Composition and Workability of Plastic Fractions Recovered from Commingled Waste Discarded by a Composting Plant

Abstract

:1. Introduction

2. Materials and Methods

2.1. Waste Recovery at the Composting Plant

2.2. Sorting of Plastic Fractions

2.3. Characterization of Separated Fractions

2.4. Processing Recycled Tensile Specimens and Testing

3. Results and Discussion

3.1. Composition of the Fraction Discarded by the Composting Plant

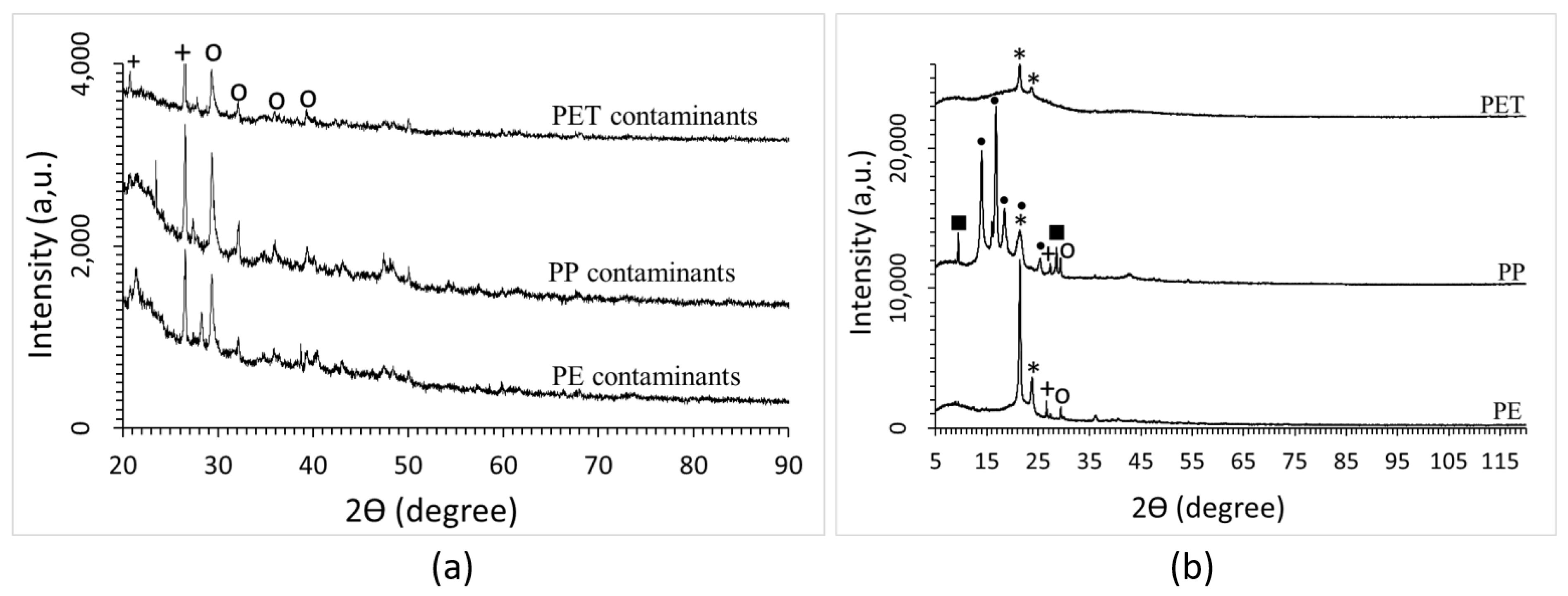

3.2. Composition of the Batches Recovered by the NIR Separator

