Effect of Hydrophilic Polyurethane on Interfacial Shear Strength of Pisha Sandstone Consolidation under Freeze–Thaw Cycles

Abstract

1. Introduction

2. Materials and Methods

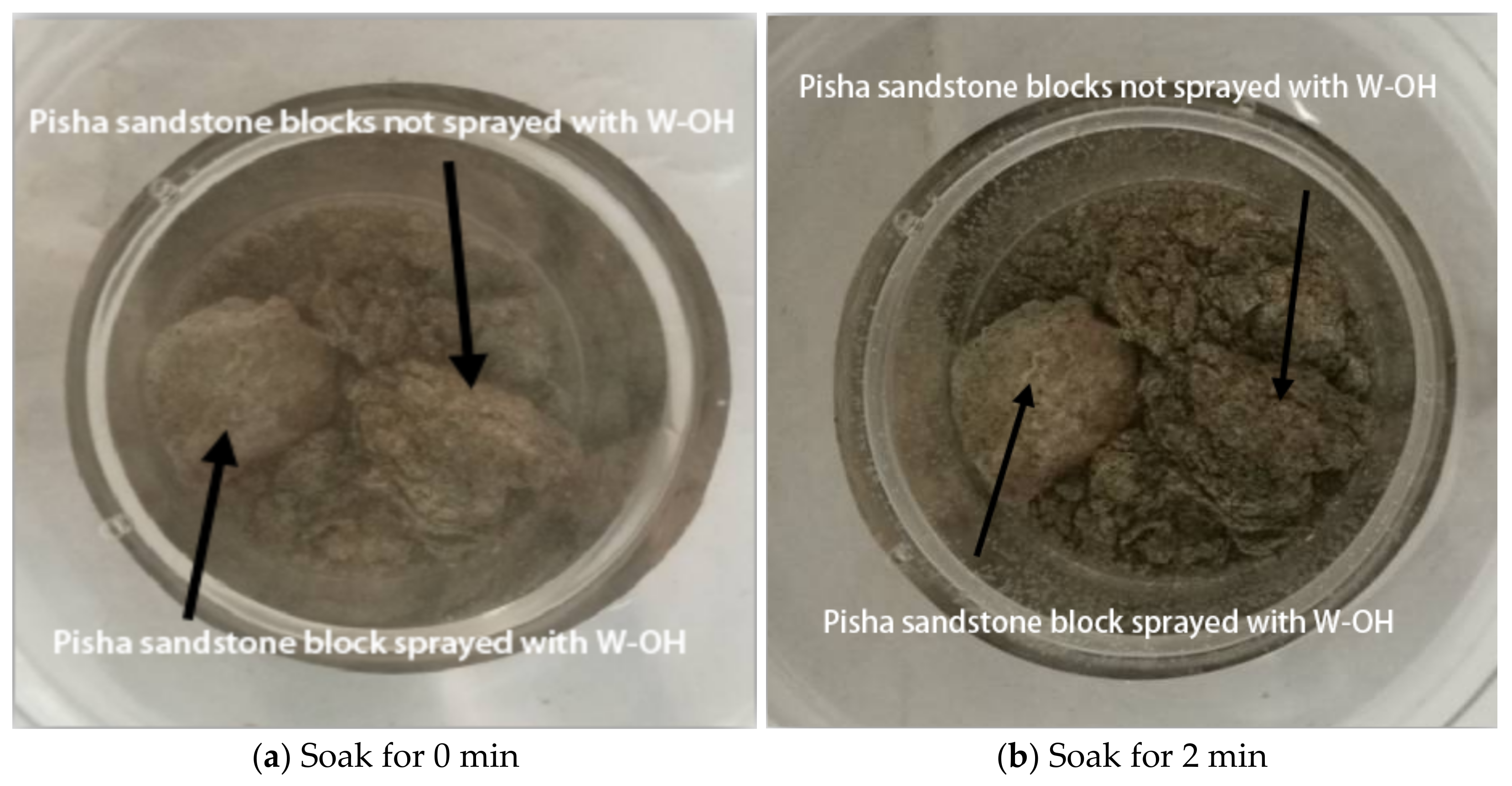

2.1. Materials

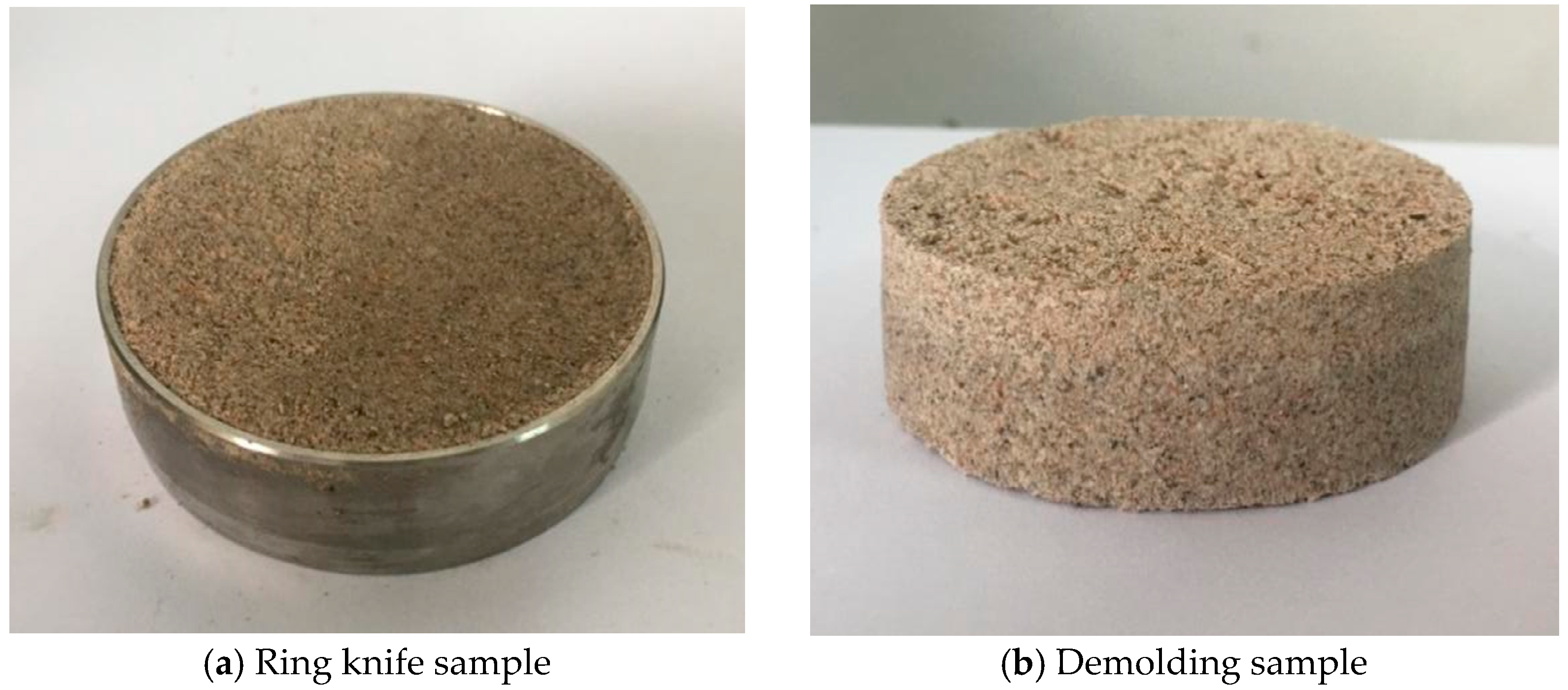

2.2. Specimen Preparation

2.3. Freeze–Thaw Cycling

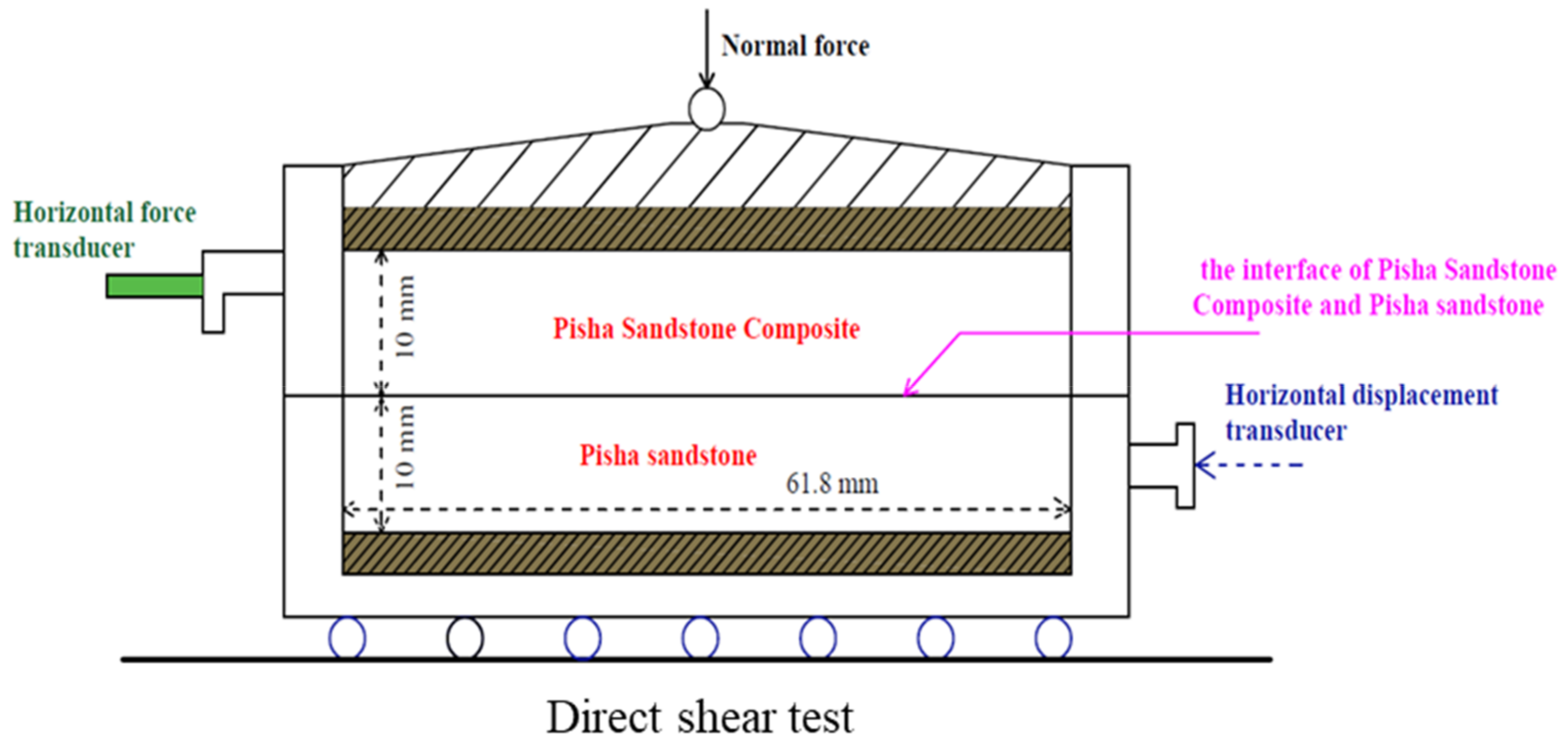

2.4. Testing Procedure

3. Experimental Results

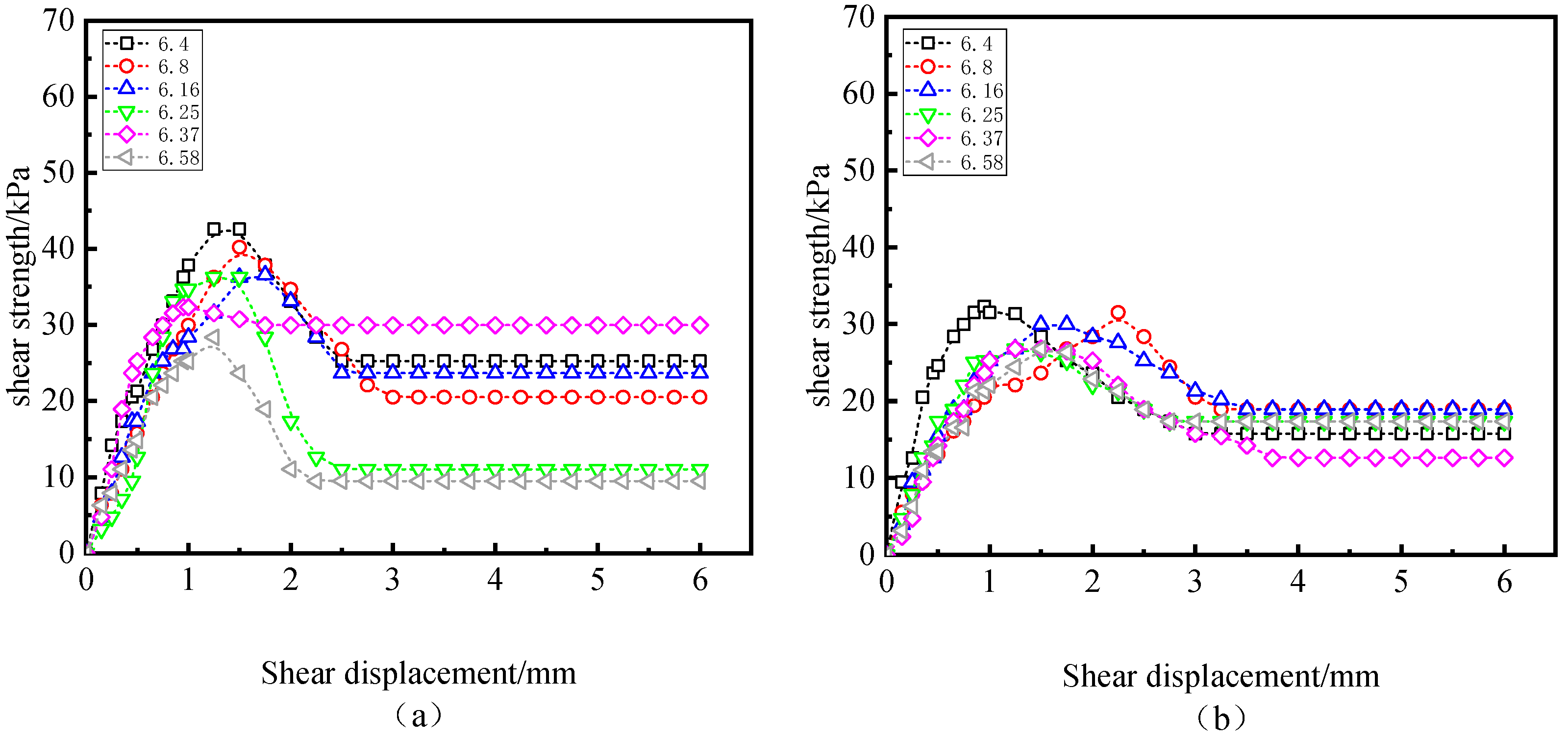

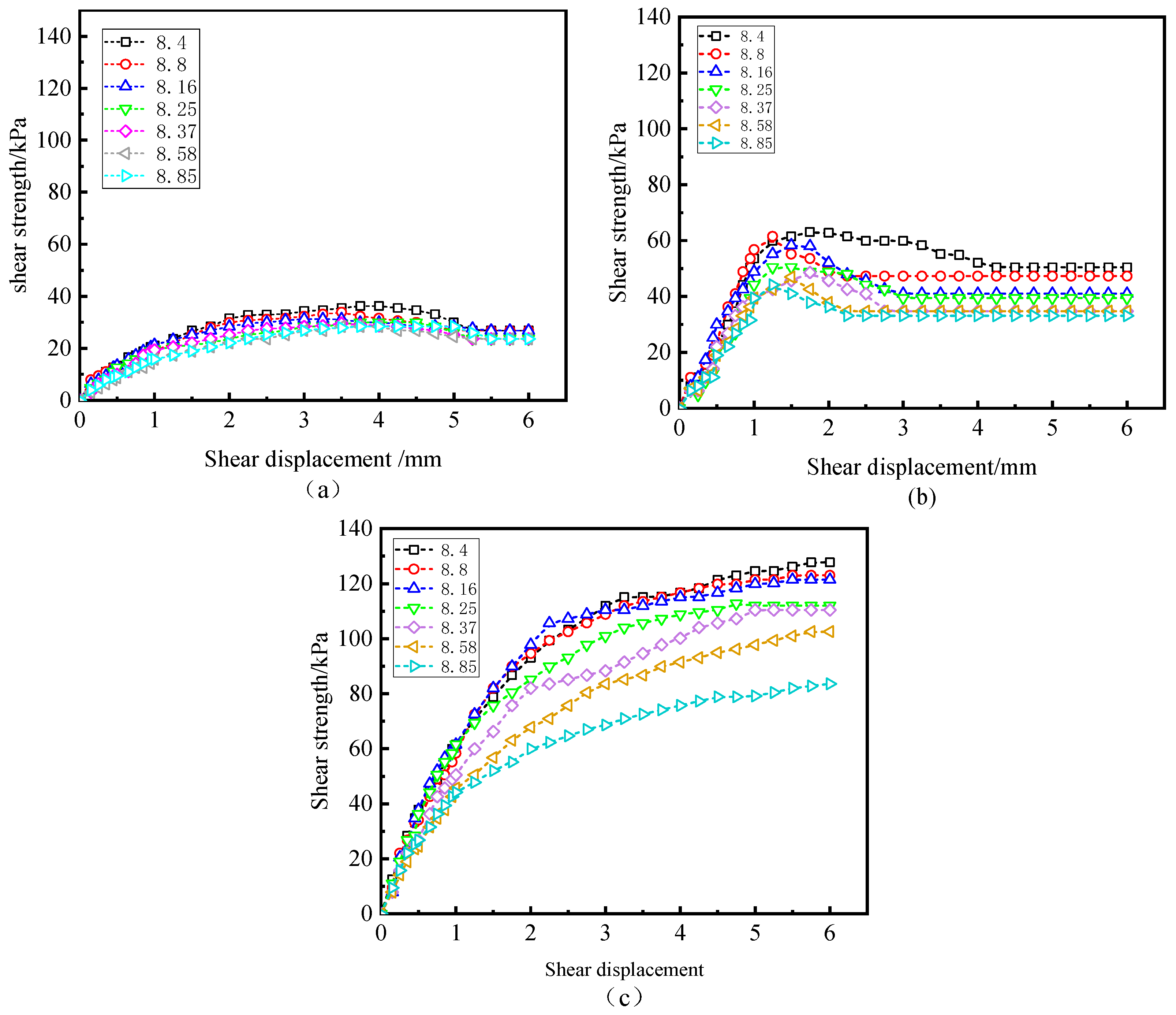

3.1. Shear Stress-Displacement

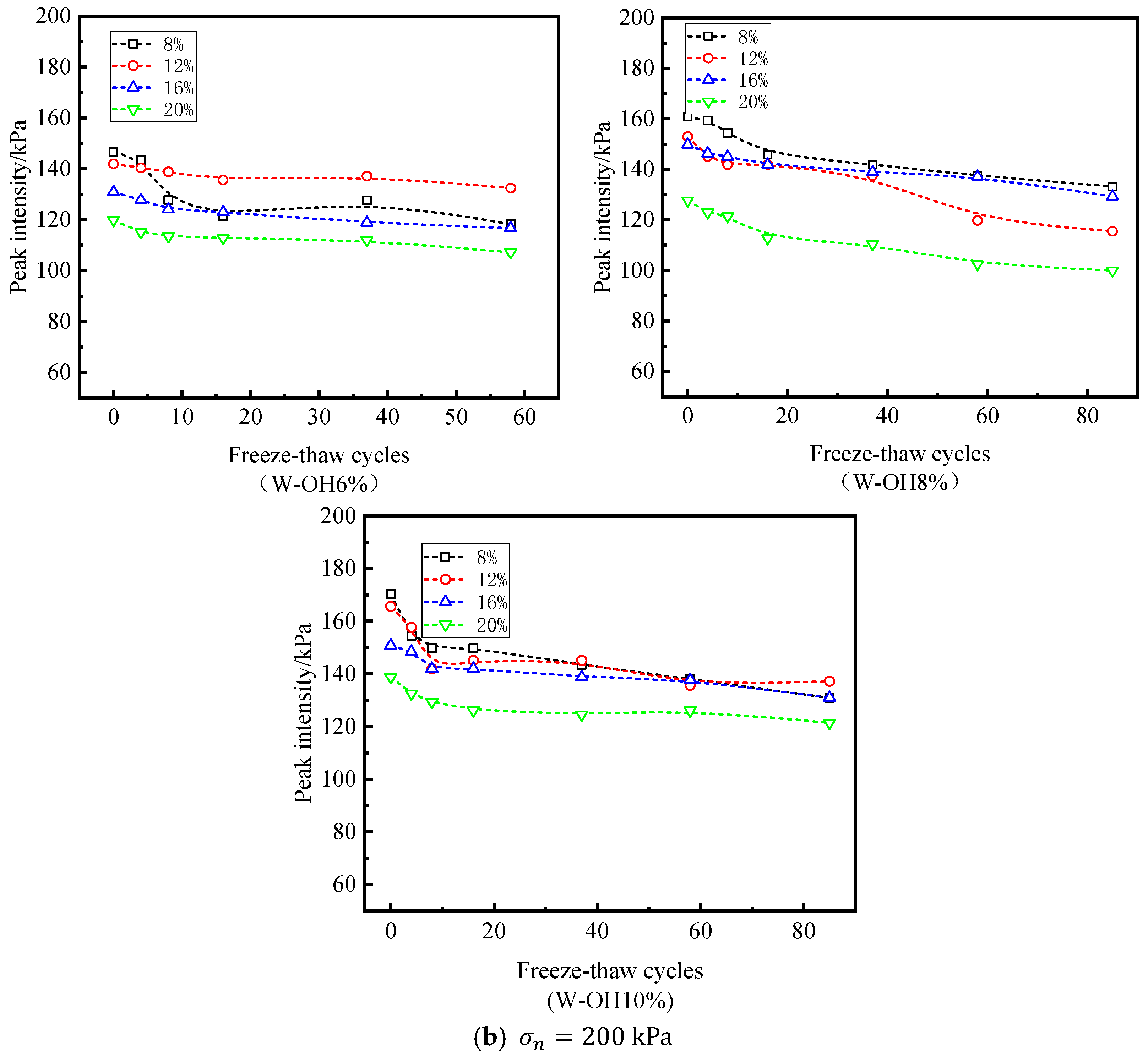

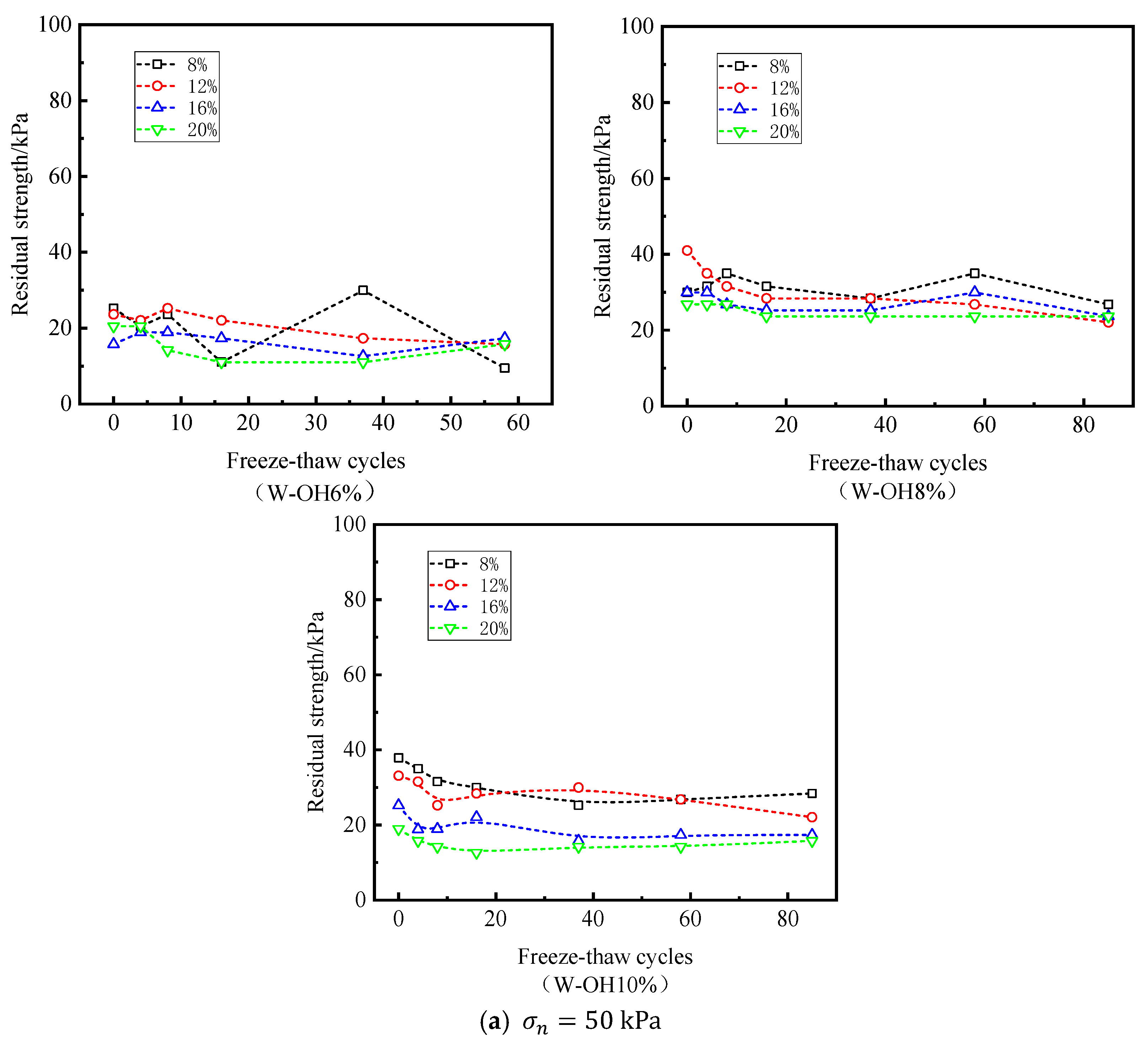

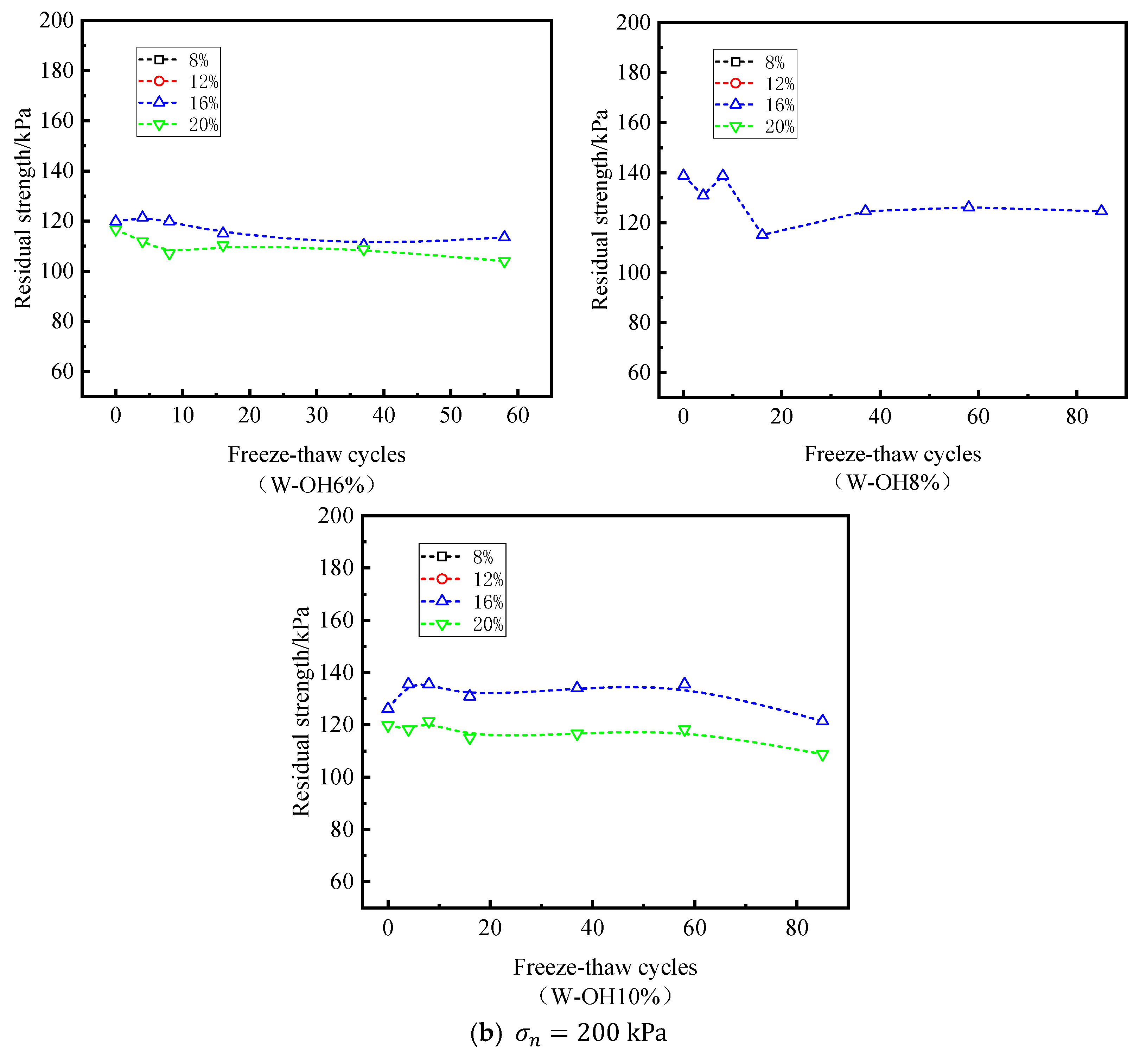

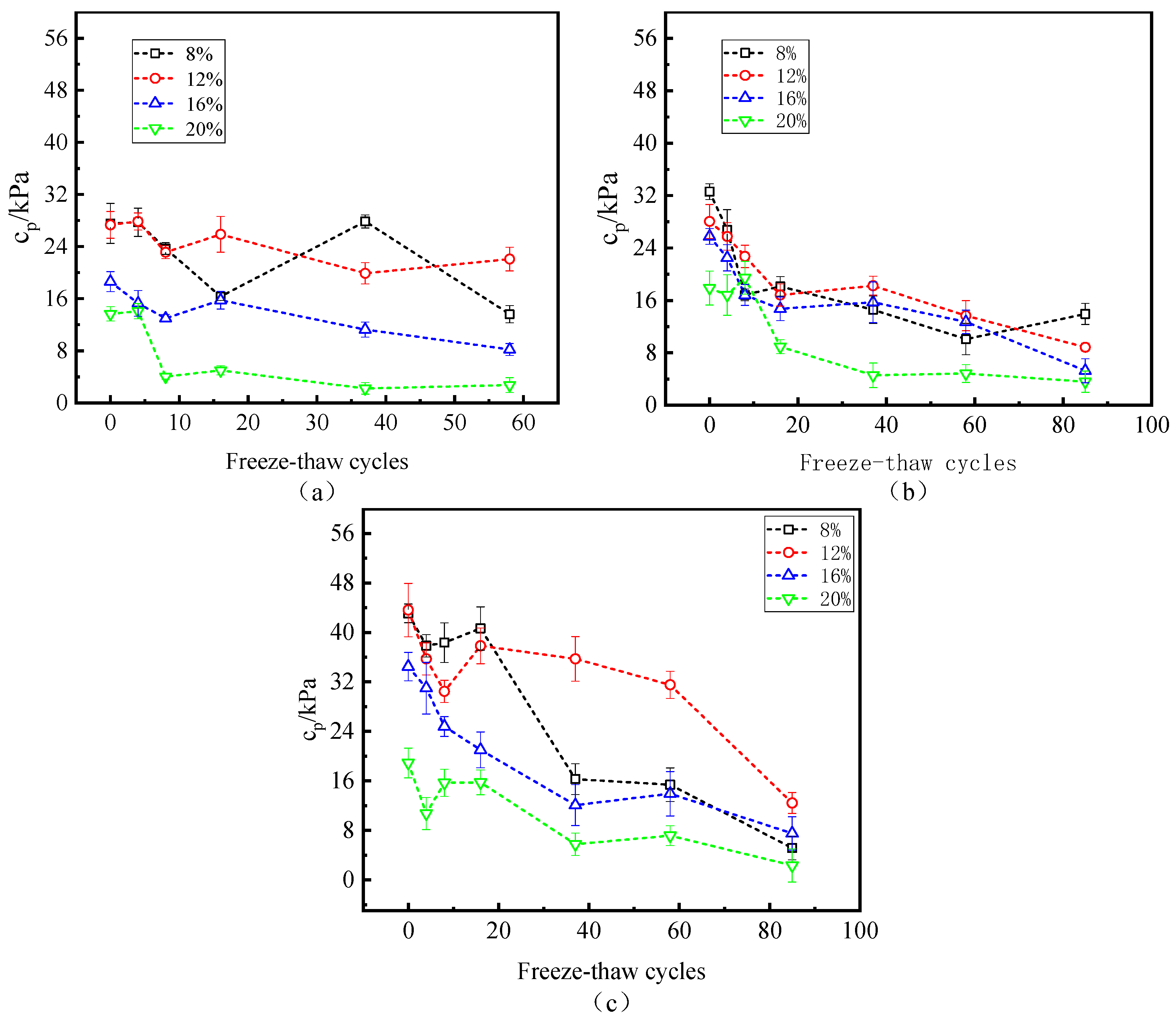

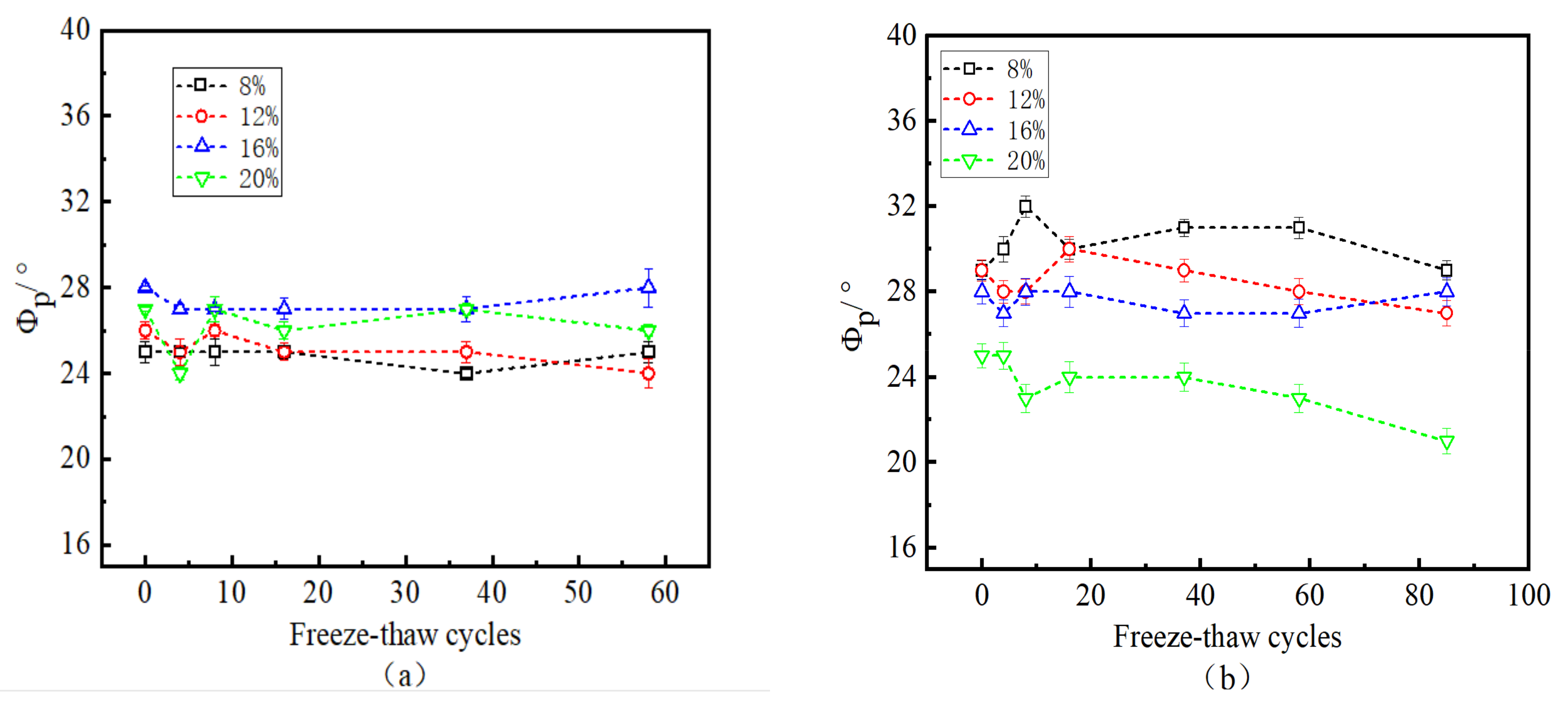

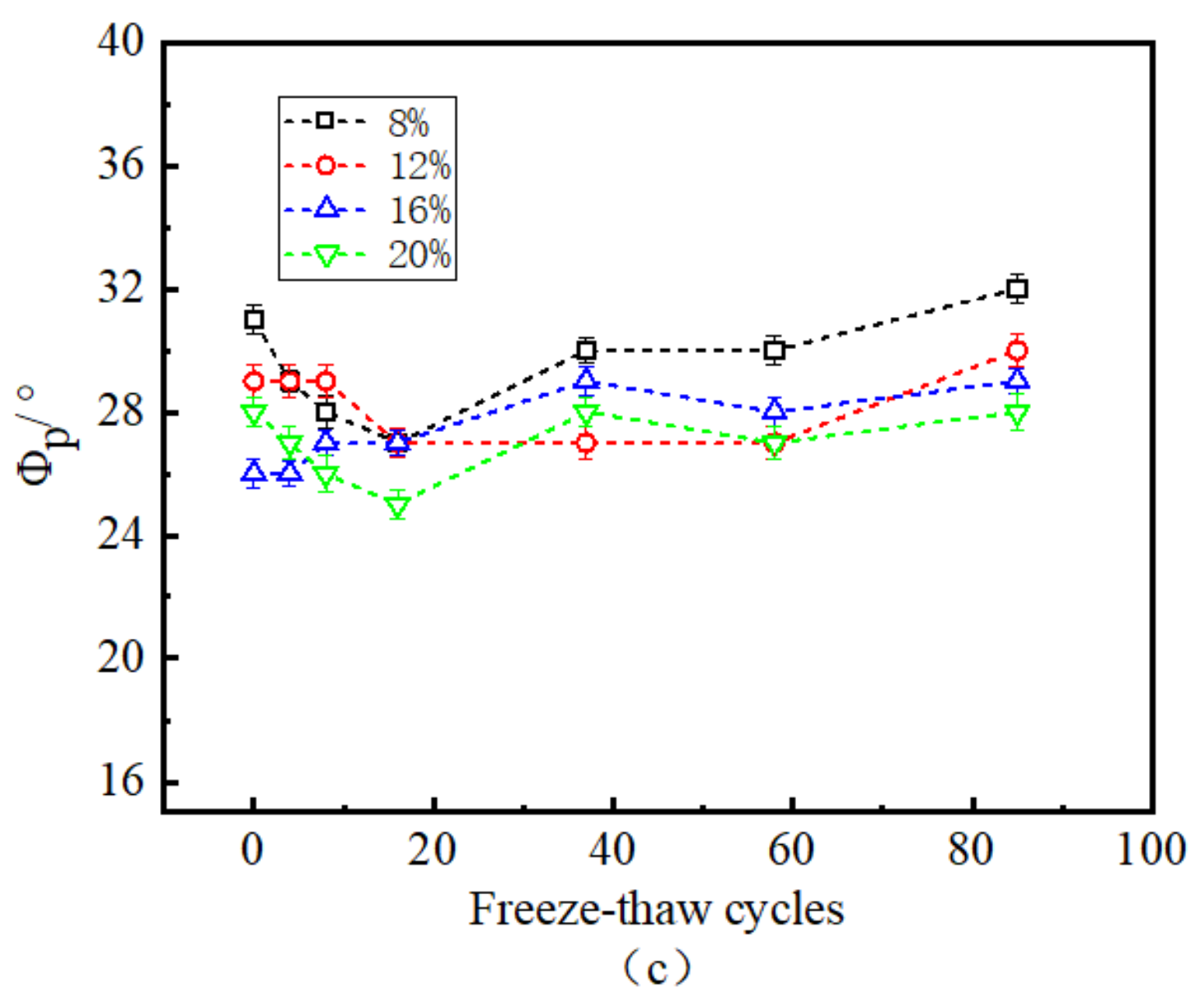

3.2. Peak and Residual Strength

3.3. Improved Interface Freeze–Thaw Cycle Durability

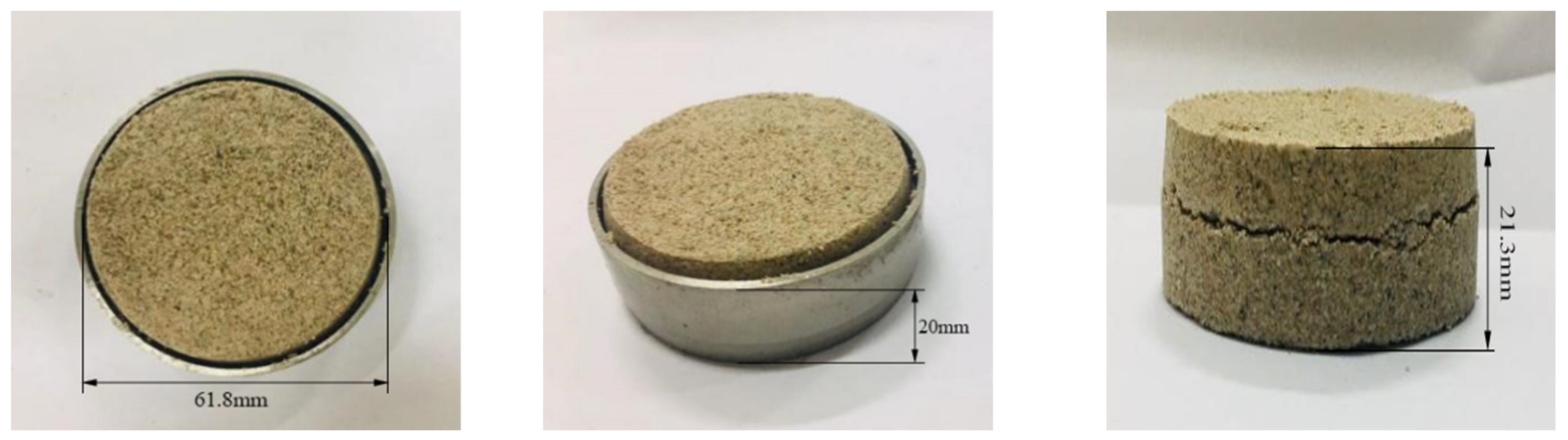

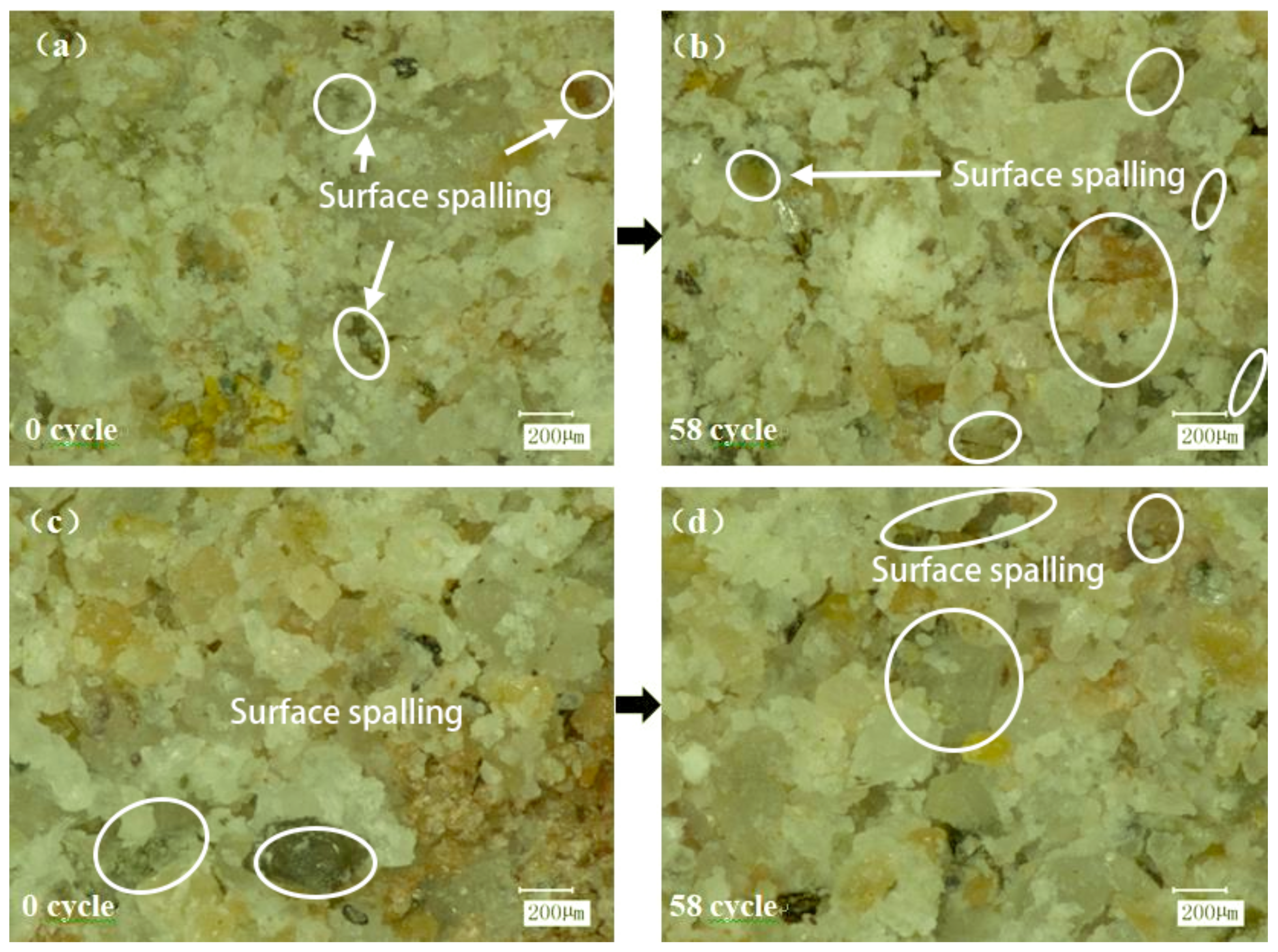

