Approaching Polycarbonate as an LFT-D Material: Processing and Mechanical Properties

Abstract

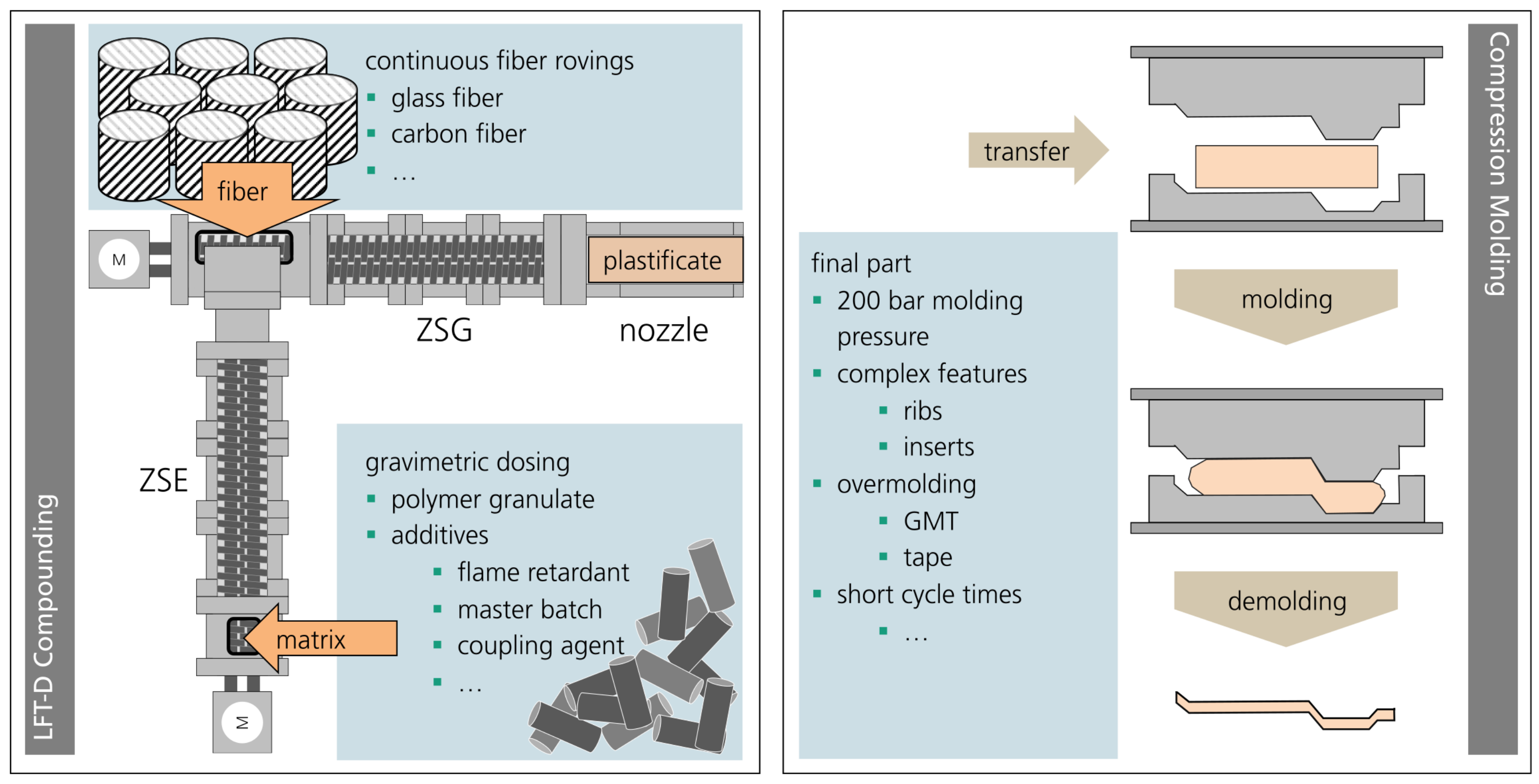

1. Introduction and State-of-the-Art

1.1. Motivation

1.2. State-of-the-Art

1.3. Outline

2. Materials and Methods

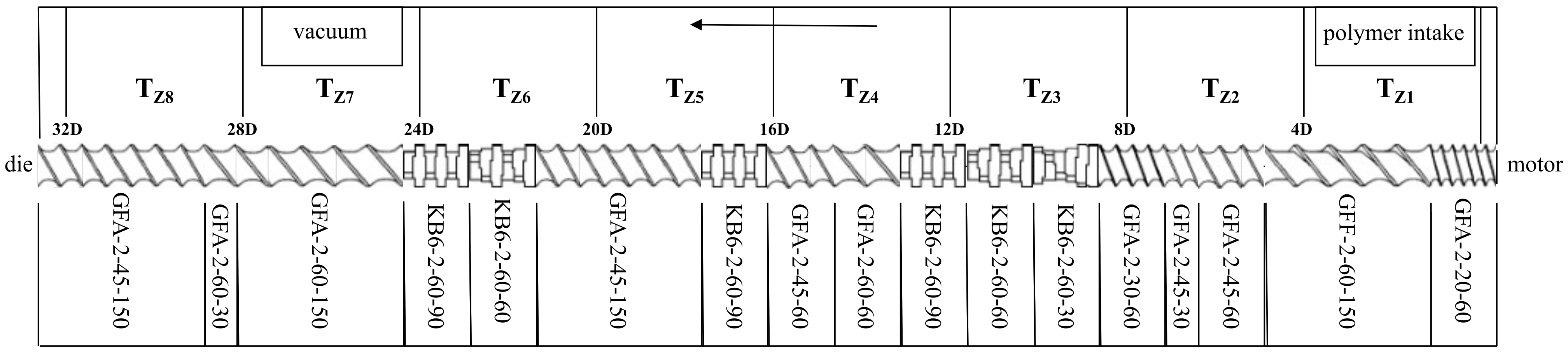

2.1. Choosing Processing Parameters

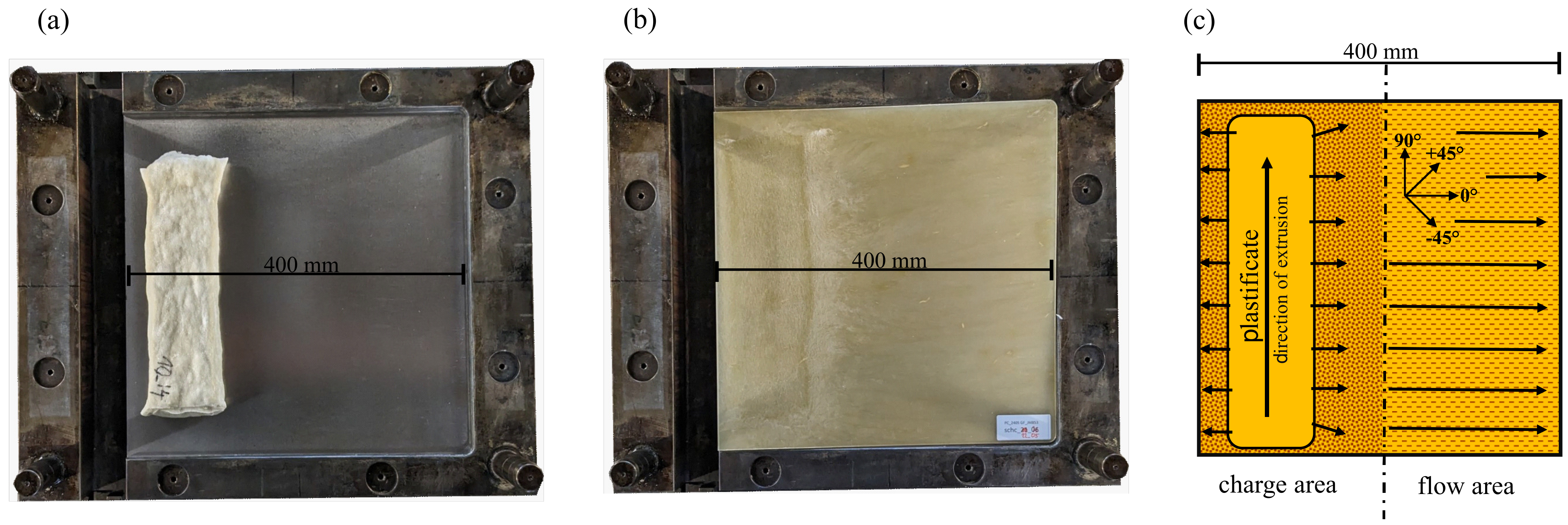

2.2. Specimen Preparation

2.2.1. Thermographic Analysis

2.2.2. Fiber Length Measurement

2.2.3. Micrographs

2.3. Mechanical Testing

2.3.1. Tensile Test

2.3.2. Bending Test

2.3.3. Puncture Impact Test

2.3.4. Charpy Impact Test

