Rigid Polyurethane Biofoams Filled with Pine Seed Shell and Yerba Mate Wastes

Abstract

:1. Introduction

2. Materials and Methods

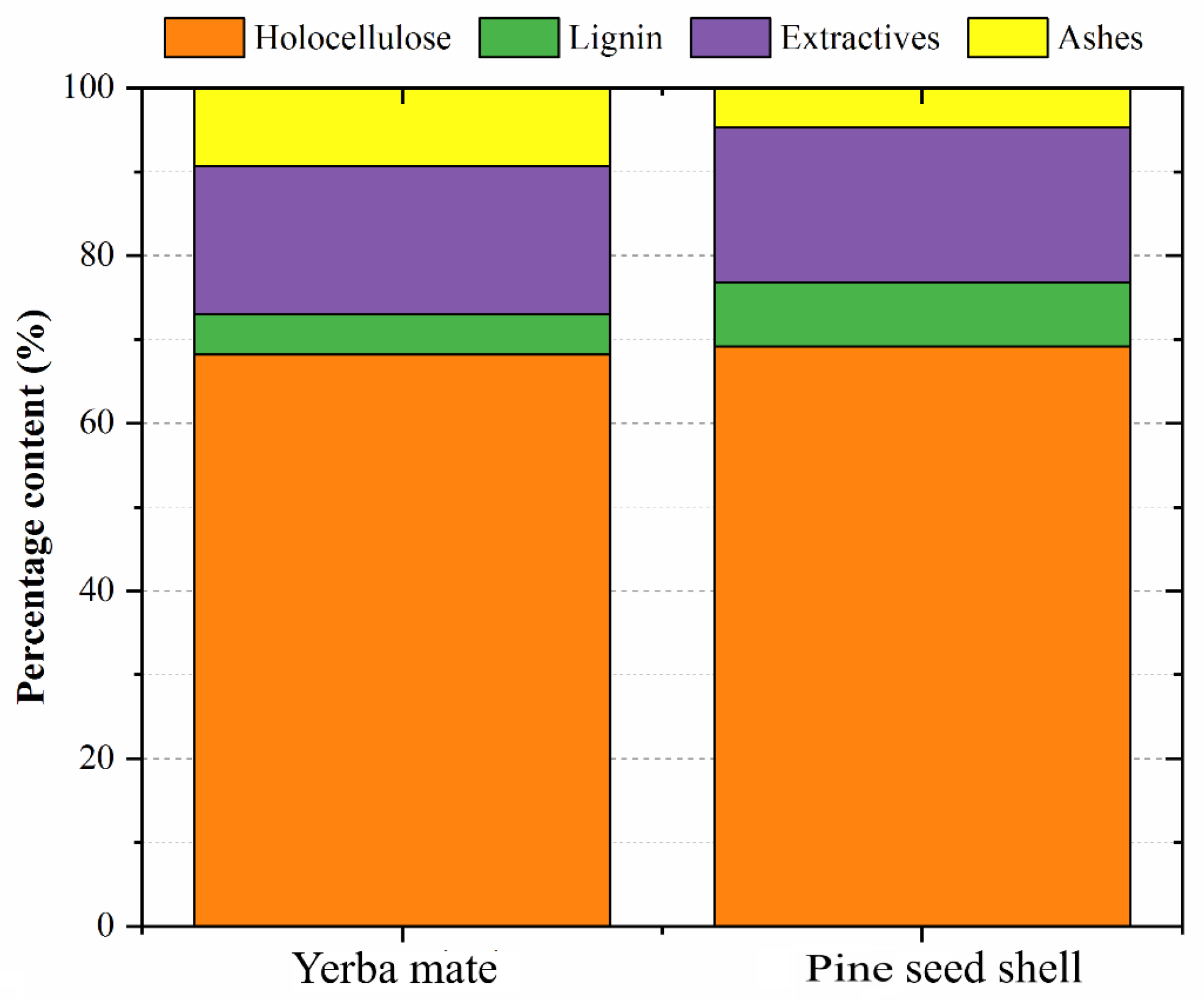

2.1. Acquisition and Characterization of Fillers

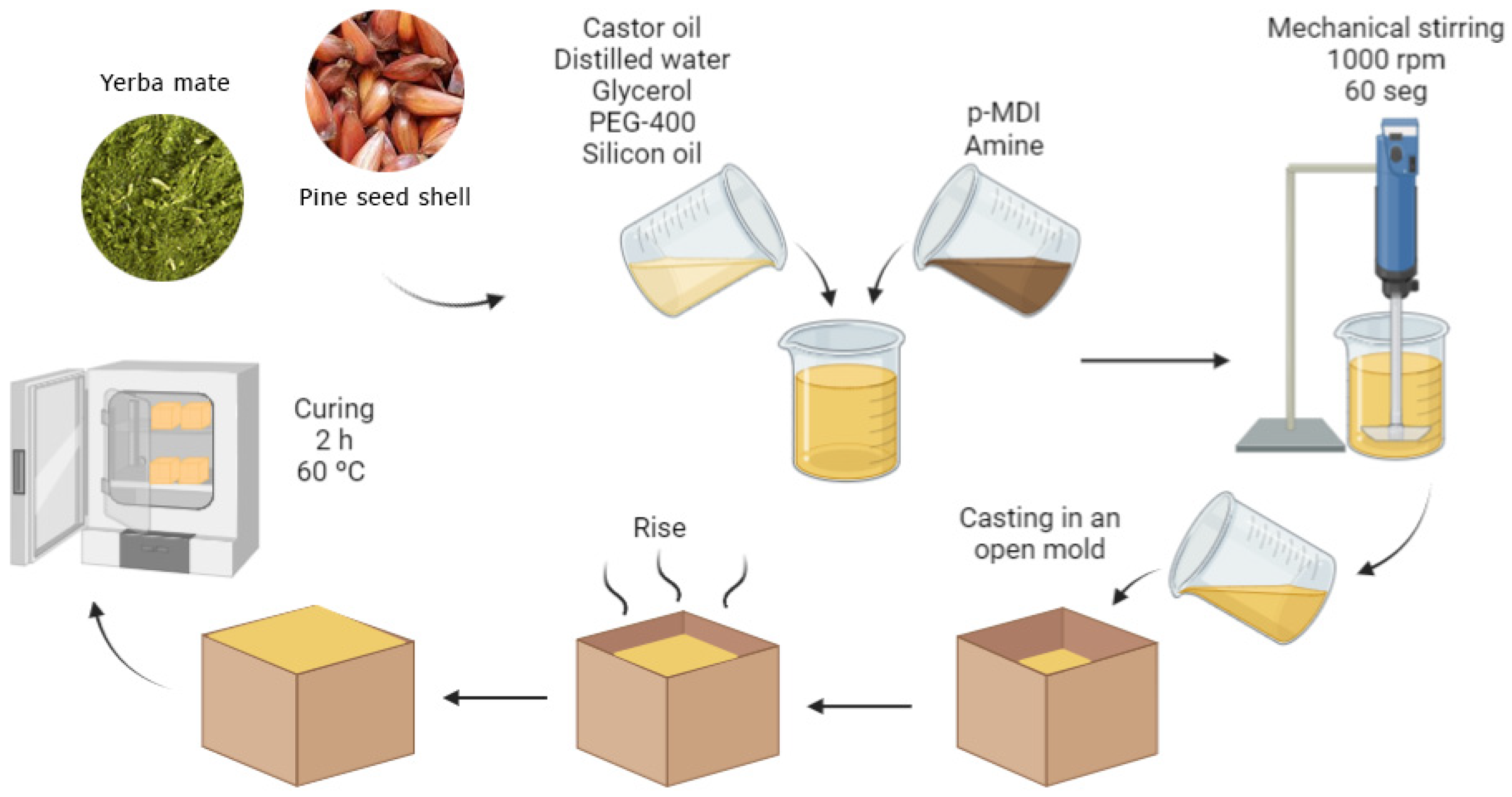

2.2. Rigid Polyurethane Foam Manufacturing

2.3. Morphology and Anisotropy Index

2.4. Chemical and Thermal Characterization

2.5. Apparent Density and Compressive Stress

2.6. Colorimetric Patterns of the RPUFs

2.7. Statistical Analyses

3. Results and Discussion

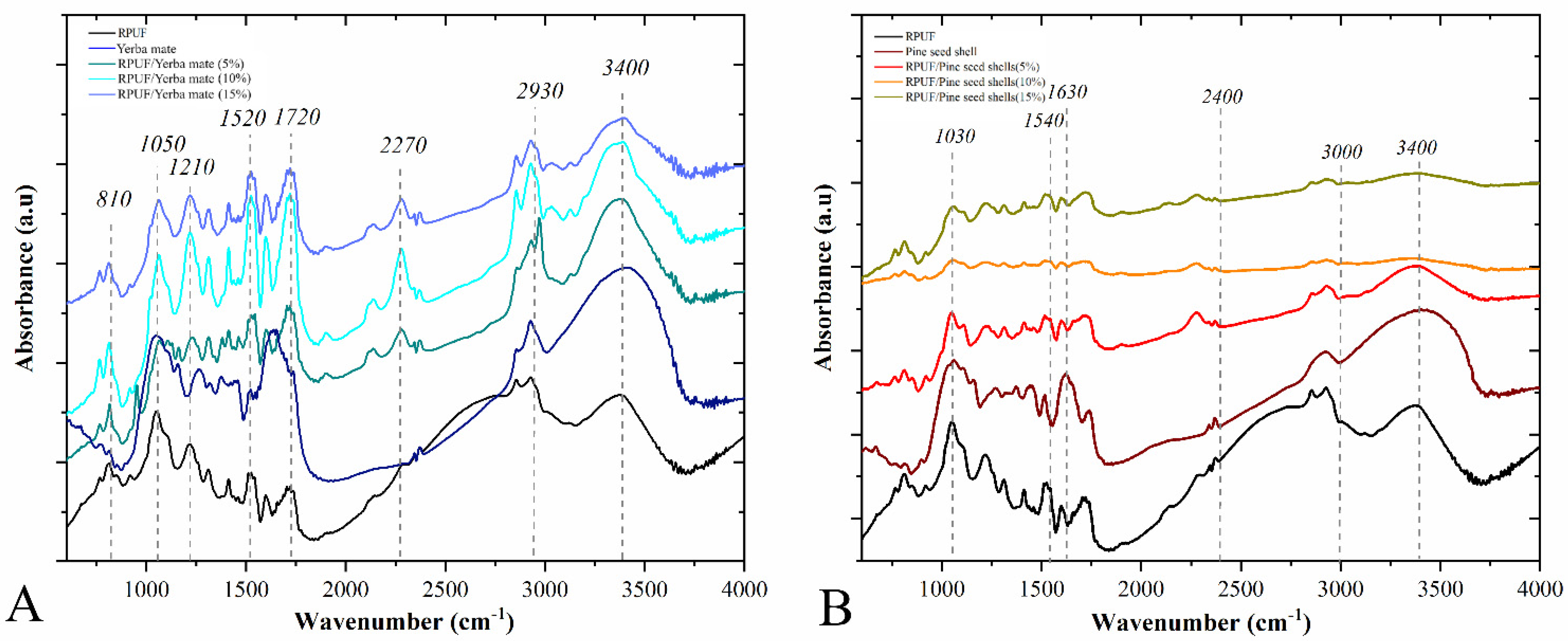

