Highly Toughened Nanostructured Self-Assembled Epoxy-Based Material—Correlation Study between Nanostructured Morphology and Fracture Toughness—Impact Characteristics

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

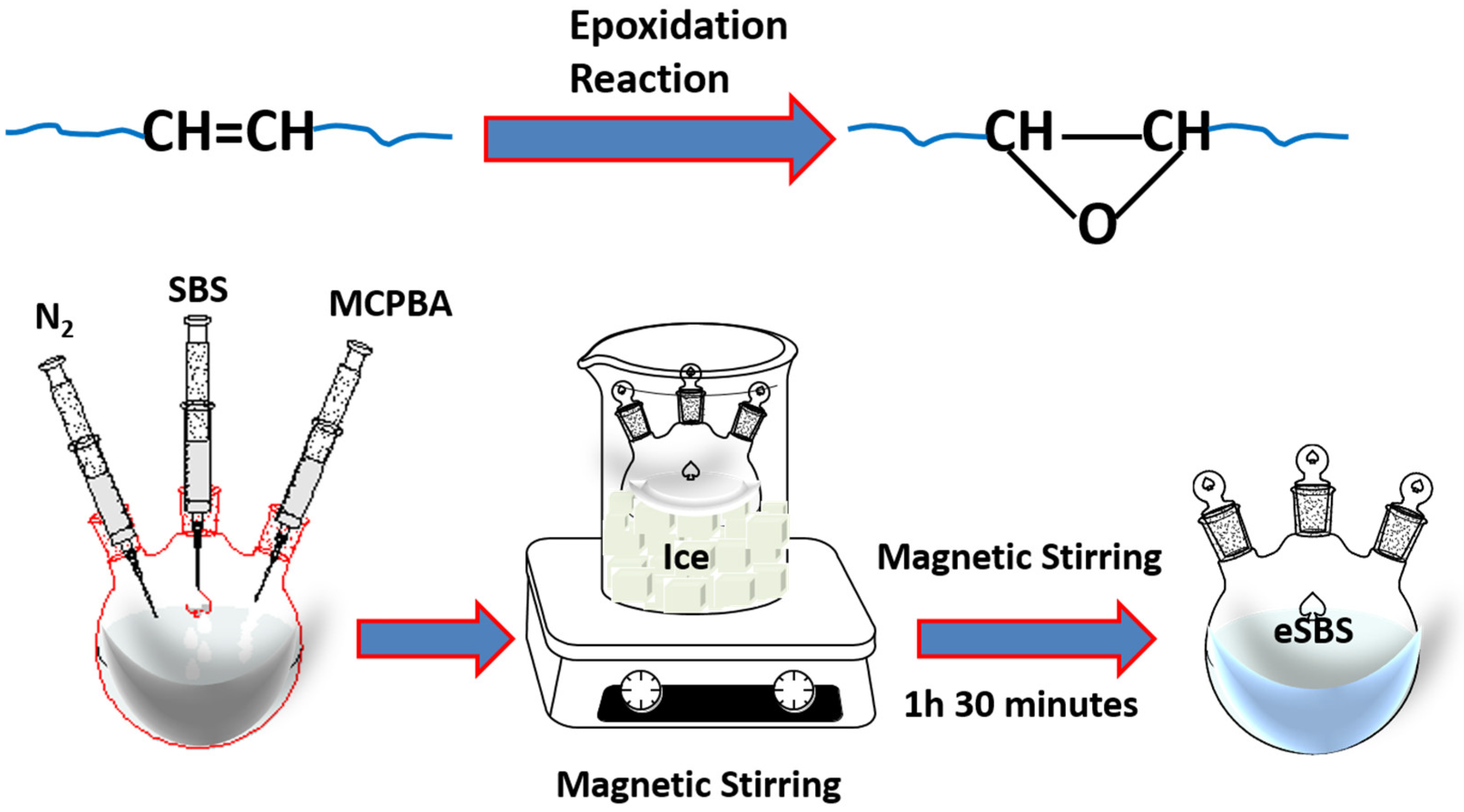

2.2.1. Preparation of eSBS55