3.3. Effectiveness of the Washing Step

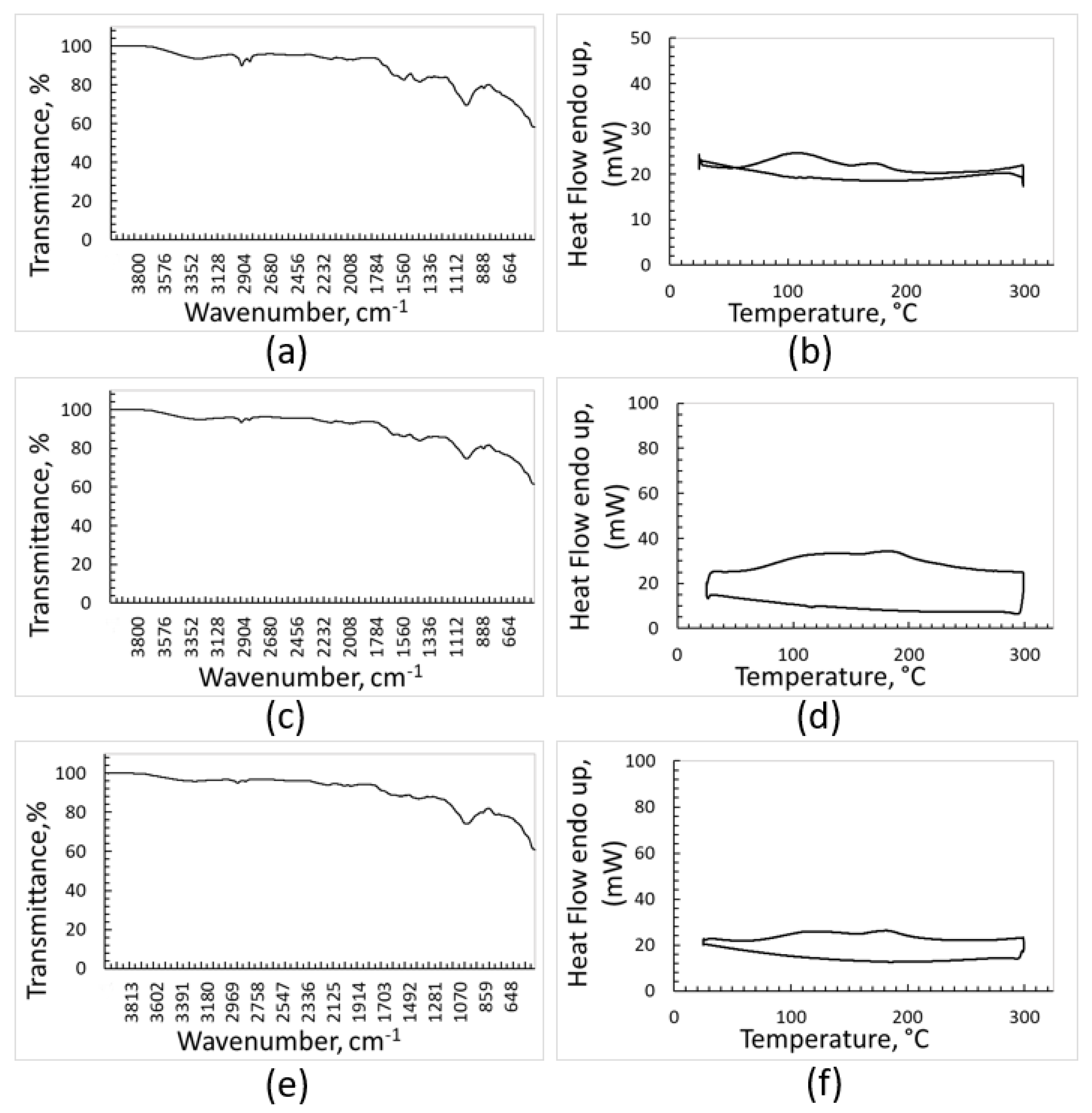

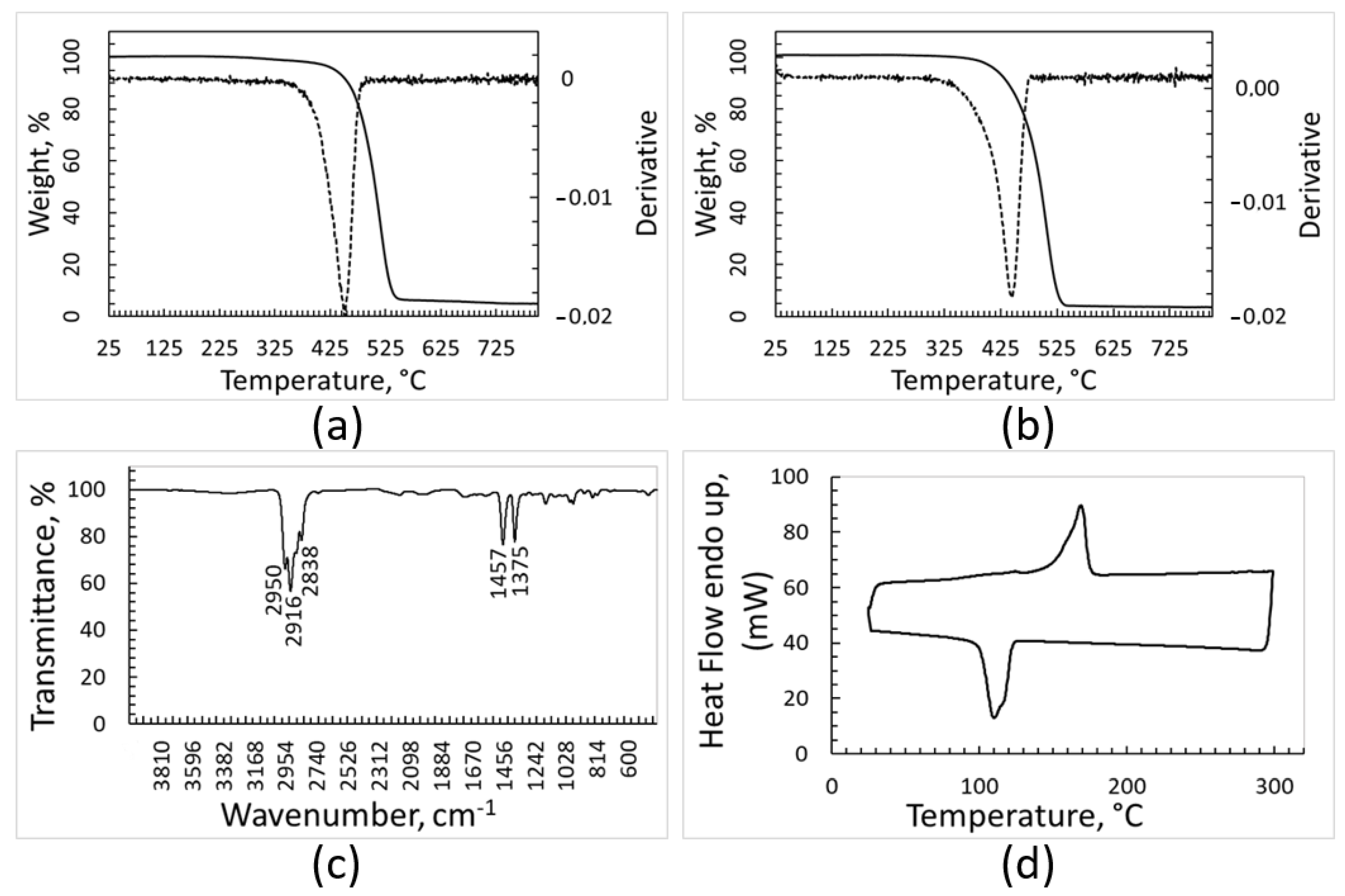

3.4. Characterization of the Cleaned PE Batch

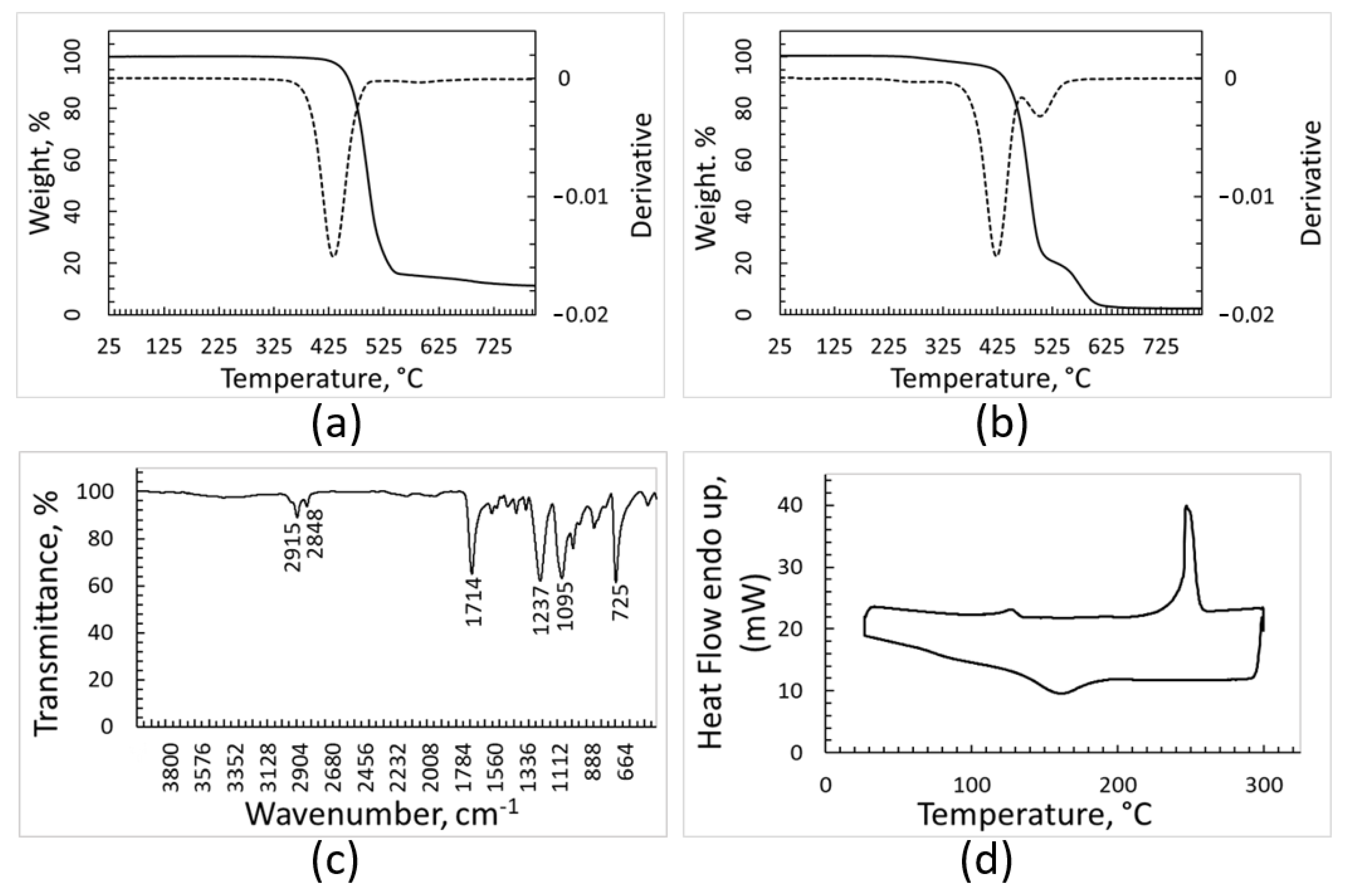

3.5. Characterization of the Cleaned PP Batch

3.6. Characterization of the Cleaned PET Batch

