Screening the Impact of Surfactants and Reaction Conditions on the De-Inkability of Different Printing Ink Systems for Plastic Packaging

Abstract

1. Introduction

1.1. Flexible Plastic Waste Management

1.2. Printing Ink as a Source of Contamination

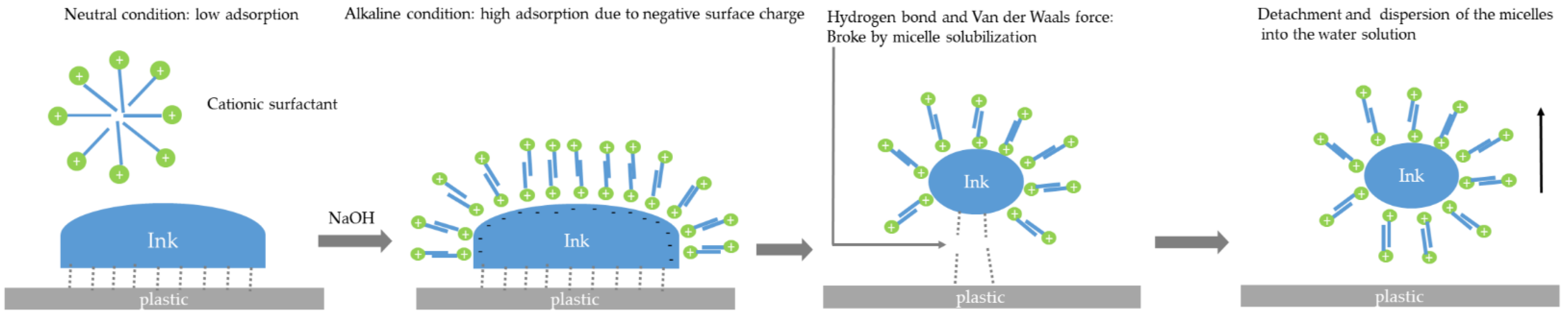

1.3. Surfactant Cleaning in the Recycling Process

- Adsorption of the surfactant on plastic surfaces;

- Removal of the printing ink (soil);

- Detachment of the mixture of ink particles and surfactant from the surface;

- Stabilization of the detached ink particles.

- To evaluate the de-inkability of common printing inks characterized by their components with existing surfactants for plastic cleaning in the recycling process, reported in the literature;

- To provide an open-source method for de-inkability evaluation;

- To derive process parameters to integrate the de-inking process into current plastic recycling plants and future “green-field” plants.

