Chitosan Polymer Functionalized-Activated Carbon/Montmorillonite Composite for the Potential Removal of Lead Ions from Wastewater

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

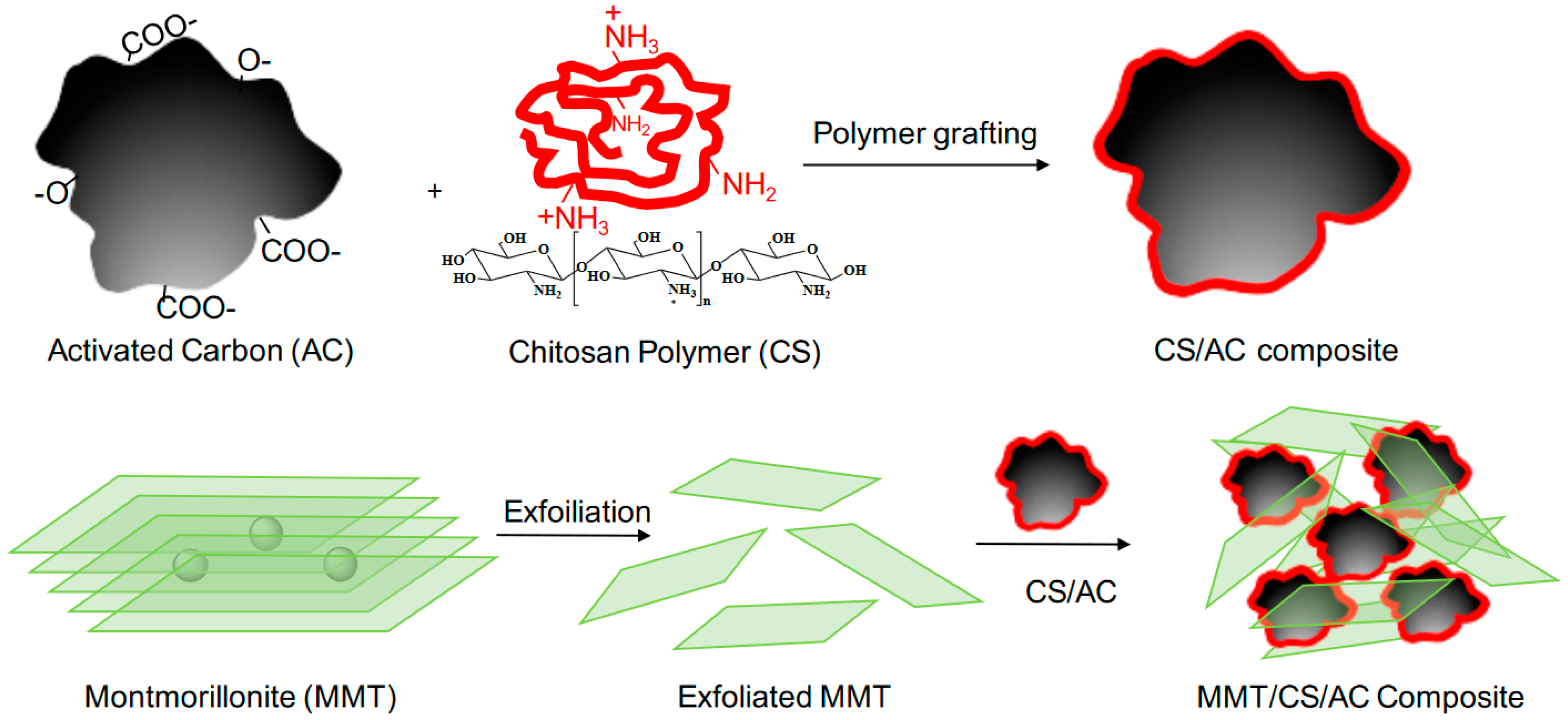

2.2.1. Delamination of AC Layers

2.2.2. Chitosan Polymer/Activated Carbon Composite Formation

2.2.3. Composite Formation of Montmorillonite/Polymer Functionalized-Activated Carbon

2.3. Adsorption Assessment

2.4. Desorption Studies

2.5. Characterization

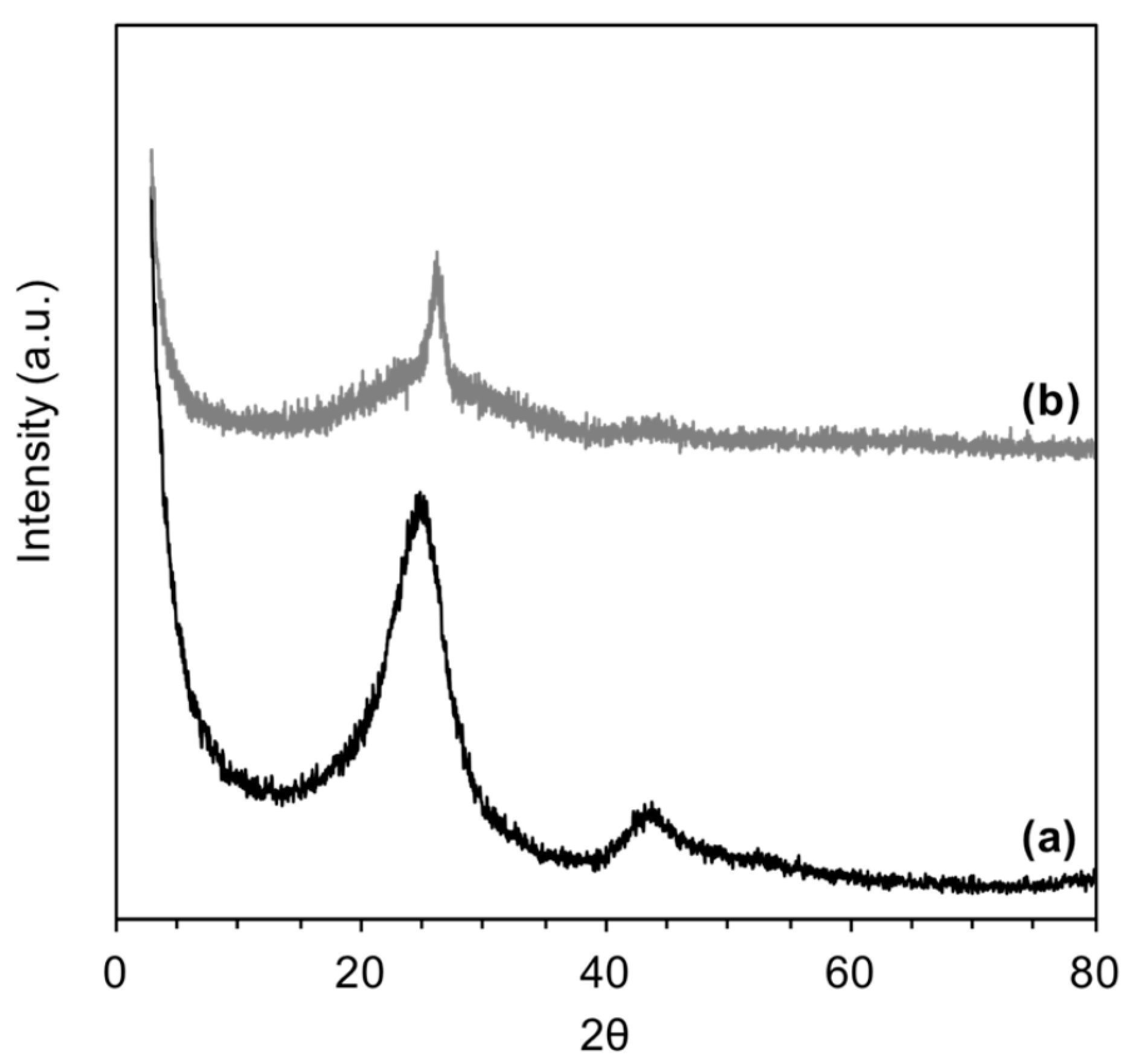

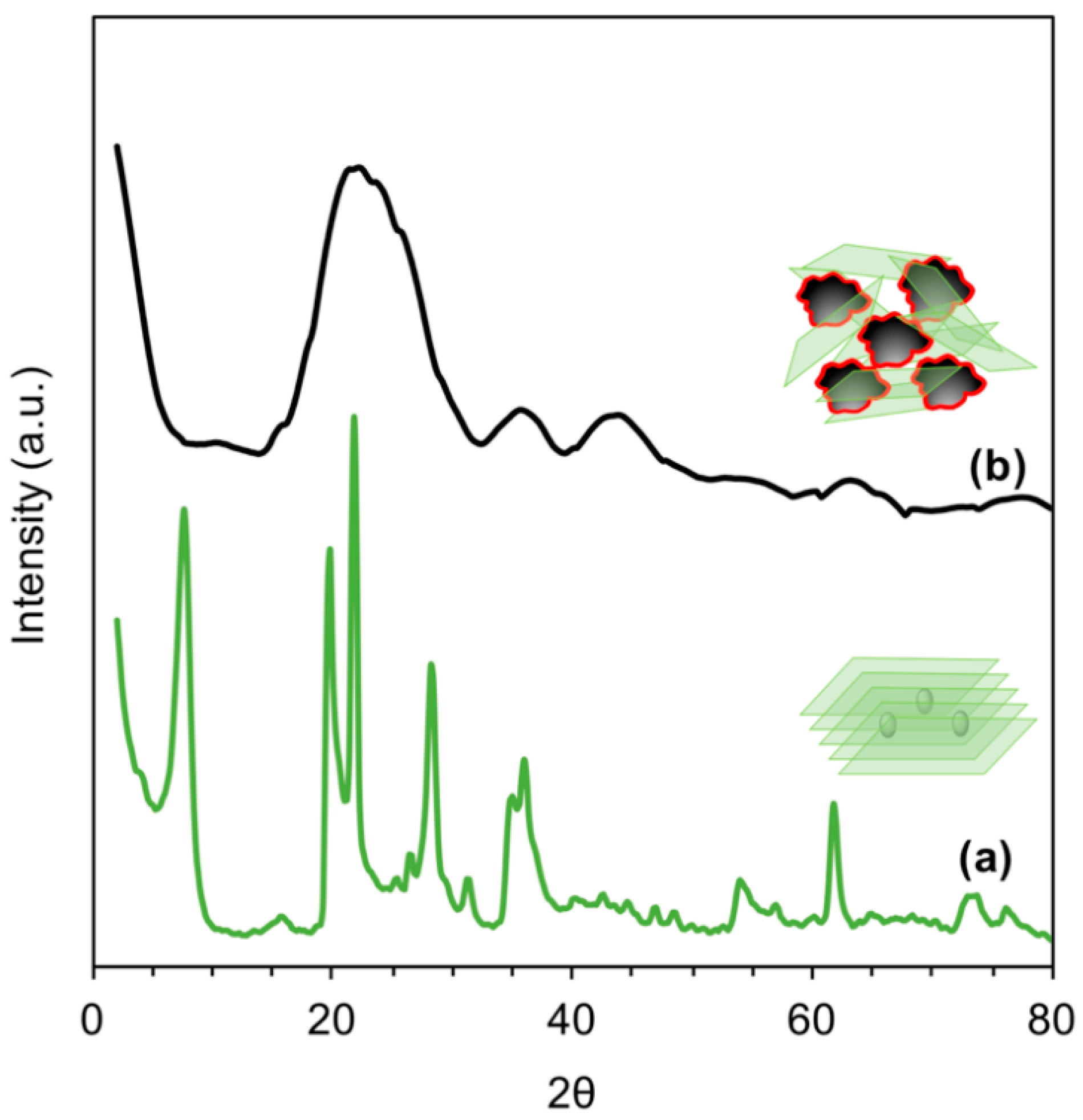

3. Result and Discussion

3.1. Batch Adsorption Assessment

