Thermal Conductivity and Mechanical Properties of Polymer Composites with Hexagonal Boron Nitride—A Comparison of Three Processing Methods: Injection Moulding, Powder Bed Fusion and Casting

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Specimen Preparation

2.3. Characterisation of hBN/Polymer Composites

2.3.1. Thermal Conductivity Measurement

2.3.2. Tensile Testing

2.3.3. Hardness Measurement

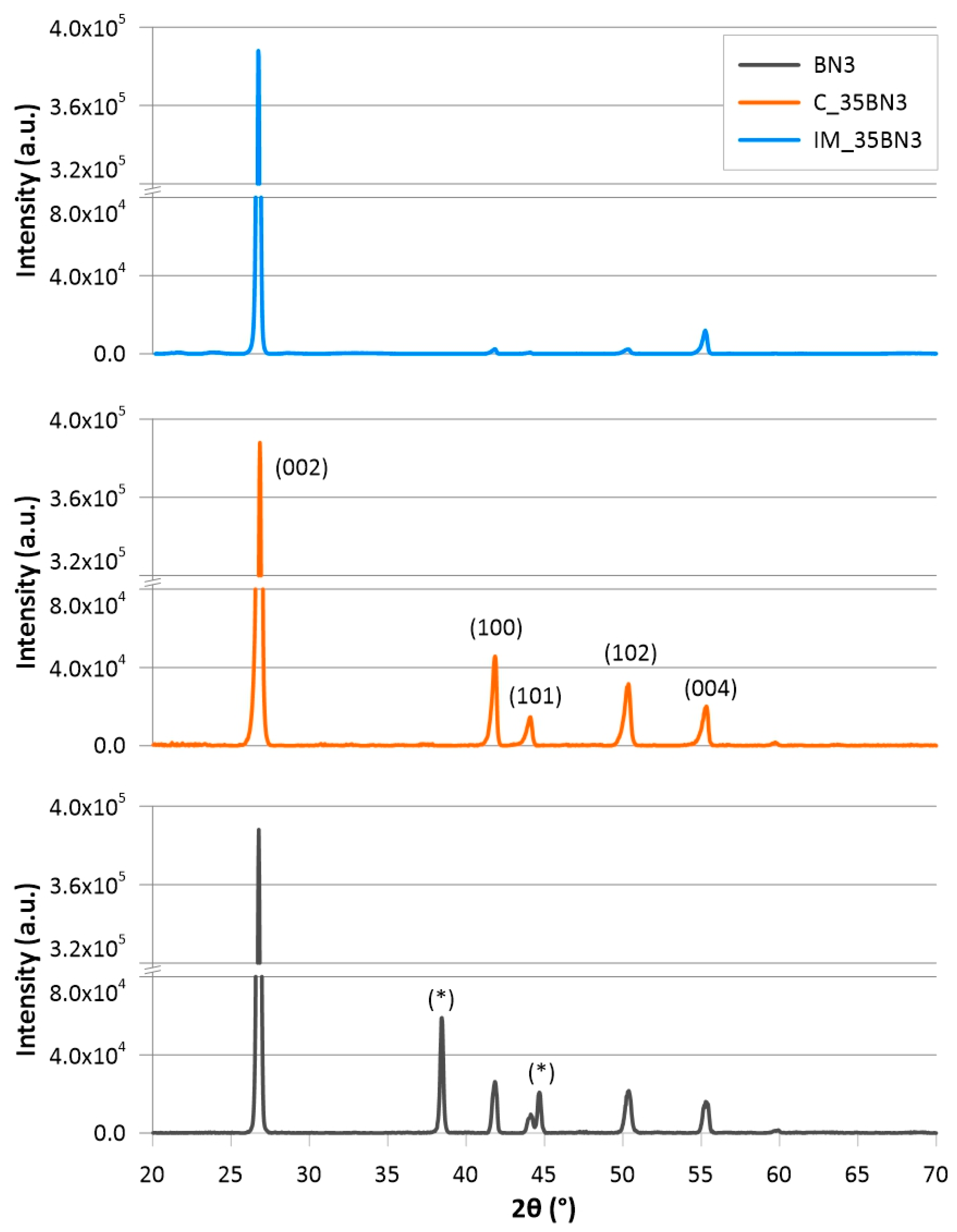

2.3.4. X-ray Diffraction (XRD)

