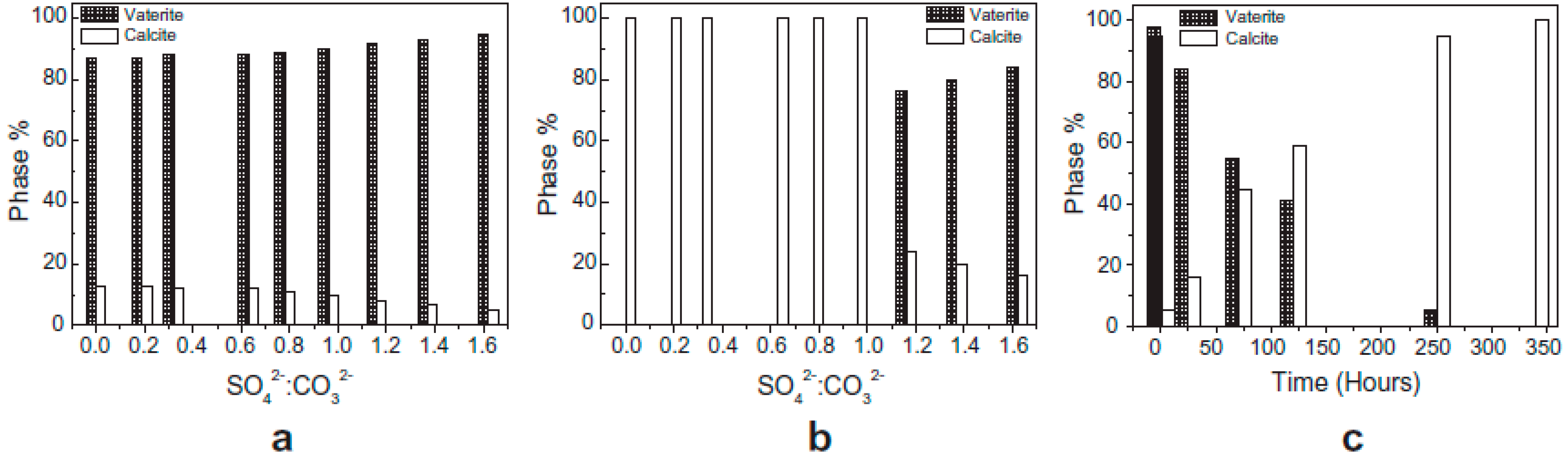

- Wagterveld, R.M.; Miedema, M.; Yu, H.; Witkamp, G.J. Polymorphic change from vaterite to aragonite under influence of sulfate: The “morning star” habit. J. Cryst. Growth 2014, 387, 29–35. [Google Scholar] [CrossRef]

- Gopi, S.; Subramanian, V.K.; Palanisamy, K. Aragonite–calcite–vaterite: A temperature influenced sequential polymorphic transformation of CaCO3 in the presence of DTPA. Mater. Res. Bull. 2013, 48, 1906–1912. [Google Scholar] [CrossRef]

- Sawada, K. The mechanisms of crystallization and transformation of calcium carbonates. Pure Appl. Chem. 1997, 69, 921–928. [Google Scholar] [CrossRef]

- Shestak, I.V.; Vorobiev, A.D.; Cherednichenko, D.V.; Vorobyova, E.V.; Laevskaya, E.V.; Astakhova, M.A. Inhibition of Calcium and Magnesium Carbonate Crystallization with Sodium Polyacrylate. Proc. Natl. Acad. Sci. Belarus Chem. Ser. 2019, 55, 377–384. [Google Scholar] [CrossRef]