2.3.5. Dynamic Mechanical Analysis

3. Results and Discussion

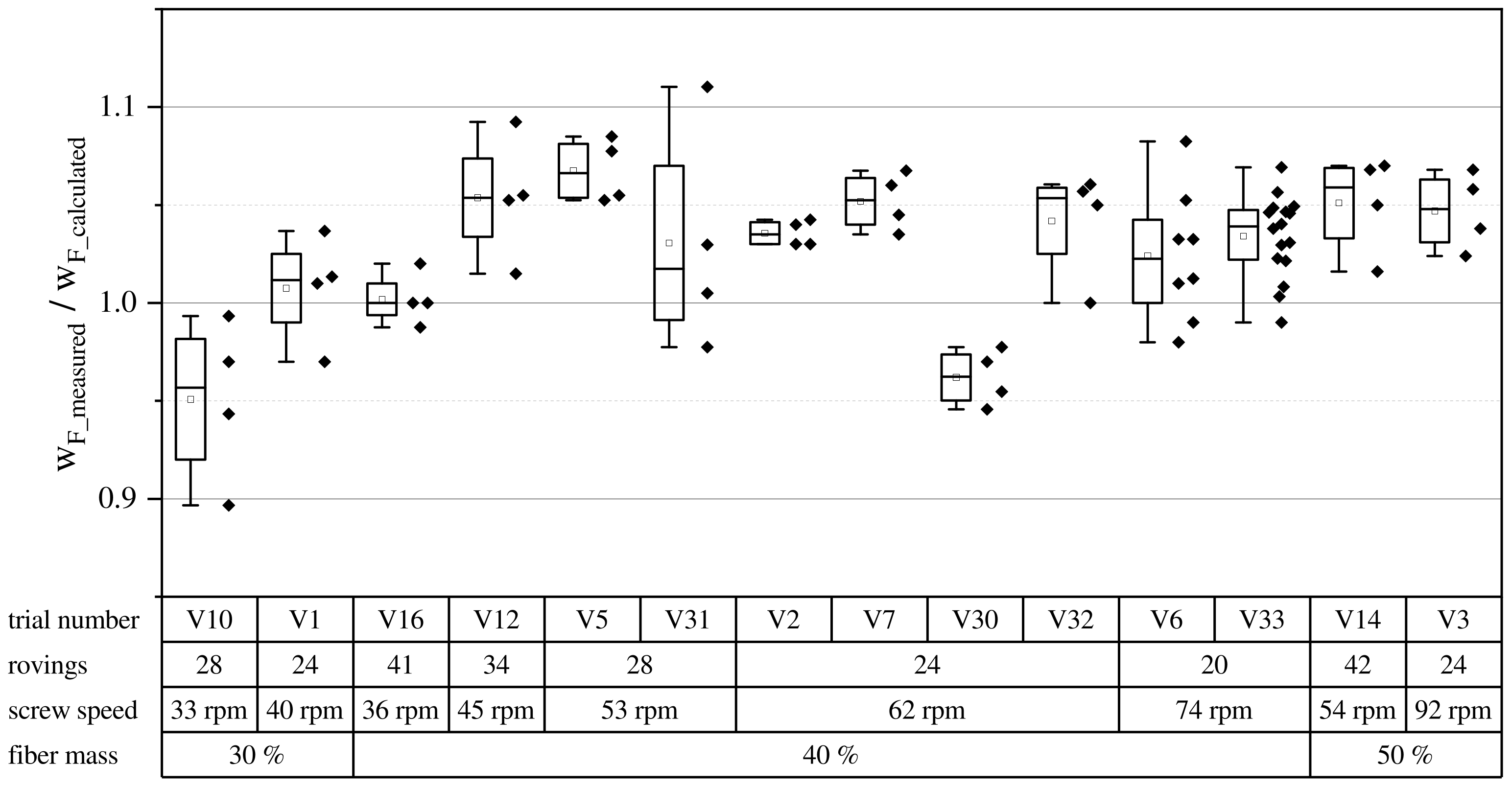

3.1. Fiber Mass Fraction Relating to Processing Parameters

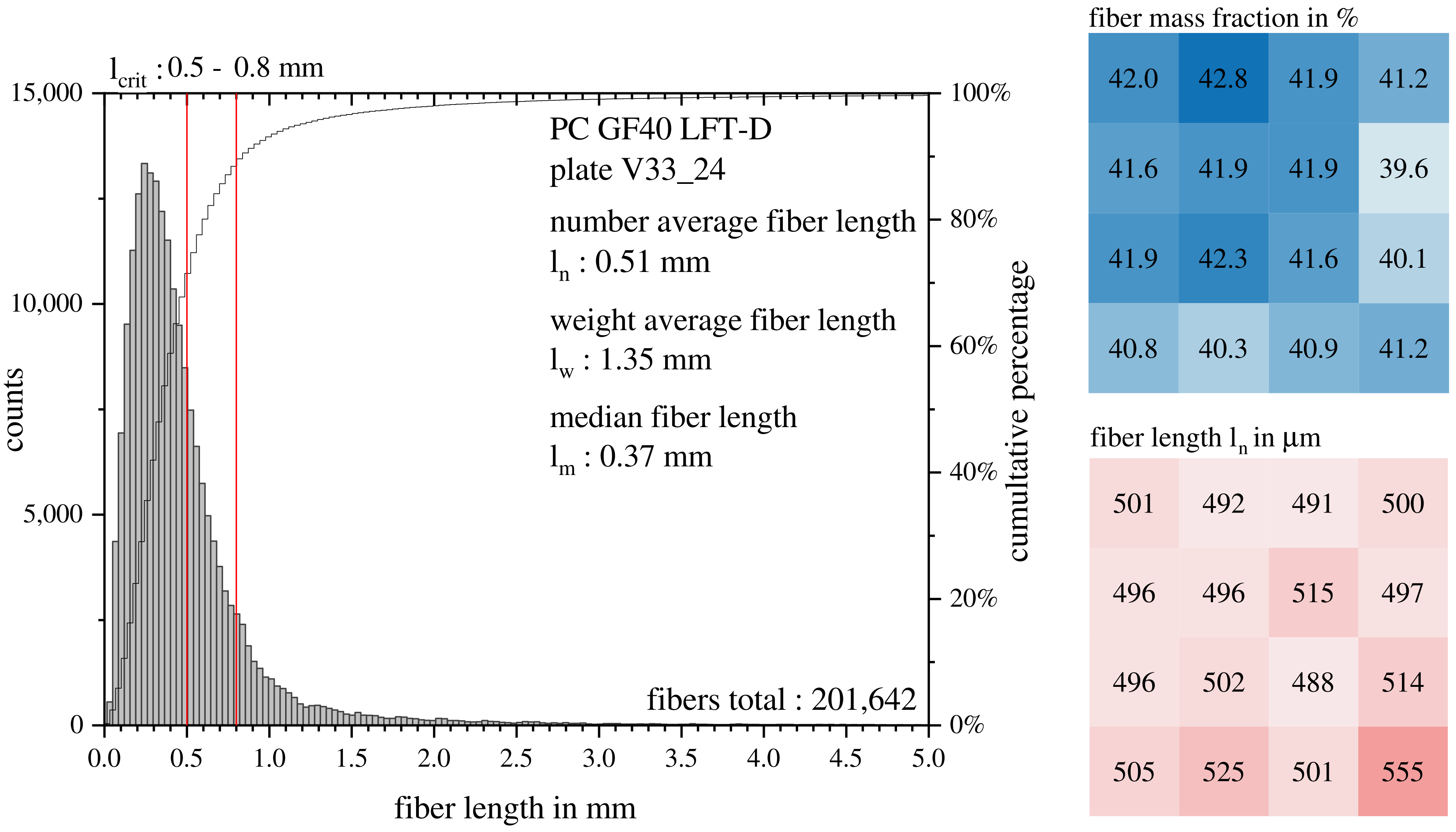

3.2. Fiber Length Relating to Processing Parameters and Processing Stability

3.3. Correlating Specific Mechanical Energy and Fiber Length

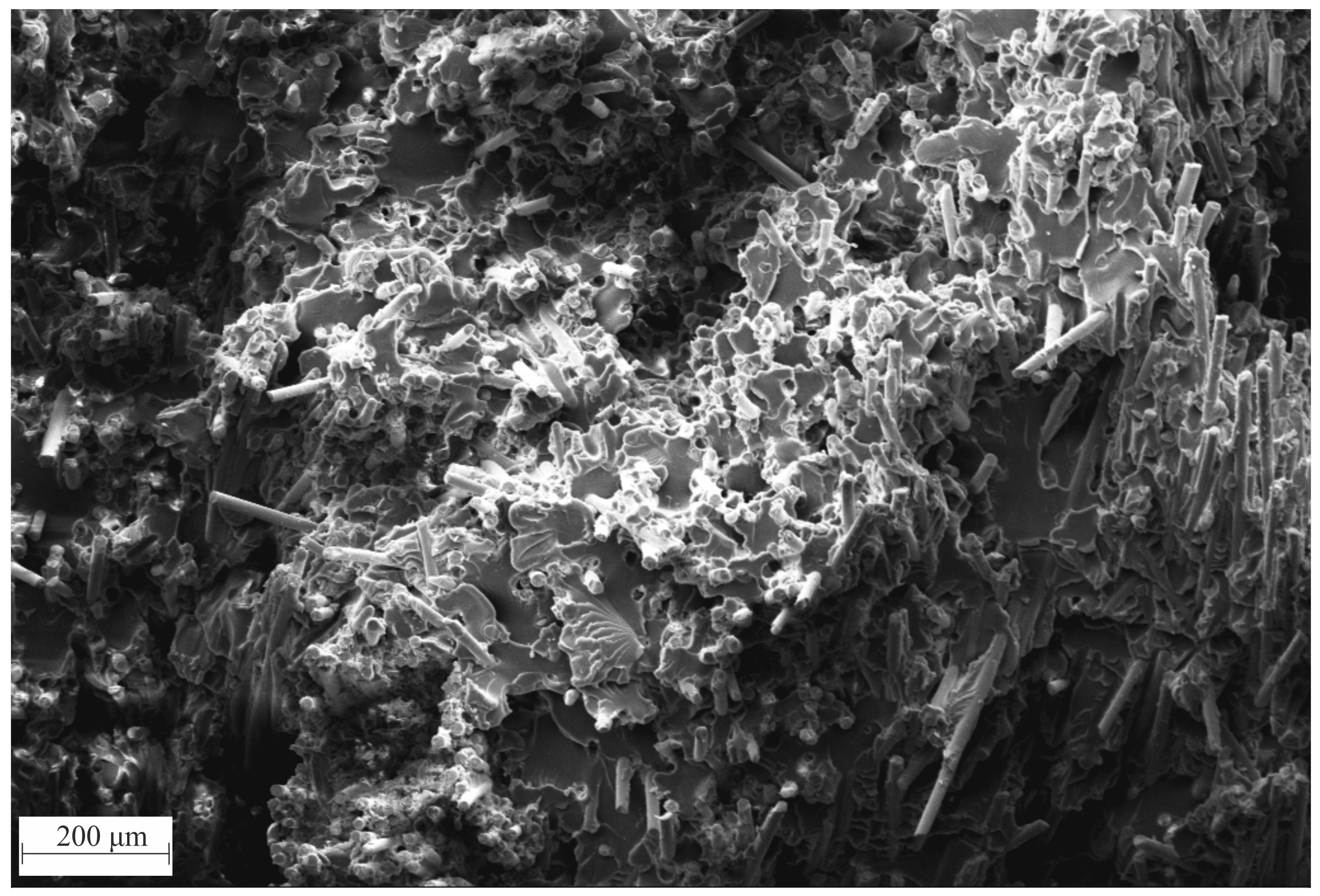

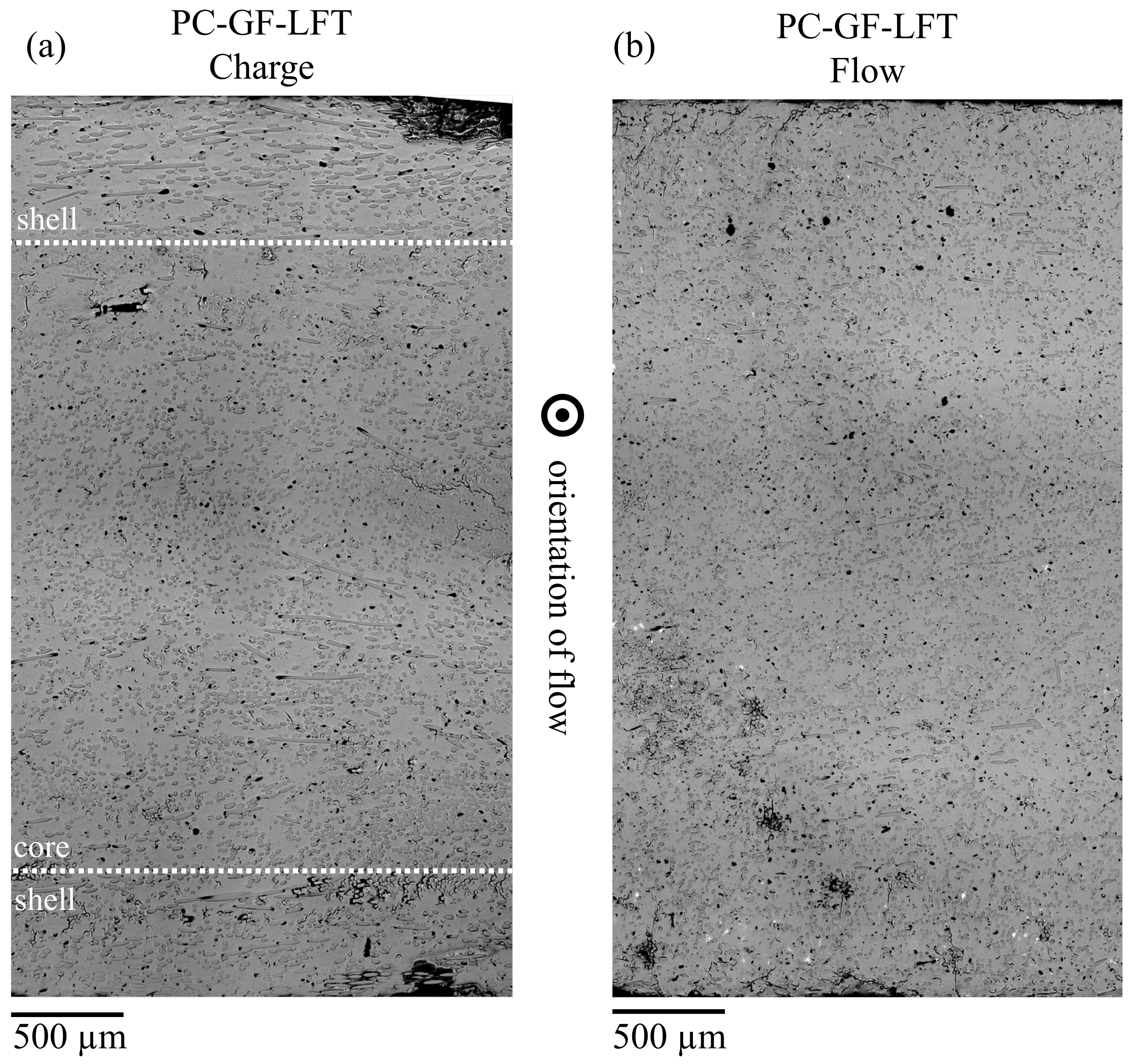

3.4. Evaluating Micrographs

- Deeply staggered fracture surfaces hint at fiber fracture rather than matrix fracture. This can be observed as the entire depiction had a noticeable depth indicated by the darker and lighter areas

- Matrix material residue on fiber indicates a previous bond between fiber and matrix. Good examples of this can be observed in the right of the figure. These fibers look like they have been pulled out.

- In the load direction (here, the direction of view), short fiber stumps, as well as shallow holes can be observed in the very center of the figure, hinting at fiber fracture, rather than pull out.

- Clean fiber front surfaces also indicate fiber fracture, as when the fiber was pulled out, matrix material could be seen there.