3. Results

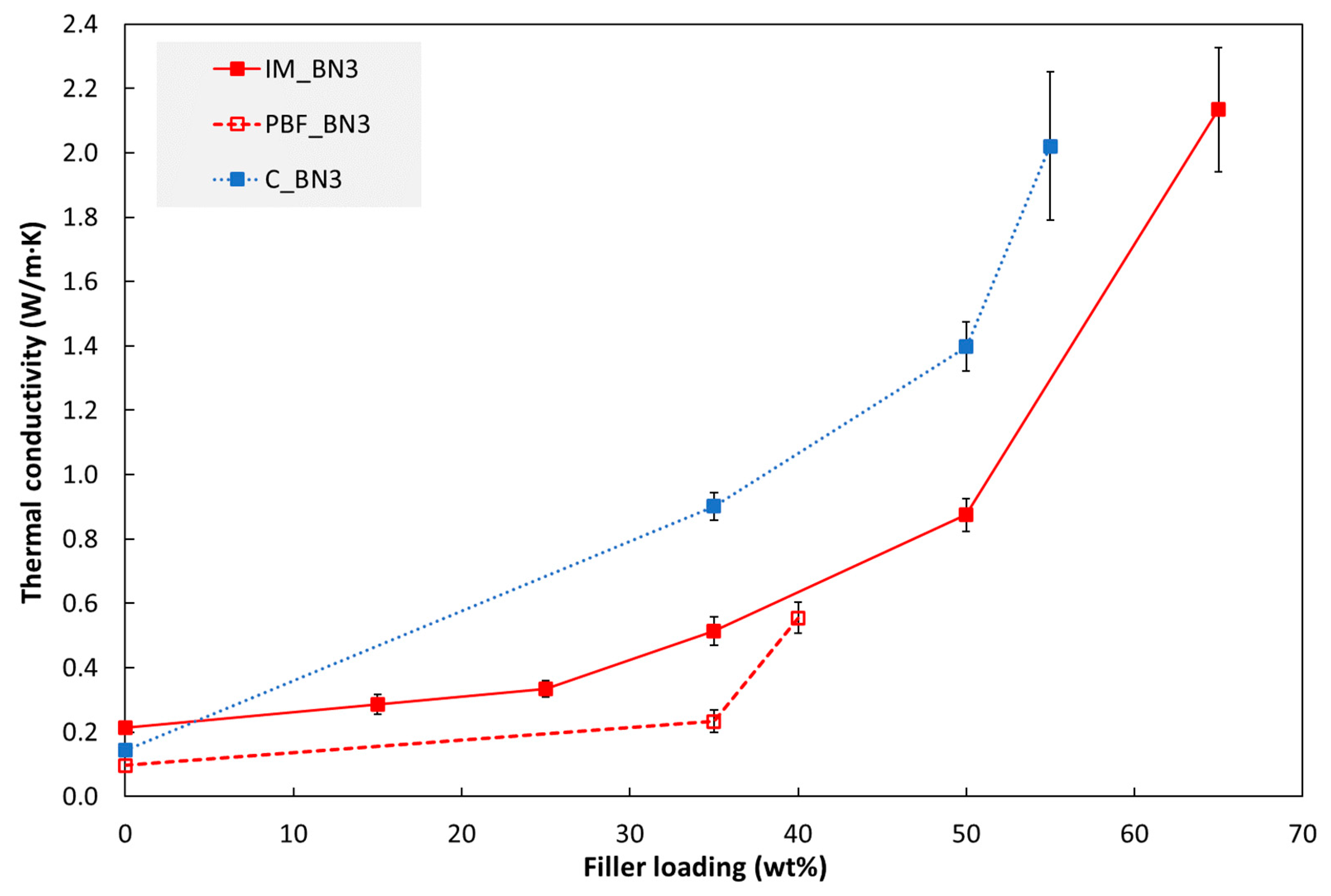

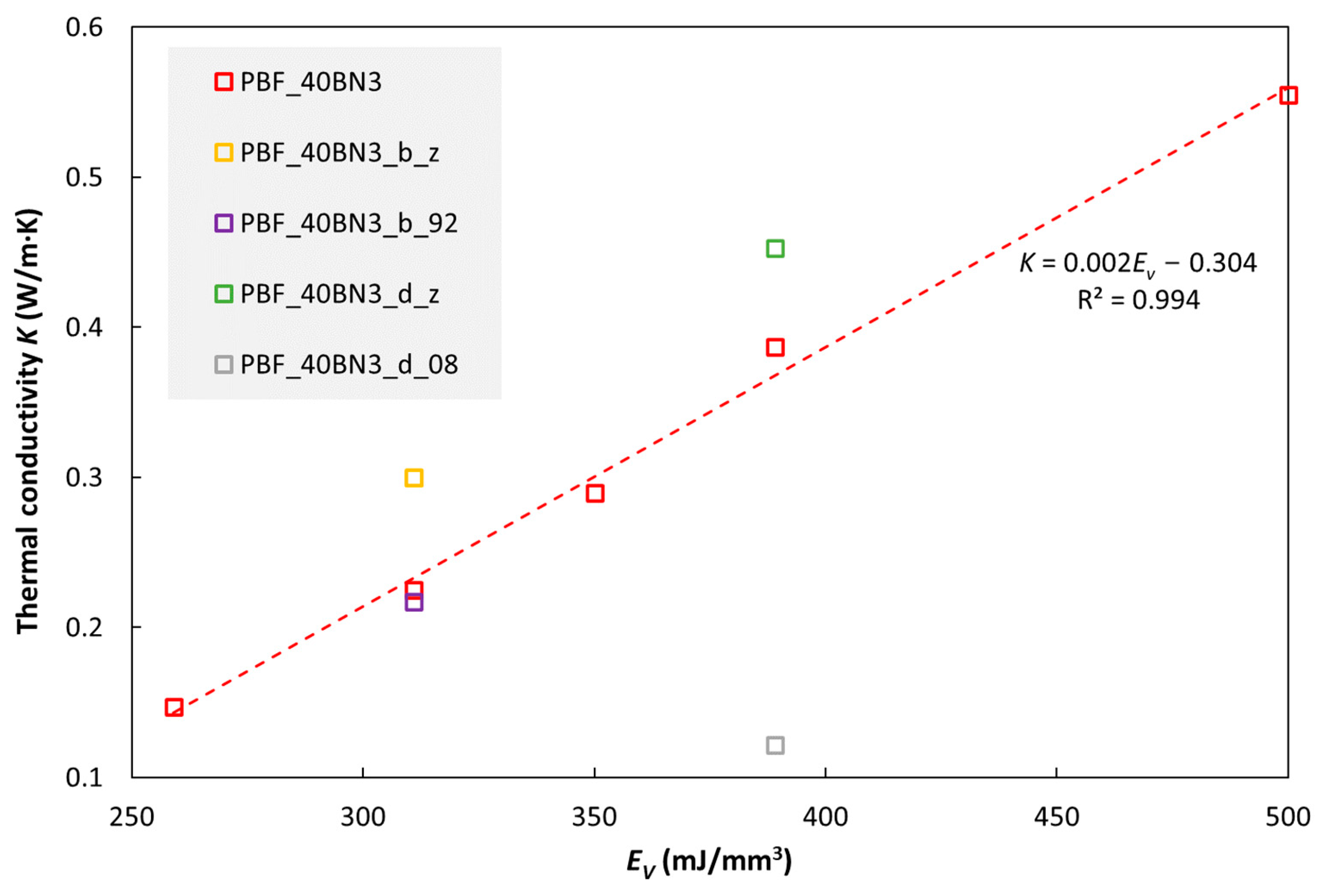

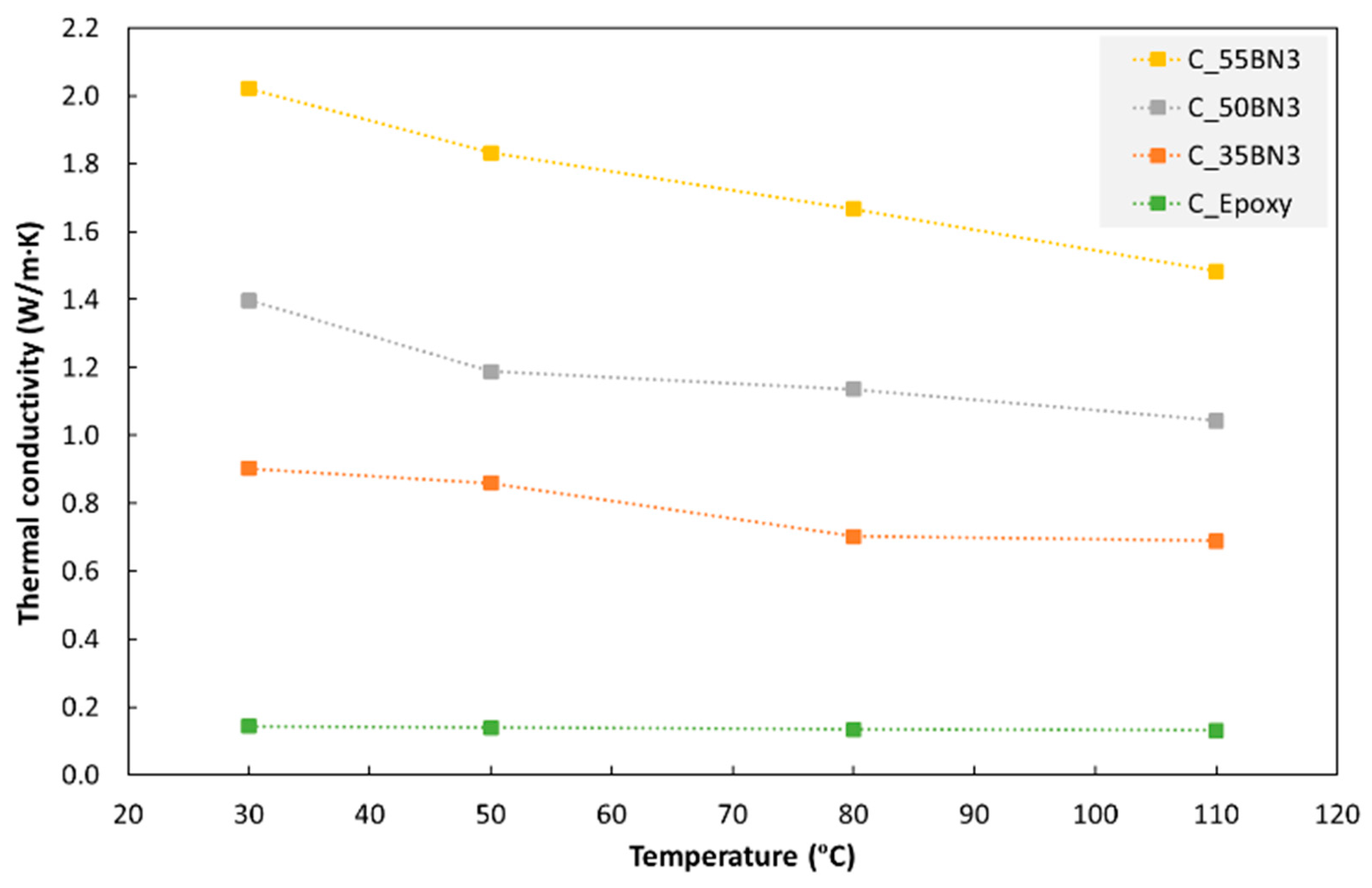

3.1. Thermal Conductivity of hBN/TPU and hBN/Epoxy Composites

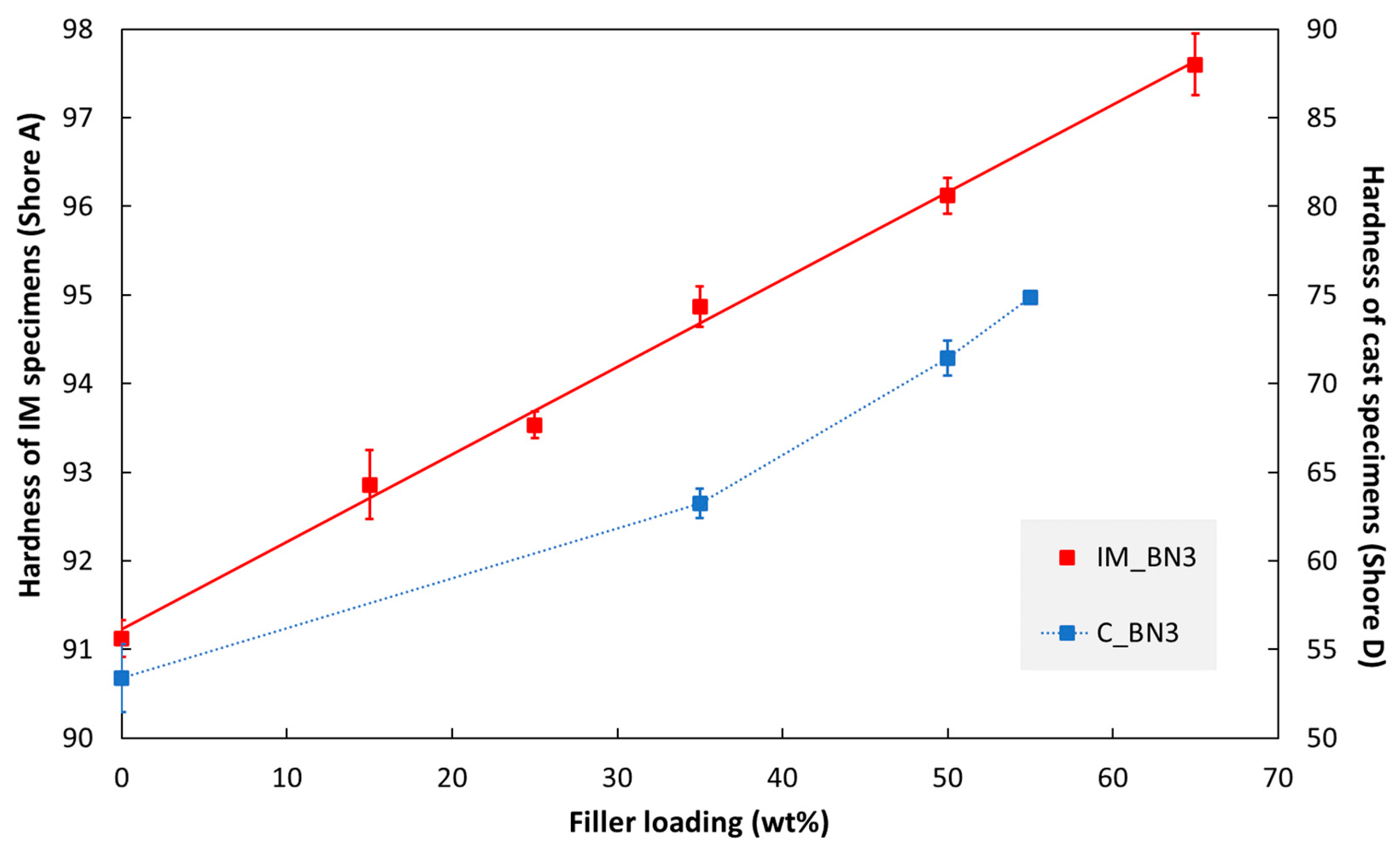

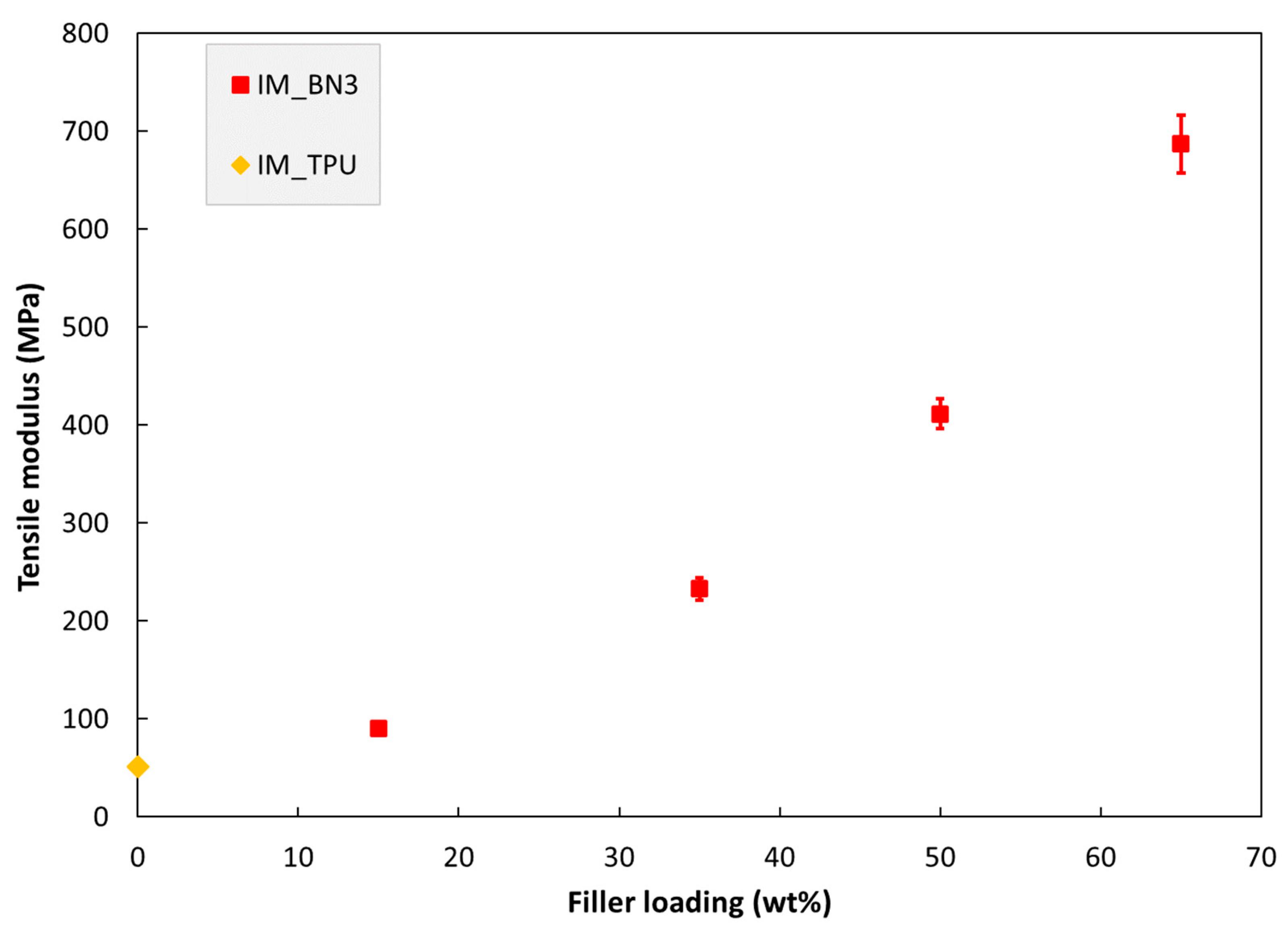

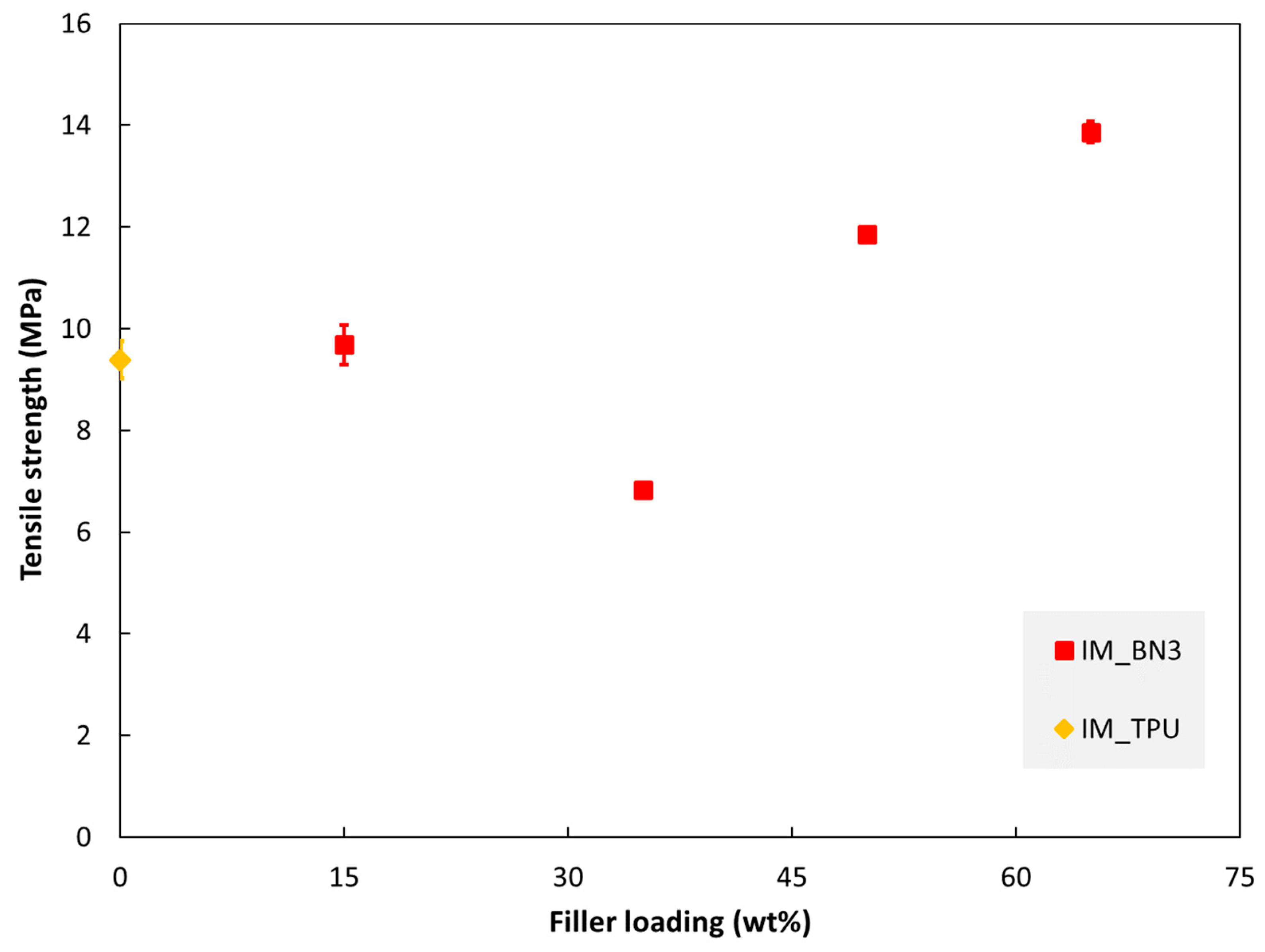

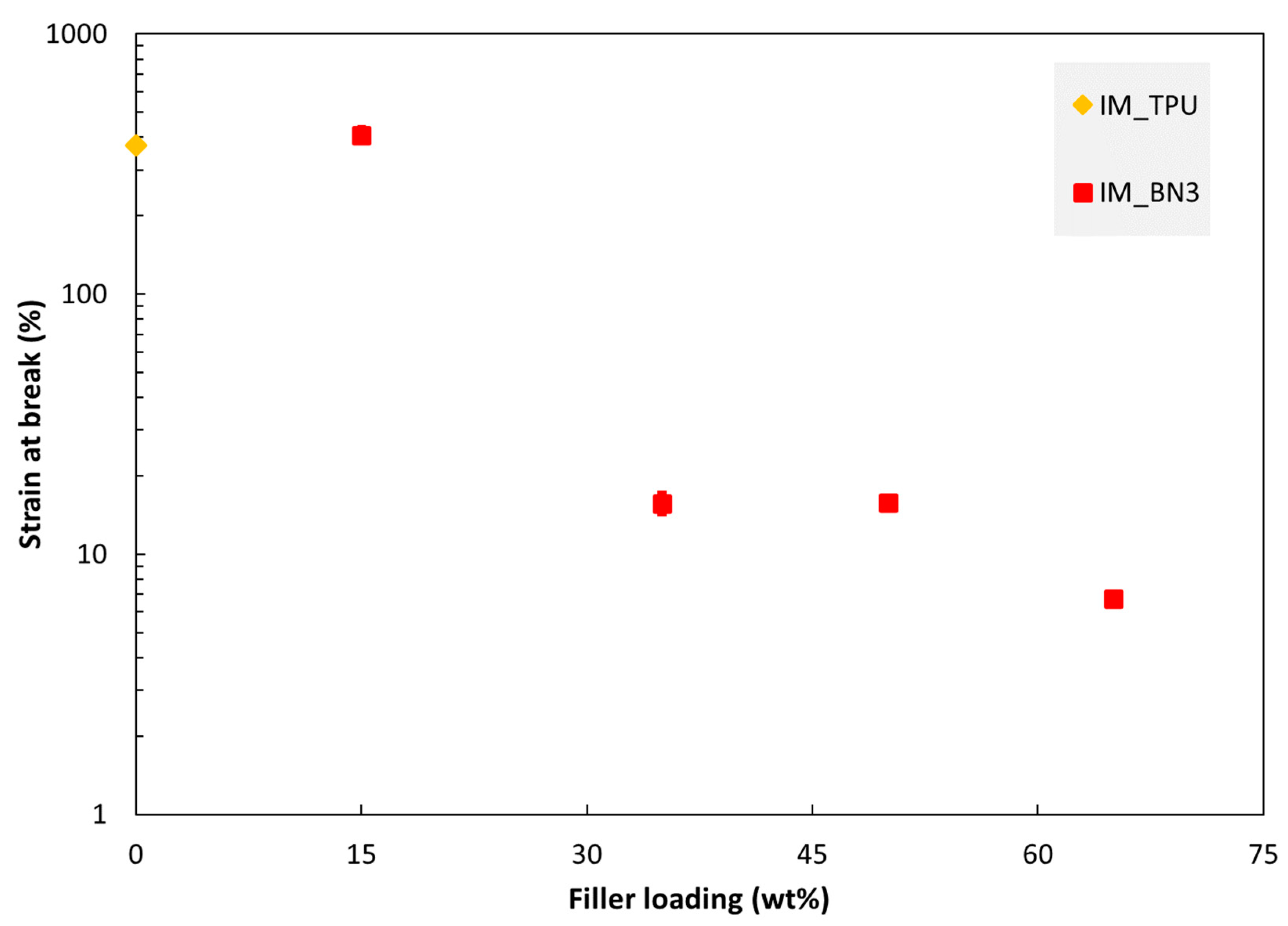

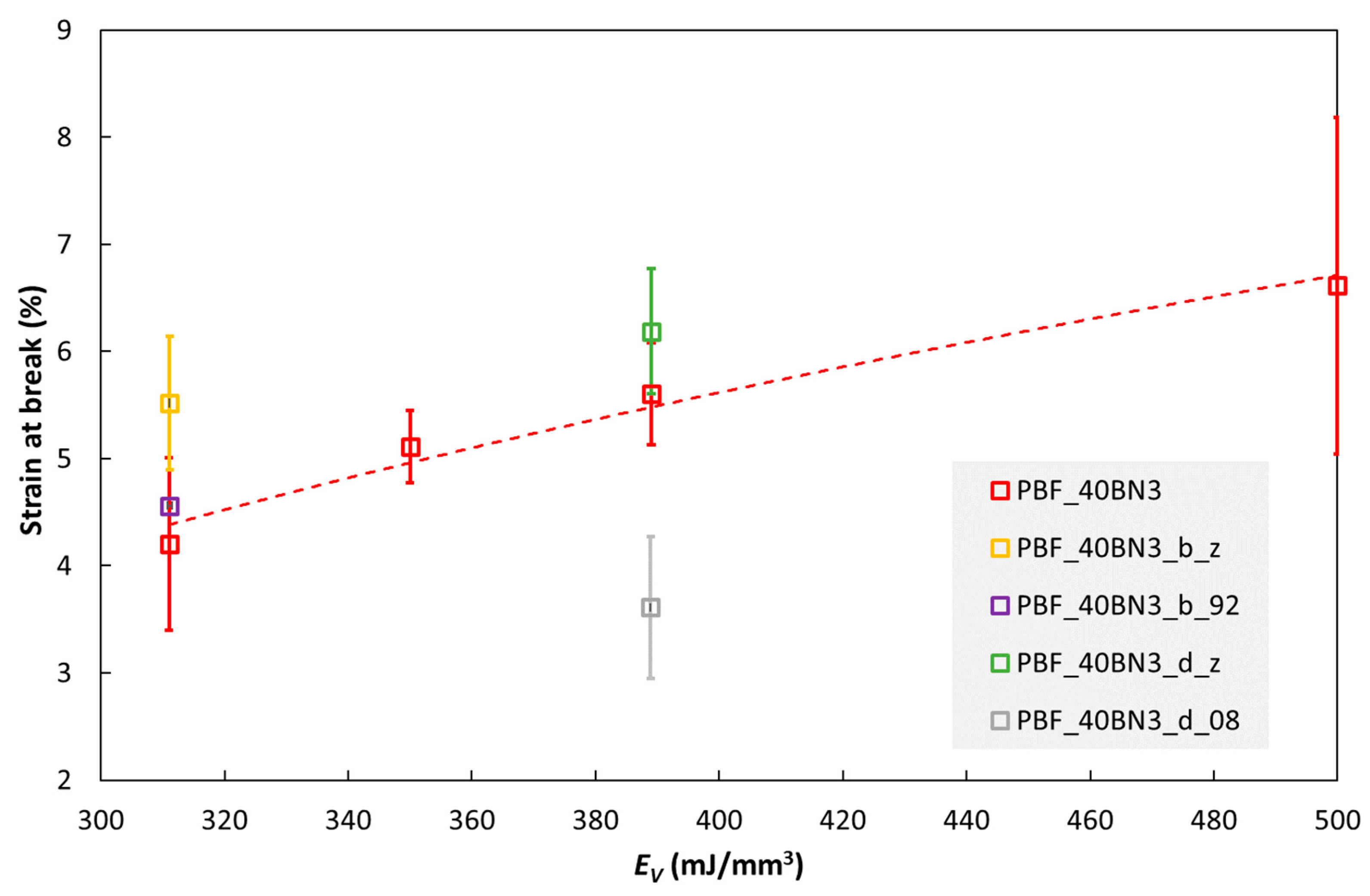

3.2. Hardness and Tensile Properties

3.3. hBN Platelet Orientation

