Theoretical and Experimental Investigations of Diffraction Characteristics Influenced by Holographic Reciprocity Effect in PQ/PMMA Polymers

Abstract

1. Introduction

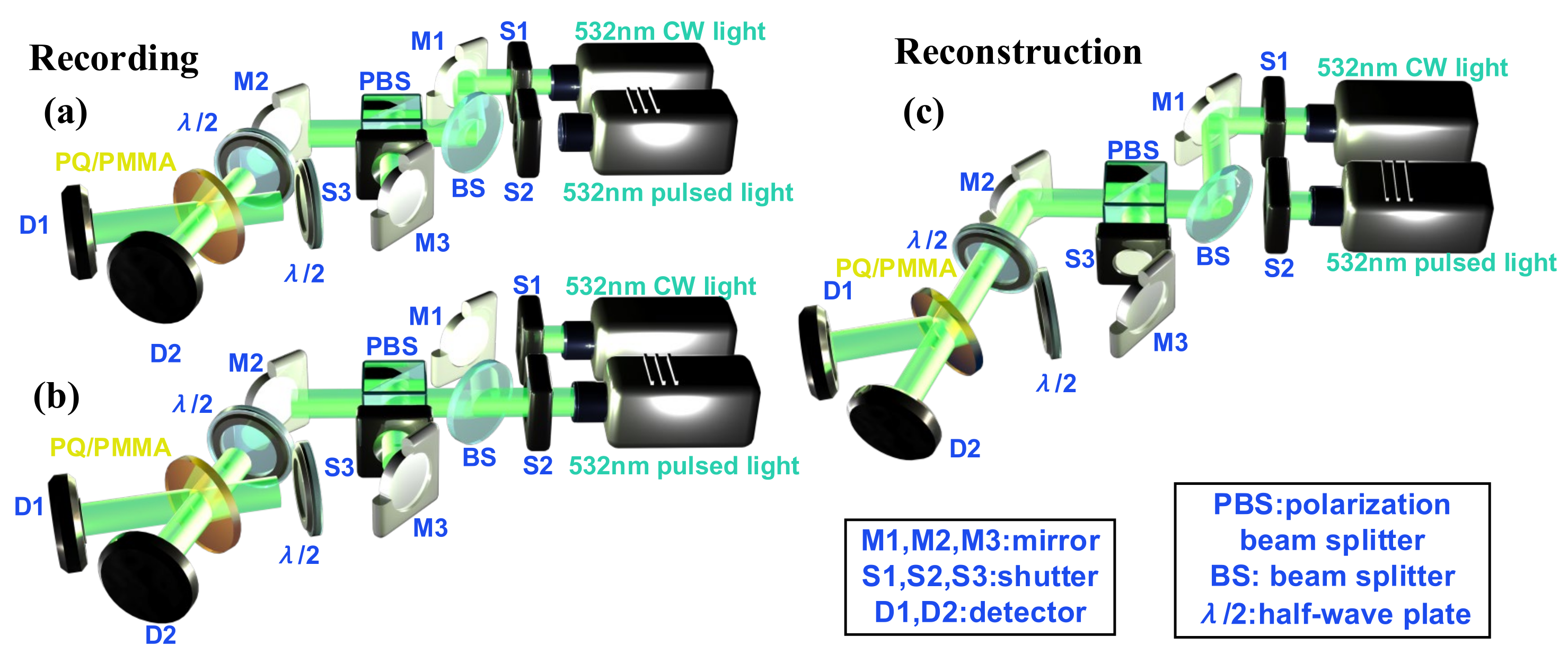

2. Materials and Methods

3. Results and Discussion

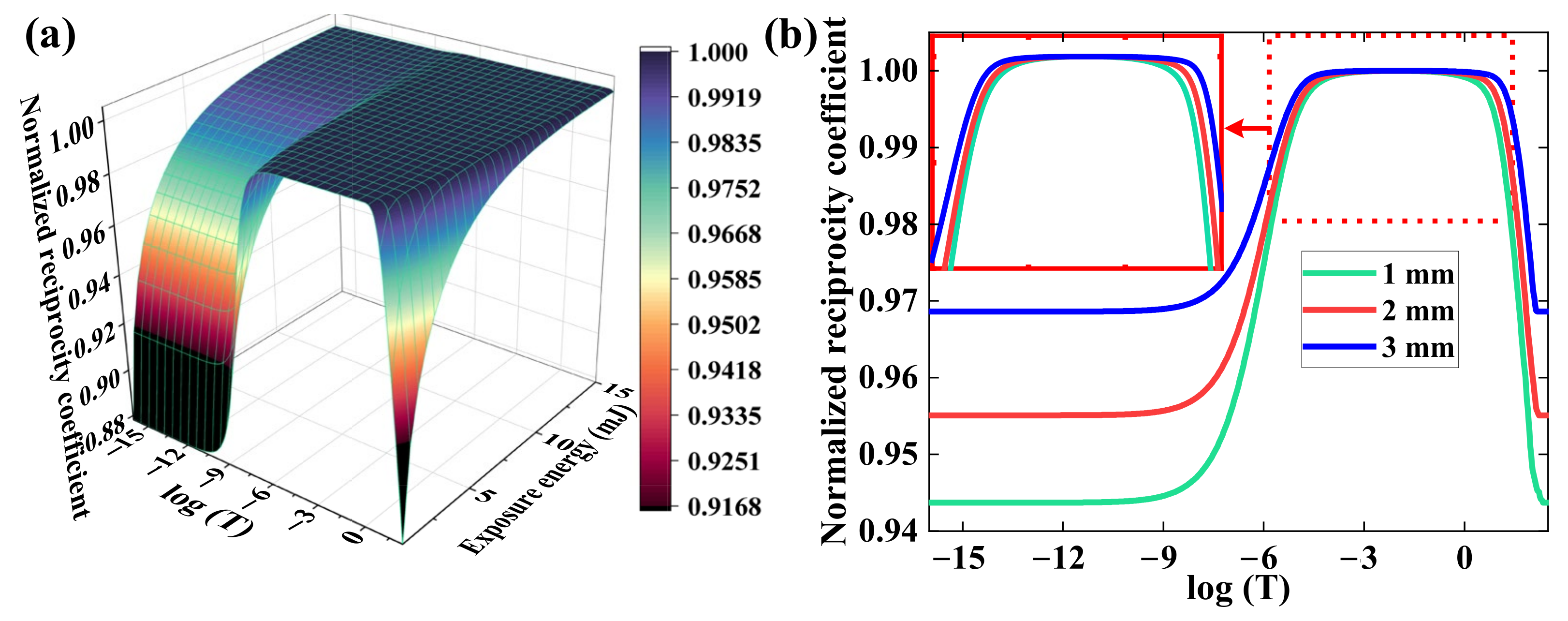

3.1. Theoretical Probabilistic Model on the HRE

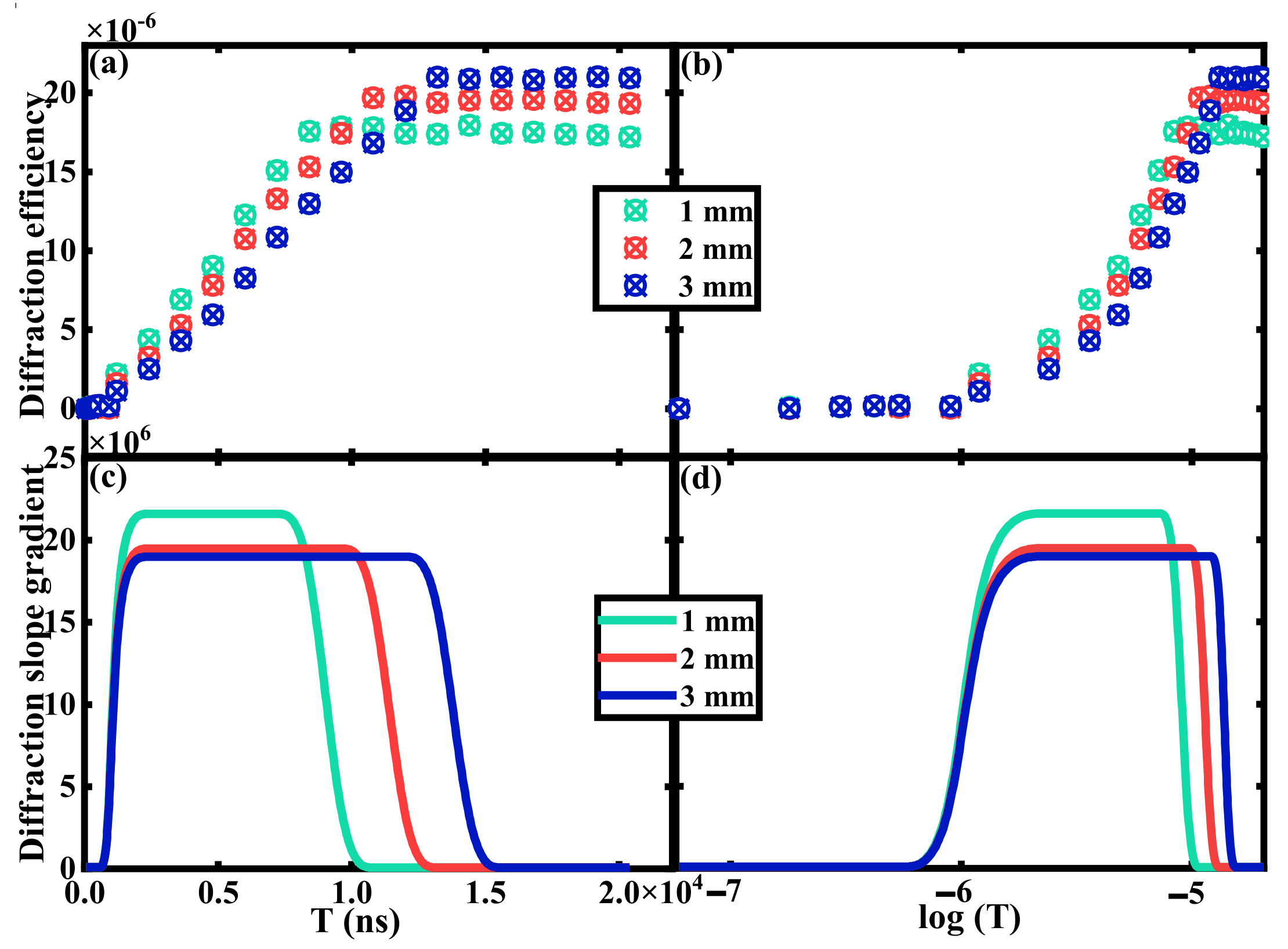

3.2. Experimental Results on the HRM and the HRF

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Hao, J.; Wang, K.; Zhang, Y.; Li, H.; Lin, X.; Huang, Z.; Tan, X. Collinear non-interferometric phase retrieval for holographic data storage. Opt. Express 2020, 28, 25795–25805. [Google Scholar] [CrossRef] [PubMed]

- Hu, P.; Li, J.; Jin, J.; Lin, X.; Tan, X. Highly Sensitive Photopolymer for Holographic Data Storage Containing Methacryl Polyhedral Oligomeric Silsesquioxane. ACS Appl. Mater. Interfaces 2022, 14, 21544–21554. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Wang, Y.; Li, X.; Xu, Z.; Li, X.; Huang, L. A deep learning approach for trustworthy high-fidelity computational holographic orbital angular momentum communication. Appl. Phy. Lett. 2021, 119, 044104. [Google Scholar] [CrossRef]

- Butler, K.T.; Davies, D.W.; Cartwright, H.; Isayev, O.; Walsh, A. Machine learning for molecular and materials science. Nature 2018, 559, 547–555. [Google Scholar] [CrossRef] [PubMed]

- Hatfield, P.W.; Gaffney, J.A.; Anderson, G.J.; Ali, S.; Antonelli, L.; Başeğmez du Pree, S.; Williams, B. The data-driven future of high-energy-density physics. Nature 2021, 593, 351–361. [Google Scholar] [CrossRef]