2.2.2. Preparation of Epoxy/Epoxidized SBS (55 mol wt%)- 4,4′-diaminodiphenylmethane (epoxy/eSBS55-DDM) Blends

2.3. Characterization Techniques

3. Results

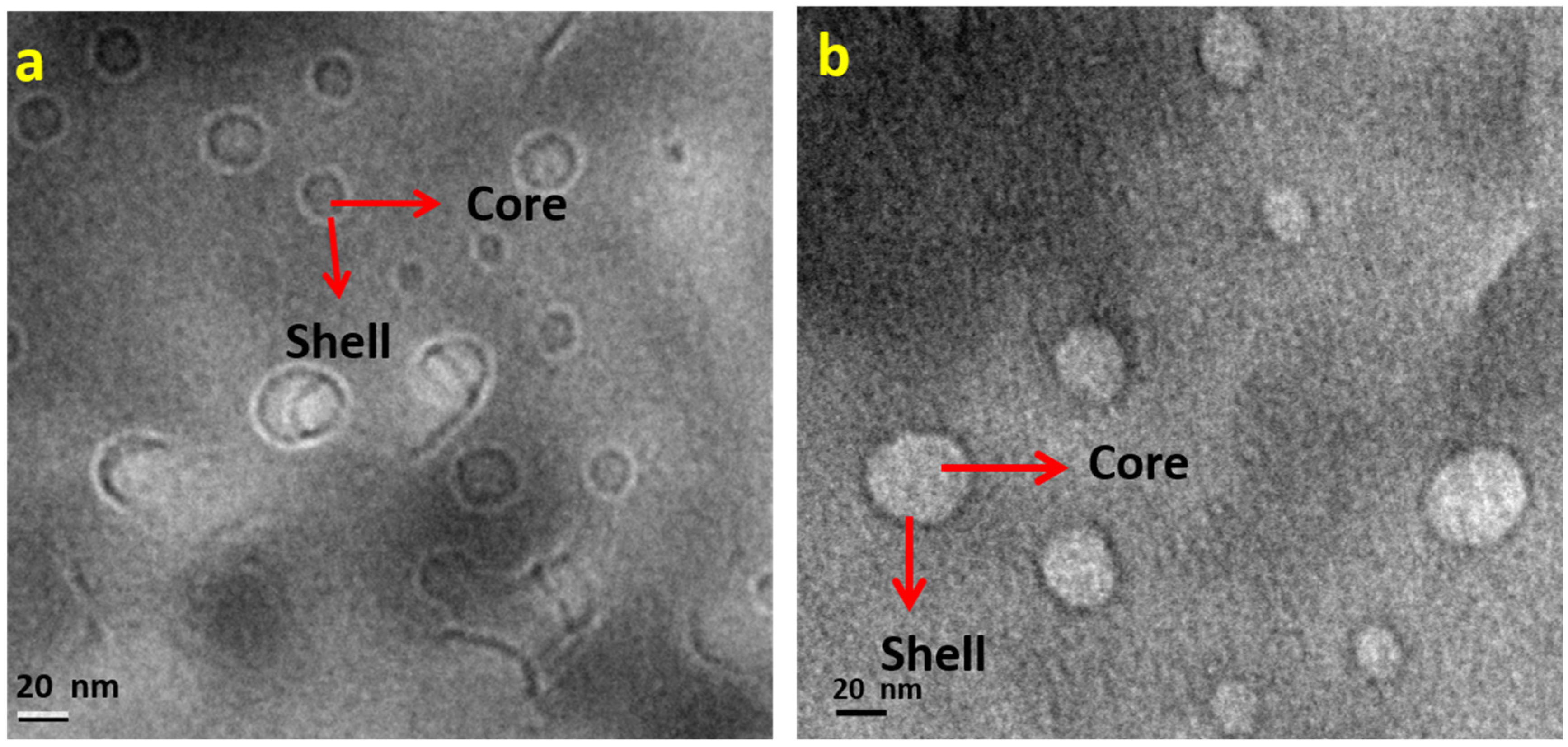

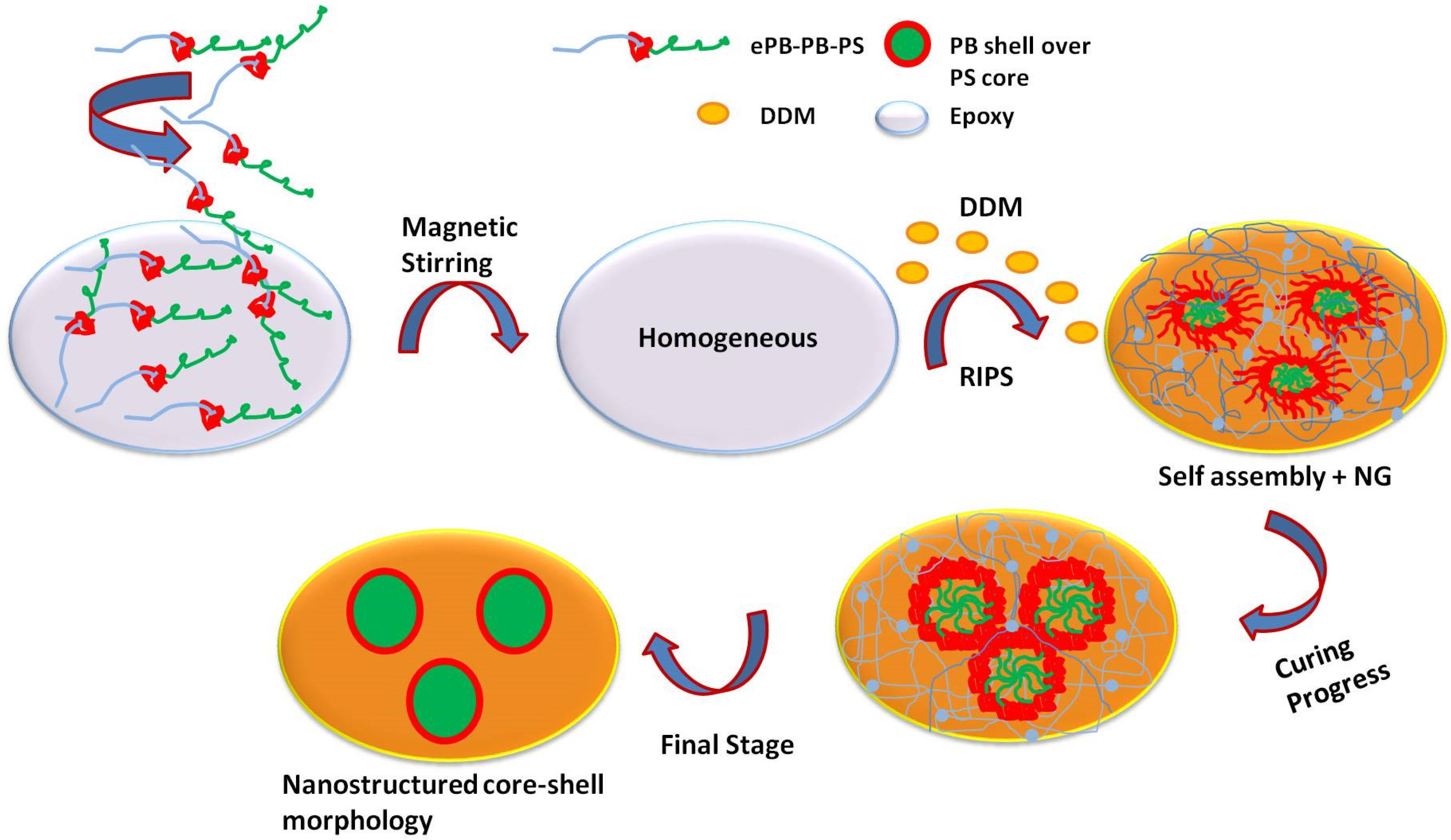

3.1. Evolution of Nanostructured Core-Shell Morphology