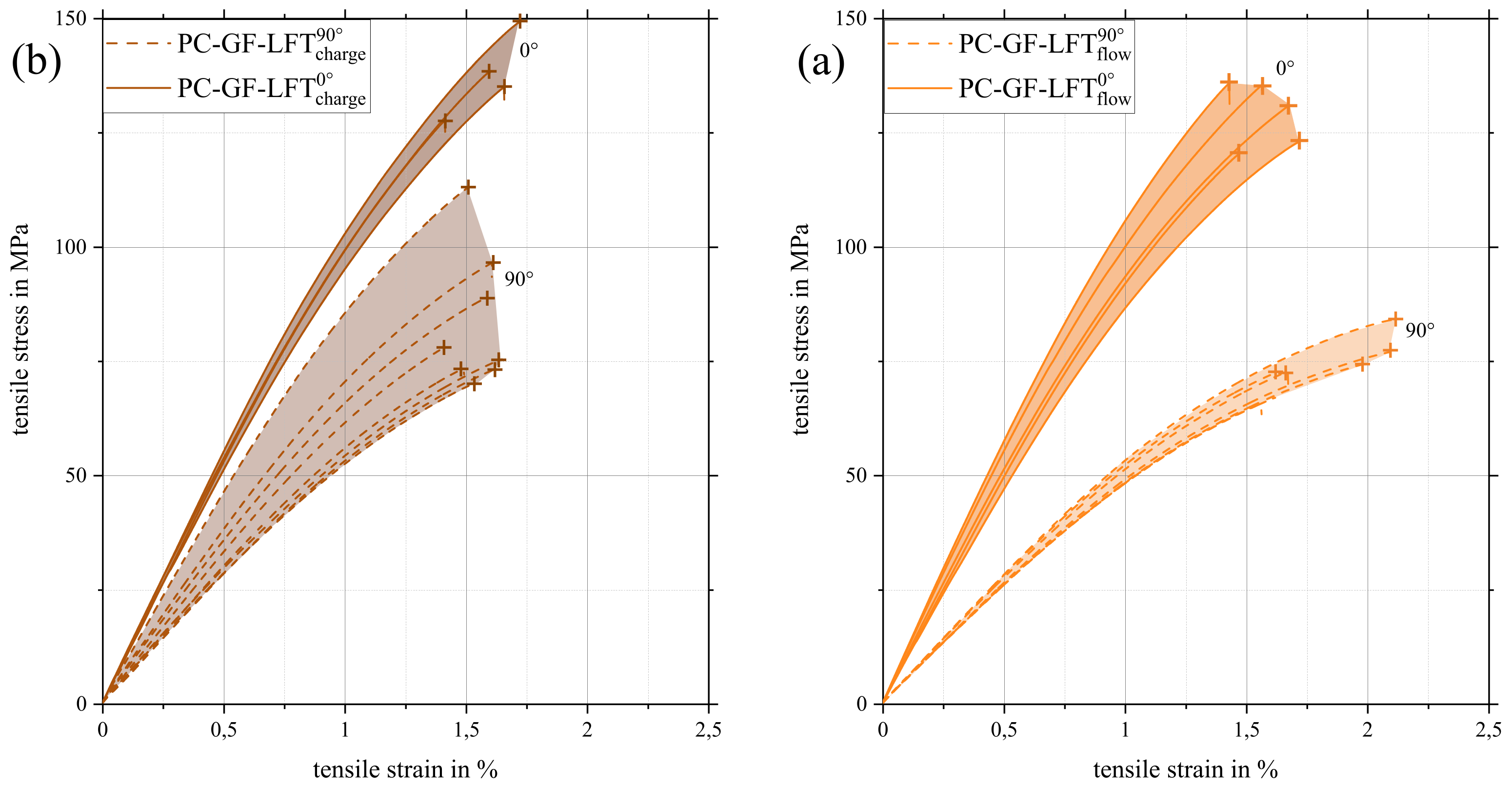

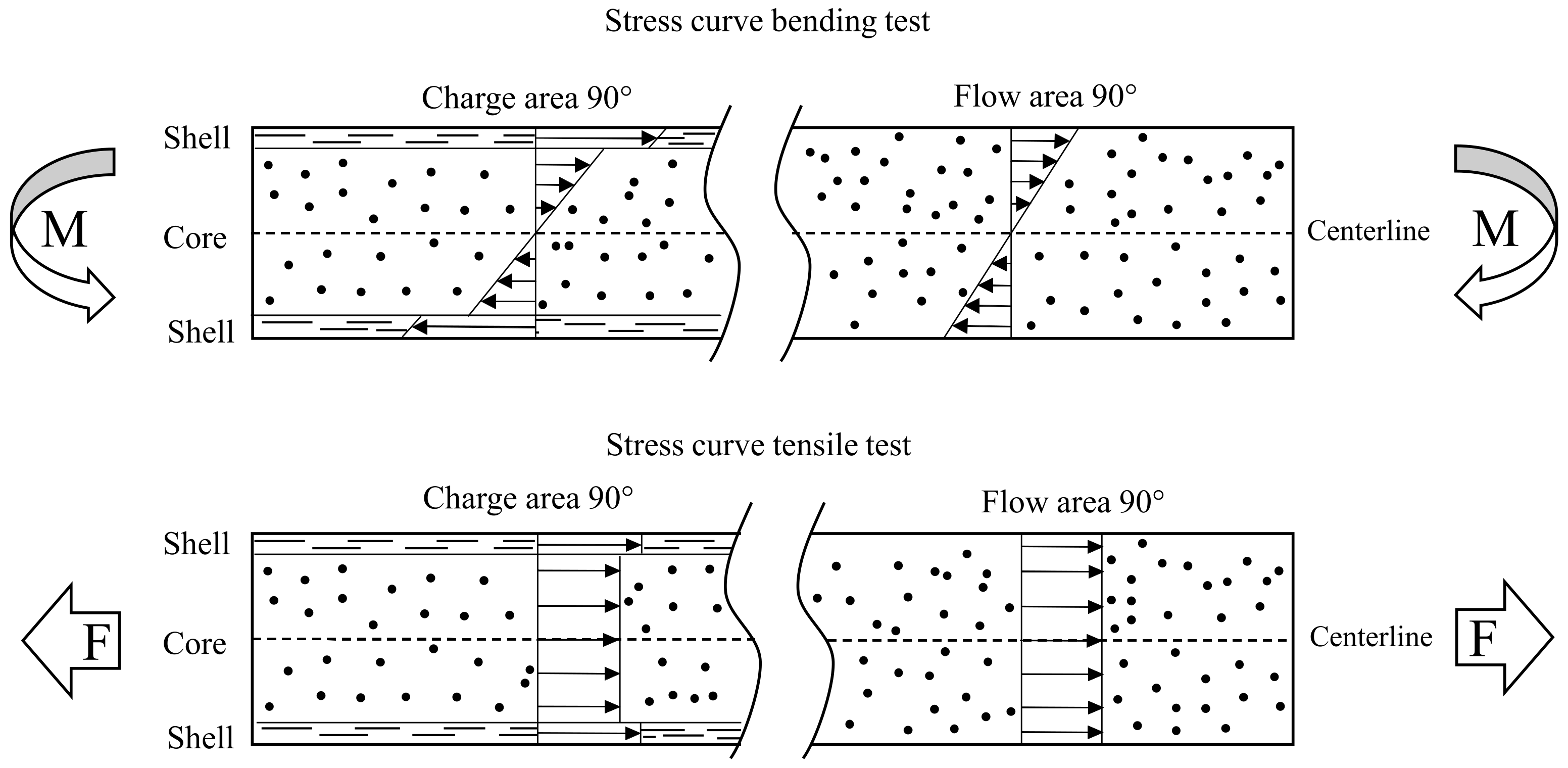

3.5. Investigation of Quasi-Static Material Behavior

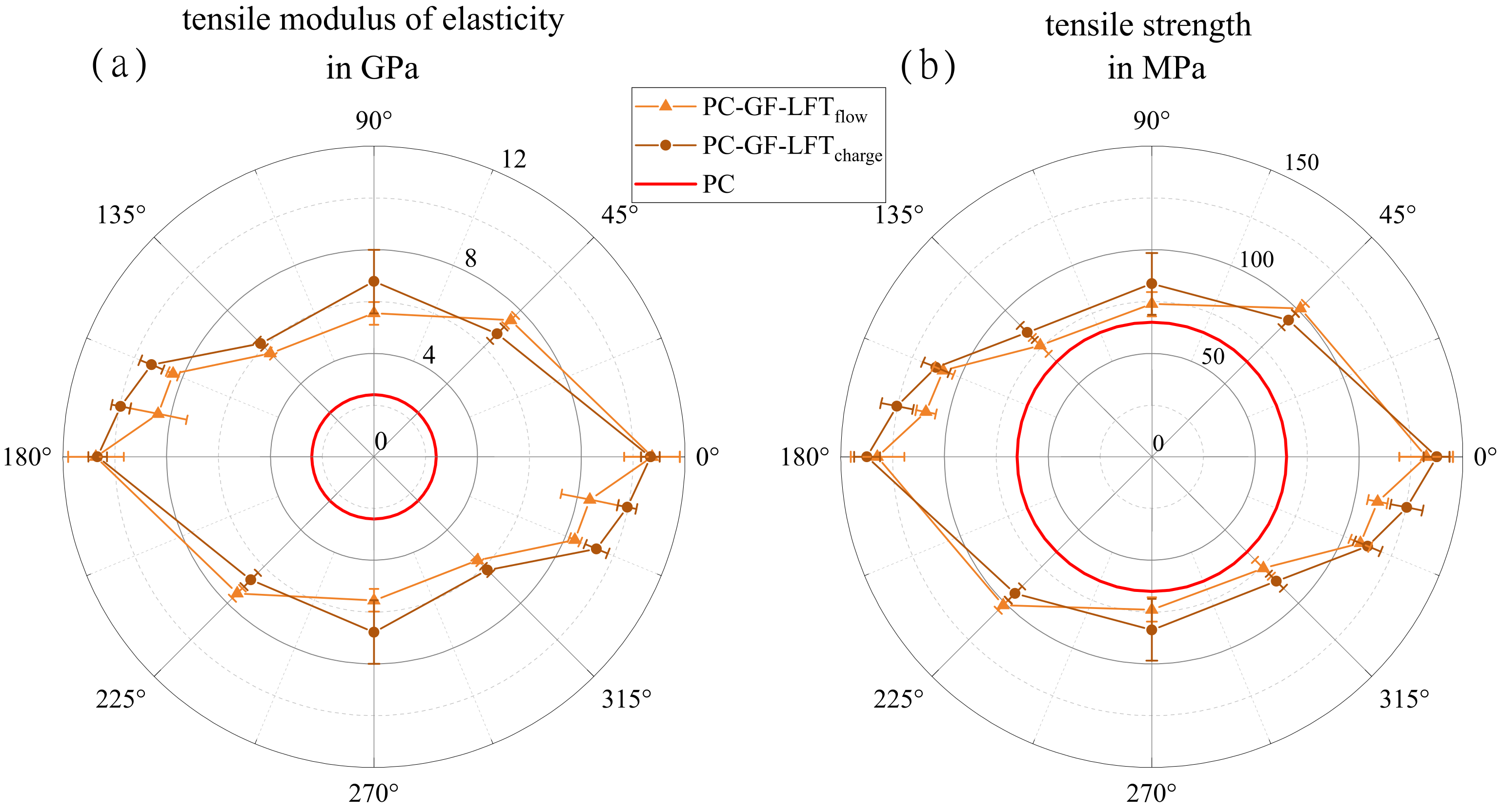

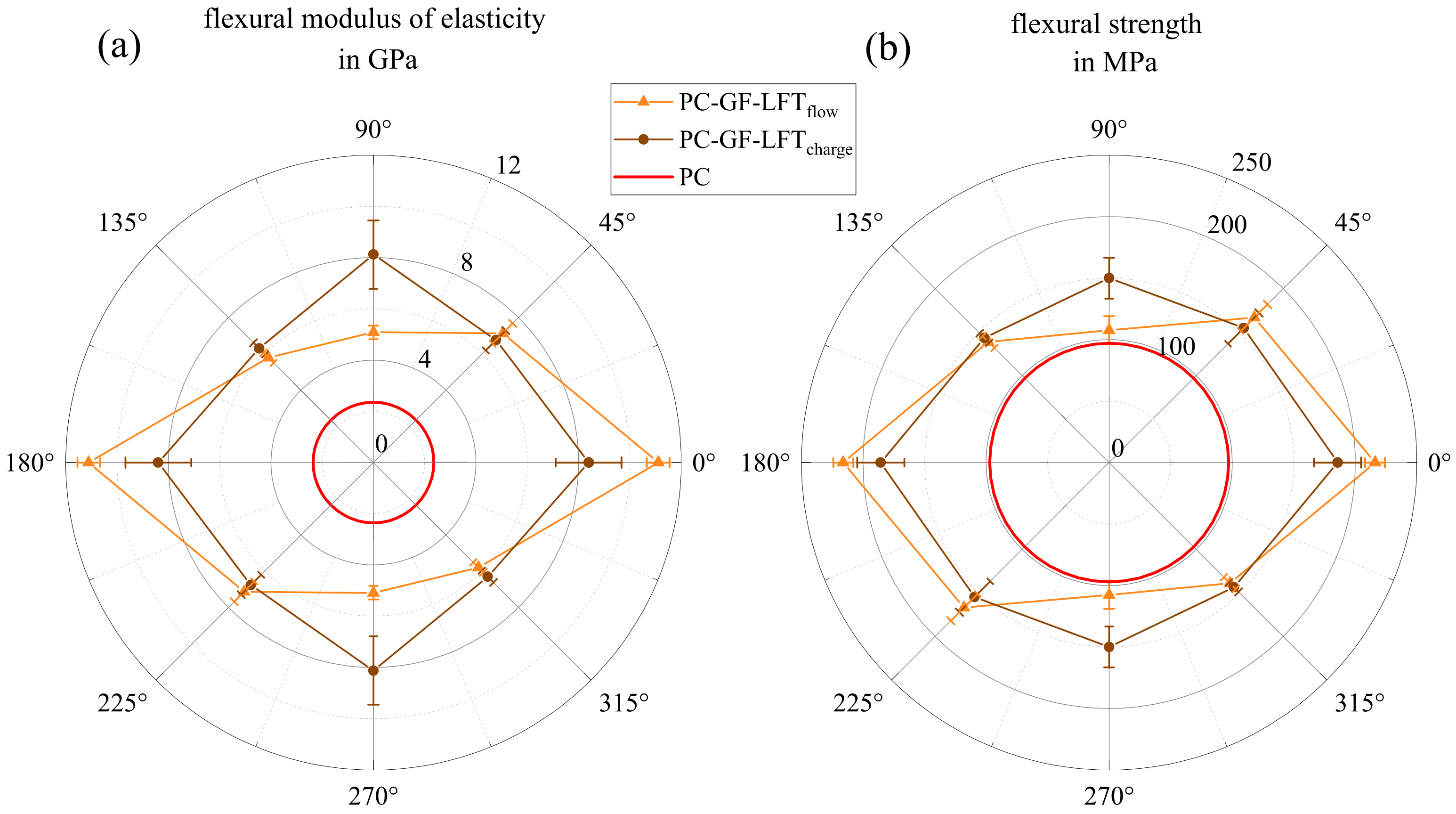

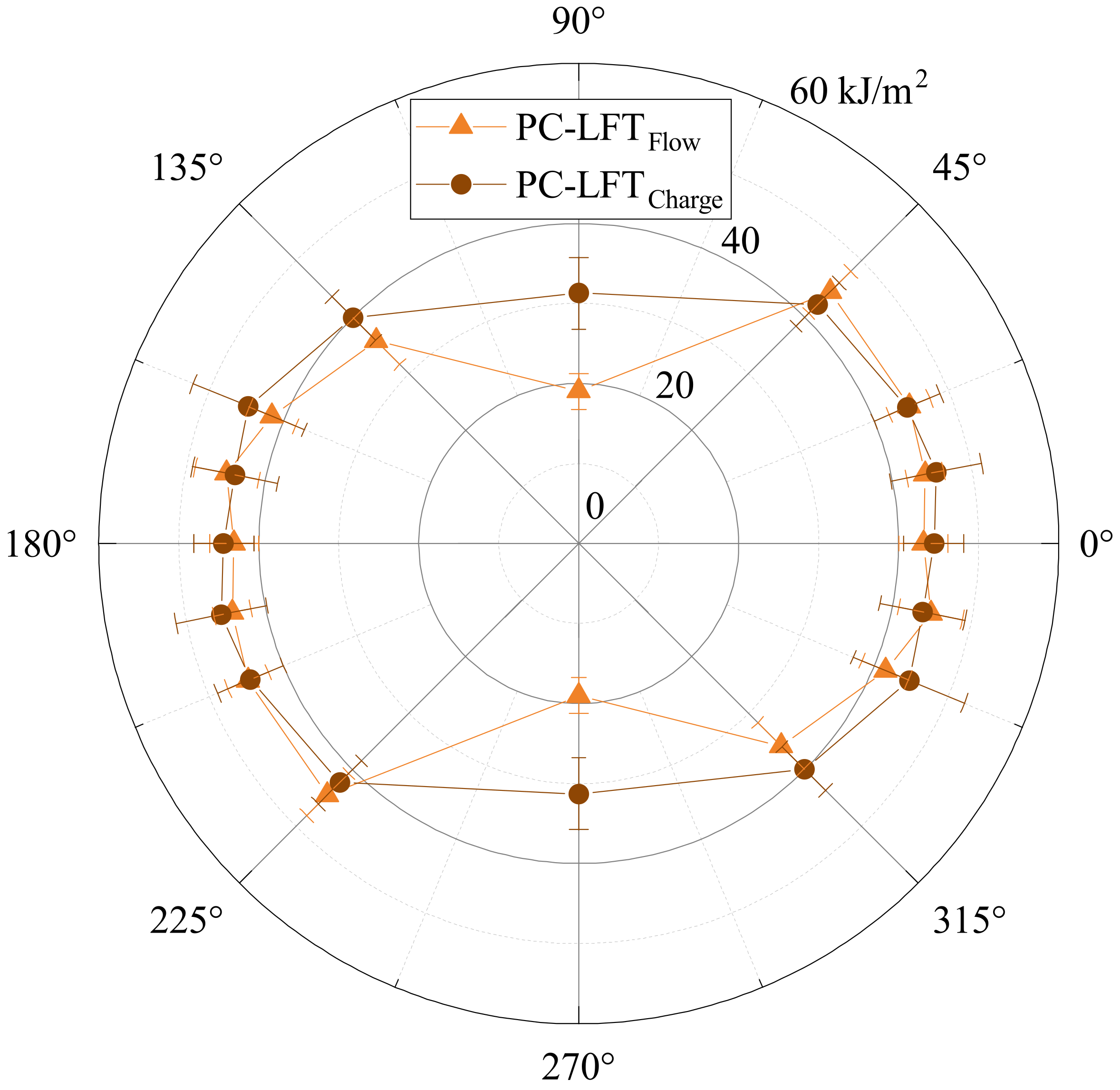

3.6. Orientation and Area Dependency of Quasi-Static Mechanical Properties

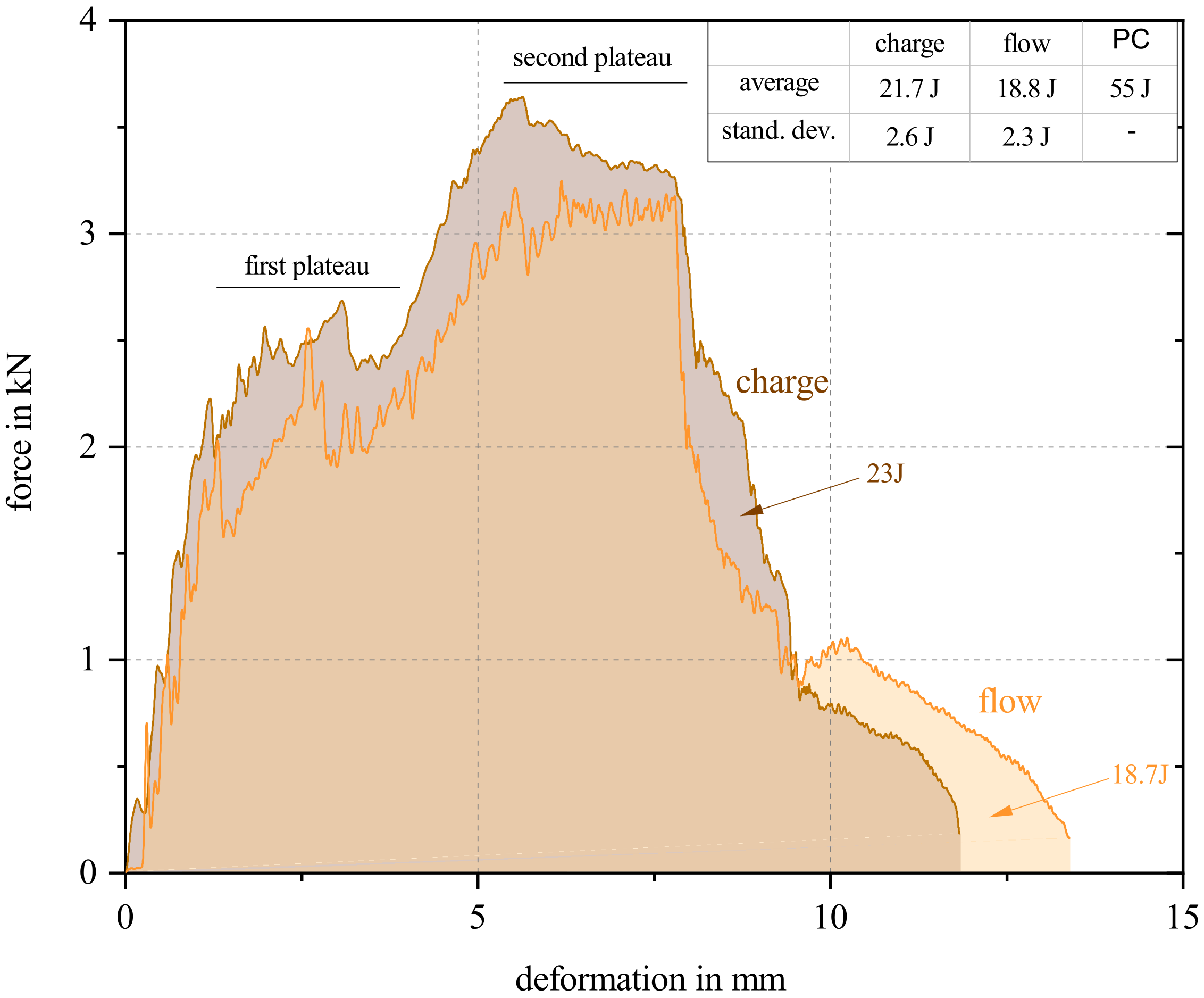

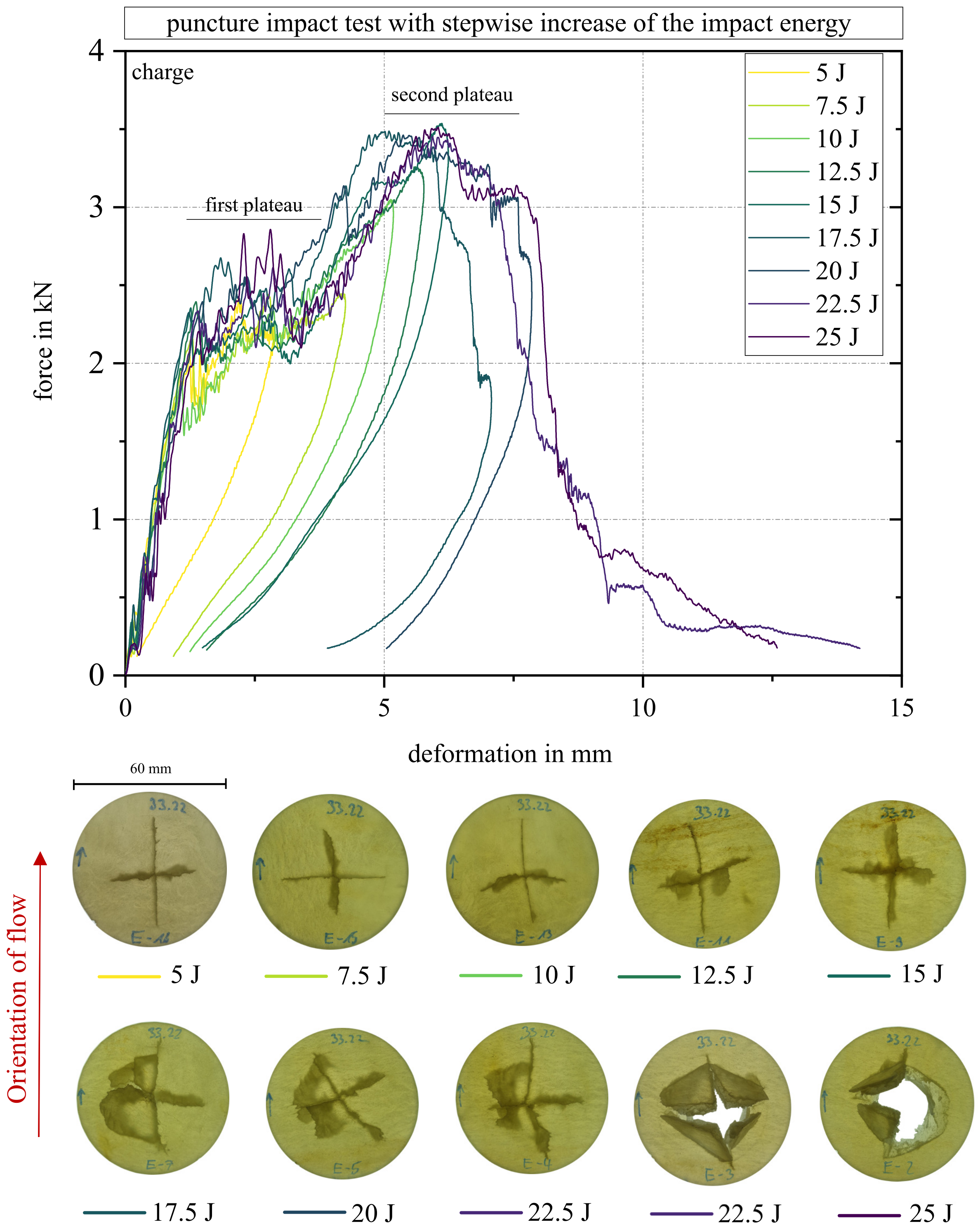

3.7. Puncture Impact Test Results

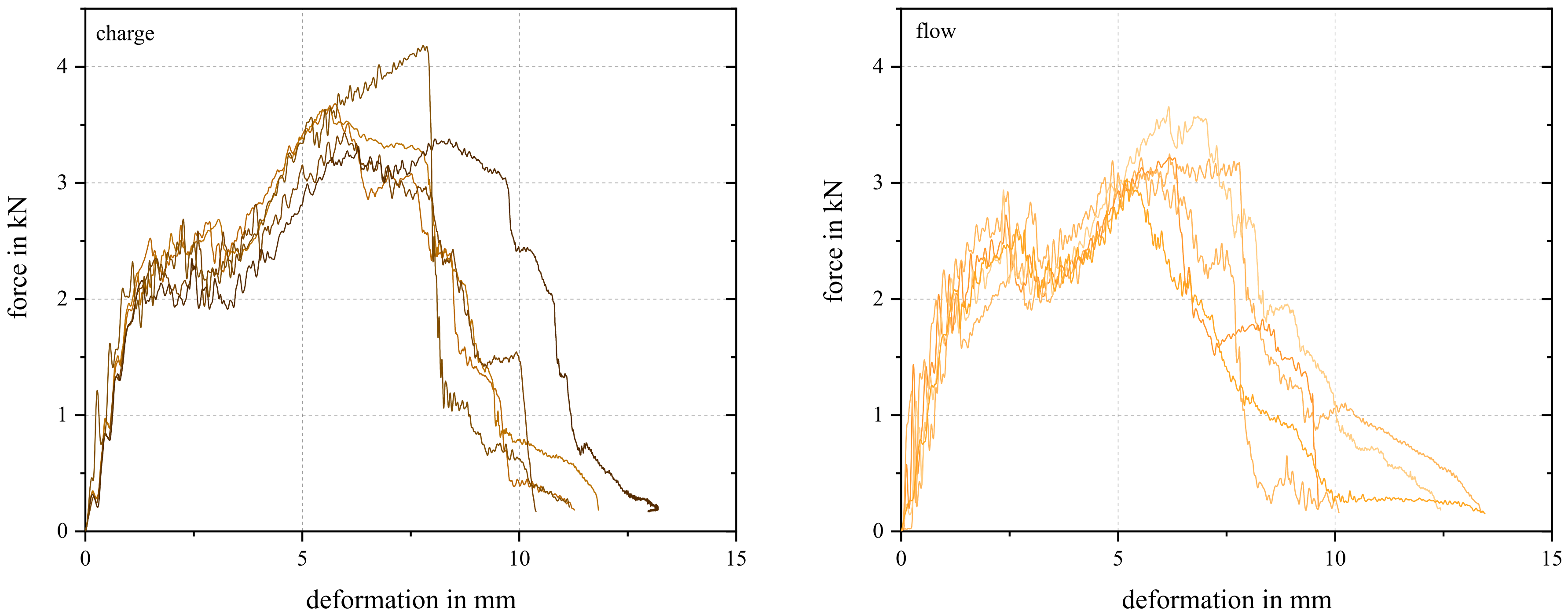

3.8. Charpy Impact Results

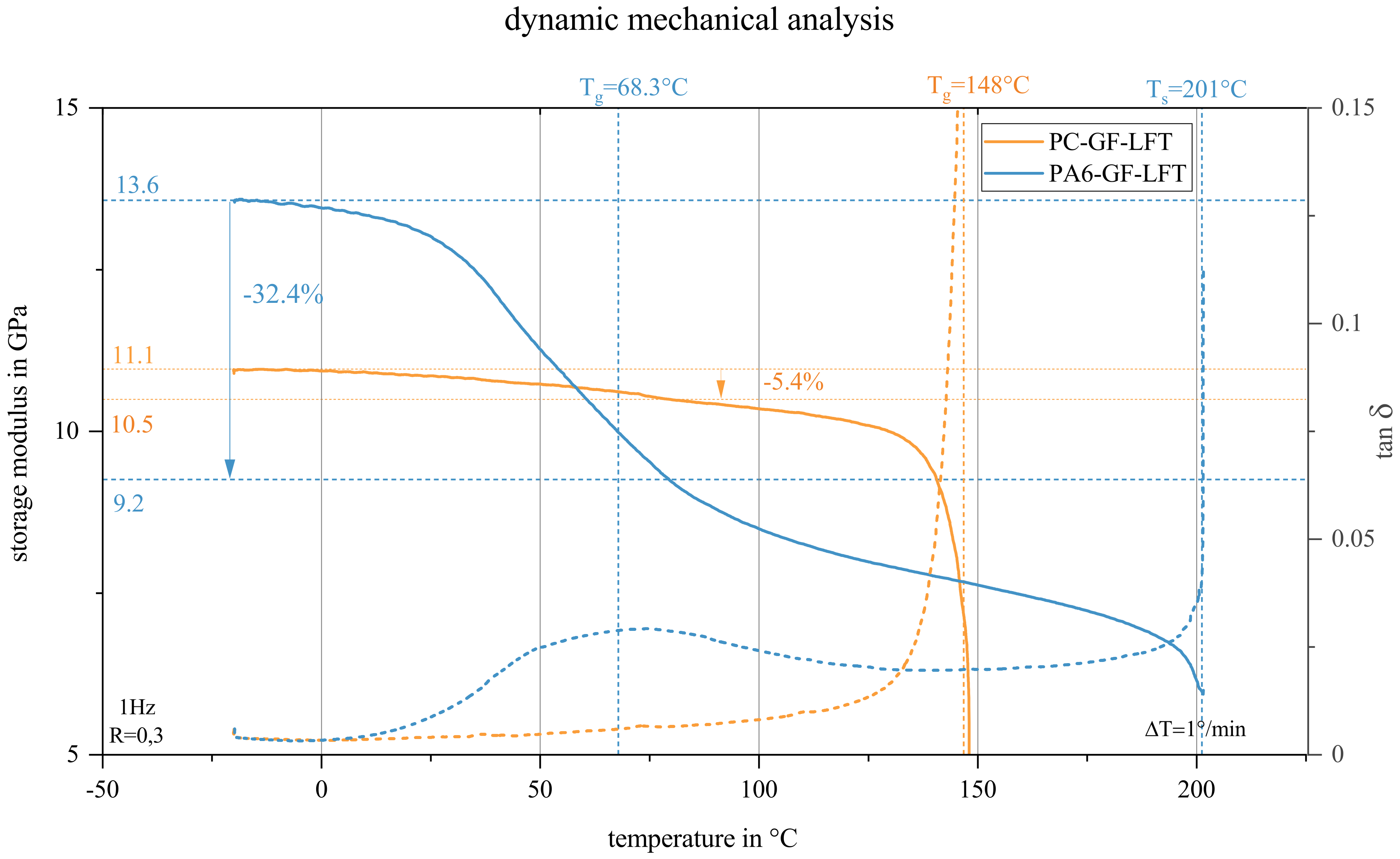

3.9. Comparing Thermoplastic LFT-D Materials in Dynamic Mechanical Analysis

4. Summary and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Puncture Impact Test

References

- Ning, H.; Lu, N.; Hassen, A.A.; Chawla, K.; Selim, M.; Pillay, S. A review of Long fibre thermoplastic (LFT) composites. Int. Mater. Rev. 2020, 65, 164–188. [Google Scholar] [CrossRef]

- Rohde-Tibitanzl, M. Direct Processing of Long Fiber Reinforced Thermoplastic Composites and Their Mechanical Behavior under Static and Dynamic Load (Print-on-Demand); Hanser Publications: Cincinnati, OH, USA, 2015. [Google Scholar] [CrossRef]

