Influence of Different Hot Runner-Systems in the Injection Molding Process on the Structural and Mechanical Properties of Regenerated Cellulose Fiber Reinforced Polypropylene

Abstract

:1. Introduction

2. Materials, Processing, and Characterization

2.1. Used Materials

2.2. Compounding

2.3. Injection Molding

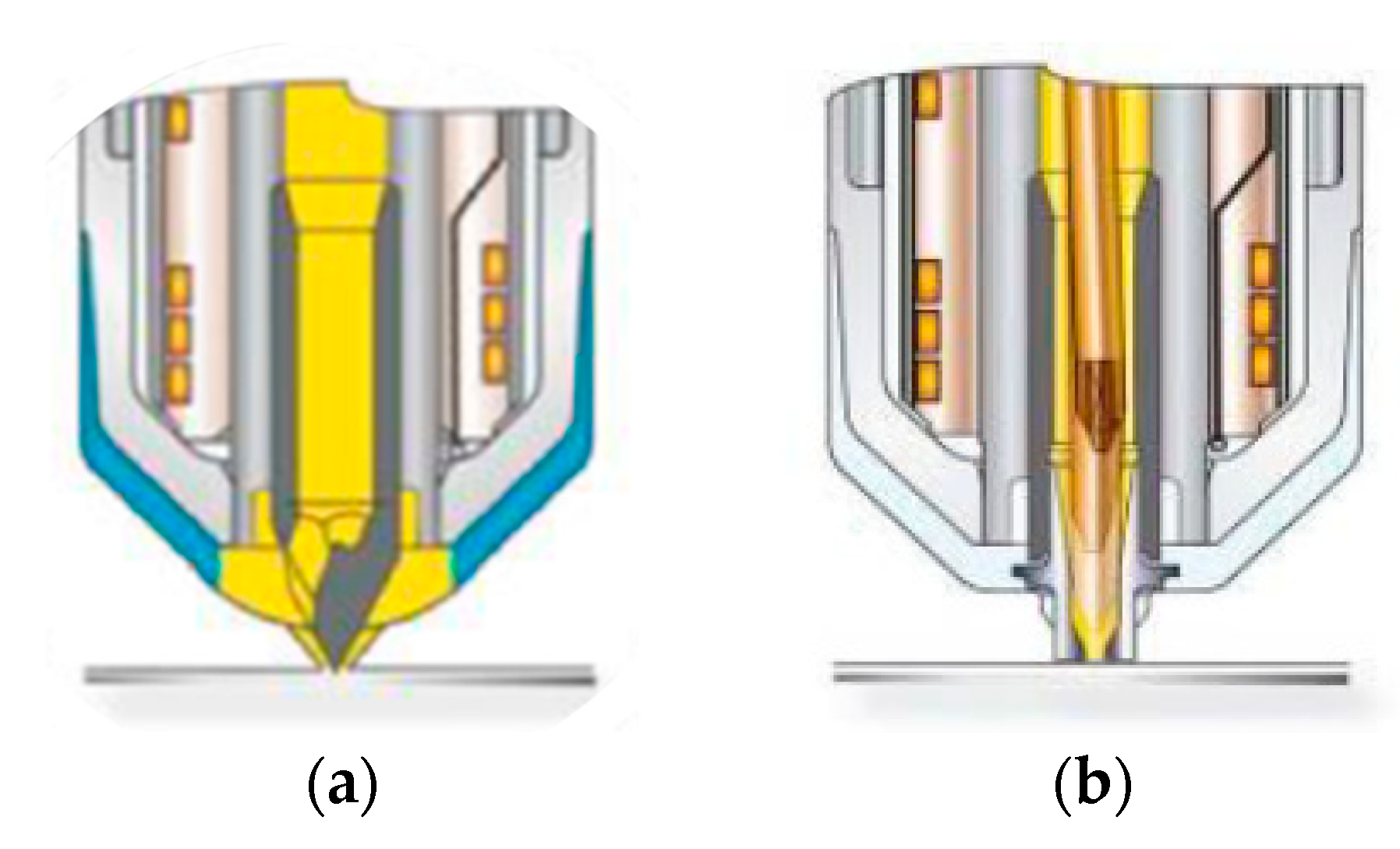

- (a)

- Open hot runner system with tip (5SHF50) with a gate diameter of 1.5 mm

- (b)

- Valve gate hot runner system (nozzle 6NHF50 LA-1.4; needle 3NHP175-1.4 (clamping force of the needle: 800 N)

- (a)

- Precise and homogeneous power distribution over the entire length of the nozzle

- (b)

- Avoidance of temperature peaks in the melt-carrying material tube

- (c)

- High power concentration in the front nozzle area.

- (d)