2. Materials and Methods

2.1. Evaluation of the De-Inking Effect

2.2. Evaluation of Detergents Applied

2.3. Water Treatment

3. Results

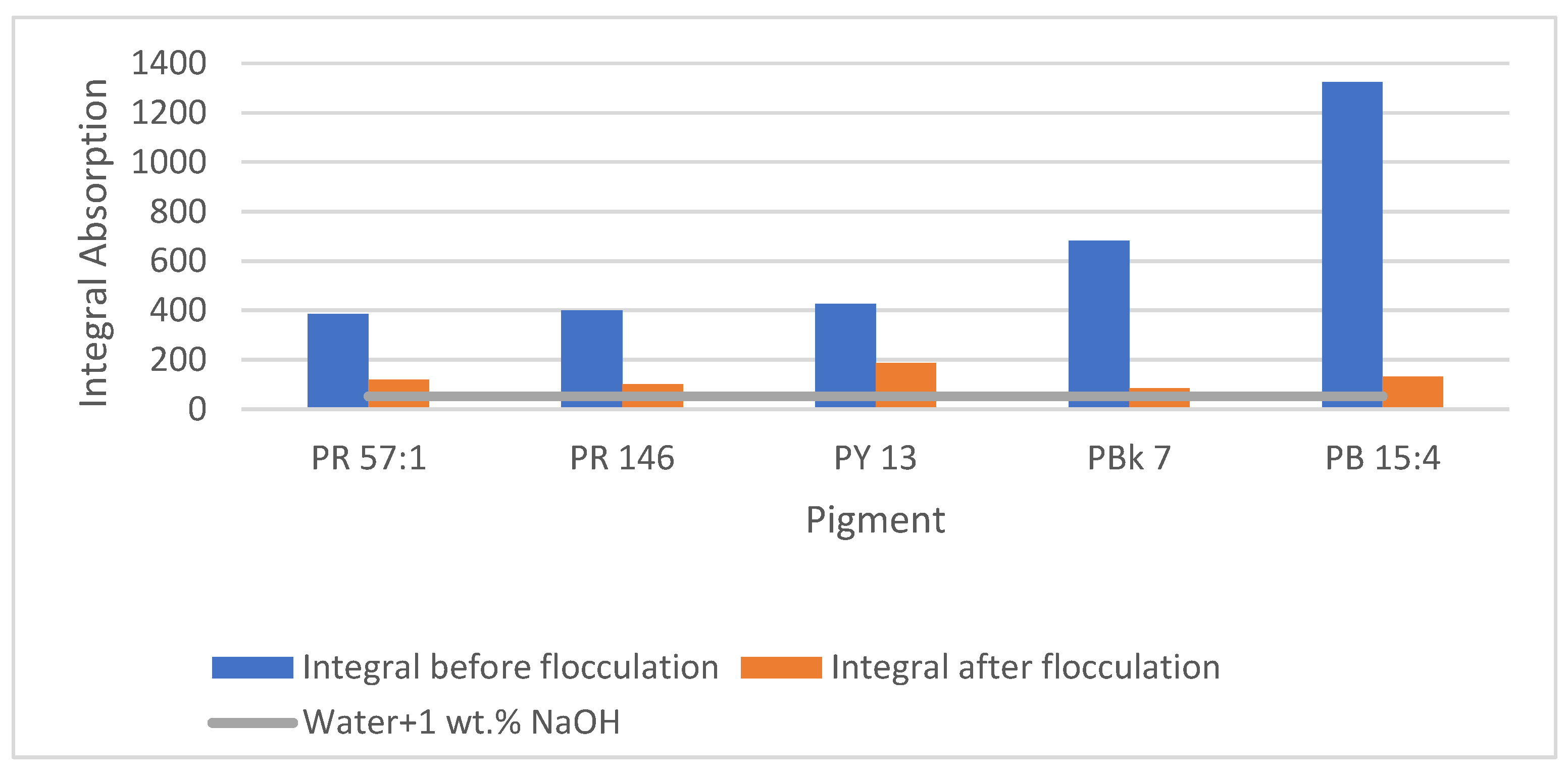

3.1. Influence of Different Pigments

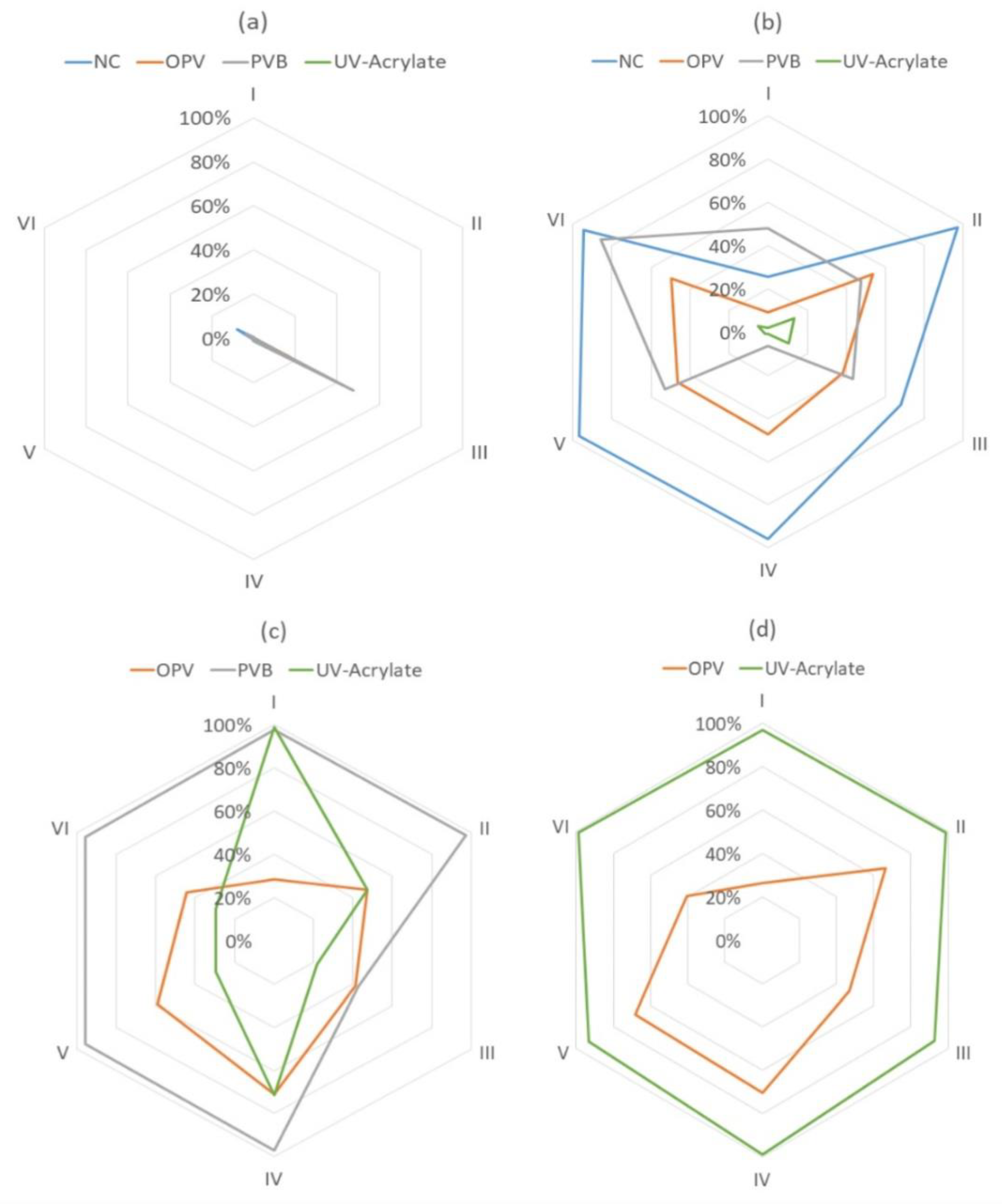

3.2. Influence of Different Binders without OPV

3.3. The Influence of OPV

3.3.1. NC Binder with Crosslinked NC OPV

3.3.2. PU Binder with Crosslinked PVB OPV

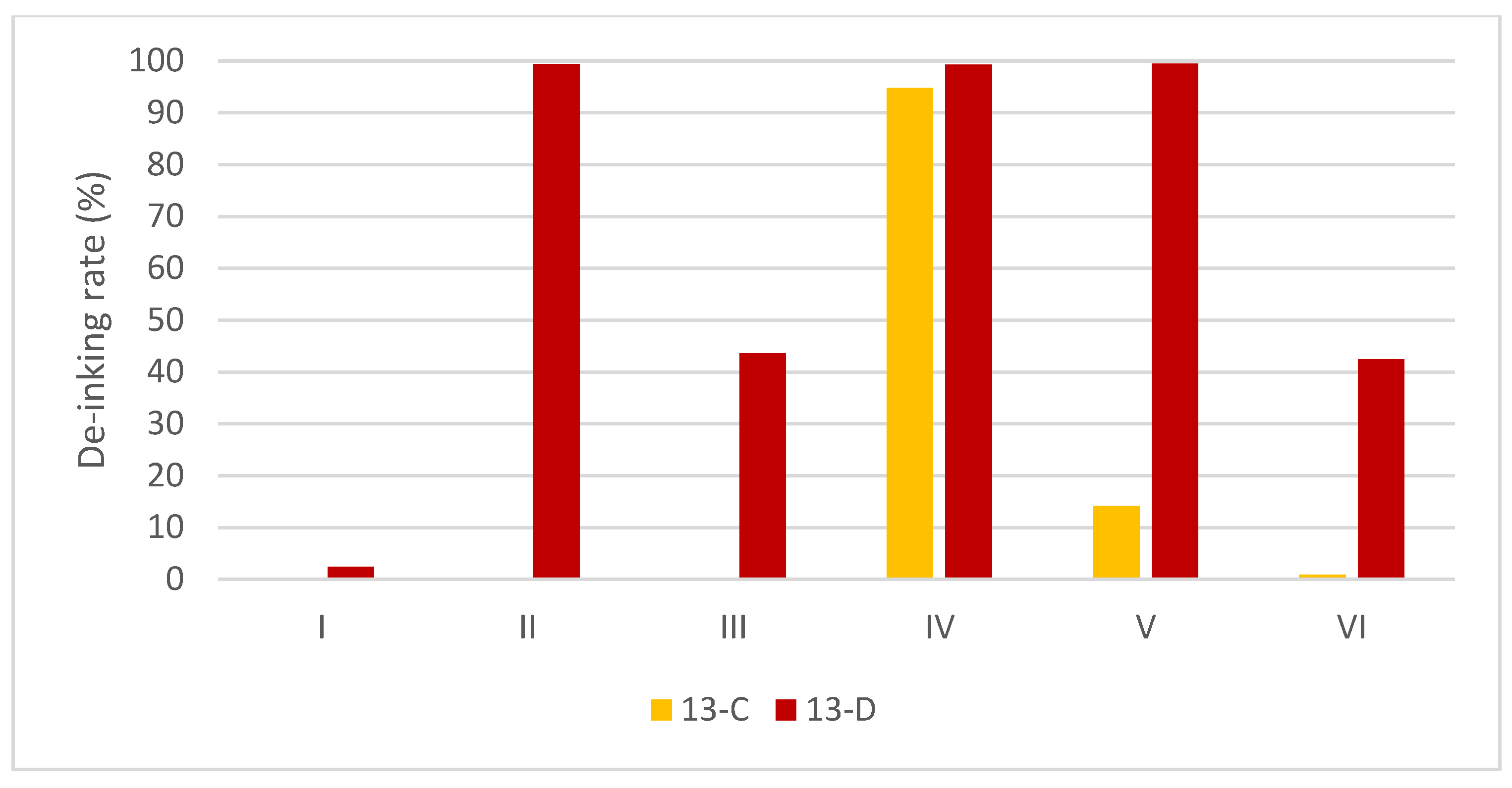

3.4. Performance of the De-Inking Detergents

| Detergent | HLB * |

|---|---|

| I | Not applicable |

| II | 7.22 |

| III | 5.33 |

| IV | 7.375 |

| V | 8.6 |

| VI | 4.8 |

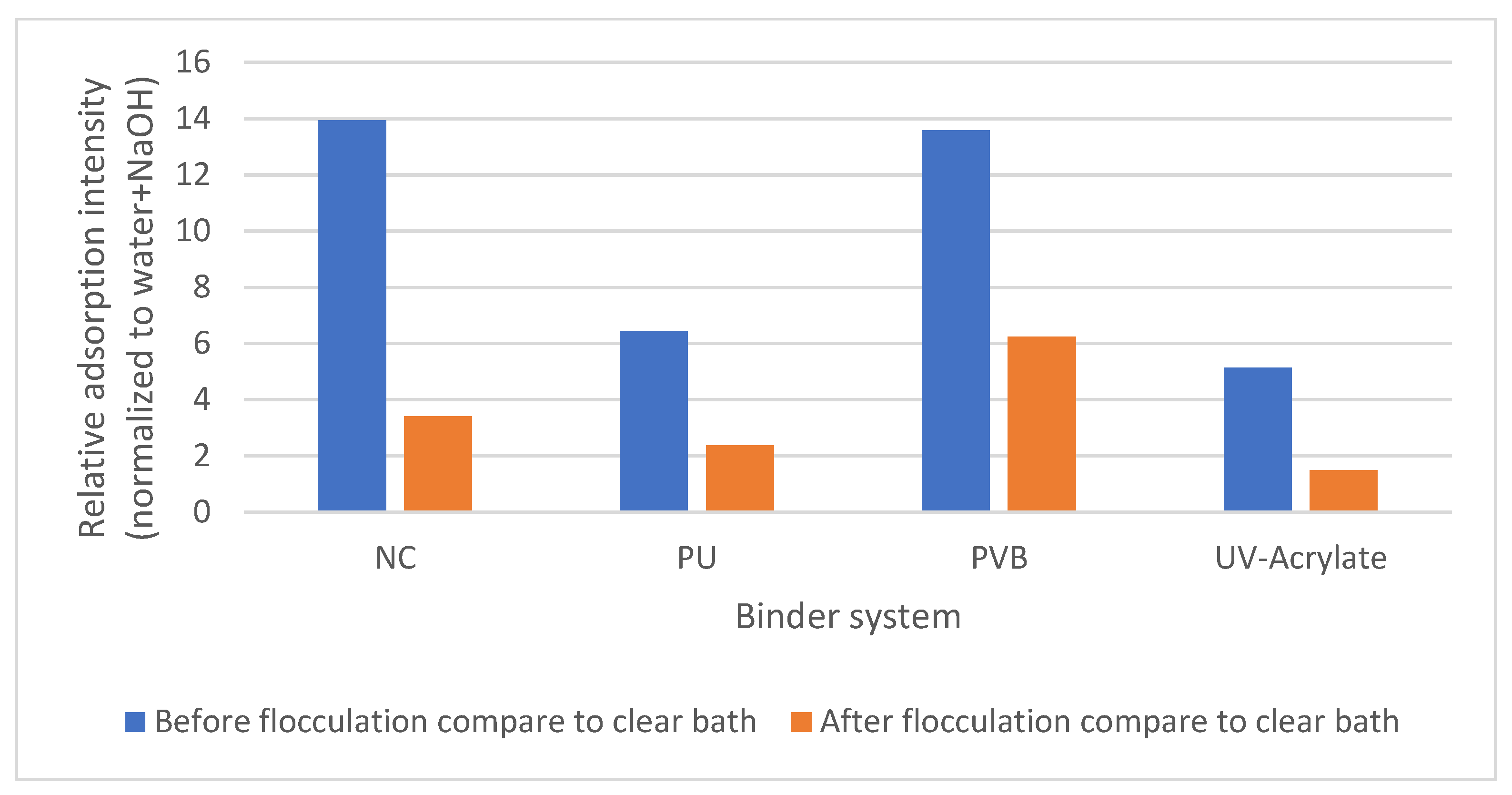

3.5. Water Treatment by Flocculation

4. Discussion

4.1. Design for Recycling in Plastic Packaging Printing Ink

- The printing ink should retain its performance under chemical, heat, and mechanical stress (scratches and abrasion), ensuring resistance for application;

- b. The printing ink should preferably be de-inkable to yield light-colored recyclates without pigments.

4.2. Extension of the De-Inking Mechanism

- Adsorption of the surfactant (ion pairing for cationic surfactant and hydrophobic bonding for nonionic surfactant);

- Breaking the covalent bonds via chemical reaction and hydrogen bonds via solubilization;

- Micelle solubilization (for non-crosslinked binder) and mechanical peel off (for crosslinked binder), to detach the printing ink from the plastic surface;

- Stabilization of the ink surface.

4.3. Inclusion of De-Inking Unit in Recycling Plants

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- OECD (Ed.) Global Plastics Outlook: Policy Scenarios to 2060; OECD Publishing: Paris, France, 2022; ISBN 9789264898813. [Google Scholar]

- Plastics Europe. Plastics—The Facts 2021: An Analysis of European Plastics Production, Demand and Waste Data. 2021. Available online: https://plasticseurope.org/wp-content/uploads/2021/12/Plastics-the-Facts-2021-web-final.pdf (accessed on 7 March 2023).

- Plastic Recycler Europe. Flexible Films Market in Europe: State of Play: Production, Collection and Recycling Data. 2020. Available online: https://743c8380-22c6-4457-9895-11872f2a708a.filesusr.com/ugd/dda42a_ff8049bc82bd408faee0d2ba4a148693.pdf (accessed on 2 March 2023).