- Lin, X.; Liu, J.; Hao, J.; Wang, K.; Zhang, Y.; Li, H.; Tan, X. Collinear holographic data storage technologies. Opto-Electron. Adv. 2020, 3, 190004. [Google Scholar] [CrossRef]

- Chrapkiewicz, R.; Dąbrowski, M.; Wasilewski, W. High-capacity angularly multiplexed holographic memory operating at the single-photon level. Phy. Rev. Lett. 2017, 118, 063603. [Google Scholar] [CrossRef]

- Hu, Y.; Kowalski, B.A.; Mavila, S.; Podgórski, M.; Sinha, J.; Sullivan, A.C.; Bowman, C.N. Holographic Photopolymer Material with High Dynamic Range (Δ n) via Thiol–Ene Click Chemistry. ACS Appl. Mater. Interfaces 2020, 12, 44103–44109. [Google Scholar] [CrossRef]

- Wang, J.; Luo, S. Volume holographic storage using sync-angular multiplexing by rotating material in thick photopolymer. Opt. Laser Tech. 2022, 153, 108295. [Google Scholar] [CrossRef]

- Yoneda, N.; Saita, Y.; Nomura, T. Computer-generated-hologram-based holographic data storage using common-path off-axis digital holography. Opt. Lett. 2020, 45, 2796–2799. [Google Scholar] [CrossRef]

- Gamboa, J.; Hamidfar, T.; Vonckx, J.; Fouda, M.; Shahriar, S.M. Thick PQ: PMMA transmission holograms for free-space optical communication via wavelength-division multiplexing. Appl. Opt. 2021, 60, 8851–8857. [Google Scholar] [CrossRef]

- Wang, J.; Pei, Y.; Shi, H.; Gao, B.; Luo, S. High-density and high-quality holographic storage in a multilayer glass-like photopolymer. Opt. Mater. Express 2022, 12, 845–853. [Google Scholar] [CrossRef]

- Hu, P.; Chen, Y.; Li, J.; Wang, J.; Liu, J.; Wu, T.; Tan, X. Impact of fullerene on the holographic properties of PQ/PMMA photopolymer. Comp. Sci. Tech. 2022, 221, 109335. [Google Scholar] [CrossRef]

- Yu, D.; Liu, H.; Jiang, Y.; Sun, X. Holographic storage stability in PQ-PMMA bulk photopolymer. Opt. Commun. 2010, 283, 4219–4223. [Google Scholar] [CrossRef]

- Liu, P.; Chang, F.; Zhao, Y.; Li, Z.; Sun, X. Ultrafast volume holographic storage on PQ/PMMA photopolymers with nanosecond pulsed exposures. Opt. Express 2018, 26, 1072–1082. [Google Scholar] [CrossRef]

- Liu, P.; Zhao, Y.; Li, Z.; Sun, X. Improvement of ultrafast holographic performance in silver nanoprisms dispersed photopolymer. Opt. Express 2019, 26, 6993–7004. [Google Scholar] [CrossRef]

- Liu, P.; Sun, X.; Zhao, Y.; Li, Z. Ultrafast volume holographic recording with exposure reciprocity matching for TI/PMMAs application. Opt. Express 2019, 27, 19583–19595. [Google Scholar] [CrossRef]

- Bjelkhagen, H.I. Silver-Halide Recording Materials for Holography and Their Processing: MATERIALS; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1995; Volume 66. [Google Scholar]

- Blanche, P.A.; Lynn, B.; Churin, D.; Kieu, K.; Norwood, R.A.; Peyghambarian, N. Diffraction response of photorefractive polymers over nine orders of magnitude of pulse duration. Sci. Rep. 2016, 6, 29027. [Google Scholar] [CrossRef]

- Zhao, G.; Mouroulis, P. Diffusion model of hologram formation in dry photopolymer materials. J. Mod. Opt. 1994, 41, 1929–1939. [Google Scholar] [CrossRef]