3.1.1. Estimate the Optimal Parameters

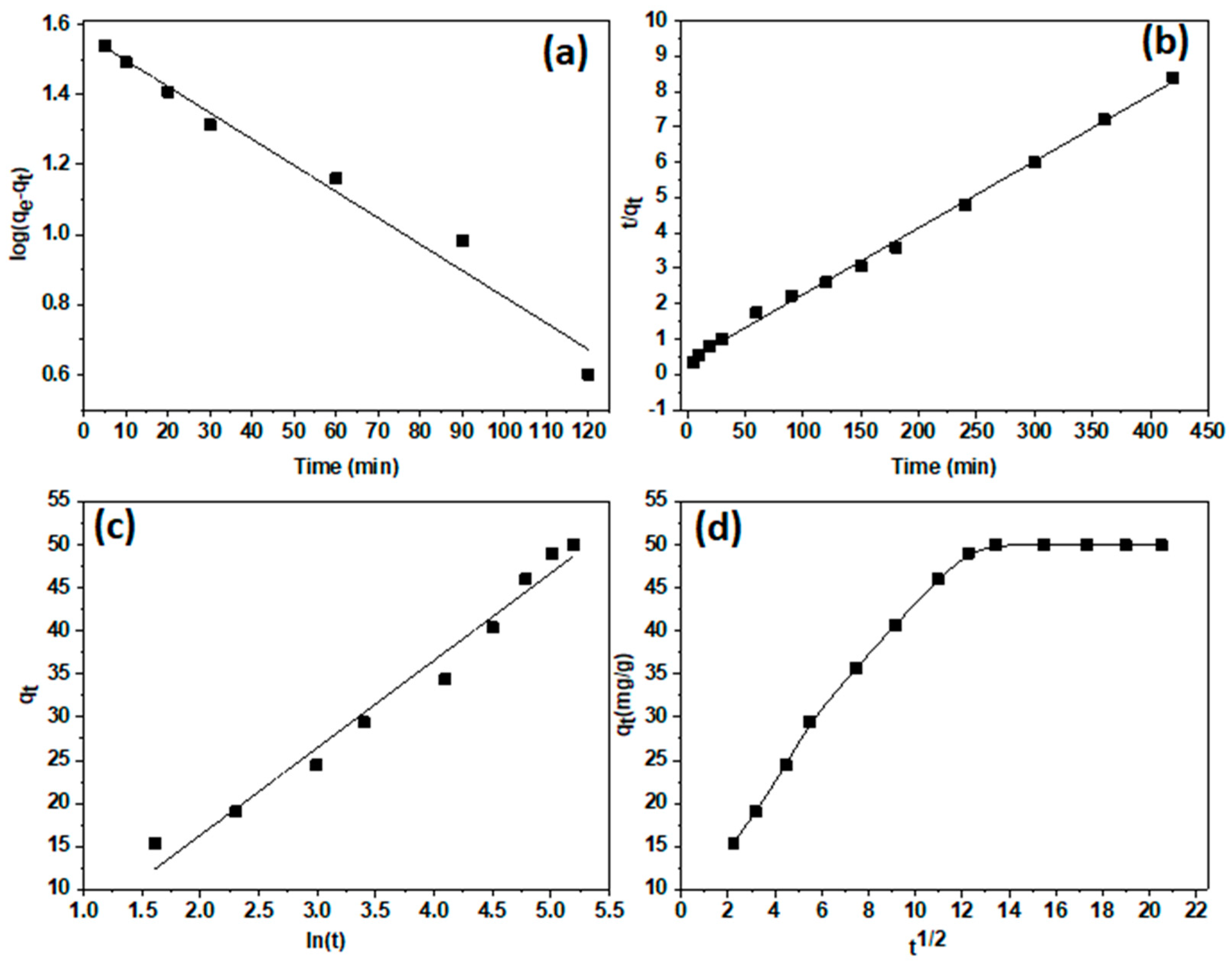

3.1.2. Kinetics Assessment

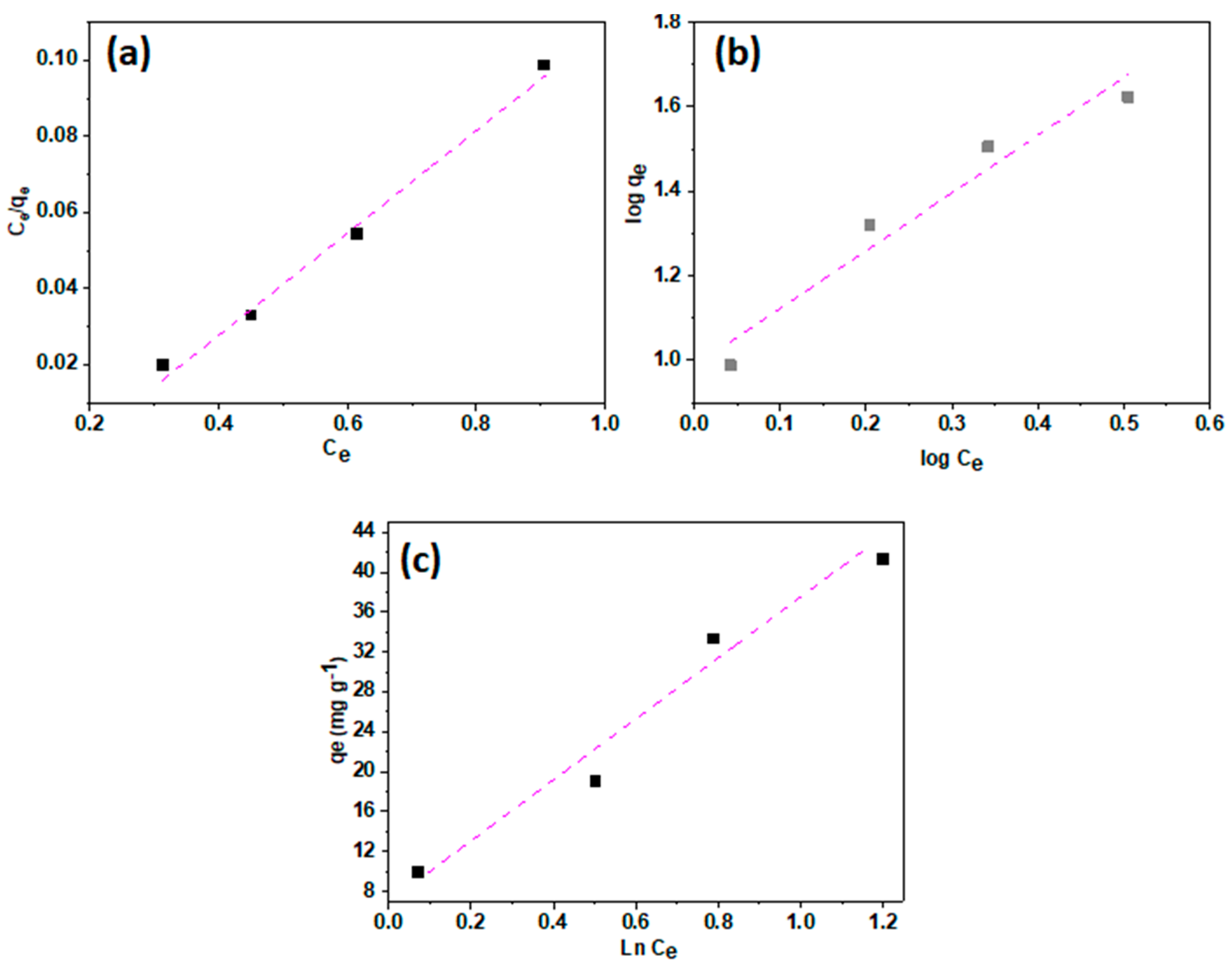

3.1.3. Adsorption Isotherms

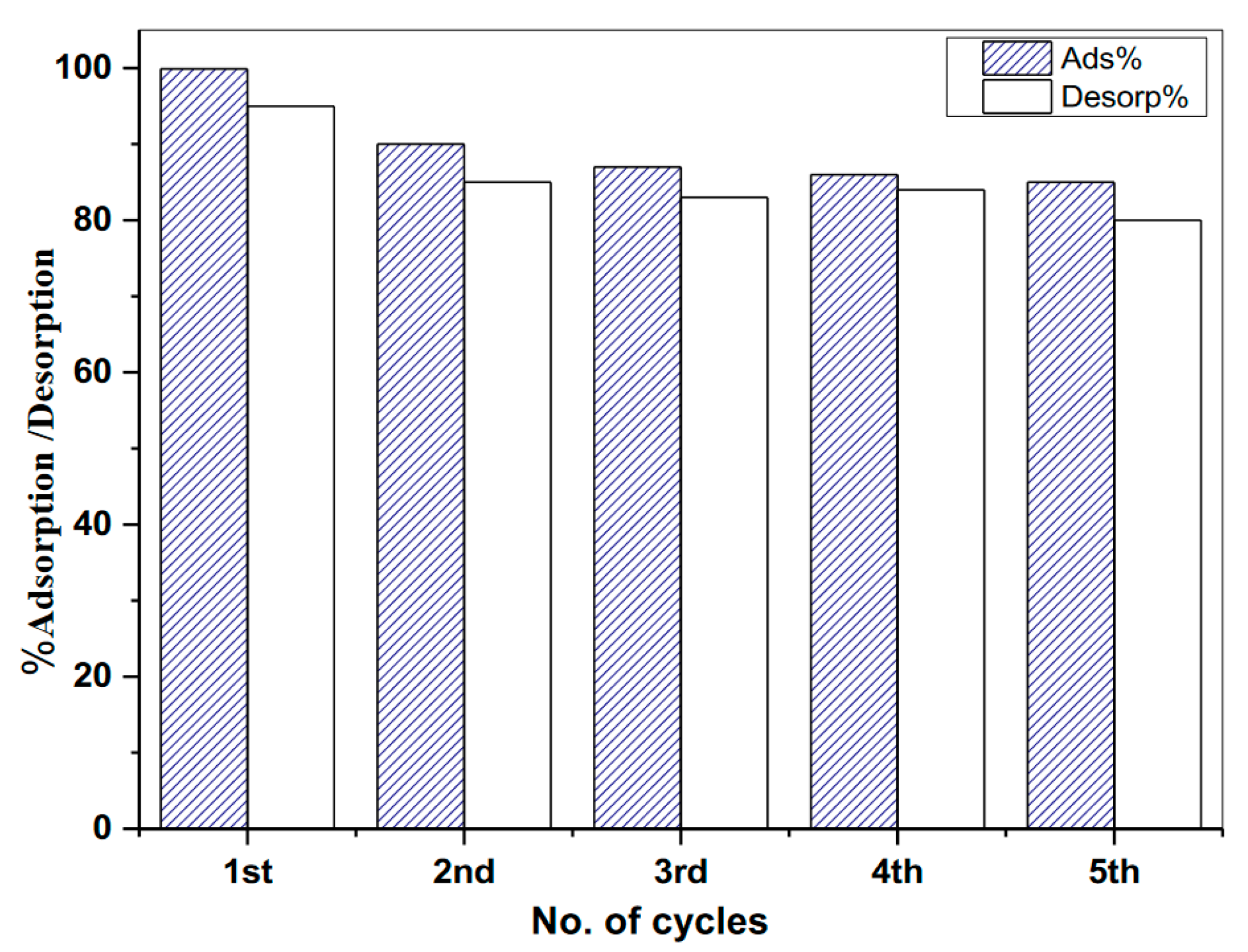

3.2. Reusability Assessment MMT/CS/AC Composite

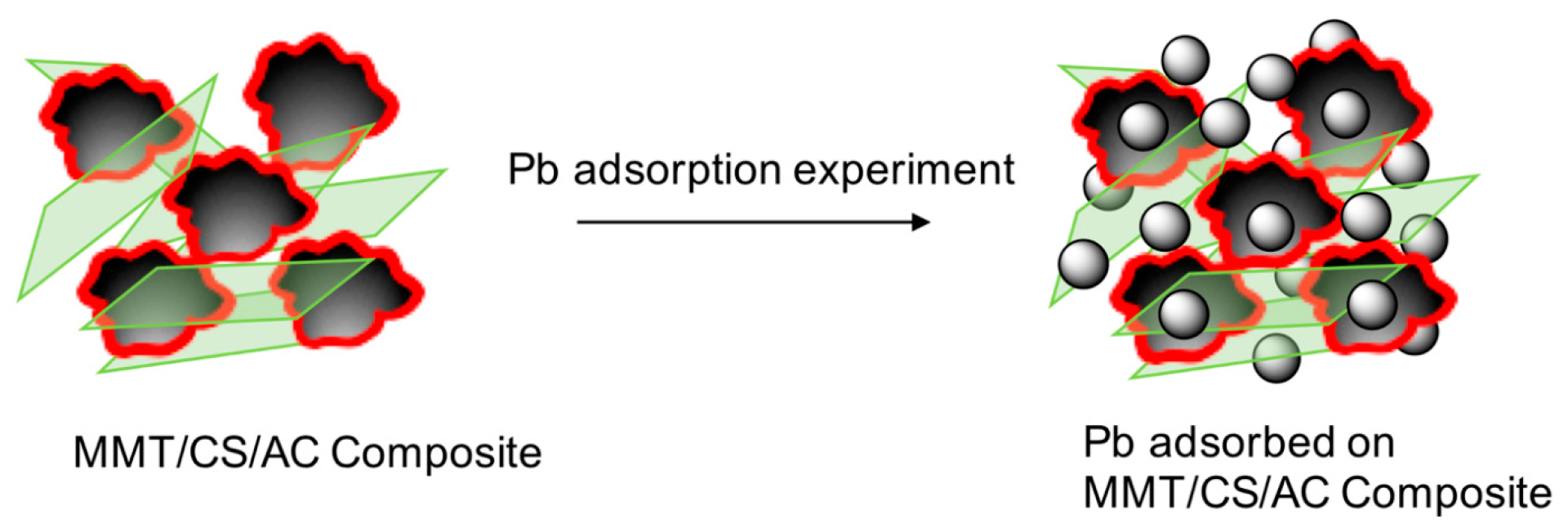

3.3. Adsorption Mechanism

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, W.; Wen, C.; Zheng, D.; Li, C.; Bian, J.; Wang, X. Simultaneous degradation of RhB and reduction of Cr (VI) by MIL-53 (Fe)/Polyaniline (PANI) with the mediation of organic acid. Chin. J. Chem. Eng. 2022, 42, 55–63. [Google Scholar] [CrossRef]