- Leimann, F.V.; Gonçalves, O.H.; Sakanaka, L.S.; Azevedo, A.S.; Lima, M.V.; Barreiro, F.; Shirai, M.A. Active Food Packaging From Botanical, Animal, Bacterial, and Synthetic Sources; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Abdel-Bary, E.M. (Ed.) Handbook of Plastic Films; Rapra Technology Limited: Shawbury, Shrewsbury, 2003; ISBN 9781859573389. [Google Scholar]

- Horodytska, O.; Valdés, F.J.; Fullana, A. Plastic flexible films waste management—A state of art review. Waste Manag. 2018, 77, 413–425. [Google Scholar] [CrossRef] [PubMed]

- Huysman, S.; de Schaepmeester, J.; Ragaert, K.; Dewulf, J.; de Meester, S. Performance indicators for a circular economy: A case study on post-industrial plastic waste. Resour. Conserv. Recycl. 2017, 120, 46–54. [Google Scholar] [CrossRef]

- Lambré, C.; Barat Baviera, J.M.; Bolognesi, C.; Chesson, A.; Cocconcelli, P.S.; Crebelli, R.; Gott, D.M.; Grob, K.; Mengelers, M.; Mortensen, A.; et al. Safety assessment of the process Loop Polymers, used to recycle polyethylene and polypropylene printed offcuts and scrap for use as food contact materials. EFSA J. 2022, 20, e07577. [Google Scholar] [CrossRef] [PubMed]

- Lase, I.S.; Bashirgonbadi, A.; van Rhijn, F.; Dewulf, J.; Ragaert, K.; Delva, L.; Roosen, M.; Brandsma, M.; Langen, M.; de Meester, S. Material flow analysis and recycling performance of an improved mechanical recycling process for post-consumer flexible plastics. Waste Manag. 2022, 153, 249–263. [Google Scholar] [CrossRef]

- Dehoust, G.; Hermann, A.; Christiani, J.; Bartnik, S.; Beckamp Bünemann, A. Ermittlung der Praxis der Sortierung und Verwertung von Verpackungen im Sinne des § 21 VerpackG; Endbericht: Dessau-Roßlau, Germany, 2021. [Google Scholar]

- Jansen, M.; van Thoden Velzen, E.; Pretz, T. (Eds.) Handbook for Sorting of Plastic Packaging Waste Concentrates: Separation Efficiencies of Common Plastic Packaging Objects in Widely Used Separaion Machines at Existing Sorting Facilities with Mixed Postconsumer Plastic Packaging Waste as Input; Wageningen UR Food & Biobased Research: Wageningen, The Netherlands, 2015; ISBN 978-94-6257-529-5. [Google Scholar]

- Ragaert, K.; Delva, L.; van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- Bashirgonbadi, A.; Saputra Lase, I.; Delva, L.; van Geem, K.M.; de Meester, S.; Ragaert, K. Quality evaluation and economic assessment of an improved mechanical recycling process for post-consumer flexible plastics. Waste Manag. 2022, 153, 41–51. [Google Scholar] [CrossRef]

- van Belle, A.; Demets, R.; Mys, N.; van Kets, K.; Dewulf, J.; van Geem, K.; de Meester, S.; Ragaert, K. Microstructural Contributions of Different Polyolefins to the Deformation Mechanisms of Their Binary Blends. Polymers 2020, 12, 1171. [Google Scholar] [CrossRef] [PubMed]

- Kaiser, K.; Schmid, M.; Schlummer, M. Recycling of Polymer-Based Multilayer Packaging: A Review. Recycling 2018, 3, 1. [Google Scholar] [CrossRef]

- Chen, X.; Kroell, N.; Feil, A.; Pretz, T. Determination of the composition of multilayer plastic packaging with nir spectroscopy. Detritus 2020, 13, 62–66. [Google Scholar] [CrossRef]

- Koinig, G.; Friedrich, K.; Rutrecht, B.; Oreski, G.; Barretta, C.; Vollprecht, D. Influence of reflective materials, emitter intensity and foil thickness on the variability of near-infrared spectra of 2D plastic packaging materials. Waste Manag. 2022, 144, 543–551. [Google Scholar] [CrossRef]

- COWI. Report: Study about Plastic Sorting and Recycling. 2019. Available online: https://plastikviden.dk/media/212448/study-about-plastic-sorting-and-recycling.pdf (accessed on 30 November 2022).

- Luijsterburg, B.J.; Jobse, P.S.; Spoelstra, A.B.; Goossens, J.G.P. Solid-state drawing of post-consumer isotactic poly(propylene): Effect of melt filtration and carbon black on structural and mechanical properties. Waste Manag. 2016, 54, 53–61. [Google Scholar] [CrossRef] [PubMed]

- Schyns, Z.O.G.; Shaver, M.P. Mechanical Recycling of Packaging Plastics: A Review. Macromol. Rapid Commun. 2021, 42, e2000415. [Google Scholar] [CrossRef]

- Antonopoulos, I.; Faraca, G.; Tonini, D. Recycling of post-consumer plastic packaging waste in the EU: Recovery rates, material flows, and barriers. Waste Manag. 2021, 126, 694–705. [Google Scholar] [CrossRef] [PubMed]

- Betz, J.; Hermann, A.; Bulach, W.; Hermann, C.; Dieroff, J.; Mehlhart, G.; Müller, R.; Wiesemann, E. Prüfung Konkreter Maßnahmen zur Steigerung der Nachfrage nach Kunststoffrezyklaten und Rezyklathaltigen Kunststoffprodukten, Dessau-Roßlau. 2022. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/479/publikationen/texte_128-2022_pruefung_konkreter_massnahmen_zur_steigerung_der_nachfrage_nach_kunststoffrezyklaten_und_rezyklathaltigen_kunststoffprodukten.pdf (accessed on 7 March 2023).

- Demets, R.; Grodent, M.; van Kets, K.; de Meester, S.; Ragaert, K. Macromolecular Insights into the Altered Mechanical Deformation Mechanisms of Non-Polyolefin Contaminated Polyolefins. Polymers 2022, 14, 239. [Google Scholar] [CrossRef] [PubMed]

- Meran, C.; Ozturk, O.; Yuksel, M. Examination of the possibility of recycling and utilizing recycled polyethylene and polypropylene. Mater. Des. 2008, 29, 701–705. [Google Scholar] [CrossRef]

- Geueke, B. Fpf Dossier: Non-Intentionally Added Substances (Nias), Zenodo. 2015. Available online: https://zenodo.org/record/33514#.ZFhqBM5ByMo (accessed on 7 March 2023).

- Horodytska, O.; Cabanes, A.; Fullana, A. Non-intentionally added substances (NIAS) in recycled plastics. Chemosphere 2020, 251, 126373. [Google Scholar] [CrossRef] [PubMed]

- Bradley, E.; Coulier, L. An Investigation into the Reaction and Breakdown Products from Starting Substances Used to Produce Food Contact Plastics; 2007. Available online: https://www.foodpackagingforum.org/fpf-2016/wp-content/uploads/2014/06/Bradley-and-Coulier-2007.pdf (accessed on 9 March 2023).

- Pfaendner, R. Restabilization—30 years of research for quality improvement of recycled plastics Review. Polym. Degrad. Stab. 2022, 203, 110082. [Google Scholar] [CrossRef]

- EuPIA. Printing Inks and Plastic Recycling—Q & A; EuPIA: Brussels, Belgium, 2021; Available online: www.eupia.org (accessed on 28 January 2023).