Characterisation of hBN Platelet Orientation by XRD

4. Discussion

4.1. Orientation of hBN Platelets

4.2. Thermal Conductivity

4.3. Comparison with Published Thermal Conductivity Values for Composites with hBN

- Compression moulded hBN/epoxy in ref. [7] achieved a thermal conductivity of 7 W/m·K with 95 wt% hBN. Cast hBN/epoxy in ref. [8] reached a thermal conductivity of 5.3 W/m·K with 57 vol% hBN (with size of 5–11 μm), but values for lower hBN loadings were not presented. Our highest thermal conductivity for cast hBN/epoxy composites was 2.0 W/m·K for 55 wt% (about 28 vol%) hBN (with size of ca. 20 μm). Our casting resin could not be processed with a filler loading higher than this.

- For injection moulding, ref. [10] achieved 3.7 W/m·K for PE with 50 vol% hBN with particle diameter 4–5 μm. Our injection moulded composite based on TPU with 65 wt% hBN (about 48 vol%) reached a thermal conductivity of 2.1 W/m·K. The higher value in ref. [10] could be due to a better dispersion and more homogeneous distribution of hBN particles.

- For PBF composites with only one filler type, our results are similar to those in ref. [11] with regard to (hBN/PA12). Ref. [11] reported a thermal conductivity of 0.55 W/m·K with 40 wt% hBN (275% higher than the pure PA12 processed with PBF). Our best PBF composite with 40 wt% hBN had a thermal conductivity of 0.56 W/m·K (ca. 460% higher than the pure TPU processed with PBF).