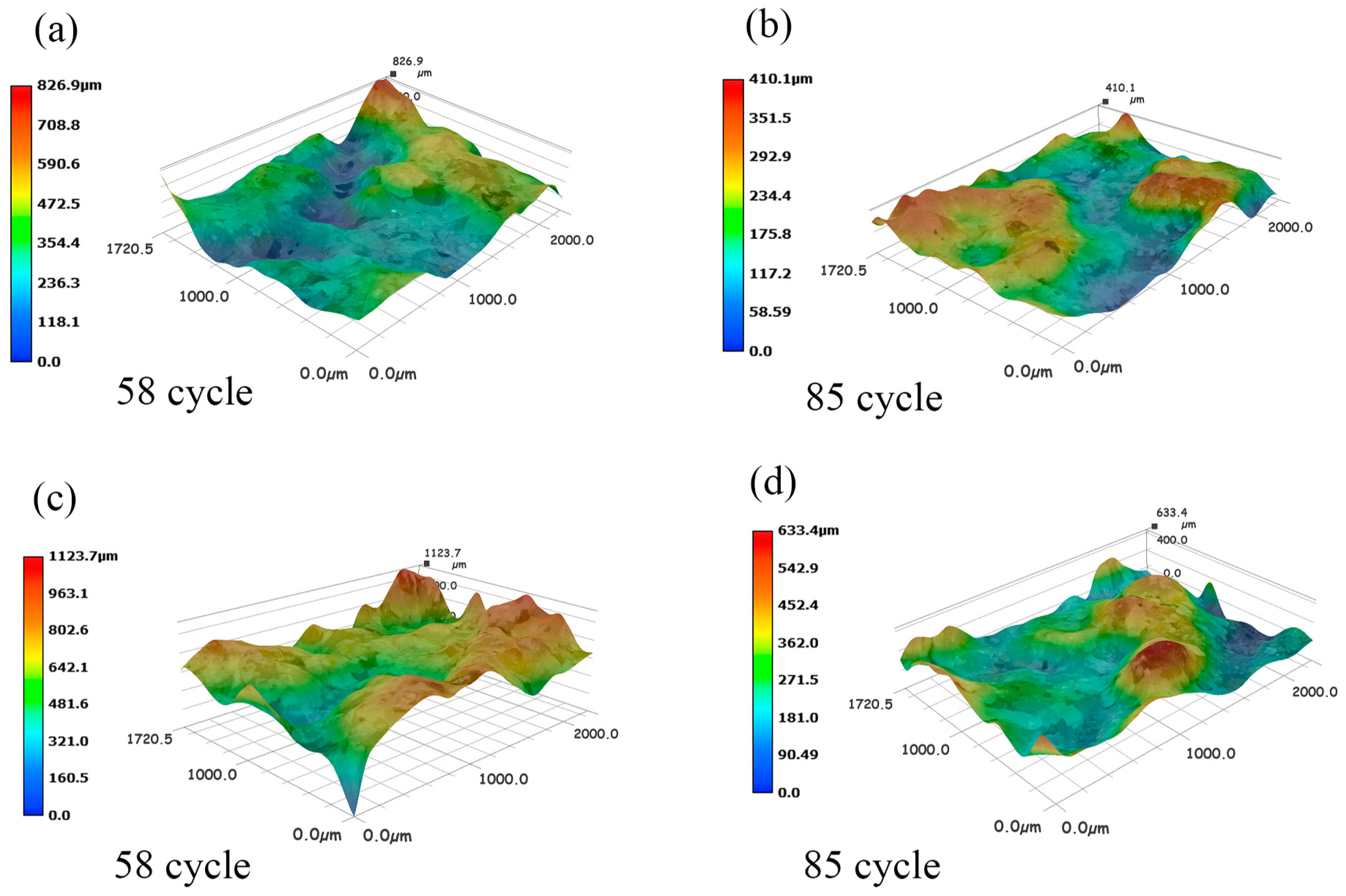

3.4. Research on Damage of Failure Surface after Freeze–Thaw Cycle

4. Discussion

5. Conclusions

- (1)

- The samples prepared with a higher concentration of W-OH solution have better resistance to freeze–thaw cycles at the interface. At low water contents (8% and 12%) between the interfaces, the volume changes in water content during freeze–thaw cycles are sufficient to inhibit such swelling and shrinkage due to the elasticity of the pores and the W-OH concretions themselves. With the increase in interfacial water content, the effect of interfacial water content on interfacial shear strength is greater than that of the W-OH materials;

- (2)

- There is no apparent correlation between freeze–thaw cycle effects, W-OH concentration, and moisture content on the internal friction angle at the interface. The development of the freeze–thaw cycle at the interface can be attributed to the repeated