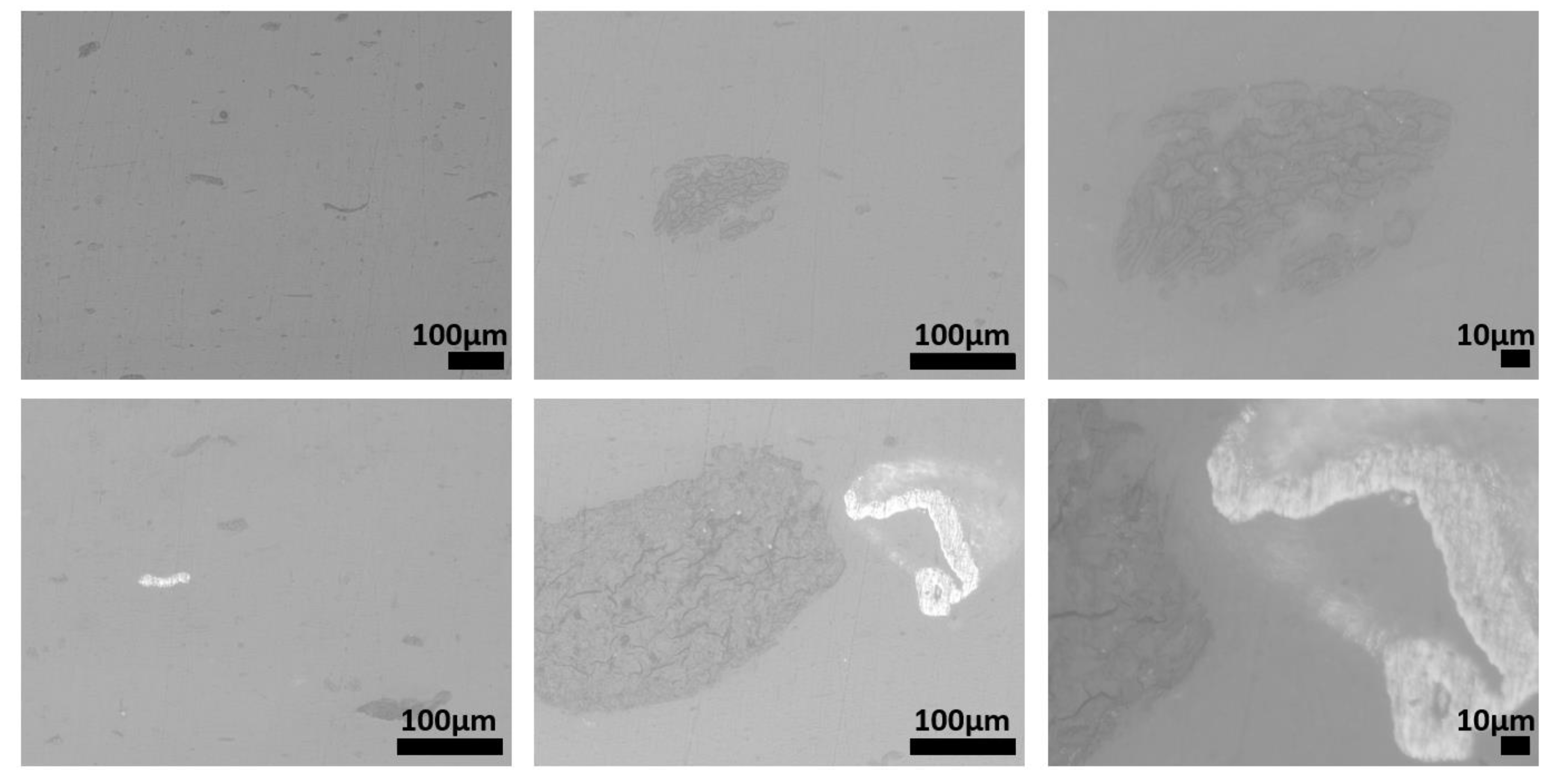

3.7. Microstructure and Tensile Properties of Recycled Polymeric Samples

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- World Bank, 2018. What a Waste: An Updated Look into the Future of Solid Waste Management an online News Article Published 20 September 2018. Available online: https://www.worldbank.org/en/search?q=https%3A%2F%2Fwww.worldbank.org%2Fen%2Fnews%2Fimmersive-story%2F2018%2F09%2F20%2Fwhat-awaste-an-updated-look-into-the-future-of-solid-waste-management (accessed on 11 January 2023).