4.4. Experimental Thermal Conductivity vs. Model Predictions

4.4.1. The Thermal Conductivity Model of Nan et al.

4.4.2. The Thermal Conductivity Model of Ordóñez-Miranda et al.

4.4.3. The Thermal Conductivity Model of Sun et al.

4.4.4. The Lewis-Nielsen Thermal Conductivity Model

4.5. Hardness and Tensile Properties

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tummala, R. Fundamentals of Microsystems Packaging; McGraw-Hill: New York, NY, USA, 2001. [Google Scholar]

- Bhanushali, S.; Ghosh, P.; Simon, G.; Cheng, W. Copper Nanowire-Filled Soft Elastomer Composites for Applications as Thermal Interface Materials. Adv. Mater. Interfaces 2017, 4, 1700387. [Google Scholar] [CrossRef]

- Bahru, R.; Hamzah, A.; Mohamed, M.A. Thermal management of wearable and implantable electronic healthcare devices: Perspective and measurement approach. Int. J. Energy Res. 2020, 45, 1517–1534. [Google Scholar] [CrossRef]

- Yuan, C.; Duan, B.; Li, L.; Xie, B.; Huang, M.; Luo, X. Thermal Conductivity of Polymer-Based Composites with Magnetic Aligned Hexagonal Boron Nitride Platelets. ACS Appl. Mater. Interfaces 2015, 7, 13000–13006. [Google Scholar] [CrossRef]

- Chen, H.; Ginzburg, V.; Yang, J.; Yang, Y.; Liu, W.; Huang, Y.; Du, L.; Chen, B. Thermal conductivity of polymer-based composites: Fundamentals and applications. Prog. Polym. Sci. 2016, 59, 41–85. [Google Scholar] [CrossRef]

- Li, D.; Zeng, D.; Chen, Q.; Wei, M.; Song, L.; Xiao, C.; Pan, D. Effect of different size complex fillers on thermal conductivity of PA6 thermal composites. Plast. Rubber Compos. 2019, 48, 347–355. [Google Scholar] [CrossRef]

- Zhu, Z.; Wang, P.; Lv, P.; Xu, T.; Zheng, J.; Ma, C.; Yu, K.; Feng, W.; Wei, W.; Chen, L. Densely packed polymer/boron nitride composite for superior anisotropic thermal conductivity. Polym. Compos. 2018, 39, E1653–E1658. [Google Scholar] [CrossRef]

- Xu, Y.; Chung, D.D.L. Increasing the thermal conductivity of boron nitride and aluminum nitride particle epoxy-matrix composites by particle surface treatments. Compos. Interfaces 2000, 7, 243–256. [Google Scholar] [CrossRef]

- Tanimoto, M.; Yamagata, T.; Miyata, K.; Ando, S. Anisotropic thermal diffusivity of hexagonal boron nitride-filled polyimide films: Effects of filler particle size, aggregation, orientation, and polymer chain rigidity. ACS Appl. Mater. Interfaces 2013, 5, 4374–4382. [Google Scholar] [CrossRef]

- Lee, G.-W.; Park, M.; Kim, J.; Lee, J.; Yoon, H.G. Enhanced thermal conductivity of polymer composites filled with hybrid filler. Compos. Part A Appl. Sci. Manuf. 2006, 37, 727–734. [Google Scholar] [CrossRef]

- Yang, L.; Wang, L.; Chen, Y. Solid-state shear milling method to prepare PA12/boron nitride thermal conductive composite powders and their selective laser sintering 3D-printing. J. Appl. Polym. Sci. 2020, 137, 1–13. [Google Scholar] [CrossRef]

- Yuan, Y.; Wu, W.; Hu, H.; Liu, D.; Shen, H.; Wang, Z. The combination of Al2O3 and BN for enhancing the thermal conductivity of PA12 composites prepared by selective laser sintering. RSC Adv. 2021, 11, 1984–1991. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, W.; Zhao, T.; Li, J. The combination of AlN and h-BN for enhancing the thermal conductivity of thermoplastic polyurethane composites prepared by selective laser sintering. J. Appl. Polym. Sci. 2022, 139, e53051. [Google Scholar] [CrossRef]

- Gao, J.; Hao, M.; Wang, Y.; Kong, X.; Yang, B.; Wang, R.; Lu, Y.; Zhang, L.; Gong, M.; Zhang, L.; et al. 3D printing boron nitride nanosheets filled thermoplastic polyurethane composites with enhanced mechanical and thermal conductive properties. Addit. Manuf. 2022, 56, 102897. [Google Scholar] [CrossRef]

- Yu, C.; Zhang, J.; Tian, W.; Fan, X.; Yao, Y. Polymer composites based on hexagonal boron nitride and their application in thermally conductive composites. RSC Adv. 2018, 8, 21948–21967. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Z.; Cox, M.; Li, B. Surface modification of hexagonal boron nitride nanomaterials: A review. J. Mater. Sci. 2018, 53, 66–99. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, W.; Li, Y.; Zhao, D.; Yin, H. Hybrid fillers of hexagonal and cubic boron nitride in epoxy composites for thermal management applications. RSC Adv. 2019, 9, 7388–7399. [Google Scholar] [CrossRef] [Green Version]

- Merlo, A.; Mokkapati, V.; Pandit, S.; Mijakovic, I. Boron nitride nanomaterials: Biocompatibility and bio-applications. Biomater. Sci. 2018, 6, 2298–2311. [Google Scholar] [CrossRef] [Green Version]

- Ciofani, G.; Genchi, G.; Liakos, I.; Athanassiou, A.; Dinucci, D.; Chiellini, F.; Mattoli, V. A simple approach to covalent functionalization of boron nitride nanotubes. J. Colloid Interface Sci. 2012, 374, 308–314. [Google Scholar] [CrossRef]

- Xue, Y.; Li, X.; Wang, H.; Zhao, F.; Zhang, D.; Chen, Y. Improvement in thermal conductivity of through-plane aligned boron nitride/silicone rubber composites. Mater. Des. 2019, 165, 107580. [Google Scholar] [CrossRef]

- Lin, Z.; Liu, Y.; Raghavan, S.; Moon, K.; Sitaraman, S.; Wong, C.P. Magnetic alignment of hexagonal boron nitride platelets in polymer matrix: Toward high performance anisotropic polymer composites for electronic encapsulation. ACS Appl. Mater. Interfaces 2013, 5, 7633–7640. [Google Scholar] [CrossRef]

- Tebeta, R.T.; Fattahi, A.; Ahmed, N.A. Experimental and numerical study on HDPE/SWCNT nanocomposite elastic properties considering the processing techniques effect. Microsyst. Technol. 2020, 26, 2423–2441. [Google Scholar] [CrossRef]

- Crawford, R.J. Plastics Engineering, 3rd ed.; Butterworth-Heinemann: Oxford, UK, 1998; p. 530. [Google Scholar]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yuan, S. Development and Optimization of Selective Laser Sintered-Composites and Structures for Functional Applications. Ph.D. Thesis, Nanyang Technological University, Singapore, 2018; pp. 26–27. [Google Scholar] [CrossRef]

- Yuan, S.; Shen, F.; Chua, C.; Zhou, K. Polymeric composites for powder-based additive manufacturing: Materials and applications. Prog. Polym. Sci. 2019, 91, 141–168. [Google Scholar] [CrossRef]

- Sillani, F.; de Gasparo, F.; Schmid, M.; Wegener, K. Influence of packing density and fillers on thermal conductivity of polymer powders for additive manufacturing. Int. J. Adv. Manuf. Technol. 2021, 117, 2049–2058. [Google Scholar] [CrossRef]