solidification–melting of water. This causes the consolidation of the failure surface to fall off and gradually produce cracks, thus reducing the bonding properties of the material—the cohesion and peak strength at the interface increase with the concentration of W-OH;

- (3)

- The addition of EVA can improve the freeze–thaw durability of the interface between W-OH-treated sandstone and the original sandstone due to the improvement in the bond strength of W-OH material.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liang, Z.; Wu, Z.; Yao, W.; Noori, M.; Yang, C.; Xiao, P.; Leng, Y.; Deng, L. Pisha sandstone: Causes, processes and erosion options for its control and prospects. Int. Soil Water Conserv. Res. 2019, 7, 1–8. [Google Scholar] [CrossRef]

- Ma, W.; Zhang, X. Effect of Pisha sandstone on water infiltration of different soils on the Chinese Loess Plateau. J. Arid Land 2016, 8, 331–340. [Google Scholar] [CrossRef][Green Version]

- Ni, H.; Zhang, L.; Zhang, D.; Wu, X.; Fu, X. Weathering of Pisha-sandstones in the wind-water erosion crisscross region on the Loess Plateau. J. Mt. Sci. 2008, 5, 340. [Google Scholar] [CrossRef]

- Guo, J.; Shi, Y.C.; Wu, L.J. Gravity erosion and lithology in Pisha sandstone in southern Inner Mongolia. J. Groundw. Sci. Eng. 2015, 3, 45–58. [Google Scholar]

- Li, C.; Zhang, T.; Wang, L. Mechanical properties and microstructure of alkali activated Pisha sandstone geopolymer composites. Constr. Build. Mater. 2014, 68, 233–239. [Google Scholar] [CrossRef]

- Wang, T.; Li, P.; Liu, Y.; Hou, J.; Li, Z.; Ren, Z.; Cheng, S.; Zhao, J.; Hinkelmann, R. Experimental investigation of freeze–thaw meltwater compound erosion and runoff energy consumption on loessal slopes. Catena 2020, 185, 104310. [Google Scholar] [CrossRef]

- Patton, A.I.; Rathburn, S.L.; Capps, D.M. Landslide response to climate change in permafrost regions. Geomorphology 2019, 340, 116–128. [Google Scholar] [CrossRef]