- Rapid thermal reaction, thereby lower energy consumption

2.4. Characterization

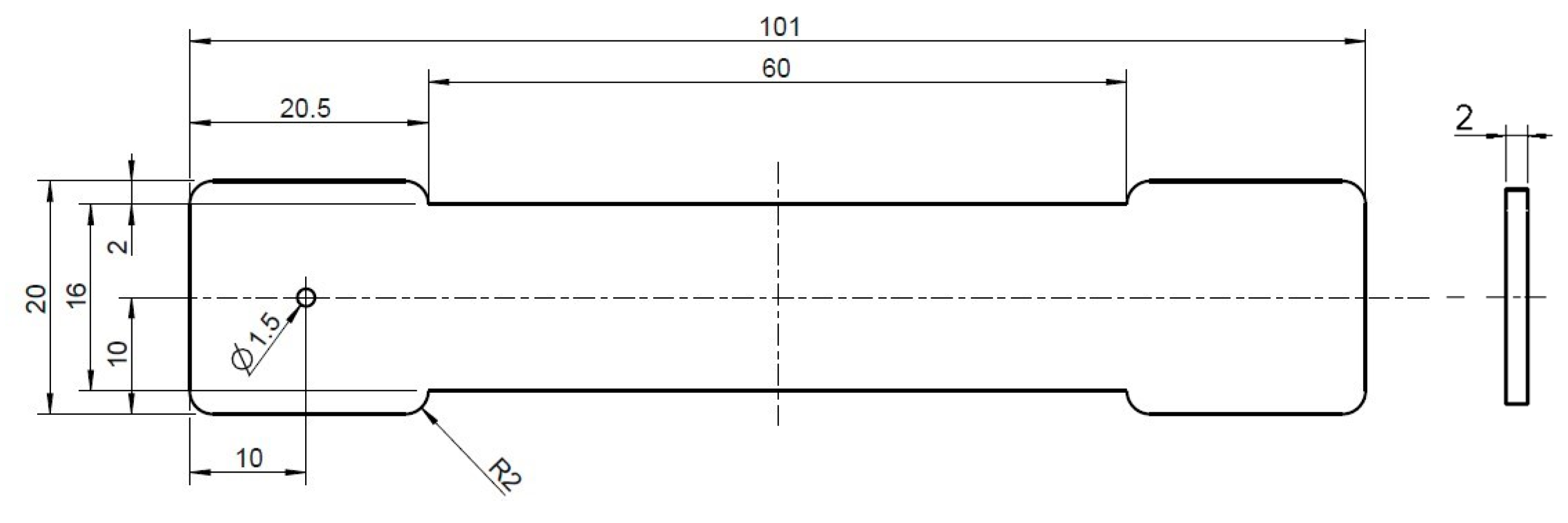

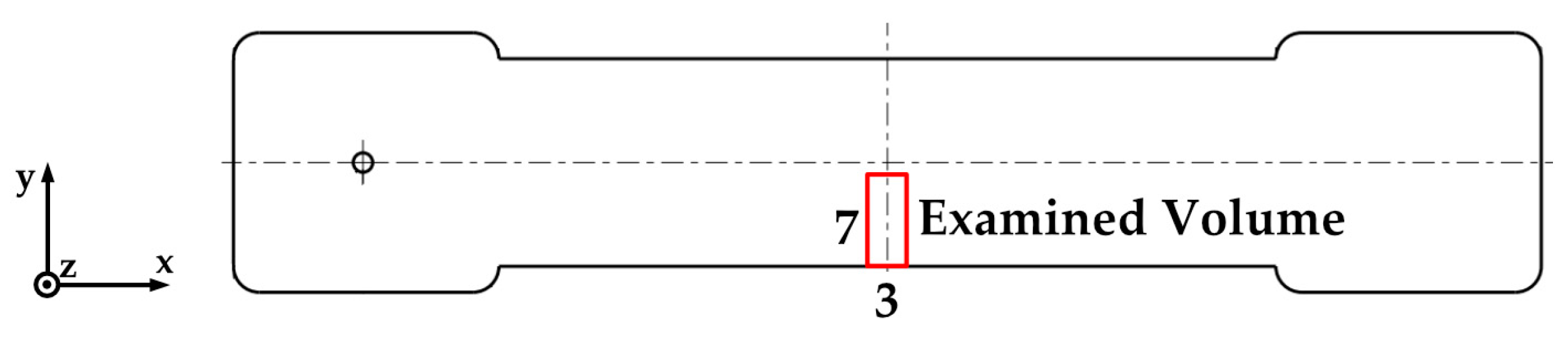

2.4.1. Tensile Test

2.4.2. Color Measurement

2.4.3. Fiber Length Measurement

2.4.4. X-ray Microtomography Analysis of the Composite Structure

3. Results

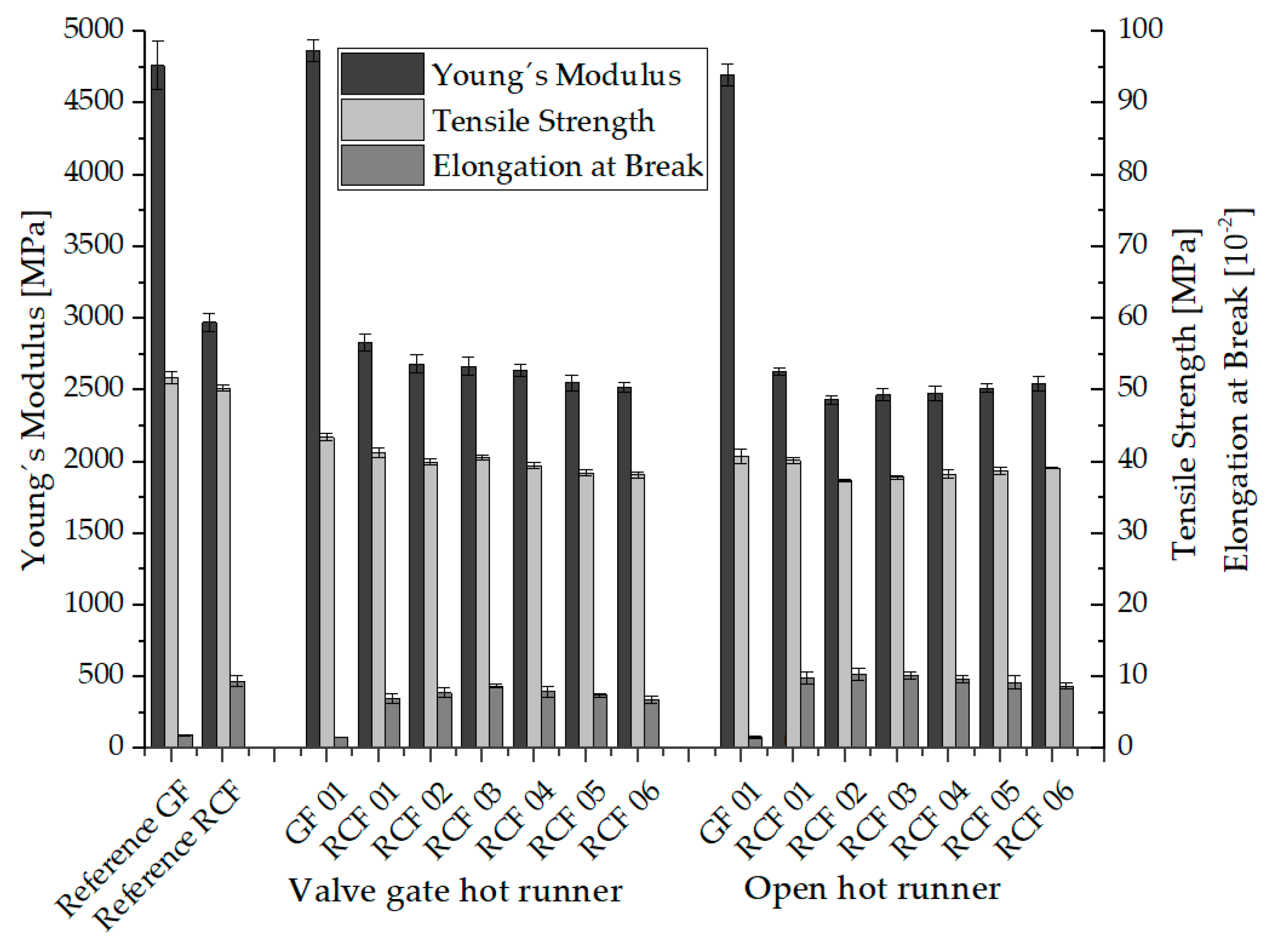

3.1. Mechanical Properties

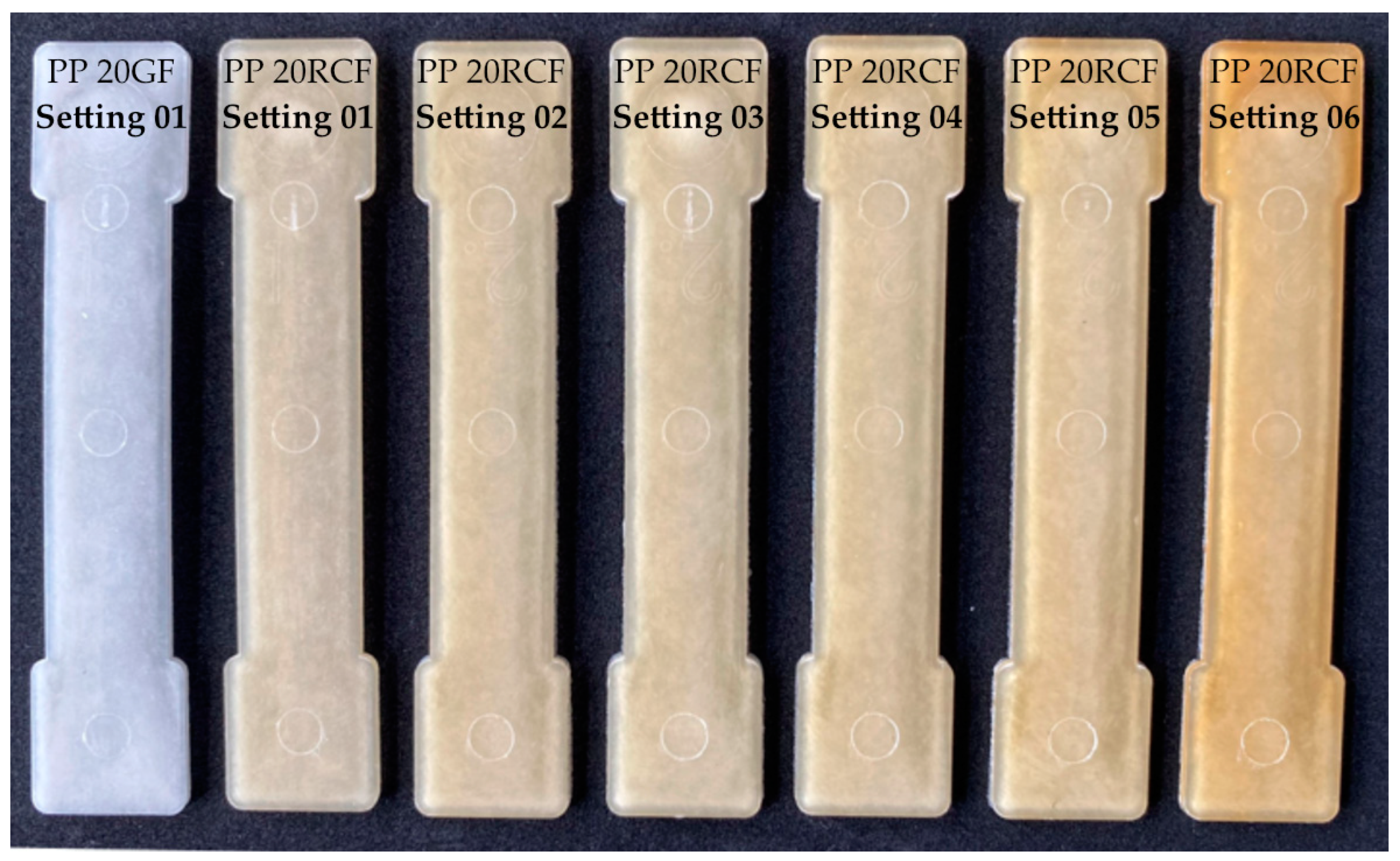

3.2. Discoloration

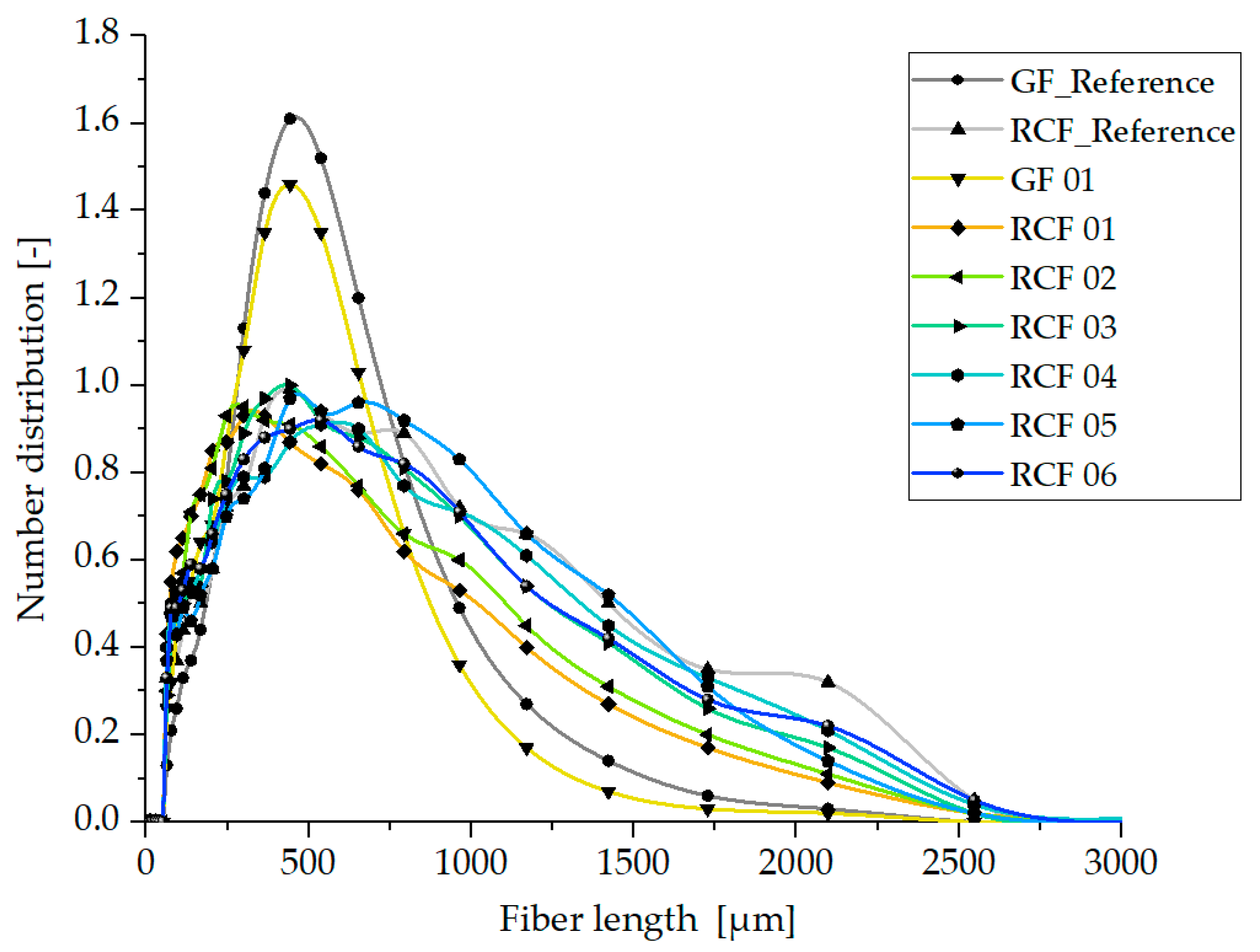

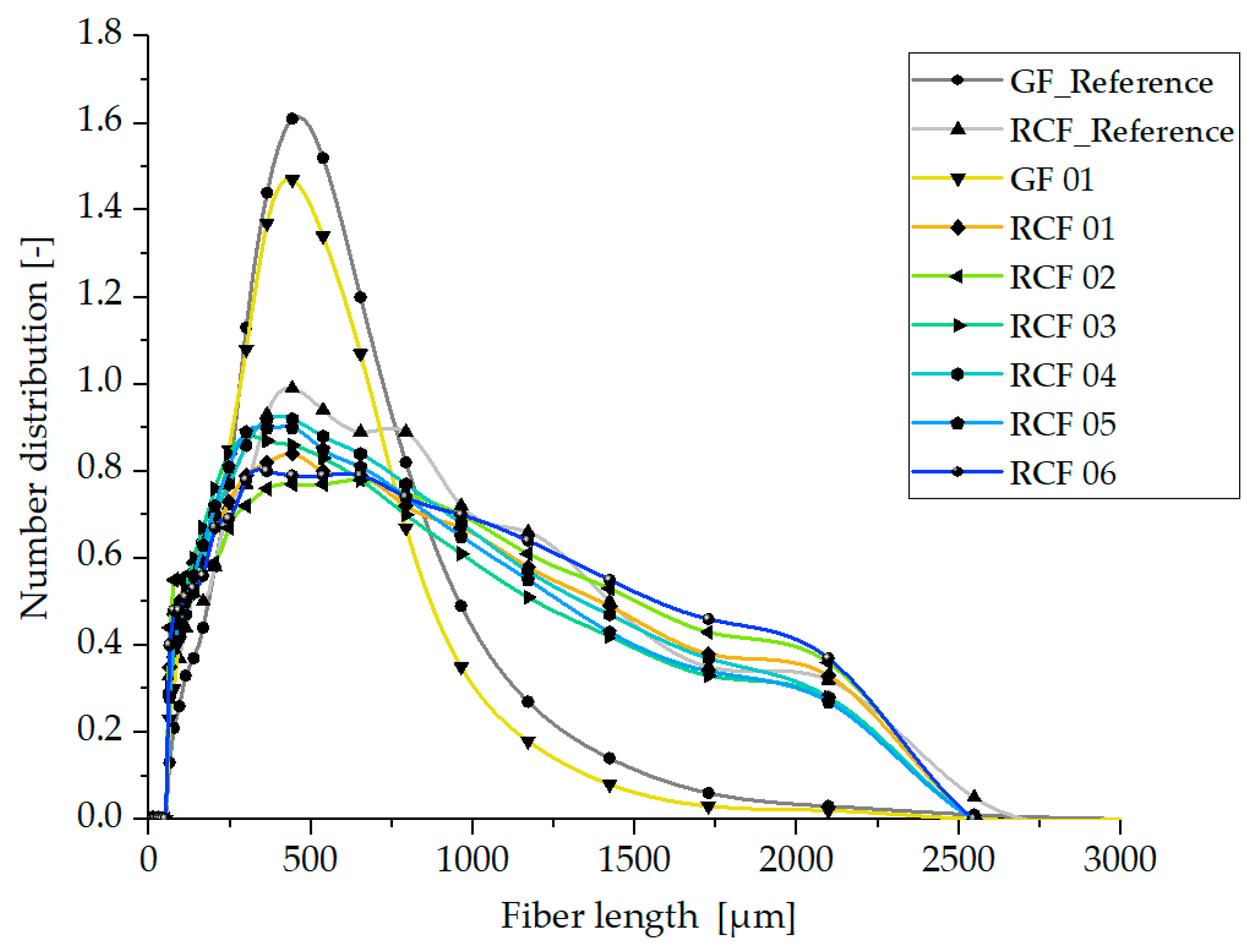

3.3. Fiber Length Distribution

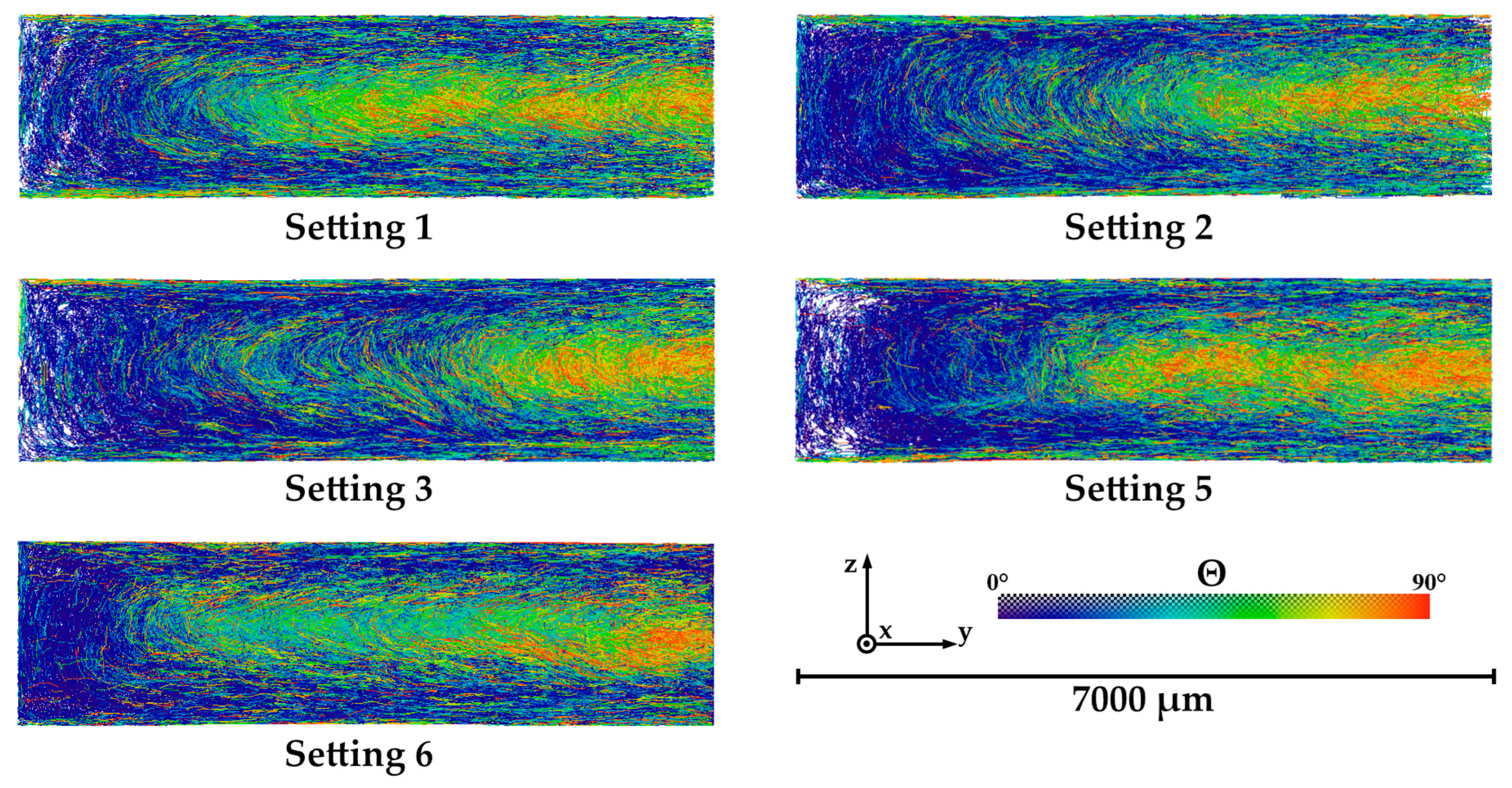

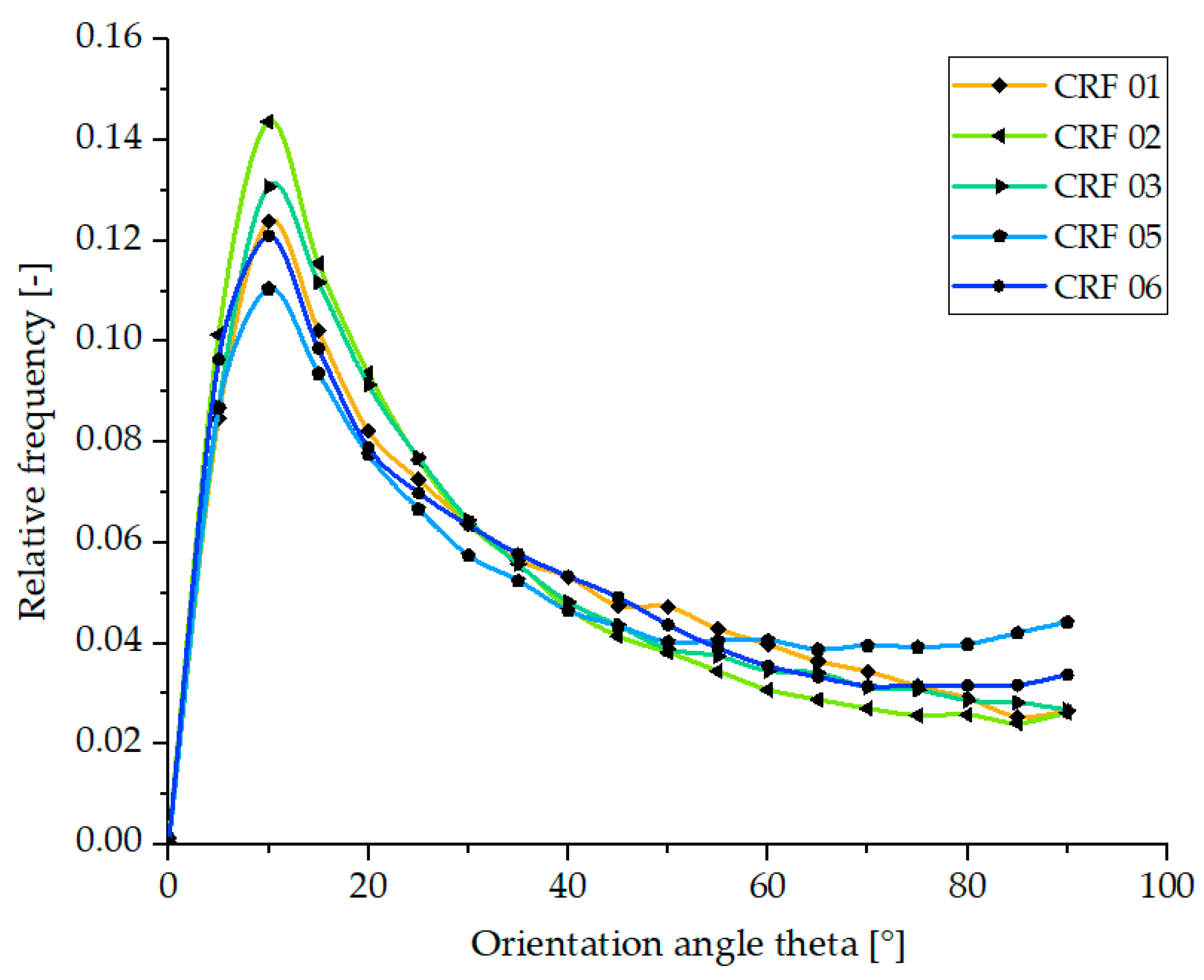

3.4. Fiber Orientation

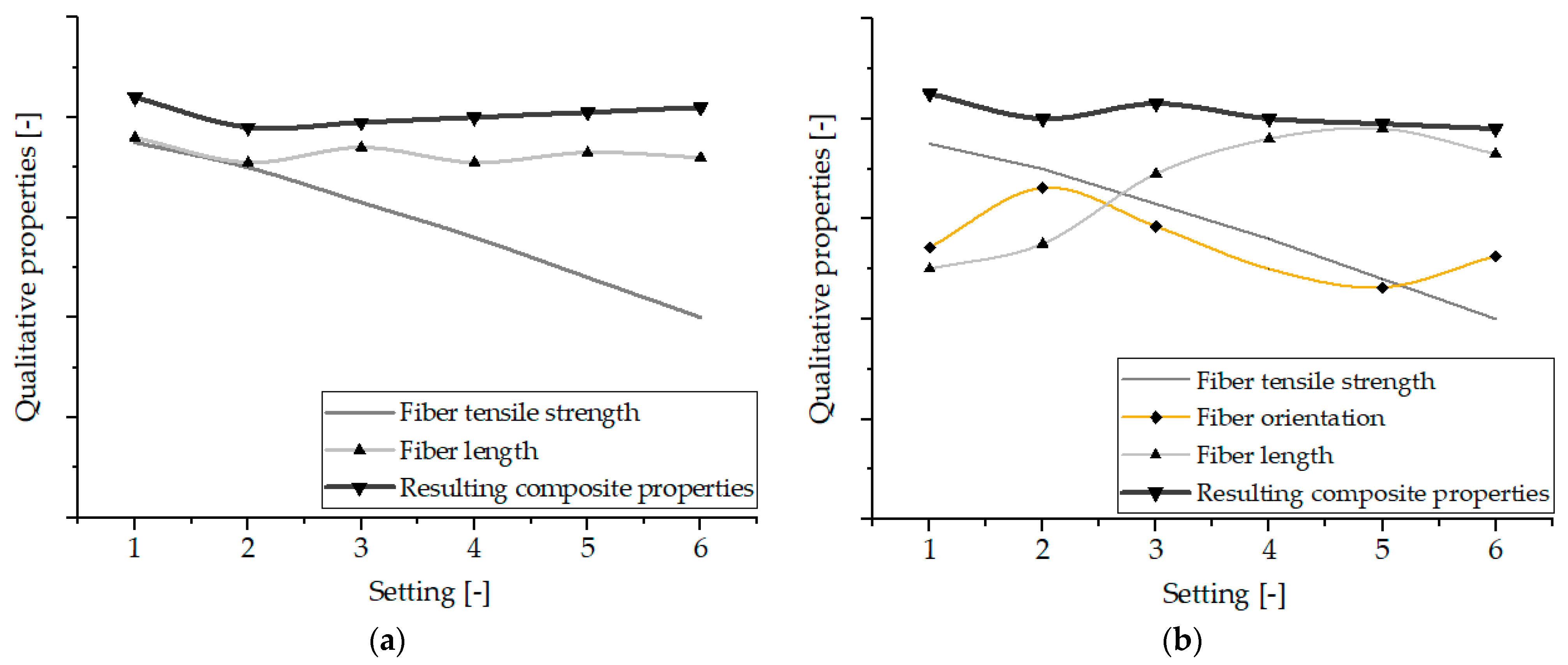