3.2. Mechanical Studies

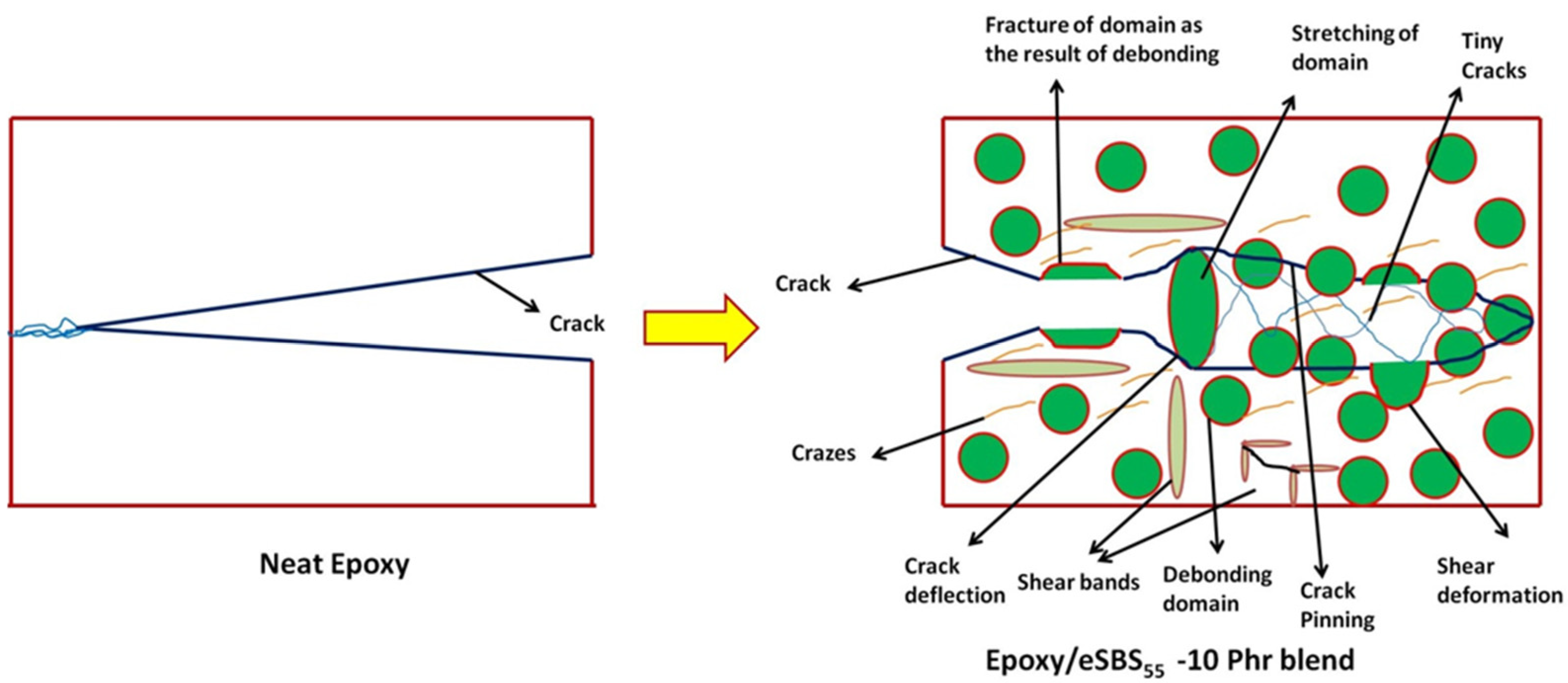

3.2.1. Fracture Toughness

3.2.2. Impact Strength

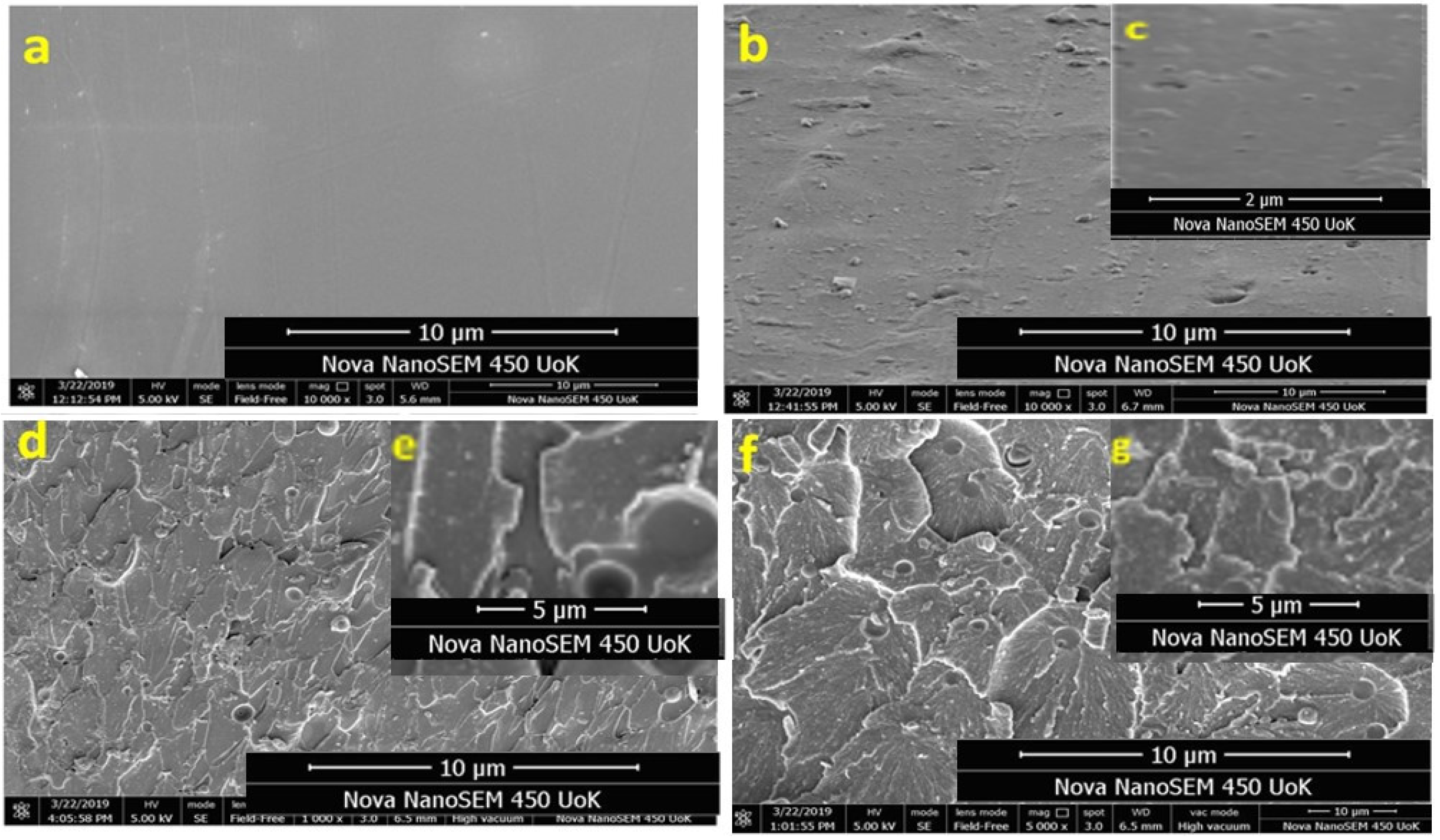

3.3. Field Emission Scanning Electron Microscopy (FE-SEM)

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Remya, V.P.R.; Varghese, R.J.; Parani, S.; Sakho, E.H.M.; Oluwafemi, O.S.; Thomas, S. Compatibilization of epoxidized triblock copolymer on the generation of self-assembled nanostructured epoxies and their surface wettability. J. Appl. Polym. Sci. 2021, 138, 49985. [Google Scholar] [CrossRef]