3.1. Chemical Properties

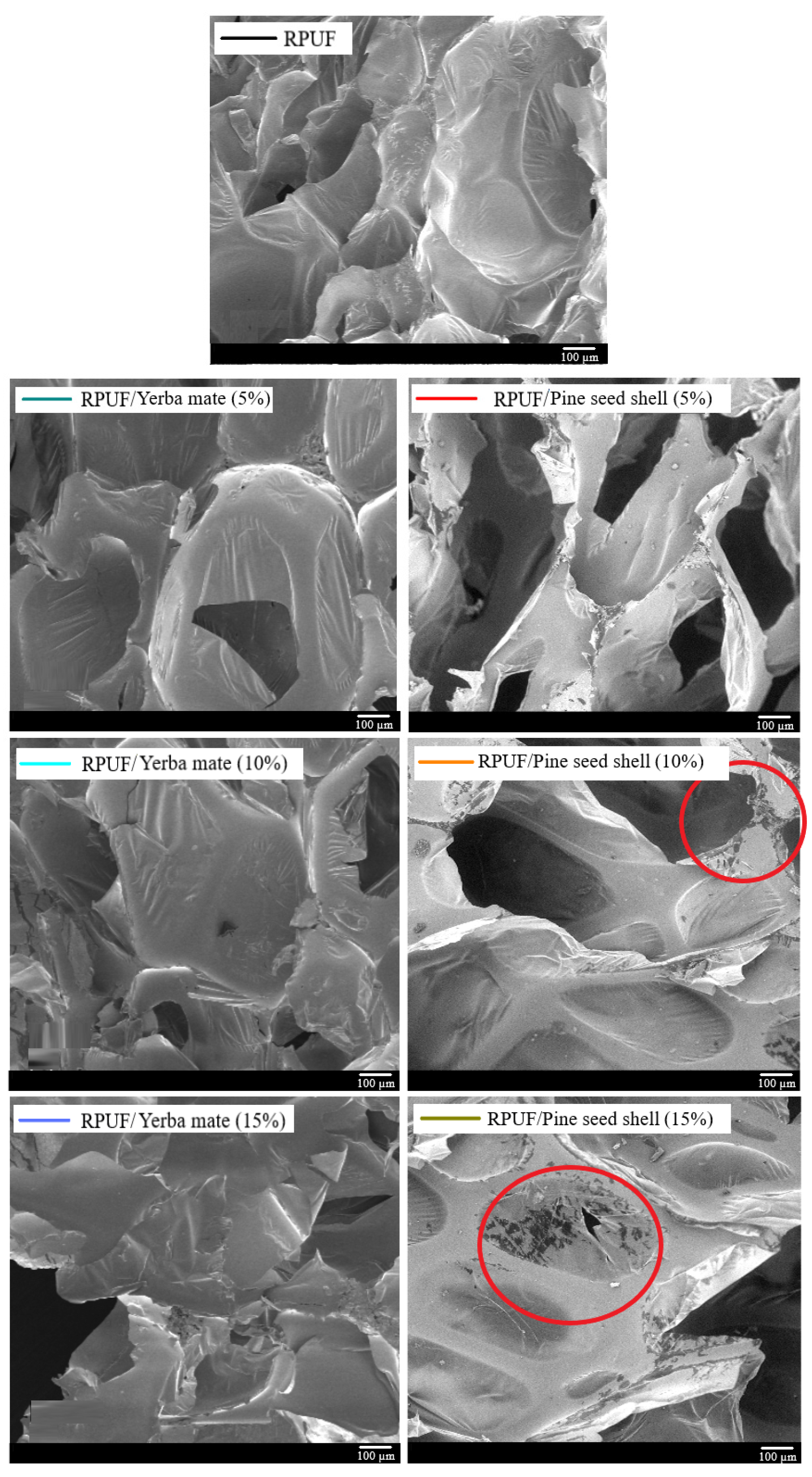

3.2. Morphology and Anisotropy Index

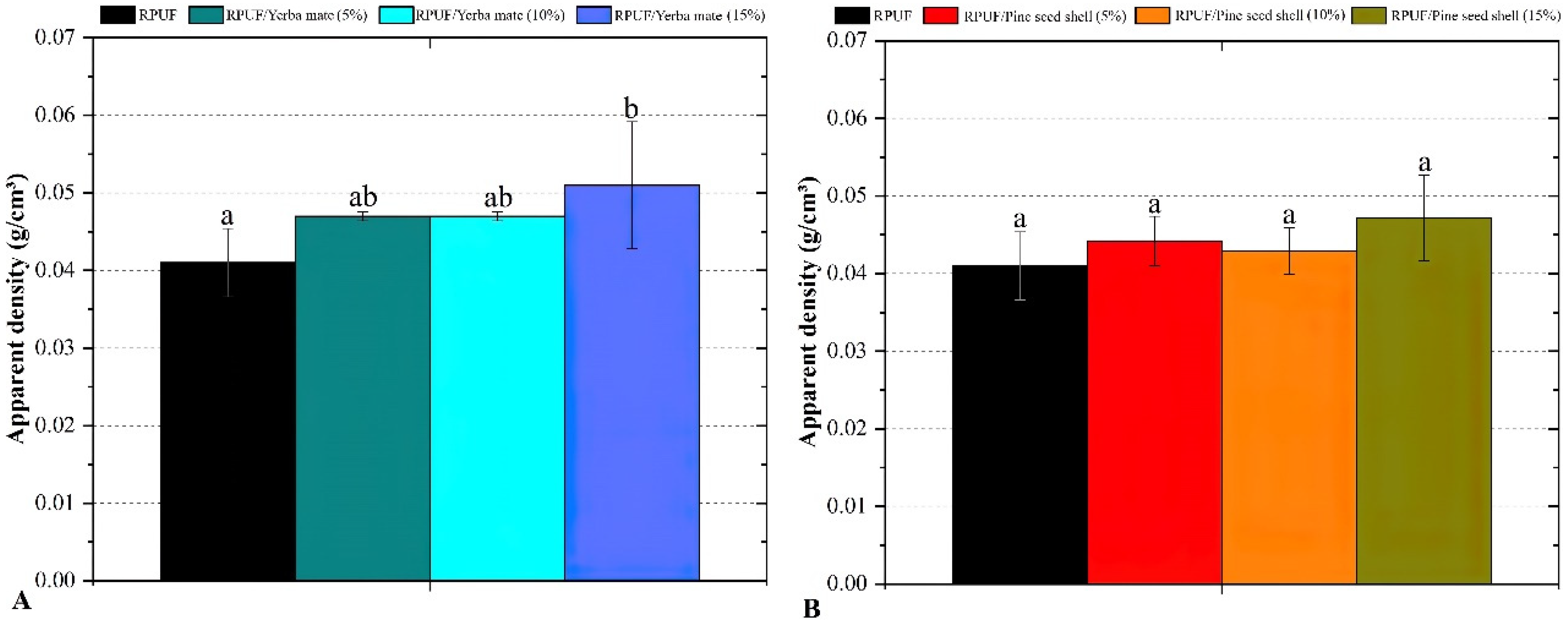

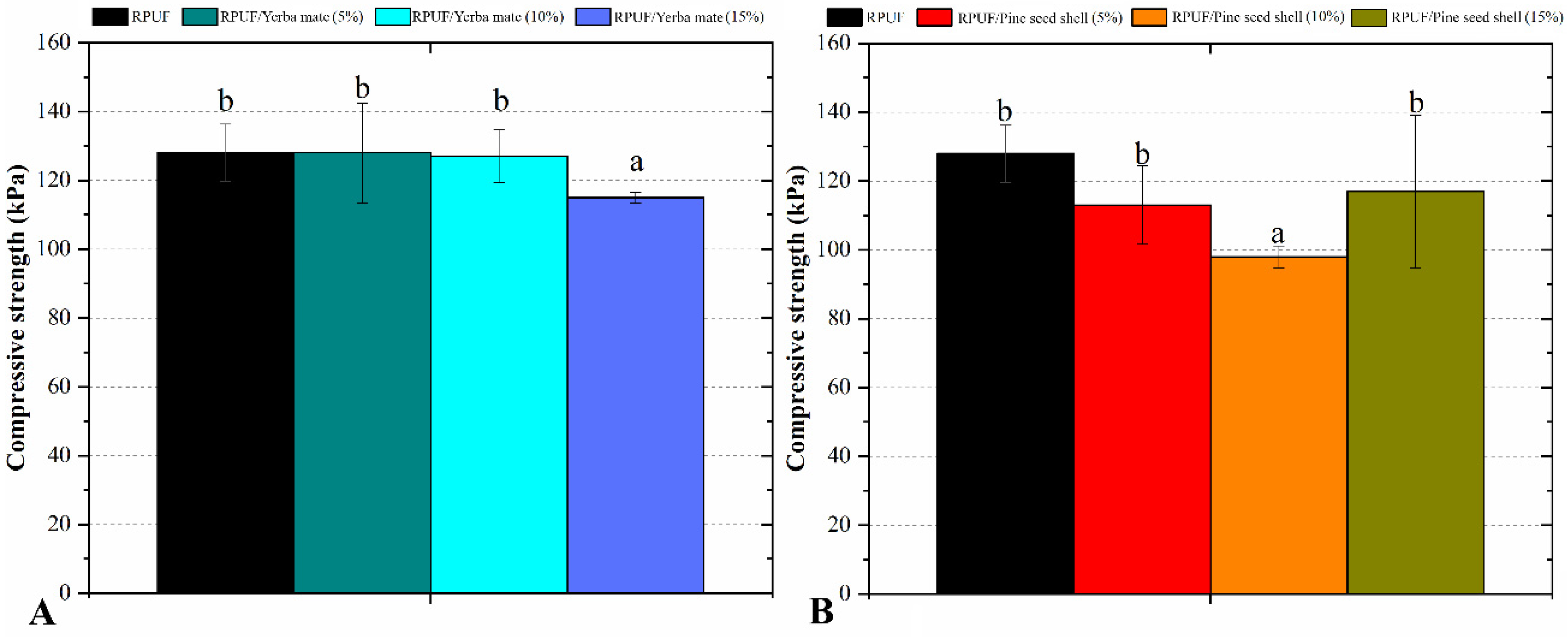

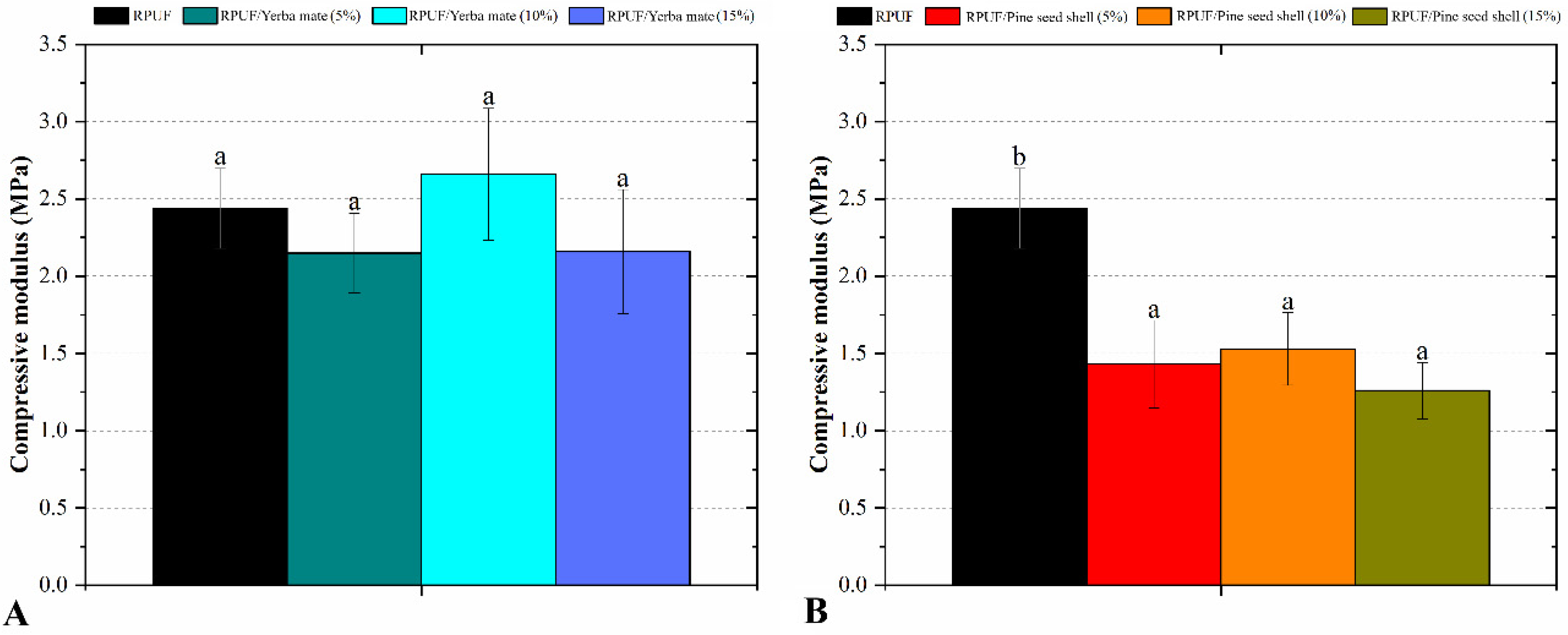

3.3. Apparent Density and Compressive Stress

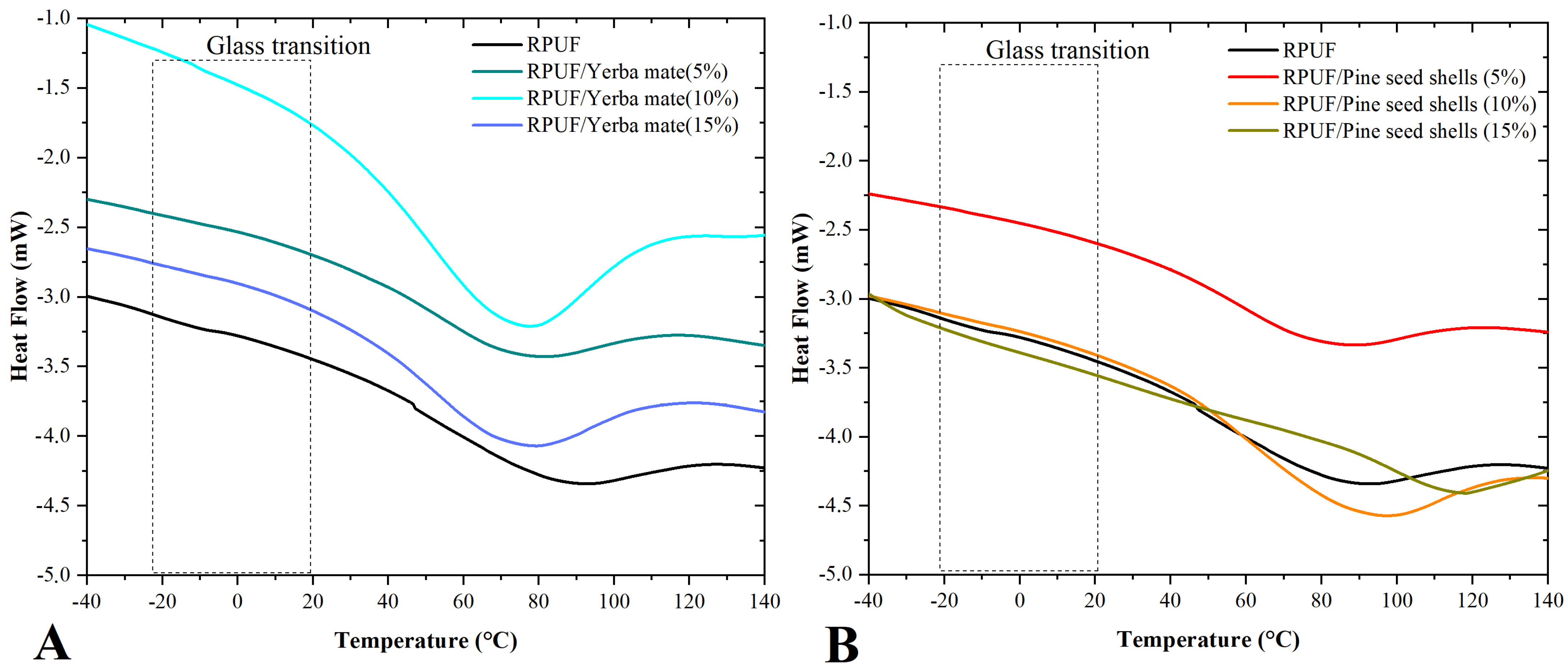

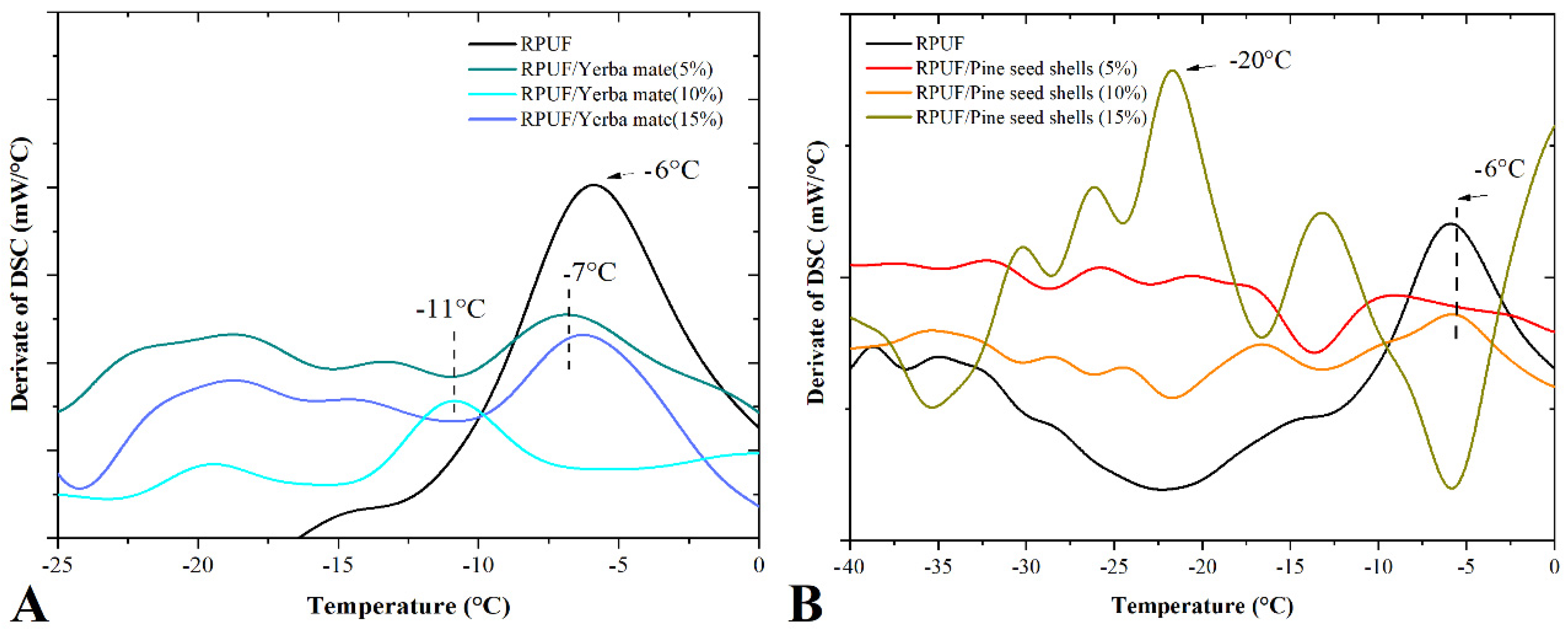

3.4. Thermal Characteristics

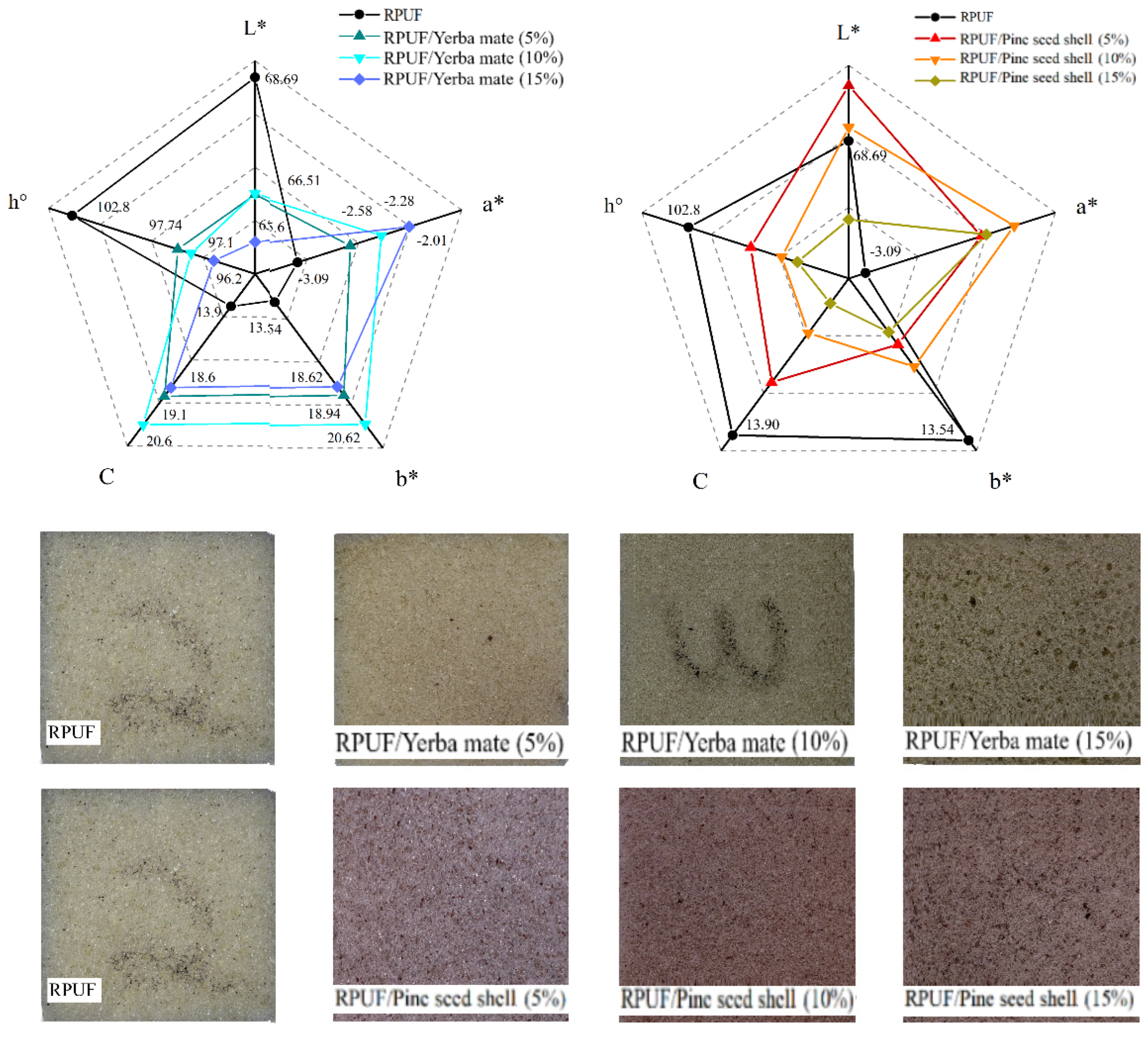

3.5. Colorimetric Patterns

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kausar, A. Polyurethane Composite Foams in High-Performance Applications: A Review. Polym.