3.5. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tirupathi; Kumar, J.S.; Hiremath, S.S. Investigation of Mechanical Characterisation and Thermal Performance of Hybrid Natural Fiber Composites for Automotive Applications. Fibers Polym. 2022, 23, 3505–3515. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Puttegowda, M.; Boonyasopon, P.; Rangappa, S.M.; Khan, A.; Siengchin, S. Recent developments and challenges in natural fiber composites: A review. Polym. Compos. 2022, 43, 2545–2561. [Google Scholar] [CrossRef]

- Dehury, J.; Mohanty, J.R.; Nayak, S.; Dehury, S. Development of natural fiber reinforced polymer composites with enhanced mechanical and thermal properties for automotive industry application. Polym. Compos. 2022, 43, 4756–4765. [Google Scholar] [CrossRef]

- Seculi, F.; Espinach, F.X.; Julián, F.; Delgado-Aguilar, M.; Mutjé, P.; Tarrés, Q. Comparative Evaluation of the Stiffness of Abaca-Fiber-Reinforced Bio-Polyethylene and High Density Polyethylene Composites. Polymers 2023, 15, 1096. [Google Scholar] [CrossRef] [PubMed]

- Sayeed, M.M.A.; Sayem, A.S.M.; Haider, J.; Akter, S.; Habib, M.M.; Rahman, H.; Shahinur, S. Assessing Mechanical Properties of Jute, Kenaf, and Pineapple Leaf Fiber-Reinforced Polypropylene Composites: Experiment and Modelling. Polymers 2023, 15, 830. [Google Scholar] [CrossRef] [PubMed]

- Silva, R.V.; Spinelli, D.; Bose Filho, W.W.; Claro Neto, S.; Chierice, G.O.; Tarpani, J.R. Fracture toughness of natural fibers/castor oil polyurethane composites. Compos. Sci. Technol. 2006, 66, 1328–1335. [Google Scholar] [CrossRef]

- Ranganathan, N.; Oksman, K.; Nayak, S.K.; Sain, M. Regenerated cellulose fibers as impact modifier in long jute fiber reinforced polypropylene composites: Effect on mechanical properties, morphology, and fiber breakage. J. Appl. Polym. Sci. 2015, 132, 41301. [Google Scholar] [CrossRef]

- Ranganathan, N.; Oksman, K.; Nayak, S.K.; Sain, M. Structure property relation of hybrid biocomposites based on jute, viscose and polypropylene: The effect of the fibre content and the length on the fracture toughness and the fatigue properties. Compos. Part A Appl. Sci. Manuf. 2016, 83, 169–175. [Google Scholar] [CrossRef]

- Zarges, J.-C.; Feldmann, M.; Heim, H.-P. Influence of the compounding process on bio-based polyamides with cellulosic fibers. In Proceedings of the 30th International Conference of the Polymer Processing Society, Cleveland, OH, USA, 6–12 June 2014. [Google Scholar]