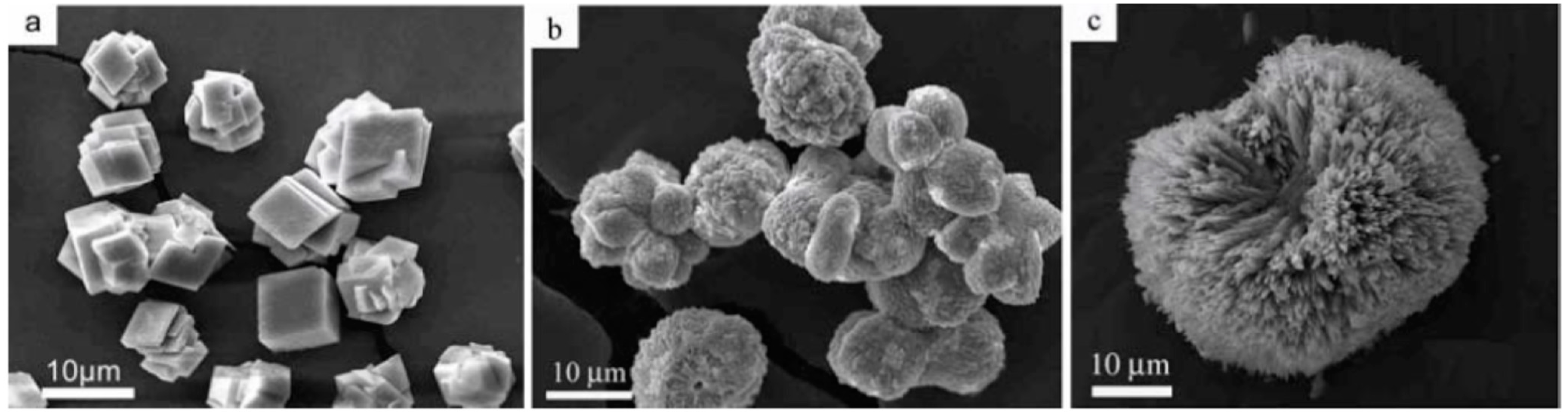

- Tang, H.; Yu, J.; Zhao, X.; Ng, H.L.D. Creation of calcite hollow microspheres with attached bundles of aragonite needles. Cryst. Res. Technol. 2008, 43, 473–478. [Google Scholar] [CrossRef]

- Fernandez-Dıaz, L.; Fernandez-Gonzalez, A.; Prieto, M. The role of sulfate groups in controlling CaCO3 polymorphism. Geochim. Cosmochim. Acta 2010, 74, 6064–6076. [Google Scholar] [CrossRef] [Green Version]

- Song, R.; Cölfen, H. Additive controlled crystallization. CrystEngComm 2011, 13, 1249–1276. [Google Scholar] [CrossRef]

