Tribological Investigation of Glass Fiber Reinforced Polymer Composites against 52100 Chrome Alloy Steel Based on ELECTRE Decision-Making Method

Abstract

:1. Introduction

2. Materials and Method

2.1. Manufacturing and Properties for GFRP Samples

2.2. Mechanical Properties of GFRP Samples

2.3. The Ball Sample

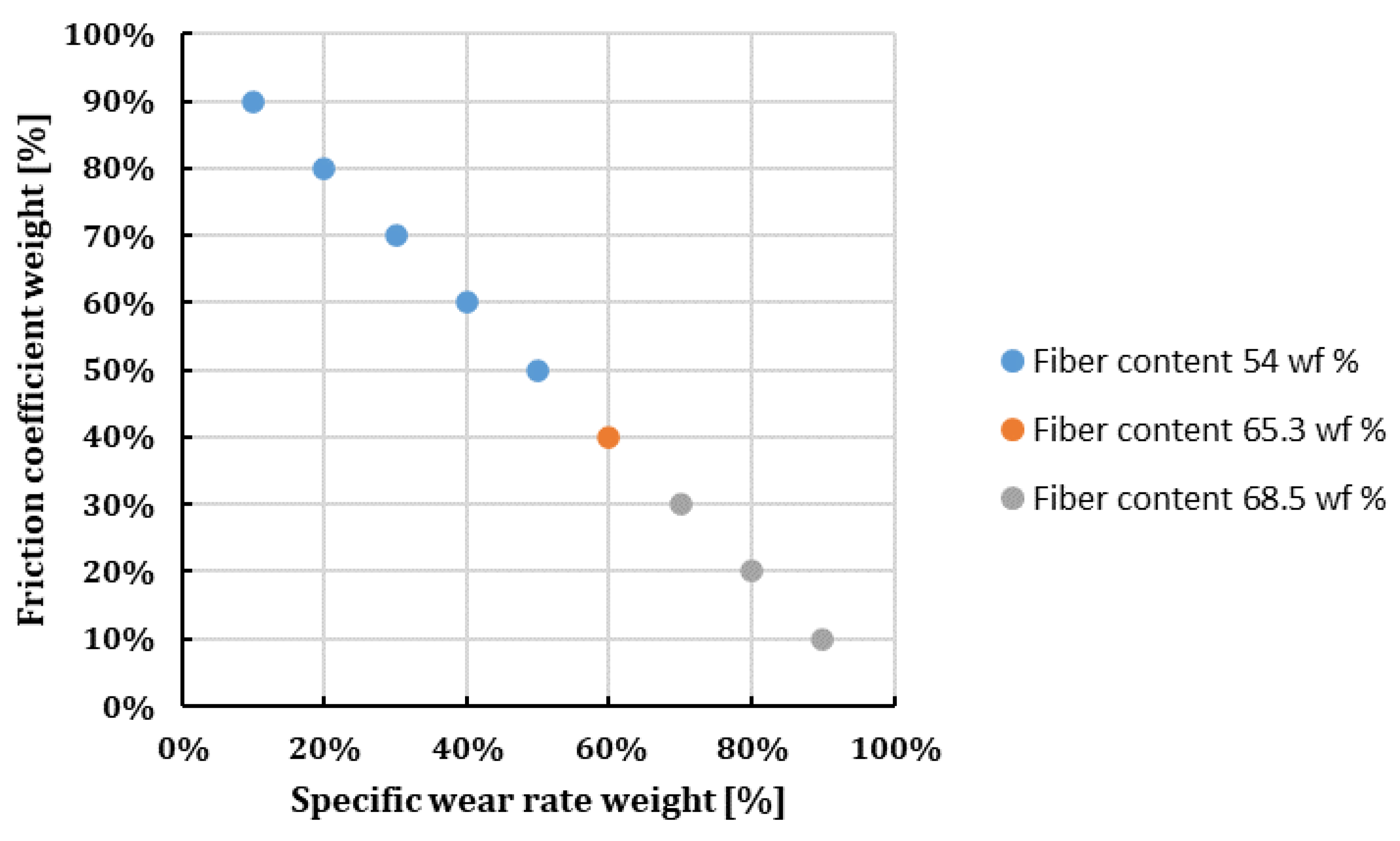

2.4. ELECTRE Decision-Making Method

- -

- for a maximum criterion:

- -

- for a minimum criterion:

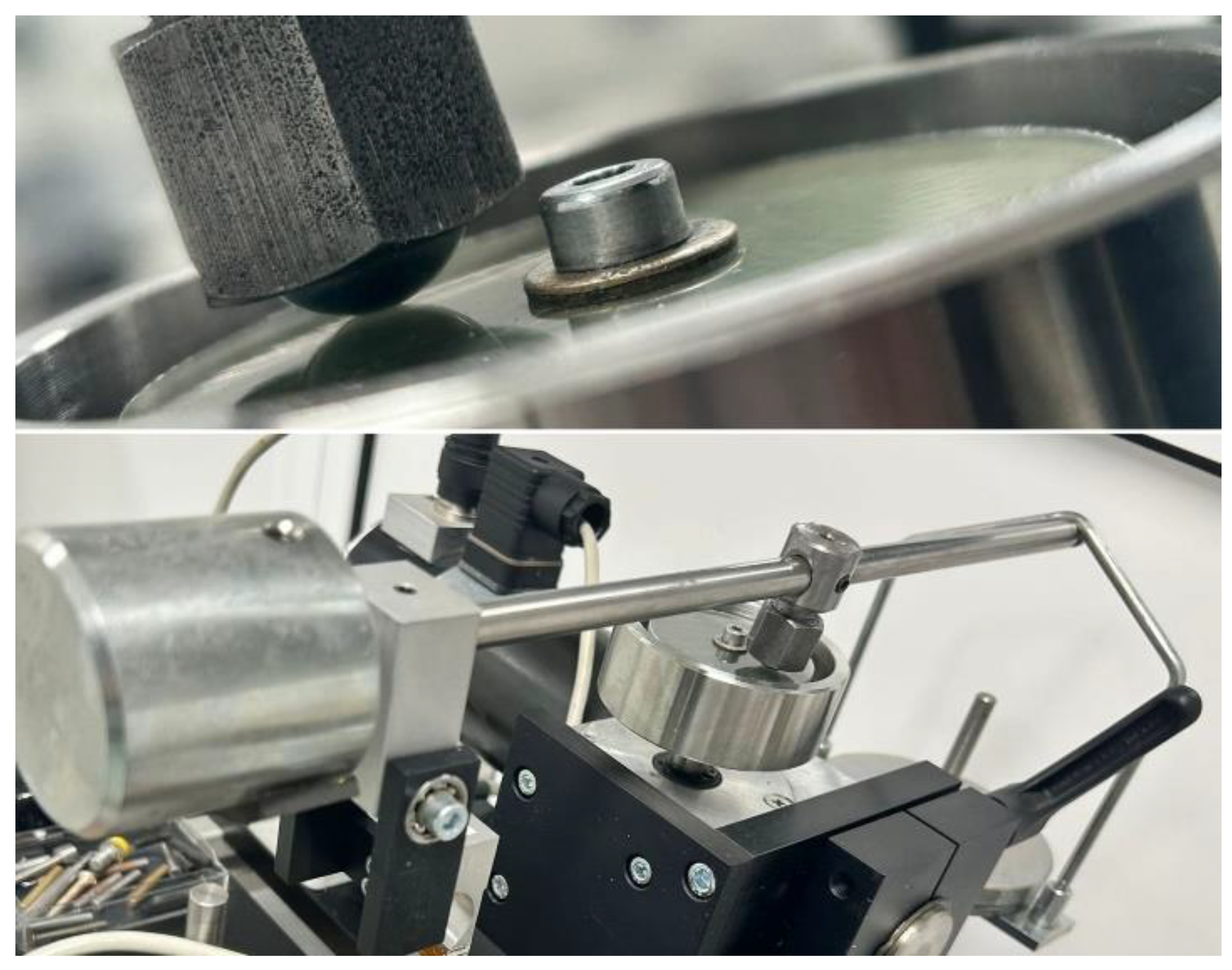

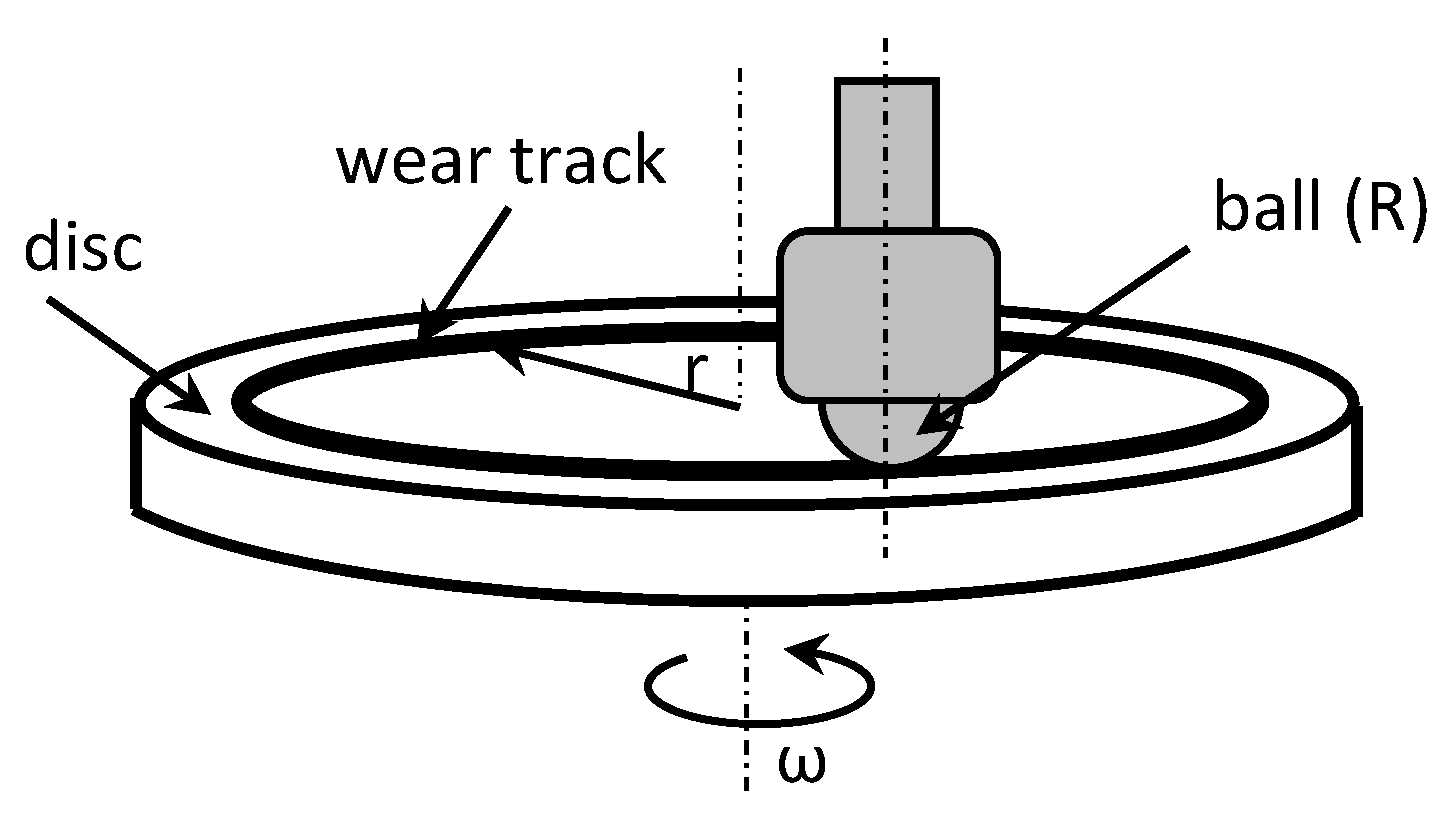

3. Experimental Method and Device

4. Experimental Results and Discussion

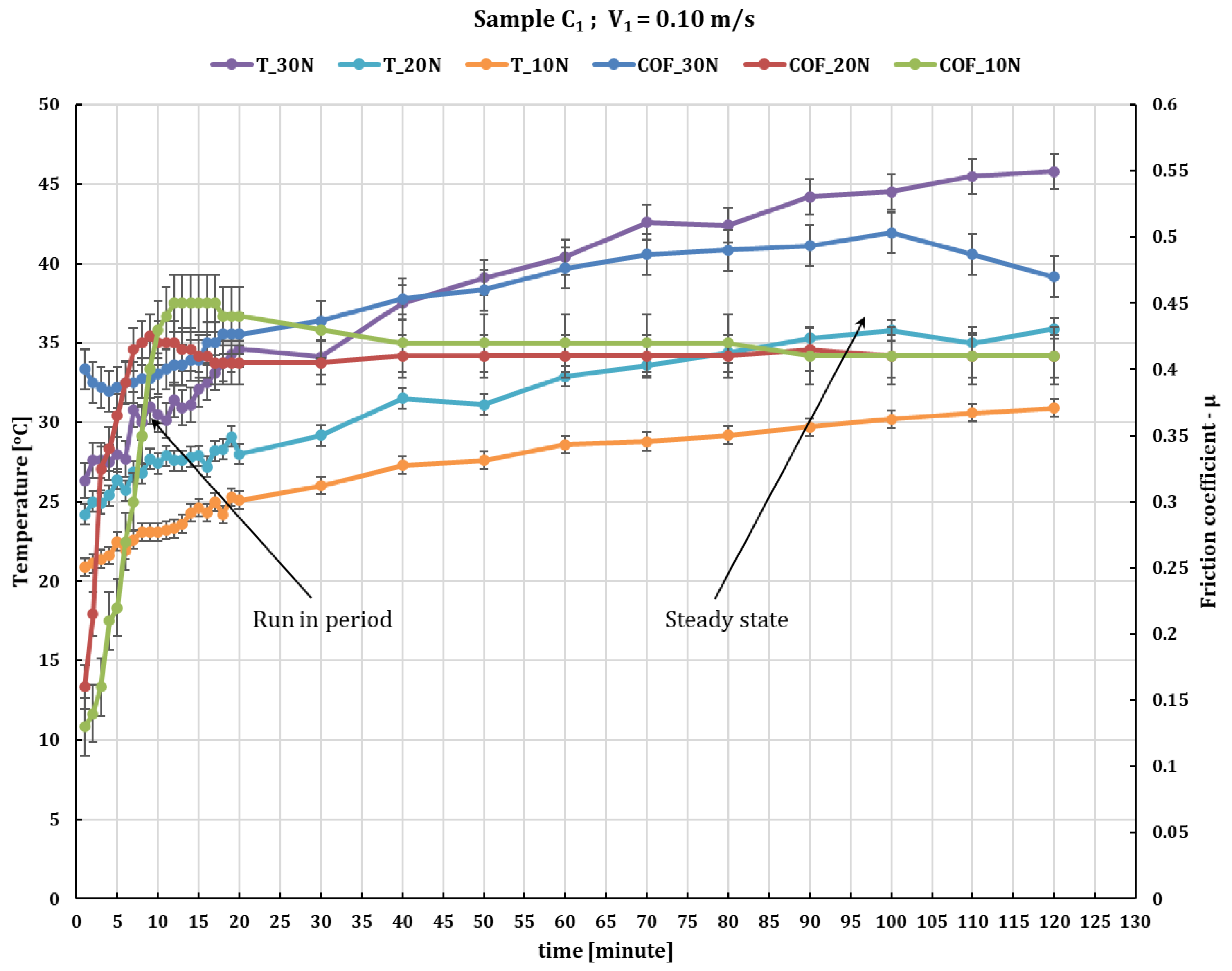

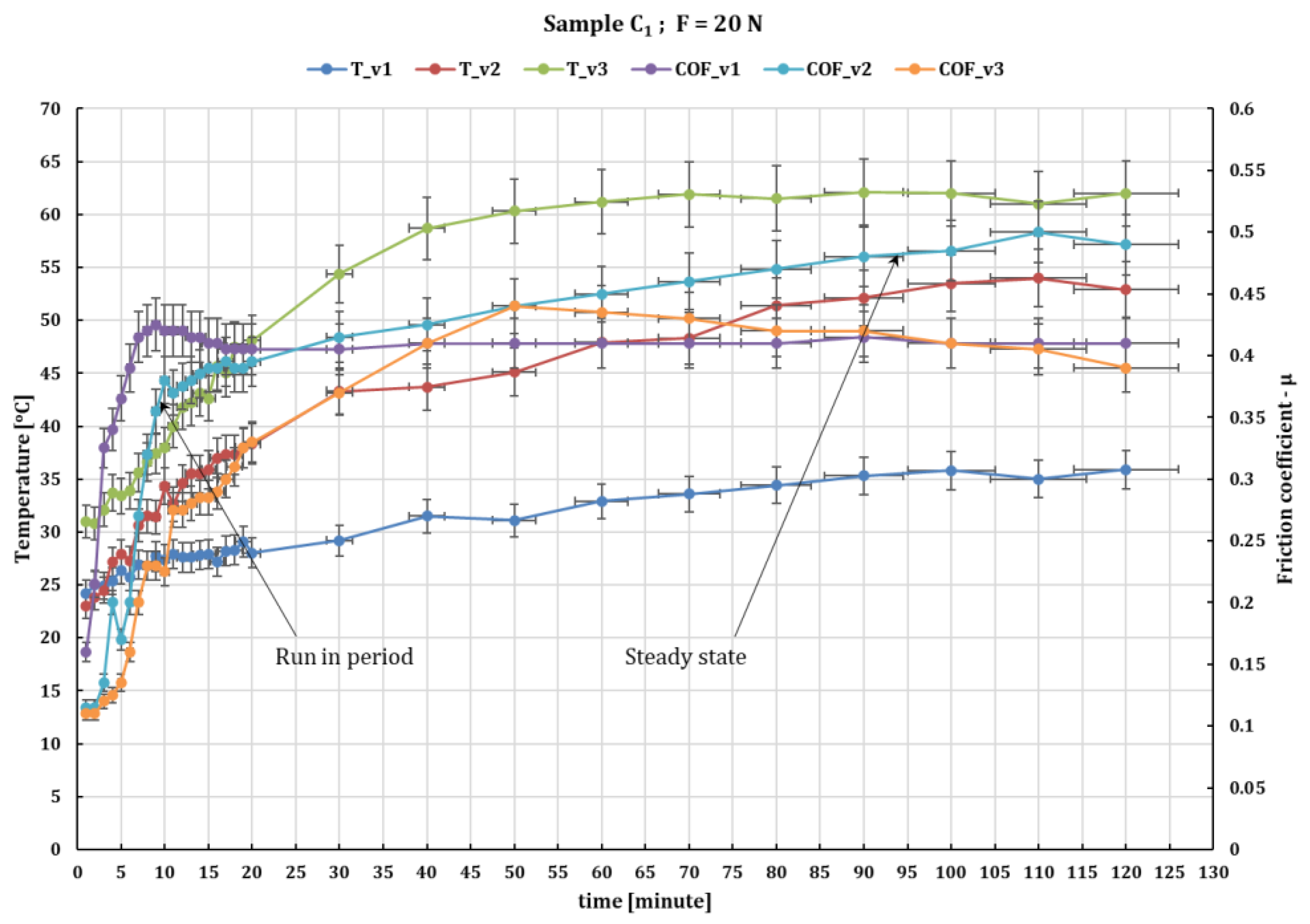

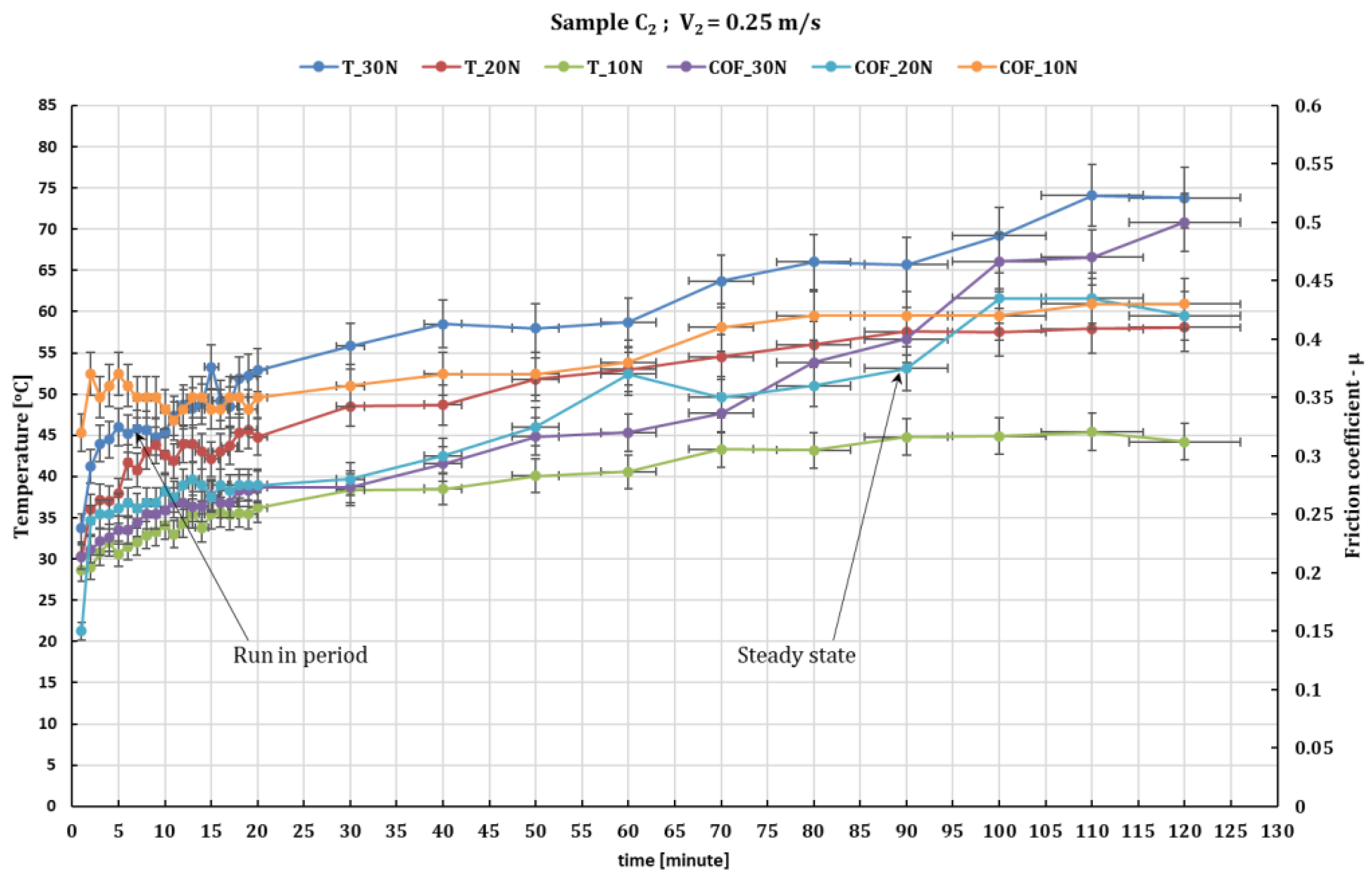

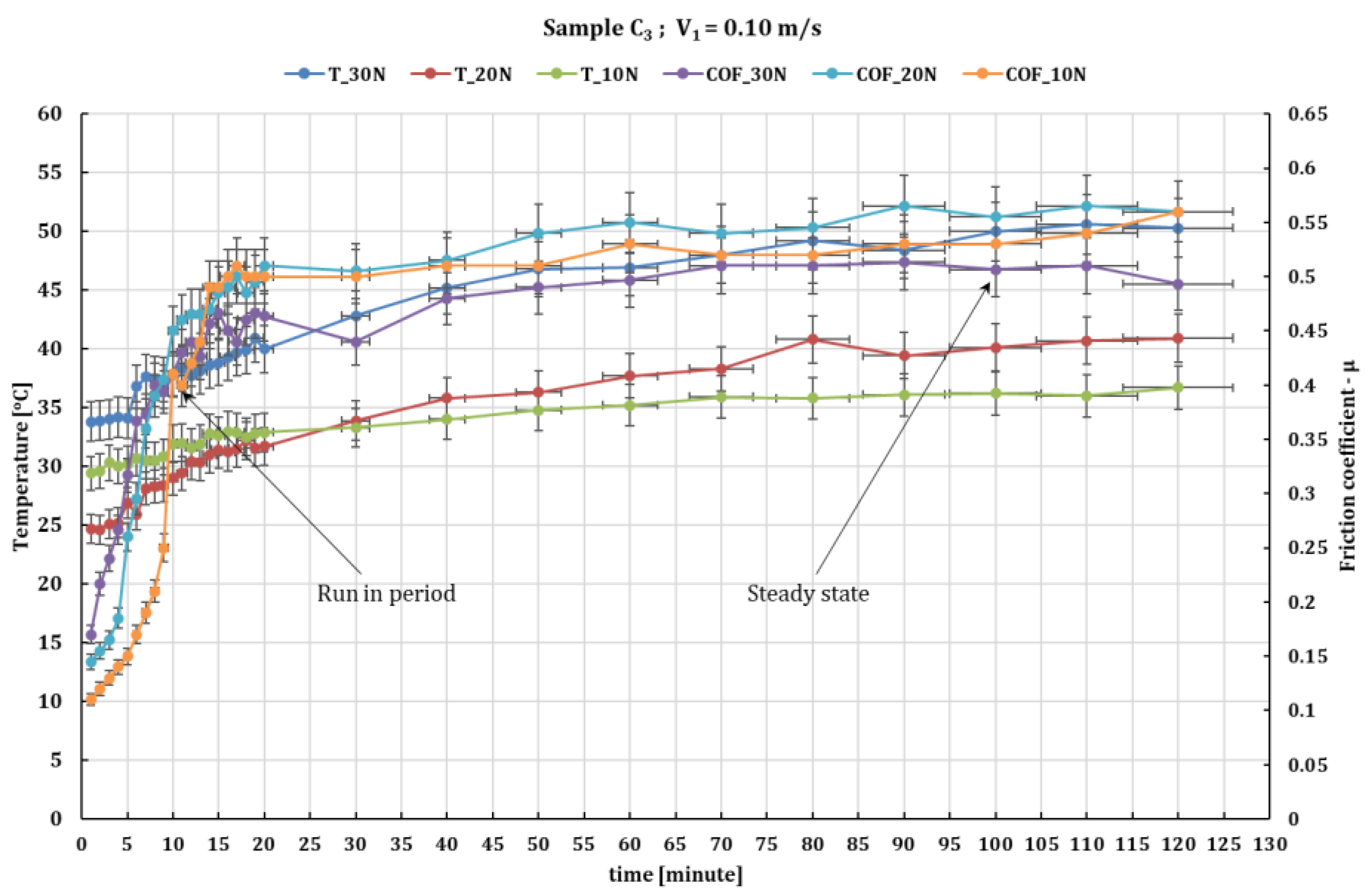

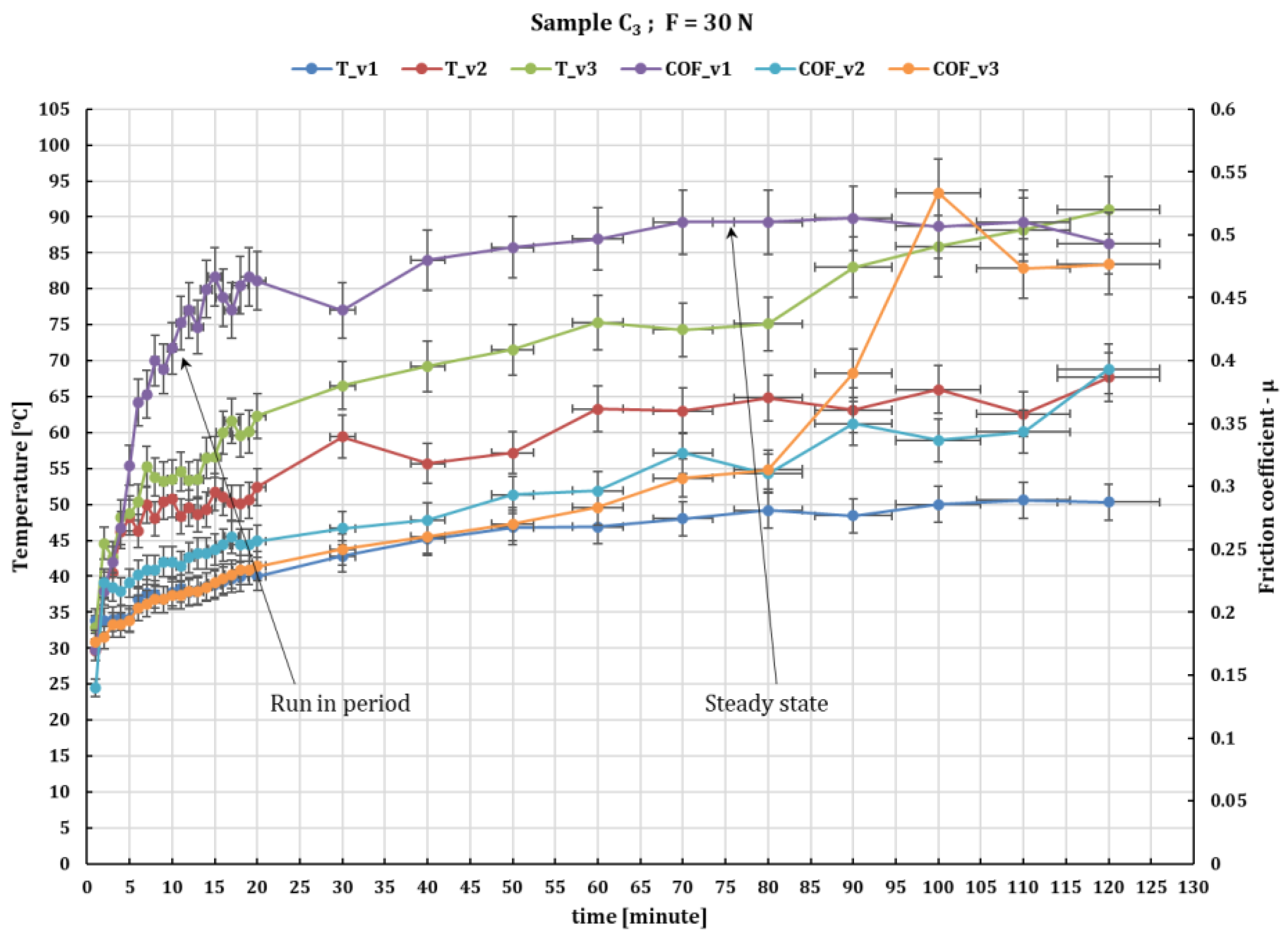

4.1. Sliding Speed Effect and Applied Load on Friction and Wear

- -

- On one side, the accumulation of debris: debris and wear particles may accumulate on the rubbing surfaces as the rubbing continues. This accumulation can lead to an increase in friction as the debris interferes with the smooth movement of the surfaces;

- -

- And on the other hand, the thermal effects: prolonged rubbing generates heat due to friction. The temperature increase can influence the material properties, potentially leading to changes in the COF. This is especially true if the temperature reaches a point where it causes alterations in the material’s structure or induces other thermal effects.