- Furtado, S.C.R.; Araújo, A.L.; Silva, A.; Alves, C.; Ribeiro, A.M.R. Natural fibre-reinforced composite parts for automotive applications. IJAUTOC 2014, 1, 18. [Google Scholar] [CrossRef]

- Clemons, C.M.; Caulfield, D.F.; Giacomin, A.J. Dynamic Fracture Toughness of Cellulose-Fiber-Reinforced Polypropylene: Preliminary Investigation of Microstructural Effects. J. Elastomers Plast. 1999, 31, 367–378. [Google Scholar] [CrossRef]

- Weigel, P.; Ganster, J.; Fink, H.P.; Gassan, J.; Uihlein, K. Polypropylene-cellulose compounds—High strength cellulose fibres strengthen injection moulded parts. Kunstst. Plast Eur. 2002, 92, 95. [Google Scholar]

- Teuber, L.; Militz, H.; Krause, A. Dynamic particle analysis for the evaluation of particle degradation during compounding of wood plastic composites. Compos. Part A Appl. Sci. Manuf. 2016, 84, 464–471. [Google Scholar] [CrossRef]

- Feldmann, M. Biobasierte Polyamide mit Cellulosefasern: Verfahren-Struktur-Eigenschaften; Kassel University Press: Kassel, Germany, 2013. [Google Scholar]

- Holbery, J.; Houston, D. Natural-fiber-reinforced polymer composites in automotive applications. JOM 2006, 58, 80–86. [Google Scholar] [CrossRef]

- Rowell, R.M. Handbook of Wood Chemistry and Wood Composites, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Bledzki, A.K.; Sperber, V.E.; Faruk, O. Natural and Wood Fibre Reinforcement in Polymers; Smithers Rapra Technology: Shrewsbury, UK, 2002; Volume 13. [Google Scholar]

- Reußmann, T. Entwicklung Eines Verfahrens zur Herstellung von Langfasergranulat mit Naturfaserverstärkung. 2003. Available online: https://www.researchgate.net/publication/28670519_Entwicklung_eines_Verfahrens_zur_Herstellung_von_Langfasergranulat_mit_Naturfaserverstarkung (accessed on 7 March 2023).

- Liu, Q.; Lv, C.; Yang, Y.; He, F.; Ling, L. Study on the pyrolysis of wood-derived rayon fiber by thermogravimetry–mass spectrometry. J. Mol. Struct. 2005, 733, 193–202. [Google Scholar] [CrossRef]

- Gassan, J.; Bledzki, A.K. Thermal degradation of flax and jute fibers. J. Appl. Polym. Sci. 2001, 82, 1417–1422. [Google Scholar] [CrossRef]

- Feldmann, M. The effects of the injection moulding temperature on the mechanical properties and morphology of polypropylene man-made cellulose fibre composites. Compos. Part A Appl. Sci. Manuf. 2016, 87, 146–152. [Google Scholar] [CrossRef]

- Carrillo, F.; Colom, X.; Suñol, J.J.; Saurina, J. Structural FTIR analysis and thermal characterisation of lyocell and viscose-type fibres. Eur. Polym. J. 2004, 40, 2229–2234. [Google Scholar] [CrossRef]

- Sälzer, P.; Feldmann, M.; Heim, H.-P. Wood-Polypropylene Composites: Influence of Processing on the Particle Shape and Size in Correlation with the Mechanical Properties Using Dynamic Image Analysis. Int. Polym. Process. 2018, 33, 677–687. [Google Scholar] [CrossRef]

- Fernandez, R.; Luis, J.; Thomason, J. Characterisation of the mechanical performance of natural fibers for lightweight automotive applications. In Proceedings of the 15th European Conference on Composite Materials, Venice, Italy, 24–28 June 2012; p. 1231. [Google Scholar]

- Pandey, J.K.; Ahn, S.H.; Lee, C.S.; Mohanty, A.K.; Misra, M. Recent Advances in the Application of Natural Fiber Based Composites. Macromol. Mater. Eng. 2010, 295, 975–989. [Google Scholar] [CrossRef]

- Njuguna, J.; Wambua, P.; Pielichowski, K.; Kayvantash, K. Natural Fibre-Reinforced Polymer Composites and Nanocomposites for Automotive Applications. In Cellulose Fibers: Bio- and Nano-Polymer Composites; Springer: Berlin/Heidelberg, Germany, 2011; pp. 661–700. [Google Scholar]

- Feldmann, M.; Bledzki, A.K. Bio-based polyamides reinforced with cellulosic fibres—Processing and properties. Compos. Sci. Technol. 2014, 100, 113–120. [Google Scholar] [CrossRef]

- Zarges, J.-C.; Kaufhold, C.; Feldmann, M.; Heim, H.-P. Single fiber pull-out test of regenerated cellulose fibers in polypropylene: An energetic evaluation. Compos. Part A Appl. Sci. Manuf. 2018, 105, 19–27. [Google Scholar] [CrossRef]

- Graupner, N.; Rößler, J.; Ziegmann, G.; Müssig, J. Fibre/matrix adhesion of cellulose fibres in PLA, PP and MAPP: A critical review of pull-out test, microbond test and single fibre fragmentation test results. Compos. Part A Appl. Sci. Manuf. 2014, 63, 133–148. [Google Scholar] [CrossRef]

- Zarges, J.-C.; Heim, H.-P. Influence of cyclic loads on the fiber-matrix-interaction of cellulose and glass fibers in polypropylene. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106491. [Google Scholar] [CrossRef]

- Zarges, J.-C.; Minkley, D.; Feldmann, M.; Heim, H.-P. Fracture toughness of injection molded, man-made cellulose fiber reinforced polypropylene. Compos. Part A Appl. Sci. Manuf. 2017, 98, 147–158. [Google Scholar] [CrossRef]

- Thomason, J.L.; Vlug, M.A. Influence of fibre length and concentration on the properties of glass fibre-reinforced polypropylene: 4. Impact properties. Compos. Part A Appl. Sci. Manuf. 1997, 28, 277–288. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Jaszkiewicz, A. Mechanical performance of biocomposites based on PLA and PHBV reinforced with natural fibres—A comparative study to PP. Compos. Sci. Technol. 2010, 70, 1687–1696. [Google Scholar] [CrossRef]

- Ganster, J.; Fink, H.-P.; Uihlein, K.; Zimmerer, B. Cellulose man-made fibre reinforced polypropylene—Correlations between fibre and composite properties. Cellulose 2008, 15, 561–569. [Google Scholar] [CrossRef]

- Feldmann, M.; Heim, H.-P.; Zarges, J.-C. Influence of the process parameters on the mechanical properties of engineering biocomposites using a twin-screw extruder. Compos. Part A Appl. Sci. Manuf. 2016, 83, 113–119. [Google Scholar] [CrossRef]

- Raphael, I.; Saintier, N.; Robert, G.; Béga, J.; Laiarinandrasana, L. On the role of the spherulitic microstructure in fatigue damage of pure polymer and glass-fiber reinforced semi-crystalline polyamide 6.6. Int. J. Fatigue 2019, 126, 44–54. [Google Scholar] [CrossRef]

- Hessman, P.A.; Riedel, T.; Welschinger, F.; Hornberger, K.; Böhlke, T. Microstructural analysis of short glass fiber reinforced thermoplastics based on x-ray micro-computed tomography. Compos. Sci. Technol. 2019, 183, 107752. [Google Scholar] [CrossRef]

- Lafranche, E.; Krawczak, P.; Ciolczyk, J.-P.; Maugey, J. Injection moulding of long glass fiber reinforced polyamide 66: Processing conditions/microstructure/flexural properties relationship. Adv. Polym. Technol. 2005, 24, 114–131. [Google Scholar] [CrossRef]