- Guo, H.; Li, H.; Jing, C.; Wang, X. Soluble polymers with intrinsic porosity for efficient removal of phenolic compounds from water. Microporous Mesoporous Mater. 2021, 319, 111068. [Google Scholar] [CrossRef]

- Uddin, M.K. A review on the adsorption of heavy metals by clay minerals, with special focus on the past decade. Chem. Eng. J. 2017, 308, 438–462. [Google Scholar] [CrossRef]

- Tsai, T.-Y.; Wen, C.-K.; Chuang, H.-J.; Lin, M.-J.; Ray, U. Effect of clay with different cation exchange capacity on the morphology and properties of poly(methyl methacrylate)/clay nanocomposites. Polym. Compos. 2009, 30, 1552–1561. [Google Scholar] [CrossRef]

- Bakandritsos, A.; Steriotis, T.; Petridis, D. High Surface Area Montmorillonite−Carbon Composites and Derived Carbons. Chem. Mater. 2004, 16, 1551–1559. [Google Scholar] [CrossRef]

- Sengwa, R.J.; Choudhary, S. Structural characterization of hydrophilic polymer blends/montmorillonite clay nanocomposites. J. Appl. Polym. Sci. 2014, 131, 40617. [Google Scholar] [CrossRef]

- Shi, J.; Yang, Z.; Dai, H.; Lu, X.; Peng, L.; Tan, X.; Shi, L.; Fahim, R. Preparation and application of modified zeolites as adsorbents in wastewater treatment. Water Sci. Technol. 2018, 2017, 621–635. [Google Scholar] [CrossRef]

- Setshedi, K.Z.; Bhaumik, M.; Songwane, S.; Onyango, M.S.; Maity, A. Exfoliated polypyrrole-organically modified montmorillonite clay nanocomposite as a potential adsorbent for Cr(VI) removal. Chem. Eng. J. 2013, 222, 186–197. [Google Scholar] [CrossRef]

- Lin, S.-H.; Juang, R.-S. Heavy metal removal from water by sorption using surfactant-modified montmorillonite. J. Hazard. Mater. 2002, 92, 315–326. [Google Scholar] [CrossRef]

- Akpomie, K.G.; Dawodu, F.A. Acid-modified montmorillonite for sorption of heavy metals from automobile effluent. Beni-Suef Univ. J. Basic Appl. Sci. 2016, 5, 1–12. [Google Scholar] [CrossRef][Green Version]