- Gandhi, U.N.; Goris, S.; Osswald, T.A.; Song, Y.Y. Discontinuous Fiber-Reinforced Composites: Fundamentals and Applications; Hanser Publishers: München, Germany, 2020. [Google Scholar] [CrossRef]

- Lin, J.; Li, J.; Li, X.; Guan, Y.; Wang, G.; Chen, L. Flame retardancy and toughening modification of glass fiber-reinforced polycarbonate composites. Polym. J. 2019, 51, 657–665. [Google Scholar] [CrossRef]

- Levchik, S.; Weil, E. Overview of recent developments in the flame retardancy of polycarbonates. Polym. Int. 2005, 54, 981–998. [Google Scholar] [CrossRef]

- Weil, E.; Levchik, S. Current Practice and Recent Commercial Developments in Flame Retardancy of Polyamides. J. Fire Sci. 2004, 22, 251–264. [Google Scholar] [CrossRef]

- McLeod, M.; Hétu, J.F.; Deaville, T.; Bureau, M.; Baril, E. Morphological and Mechanical Comparision of Injection and Compression Moulding In-Line Compounding of Direct Long Fibre Thermoplastics. In Proceedings of the 10th Annual SPE ACCE, Detroit, MI, USA, 15–16 September 2010; pp. 109–119. [Google Scholar]