- Kol, R.; Roosen, M.; Ügdüler, S.; van Geem, K.M.; Ragaert, K.; Achilias, D.S.; de Meester, S. Recent Advances in Pre-Treatment of Plastic Packaging Waste; IntechOpen: London, UK, 2021. [Google Scholar]

- Pekarovicova, A.; Husovska, V. (Eds.) Printing Ink Formulations; William Andrew: Norwich, NY, USA, 2016. [Google Scholar]

- Leach, R.H.; Pierce, R.J.; Hickman, E.P.; Mackenzie, M.J.; Smith, H.G. The Printing Ink Manual; Springer: Dordrecht, The Netherlands, 1993; ISBN 978-1-4020-6187-5. [Google Scholar]

- Flick, E.W. Printing Ink and Overprint Varnish Formulations, 2nd ed.; Noyes Publications: Norwich, NY, USA, 1999; ISBN 9780815514404. [Google Scholar]

- Galbiati, E.; Jacxsens, L.; de Meulenaer, B. Hazard prioritisation of substances in printing inks and adhesives applied to plastic food packaging. Food Addit. Contam. Part A Chem. Anal. Control Expo. Risk Assess. 2021, 38, 1608–1626. [Google Scholar] [CrossRef]

- Aydemir, C.; Altay, B.N.; Akyol, M. Surface analysis of polymer films for wettability and ink adhesion. Color Res. Appl. 2021, 46, 489–499. [Google Scholar] [CrossRef]

- Al-Gunaid, T.A.; Krupa, I.; Ouederni, M.; Krishnamoorthy, S.K.; Popelka, A. Enhancement of Adhesion Characteristics of Low-Density Polyethylene Using Atmospheric Plasma Initiated-Grafting of Polyethylene Glycol. Polymers 2021, 13, 1309. [Google Scholar] [CrossRef]

- Popelka, A.; Novák, I.; Al-Maadeed, M.A.S.; Ouederni, M.; Krupa, I. Effect of corona treatment on adhesion enhancement of LLDPE. Surf. Coat. Technol. 2018, 335, 118–125. [Google Scholar] [CrossRef]

- Kühn, G.; St. Weidner; Decker, R.; Ghode, A.; Friedrich, J. Selective surface functionalization of polyolefins by plasma treatment followed by chemical reduction. Surf. Coat. Technol. 1999, 116-119, 796–801. [Google Scholar] [CrossRef]

- Gecol, H.; Scamehorn, J.F.; Christian, S.D.; Grady, B.P.; Riddell, F.E. Deinking of water-based ink printing from plastic film using nonionic surfactants. J. Surfact. Deterg. 2002, 5, 363–374. [Google Scholar] [CrossRef]

- Guo, J.; Kim, Y.; Chong, Z.K.; Alassali, A.; Chacon, J.P.; Gottschalk, D.; Kitzberger, M.; Kuchta, K. Quality Changes of Low-Density Polyethylene (LDPE) Recyclates from the Pretreatment Process with a Cationic Surfactant and a Nonionic Surfactant as Cleaning Agents Upstream of Extrusion. Processes 2022, 10, 2174. [Google Scholar] [CrossRef]

- Wagner, J.R.; Mount, E.M.; Giles, H.F.; Giles Jr, H.F.; Wagner, J.R. (Eds.) Extrusion (Second Edition)//Extrusion: The Definitive Processing Guide and Handbook, 2nd ed.; Elsevier Science: Burlington, VT, USA, 2014; ISBN 978-1-4377-3481-2. [Google Scholar]

- Jin, H.; Gonzalez-Gutierrez, J.; Oblak, P.; Zupančič, B.; Emri, I. The effect of extensive mechanical recycling on the properties of low density polyethylene. Polym. Degrad. Stab. 2012, 97, 2262–2272. [Google Scholar] [CrossRef]

- DIN EN ISO 1133-1:2012-03; Kunststoffe—Bestimmung der Schmelze-Massefließrate (MFR) und der Schmelze-Volumenfließrate (MVR) von Thermoplasten—Teil_1: Allgemeines Prüfverfahren (ISO_1133-1:2011); Deutsche Fassung EN_ISO_1133-1:2011. Beuth Verlag GmbH: Berlin, Germany, 2011.

- Dave, P.Y. Short Review on Printing Ink Technology to Prevent Counterfeit of the Products. J. Adv. Chem. Sci. 2020, 6, 693–697. [Google Scholar] [CrossRef]

- Abd El-Wahab, H.; El-Meligi, G.; Hassaan, M.G.; Kazlauciunas, A.; Lin, L. New water-based copolymer nanoparticles and their use as eco-friendly binders for industry of flexographic ink, part I. PRT 2020, 49, 239–248. [Google Scholar] [CrossRef]

- Devra, R.S.; Srivastava, N.; Vadali, M.; Arora, A. Polymer Filament Extrusion Using LDPE Waste Polymer: Effect of Processing Temperature. In Proceedings of the ASME 2022 17th International Manufacturing Science and Engineering Conference, West Lafayette, IN, USA, 27 June–1 July 2022. [Google Scholar] [CrossRef]

- Nerin, C.; Alfaro, P.; Aznar, M.; Domeño, C. The challenge of identifying non-intentionally added substances from food packaging materials: A review. Anal. Chim. Acta 2013, 775, 14–24. [Google Scholar] [CrossRef]

- Chai, H.; Duan, Q.; Cao, H.; Li, M.; Qi, K.; Sun, J.; Yang, X. Experimental study on the effect of storage conditions on thermal stability of nitrocellulose. Appl. Therm. Eng. 2020, 180, 115871. [Google Scholar] [CrossRef]

- PrintCYC Initiative. PrintCYC Entwickelt Recycling von Bedruckten Kunststoff-Folien. Available online: https://packaging-journal.de/printcyc-initiative-entwickelt-recycling-von-bedruckten-kunststoff-folien/ (accessed on 13 March 2023).

- SY Chemical. Pigment Red 146. Available online: https://www.sypigment.com/pigment-red-146.html (accessed on 17 January 2023).

- Cox, M.F. Surfactants for hard-surface cleaning: Mechanisms of solid soil removal. J. Am. Oil Chem. Soc. 1986, 63, 559–565. [Google Scholar] [CrossRef]

- Gamma Meccanica. Cleaning System for the Removal of Printing Ink from Flexible Plastic Films. Available online: https://www.gamma-meccanica.it/en/plastic-recycling/eco-clean/ (accessed on 7 March 2023).

- Polymont. Polymount Film Cleaner. Available online: https://www.polymount-int.com/en/film-cleaner (accessed on 7 March 2023).