- Mercier, L.; Detellier, C. Preparation, Characterization, and Applications as Heavy Metals Sorbents of Covalently Grafted Thiol Functionalities on the Interlamellar Surface of Montmorillonite. Environ. Sci. Technol. 1995, 29, 1318–1323. [Google Scholar] [CrossRef] [PubMed]

- Kumrić, K.; Đukić, A.B.; Trtic-Petrovic, T.; Vukelić, N.S.; Stojanović, Z.S.; Novakovic, J.G.; Matovic, L. Simultaneous Removal of Divalent Heavy Metals from Aqueous Solutions Using Raw and Mechanochemically Treated Interstratified Montmorillonite/Kaolinite Clay. Ind. Eng. Chem. Res. 2013, 52, 7930–7939. [Google Scholar] [CrossRef]

- Zhang, C.; Luan, J.; Chen, W.; Ke, X.; Zhang, H. Preparation of graphene oxide–montmorillonite nanocomposite and its application in multiple-pollutants removal from aqueous solutions. Water Sci. Technol. 2019, 79, 323–333. [Google Scholar] [CrossRef]

- Marsh, H.; Rodríguez-Reinoso, F. CHAPTER 4-Characterization of Activated Carbon. In Activated Carbon; Marsh, H., Rodríguez-Reinoso, F., Eds.; Elsevier Science Ltd.: Oxford, UK, 2006; pp. 143–242. [Google Scholar]

- Ghaedi, M.; Nasab, A.G.; Khodadoust, S.; Rajabi, M.; Azizian, S. Application of activated carbon as adsorbents for efficient removal of methylene blue: Kinetics and equilibrium study. J. Ind. Eng. Chem. 2014, 20, 2317–2324. [Google Scholar] [CrossRef]

- Bhatnagar, A.; Hogland, W.; Marques, M.; Sillanpää, M. An overview of the modification methods of activated carbon for its water treatment applications. Chem. Eng. J. 2013, 219, 499–511. [Google Scholar] [CrossRef]

- Balcerek, M.; Pielech-Przybylska, K.; Patelski, P.; Dziekońska-Kubczak, U.; Jusel, T. Treatment with activated carbon and other adsorbents as an effective method for the removal of volatile compounds in agricultural distillates. Food Addit. Contam. Part A 2017, 34, 714–727. [Google Scholar] [CrossRef]

- Altmann, J.; Rehfeld, D.; Träder, K.; Sperlich, A.; Jekel, M. Combination of granular activated carbon adsorption and deep-bed filtration as a single advanced wastewater treatment step for organic micropollutant and phosphorus removal. Water Res. 2016, 92, 131–139. [Google Scholar] [CrossRef]

- Slyusarenko, N.V.; Vasilyeva, N.Y.; Kazachenko, A.S.; Gerasimova, M.A.; Romanchenko, A.S.; Slyusareva, E.A. Synthesis and properties of interpolymer complexes based on chitosan and sulfated arabinogalactan. Polym. Sci. Ser. B 2020, 62, 272–278. [Google Scholar] [CrossRef]

- Dadou, S.M.; El-Barghouthi, M.I.; Alabdallah, S.K.; Badwan, A.A.; Antonijevic, M.D.; Chowdhry, B.Z. Effect of Protonation State and N-Acetylation of Chitosan on Its Interaction with Xanthan Gum: A Molecular Dynamics Simulation Study. Mar. Drugs 2017, 15, 298. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Ahmad, M.; Manzoor, K.; Ikram, S. Versatile nature of hetero-chitosan based derivatives as biodegradable adsorbent for heavy metal ions; a review. Int. J. Biol. Macromol. 2017, 105, 190–203. [Google Scholar] [CrossRef] [PubMed]

- Aldawsari, A.; Khan, M.A.; Hameed, B.H.; Alqadami, A.A.; Siddiqui, M.R.; Alothman, Z.; Ahmed, A.Y.B.H. Mercerized mesoporous date pit activated carbon—A novel adsorbent to sequester potentially toxic divalent heavy metals from water. PLoS ONE 2017, 12, e0184493. [Google Scholar] [CrossRef][Green Version]

- Wang, Q.Z.; Chen, X.G.; Liu, N.; Wang, S.X.; Liu, C.S.; Meng, X.H.; Liu, C.G. Protonation constants of chitosan with different molecular weight and degree of deacetylation. Carbohydr. Polym. 2006, 65, 194–201. [Google Scholar] [CrossRef]

- Chaudhary, D.; Liu, H. Ultrasonic treatment and synthesis of sugar alcohol modified Na+-montmorillonite clay. Ultrason. Sonochemistry 2013, 20, 63–68. [Google Scholar] [CrossRef] [PubMed]

- Jokar, A.; Azizi, M.H.; Esfehani, Z.H.; Abbasi, S. Effects of ultrasound time on the properties of methylcellulose-montmorillonite films. Int. Nano Lett. 2017, 7, 59–68. [Google Scholar] [CrossRef][Green Version]

- Zhu, T.T.; Zhou, C.H.; Kabwe, F.B.; Wu, Q.Q.; Li, C.S.; Zhang, J.R. Exfoliation of montmorillonite and related properties of clay/polymer nanocomposites. Appl. Clay Sci. 2019, 169, 48–66. [Google Scholar] [CrossRef]

- Lazzarini, A.; Piovano, A.; Pellegrini, R.; Agostini, G.; Rudic, S.; Lamberti, C.; Groppo, E. Graphitization of Activated Carbons: A Molecular-level Investigation by INS, DRIFT, XRD and Raman Techniques. Phys. Procedia 2016, 85, 20–26. [Google Scholar] [CrossRef]

- Girgis, B.S.; Temerk, Y.M.; Gadelrab, M.M.; Abdullah, I.D. X-ray Diffraction Patterns of Activated Carbons Prepared under Various Conditions. Carbon Lett. 2007, 8, 95–100. [Google Scholar] [CrossRef][Green Version]