- Lupone, F.; Padovano, E.; Ostrovskaya, O.; Russo, A.; Badini, C. Innovative approach to the development of conductive hybrid composites for Selective Laser Sintering. Compos. Part A Appl. Sci. Manuf. 2021, 147, 106429. [Google Scholar] [CrossRef]

- Yuan, S.; Zheng, Y.; Chua, C.; Yan, Q.; Zhou, K. Electrical and thermal conductivities of MWCNT/polymer composites fabricated by selective laser sintering. Compos. Part A Appl. Sci. Manuf. 2018, 105, 203–213. [Google Scholar] [CrossRef]

- Ronca, A.; Rollo, G.; Cerruti, P.; Fei, G.; Gan, X.; Buonocore, G.; Lavorgna, M.; Xia, H.; Silvestre, C.; Ambrosio, L. Selective Laser Sintering Fabricated Thermoplastic Polyurethane/Graphene Cellular Structures with Tailorable Properties and High Strain Sensitivity. Appl. Sci. 2019, 9, 864. [Google Scholar] [CrossRef] [Green Version]

- Lanzl, L.; Wudy, K.; Greiner, S.; Drummer, D. Selective laser sintering of copper filled polyamide 12: Characterization of powder properties and process behavior. Polym. Compos. 2019, 40, 1801–1809. [Google Scholar] [CrossRef]

- Gruber, P.; Ziółkowski, G.; Olejarczyk, M.; Grochowska, E.; Hoppe, V.; Szymczyk-Ziółkowska, P.; Kurzynowski, T. Influence of bioactive metal fillers on microstructural homogeneity of PA12 composites produced by polymer Laser Sintering. Arch. Civ. Mech. Eng. 2022, 22, 117. [Google Scholar] [CrossRef]

- Hon, K.K.B.; Gill, T.J. Selective Laser Sintering of SiC/Polyamide Composites. CIRP Annals. 2003, 52, 173–176. [Google Scholar] [CrossRef]

- Do, N.B.D.; Andreassen, E.; Edwardsen, S.; Lifjeld, A.; Aasmundtveit, K.; Nguyen, H.-V.; Imenes, K. Thermal management of an interventional medical device with double layer encapsulation. Exp. Heat Transf. 2021, 25, 708–725. [Google Scholar] [CrossRef]

- Frick, A.; Rochman, A. Characterization of TPU-elastomers by thermal analysis (DSC). Polym. Test. 2004, 23, 413–417. [Google Scholar] [CrossRef]

- Nan, C.W.; Birringer, R.; Clarke, D.; Gleiter, H. Effective thermal conductivity of particulate composites with interfacial thermal resistance. J. Appl. Phys. 1997, 81, 6692–6699. [Google Scholar] [CrossRef]

- Ordóñez-Miranda, J.; Alvarado-Gil, J.; Medina-Ezquivel, R. Generalized Bruggeman Formula for the Effective Thermal Conductivity of Particulate Composites with an Interface Layer. Int. J. Thermophys. 2010, 31, 975–986. [Google Scholar] [CrossRef]

- Sun, Y.; Zhou, L.; Han, Y.; Cui, L.; Chen, L. A new anisotropic thermal conductivity equation for h-BN/polymer composites using finite element analysis. Int. J. Heat Mass Transf. 2020, 160, 120157. [Google Scholar] [CrossRef]

- Heinle, C.; Brocka, Z.; Hülder, G.; Ehrenstein, G.; Osswald, T. Thermal conductivity of polymers filled with non-isometric fillers: A process dependent, anisotropic property. In Proceedings of the 67th Annual Technical Conference of the Society of Plastics Engineers (ANTEC 2009, Chicago), Chicago, IL, USA, 22–24 June 2009; pp. 883–889. [Google Scholar]

- Henze Boron Nitride Products AG. HeBoFill ® CL-ADH 020. In Technical Datasheet; Henze BNP AG: Lauben, Germany, 2020; pp. 49–50. [Google Scholar]

- Zajas, J.; Heiselberg, P. Measurements of thermal diffusivity, specific heat capacity and thermal conductivity with LFA 447 apparatus. Aalb. Univ. 2013, 144, 5–11. [Google Scholar]

- Salmon, D.R.; Brandt, R.; Tye, R.P. Pyroceram 9606, A certified ceramic reference material for high-temperature thermal transport properties: Part 2-certification measurements. Int. J. Thermophys. 2010, 31, 355–373. [Google Scholar] [CrossRef]

- Polymer Orientation. Available online: http://www.personal.psu.edu/irh1/PDF/Orientation.pdf (accessed on 23 October 2021).

- Girgsdies, F. Peak Profile Analysis in X-ray Powder Diffraction; Electron Microscopy Group, Department of Inorganic Chemistry, Fritz-Haber-Institut der MPG: Berlin, Germany, 2015; p. 12. [Google Scholar]

- Jørgensen, J.K.; Andreassen, E.; Salaberger, D. The effect of fiber concentration on fiber orientation in injection molded film gated rectangular plates. Polym. Compos. 2019, 40, 615–629. [Google Scholar] [CrossRef]

- Granlund, H.; Andreassen, E.; Skjønsfjell, E.; Høydalsvik, K.; Diaz, A.; Breiby, D.W. Measuring and simulating morphology gradients in injection-molded talc-reinforced isotactic polypropylene. J. Polym. Sci. B Polym. Phys. 2014, 52, 1157–1167. [Google Scholar] [CrossRef]

- Kugler, S.K.; Kech, A.; Cruz, C.; Osswald, T. Fiber Orientation Predictions—A Review of Existing Models. J. Compos. Sci. 2020, 4, 69. [Google Scholar] [CrossRef]

- Chen, H.; Zhu, W.; Tang, H.; Yan, W. Oriented structure of short fiber reinforced polymer composites processed by selective laser sintering: The role of powder-spreading process. Int. J. Mach. Tools Manuf. 2021, 163, 103703. [Google Scholar] [CrossRef]

- Khudiakova, A.; Berer, M.; Niedermair, S.; Plank, B.; Truszkiewicz, E.; Meier, G.; Stepanovsky, H.; Wolfahrt, M.; Pinter, G.; Lackner, J. Systematic analysis of the mechanical anisotropy of fibre-reinforced polymer specimens produced by laser sintering. Addit. Manuf. 2020, 36, 101671. [Google Scholar] [CrossRef]

- Heckner, T.; Seitz, M.; Raisch, S.; Huelder, G.; Middendorf, P. Selective Laser Sintering of PA6: Effect of Powder Recoating on Fibre Orientation. J. Compos. Sci. 2020, 4, 108. [Google Scholar] [CrossRef]

- Tan, P.; Shen, F.; Tey, W.; Zhou, K. A numerical study on the packing quality of fibre/polymer composite powder for powder bed fusion additive manufacturing. Virtual Phys Prototyp. 2021, 16, S1–S18. [Google Scholar] [CrossRef]

- Kargar, F.; Barani, Z.; Salgado, R.; Debnath, B.; Lewis, J.; Aytan, E.; Lake, R.; Balandin, A.A. Thermal Percolation Threshold and Thermal Properties of Composites with High Loading of Graphene and Boron Nitride Fillers. ACS Appl. Mater. Interfaces 2018, 10, 37555–37565. [Google Scholar] [CrossRef]