- Niaounakis, M. Solvent- and/or Chemical Agent-Based Separation. In Recycling of Flexible Plastic Packaging; Elsevier: Amsterdam, The Netherlands, 2020; pp. 211–264. [Google Scholar]

- van Thoden Velzen, E.; Jansen, M. (Eds.) Solvent Extraction as Additional Purification Method for Postconsumer Plastic Packaging Waste; Wageningen UR Food & Biobased Research: Wageningen, The Netherlands, 2011; ISBN 9789461730640. [Google Scholar]

- Lorenz, A.; Walser, H.P. A Method for the Removal of Solvent and/or Nitrocellulose Residues from Precleaned Polyolefin. 92110894.0, 26 June 1992. [Google Scholar]

- Ügdüler, S.; van Laere, T.; de Somer, T.; Gusev, S.; van Geem, K.M.; Kulawig, A.; Leineweber, R.; Defoin, M.; van den Bergen, H.; Bontinck, D.; et al. Understanding the complexity of deinking plastic waste: An assessment of the efficiency of different treatments to remove ink resins from printed plastic film. J. Hazard. Mater. 2023, 452, 131239. [Google Scholar] [CrossRef] [PubMed]

- Rosen, M.J. Detergency and Its Modification by Surfactants//Surfactants and Interfacial Phenomena, 4th ed.; Wiley: Hoboken, NJ, USA, 2012; ISBN 9781118228920. [Google Scholar]

- Chotipong, A.; Scamehorn, J.F.; Rirksomboon, T.; Chavadej, S.; Supaphol, P. Removal of solvent-based ink from printed surface of high-density polyethylene bottles by alkyltrimethylammonium bromides: Effects of pH, temperature, and salinity. Colloids Surf. A: Physicochem. Eng. Asp. 2007, 297, 163–171. [Google Scholar] [CrossRef]

- Pastor-Blas, M.M.; Martín-Martínez, J.M.; Boerio, F.J. Mechanisms of Adhesion in Surface Chlorinated Thermoplastic Rubber/Thermoplastic Polyurethane Adhesive Joints. Rubber Chem. Technol. 2002, 75, 825–838. [Google Scholar] [CrossRef]

- Tyczkowski, J.; Krawczyk-Kłys, I.; Kuberski, S.; Makowski, P. Chemical nature of adhesion: Plasma modified styrene–butadiene elastomer and polyurethane adhesive joints. Eur. Polym. J. 2010, 46, 767–773. [Google Scholar] [CrossRef]

- Lei, L.; Xia, Z.; Ou, C.; Zhang, L.; Zhong, L. Effects of crosslinking on adhesion behavior of waterborne polyurethane ink binder. Prog. Org. Coat. 2015, 88, 155–163. [Google Scholar] [CrossRef]

- Thompson, C.J.; Ainger, N.; Starck, P.; Mykhaylyk, O.O.; Ryan, A.J. Shampoo Science: A Review of the Physiochemical Processes behind the Function of a Shampoo. Macro Chem. Phys. 2023, 224, 2200420. [Google Scholar] [CrossRef]

- Gecol, H.; Scamehorn, J.F.; Christian, S.D.; Grady, B.P.; Riddell, F. Use of surfactants to remove water based inks from plastic films. Colloids Surf. A: Physicochem. Eng. Asp. 2001, 189, 55–64. [Google Scholar] [CrossRef]

- Gecol, H.; Scamehorn, J.F.; Christian, S.D.; Riddell, F.E. Use of surfactants to remove solvent-based inks from plastic films. Colloid Polym. Sci. 2003, 281, 1172–1177. [Google Scholar] [CrossRef]

- El-Sherbiny, S.I.; Morsy, F.A.; Atta, A.M. Synthesis of new cationic surfactants based on recycled poly(ethylene terephthalate) for deinking of solvent-based ink from low-density polyethylene surface. J. Appl. Polym. Sci. 2010, 118, 1160–1172. [Google Scholar] [CrossRef]

- Ye, X.; Wu, Z.; Wang, M.; Lv, Y.; Huang, X.; Liu, Y.; Lin, C. Effectively remove printing ink from plastic surface over quaternary ammonium-modified waste cooking oil. Environ. Technol. 2022, 44, 1071–1082. [Google Scholar] [CrossRef]

- Bozzola, F.; do Nascimento, B.G.; Vasco, J.C.; Silva, N.; Lagoa, F.; Capela, C.; Heleno, L.; Gaspar, M.; Oliveira, N.S. (Eds.) Ink Removal on Plastic Films Printed by Flexography; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Fullana, A.; Lozano, M.A. Method for Removing Ink Printed on Plastic Films. EP2832459A1, 26 April 2017. [Google Scholar]

- RecyClass. Recyclability Evaluation Protocol for HDPE Containers: Standard Laboratory Practice. 2022. Available online: https://recyclass.eu/wp-content/uploads/2022/02/RecyClass-Recyclability-Evaluation-Protocol-for-HDPE-containers-v.3.0-FINAL.pdf (accessed on 2 February 2023).

- The Association of Plastic Recyclers. PET Standard Laboratory Processing Practices: Document Number PET-P-00. 2022. Available online: https://plasticsrecycling.org/images/Design-Guidance-Tests/APR-PET-P-00-practices.pdf (accessed on 10 March 2023).

- Boz Noyan, E.C.; Venkatesh, A.; Boldizar, A. Washing Post-Consumer Flexible Polyethylene Packaging Waste. Recycling 2022, 7, 90. [Google Scholar] [CrossRef]

- ICC-International Color Consortium. Specification ICC.1:2004-10: Mage Technology Colour Management—Architecture, Profile Format, and Data Structure. 2004. Available online: https://www.color.org/icc1v42.pdf (accessed on 13 March 2023).

- Carter, E.C.; Ohno, Y.; Pointer, M.R.; Robertson, A.R.; Seve, R.; Schanda, J.D.; Witt, K. Colorimetry, 3rd ed.; CIE Central Bureau: Vienna, Austria, 2004; ISBN 978 3 901906 33 6. [Google Scholar]

- Davies, J.E. (Ed.) A Quantitative Kinetic Theory of Emulsion Type. I. Physical Chemistry of the Emulsifying, 2nd ed.; International Congress Surface Activity: London, UK, 1957. [Google Scholar]

- Barret, R. Importance and Evaluation of Lipophilicity//Therapeutical Chemistry: Fundamentals; Elsevier: San Diego, CA, USA, 2018; ISBN 978-1-78548-288-5. [Google Scholar]

- Sahu, V.; Shekhar, S.; Ahuja, P.; Gupta, G.; Singh, S.K.; Sharma, R.K.; Singh, G. Synthesis of hydrophilic carbon black; role of hydrophilicity in maintaining the hydration level and protonic conduction. RSC Adv. 2013, 3, 3917. [Google Scholar] [CrossRef]

- Sis, H.; Birinci, M. Effect of nonionic and ionic surfactants on zeta potential and dispersion properties of carbon black powders. Colloids Surf. A: Physicochem. Eng. Asp. 2009, 341, 60–67. [Google Scholar] [CrossRef]

- Myers, D. Polymeric Surfactants and Surfactant-Polymer Interactions//Surfactant Science and Technology, 3rd ed.; J. Wiley: Hoboken, NJ, USA, 2006; ISBN 9780471680246. [Google Scholar]

- Baglioni, M.; Poggi, G.; Ciolli, G.; Fratini, E.; Giorgi, R.; Baglioni, P. A Triton X-100-Based Microemulsion for the Removal of Hydrophobic Materials from Works of Art: SAXS Characterization and Application. Materials 2018, 11, 1144. [Google Scholar] [CrossRef] [PubMed]

- Theodorou, V.; Paraskevopoulos, G.; Skobridis, K. A mild alkaline hydrolysis of N- and N,N-substituted amides and nitriles. Arkivoc 2015, 2015, 101–112. [Google Scholar] [CrossRef]

- Maeng, D.Y.; Mcneill, V.F. Kinetics of Alkaline Hydrolysis of Synthetic Organic Esters; John Wiley & Sons, Inc.: New York, NY, USA, 2021; Available online: https://chemrxiv.org/engage/api-gateway/chemrxiv/assets/orp/resource/item/60c759404c8919f19ead4d2f/original/kinetics-of-alkaline-hydrolysis-of-synthetic-organic-esters.pdf (accessed on 23 March 2023).