- Gu, B.; Tang, X.; Liu, L.; Li, Y.; Fujiwara, T.; Sun, H.; Gu, A.; Yao, Y.; Duan, R.; Song, J.; et al. The recyclable waste recycling potential towards zero waste Cities—A comparison of three cities in China. J. Clean. Prod. 2021, 295, 126358. [Google Scholar] [CrossRef]

- Gundupalli, S.P.; Hait, S.; Thakur, A. A review on automated sorting of source-separated municipal solid waste for recycling. Waste Manag. 2017, 60, 56–74. [Google Scholar] [CrossRef] [PubMed]

- Shi, K.; Zhou, Y.; Zhang, Z. Mapping the Research Trends of HouseholdWaste Recycling: A Bibliometric Analysis. Sustainability 2021, 13, 6029. [Google Scholar] [CrossRef]

- Xevgenos, D.; Papadaskalopoulou, C.; Panaretou, V.; Moustakas, K.; Malamis, D. Success Stories for Recycling of MSW at Municipal Level: A Review. Waste Biomass Valor 2015, 6, 657–684. [Google Scholar] [CrossRef]

- Okoligwe, O.; Radu, T.; Leaper, M.C.; Wagner, J.L. Characterization of municipal solid waste residues for hydrothermal liquefaction into liquid transportation fuels. Waste Manag. 2022, 140, 133–142. [Google Scholar] [CrossRef]

- Chew, K.W.; Chia, S.R.; Chia, W.Y.; Cheah, W.Y.; Munawaroh, H.S.H.; Ong, W.-J. Abatement of hazardous materials and biomass waste via pyrolysis and co-pyrolysis for environmental sustainability and circular economy. Environ. Pollut. 2021, 278, 116836. [Google Scholar] [CrossRef]

- Pierini, V.I.; Mazzeo, N.; Cazenave, M.; Semmartin, M. Waste generation and pro-environmental behaviors at household level: A citizen science study in Buenos Aires (Argentina). Resour. Conserv. Recycl. 2021, 170, 105560. [Google Scholar] [CrossRef]

- Bernat, K.; Wojnowska-Baryła, I.; Zaborowska, M.; Samul, I. Insight into the Composition of the Stabilized Residual from a Full-Scale Mechanical-Biological Treatment (MBT) Plant in Terms of the Potential Recycling and Recovery of Its Contaminants. Sustainability 2021, 13, 5432. [Google Scholar] [CrossRef]

- Horodytska, O.; Cabanes, A.; Fullana, A. Non-intentionally added substances (NIAS) in recycled plastics. Chemosphere 2020, 251, 126373. [Google Scholar] [CrossRef]

- Suthar, S.; Rayal, P.; Ahada, C.P.S. Role of different stakeholders in trading of reusable/recyclable urbansolid waste materials: A case study. Sustain. Cities Soc. 2016, 22, 104–115. [Google Scholar] [CrossRef]

- Dennison, G.J.; Dodda, V.A.; Whelanb, B. A socio-economic based survey of household waste characteristics in the city of Dublin, Ireland. I. Waste composition. Resour. Conserv. Recycl. 1996, 17, 227–244. [Google Scholar] [CrossRef]

- Kadir, A.A.; Abidin, S.S.S.Z. Solid Waste Composition and Quantification at Taman Melewar, Parit Raja, Batu Pahat. IOP Conf. Ser. Mater. Sci. Eng. 2016, 136, 012047. [Google Scholar] [CrossRef] [Green Version]

- Bernache-Pérez, G.; Sánchez-Colón, S.; Garmendia, A.M. Solid waste characterisation study in the Guadalajara Metropolitan Zone, Mexico. Waste Manag. Res. 2001, 19, 413–424. [Google Scholar] [CrossRef] [PubMed]

- Cimpan, C.; Maul, A.; Jansen, M.; Pretz, T.; Wenzel, H. Central sorting and recovery of MSW recyclable materials: A review of technological state-of-the-art, cases, practice and implications for materials recycling. J. Environ. Manag. 2015, 156, 181–199. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. Recycling and recovery routes of plastic solid waste (PSW): A review. Waste Manag. 2009, 29, 2625–2643. [Google Scholar] [CrossRef] [PubMed]