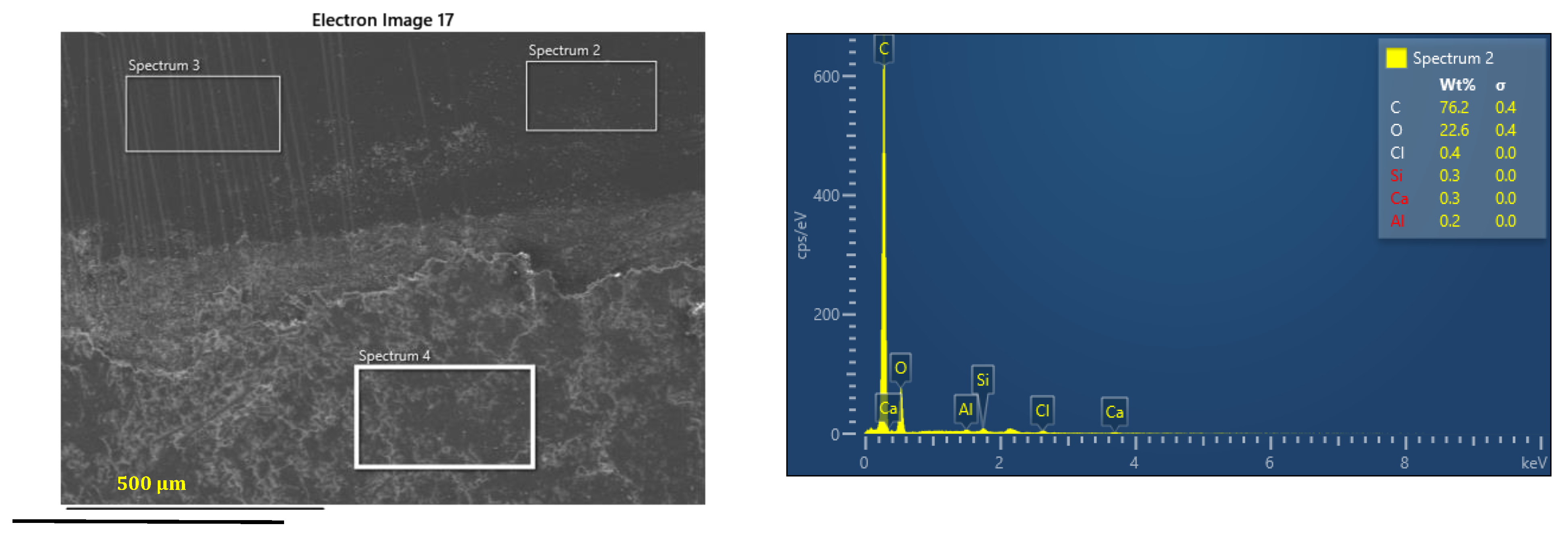

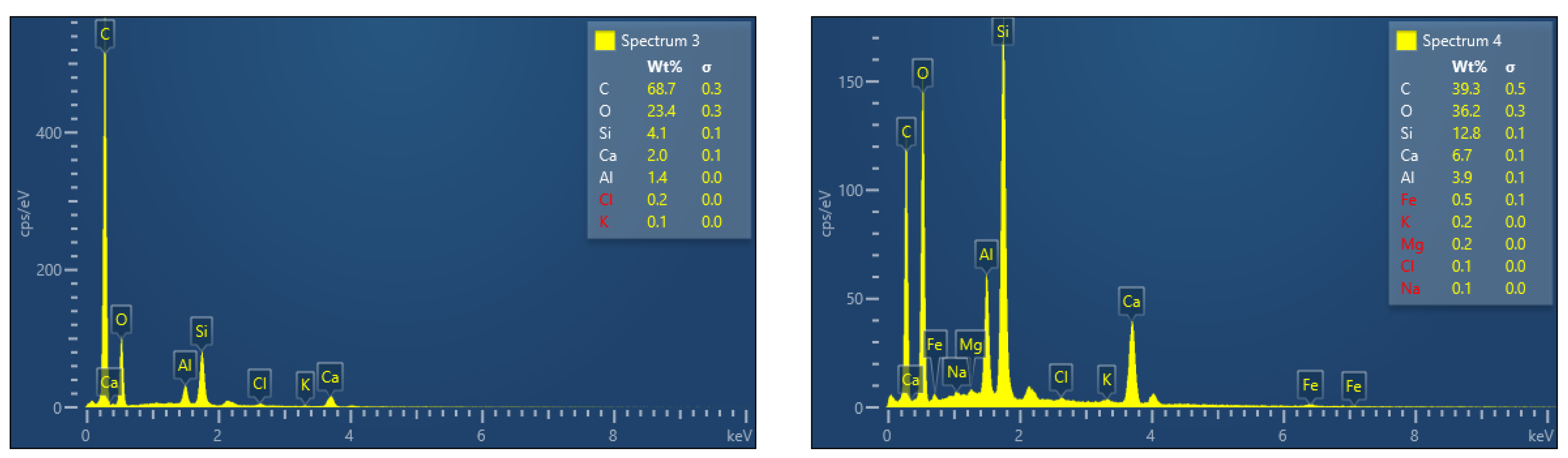

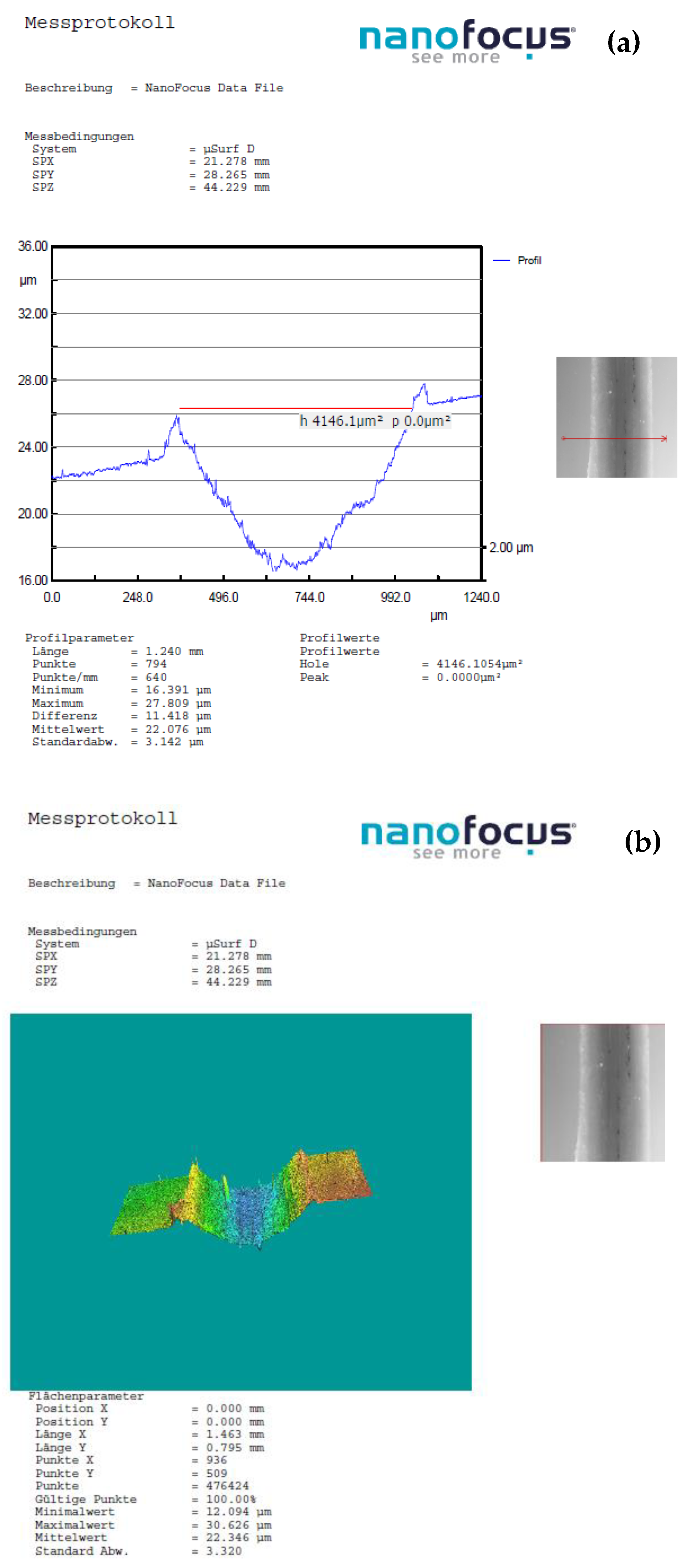

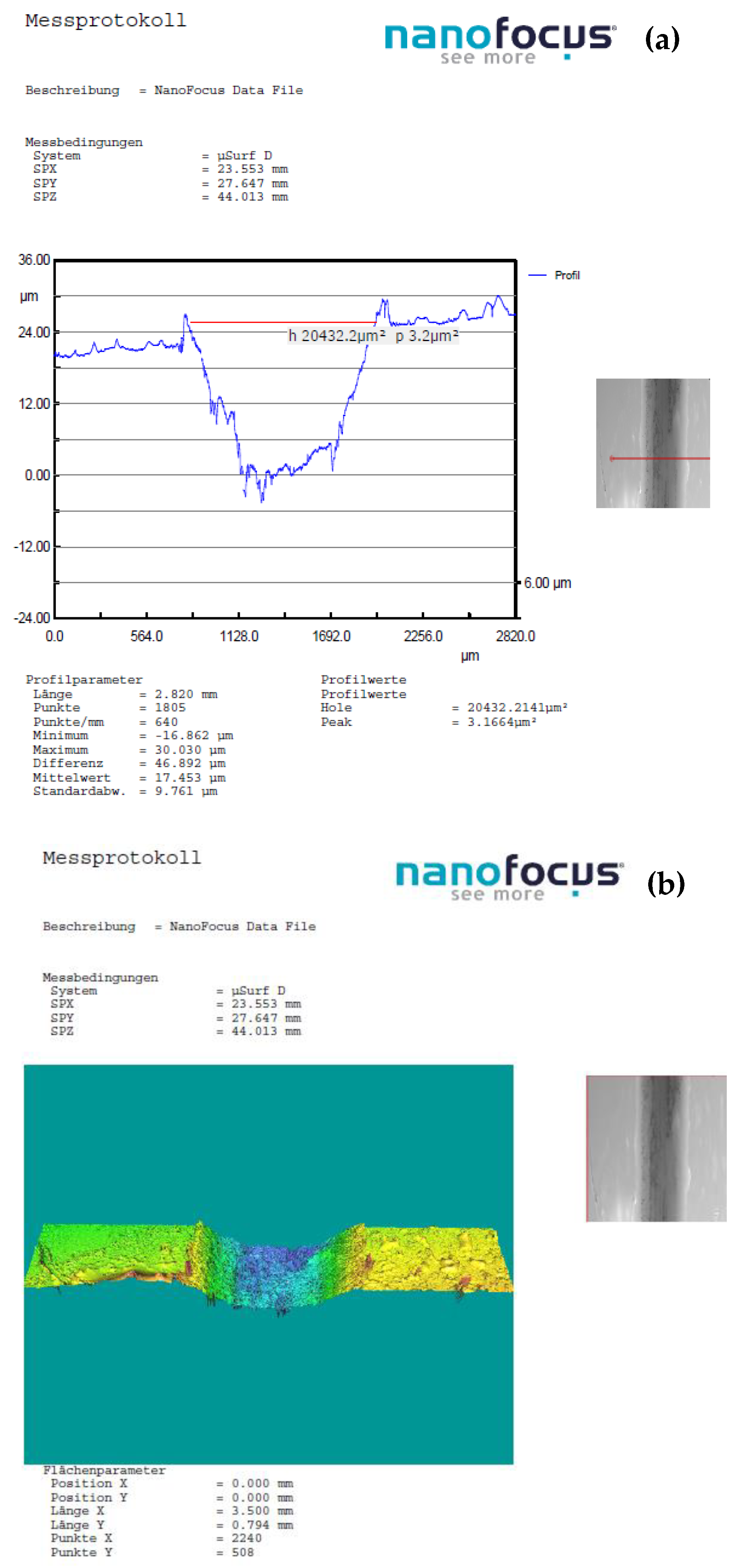

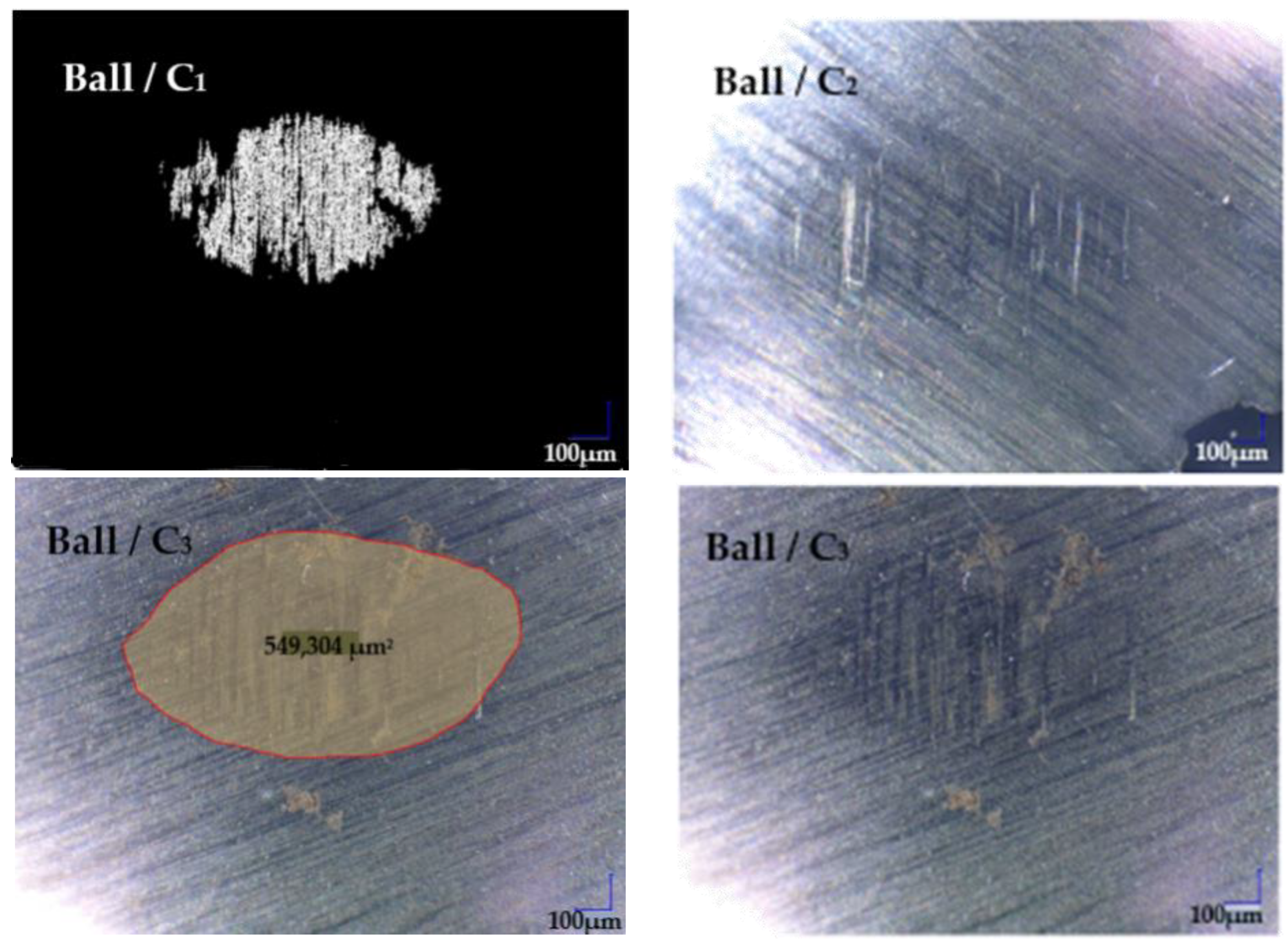

4.2. Wear Pattern and 3D Optical Scan of Used Ball and GFRP Specimens

- -

- Chromium alloy steel is known for its hardness and wear resistance. The surface of the steel balls is sufficiently hard; it may resist deformation and wear, leading to only minor scratches. The material may also have a good balance of hardness and toughness, allowing it to absorb and resist wear without significant damage;

- -

- The properties of the chrome alloy steel are compatible with the glass fiber composite, resulting in reduced wear. This could include similar coefficients of thermal expansion, which can help minimize thermal stresses;

- -

- And the thermal reactions occurring at the interface between the steel and composite materials may form protective layers that reduce wear (Figure 10).

5. Design of Experiments

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Sathishkumar, T.P.; Satheeshkumar, S.; Naveen, J. Glass fiber-reinforced polymer composites—A review. J. Reinf. Plast. Compos. 2014, 33, 1258–1275. [Google Scholar] [CrossRef]

- Arun, A.; Singh, K.K. Friction and wear behaviour of glass fibre reinforced polymer composite (GFRP) under dry and oil lubricated environmental conditions. Mater. Today Proc. 2017, 4, 7285–7292. [Google Scholar] [CrossRef]

- El-Tayeb, N.S.M.; Yousif, B.F.; Yap, T.C. An investigation on worn surfaces of chopped glass fibre reinforced polyester through SEM observations. Tribol. Int. 2008, 41, 331–340. [Google Scholar] [CrossRef]

- Birleanu, C.; Pustan, M.; Cioaza, M.; Bere, P.; Contiu, G.; Dudescu, M.C.; Filip, D. Tribo-Mechanical Investigation of Glass Fiber Reinforced Polymer Composites under Dry Conditions. Polymers 2023, 15, 2733. [Google Scholar] [CrossRef] [PubMed]