-Plast. Technol. Eng. 2018, 57, 346–369. [Google Scholar] [CrossRef]

- Das, A.; Mahanwar, P. A Brief Discussion on Advances in Polyurethane Applications. Adv. Ind. Eng. Polym. Res. 2020, 3, 93–101. [Google Scholar] [CrossRef]

- Akindoyo, J.O.; Beg, M.D.H.; Ghazali, S.; Islam, M.R.; Jeyaratnam, N.; Yuvaraj, A.R. Polyurethane Types, Synthesis and Applications-a Review. RSC Adv. 2016, 6, 114453–114482. [Google Scholar] [CrossRef]

- Mosiewicki, M.A.; Dell’Arciprete, G.A.; Aranguren, M.I.; Marcovich, N.E. Polyurethane Foams Obtained from Castor Oil-Based Polyol and Filled with Wood Flour. J. Compos. Mater. 2009, 43, 3057–3072. [Google Scholar] [CrossRef]

- Gu, R.; Sain, M.M. Effects of Wood Fiber and Microclay on the Performance of Soy Based Polyurethane Foams. J. Polym. Environ. 2013, 21, 30–38. [Google Scholar] [CrossRef]

- Septevani, A.A.; Evans, D.A.C.; Chaleat, C.; Martin, D.J.; Annamalai, P.K. A Systematic Study Substituting Polyether Polyol with Palm Kernel Oil Based Polyester Polyol in Rigid Polyurethane Foam. Ind. Crops Prod. 2015, 66, 16–26. [Google Scholar] [CrossRef]