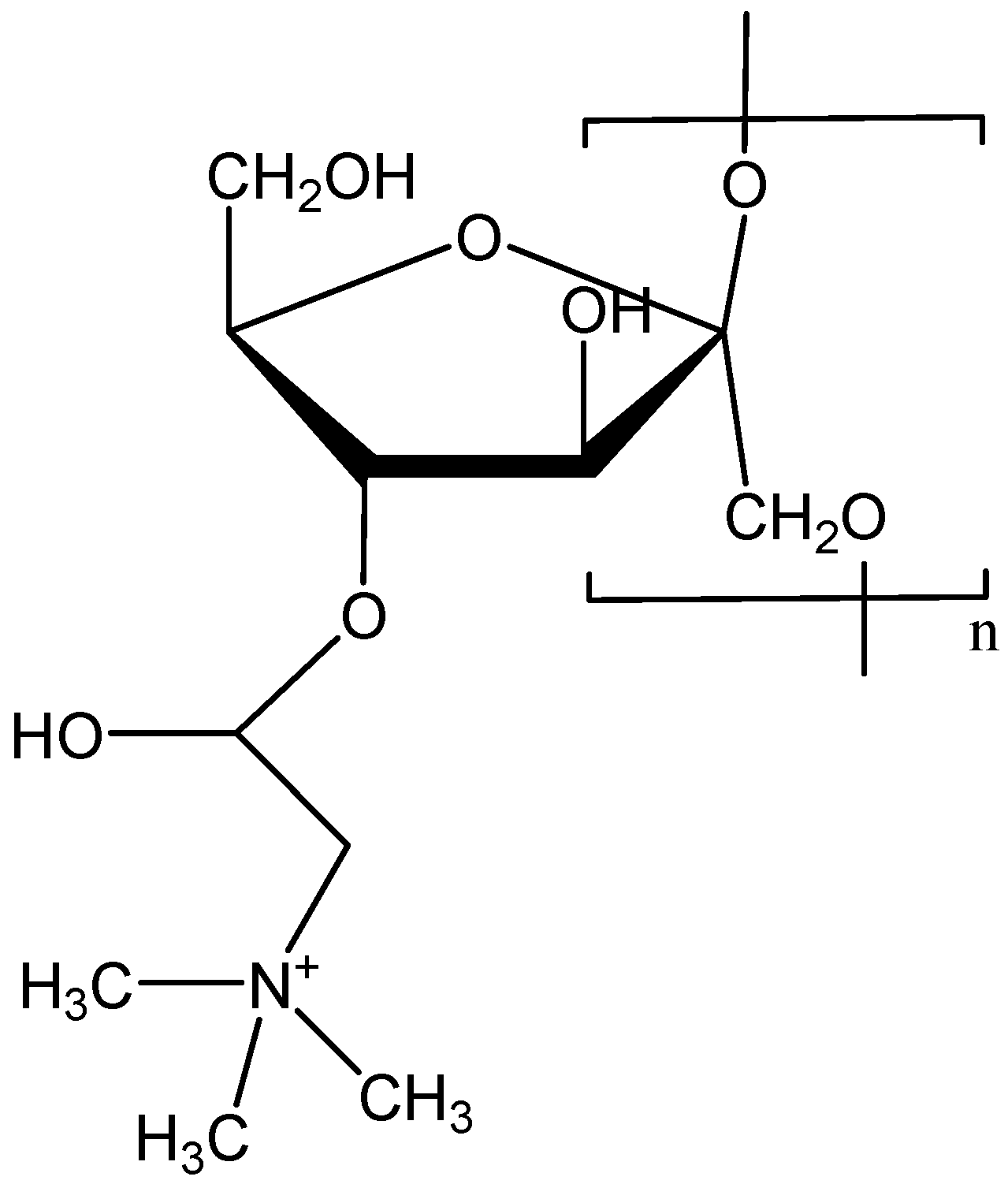

- Cantaert, B.; Kim, Y.Y.; Ludwig, H.; Nudelman, F.; Sommerdijk, N.A.; Meldrum, F.C. Think positive: Phase separation enables a positively charged additive to induce dramatic changes in calcium carbonate morphology. Adv. Funct. Mater. 2012, 22, 907–915. [Google Scholar] [CrossRef]

- Meldrum, F.C.; Colfen, H. Controlling mineral morphologies and structures in biological and synthetic systems. Chem. Rev. 2008, 108, 4332–4432. [Google Scholar] [CrossRef]

- Lam, R.S.; Charnock, J.M.; Lenniem, A.; Meldrum, F.C. Synthesis dependant structural variations in amorphous calcium carbonate. CrystEngComm 2007, 9, 1226–1236. [Google Scholar] [CrossRef]

- Studart, A.R.; Amstad, E.; Gauckler, L.J. Colloidal stabilization of nanoparticles in concentrated suspensions. Langmuir 2007, 23, 1081–1090. [Google Scholar] [CrossRef] [PubMed]

- Sangwal, K. Additives and Crystallization Processes: From Fundamentals to Applications; JWS: Hoboken, NJ, USA, 2007. [Google Scholar] [CrossRef]

- Berkovitch-Yellin, Z.; van Mil, J.; Addadi, L.; Idelson, M.; Lahav, M.; Leiserowitz, L. Crystal morphology engineering by “tailor-made” inhibitors; a new probe to fine intermolecular interactions. J. Am. Chem. Soc. 1985, 107, 3111–3122. [Google Scholar] [CrossRef]

- Shtukenberg, A.G.; Ward, M.D.; Kahr, B. Crystal Growth with Macromolecular Additives. Chem. Rev. 2017, 117, 14042–14090. [Google Scholar] [CrossRef]

- Gebauer, D. How can additives control the early stages of mineralisation? Minerals 2018, 8, 179. [Google Scholar] [CrossRef] [Green Version]

- Nicoleau, L.; Van Driessche, A.E.; Kellermeier, M. A kinetic analysis of the role of polymers in mineral nucleation. The example of gypsum. Cem. Concr. Res. 2019, 124, 105837. [Google Scholar] [CrossRef]

- Liang, P.; Zhao, Y.; Shen, Q.; Wang, D.; Xu, D. The effect of carboxymethyl chitosan on the precipitation of calcium carbonate. J. Cryst. Growth 2004, 261, 571–576. [Google Scholar] [CrossRef]

- Rodriguez-Navarro, C.; Benning, L.G. Control of crystal nucleation and growth by additives. Elements 2013, 9, 203–209. [Google Scholar] [CrossRef]

- Zhang, P.; Kan, A.T.; Tomson, M.B. Oil Field Mineral Scale Control. In Mineral Scales and Deposits; CRC Press: Boca Rator, FL, USA, 2015. [Google Scholar]