- Manoharan, S.; Vijay, R.; Singaravelu, D.L.; Krishnaraj, S.; Suresha, B. Tribological characterization of recycled basalt-aramid fiber reinforced hybrid friction composites using grey-based Taguchi approach. Mater. Res. Express 2019, 6, 065301. [Google Scholar] [CrossRef]

- Birleanu, C.; Pustan, M.; Pop, G.; Cioaza, M.; Popa, F.; Lazarescu, L.; Contiu, G. Experimental Investigation of the Tribological Behaviors of Carbon Fiber Reinforced Polymer Composites under Boundary Lubrication. Polymers 2022, 14, 3716. [Google Scholar] [CrossRef] [PubMed]

- Erden, S.; Sever, K.; Seki, Y.; Sarikanat, M. Enhancement of the mechanical properties of glass/polyester composites via matrix modification glass/polyester composite siloxane matrix modification. Fibers Polym. 2010, 11, 732–737. [Google Scholar] [CrossRef]

- Sampathkumaran, P.; Seetharamu, S.; Vynatheya, S.; Murali, A.; Kumar, R.K. SEM observations of the effects of velocity and load on the sliding wear characteristics of glass fabric–epoxy composites with different fillers. Wear 2000, 237, 20–27. [Google Scholar]

- Ando, M.; Sukumaran, J. Effect on Friction for Different Parameters in Roll–Slip of Polyamide–Steel Nonconformal Contacts. Tribol. Trans. 2012, 55, 109–116. [Google Scholar] [CrossRef]

- Autay, R.; Missaoui, S.; Mars, J.; Dammak, F. Mechanical and tribological study of short glass fiber-reinforced PA 66. Polym. Polym. Compos. 2019, 27, 587–596. [Google Scholar] [CrossRef]

- Srinath, G.; Gnanamoorthy, R. Effect of short fibre reinforcement on the friction and wear behaviour of nylon 66. Appl. Compos. Mater. 2005, 12, 369–383. [Google Scholar] [CrossRef]

- Kim, S.S.; Shin, M.W.; Jang, H. Tribological properties of short glass fiber reinforced polyamide 12 sliding on medium carbon steel. Wear 2012, 274, 34–42. [Google Scholar] [CrossRef]

- Byett, J.H.; Allen, C. Dry sliding wear behaviour of polyamide 66 and polycarbonate composites. Tribol. Int. 1992, 25, 237–246. [Google Scholar] [CrossRef]