- Pan, C.; Zhang, J.; Kou, K.; Zhang, Y.; Wu, G. Investigation of the through-plane thermal conductivity of polymer composites with in-plane oriented hexagonal boron nitride. Int. J. Heat Mass Transf. 2018, 120, 1–8. [Google Scholar] [CrossRef]

- Ding, D.; Zou, M.; Wang, X.; Qin, G.; Zhang, S.; Chan, S.; Meng, Q.; Liu, Z.; Zhang, Q.; Chen, Y. Thermal conductivity of polydisperse hexagonal BN/polyimide composites: Iterative EMT model and machine learning based on first principles investigation. Chem. Eng. J. 2022, 437, 135438. [Google Scholar] [CrossRef]

- Liu, J.; Li, W.; Guo, Y.; Zhang, H.; Zhang, Z. Improved thermal conductivity of thermoplastic polyurethane via aligned boron nitride platelets assisted by 3D printing. Compos. Part A Appl. Sci. Manuf. 2019, 120, 140–146. [Google Scholar] [CrossRef]

- Ordonez-Miranda, J.; Alvarado-Gil, J.J. Thermal conductivity of nanocomposites with high volume fractions of particles. Compos. Sci. Technol. 2012, 72, 853–857. [Google Scholar] [CrossRef]

- Jing, X.; Zhao, W.; Lan, L. The effect of particle size on electric conducting percolation threshold in polymer/conducting particle composites. J. Mater. Sci. Lett. 2000, 19, 377–379. [Google Scholar] [CrossRef]

- Li, T.-L.; Hsu, S.L.-C. Enhanced Thermal Conductivity of Polyimide Films via a Hybrid of Micro- and Nano-Sized Boron Nitride. J. Phys. Chem. B 2010, 114, 6825–6829. [Google Scholar] [CrossRef]

- Pietrak, K.; Wiśniewski, T. A review of models for effective thermal conductivity of composite materials. J. Power Technol. 2014, 95, 14–24. [Google Scholar]

- Daneshmehr, S.; Román, F.; Hutchinson, J.M. The surface modification of boron nitride particles. J. Therm. Anal. Calorim. 2019, 143, 151–163. [Google Scholar] [CrossRef]

- Cui, Z.; Oyer, A.; Glover, A.; Schniepp, H.; Adamson, D.H. Large scale thermal exfoliation and functionalization of boron nitride. Small 2014, 10, 2352–2355. [Google Scholar] [CrossRef] [PubMed]

- Ryu, S.; Kim, K.; Kim, J. Silane surface treatment of boron nitride to improve the thermal conductivity of polyethylene naphthalate requiring high temperature molding. Polym. Compos. 2018, 39, E1692–E1700. [Google Scholar] [CrossRef]

- Hill, R.F.; Supancic, P.H. Thermal Conductivity of Platelet-Filled Polymer Composites. J. Am. Ceram. Soc. 2004, 85, 851–857. [Google Scholar] [CrossRef]

- Prindl, J. Enhancing Thermal Conductivity of Hexagonal Boron Nitride Filled Thermoplastics for Thermal Interface Management. Master’s Thesis, Lehigh University, Bethlehem, PA, USA, 2015. [Google Scholar]

- Henze Boron Nitride Products AG. HeBoFill ® LL-SP 120. In Technical Datasheet; Henze BNP AG: Lauben, Germany, 2020; p. 8374. [Google Scholar]

- Tseng, H.-C.; Chang, R.-Y.; Hsu, C.-H. Comparison of recent fiber orientation models in injection molding simulation of fiber-reinforced composites. J. Thermoplast. Compos. Mater. 2020, 33, 35–52. [Google Scholar] [CrossRef]

- Mazahir, S.M.; Velez-Garcia, G.M.; Wapperom, P.; Baird, D. Fiber orientation in the frontal region of a center-gated disk: Experiments and simulation. J. Nonnewton Fluid Mech. 2015, 216, 31–44. [Google Scholar] [CrossRef] [Green Version]

| Materials | Filler Loading | Processing Method | Thermal Conductivity |

|---|---|---|---|

| hBN/epoxy [7] | 95 wt% | Compression moulding | 21.3 W/m·K (in-plane) 7 W/m·K (through-plane) |

| hBN/epoxy [8] | 57 vol% | Casting | 5.27 W/m·K (through-plane) |

| hBN/polyimide [9] | 60 vol% | Spin-cast (film) | 17.5 W/m·K (in-plane) 5.4 W/m·K (through-plane) |

| hBN/PE [10] | 50 vol% | Injection moulding | 3.66 W/m·K |

| hBN/PA12 [11] | 40 wt% | Powder bed fusion | 0.55 W/m·K (77% higher than pure PA12) |

| hBN/Al2O3/PA12 [12] | 15 wt% hBN and 35 wt% Al2O3 | Powder bed fusion | 1.05 W/m·K (275% higher than pure PA12) |

| hBN/AlN/TPU [13] | 15 wt% hBN and 20 wt% AlN | Powder bed fusion | 0.9 W/m·K (391% higher than pure TPU) |

| hBN/TPU [14] | 30 wt% | Fused deposition modelling (material extrusion) | 1.51 W/m·K (in-plane) 1.26 W/m·K (through-plane) |

| Short Name | Description | Product Name, Supplier |

|---|---|---|

| BN3 a | hBN powder. Platelet agglomerates with D50 of 20 µm and size distribution in the range (0.5–31) µm, BET ~4 m2/g | HeBoFill CL-ADH 020, Henze Boron Nitride Products AG, Lauben, Germany |

| TPU | Thermoplastic polyurethane (in the form of powder). An elastomer with Shore A hardness 88. | Ultrasint TPU 88A, BASF, Ludwigshafen am Rhein, Germany |

| Epoxy b | An epoxy system (for casting) containing:

| Huntsman, The Woodlands, TX, USA |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Do, N.B.D.; Imenes, K.; Aasmundtveit, K.E.; Nguyen, H.-V.; Andreassen, E. Thermal Conductivity and Mechanical Properties of Polymer Composites with Hexagonal Boron Nitride—A Comparison of Three Processing Methods: Injection Moulding, Powder Bed Fusion and Casting. Polymers 2023, 15, 1552. https://doi.org/10.3390/polym15061552

Do NBD, Imenes K, Aasmundtveit KE, Nguyen H-V, Andreassen E. Thermal Conductivity and Mechanical Properties of Polymer Composites with Hexagonal Boron Nitride—A Comparison of Three Processing Methods: Injection Moulding, Powder Bed Fusion and Casting. Polymers. 2023; 15(6):1552. https://doi.org/10.3390/polym15061552

Chicago/Turabian StyleDo, Nu Bich Duyen, Kristin Imenes, Knut E. Aasmundtveit, Hoang-Vu Nguyen, and Erik Andreassen. 2023. "Thermal Conductivity and Mechanical Properties of Polymer Composites with Hexagonal Boron Nitride—A Comparison of Three Processing Methods: Injection Moulding, Powder Bed Fusion and Casting" Polymers 15, no. 6: 1552. https://doi.org/10.3390/polym15061552

APA StyleDo, N. B. D., Imenes, K., Aasmundtveit, K. E., Nguyen, H.-V., & Andreassen, E. (2023). Thermal Conductivity and Mechanical Properties of Polymer Composites with Hexagonal Boron Nitride—A Comparison of Three Processing Methods: Injection Moulding, Powder Bed Fusion and Casting. Polymers, 15(6), 1552. https://doi.org/10.3390/polym15061552