- Salim, N.V.; Hameed, N.; Fox, B.L.; Hanley, T.L. Novel Approach to Trigger Nanostructures in Thermosets Using Competitive Hydrogen-Bonding-Induced Phase Separation (CHIPS). Macromolecules 2015, 48, 8337–8345. [Google Scholar] [CrossRef]

- Thomas, R.; Yumei, D.; Yuelong, H.; Le, Y.; Moldenaers, P.; Weimin, Y.; Czigany, T.; Thomas, S. Miscibility, morphology, thermal, and mechanical properties of a DGEBA based epoxy resin toughened with a liquid rubber. Polymer 2008, 49, 278–294. [Google Scholar] [CrossRef]

- Pillai, J.P.; Pionteck, J.; Häßler, R.; Sinturel, C.; Mathew, V.S.; Thomas, S. Effect of Cure Conditions on the Generated Morphology and Viscoelastic Properties of a Poly(acrylonitrile–butadiene–styrene) Modified Epoxy–Amine System. Ind. Eng. Chem. Res. 2012, 51, 2586–2595. [Google Scholar] [CrossRef]

- Phong, N.T.; Gabr, M.H.; Okubo, K.; Chuong, B.; Fujii, T. Enhancement of mechanical properties of carbon fabric/epoxy composites using micro/nano-sized bamboo fibrils. Mater. Des. 2013, 47, 624–632. [Google Scholar] [CrossRef]

- Kinloch, A.J.; Masania, K.; Taylor, A.C.; Sprenger, S.; Egan, D. The fracture of glass-fibre-reinforced epoxy composites using nanoparticle-modified matrices. J. Mater. Sci. 2007, 43, 1151–1154. [Google Scholar] [CrossRef]

- Domun, N.; Hadavinia, H.; Zhang, T.; Sainsbury, T.; Liaghat, G.H.; Vahid, S. Improving the fracture toughness and the strength of epoxy using nanomaterials—A review of the current status. Nanoscale 2015, 7, 10294–10329. [Google Scholar] [CrossRef] [PubMed]

- Vijayan, P.P.; Puglia, D.; Al-Maadeed, M.A.S.A.; Kenny, J.M.; Thomas, S. Elastomer/thermoplastic modified epoxy nanocomposites: The hybrid effect of ‘micro’ and ‘nano’ scale. Mater. Sci. Eng. R Rep. 2017, 116, 1–29. [Google Scholar] [CrossRef]

- Liu, X.-F.; Luo, X.; Liu, B.-W.; Zhong, H.-Y.; Guo, D.-M.; Yang, R.; Chen, L.; Wang, Y.-Z. Toughening Epoxy Resin Using a Liquid Crystalline Elastomer for Versatile Application. ACS Appl. Polym. Mater. 2019, 1, 2291–2301. [Google Scholar] [CrossRef]

- Yee, A.F.; Pearson, R.A. Toughening mechanisms in elastomer-modified epoxies. J. Mater. Sci. 1986, 21, 2462–2474. [Google Scholar] [CrossRef]

- Meijerink, J.I.; Eguchi, S.; Ogata, M.; Ishii, T.; Amagi, S.; Numata, S.; Sashima, H. The influence of siloxane modifiers on the thermal expansion coefficient of epoxy resins. Polymer 1994, 35, 179–186. [Google Scholar] [CrossRef]

- Song, X.; Zheng, S.; Huang, J.; Zhu, P.; Guo, Q. Miscibility and Mechanical Properties of Tetrafunctional Epoxy Resin/Phenolphthalein Poly (ether ether ketone) Blends. J. Appl. Polym. Sci. 2001, 79, 598–607. [Google Scholar] [CrossRef]

- Zheng, S.; Wang, J.; Guo, Q.; Wei, J.; Li, J. Miscibility, morphology and fracture toughness of epoxy resin/poly (styrene-co-acrylonitrile) blends. Polymer 1996, 37, 4667–4673. [Google Scholar] [CrossRef]

- Zhong, Z.; Zheng, S.; Huang, J.; Cheng, X.; Guo, Q.; Wei, J. Phase behaviour and mechanical properties of epoxy resin containing phenolphthalein poly(ether ether ketone). Polymer 1998, 39, 1075–1080. [Google Scholar] [CrossRef]

- Zheng, S.; Hu, Y.; Guo, Q.; Wei, J. Miscibility, morphology and fracture toughness of epoxy resin/poly (vinyl acetate) blends. Colloid Polym. Sci. 1996, 274, 410–417. [Google Scholar] [CrossRef]

- Ritzenthaler, S.; Court, F.; David, L.; Girard-Reydet, E.; Leibler, L.; Pascault, J.P. ABC Triblock Copolymers/Epoxy−Diamine Blends. 1. Keys To Achieve Nanostructured Thermosets. Macromolecules 2002, 35, 6245–6254. [Google Scholar] [CrossRef]