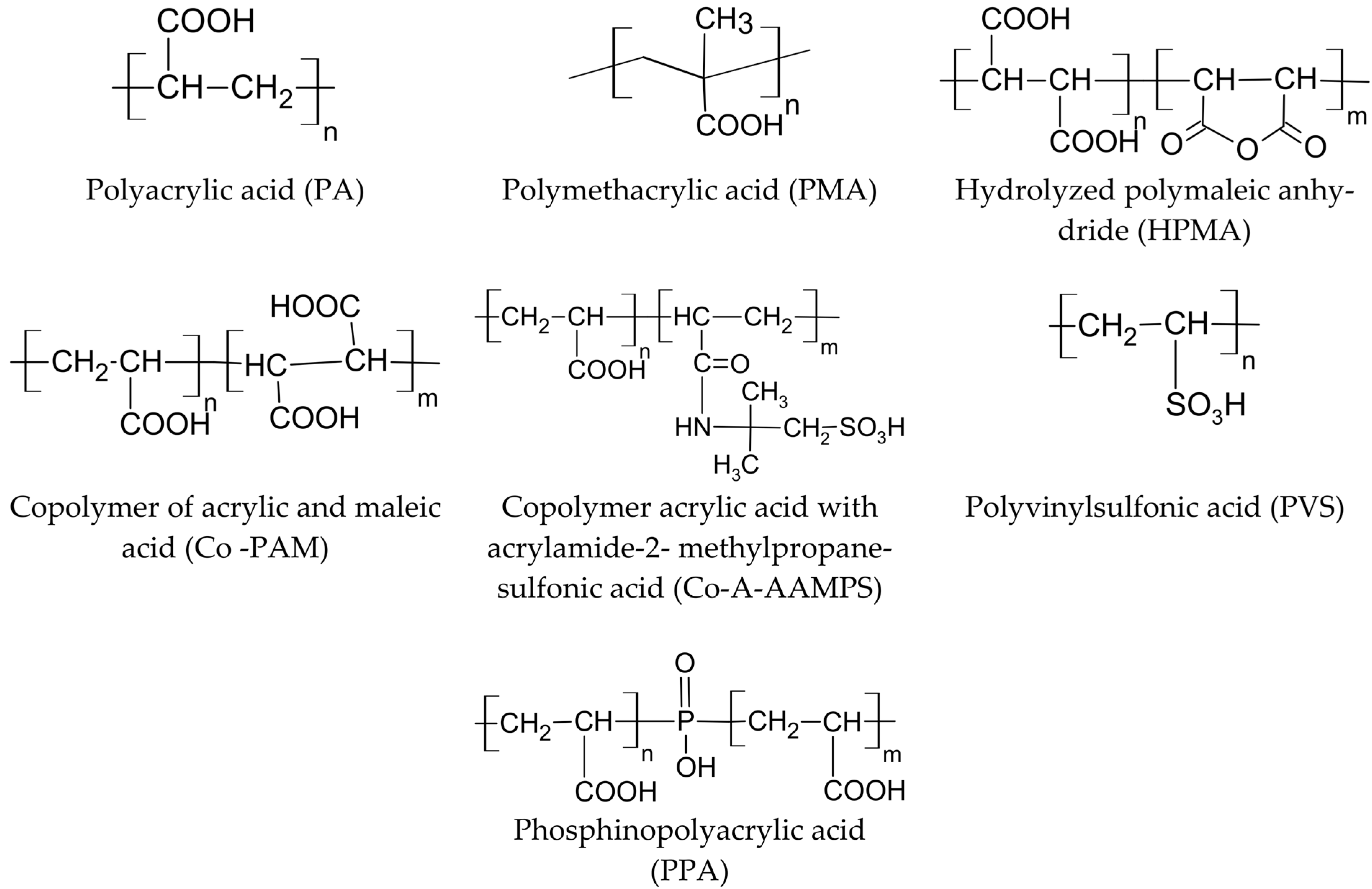

- Spinthaki, A.; Demadis, K.D. Chemical Methods for Scaling Control. In Corrosion and Fouling Control in Desalination Industry; Saji, V.S., Meroufel, A.A., Sorour, A.A., Eds.; Springer: New York, NY, USA; Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Sevrain, C.M.; Berchel, M.; Couthon, H.; Jaffrès, P.-A. Phosphonic acid: Preparation and applications. Beilstein J. Org. Chem. 2017, 13, 2186–2213. [Google Scholar] [CrossRef] [PubMed]

- Deluchat, V.; Serpaud, B.; Alves, E.; Caullet, C.; Bollinger, J.-C. Protonation and complexation constants of phosphonic acids with cations of environmental interest. Phosphorus Sulfur Silicon Relat. Elem. 1996, 109, 209–212. [Google Scholar] [CrossRef]

- Jain, T.; Sanchez, E.; Owens-Bennett, E.; Trussell, R.; Walker, S.; Liu, H. Impacts of antiscalantson the formation of calcium solids: Implication on scaling potential of desalination concentrate. Environ. Sci. Water Res. Technol. 2019, 5, 1285–1294. [Google Scholar] [CrossRef]

- Wada, N.; Yamashita, K.; Umegaki, T. Effects of carboxylic acids on calcite formation in thepresence of Mg2+ ions. J. Colloid Interface Sci. 1999, 212, 357–364. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Zhou, Y.; Yao, Q.; Bu, Y.; Wang, H.; Wu, W.; Sun, W. Preparation of a low-phosphorous terpolymer as a scale, corrosion inhibitor, and dispersant for ferric oxide. J. Appl. Polym. Sci. 2015, 132, 41447. [Google Scholar] [CrossRef]

- Ahmed, S.B.; Tlili, M.M.; Amor, M.B. Influence of a polyacrylate antiscalant on gypsum nucleation and growth. Cryst. Res. Technol. 2008, 43, 935–942. [Google Scholar] [CrossRef]