- Gong, L.; Liao, G.; Luan, H.; Chen, Q.; Nie, X.; Liu, D.; Feng, Y. Oil solubilization in sodium dodecylbenzenesulfonate micelles: New insights into surfactant enhanced oil recovery. J. Colloid Interface Sci. 2020, 569, 219–228. [Google Scholar] [CrossRef]

- Genot, C.; Kabri, T.-H.; Meynier, A. Stabilization of Omega-3 Oils and Enriched Foods Using Emulsifiers//Food Enrichment with Omega-3 Fatty Acids; Woodhead Publ: Oxford, UK, 2013; ISBN 978-0-85709-428-5. [Google Scholar]

- Aulton, M.E. (Ed.) Pharmaceutics: The Science of Dosage Form Design, 2nd ed.; Churchill Livingstone: Edinburgh, Scotland, 2002; ISBN 9780443055171. [Google Scholar]

- Berry, J.D.; Neeson, M.J.; Dagastine, R.R.; Chan, D.Y.C.; Tabor, R.F. Measurement of surface and interfacial tension using pendant drop tensiometry. J. Colloid Interface Sci. 2015, 454, 226–237. [Google Scholar] [CrossRef]

- Tavana, H.; Neumann, A.W. Recent progress in the determination of solid surface tensions from contact angles. Adv. Colloid Interface Sci. 2007, 132, 1–32. [Google Scholar] [CrossRef]

- Yuan, Y.; Lee, T.R. Contact Angle and Wetting Properties. In Surface Science Techniques; Springer Series in Surface Sciences; Bracco, G., Holst, B., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; Volume 51, pp. 3–34. [Google Scholar] [CrossRef]

- Huhtamäki, T.; Tian, X.; Korhonen, J.T.; Ras, R.H.A. Surface-wetting characterization using contact-angle measurements. Nat. Protoc. 2018, 13, 1521–1538. [Google Scholar] [CrossRef]

- Kaedin-Koppers, A. PrintCYC liefert wichtigen Input für „Design for Recycling“-Richtlinien: Industrielle Forschung über den Einfluss von Druckfarben auf die Recyclingfähigkeit von Kunststoff-Folien; Flexo+Tief-Druck; G&K TechMedia: Emmendigen, Germany, 2023; pp. 10–11. [Google Scholar]

- Schmidt, J.; Auer, M.; Moesslein, J.; Wendler, P.; Wiethoff, S.; Lang-Koetz, C.; Woidasky, J. Challenges and Solutions for Plastic Packaging in a Circular Economy. Chemie Ingenieur Technik 2021, 93, 1751–1762. [Google Scholar] [CrossRef]

- Ceflex. Designing for a Circular Economy: Recyclability of Polyolefin-Based Flexible Packaging; Technical Report. 2020. Available online: https://guidelines.ceflex.eu/resources/ (accessed on 19 March 2023).

- Kemona, A.; Piotrowska, M. Polyurethane Recycling and Disposal: Methods and Prospects. Polymers 2020, 12, 1752. [Google Scholar] [CrossRef] [PubMed]

- PST. Why Accurate Moisture Measurement is Essential for the Quality of Polyethylene Terephthalate. Available online: https://www.processsensing.com/en-us/blog/accurate-moisture-measurement-for-quality-of-polyethylene-terephthalate.htm?utm_source=Directindustry&utm_medium=Local%20directories&utm_campaign=PET%20blog (accessed on 18 March 2023).

- Peltovuori, M. PET Extrusion Coating—Taking Extrusion Coating to a New Level; Karhula Finland. Available online: https://www.tappi.org/content/events/07europlace/papers/07europl41.pdf (accessed on 23 March 2023).

- Grummt, S. Praxis der Sortierung und Verwertung von Verpackungen im Sinne des § 21 VerpackG 2020/2021. Teilbericht, Dessau-Roßlau. 2022. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/1410/publikationen/2023-01-05_texte_125-2022_praxis_der_sortierung_und_verwertung_von_verpackungen.pdf (accessed on 17 March 2023).

- Soto, J.M.; Martín-Lara, M.A.; Blázquez, G.; Godoy, V.; Quesada, L.; Calero, M. Novel pre-treatment of dirty post-consumer polyethylene film for its mechanical recycling. Process Saf. Environ. Prot. 2020, 139, 315–324. [Google Scholar] [CrossRef]

- Streit, A.F.M.; de Santana, M.P.; de Oliveira Júnior, D.L.; Bassaco, M.M.; Tanabe, E.H.; Dotto, G.L.; Bertuol, D.A. Development of a pre-treatment process of polymeric wastes (HDPE, LDPE/LLDPE, PP) for application in the qualification of selectors of recyclable materials. Environ. Dev. Sustain. 2022, 24, 6349–6371. [Google Scholar] [CrossRef]

- Roosen, M.; Harinck, L.; Ügdüler, S.; de Somer, T.; Hucks, A.-G.; Belé, T.G.A.; Buettner, A.; Ragaert, K.; van Geem, K.M.; Dumoulin, A.; et al. Deodorization of post-consumer plastic waste fractions: A comparison of different washing media. Sci. Total Environ. 2022, 812, 152467. [Google Scholar] [CrossRef]

| Plastic Printing Ink Component | Common Chemical Composition | Typical Content (wt.%) |

|---|---|---|

| Solvents | Organic solvents (e.g., alcohol, esters, ketones, etc.) for solvent-based ink Water with alcohols for water-based ink Liquid but reactive substances for UV and EB inks | 50–70 |

| Binders | Nitrocellulose (NC), polyurethane (PU), polyvinyl butyral (PVB), acrylate, cellulose acetate propionate (CAP), and mixtures thereof | 20–30 |

| Pigments | Organic and inorganic substances, named mainly by their color index (e.g., Pbk7) | 6–30 |

| Additives | Wax, surfactants, crosslinkers, dispersants, etc. | 1–10 |

| De-Inked Sample | Surfactant | Surfactant Category | Result | Source |

|---|---|---|---|---|

| 70% LDPE and 30% HDPE film, with water-based inks (color: black, white, purple, pink, and orange) | Sodium dodecyl sulfate (SDS) | Anionic | Partially de-inking above the CMC concentration at pH 8–9, increasing pH only contributed slight improvement | [64] |

| Cetrimonium bromide (CTAB) | Cationic | Effective de-inking above CMC at pH 5–12 | ||

| Hexadecylpyridinium chloride (CPC) | Cationic | Effective de-inking above CMC at pH 5–12 | ||

| Nonylphenol polyethoxylated (NP(EO)10) | Nonionic | Almost complete de-inking at pH 10–12 above CMC | ||