- Ju, Z.; He, Q.; Zhan, T.; Zhang, H.; Sun, L.; Hong, L.; Shi, X.; Lu, X. Steam Exploded Peanut Shell Fiber as the Filler in the Rigid Polyurethane Foams. J. Renew. Mater. 2019, 7, 1077–1091. [Google Scholar] [CrossRef]

- Wahab, H.A.; Rus, A.Z.M.; Moen, A.T.; Ngadimon, K.N.; Noor, F.M. Optimization of Acoustical Properties Polyurethane (PU) Wood Fibres Foam Composites. IOP Conf. Ser. Mater. Sci. Eng. 2020, 824, 012016. [Google Scholar] [CrossRef]

- Ghasemi, S.; Amini, E.N.; Tajvidi, M.; Kiziltas, A.; Mielewski, D.F.; Gardner, D.J. Flexible Polyurethane Foams Reinforced with Organic and Inorganic Nanofillers. J. Appl. Polym. Sci. 2021, 138, 10–14. [Google Scholar] [CrossRef]

- Kılınç, K.; Kanbur, Y.; Tayfun, Ü. Mechanical, Thermo-Mechanical and Water Uptake Performance of Wood Flour Filled Polyurethane Elastomer Eco-Composites: Influence of Surface Treatment of Wood Flour. Holzforschung 2019, 73, 401–407. [Google Scholar] [CrossRef]

- Mirski, R.; Dukarska, D.; Walkiewicz, J.; Derkowski, A. Waste Wood Particles from Primary Wood Processing as a Filler of Insulation Pur Foams. Materials 2021, 14, 4781. [Google Scholar] [CrossRef]