- Carvalho, S.P.; Palermo, L.C.M.; Boak, L.; Sorbie, K.; Lucas, E.F. The influence of terpolymer based on amide, carboxylic and sulfonic groups on the barium sulphate inhibition. Energy Fuels 2017, 31, 10648–10654. [Google Scholar] [CrossRef]

- Amjad, Z.; Koutsoukos, P.G. Evaluation of maleic acid based polymers as scale inhibitors and dispersants for industrial water applications. Desalination 2014, 335, 55–63. [Google Scholar] [CrossRef]

- Senthilmurugan, B.; Ghosh, B.; Kundu, S.; Haroun, M.; Kameshwari, B. Maleic acid based scale inhibitors for calcium sulfate scale inhibition in high temperature application. J. Petr. Sci. Eng. 2010, 75, 189–195. [Google Scholar] [CrossRef]

- Annenkov, V.V.; Danilovtseva, E.N.; Filina, E.A.; Likhoshway, Y.V. Interaction of silicic acid with poly(1-vinylimidazole). J Polym. Sci. A Polym. Chem. 2006, 44, 820–827. [Google Scholar] [CrossRef] [Green Version]

- Neofotistou, E.; Demadis, K.D. Silica scale inhibition by polyaminoamide STARBURST® dendrimers. Colloids Surf. A Physicochem. Eng. Asp. 2004, 242, 213–216. [Google Scholar] [CrossRef]

- Demadis, K.D. A structure/function study of polyaminoamide dendrimers as silica scale growth inhibitors. J. Chem. Technol. Biotechnol. 2005, 80, 630–640. [Google Scholar] [CrossRef]

- Demadis, K.D.; Neofotistou, E. Synergistic effects of combinations of cationic polyaminoamide dendrimers/anionic polyelectrolytes on amorphous silica formation: A bioinspired approach. Chem. Mater. 2007, 19, 581–587. [Google Scholar] [CrossRef]

- Sun, Y.; Yin, X.; Chen, Z.; Yang, W.; Chen, Y.; Liu, Y.; Zuo, Y.; Li, L. Use of polyaminoamide dendrimers starting from different core-initial molecules for inhibition of silica scale: Experiment and theory. Colloids Surf. A Physicochem. Eng. Asp. 2021, 613, 126095. [Google Scholar] [CrossRef]

- Stathoulopoulou, A.; Demadis, K.D. Enhancement of silicate solubility by use of “green” additives: Linking green chemistry and chemical water treatment. Desalination 2008, 224, 223–230. [Google Scholar] [CrossRef]

- Demadis, K.D.; Stathoulopoulou, A. Multifunctional, Environmentally Friendly Additives for Control of Inorganic Foulants in Industrial Water and Process Applications. Mater. Perform. 2006, 45, 40–44. [Google Scholar]

- Demadis, K.D.; Stathoulopoulou, A. Solubility enhancement of silicate with polyamine/polyammonium cationic macromolecules: Relevance to silica-laden process waters. Ind. Eng. Chem. Res. 2006, 45, 4436–4440. [Google Scholar] [CrossRef]

- Ketsetzi, A.; Stathoulopoulou, A.; Demadis, K.D. Being “green” in chemical water treatment technologies: Issues, challenges and developments. Desalination 2008, 223, 487–493. [Google Scholar] [CrossRef]

- Spinde, K.; Pachis, K.; Antonakaki, I.; Brunner, E.; Demadis, K.D. Influence of polyamines and related macromolecules on silicic acid polycondensation: Relevance to “soluble silicon pools”? Chem. Mater. 2011, 23, 4676–4687. [Google Scholar] [CrossRef]

- Preari, M.; Spinde, K.; Lazic, J.; Brunner, E.; Demadis, K.D. Bioinspired insights into silicic acid stabilization mechanisms: The dominant role of polyethylene glycol-induced hydrogen bonding. J. Am. Chem. Soc. 2014, 136, 4236–4244. [Google Scholar] [CrossRef]

- Neofotistou, E.; Demadis, K.D. Use of antiscalants for mitigation of silica (SiO2) fouling and deposition: Fundamentals and applications in desalination systems. Desalination 2004, 167, 257–272. [Google Scholar] [CrossRef]

- Skordalou, G.; Korey, M.; Youngblood, J.P.; Demadis, K.D. Pleiotropic action of pH-responsive poly(pyridine/PEG) copolymers in the stabilization of silicic acid or the enhancement of its polycondensation. React. Funct. Polym. 2020, 157, 104775. [Google Scholar] [CrossRef]

- Öner, M.; Uysal, U. Synthesis of hydroxyapatite crystals using carboxymethyl inulin for use as a delivery of ibuprofen. Mater. Sci. Eng. C 2013, 33, 482–489. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Luo, X.; Lin, X.; Tang, P.; Lu, X.; Yang, M.; Tang, Y. Biodegradable carboxymethyl inulin as a scale inhibitor for calcite crystal growth: Molecular level understanding. Desalination 2016, 381, 1–7. [Google Scholar] [CrossRef]