- Hersh, B.; Mirkouei, A. Life cycle assessment of pyrolysis-derived biochar from organic wastes and advanced feedstocks. In Proceedings of the ASME 2019 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference IDETC/CIE2019, Anaheim, CA, USA, 18–21 August 2019. DETC2019-97896. [Google Scholar]

- Fendel, V.; Maurer, C.; Kranert, M.; Huang, J.; Schäffner, B. The Potential of the Co-Recycling of Secondary Biodegradable Household Resources Including Wild Plants to Close Nutrient and Carbon Cycles in Agriculture in Germany. Sustainability 2022, 14, 5277. [Google Scholar] [CrossRef]

- Castro, V.O.F.; Teixeira, J.C.; Carvalho, A.R.J.; Vilarinho, M.C. Physicochemical characterization of the rejected waste from the mechanical and biological treatment of municipal solid waste. In Proceedings of the ASME 2021 International Mechanical Engineering Congress and Exposition IMECE2021, Virtual, 1–5 November 2021. IMECE2021-73595. [Google Scholar]

- Morris, J. Comparative LCAs for Curbside Recycling Versus Either Landfilling or Incineration with Energy Recovery. Int. J. LCA 2005, 10, 273–284. [Google Scholar] [CrossRef]

- García Ibarra, V.; Rodríguez Bernaldo de Quiros, A.; Paseiro Losada, P.; Sendon, R. Identification of intentionally and non-intentionally added substances in plastic packaging materials and their migration into food products. Anal. Bioanal. Chem. 2018, 410, 3789–3803. [Google Scholar] [CrossRef]

- Geueke, B. Dossier-Non-Intentionally added substances (NIAS). Food Packag. Forum 2018, 7, 1–10. [Google Scholar] [CrossRef]

- Madhu, G.; Bhunia, H.; Bajpai, P.K.; Chaudhary, V. Mechanical and morphological properties of high density polyethylene and polylactide blends. J. Polym. Eng. 2014, 34, 813–821. [Google Scholar] [CrossRef]

- Lin, J.H.; Pan, Y.J.; Liu, C.F.; Huang, C.L.; Hsieh, C.T.; Chen, C.K.; Lin, Z.-I.; Lou, C.-W. Preparation and compatibility evaluation of polypropylene/high density polyethylene polyblends. Materials 2015, 8, 8850–8859. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Niu, P.; Liu, B.; Wei, X.; Wang, X.; Yang, J. Study on mechanical properties and thermal stability of polypropylene/hemp fiber composites. J. Reinf. Plast. Compos. 2011, 30, 36–44. [Google Scholar] [CrossRef]

- Yang, J.; Gao, M.; Zhao, H.; Liu, S.; Hu, M.; Xie, S. Space charge characteristics of polypropylene modified by rare earth nucleating agent for β crystallization. Materials 2018, 12, 42. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liang, H.; Xie, F.; Guo, F.; Chen, B.; Luo, F.; Jin, Z. Non-isothermal Crystallization Behavior of Poly(ethylene terephthalate)/Poly(trimethylene terephthalate) Blends. Polym. Bull. 2008, 60, 115–127. [Google Scholar] [CrossRef]

- Demirel, B.; Yaras, A.; Elcicek, H. Crystallization Behavior of PET Materials. BAÜ Fen Bil. Enst. Derg. Cilt 2011, 13, 26–35. [Google Scholar]

- Al-Bayaty, S.A.; Al-Uqaily, R.A.; Hameed, S. Study of thermal degradation kinetics of high density polyethlyene (HDPE) by using TGA technique. AIP Conf. Proc. 2020, 2290, 020001. [Google Scholar] [CrossRef]

- Awad, S.A. Mechanical and thermal characterisations of low-density polyethylene/nanoclay composites. Polym. Polym. Compos. 2021, 29, 1322–1325. [Google Scholar] [CrossRef]

- Medupin, R.O.; Abubakre, O.K.; Abdulkareem, A.S.; Muriana, R.A.; Kariim, I.; Bada, S.O. Thermal and physico-mechanical stability of recycled high density polyethylene reinforced with oil palm fibres. Eng. Sci. Technol. Int. J. 2017, 20, 1623–1631. [Google Scholar] [CrossRef]