- Jojith, R.; Sam, M.; Radhika, N. Recent advances in tribological behavior of functionally graded composites: A review. Eng. Sci. Technol. Int. J. 2022, 25, 100999. [Google Scholar] [CrossRef]

- Srivastava, J.P.; Kumar, P. Introduction to Glass Fiber-Based Composites and Structures. In Natural and Synthetic Fiber Reinforced Composites: Synthesis, Properties and Applications; Wiley-VCH: Hoboken, NJ, USA, 2022; pp. 1–16. [Google Scholar]

- Huang, C.T.; Chen, X.W.; Fu, W.W. Investigation on the fiber orientation distributions and their influence on the mechanical property of the co-injection molding products. Polymers 2019, 12, 24. [Google Scholar] [CrossRef] [PubMed]

- Udo, M.; Babalola, P.; Ongbali, S.; Banjo, S.; Obasa, V.; Adelore, J. Effect of Fibre Glass Addition on the Mechanical Properties of Glass Fibre Reinforced Polymer (GFRP) Composite. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1107, p. 012012. [Google Scholar]

- Zhao, Z.-K.; Du, S.-S.; Li, F.; Xiao, H.-M.; Li, Y.-Q.; Zhang, W.-G.; Hu, N.; Fu, S.-Y. Mechanical and tribological properties of short glass fiber and short carbon fiber reinforced polyethersulfone composites: A comparative study. Compos. Commun. 2018, 8, 1–6. [Google Scholar] [CrossRef]

- Alhazmi, W.; Jazaa, Y.; Althahban, S.; Mousa, S.; Abu-Sinna, A.; Abd-Elhady, A.; Sallam, H.E.-D.; Atta, M. Mechanical and tribological behavior of functionally graded unidirectional glass fiber-reinforced epoxy composites. Polymers 2022, 14, 2057. [Google Scholar] [CrossRef] [PubMed]

- El-Tayeb, N.S.; Gadelrab, R.M. Friction and wear properties of E-glass fiber reinforced epoxy composites under different sliding contact conditions. Wear 1996, 192, 112–117. [Google Scholar] [CrossRef]

- Crișan, H.G.; Șerdean, F.; Bîrleanu, C.; Pustan, M.; Crișan, O.A. An Efficient Method for Testing the Quality of Drinking-Water Filters Used for Home Necessities. Int. J. Environ. Res. Public Health 2022, 19, 4085. [Google Scholar] [CrossRef] [PubMed]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2014.