- Demadis, K.; Léonard, I. Green Polymeric Additives for Calcium Oxalate Control in Industrial Water and Process Applications. Mater. Perform. 2011, 50, 40–44. [Google Scholar]

- Boels, L.; Witkamp, G.-J. Carboxymethyl Inulin Biopolymers: A Green Alternative for Phosphonate Calcium Carbonate Growth Inhibitors. Cryst. Growth Des. 2011, 11, 4155–4165. [Google Scholar] [CrossRef]

- Zhao, Y.; Xu, Z.; Wang, B.; He, J. Scale inhibition performance of sodium carboxymethyl cellulose on heat transfer surface at various temperatures: Experiments and molecular dynamics simulation. Int. J. Heat Mass Transf. 2019, 141, 457–463. [Google Scholar] [CrossRef]

- Xu, Z.; Zhao, Y.; Wang, J.; Chang, H. Inhibition of calcium carbonate fouling on heat transfer surface using sodium carboxymethyl cellulose. Appl. Therm. Eng. 2019, 148, 1074–1080. [Google Scholar] [CrossRef]

- Xu, Z.; Zhao, Y.; He, J.; Qu, H.; Wang, Y.; Wang, B. Fouling characterization of calcium carbonate on heat transfer surfaces with sodium carboxymethyl cellulose as an inhibitor. Int. J. Therm. Sci. 2021, 162, 106790. [Google Scholar] [CrossRef]

- Fakhreeva, A.V.; Gusakov, V.N.; Voloshin, A.I.; Tomilov, Y.V.; Nifant’ev, N.E.; Dokichev, V.A. Effect of sodium-carboxymethylcellulose on inhibition of scaling by calcium carbonate and sulfate. Russ. J. Appl. Chem. 2016, 89, 1955–1959. [Google Scholar] [CrossRef]

- Yu, W.; Yang, H. Chain architectures of various cellulose-based antiscalants on the inhibition of calcium carbonate scale. Sci. Rep. 2020, 10, 21906. [Google Scholar] [CrossRef]

- Demadis, K.D.; Öner, M. Inhibitory effects of “green” additives on the crystal growth of sparingly soluble scale. In Green Chemistry Research Trends; Pearlman, J.T., Ed.; Nova Science Publishers: New York, NY, USA, 2009; pp. 265–287. [Google Scholar]

- Hood, M.A.; Landfester, K.; Muñoz-Espí, R. Chitosan nanoparticles affect polymorph selection in crystallization of calcium carbonate. Colloids Surf. A Physicochem. Eng. Asp. 2018, 540, 48–52. [Google Scholar] [CrossRef]

- Macedo, R.G.M.D.A.; Marques, N.D.N.; Paulucci, L.C.S.; Cunha, J.V.M.; Villetti, M.A.; Castro, B.B.; Balaban, R.D.C. Water-soluble carboxymethylchitosan as green scale inhibitor in oil wells. Carbohydr. Polym. 2019, 215, 137–142. [Google Scholar] [CrossRef] [PubMed]

- Ozaki, N.; Sakuda, S.; Nagasawa, H. A novel highly acidic polysaccharide with inhibitory activity on calcification from the calcified scale “coccolith” of a coccolithophorid alga, Pleurochrysis haptonemofera. Biochem. Biophys. Res. Commun. 2007, 357, 1172–1176. [Google Scholar] [CrossRef] [PubMed]

- Kayano, K.; Shiraiwa, Y. Physiological regulation of coccolith polysaccharide production by phosphate availability in the coccolithophorid Emiliania huxleyi. Plant Cell Physiol. 2009, 50, 1522–1531. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ozaki, N.; Okazaki, M.; Kogure, T.; Sakuda, S.; Nagasawa, H. Structural and functional diversity of acidic polysaccharides from various species of coccolithophorid algae. Thalassas 2004, 20, 59–68. [Google Scholar]

- Young, J.R. Biomineralization Within Vesicles: The Calcite of Coccoliths. Rev. Mineral. Geochem. 2003, 54, 189–215. [Google Scholar] [CrossRef]

- Van Driessche, A.E.S.; Kellermeier, M.; Benning, L.G.; Gebauer, D. (Eds.) New Perspectives on Mineral Nucleation and Growth; Springer: New York, NY, USA, 2017. [Google Scholar] [CrossRef]

- Gebauer, D.; Colfen, H.; Verch, A.; Antonietti, M. The multiple roles of additives in CaCO3 crystallization: A quantitative case study. Adv. Mater. 2009, 21, 435–439. [Google Scholar] [CrossRef]