- Ye, W.; Li, C. The consequences of changes in the structure of loess as a result of cyclic freezing and thawing. Bull. Eng. Geol. Environ. 2019, 78, 2125–2138. [Google Scholar] [CrossRef]

- Ma, Q.; Zhang, K.; Jabro, J.D.; Ren, L.; Liu, H. Freeze–thaw cycles effects on soil physical properties under different degraded conditions in Northeast China. Environ. Earth Sci. 2019, 78, 321. [Google Scholar] [CrossRef]

- Jin, J.; Li, S.; Song, C.; Zhang, X.; Lv, X. Ageing deformation of tailings dams in seasonally frozen soil areas under freeze–thaw cycles. Sci. Rep. 2019, 9, 15033. [Google Scholar] [CrossRef][Green Version]

- Qin, Z.; Lai, Y.; Tian, Y.; Zhang, M. Stability behavior of a reservoir soil bank slope under freeze–thaw cycles in cold regions. Cold Reg. Sci. Technol. 2021, 181, 103181. [Google Scholar] [CrossRef]

- Nguyen, H.; Wong, H.; Fabbri, A.; Georgin, J.; Prud’Homme, E. Analytical study of freezing behavior of a cavity in thermo-poro-elastic medium. Comput. Geotech. 2015, 67, 33–45. [Google Scholar] [CrossRef]

- Subramanian, S.S.; Ishikawa, T.; Tokoro, T. Stability assessment approach for soil slopes in seasonal cold regions. Eng. Geol. 2017, 221, 154–169. [Google Scholar] [CrossRef]

- Tian, D.; Xie, Q.; Fu, X.; Zhang, J. Experimental study on the effect of fine contents on internal erosion in natural soil deposits. Bull. Eng. Geol. Environ. 2020, 79, 4135–4150. [Google Scholar] [CrossRef]

- Xie, S.-B.; Jian-Jun, Q.; Yuan-Ming, L.; Zhi-Wei, Z.; Xiang-Tian, X. Effects of freeze–thaw cycles on soil mechanical and physical properties in the Qinghai-Tibet Plateau. J. Mt. Sci. 2015, 12, 999–1009. [Google Scholar] [CrossRef]

- Ma, W.; Xu, X.Z.; Zhang, L.X. Influence of frost and thaw cycles on shear strength of lime silt. Chin. J. Geotech. Eng. 1999, 21, 158–160. [Google Scholar]