- Li, H.; Yuan, Z.; Zhang, Y.; Chang, C. Synthesis of Biobased Polyurethane Foams from Agricultural and Forestry Wastes. In Reactive and Functional Polymers Volume One; Springer: Cham, Switzerland, 2020; pp. 137–156. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Kairytė, A. Effect of Walnut Shells and Silanized Walnut Shells on the Mechanical and Thermal Properties of Rigid Polyurethane Foams. Polym. Test. 2020, 87, 106534. [Google Scholar] [CrossRef]

- Olcay, H.; Kocak, E.D. The Mechanical, Thermal and Sound Absorption Properties of Flexible Polyurethane Foam Composites Reinforced with Artichoke Stem Waste Fibers. J. Ind. Text. 2022, 51, 8738S–8763S. [Google Scholar] [CrossRef]

- de Avila Delucis, R.; Magalhães, W.L.E.; Petzhold, C.L.; Amico, S.C. Forest-Based Resources as Fillers in Biobased Polyurethane Foams. J. Appl. Polym. Sci. 2018, 135, 45684. [Google Scholar] [CrossRef]

- Acosta, A.P.; Otoni, C.G.; Missio, A.L.; Amico, S.C.; Delucis, R. de A. Rigid Polyurethane Biofoams Filled with Chemically Compatible Fruit Peels. Polymers 2022, 14, 4526. [Google Scholar] [CrossRef]

- Nascimento, B.; Sá, A.C.S.; Bittencourt, L.; Trautmann, D.; Navroski, M.C.; Mantovani, A. Rooting Potential of Ilex Paraguariensis Cuttings of Two Populations of Southern Brazil in Two Rooting Environments. Floresta 2022, 52, 367–376. [Google Scholar] [CrossRef]

- Agüero, Á.; Corral Perianes, E.; Abarca de las Muelas, S.S.; Lascano, D.; de la Fuente García-Soto, M.D.M.; Peltzer, M.A.; Balart, R.; Arrieta, M.P. Plasticized Mechanical Recycled PLA Films Reinforced with Microbial Cellulose Particles Obtained from Kombucha Fermented in Yerba Mate Waste. Polymers 2023, 15, 285. [Google Scholar] [CrossRef] [PubMed]

- Mattos, B.D.; de Souza Brites Queiroz, L.M.R.; Mieko Nishidate Kumode, M.; Luiz Esteves Magalhães, W. Thermosetting Composites Prepared Using Husk of Pine Nuts from Araucaria Angustifolia. Polym. Compos. 2018, 39, 476–483. [Google Scholar] [CrossRef]

- IBRAMATE IBRAMATE. Available online: https://www.ibramate.com.br (accessed on 20 March 2023).

- Embrapa. Boletim de Pesquisa E Desenvolvimento 58; Embrapa: Brasília, Brazil, 2021. [Google Scholar]

- de Avila Delucis, R.; Magalhães, W.L.E.; Petzhold, C.L.; Amico, S.C. Thermal and Combustion Features of Rigid Polyurethane Biofoams Filled with Four Forest-Based Wastes. Polym. Compos. 2018, 39, E1770–E1777. [Google Scholar] [CrossRef]

- Kirpluks, M.; Cabulis, U.; Ivdre, A.; Kuranska, M.; Zieleniewska, M.; Auguscik, M. Mechanical and Thermal Properties of High-Density Rigid Polyurethane Foams from Renewable Resources. J. Renew. Mater. 2016, 4, 86–100. [Google Scholar] [CrossRef]

- Bryśkiewicz, A.; Zieleniewska, M.; Przyjemska, K.; Chojnacki, P.; Ryszkowska, J. Modification of Flexible Polyurethane Foams by the Addition of Natural Origin Fillers. Polym. Degrad. Stab. 2016, 132, 32–40. [Google Scholar] [CrossRef]

- Queirós, C.S.G.P.; Cardoso, S.; Lourenço, A.; Ferreira, J.; Miranda, I.; Lourenço, M.J.V.; Pereira, H. Characterization of Walnut, Almond, and Pine Nut Shells Regarding Chemical Composition and Extract Composition. Biomass Convers. Biorefinery 2020, 10, 175–188. [Google Scholar] [CrossRef]

- Domingos, I.; Ferreira, J.; Cruz-lopes, L.; Esteves, B. Food and Bioproducts Processing Polyurethane Foams from Liquefied Orange Peel Wastes. Food Bioprod. Process. 2019, 115, 223–229. [Google Scholar] [CrossRef]

- Ben, H.; Chen, X.; Han, G.; Shao, Y.; Jiang, W.; Pu, Y.; Ragauskas, A.J. Characterization of Whole Biomasses in Pyridine Based Ionic Liquid at Low Temperature by 31P NMR: An Approach to Quantitatively Measure Hydroxyl Groups in Biomass as Their Original Structures. Front. Energy Res. 2018, 6, 13. [Google Scholar] [CrossRef]

- Tapias, Y.A.R.; Di Monte, M.V.; Peltzer, M.A.; Salvay, A.G. Kombucha Fermentation in Yerba Mate: Cellulose Production, Films Formulation and Its Characterisation. Carbohydr. Polym. Technol. Appl. 2023, 5, 100310. [Google Scholar] [CrossRef]

- Ramírez Tapias, Y.A.; Di Monte, M.V.; Peltzer, M.A.; Salvay, A.G. Bacterial Cellulose Films Production by Kombucha Symbiotic Community Cultured on Different Herbal Infusions. Food Chem. 2022, 372, 131346. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, C.; Zang, E.; Shi, R.; Liu, Q.; Zhang, M.; Zhang, K.; Li, M. Review on Herbal Tea as a Functional Food: Classification, Active Compounds, Biological Activity, and Industrial Status. J. Future Foods 2023, 3, 206–219. [Google Scholar] [CrossRef]

- Luo, S.; Gao, L.; Guo, W. Effect of Incorporation of Lignin as Bio-Polyol on the Performance of Rigid Lightweight Wood–polyurethane Composite Foams. J. Wood Sci. 2020, 66, 23. [Google Scholar] [CrossRef]

- Thomas, M.G.; Abraham, E.; Jyotishkumar, P.; Maria, H.J.; Pothen, L.A.; Thomas, S. Nanocelluloses from Jute Fibers and Their Nanocomposites with Natural Rubber: Preparation and Characterization. Int. J. Biol. Macromol. 2015, 81, 768–777. [Google Scholar] [CrossRef]

- Franco, M. Impact of the Processing Method on the Properties of Castor Oil / Cellulose Acetate Polyurethane Adhesives for Bonding Wood. Int. J. Adhes. Adhes. 2022, 116, 103153. [Google Scholar] [CrossRef]