- Vincent, M.; Giroud, T.; Clarke, A.; Eberhardt, C. Description and modeling of fiber orientation in injection molding of fiber reinforced thermoplastics. Polymer 2005, 46, 6719–6725. [Google Scholar] [CrossRef]

- Mortazavian, S.; Fatemi, A. Fatigue behavior and modeling of short fiber reinforced polymer composites including anisotropy and temperature effects. Int. J. Fatigue 2015, 77, 12–27. [Google Scholar] [CrossRef]

- SadAbadi, H.; Ghasemi, M. Effects of Some Injection Molding Process Parameters on Fiber Orientation Tensor of Short Glass Fiber Polystyrene Composites (SGF/PS). J. Reinf. Plast. Compos. 2007, 26, 1729–1741. [Google Scholar] [CrossRef]

- Santharam, P.; Marco, Y.; Le Saux, V.; Le Saux, M.; Robert, G.; Raoult, I.; Guévenoux, C.; Taveau, D.; Charrier, P. Fatigue criteria for short fiber-reinforced thermoplastic validated over various fiber orientations, load ratios and environmental conditions. Int. J. Fatigue 2020, 135, 105574. [Google Scholar] [CrossRef]

- Abdo, D.; Gleadall, A.; Silberschmidt, V. Damage and damping of short-glass-fibre-reinforced PBT composites under dynamic conditions: Effect of matrix behaviour. Compos. Struct. 2019, 226, 111286. [Google Scholar] [CrossRef]

- Fouchier, N.; Nadot-Martin, C.; Conrado, E.; Bernasconi, A.; Castagnet, S. Fatigue life assessment of a Short Fibre Reinforced Thermoplastic at high temperature using a Through Process Modelling in a viscoelastic framework. Int. J. Fatigue 2019, 124, 236–244. [Google Scholar] [CrossRef]

- Dar, U.A.; Xu, Y.J.; Zakir, S.M.; Saeed, M.-U. The effect of injection molding process parameters on mechanical and fracture behavior of polycarbonate polymer. J. Appl. Polym. Sci. 2017, 134, 44474. [Google Scholar] [CrossRef]

- Farotti, E.; Natalini, M. Injection molding. Influence of process parameters on mechanical properties of polypropylene polymer. A first study. Procedia Struct. Integr. 2018, 8, 256–264. [Google Scholar] [CrossRef]

- Bernasconi, A.; Davoli, P.; Filippi, A. Effect of fibre orientation on the fatigue behaviour of a short glass fibre reinforced polyamide-6. Int. J. Fatigue 2007, 29, 199–208. [Google Scholar] [CrossRef]

- Mrzljak, S.; Delp, A.; Schlink, A.; Zarges, J.-C.; Hülsbusch, D.; Heim, H.-P.; Walther, F. Constant Temperature Approach for the Assessment of Injection Molding Parameter Influence on the Fatigue Behavior of Short Glass Fiber Reinforced Polyamide 6. Polymers 2021, 13, 1569. [Google Scholar] [CrossRef]

- Makarov, I.S.; Golova, L.K.; Smyslov, A.G.; Vinogradov, M.I.; Palchikova, E.E.; Legkov, S.A. Flax Noils as a Source of Cellulose for the Production of Lyocell Fibers. Fibers 2022, 10, 45. [Google Scholar] [CrossRef]

- Klemm, D.; Heublein, B.; Fink, H.-P.; Bohn, A. Cellulose: Faszinierendes Biopolymer und nachhaltiger Rohstoff. Angew. Chem. 2005, 117, 3422–3458. [Google Scholar] [CrossRef]

- Zarges, J.-C. Charakterisierung des Bruchverhaltens von Polypropylen-Celluloseregeneratfaser-Verbunden; Kassel University Press: Kassel, Germany, 2018. [Google Scholar]

- Fink, H.-P.; Ganster, J. Novel Thermoplastic Composites from Commodity Polymers and Man-Made Cellulose Fibers. Macromol. Symp. 2006, 244, 107–118. [Google Scholar] [CrossRef]

- Adusumali, R.-B.; Reifferscheid, M.; Weber, H.; Roeder, T.; Sixta, H.; Gindl, W. Mechanical Properties of Regenerated Cellulose Fibres for Composites. Macromol. Symp. 2006, 244, 119–125. [Google Scholar] [CrossRef]

- Ganster, J.; Fink, H.-P.; Pinnow, M. High-tenacity man-made cellulose fibre reinforced thermoplastics—Injection moulding compounds with polypropylene and alternative matrices. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1796–1804. [Google Scholar] [CrossRef]

- Bax, B.; Müssig, J. Impact and tensile properties of PLA/Cordenka and PLA/flax composites. Compos. Sci. Technol. 2008, 68, 1601–1607. [Google Scholar] [CrossRef]

- Jiang, G.; Huang, W.; Li, L.; Wang, X.; Pang, F.; Zhang, Y.; Wang, H. Structure and properties of regenerated cellulose fibers from different technology processes. Carbohydr. Polym. 2012, 87, 2012–2018. [Google Scholar] [CrossRef]

- Erdmann, J.; Ganster, J. Einfluss des Faserdurchmessers auf die Struktur und Mechanik Cellulosefaser verstärkter PLA-Komposite. Lenzing. Ber. 2011, 89, 91–102. [Google Scholar]

- CORDENKA GmbH & Co. KG. High-Tenacity Rayon Filament: Profile of Premium Rayon Reinforcement for High Performance Tires; CORDENKA GmbH & Co. KG.: Obernburg am Main, Germany, 2013. [Google Scholar]

- CORDENKA GmbH & Co. KG. Performance Rayon Reinforcement: For Brake Hoses and Industrial Hoses; CORDENKA GmbH & Co. KG.: Obernburg am Main, Germany, 2013. [Google Scholar]

- Ganster, J.; Lehmann, A.; Erdmann, J.; Fink, H.-P. Biobasierte Technische Fasern und Composite; Fraunhofer Society: Wolfsburg, Germany, 2012. [Google Scholar]

- Klemm, D.; Schmauder, H.-P.; Heinze, T. Cellulose. In Biopolymers: Biology, Chemistry, Biotechnology, Applications: Lignin, Humic Substances and Coal; Steinbüchel, A., Matsumura, S., Hofrichter, M., Koyama, T., Vandamme, E.J., Baets, S.d., Fahnestock, S.R., Eds.; Wiley-VCH: Weinheim, Germany, 2005. [Google Scholar]

- Hatakeyama, T.; Ikeda, Y.; Hatakeyama, H. Effect of bound water on structural change of regenerated cellulose. Makromol. Chem. 1987, 188, 1875–1884. [Google Scholar] [CrossRef]

- Müssig, J. Industrial Applications of Natural Fibres: Structure, Properties and Technical Applications; John Wiley & Sons: New York, NY, USA, 2010. [Google Scholar]

- Lee, S.B.; Kim, I.H.; Ryu, D.D.; Taguchi, H. Structural properties of cellulose and cellulase reaction mechanism. Biotechnol. Bioeng. 1983, 25, 33–51. [Google Scholar] [CrossRef]

- Le Baillif, M.; Oksman, K. The Effect of Processing on Fiber Dispersion, Fiber Length, and Thermal Degradation of Bleached Sulfite Cellulose Fiber Polypropylene Composites. J. Thermoplast. Compos. Mater. 2009, 22, 115–133. [Google Scholar] [CrossRef]

- Caulfield, D.F.; Jacobson, R.E.; Sears, K.D.; Underwood, J.H. Fiber reinforced engineering plastics. In Proceedings of the 2nd International Conference on Advanced Engineered Wood Composites, Bethel, ME, USA, 14–16 August 2001. [Google Scholar]