- Kellermeier, M.; Gebauer, D.; Melero-García, E.; Drechsler, M.; Talmon, Y.; Kienle, L.; Cölfen, H.; García-Ruiz, J.M.; Kunz, W. Colloidal stabilization of calcium carbonate prenucleation clusters with silica. Adv. Funct. Mater. 2012, 22, 4301–4311. [Google Scholar] [CrossRef] [Green Version]

- Braccini, I.; Perez, S. Molecular Basis of Ca2+ -Induced Gelation in Alginates and Pectins: The Egg-Box Model Revisited. Biomacromolecules 2001, 2, 1089–1096. [Google Scholar] [CrossRef]

- Fraser-Reid, B.O.; Tatsuta, K.; Thiem, J.; Cote, G.L.; Flitsch, S.; Ito, Y.; Kondo, H.; Nishimura, S.I.; Yu, B. (Eds.) Glycoscience. Chemistry and Chemical Biology; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2008; 2874. [Google Scholar] [CrossRef] [Green Version]

- Hasson, D.; Shemer, H.; Sher, A. State of the Art of Friendly “Green” Scale Control Inhibitors: A Review Article. Ind. Eng. Chem. Res. 2011, 50, 7601–7607. [Google Scholar] [CrossRef]

- Kesavan, S.; Windsor, E.; Woodward, G.; Decampo, F. Polysaccharide Based Scale Inhibitor. U.S. Patent 8,215,398 B2, 2012. [Google Scholar]

- Strizhnev, K.V.; Gumerov, R.R.; Alekseev, Y.V.; Sagirova, L.R.; Suleimanov, A.G.; Zuevskly, I.A. Destructed guar gel effect on the mechanism of formation of calcite deposits in the high-pressure conduits of Southern section of the Priobskoye field. Oil Ind. 2009, 12, 56–58. [Google Scholar]

- Baraka-Lokmane, S.; Sorbie, K.S.; Poisson, N.; Lecocq, P. Application of environmentally friendly scale inhibitors in carbonate core flooding experiments. In Proceedings of the Intenational Symposium of the Society of Core Analyst, Abu Dhabi, United Arab Emirates, 29 October–2 November 2008; Volume 5, pp. 1–12. [Google Scholar]

- Klemm, D.; Schmauder, H.; Heinze, T. Cellulose. In Biopolymers: Biology, Chemistry, Biotechnology, Application, Polysaccharide II; de Baets, S., Vandamme, E.J., Steinbüchel, A., Eds.; Wiley-VCH: Weinheim, Germany, 2002; Volume 6, pp. 275–319. [Google Scholar]

- Batelaan, J.G.; Van Ginkel, C.G.; Balk, F. Carboxymethylcellulose (CMC). In The Handbook of Enviromentale Chemistry 3, Part F; Hutzinger, O., Ed.; Springer: Baden-Württemberg, Germany, 1992; pp. 329–336. [Google Scholar]

- Gebauer, D.; Oliynyk, V.; Salajkova, M.; Sort, J.; Zhou, Q.; Bergstroma, L.; Salazar-Alvarezad, G. A transparent hybrid of nanocrystalline cellulose and amorphous calcium carbonate nanoparticlest. Nanoscale 2011, 3, 3563. [Google Scholar] [CrossRef] [Green Version]

- Fagundes, K.R.S.; Luz, R.C.S.; Fagundes, F.P.; Balaban, R.C. Effect of carboxymethylcellulose on colloidal properties of calcite suspensions in drilling fluids. Polímeros 2018, 28, 373–379. [Google Scholar] [CrossRef]

- Li, W.; Sun, S.; Yu, Q.; Wu, P. Controlling the Morphology of BaCO3 Aggregates by Carboxymethyl Cellulose through Polymer Induced Needle-Stacking Self-Assembly. Cryst. Growth Des. 2010, 10, 2685–2692. [Google Scholar] [CrossRef]

- Fakhreeva, A.V.; Manaure, D.A.; Dokichev, V.A.; Voloshin, A.I.; Telin, A.G.; Tomilov, Y.V.; Nifantiev, N.E. Environmentally safe oil-field reagents for development and operation of oil-gas deposits. IOP Conf. Ser. Mater. Sci. Eng. 2018, 347, 012029. [Google Scholar] [CrossRef] [Green Version]

- Medvedeva, E.; Babkin, V.A.; Ostroukhov, L.A. Arabinogalactan from larch—Properties and usage perspectives (review). Chem. Plant Raw Mater. 2003, 1, 27–37. [Google Scholar]

- Voloshin, A.I.; Gusakov, V.N.; Fakhreeva, A.V.; Dokichev, V.A. Scaling prevention inhibitors in oil production. Oilfield Eng. 2018, 11, 60–72. [Google Scholar] [CrossRef]