- Grubbs, R.B.; Dean, J.M.; Broz, M.E.; Bates, F.S. Reactive Block Copolymers for Modification of Thermosetting Epoxy. Macromolecules 2000, 33, 9522–9534. [Google Scholar] [CrossRef]

- Remya, V.R.; Pious, C.V.; Adeyemi, O.O.; Parani, S.; Sakho, E.H.; Rajendran, J.V.; Maluleke, R.; Kalarikkal, N.; Thomas, S.; Oluwafemi, O.S. Self-assembled nanostructured viscoelastic and thermally stable high performance epoxy based nanomaterial for aircraft and automobile applications: An experimental and theoretical modeling approach. Colloids Surf. A Physicochem. Eng. Asp. 2021, 627, 127236. [Google Scholar] [CrossRef]

- Hillmyer, M.A.; Lipic, P.M.; Hajduk, D.A.; Almdal, K.; Bates, F.S. Self-Assembly and Polymerization of Epoxy Resin-Amphiphilic Block Copolymer Nanocomposites. J. Am. Chem. Soc. 1997, 119, 2749–2750. [Google Scholar] [CrossRef]

- Lipic, P.M.; Bates, F.S.; Hillmyer, M.A. Nanostructured Thermosets from Self-Assembled Amphiphilic Block Copolymer/Epoxy Resin Mixtures. J. Am. Chem. Soc. 1998, 120, 8963–8970. [Google Scholar] [CrossRef]

- Hameed, N.; Guo, Q.; Xu, Z.; Hanley, T.L.; Mai, Y.-W. Reactive block copolymer modified thermosets: Highly ordered nanostructures and improved properties. Soft Matter 2010, 6, 6119–6129. [Google Scholar] [CrossRef]

- Kosonen, H.; Ruokolainen, J.; Nyholm, P.; Ikkala, O. Self-Organized Thermosets: Blends of Hexamethyltetramine Cured Novolac with Poly (2-vinylpyridine)-block-poly (isoprene). Macromolecules 2001, 34, 3046–3049. [Google Scholar] [CrossRef]

- Dean, J.M.; Lipic, P.M.; Grubbs, R.B.; Cook, R.F.; Bates, F.S. Micellar structure and mechanical properties of block copolymer-modified epoxies. J. Polym. Sci. Part B Polym. Phys. 2001, 39, 2996–3010. [Google Scholar] [CrossRef]

- Guo, Q.; Thomann, R.; Gronski, W.; Thurn-Albrecht, T. Phase Behavior, Crystallization, and Hierarchical Nanostructures in Self-Organized Thermoset Blends of Epoxy Resin and Amphiphilic Poly (ethylene oxide)-block-poly (propylene oxide)-block-poly (ethylene oxide) Triblock Copolymers. Macromolecules 2002, 35, 3133–3144. [Google Scholar] [CrossRef]

- Ritzenthaler, S.A.B.C.; Court, F.; Girard-Reydet, E.; Leibler, L.; Pascault, J.P. ABC Triblock Copolymers/Epoxy−Diamine Blends. 2. Parameters Controlling the Morphologies and Properties. Macromolecules 2002, 36, 118–126. [Google Scholar] [CrossRef]

- Guo, Q.; Thomann, R.; Gronski, W.; Staneva, R.; Ivanova, R.; Stühn, B. Nanostructures, Semicrytalline Morphology, and Nanoscale Confinement Effect on the Crystallization Kinetics in Self-Organized Block Copolymer/Thermoset Blends. Macromolecules 2003, 36, 3635–3645. [Google Scholar] [CrossRef]

- Zucchi, I.A.; Galante, M.J.; Williams, R.J.J. Comparison of morphologies and mechanical properties of crosslinked epoxies modified by polystyrene and poly (methyl methacrylate)) or by the corresponding block copolymer polystyrene-b-poly (methyl methacrylate). Polymer 2005, 46, 2603–2609. [Google Scholar] [CrossRef]

- Wu, J.; Thio, Y.S.; Bates, F.S. Structure and properties of PBO–PEO diblock copolymer modified epoxy. J. Polym. Sci. Part B Polym. Phys. 2005, 43, 1950–1965. [Google Scholar] [CrossRef]

- Serrano, E.; Tercjak, A.; Kortaberria, G.; Pomposo, J.A.; Mecerreyes, D.; Zafeiropoulos, N.E.; Stamm, M.; Mondragon, I. Nanostructured Thermosetting Systems by Modification with Epoxidized Styrene−Butadiene Star Block Copolymers. Effect of Epoxidation Degree. Macromolecules 2006, 39, 2254–2261. [Google Scholar] [CrossRef]

- Thio, Y.S.; Wu, J.; Bates, F.S. Epoxy toughening using low molecular weight poly (hexylene oxide)-poly (ethylene oxide) diblock copolymers. Macromolecules 2006, 39, 7187–7189. [Google Scholar] [CrossRef]