- Xu, P.; Luo, Y.; Zhang, P. Interfacial Architecting of Organic–inorganic Hybrid toward Mechanically Reinforced, Fire-Resistant and Smoke-Suppressed Polyurethane Composites. J. Colloid Interface Sci. 2022, 621, 385–397. [Google Scholar] [CrossRef] [PubMed]

- Gu, R.; Sain, M.M.; Konar, S.K. A Feasibility Study of Polyurethane Composite Foam with Added Hardwood Pulp. Ind. Crops Prod. 2013, 42, 273–279. [Google Scholar] [CrossRef]

- Tang, Z.; Maroto-Valer, M.M.; Andrésen, J.M.; Miller, J.W.; Listemann, M.L.; McDaniel, P.L.; Morita, D.K.; Furlan, W.R. Thermal Degradation Behavior of Rigid Polyurethane Foams Prepared with Different Fire Retardant Concentrations and Blowing Agents. Polymer 2002, 43, 6471–6479. [Google Scholar] [CrossRef]

- Missio, A.L.; Mattos, B.D.; Gatto, D.A.; De Lima, E.A. Thermal Analysis of Charcoal from Fast-Growing Eucalypt Wood: Influence of Raw Material Moisture Content. J. Wood Chem. Technol. 2014, 34, 191–201. [Google Scholar] [CrossRef]

- Zieleniewska, M.; Leszczyński, M.K.; Szczepkowski, L.; Bryśkiewicz, A.; Krzyżowska, M.; Bień, K.; Ryszkowska, J. Development and Applicational Evaluation of the Rigid Polyurethane Foam Composites with Egg Shell Waste. Polym. Degrad. Stab. 2016, 132, 78–86. [Google Scholar] [CrossRef]

- Yang, F.; Xie, M.; Yudi, Z.; Xu, X. Effect of Multi-Walled Carbon Nanotubes with Different Diameters on Morphology and Thermal and Mechanical Properties of Flexible Polyurethane Foams. Cell. Polym. 2021, 40, 165–179. [Google Scholar] [CrossRef]

- Shaayegan, V.; Wang, G.; Park, C.B. Effect of Foam Processing Parameters on Bubble Nucleation and Growth Dynamics in High-Pressure Foam Injection Molding. Chem. Eng. Sci. 2016, 155, 27–37. [Google Scholar] [CrossRef]

- Nayak, B.; Liu, R.H.; Tang, J. Effect of Processing on Phenolic Antioxidants of Fruits, Vegetables, and Grains—A Review. Crit. Rev. Food Sci. Nutr. 2015, 8398, 887–918. [Google Scholar] [CrossRef]

- Dulo, B.; De Somer, T.; Phan, K.; Roosen, M.; Githaiga, J.; Raes, K.; Meester, S. De Evaluating the Potential of Natural Dyes from Nutshell Wastes: Sustainable Colouration and Functional Finishing of Wool Fabric. Sustain. Mater. Technol. 2022, 34, e00518. [Google Scholar] [CrossRef]

- Ghaheh, F.S. Comparison of the Effect of Metal Mordants and Bio-Mordants on the Colorimetric and Antibacterial Properties of Natural Dyes on Cotton Fabric. Color. Technol. 2021, 137, 689–698. [Google Scholar] [CrossRef]

| Component | Function | Parts by Weight (php) |

|---|---|---|

| Castor oil | Polyol | 24.0 |

| Glycerol | Polyol | 8.0 |

| PEG-400 | Chain extender | 3.5 |

| Amine | Catalyst | 0.4 |

| Silicon oil | Surfactant | 1.0 |

| p-MDI | Polymeric MDI | 64.4 |

| Group | Cell Length (µm) | Cell Width (µm) | Anisotropy Index |

|---|---|---|---|

| RPUF | 569 (130 cd) | 436 (95 c) | 1.34 (0.31 ab) |

| RPUF/Yerba mate (5%) | 659 (266 de) | 565 (202 d) | 1.20 (0.33 ab) |

| RPUF/Yerba mate (10%) | 652 (164 de) | 428 (101 bc) | 1.54 (0.31 c) |

| RPUF/Yerba mate (15%) | 723 (271 e) | 572 (181 d) | 1.37 (0.33 bc) |

| RPUF/Pine seed shell (5%) | 508 (113 bc) | 422 (132 bc) | 1.35 (0.56 ab) |

| RPUF/Pine seed shell (10%) | 397 (105 ab) | 271 (66 a) | 1.48 (0.30 ab) |

| RPUF/Pine seed shell (15%) | 323 (83 a) | 319 (66 ab) | 1.07 (0.36 a) |

| Group | T2% | T5% | T50% | Residue at 800 °C (%) |

|---|---|---|---|---|

| RPUF | 160 | 262 | 404 | 12 |

| Yerba mate | 62 | 135 | 355 | 25 |

| RPUF/Yerba mate (5%) | 218 | 266 | 409 | 12 |

| RPUF/Yerba mate (10%) | 119 | 247 | 405 | 11 |

| RPUF/Yerba mate (15%) | 215 | 256 | 404 | 14 |

| Pine seed shell | 45 | 70 | 599 | 45 |

| RPUF/Pine seed shell (5%) | 103 | 241 | 398 | 12 |

| RPUF/Pine seed shell (10%) | 157 | 251 | 401 | 19 |

| RPUF/Pine seed shell (15%) | 121 | 252 | 402 | 21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Acosta, A.P.; Kairytė, A.; Członka, S.; Miedzińska, K.; Aramburu, A.B.; Barbosa, K.T.; Amico, S.C.; Delucis, R.d.A. Rigid Polyurethane Biofoams Filled with Pine Seed Shell and Yerba Mate Wastes. Polymers 2023, 15, 2194. https://doi.org/10.3390/polym15092194

Acosta AP, Kairytė A, Członka S, Miedzińska K, Aramburu AB, Barbosa KT, Amico SC, Delucis RdA. Rigid Polyurethane Biofoams Filled with Pine Seed Shell and Yerba Mate Wastes. Polymers. 2023; 15(9):2194. https://doi.org/10.3390/polym15092194

Chicago/Turabian StyleAcosta, Andrey Pereira, Agnė Kairytė, Sylwia Członka, Karolina Miedzińska, Arthur Behenck Aramburu, Kelvin Techera Barbosa, Sandro Campos Amico, and Rafael de Avila Delucis. 2023. "Rigid Polyurethane Biofoams Filled with Pine Seed Shell and Yerba Mate Wastes" Polymers 15, no. 9: 2194. https://doi.org/10.3390/polym15092194