- Buck, F.; Brylka, B.; Müller, V.; Müller, T.; Weidenmann, K.A.; Hrymak, A.N.; Henning, F.; Böhlke, T. Two-scale structural mechanical modeling of long fiber reinforced thermoplastics. Compos. Sci. Technol. 2015, 117, 159–167. [Google Scholar] [CrossRef]

- Knutsson, B.A.; White, J.L.; Abbas, K.B. Rheological and extrusion characteristics of glass fiber-reinforced polycarbonate. J. Appl. Polym. Sci. 1981, 26, 2347–2362. [Google Scholar] [CrossRef]

- Dahl, J.S.; Blanchard, P.J.; Rodgers, W.R. Direct compounding of a carbon fiber reinforced polyamide 66 composite. In Proceedings of the SAMPE Conference, Baltimore, MD, USA, 21–24 May 2012. [Google Scholar]

- Bondy, M.; Altenhof, W. Low velocity impact testing of direct/inline compounded carbon fibre/polyamide-6 long fibre thermoplastic. Int. J. Impact Eng. 2018, 111, 66–76. [Google Scholar] [CrossRef]

- Tröster, S. Materialentwicklung und -Charakterisierung für Thermoplastische Faserverbundwerkstoffe im Direktverfahren. Ph.D. Thesis, Universität Stuttgart, Stuttgart, Germany, 2004. [Google Scholar]

- Henning, F.; Ernst, H.; Brüssel, R. LFTs for automotive applications. Reinf. Plast. 2005, 49, 24–33. [Google Scholar] [CrossRef]

- Geiger, O.; Henning, F.; Eyerer, P. Back-Molding of High-Gloss Films with Long Fiber-Reinforced Thermoplastics. In Proceedings of the ANTEC Conference, Boston, MA, USA, 1–5 May 2005. [Google Scholar]

- Geiger, O.; Henning, F.; Eyerer, P.; Brüssel, R.; Ernst, H. LFT-D: Materials tailored for new applications. Reinf. Plast. 2006, 50, 30–35. [Google Scholar] [CrossRef]

- Radtke, A. Steifigkeitsberechnung von Diskontinuierlich Faserverstärkten Thermoplasten auf der Basis von Faserorientierungs- und Faserlängenverteilungen; Universität Stuttgart: Stuttgart, Germany, 2009. [Google Scholar] [CrossRef]

- Smith, G.; Zhao, H.; Shewey, M. Direct compounding and compression molding ofcarbon and glass fiber reinforced polyamide 66—Tensile and compressive test results. In Proceedings of the SPE ACCE, Virtual, 9–11 September 2020. [Google Scholar]