- Nidzam, R.M.; Norsalisma, I.; Kinuthia, J.M. Strength and environmental evaluation of stabilised Clay-PFA eco-friendly bricks. Constr. Build. Mater. 2016, 125, 964–973. [Google Scholar] [CrossRef]

- Gallala, W.; Gaied, M.E.; Tlili, A.; Montacer, M. Factors influencing the reactivity of quicklime. Proc. Inst. Civ. Eng. Constr. Mater. 2008, 161, 25–30. [Google Scholar] [CrossRef]

- Oti, J.E.; Kinuthia, J.M.; Bai, J. Developing unfired stabilised building materials in the UK. In Proceedings of the Institution of Civil Engineers-Engineering Sustainability; Thomas Telford Ltd.: London, UK, 2008; pp. 211–218. [Google Scholar]

- Lai, Y.; Zhang, S.; Yu, W. A new structure to control frost boiling and frost heave of embankments in cold regions. Cold Reg. Sci. Technol. 2012, 79, 53–66. [Google Scholar] [CrossRef]

- Wang, C.; Guo, C.; Du, X.; Shi, M.; Liu, Q.; Xia, Y. Reinforcement of silty soil with permeable polyurethane by penetration injection. Constr. Build. Mater. 2021, 310, 124829. [Google Scholar] [CrossRef]