- ASTM D790-03; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM: West Conshohocken, PA, USA, 2003.

- Kukureka, S.N.; Hooke, C.J.; Rao, M.; Liao, P.; Chen, Y.K. The effect of fibre reinforcement on the friction and wear of polyamide 66 under dry rolling–sliding contact. Tribol. Int. 1999, 32, 107–116. [Google Scholar] [CrossRef]

| Specimen Type | Flexure Stress (MPa) | Flexure Strain (%) | E-Modulus (MPa) |

|---|---|---|---|

| GFRP 68.5% | 415.5 (21.5) | 3.1 (0.13) | 18,218 (392) |

| GFRP 65.3% | 388.6 (37) | 2.4 (0.25) | 21,009 (484) |

| GFRP 54% | 464.8 (11.5) | 3.8 (0.16) | 14,935 (199) |

| Specimen Type | Tensile Strength (MPa) | Tensile Strain at Tensile Strength (mm/mm) | E-Modulus (MPa) |

|---|---|---|---|

| GFRP 68.5% | 480.1 (26) | 2.9 (0.15) | 22,182 (253) |

| GFRP 65.3% | 376.57 (24.5) | 2.6 (0) | 18,721 (316) |

| GFRP 54% | 301.8 (18) | 2.85 (0) | 12,602 (301) |

| Specimen Type | C1-GFRP 68.5% | C2-GFRP 65.3% | C3-GFRP 54% |

|---|---|---|---|

| Hardness HR-30Tscale (MPa) | 47.1 | 41.5 | 22.4 |

| Equivalent HRB scale (MPa) | 46 | 38 | 11 |

| Roughness Ra (µm) | 0.37 | 0.34 | 0.069 |

| Ball Type (12.7 mm) | Hardness HRC Scale | Compressive Strength (MPa) | Yield Strength (MPa) | Young’s Modulus (GPa) | Poisson’s Ratio | Roughness Ra (µm) |

|---|---|---|---|---|---|---|

| 52100 Chrome Alloy Steel ρ = 7.81 g/cm3 | 54–58 | 2100–2200 | 2000 | 200 | 0.3 | 0.282–0.30 |

| Criteria | Cr1 | Cr2 | ... | Crj | ... | Crn |

|---|---|---|---|---|---|---|

| Weights | w1 | w2 | ... | wj | ... | wn |

| Options | ||||||

| O1 | o11 | o12 | ... | o1j | ... | o1n |

| O2 | o21 | o22 | ... | o23 | ... | o2n |

| ... | ... | ... | ||||

| Oi | oi1 | oi2 | ... | oij | ... | oin |

| ... | ... | ... | ||||

| Om | om1 | om2 | ... | om3 | ... | omn |

| Factor | Description | Level I | Level II | Level III |

|---|---|---|---|---|

| F | Normal load (N) | 10 | 20 | 30 |

| v | Sliding velocity (m s−1) | 0.1 | 0.25 | 0.36 |

| C | Fiber content (wt%) * | 68.5% | 65.3% | 54% |

| Experimental Parameters | Optimizing Parameters | ||||

|---|---|---|---|---|---|

| Exp.no. | Applied Load F (N) | Sliding Speed v (ms−1) | Fiber Content C (wt%) | Specific Wear Rate K [10−⁵ mm3 × (Nm)−1] | Coefficient of Friction (µ) Average of the Last 60 min |

| 1 | 10 | 0.1 | 68.5 | 1.5488 | 0.43 |

| 2 | 10 | 0.1 | 65.3 | 3.42 | 0.5 |

| 3 | 10 | 0.1 | 54 | 5.758 | 0.54 |

| 4 | 10 | 0.25 | 68.5 | 6.4267 | 0.38 |

| 5 | 10 | 0.25 | 65.3 | 12.2667 | 0.39 |

| 6 | 10 | 0.25 | 54 | 20.985 | 0.4 |

| 7 | 10 | 0.36 | 68.5 | 9.59 | 0.34 |

| 8 | 10 | 0.36 | 65.3 | 16.0216 | 0.38 |

| 9 | 10 | 0.36 | 54 | 14.90746 | 0.33 |

| 10 | 20 | 0.1 | 68.5 | 11.456 | 0.41 |

| 11 | 20 | 0.1 | 65.3 | 14.1887 | 0.48 |

| 12 | 20 | 0.1 | 54 | 15.208 | 0.54 |

| 13 | 20 | 0.25 | 68.5 | 6.12 | 0.42 |

| 14 | 20 | 0.25 | 65.3 | 32.737 | 0.43 |

| 15 | 20 | 0.25 | 54 | 24.906 | 0.28 |

| 16 | 20 | 0.36 | 68.5 | 4.42 | 0.35 |

| 17 | 20 | 0.36 | 65.3 | 23.291 | 0.36 |

| 18 | 20 | 0.36 | 54 | 26.0193 | 0.37 |

| 19 | 30 | 0.1 | 68.5 | 14.4255 | 0.48 |

| 20 | 30 | 0.1 | 65.3 | 18.2557 | 0.49 |

| 21 | 30 | 0.1 | 54 | 21.6711 | 0.51 |

| 22 | 30 | 0.25 | 68.5 | 14.34102 | 0.33 |

| 23 | 30 | 0.25 | 65.3 | 23.727 | 0.36 |

| 24 | 30 | 0.25 | 54 | 32.3849 | 0.37 |

| 25 | 30 | 0.36 | 68.5 | 10.4919 | 0.47 |

| 26 | 30 | 0.36 | 65.3 | 19.1906 | 0.48 |

| 27 | 30 | 0.36 | 54 | 14.488 | 0.49 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Birleanu, C.; Cioaza, M.; Serdean, F.; Pustan, M.; Bere, P.; Contiu, G. Tribological Investigation of Glass Fiber Reinforced Polymer Composites against 52100 Chrome Alloy Steel Based on ELECTRE Decision-Making Method. Polymers 2024, 16, 62. https://doi.org/10.3390/polym16010062

Birleanu C, Cioaza M, Serdean F, Pustan M, Bere P, Contiu G. Tribological Investigation of Glass Fiber Reinforced Polymer Composites against 52100 Chrome Alloy Steel Based on ELECTRE Decision-Making Method. Polymers. 2024; 16(1):62. https://doi.org/10.3390/polym16010062

Chicago/Turabian StyleBirleanu, Corina, Mircea Cioaza, Florina Serdean, Marius Pustan, Paul Bere, and Glad Contiu. 2024. "Tribological Investigation of Glass Fiber Reinforced Polymer Composites against 52100 Chrome Alloy Steel Based on ELECTRE Decision-Making Method" Polymers 16, no. 1: 62. https://doi.org/10.3390/polym16010062

APA StyleBirleanu, C., Cioaza, M., Serdean, F., Pustan, M., Bere, P., & Contiu, G. (2024). Tribological Investigation of Glass Fiber Reinforced Polymer Composites against 52100 Chrome Alloy Steel Based on ELECTRE Decision-Making Method. Polymers, 16(1), 62. https://doi.org/10.3390/polym16010062