- Viloria, A.; Castillo, L.; Garcia, J.A.; Biomorgi, J. Aloe Derived Scale Inhibitor. U.S. Patent 7737090 B2, 15 June 2010. [Google Scholar]

- Zhang, H.; Cai, Z.; Jin, X.; Sun, D.; Wang, D.; Yang, T.; Zhang, J.; Han, X. Preparation of modified oligochitosan and evaluation of its scale inhibition and fluorescence properties. J. Appl. Polym. Sci. 2015, 132, 42518. [Google Scholar] [CrossRef]

| CaCO3 Form | −lg(pKsp) |

|---|---|

| Amorphous (monohydrate) | 6.4 |

| Ikaite (hexahydrate) | 6.62 |

| Vaterite (anhydrous) | 7.91 |

| Aragonite (anhydrous) | 8.34 |

| Calcite | 8.48 |

| Hematite (FeCO3) | 10.50 |

| MgCO3 | 4.67 |

| Sediments | Formula | Nature and Water Source | Conditions of Formation | Basic Crystalline Form | Reference |

|---|---|---|---|---|---|

| Calcium carbonate | CaCO3 | Reservoir water, recycled water | Pressure reduction, temperature increase | Calcite, aragonite, vaterite | [4,5,6] |

| Calcium sulfate | CaSO4.nH2O | Formation mineralized water, natural surface water, sea water | Mixing of surface water and underground water with sea water, temperature increase | Gypsum, anhydrite, bassanite | [1,2,3,4,5,6] |

| Strontium sulfate | SrSO4 | Formation mineralized water, seawater | Mixing of surface water and underground water with seawater | Celestine | [2,3] |

| Iron carbonate | FeCO3 | Reservoir water, seawater, recycled water supply | High content of dissolved CO2 in water, corrosion of low-carbon steels | Siderite | [59] |

| Iron oxides, hydroxides | Fe(OH)3, Fe2O3, Fe3O4 | Surface water | Oxygen-rich air-injected water | Magnetite, hematite | [7] |

| Iron sulfide | FeS, FeS2 | Water with a developed biocenosis of sulfate-reducing bacteria | High content of H2S in water, elevated temperature | Pyrite, marcasite, mackinawite, greigite, muscovite | [7] |

| Sodium chloride | NaCl | Formation mineralized water | Temperature reduction, processes of degassing, removal of water in the form of steam, concentration of solutions | Halite | [56] |

| Polymer | Molar Mass, Mw, g/mol | Inhibitor Concentration, Ci · 109 mol/L | CaCO3 Crystal Growth Rate, Ri · 105, mol/(m2.min) | Inhibition Efficiency, % |

|---|---|---|---|---|

| Blank | - | - | 9.16 | - |

| CMI-15 | 3927 | 10 | 4.37 | 52.3 |

| 15 | 2.69 | 70.6 | ||

| 20 | 1.97 | 78.5 | ||

| 25 | 1.47 | 84.0 | ||

| CMI-20 | 3524 | 5 | 5.22 | 43.0 |

| 10 | 2.59 | 71.7 | ||

| 15 | 1.82 | 80.1 | ||

| 20 | 0.47 | 95.0 | ||

| CMI-25 | 10,937 | 2.5 | 4.59 | 49.9 |

| 5 | 3.66 | 60.0 | ||

| 10 | 1.70 | 81.4 | ||

| 15 | 0.50 | 94.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fakhreeva, A.V.; Nosov, V.V.; Voloshin, A.I.; Dokichev, V.A. Polysaccharides as Effective and Environmentally Friendly Inhibitors of Scale Deposition from Aqueous Solutions in Technological Processes. Polymers 2023, 15, 1478. https://doi.org/10.3390/polym15061478

Fakhreeva AV, Nosov VV, Voloshin AI, Dokichev VA. Polysaccharides as Effective and Environmentally Friendly Inhibitors of Scale Deposition from Aqueous Solutions in Technological Processes. Polymers. 2023; 15(6):1478. https://doi.org/10.3390/polym15061478

Chicago/Turabian StyleFakhreeva, Alsu Venerovna, Vasily Viktorovich Nosov, Alexander Iosifovich Voloshin, and Vladimir Anatolyevich Dokichev. 2023. "Polysaccharides as Effective and Environmentally Friendly Inhibitors of Scale Deposition from Aqueous Solutions in Technological Processes" Polymers 15, no. 6: 1478. https://doi.org/10.3390/polym15061478

APA StyleFakhreeva, A. V., Nosov, V. V., Voloshin, A. I., & Dokichev, V. A. (2023). Polysaccharides as Effective and Environmentally Friendly Inhibitors of Scale Deposition from Aqueous Solutions in Technological Processes. Polymers, 15(6), 1478. https://doi.org/10.3390/polym15061478