- Guo, Q.; Wang, K.; Chen, L.; Zheng, S.; Halley, P.J. Phase behavior, crystallization, and nanostructures in thermoset blends of epoxy resin and amphiphilic star-shaped block copolymers. J. Polym. Sci. Part B Polym. Phys. 2006, 44, 975–985. [Google Scholar] [CrossRef]

- Guo, Q.; Chen, F.; Wang, K.; Chen, L. Nanostructured thermoset epoxy resin templated by an amphiphilic poly (ethylene oxide)-block-poly (dimethylsiloxane) diblock copolymer. J. Polym. Sci. Part B Polym. Phys. 2006, 44, 3042–3052. [Google Scholar] [CrossRef]

- Maiez-Tribut, S.; Pascault, J.P.; Soulé, E.R.; Borrajo, J.; Williams, R.J.J. Nanostructured Epoxies Based on the Self-Assembly of Block Copolymers: A New Miscible Block That Can Be Tailored to Different Epoxy Formulations. Macromolecules 2007, 40, 1268–1273. [Google Scholar] [CrossRef]

- Sinturel, C.; Vayer, M.; Erre, R.; Amenitsch, H. Nanostructured Polymers Obtained from Polyethylene-block-poly (ethylene oxide) Block Copolymer in Unsaturated Polyester. Macromolecules 2007, 40, 2532–2538. [Google Scholar] [CrossRef]

- Ocando, C.; Serrano, E.; Tercjak, A.; Pena, C.; Kortaberria, G.; Calberg, C.; Grignard, B.; Jerome, R.; Carrasco, P.M.; Mecerreyes, D.; et al. Structure and Properties of a Semifluorinated Diblock Copolymer Modified Epoxy Blend. Macromolecules 2007, 40, 4068–4074. [Google Scholar] [CrossRef]

- Xu, Z.; Zheng, S. Reaction-Induced Microphase Separation in Epoxy Thermosets Containing Poly (ε-caprolactone)-block-poly (n-butyl acrylate) Diblock Copolymer. Macromolecules 2007, 40, 2548–2558. [Google Scholar] [CrossRef]

- Ruiz-Pérez, L.; Royston, G.J.; Fairclough, J.P.A.; Ryan, A.J. Toughening by nanostructure. Polymer 2008, 49, 4475–4488. [Google Scholar] [CrossRef]

- Meng, F.; Xu, Z.; Zheng, S. Microphase Separation in Thermosetting Blends of Epoxy Resin and Poly (ε-caprolactone)-block-Polystyrene Block Copolymers. Macromolecules 2008, 41, 1411–1420. [Google Scholar] [CrossRef]

- Gong, W.; Zeng, K.; Wang, L.; Zheng, S. Poly (hydroxyether of bisphenol A)-block-polydimethylsiloxane alternating block copolymer and its nanostructured blends with epoxy resin. Polymer 2008, 49, 3318–3326. [Google Scholar] [CrossRef]

- Ruzette, A.-V.; Leibler, L. Block copolymers in tomorrow’s plastics. Nat. Mater. 2005, 4, 19–31. [Google Scholar] [CrossRef]

- Hameed, N.; Guo, Q.; Hanley, T.; Mai, Y.-W. Hydrogen bonding interactions, crystallization, and surface hydrophobicity in nanostructured epoxy/block copolymer blends. J. Polym. Sci. Part B Polym. Phys. 2010, 48, 790–800. [Google Scholar] [CrossRef]

- Pascault, J.P.; Williams, R.J. Epoxy Polymers: New Materials and Innovations; John Wiley & Sons: Hoboken, NJ, USA, 2009; p. 367. [Google Scholar]

- Mathis, E.; Michon, M.-L.; Billaud, C.; Vergelati, C.; Clarke, N.; Jestin, J.R.; Long, D. Controlling the Morphology in Epoxy/Thermoplastic Systems. ACS Appl. Polym. Mater. 2022, 4, 2091–2104. [Google Scholar] [CrossRef]

- Liu, J.D.; Thompson, Z.J.; Sue, H.-J.; Bates, F.S.; Hillmyer, M.A.; Dettloff, M.; Jacob, G.; Verghese, N.; Pham, H. Toughening of Epoxies with Block Copolymer Micelles of Wormlike Morphology. Macromolecules 2010, 43, 7238–7243. [Google Scholar] [CrossRef]

- Yi, F.; Zheng, S.; Liu, T. Nanostructures and Surface Hydrophobicity of Self-Assembled Thermosets Involving Epoxy Resin and Poly (2,2,2-trifluoroethyl acrylate)-block-Poly (ethylene oxide) Amphiphilic Diblock Copolymer. J. Phys. Chem. B 2009, 113, 1857–1868. [Google Scholar] [CrossRef] [PubMed]

- Hu, D.; Zhang, C.; Yu, R.; Wang, L.; Zheng, S. Self-organized thermosets involving epoxy and poly (ε-caprolactone)-block-poly (ethylene-co-ethylethylene)-block-poly (ε-caprolactone) amphiphilic triblock copolymer. Polymer 2010, 51, 6047–6057. [Google Scholar] [CrossRef]