- Rohan, K.; McDonough, T. Mechanical study on long fiber thermoplastic carbon/polyamide 6 and its relations to processing parameters. In Proceedings of the 14th Annual SPE Automotive Composites Conference and Exhibition, Novi, MI, USA, 9–11 September 2015. [Google Scholar]

- Huembert, S. Influence of the Screw Configuration on the LFT-D Processing of Glass Fiber Reinforced PA6. Master’s Thesis, Karlsruhe Institute of Technology, Karlsruhe, Germany, 2016. [Google Scholar]

- Kohlgrüber, K. Co-Rotating Twin-Screw Extruders—Two Volume Set; Carl Hanser Verlag GmbH & Co. KG: München, Germany, 2020. [Google Scholar]

- Inceoglu, F.; Ville, J.; Ghamri, N.; Pradel, J.L.; Durin, A.; Valette, R.; Vergnes, B. Correlation between processing conditions and fiber breakage during compounding of glass fiber-reinforced polyamide. Polym. Compos. 2011, 32, 1842–1850. [Google Scholar] [CrossRef]

- Truckenmüller, F.; Fritz, H.-G. Injection molding of long fiber-reinforced thermoplastics: A comparison of extruded and pultruded materials with direct addition of roving strands. Polym. Eng. Sci. 1991, 31, 1316–1329. [Google Scholar] [CrossRef]

- Cox, H.L. The elasticity and strength of paper and other fibrous materials. Br. J. Appl. Phys. 1952, 3, 72–79. [Google Scholar] [CrossRef]

- Cottrell, A.H. Strong solids. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1964, 282, 2–9. [Google Scholar] [CrossRef]

- Kelly, A.; Tyson, W.R. Tensile properties of fibre-reinforced metals: Copper/tungsten and copper/molybdenum. J. Mech. Phys. Solids 1965, 13, 329–350. [Google Scholar] [CrossRef]

- Thomason, J.L.; Vlug, M.A. Influence of fibre length and concentration on the properties of glass fibre-reinforced polypropylene: 1. Tensile and flexural modulus. Compos. Part A Appl. Sci. Manuf. 1996, 27, 477–484. [Google Scholar] [CrossRef]

- Thomason, J.L. Structure-property relationships in glass-reinforced polyamide, part 1: The effects of fiber content. Polym. Compos. 2006, 27, 552–562. [Google Scholar] [CrossRef]

- Goris, S.; Back, T.; Yanev, A.; Brands, D.; Drummer, D.; Osswald, T.A. A novel fiber length measurement technique for discontinuous fiber-reinforced composites: A comparative study with existing methods. Polym. Compos. 2018, 39, 4058–4070. [Google Scholar] [CrossRef]

- Nam, G.J.; Kim, H.; Lee, J.W. Interfacial shear strength and wettability between glass fiber and PC/SAN/SMA blends. Polym. Compos. 2003, 24, 487–497. [Google Scholar] [CrossRef]

- Uematsu, H.; Naganawa, R.; Higashitani, N.; Yamaguchi, A.; Yamane, M.; Ozaki, Y.; Tanoue, S. Interfacial shear strength and interaction between polycarbonate and reinforcement fibers. Polymer 2021, 213, 123301. [Google Scholar] [CrossRef]

- Wongpajan, R.; Mathurosemontri, S.; Takematsu, R.; Xu, H.Y.; Uawongsuwan, P.; Thumsorn, S.; Hamada, H. Interfacial Shear Strength of Glass Fiber Reinforced Polymer Composites by the Modified Rule of Mixture and Kelly-Tyson Model. Energy Procedia 2016, 89, 328–334. [Google Scholar] [CrossRef]

- Uawongsuwan, P.; Inoya, H.; Hamada, H. Direct Fiber Feeding Injection Molding of Carbon Fiber Reinforced Polycarbonate Composites. In Proceedings of the SPE ACCE, Novi, MI, USA, 9–11 September 2014. [Google Scholar]

- Hirata, K.; Ishida, H.; Hiragohri, M.; Nakayama, Y.; Kajiwara, T. Experimental Assessment of Dispersion Failure of Glass Fiber Reinforced Plastics in a Twin Screw Extruder. Int. Polym. Process. 2013, 28, 368–375. [Google Scholar] [CrossRef]

- Eyerer, P.; Krause, W.; Geiger, O.; Henning, F. Development of a Technology for the Large-Scale Production of Continuous Fiber Reinforced Composites. In Proceedings of the 46th SPE Annual Technical Conference ANTEC, Charlotte, NC, USA, 7–11 May 2006. [Google Scholar]

- Henning, F. Verfahrensentwicklung für Lang- und Endlosglasfaserverstärkte Thermoplastische Sandwich-Bauteile mit Geschlossenem Werkstoff-Kreislauf. Ph.D. Thesis, Universität Stuttgart, Stuttgart, Germany, 2001. [Google Scholar]

- Hartwich, M.R.; Höhn, N.; Mayr, H.; Sandau, K.; Stengler, R. FASEP ultra-automated analysis of fibre length distribution in glass-fibre-reinforced products. In Proceedings of the Optical Measurement Systems for Industrial Inspection, Munich, Germany, 15–18 June 2009. [Google Scholar] [CrossRef]

- Sharma, B.N.; Naragani, D.; Nguyen, B.N.; Tucker, C.L.; Sangid, M.D. Uncertainty quantification of fiber orientation distribution measurements for long-fiber-reinforced thermoplastic composites. J. Compos. Mater. 2018, 52, 1781–1797. [Google Scholar] [CrossRef]

- Halpin, J.C.; Pagano, N.J. The Laminate Approximation for Randomly Oriented Fibrous Composites. J. Compos. Mater. 1969, 3, 720–724. [Google Scholar] [CrossRef]

- Durin, A.; de Micheli, P.; Ville, J.; Inceoglu, F.; Valette, R.; Vergnes, B. A matricial approach of fibre breakage in twin-screw extrusion of glass fibers reinforced thermoplastics. Compos. Part A Appl. Sci. Manuf. 2013, 48, 47–56. [Google Scholar] [CrossRef]

- Forgacs, O.; Mason, S. Particle motions in sheared suspensions. J. Colloid Sci. 1959, 14, 457–472. [Google Scholar] [CrossRef]

- Therolf, D. Verfahren und Plastifizierextruder zur Herstellung von Faserverstärkten Kunststoffmassen. German Patent DE19836787A1, 17 February 2000. [Google Scholar]

- Wolf, H.J. Screw plasticating of discontinuous fiber filled thermoplastic: Mechanisms and prevention of fiber attrition. Polym. Compos. 1994, 15, 375–383. [Google Scholar] [CrossRef]

- Priebe, M.; Schledjewski, R. Processing and properties of glass/polypropylene in long fibre compounding extrusion. Plast. Rubber Compos. 2011, 40, 374–379. [Google Scholar] [CrossRef]

| Trial # | Fiber Mass Fraction in % | Screw Speed in rpm | Rovings in pcs | Total Throughput in kg/h |

|---|---|---|---|---|

| V10 | 30 | 33 | 28 | 42.86 |

| V16 | 40 | 36 | 41 | 50 |

| V12 | 40 | 45 | 34 | 50 |

| V14 | 50 | 54 | 42 | 60 |

| Trial # | Fiber Mass Fraction in % | Screw Speed in rpm | Rovings in pcs | Total Throughput in kg/h |

|---|---|---|---|---|

| V1 | 30 | 40 | 24 | 42.86 |

| V5 | 40 | 53 | 28 | 50 |

| V31 | 40 | 53 | 28 | 50 |

| V2 | 40 | 62 | 24 | 50 |

| V7 | 40 | 62 | 24 | 50 |

| V30 | 40 | 62 | 24 | 50 |

| V32 | 40 | 62 | 24 | 50 |

| V6 | 40 | 74 | 20 | 50 |

| V33 | 40 | 74 | 20 | 50 |

| V3 | 50 | 92 | 24 | 60 |

| Height Above Zero in mm | Closing Speed in mm/s |

|---|---|

| 50 | 80 |

| 30 | 30 |

| 15 | 5 |

| 0 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schelleis, C.; Scheuring, B.M.; Liebig, W.V.; Hrymak, A.N.; Henning, F. Approaching Polycarbonate as an LFT-D Material: Processing and Mechanical Properties. Polymers 2023, 15, 2041. https://doi.org/10.3390/polym15092041

Schelleis C, Scheuring BM, Liebig WV, Hrymak AN, Henning F. Approaching Polycarbonate as an LFT-D Material: Processing and Mechanical Properties. Polymers. 2023; 15(9):2041. https://doi.org/10.3390/polym15092041

Chicago/Turabian StyleSchelleis, Christoph, Benedikt M. Scheuring, Wilfried V. Liebig, Andrew N. Hrymak, and Frank Henning. 2023. "Approaching Polycarbonate as an LFT-D Material: Processing and Mechanical Properties" Polymers 15, no. 9: 2041. https://doi.org/10.3390/polym15092041

APA StyleSchelleis, C., Scheuring, B. M., Liebig, W. V., Hrymak, A. N., & Henning, F. (2023). Approaching Polycarbonate as an LFT-D Material: Processing and Mechanical Properties. Polymers, 15(9), 2041. https://doi.org/10.3390/polym15092041