- Ho, M.-P.; Wang, H.; Lee, J.-H.; Ho, C.-K.; Lau, K.-T.; Leng, J.; Hui, D. Critical factors on manufacturing processes of natural fibre composites. Compos. Part B Eng. 2012, 43, 3549–3562. [Google Scholar] [CrossRef]

- Thomas, S.; John, M. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar]

- Zhou, Y.; Mallick, P.K. Effects of melt temperature and hold pressure on the tensile and fatigue properties of an injection molded talc-filled polypropylene. Polym. Eng. Sci. 2005, 45, 755–763. [Google Scholar] [CrossRef]

- Zarges, J.-C.; Sälzer, P.; Feldmann, M.; Heim, H.-P. Determining Viscosity Directly in the Injection Molding Process. Kunstst. Int. 2016, 106, 106–109. [Google Scholar]

- Tseng, H.-C.; Chang, R.-Y.; Hsu, C.-H. Predictions of fiber concentration in injection molding simulation of fiber-reinforced composites. J. Thermoplast. Compos. Mater. 2018, 31, 1529–1544. [Google Scholar] [CrossRef]

- Mondy, L.A.; Brenner, H.; Altobelli, S.A.; Abbott, J.R.; Graham, A.L. Shear-induced particle migration in suspensions of rods. J. Rheol. 1994, 38, 444–452. [Google Scholar] [CrossRef]

- Folgar, F.; Tucker, C.L. Orientation behavior of fibers in concentrated suspensions. J. Reinf. Plast. Compos. 1984, 3, 98–119. [Google Scholar] [CrossRef]

- Cosmi, F.; Bernasconi, A. Fatigue Behaviour of Short Fibre Reinforced Polyamide: Morphological and Numerical Analysis of Fibre Orientation Effects. Forni Sopra. 2009, 17, 6–10. [Google Scholar]

| Initial Length [mm] | Diameter [µm] | Young´s Modulus [GPa] | Tensile Strength [MPa] | Elongation [%] | |

|---|---|---|---|---|---|

| Cordenka Rayon (Viscose Fiber) | 2.3 | 12 | 22 | 778 | 13 |

| Tencel FCP (Lyocell Fiber) | 0.4–6 | f | 15 | 556 | 11 |

| Arbocel BC1000 (pure Cellulose) | 0.7 | 20 | [-] * | [-] * | [-] * |

| Feeding Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Zone 5 | Zone 6 | Zone 7 | |

|---|---|---|---|---|---|---|---|---|

| Temperature [°C] | 200 | 200 | 180 | 180 | 160 | 140 | 140 | 160 |

| Feeding Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | |

|---|---|---|---|---|---|

| Temperature [°C] | 40 | 200 | 200 | 200 | 200 |

| Material | Setting | Hot Runner Temperature [°C] | Cooling Time [s] | Injection Time [s] | Holding Pressure [bar] | Holding Time [s] | Dwell Time [s] |

|---|---|---|---|---|---|---|---|

| PP 20GF | 01 | 200 | 8 | 0.50 | 300 | 3 | 16 |

| PP 20RCF | 01 | 200 | 8 | 0.65 | 300 | 3 | 16 |

| PP 20RCF | 02 | 200 | 8 | 0.30 | 300 | 3 | 16 |

| PP 20RCF | 03 | 200 | 20 | 0.30 | 300 | 3 | 28 |

| PP 20RCF | 04 | 220 | 20 | 0.30 | 300 | 3 | 28 |

| PP 20RCF | 05 | 240 | 20 | 0.30 | 300 | 3 | 28 |

| PP 20RCF | 06 | 240 | 40 | 0.30 | 300 | 3 | 48 |

| XFiber Parameter | Setting | |||||

|---|---|---|---|---|---|---|

| 01 | 02 | 03 | 05 | 06 | ||

| Cylinder length | [μm] | 38 | 38 | 38 | 38 | 38 |

| Angular sampling | [-] | 5 | 5 | 5 | 5 | 5 |

| Mask cylinder radius | [μm] | 8.3 | 8.3 | 8.3 | 8.3 | 8.3 |

| Outer cylinder radius | [μm] | 6.3 | 6.3 | 6.3 | 6.3 | 6.3 |

| Minimum seed correlation | [-] | 203 | 203 | 203 | 196 | 198 |

| Minimum continuation quality | [-] | 140 | 123 | 107 | 98 | 89 |

| Direction coefficient | [-] | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| Minimum distance | [μm] | 3 | 3 | 3 | 3 | 3 |

| Minimum length | [μm] | 38 | 38 | 38 | 38 | 38 |

| Composite | System | x10 [µm] | x50 [µm] | x90 [µm] |

|---|---|---|---|---|

| Reference GF | cold runner | 108.6 | 436.1 | 1311.3 |

| Reference RCF | cold runner | 143.1 | 411.7 | 832.9 |

| PP 20GF 01 | open hot runner | 110.4 | 357.1 | 742.0 |

| PP 20RCF 01 | open hot runner | 90.9 | 303.4 | 979.9 |

| PP 20RCF 02 | open hot runner | 98.9 | 324.6 | 1033.8 |

| PP 20RCF 03 | open hot runner | 103.3 | 386.9 | 1155.4 |

| PP 20RCF 04 | open hot runner | 94.8 | 390.9 | 1233.9 |

| PP 20RCF 05 | open hot runner | 102.0 | 422.7 | 1192.9 |

| PP 20RCF 06 | open hot runner | 98.7 | 391.9 | 1232.2 |

| PP 20GF 01 | valve gate hot runner | 111.4 | 361.1 | 747.1 |

| PP 20RCF 01 | valve gate hot runner | 96.5 | 404.8 | 1444.3 |

| PP 20RCF 02 | valve gate hot runner | 106.9 | 384.9 | 1311.5 |

| PP 20RCF 03 | valve gate hot runner | 106.4 | 399.9 | 1324.1 |

| PP 20RCF 04 | valve gate hot runner | 102.4 | 371.8 | 1310.9 |

| PP 20RCF 05 | valve gate hot runner | 90.9 | 398.5 | 1444.5 |

| PP 20RCF 06 | valve gate hot runner | 97.6 | 388.6 | 1392.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zarges, J.-C.; Schlink, A.; Lins, F.; Essinger, J.; Sommer, S.; Heim, H.-P. Influence of Different Hot Runner-Systems in the Injection Molding Process on the Structural and Mechanical Properties of Regenerated Cellulose Fiber Reinforced Polypropylene. Polymers 2023, 15, 1924. https://doi.org/10.3390/polym15081924

Zarges J-C, Schlink A, Lins F, Essinger J, Sommer S, Heim H-P. Influence of Different Hot Runner-Systems in the Injection Molding Process on the Structural and Mechanical Properties of Regenerated Cellulose Fiber Reinforced Polypropylene. Polymers. 2023; 15(8):1924. https://doi.org/10.3390/polym15081924

Chicago/Turabian StyleZarges, Jan-Christoph, André Schlink, Fabian Lins, Jörg Essinger, Stefan Sommer, and Hans-Peter Heim. 2023. "Influence of Different Hot Runner-Systems in the Injection Molding Process on the Structural and Mechanical Properties of Regenerated Cellulose Fiber Reinforced Polypropylene" Polymers 15, no. 8: 1924. https://doi.org/10.3390/polym15081924

APA StyleZarges, J.-C., Schlink, A., Lins, F., Essinger, J., Sommer, S., & Heim, H.-P. (2023). Influence of Different Hot Runner-Systems in the Injection Molding Process on the Structural and Mechanical Properties of Regenerated Cellulose Fiber Reinforced Polypropylene. Polymers, 15(8), 1924. https://doi.org/10.3390/polym15081924