- Kennedy, L.J.; Vijaya, J.J.; Kayalvizhi, K.; Sekaran, G. Adsorption of phenol from aqueous solutions using mesoporous carbon prepared by two-stage process. Chem. Eng. J. 2007, 132, 279–287. [Google Scholar] [CrossRef]

- Yakout, S.M.; Sharaf El-Deen, G. Characterization of activated carbon prepared by phosphoric acid activation of olive stones. Arab. J. Chem. 2016, 9, S1155–S1162. [Google Scholar] [CrossRef][Green Version]

- Danish, M.; Ahmad, T.; Nadhari, W.N.A.W.; Ahmad, M.; Khanday, W.A.; Ziyang, L.; Pin, Z. Optimization of banana trunk-activated carbon production for methylene blue-contaminated water treatment. Appl. Water Sci. 2018, 8, 9. [Google Scholar] [CrossRef][Green Version]

- Hossain, K.F.B.; Sikder, M.T.; Rahman, M.M.; Uddin, M.K.; Kurasaki, M. Investigation of Chromium Removal Efficacy from Tannery Effluent by Synthesized Chitosan from Crab Shell. Arab. J. Sci. Eng. 2017, 42, 1569–1577. [Google Scholar] [CrossRef]

- Dimzon, I.K.D.; Knepper, T.P. Degree of deacetylation of chitosan by infrared spectroscopy and partial least squares. Int. J. Biol. Macromol. 2015, 72, 939–945. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Pitto-Barry, A.; Habtemariam, A.; Romero-Canelon, I.; Sadler, P.J.; Barry, N.P.E. Nanoparticles of chitosan conjugated to organo-ruthenium complexes. Inorg. Chem. Front. 2016, 3, 1058–1064. [Google Scholar] [CrossRef][Green Version]

- Kumirska, J.; Czerwicka, M.; Kaczyński, Z.; Bychowska, A.; Brzozowski, K.; Thöming, J.; Stepnowski, P. Application of spectroscopic methods for structural analysis of chitin and chitosan. Mar. Drugs 2010, 8, 1567–1636. [Google Scholar] [CrossRef][Green Version]

- Zhang, X.; Yi, H.; Bai, H.; Zhao, Y.; Min, F.; Song, S. Correlation of montmorillonite exfoliation with interlayer cations in the preparation of two-dimensional nanosheets. RSC Adv. 2017, 7, 41471–41478. [Google Scholar] [CrossRef][Green Version]

- Calabria-Holley, J.; Papatzani, S.; Naden, B.; Mitchels, J.; Paine, K. Tailored montmorillonite nanoparticles and their behaviour in the alkaline cement environment. Appl. Clay Sci. 2017, 143, 67–75. [Google Scholar] [CrossRef]

- Ismail, N.I.N.; Ansarifar, A.; Song, M. Preparation and characterization of high performance exfoliated montmorillonite/silicone rubber nanocomposites with enhanced mechanical properties. Polym. Eng. Sci. 2013, 53, 2603–2614. [Google Scholar] [CrossRef][Green Version]

- Ho, Y.S.; McKay, G. Sorption of dye from aqueous solution by peat. Chem. Eng. J. 1998, 70, 115–124. [Google Scholar] [CrossRef]

- Alhumaimess, M.S. Sulfhydryl functionalized activated carbon for Pb(II) ions removal: Kinetics, isotherms, and mechanism. Sep. Sci. Technol. 2019, 55, 1303–1316. [Google Scholar] [CrossRef]

- Li, Y.; Sun, J.; Du, Q.; Zhang, L.; Yang, X.; Wu, S.; Xia, Y.; Wang, Z.; Xia, L.; Cao, A. Mechanical and dye adsorption properties of graphene oxide/chitosan composite fibers prepared by wet spinning. Carbohydr. Polym. 2014, 102, 755–761. [Google Scholar] [CrossRef]

- Sisombath, N.S.; Jalilehvand, F.; Schell, A.C.; Wu, Q. Lead(II) Binding to the Chelating Agent d-Penicillamine in Aqueous Solution. Inorg. Chem. 2014, 53, 12459–12468. [Google Scholar] [CrossRef]

- Lu, X.; Jiang, J.; Sun, K.; Zhu, G.; Lin, G. Colloids Surfaces A Physicochem. Eng. Asp. 2016, 506, 637–645. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, R.; Gu, X.; Lu, J. Adsorption of Divalent Heavy Metal Ions from Aqueous Solution by Citric Acid Modified Pine Sawdust. Sep. Sci. Technol. 2015, 50, 245–252. [Google Scholar] [CrossRef]

- Seremeta, D.C.H.; da Silva, C.P.; Zitte, R.; de Campos, S.X. Pb2+ adsorption by a compost obtained from the treatment of tobacco from smuggled cigarettes and industrial sewage sludge. Environ. Sci. Pollut. Res. 2019, 26, 797–805. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Cao, B.; Zhao, L.; Sun, L.; Gao, Y.; Li, J.; Yang, F. Biochar-supported reduced graphene oxide composite for adsorption and coadsorption of atrazine and lead ions. Appl. Surf. Sci. 2018, 427, 147–155. [Google Scholar] [CrossRef]

- Montazer-Rahmati, M.M.; Rabbani, P.; Abdolali, A.; Keshtkar, A.R. Kinetics and equilibrium studies on biosorption of cadmium, lead, and nickel ions from aqueous solutions by intact and chemically modified brown algae. J. Hazard. Mater. 2011, 185, 401–407. [Google Scholar] [CrossRef] [PubMed]

- Velazquez-Jimenez, L.H.; Pavlick, A.; Rangel-Mendez, J.R. Chemical Characterization of raw and treated agave bagasse and its potential as adsorbent of metal cations from water. Ind. Crops Prod. 2013, 43, 200–206. [Google Scholar] [CrossRef]