| Dimethyl dodecyl amine oxide (DDAO) | Amphoteric | No relevance between pH and de-inking rate; effective de-inking effects were obtained at pH 5, 7, 11, and 12, above the CMC | ||

| 70% LDPE and 30% HDPE film, with water-based inks (color: black, white, purple, pink, and orange) | Ethoxylated alcohol (AEO5) | Nonionic | Effective ink removal above CMC at pH 10–12 | [39] |

| Ethoxylated amine (AMEO5) | Nonionic | Effective ink removal above CMC at pH 8–12 | ||

| 70% LDPE and 30% HDPE film, with solvent-based inks (color: either yellow, pink, red, green, gold, black, or violet) | Sodium dodecyl sulfate (SDS) | anionic | No de-inking effect at pH 10–12 | [65] |

| Sodium dioctyl sulfosuccinate (SDOSS) | anionic | No de-inking effect at pH 10–12 | ||

| Polyalkylene oxide modified polydimethylsiloxanes (molecular weight 600) | Nonionic | No de-inking effect at pH 10–12 | ||

| Polyalkylene oxide modified polydimethylsiloxanes (molecular weight 1000) | Nonionic | No de-inking effect at pH 10–11, over 90% de-inking effect at pH 11.5 and 12 | ||

| Dimethyl dodecylamine oxide (DDAO) | Amphoteric | No de-inking effect at pH 10–11, and slight de-inking effect at pH 11.5 and 12 | ||

| Ethoxylated amine (AMEO5) | Nonionic | No de-inking effect at pH 10–11, and slight de-inking effect at pH 11.5 and 12 | ||

| Cetrimonium bromide (CTAB) | Cationic | Complete de-inking at pH 11.5 and 12 with 1–2 h soaking | ||

| Solvent-based ink with epoxy resin as a binder on HDPE bottles | DTAB | Cationic | Complete de-inking at 30 °C, 24 CMC, and 2 h retention time | [59] |

| TTAB | Cationic | Complete de-inking at 30 °C, 8 CMC, and 2 h retention time | ||

| CTAB | Cationic | Complete de-inking at 30 °C, 4 CMC, and 2 h retention time | ||

| Solvent-based ink with blue color printed on LDPE film | De-inking agent converted from PET named “GD-pyr-Br” and “GT-pyr-Br” | Cationic | GD-pyr-Br showed a de-inking effect at pH 12.5 and 13, while GT-pyr-Br was effective at pH 1–3 | [66] |

| PE film with brown and green solvent-based printing inks; PP with red ink | De-inking agent from waste cooking oil | Cationic | 70% de-inking effect after 15 h at pH 12 and 50 °C | [67] |

| Post-consumer LDPE film | W111+DA850 | Nonionic | Effective (70–80%) de-inking in 15 min, at 40 °C and pH 12 | [40] |

| Flexographic printed with different colors | Biosurfactant without known composition | Complete de-inking with 5% surfactant at 40 °C with brushing | [68] |

| Sample No. | Substrate | Binder | Pigment | OPV | Crosslinked Binder (y/n) | Crosslinked OPV (y/n) | Construction (Outside–Inside) |

|---|---|---|---|---|---|---|---|

| 1 | LDPE | NC | PR 57:1 | n | n | Print–Substrate | |

| 2 | LDPE | NC | PR 146 | n | n | Print–Substrate | |

| 3 | LDPE | NC | PY 13 | n | n | Print–Substrate | |

| 4 | LDPE | NC | PBk 7 | n | n | Print–Substrate | |

| 5 | LDPE | NC | PB 15:4 | n | n | Print–Substrate | |

| 6 | oPP | NC | PBk 7 | n | n | Print–Substrate | |

| 7 | LDPE | NC | PB 15:4 | NC with 13 wt.% crosslinking agent | n | y | OPV–Print–Substrate |

| 8 | LDPE | NC | PB 15:4 | NC | n | n | OPV–Print–Substrate |

| 9 | LDPE | NC | PR 146 | CAP with 31 wt.% crosslinking agent | n | y | OPV–Print–Substrate |

| 10 | oPP | NC | PB 15:4 | NC with 20 wt.% crosslinking agent | n | y | Print–OPV–Substrate |

| 11 | LDPE | PVB | PR 146 | Release lacquer | n | n | Print–Substrate |

| 12 | LDPE | PU | PR 146 | n | n | Print–Substrate | |

| 13 | LDPE | PU | PR 146 | PVB with 20 wt.% crosslinking agent | n | y | OPV–Print–Substrate |

| 14 | LDPE | Acrylate | PR 146 | n | y | y | OPV–Print–Substrate |

| No. | Surfactant | Source |

|---|---|---|

| I | No surfactant | [10] |

| II | Commercial cleaning agent (main component CTAC) | Siegwerk |

| III | W111+DA850 | [40] |

| IV | CTAB | [59,65,69] |

| V | Triton X100 | [70] |

| VI | Commercial cleaning agent for PET | [71] |

| Condition | NaOH (wt.%) | T (°C) | Surfactant (wt.%) | Retention Time (min) | Remarks |

|---|---|---|---|---|---|

| A | 0 | 40 | 0.25 | 15 | State of the art |

| B | 1 | 55 | 0.25 | 15 | “Middle point” condition |

| C | 2 | 70 | 0.25 | 15 | Hot washing condition |

| D | 5 | 80 | 0.25 | 60 | Only samples showed no de-inking effect under A–C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, J.; Luo, C.; Wittkowski, C.; Fehr, I.; Chong, Z.; Kitzberger, M.; Alassali, A.; Zhao, X.; Leineweber, R.; Feng, Y.; et al. Screening the Impact of Surfactants and Reaction Conditions on the De-Inkability of Different Printing Ink Systems for Plastic Packaging. Polymers 2023, 15, 2220. https://doi.org/10.3390/polym15092220

Guo J, Luo C, Wittkowski C, Fehr I, Chong Z, Kitzberger M, Alassali A, Zhao X, Leineweber R, Feng Y, et al. Screening the Impact of Surfactants and Reaction Conditions on the De-Inkability of Different Printing Ink Systems for Plastic Packaging. Polymers. 2023; 15(9):2220. https://doi.org/10.3390/polym15092220

Chicago/Turabian StyleGuo, Jinyang, Cong Luo, Christian Wittkowski, Ingo Fehr, Zhikai Chong, Magdalena Kitzberger, Ayah Alassali, Xuezhi Zhao, Ralf Leineweber, Yujun Feng, and et al. 2023. "Screening the Impact of Surfactants and Reaction Conditions on the De-Inkability of Different Printing Ink Systems for Plastic Packaging" Polymers 15, no. 9: 2220. https://doi.org/10.3390/polym15092220

APA StyleGuo, J., Luo, C., Wittkowski, C., Fehr, I., Chong, Z., Kitzberger, M., Alassali, A., Zhao, X., Leineweber, R., Feng, Y., & Kuchta, K. (2023). Screening the Impact of Surfactants and Reaction Conditions on the De-Inkability of Different Printing Ink Systems for Plastic Packaging. Polymers, 15(9), 2220. https://doi.org/10.3390/polym15092220