- Lin, S.H.; Hsu, K.Y.; Chen, W.Z.; Whang, W.T. Phenanthrenequinone-doped poly (methyl methacrylate) photopolymer bulk for volume holographic data storage. Opt. Lett. 2000, 25, 451–453. [Google Scholar] [CrossRef]

- Tolstik, E.; Kashin, O.; Matusevich, A.; Matusevich, V.; Kowarschik, R.; Matusevich, Y.I.; Krul, L.P. Non-local response in glass-like polymer storage materials based on poly (methylmethacrylate) with distributed phenanthrenequinone. Opt. Express 2008, 16, 11253–11258. [Google Scholar] [CrossRef] [PubMed]

- Utsugi, T. Holographic scattering in an angular-multiplexed hologram on a photopolymer. Appl. Opt. 2018, 57, 527. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, N.; Tomita, Y. Holographic scattering in SiO 2 nanoparticle-dispersed photopolymer films. Appl. Opt. 2007, 46, 6809. [Google Scholar] [CrossRef]

- Clark, D.C.; Kim, M.K. Determination of absorption coefficient by digital holographic measurement of optical excitation. Appl. Opt. 2011, 50, 1668. [Google Scholar] [CrossRef] [PubMed]

- Neipp, C.; Beléndez, A.; Gallego, S.; Ortuño, M.; Pascual, I.; Sheridan, J.T. Angular responses of the first and second diffracted orders in transmission diffraction grating recorded on photopolymer material. Opt. Express 2003, 11, 1835. [Google Scholar] [CrossRef]

- Sakhno, O.; Yezhov, P.; Hryn, V.; Rudenko, V.; Smirnova, T. Optical and nonlinear properties of photonic polymer nanocomposites and holographic gratings modified with noble metal nanoparticles. Polymers 2020, 12, 480. [Google Scholar] [CrossRef]

- Yu, D.; Liu, H.; Geng, Y.; Wang, W.; Zhao, Y. Radical polymerization in holographic grating formation in PQ-PMMA photopolymer part I: Short exposure. Opt. Commun. 2014, 330, 191. [Google Scholar] [CrossRef]

- Yu, D.; Liu, H.; Geng, Y.; Wang, W.; Zhao, Y. Radical polymerization in holographic grating formation in PQ-PMMA photopolymer part II: Consecutive exposure and dark decay. Opt. Commun. 2014, 330, 199. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhong, J.; Ye, Y.; Luo, Z.; Li, J.; Li, Z.; Zhu, J. Sensitive polyvinyl alcohol/acrylamide based photopolymer for single pulse holographic recording. Mater. Lett. 2015, 138, 284. [Google Scholar] [CrossRef]

- Yu, D.; Liu, H.; Mao, D.; Geng, Y.; Wang, W.; Sun, L.; Lv, J. Enhancement of spectrum strength in holographic sensing in nanozeolites dispersed acrylamide photopolymer. Opt. Express 2015, 23, 29113. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, P.; Sun, X. Theoretical and Experimental Investigations of Diffraction Characteristics Influenced by Holographic Reciprocity Effect in PQ/PMMA Polymers. Polymers 2023, 15, 1486. https://doi.org/10.3390/polym15061486

Liu P, Sun X. Theoretical and Experimental Investigations of Diffraction Characteristics Influenced by Holographic Reciprocity Effect in PQ/PMMA Polymers. Polymers. 2023; 15(6):1486. https://doi.org/10.3390/polym15061486

Chicago/Turabian StyleLiu, Peng, and Xiudong Sun. 2023. "Theoretical and Experimental Investigations of Diffraction Characteristics Influenced by Holographic Reciprocity Effect in PQ/PMMA Polymers" Polymers 15, no. 6: 1486. https://doi.org/10.3390/polym15061486

APA StyleLiu, P., & Sun, X. (2023). Theoretical and Experimental Investigations of Diffraction Characteristics Influenced by Holographic Reciprocity Effect in PQ/PMMA Polymers. Polymers, 15(6), 1486. https://doi.org/10.3390/polym15061486