- Putra, W.P.; Kamari, A.; Mohd Yusoff, S.N.; Ishak, C.F.; Mohamed, A.; Hashim, N.; Isa, I.M. Biosorption of Cu(II), Pb(II) and Zn(II) ions from aqueous solutions using selected waste materials: Adsorption and characterization studies. J. Encapsul. Adsorpt. Sci. 2014, 4, 25–35. [Google Scholar]

- Boujelben, N.; Bouzid, J.; Elouear, Z. Removal of lead (II) ions from aqueous solutions using manganese oxide-coated adsorbents: Characterization and kinetic study. Adsorpt. Sci. Technol. 2009, 27, 177–191. [Google Scholar] [CrossRef]

- Ji, L.; Zhou, L.; Bai, X.; Shao, Y.; Zhao, G.; Qu, Y.; Li, Y. Facile synthesis of multiwall carbon nanotubes/iron oxides for removal of tetrabromobisphenol A and Pb (II). J. Mater. Chem. 2012, 22, 15853–15862. [Google Scholar] [CrossRef]

| Parameters | Adsorbent |

|---|---|

| MMT/CS/AC Composite | |

| Pseudo first-order | |

| r2 | 0.97289 |

| k1 (min−1) | 0.01727 |

| Qe (mg g−1) | 48.2 |

| Experimental qe(mg g−1) | 50 |

| Pseudo second-order | |

| r2 | 0.9994 |

| k2 (g mg−1 min−1) | 1.056 × 10−3 |

| Qe (mg g−1) | 49.9 |

| Experimental qe (mg g−1) | 50 |

| Elovich model | |

| r2 | 0.9706 |

| α | 6.437 × 10−3 |

| β | 9.8 × 10−4 |

| Intraparticle diffusion | |

| r2 | 0.8182 |

| Kint (mg g−1 min−1/2) | 1.943 |

| Ci (ppm) | 18.153 |

| qm,exp. (mg/g) | Langmuir Isotherm | Freundlich Isotherm | Temkin Isotherm | ||||||

|---|---|---|---|---|---|---|---|---|---|

| qm,cal. (mg/g) | KL (L/mg) | r2 | KF (mg/g) (L/mg)1/n | n | r2 | bT (J/mol K) | AT (L/g) | r2 | |

| 50 | 46.3 | 0.041 | 0.997 | 9.71 | 0.733 | 0.924 | 99.7 | 47.1 | 0.911 |

| Adsorbent | Experimental Conditions | Equilibrium Time (min) | qm (mg/g) | Ref. |

|---|---|---|---|---|

| A commercial activated carbon adsorbent (CGAC) | Co: 50–500 mg/L; pH: 7; T: 298 K; m: 2 g | 180 | 20.3 | [43] |

| Citric acid modified pine sawdust (CA-PS) | Co: 5–220 mg/L; pH: 5; T: 298 K; m: 0.2 g | 120 | 16.19 | [44] |

| Pb2+ adsorption by a compost | Co: 2–50 mg/L; pH: 5; T: 298 K; 3.0 g/L adsorbent | 1440 | 21.45 | [45] |

| Biochar-supported graphene oxide composite for removal of lead ion | pH: 5; T: 298 K | 900 | 26.1 | [46] |

| Algal biomass Sargassum glaucescens | Co: 0–100 mg/L, 2.0 g/L adsorbent | 120 | 45.8 | [47] |

| Raw agave bagasse | Co: 0–100 mg/L, 1.0–2.0 g/L adsorbent | - | 35.6 | [48] |

| Coconut tree sawdust | Co: 10–200 mg/L, 4.0 g/L adsorbent | 90 | 25 | [49] |

| Manganese oxide coated crushed brick | Co: 0–35 mg/L; pH: 5; T: 293 K; 20.0 g/L adsorbent | 250 | 6.42 | [50] |

| MWCNTs/Fe3O4 | Co: 5–40 mg/L; pH: 5.3; T: 298 K; 0.5 g/L adsorbent | - | 13.04 | [51] |

| MMT/CS/AC | Co: 5–20 mg/L; pH: 5.5; T: 298 K | 150 | 50 | This study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alsohaimi, I.H.; Alhumaimess, M.S.; Hassan, H.M.A.; Reda, M.; Aldawsari, A.M.; Chen, Q.; Kariri, M.A. Chitosan Polymer Functionalized-Activated Carbon/Montmorillonite Composite for the Potential Removal of Lead Ions from Wastewater. Polymers 2023, 15, 2188. https://doi.org/10.3390/polym15092188

Alsohaimi IH, Alhumaimess MS, Hassan HMA, Reda M, Aldawsari AM, Chen Q, Kariri MA. Chitosan Polymer Functionalized-Activated Carbon/Montmorillonite Composite for the Potential Removal of Lead Ions from Wastewater. Polymers. 2023; 15(9):2188. https://doi.org/10.3390/polym15092188

Chicago/Turabian StyleAlsohaimi, Ibrahim Hotan, Mosaed S. Alhumaimess, Hassan M. A. Hassan, Mohamed Reda, Abdullah M. Aldawsari, Qiao Chen, and Mohammed Abdo Kariri. 2023. "Chitosan Polymer Functionalized-Activated Carbon/Montmorillonite Composite for the Potential Removal of Lead Ions from Wastewater" Polymers 15, no. 9: 2188. https://doi.org/10.3390/polym15092188

APA StyleAlsohaimi, I. H., Alhumaimess, M. S., Hassan, H. M. A., Reda, M., Aldawsari, A. M., Chen, Q., & Kariri, M. A. (2023). Chitosan Polymer Functionalized-Activated Carbon/Montmorillonite Composite for the Potential Removal of Lead Ions from Wastewater. Polymers, 15(9), 2188. https://doi.org/10.3390/polym15092188