- Tercjak, A.; Larrañaga, M.; Martin, M.; Mondragon, I. Thermally reversible nanostructured thermosetting blends modified with poly (ethylene-b-ethylene oxide) diblock copolymer. J. Therm. Anal. Calorim. 2006, 86, 663–667. [Google Scholar] [CrossRef]

- Declet-Perez, C.; Redline, E.M.; Francis, L.F.; Bates, F.S. Role of Localized Network Damage in Block Copolymer Toughened Epoxies. ACS Macro Lett. 2012, 1, 338–342. [Google Scholar] [CrossRef]

- Dean, J.M.; Verghese, N.E.; Pham, H.Q.; Bates, F.S. Nanostructure Toughened Epoxy Resins. Macromolecules 2003, 36, 9267–9270. [Google Scholar] [CrossRef]

- Klingler, A.; Bajpai, A.; Wetzel, B. The effect of block copolymer and core-shell rubber hybrid toughening on morphology and fracture of epoxy-based fibre reinforced composites. Eng. Fract. Mech. 2018, 203, 81–101. [Google Scholar] [CrossRef]

- Yamanaka, K.; Takagi, Y.; Inoue, T. Reaction-induced phase separation in rubber-modified epoxy resins. Polymer 1989, 30, 1839–1844. [Google Scholar] [CrossRef]

- George, S.M.; Puglia, D.; Kenny, J.M.; Causin, V.; Parameswaranpillai, J.; Thomas, S. Morphological and Mechanical Characterization of Nanostructured Thermosets from Epoxy and Styrene-block-Butadiene-block-Styrene Triblock Copolymer. Ind. Eng. Chem. Res. 2013, 52, 9121–9129. [Google Scholar] [CrossRef]

- George, S.M.; Puglia, D.; Kenny, J.M.; Parameswaranpillai, J.; Thomas, S. Reaction-Induced Phase Separation and Thermomechanical Properties in Epoxidized Styrene-block-butadiene-block-styrene Triblock Copolymer Modified Epoxy/DDM System. Ind. Eng. Chem. Res. 2014, 53, 6941–6950. [Google Scholar] [CrossRef]

- Yeganeh, J.K. Dynamics of nucleation and growth mechanism in the presence of nanoparticles or block copolymers: Polystyrene/poly (vinyl methyl ether). Polym. Bull. 2017, 75, 1–15. [Google Scholar] [CrossRef]

| Specimen | Impact Strength (J/m2) | Impact Energy (J/m) | Fracture Toughness KIC (MPa m1/2) |

|---|---|---|---|

| Neat Epoxy | 2590 ± 42 | 27 ± 3 | 1.54 |

| Epoxy/eSBS-5 phr blend | 3668 ± 56 | 36 ± 5 | 1.62 |

| Epoxy/eSBS-10 phr blend | 5597 ± 62 | 58 ± 6 | 2.54 |

| Epoxy/eSBS-20 phr blend | 4149 ± 34 | 43 ± 5 | 1.86 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Remya, V.P.; Parani, S.; Sakho, E.H.M.; Rajendran, J.V.; Maluleke, R.; Lebepe, T.C.; Masha, S.; Hameed, N.; Thomas, S.; Oluwafemi, O.S. Highly Toughened Nanostructured Self-Assembled Epoxy-Based Material—Correlation Study between Nanostructured Morphology and Fracture Toughness—Impact Characteristics. Polymers 2023, 15, 1689. https://doi.org/10.3390/polym15071689

Remya VP, Parani S, Sakho EHM, Rajendran JV, Maluleke R, Lebepe TC, Masha S, Hameed N, Thomas S, Oluwafemi OS. Highly Toughened Nanostructured Self-Assembled Epoxy-Based Material—Correlation Study between Nanostructured Morphology and Fracture Toughness—Impact Characteristics. Polymers. 2023; 15(7):1689. https://doi.org/10.3390/polym15071689

Chicago/Turabian StyleRemya, Vasudevan Pillay, Sundararajan Parani, El Hadji Mamour Sakho, Jose Varghese Rajendran, Rodney Maluleke, Thabang Calvin Lebepe, Sam Masha, Nishar Hameed, Sabu Thomas, and Oluwatobi Samuel Oluwafemi. 2023. "Highly Toughened Nanostructured Self-Assembled Epoxy-Based Material—Correlation Study between Nanostructured Morphology and Fracture Toughness—Impact Characteristics" Polymers 15, no. 7: 1689. https://doi.org/10.3390/polym15071689

APA StyleRemya, V. P., Parani, S., Sakho, E. H. M., Rajendran, J. V., Maluleke, R., Lebepe, T. C., Masha, S., Hameed, N., Thomas, S., & Oluwafemi, O. S. (2023). Highly Toughened Nanostructured Self-Assembled Epoxy-Based Material—Correlation Study between Nanostructured Morphology and Fracture Toughness—Impact Characteristics. Polymers, 15(7), 1689. https://doi.org/10.3390/polym15071689