- Linag, Z.; Wu, Z.; Noori, M.; Yang, C.; Yao, W. A new ecological control method for Pisha sandstone based on hydrophilic polyurethane. J. Arid. Land 2017, 9, 790–796. [Google Scholar] [CrossRef]

- Yao, W.; Wu, Z.; Liu, H.; Xiao, P.Q.; Yang, C.Q. Experimental research on the anti-Erosion and vegetation promotion for sandstone region in the Yellow River basin. Yellow River 2015, 37, 6–10. [Google Scholar]

- Ma, W.; Gao, W.; Guo, S.; Zhao, Y.; Wu, Z.; Yang, C. Evaluation and improvement on the freeze–thaw durability performance of the polyurethane stabilized Pisha sandstone for water and soil conservation. Cold Reg. Sci. Technol. 2020, 177, 103065. [Google Scholar] [CrossRef]

- Liang, Z.; Wu, Z.; Yang, C.; Yao, W.Y.; Deng, L. Study on water resistance, antierosion and UV durability of Pisha sandstone solidified body. Yellow River 2016, 36, 46–48. [Google Scholar]

- Li, X.; Zhai, T.; Zhang, Q. Experiment on mechanical properties of Pisha-sandstone at recurrent shear. Trans. Chin. Soc. Agric. Eng. 2015, 31, 154–159. [Google Scholar]

- Li, S.X.; Nan, Z.T.; Zhao, L. Impact of freezing and thawing on energy exchange between the system and environment. J. Glaciol. Geocryol. 2002, 24, 109–115. [Google Scholar]

- Ghazavi, M.; Roustaie, M. The influence of freeze–thaw cycles on the unconfined compressive strength of fiber-reinforced clay. Cold Reg. Sci. Technol. 2010, 61, 125–131. [Google Scholar] [CrossRef]

- Liu, J.; Chang, D.; Yu, Q. Influence of freeze–thaw cycles on mechanical properties of a silty sand. Eng. Geol. 2016, 210, 23–32. [Google Scholar] [CrossRef]

- Feng, Z.; Zheng, F.; Hu, W.; Li, G.; Xu, X. Impacts of mollic epipedon thickness and overloaded sediment deposition on corn yield in the Chinese Mollisol region. Agric. Ecosyst. Environ. 2018, 257, 175–182. [Google Scholar] [CrossRef]

- Eigenbrod, K.D. Effects of cyclic freezing and thawing on volume changes and permeabilities of soft fine-gained soils. Can. Geotech. J. 1996, 33, 529–537. [Google Scholar] [CrossRef]

- Dagesse, D. Effect of freeze-drying on soil aggregate stability. Soil Sci. Soc. Am. J. 2011, 75, 2111–2121. [Google Scholar] [CrossRef]

| Water Content/% | Porosity/% | Liquid Limit/% | Plasticity Index/% | Osmotic Coefficient/ | |

|---|---|---|---|---|---|

| 7.70–21.1 | 1.85–1.96 | 31.04–35.15 | 19.6 | 9.40 |

| Water Content/% | W-OH Concentration/% | EVA Concentration/% | |

|---|---|---|---|

| Group 1 | (8/12/16/20) | - | - |

| Group 2 | (8/12/16/20) | 6 | - |

| Group 3 | (8/12/16/20) | 8 | - |

| Group 4 | (8/12/16/20) | 10 | - |

| Group 5 | (8/12/16/20) | 6 | 5 |

| Group 6 | (8/12/16/20) | 6 | 10 |

| Group 7 | (8/12/16/20) | 8 | 5 |

| Group 8 | (8/12/16/20) | 8 | 10 |

| Group 9 | (8/12/16/20) | 10 | 5 |

| Group 10 | (8/12/16/20) | 10 | 10 |

| Water | W-OH | EVA | Normal | Freeze–Thaw |

|---|---|---|---|---|

| Content/% | Concentration/% | Concentration/% | Stress | Cycles |

| 8 | 6 | - | 50 | 85 |

| 12 | 6 | - | 50 | 85 |

| 16 | 6 | - | 50 | 85 |

| 20 | 6 | - | 50 | 85 |

| 8 | 6 | - | 100 | 85 |

| 12 | 6 | - | 100 | 85 |

| 16 | 6 | - | 100 | 85 |

| 20 | 6 | - | 100 | 85 |

| 8 | 6 | - | 200 | 85 |

| 12 | 6 | - | 200 | 85 |

| 16 | 6 | - | 200 | 85 |

| 20 | 6 | - | 200 | 85 |

| 8 | 8 | - | 50 | 85 |

| 12 | 8 | - | 50 | 85 |

| 16 | 8 | - | 50 | 85 |

| 20 | 8 | - | 50 | 85 |

| 8 | 8 | - | 100 | 85 |

| 12 | 8 | - | 100 | 85 |

| 16 | 8 | - | 100 | 85 |

| 20 | 8 | - | 100 | 85 |

| 8 | 8 | - | 200 | 85 |

| 12 | 8 | - | 200 | 85 |

| 16 | 8 | - | 200 | 85 |

| 20 | 8 | - | 200 | 85 |

| 8 | 10 | - | 50 | 85 |

| 12 | 10 | - | 50 | 85 |

| 16 | 10 | - | 50 | 85 |

| 20 | 10 | - | 50 | 85 |

| 8 | 10 | - | 100 | 85 |

| 12 | 10 | - | 100 | 85 |

| 16 | 10 | - | 100 | 85 |

| 20 | 10 | - | 100 | 85 |

| 8 | 10 | - | 200 | 85 |

| 12 | 10 | - | 200 | 85 |

| 16 | 10 | - | 200 | 85 |

| 20 | 10 | - | 200 | 85 |

| 8 | 6 | 5 | 50 | 85 |

| 12 | 6 | 5 | 50 | 85 |

| 16 | 6 | 5 | 50 | 85 |

| 20 | 6 | 5 | 50 | 85 |

| 8 | 6 | 5 | 100 | 85 |

| 12 | 6 | 5 | 100 | 85 |

| 16 | 6 | 5 | 100 | 85 |

| 20 | 6 | 5 | 100 | 85 |

| 8 | 6 | 5 | 200 | 85 |

| 12 | 6 | 5 | 200 | 85 |

| 16 | 6 | 5 | 200 | 85 |

| 20 | 6 | 5 | 200 | 85 |

| 8 | 6 | 10 | 50 | 85 |

| 12 | 6 | 10 | 50 | 85 |

| 16 | 6 | 10 | 50 | 85 |

| 20 | 6 | 10 | 50 | 85 |

| 8 | 6 | 10 | 100 | 85 |

| 12 | 6 | 10 | 100 | 85 |

| 16 | 6 | 10 | 100 | 85 |

| 20 | 6 | 10 | 100 | 85 |

| 8 | 6 | 10 | 200 | 85 |

| 12 | 6 | 10 | 200 | 85 |

| 16 | 6 | 10 | 200 | 85 |

| 20 | 6 | 10 | 200 | 85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, W.; Yang, K.; Zhou, X.; Luo, Z.; Guo, Y. Effect of Hydrophilic Polyurethane on Interfacial Shear Strength of Pisha Sandstone Consolidation under Freeze–Thaw Cycles. Polymers 2023, 15, 2131. https://doi.org/10.3390/polym15092131

Ma W, Yang K, Zhou X, Luo Z, Guo Y. Effect of Hydrophilic Polyurethane on Interfacial Shear Strength of Pisha Sandstone Consolidation under Freeze–Thaw Cycles. Polymers. 2023; 15(9):2131. https://doi.org/10.3390/polym15092131

Chicago/Turabian StyleMa, Wenbo, Ke Yang, Xuan Zhou, Zhengdong Luo, and Yuefei Guo. 2023. "Effect of Hydrophilic Polyurethane on Interfacial Shear Strength of Pisha Sandstone Consolidation under Freeze–Thaw Cycles" Polymers 15, no. 9: 2131. https://doi.org/10.3390/polym15092131

APA StyleMa, W., Yang, K., Zhou, X., Luo, Z., & Guo, Y. (2023). Effect of Hydrophilic Polyurethane on Interfacial Shear Strength of Pisha Sandstone Consolidation under Freeze–Thaw Cycles. Polymers, 15(9), 2131. https://doi.org/10.3390/polym15092131