- Kristl, M.; Muršec, M.; Šuštar, V.; Kristl, J. Application of thermogravimetric analysis for the evaluation of organic and inorganic carbon contents in agricultural soils. J. Ther. Anal. Calorim. 2016, 123, 2139–2214. [Google Scholar] [CrossRef]

- Dubdub, I. Kinetics Study of Polypropylene Pyrolysis by Non-Isothermal Thermogravimetric Analysis. Materials 2023, 16, 584. [Google Scholar] [CrossRef]

- Singh, R.K.; Ruj, B.; Sadhukhan, A.K.; Gupta, P. Thermal degradation of waste plastics under non-sweeping atmosphere: Part 1: Effect of temperature, product optimization, and degradation mechanism. J. Environ. Manag. 2019, 239, 395–406. [Google Scholar] [CrossRef] [PubMed]

- Esmizadeh, E.; Tzoganakis, C.; Mekonnen, T.H. Degradation Behavior of Polypropylene during Reprocessing and Its Biocomposites: Thermal and Oxidative Degradation Kinetics. Polymers 2020, 12, 1627. [Google Scholar] [CrossRef] [PubMed]

- Das, P.; Tiwari, P. Thermal degradation study of waste polyethylene terephthalate (PET) under inert and oxidative environments. Thermochim. Acta 2019, 679, 178340. [Google Scholar] [CrossRef]

- MatWeb, Material Property Data. Available online: https://www.matweb.com/search/DataSheet.aspx?MatGUID=a882a1c603374e278d062f106dfda95b&ckck=1 (accessed on 11 January 2023).

| Polymeric Fractions | Selected Polymer | Organic and Inorganic Contaminants | Water |

|---|---|---|---|

| Polyethylene (PE) | 58% | 36% | 6% |

| Polypropylene (PP) | 57% | 30% | 13% |

| Polyethylene terephthalate (PET) | 68% | 24% | 8% |

| Density (g/cm3) | PE | PP | PET |

|---|---|---|---|

| Theoretical | 0.86–0.97 | 0.90–0.91 | 1.30–1.40 |

| Pellets | 1.00 | 0.89 | 1.19 |

| Printed samples | 1.11 | 0.93 | 1.24 |

| Recycled Polymers | Tensile Strength | Elastic Modulus | Strain at Break |

|---|---|---|---|

| σmax ± SD (MPa) | E ± SD (GPa) | ε ± SD (%) | |

| Polyethylene | 21.8 ± 0.6 | 1.397 ± 0.024 | 10.0 ± 0.9 |

| Polypropylene | 28.0 ± 0.3 | 1.279 ± 0.050 | 524.2 ± 44.6 |

| Polyethylene terephthalate | 22.1 ± 2.6 | 1.968 ± 0.109 | 2.1 ± 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Badini, C.; Ostrovskaya, O.; Bernagozzi, G.; Artusio, A. Composition and Workability of Plastic Fractions Recovered from Commingled Waste Discarded by a Composting Plant. Polymers 2023, 15, 1690. https://doi.org/10.3390/polym15071690

Badini C, Ostrovskaya O, Bernagozzi G, Artusio A. Composition and Workability of Plastic Fractions Recovered from Commingled Waste Discarded by a Composting Plant. Polymers. 2023; 15(7):1690. https://doi.org/10.3390/polym15071690

Chicago/Turabian StyleBadini, Claudio, Oxana Ostrovskaya, Giulia Bernagozzi, and Andrea Artusio. 2023. "Composition and Workability of Plastic Fractions Recovered from Commingled Waste Discarded by a Composting Plant" Polymers 15, no. 7: 1690. https://doi.org/10.3390/polym15071690

APA StyleBadini, C., Ostrovskaya, O., Bernagozzi, G., & Artusio, A. (2023). Composition and Workability of Plastic Fractions Recovered from Commingled Waste Discarded by a Composting Plant. Polymers, 15(7), 1690. https://doi.org/10.3390/polym15071690