Fabrication and Performance of Continuous 316 Stainless Steel Fibre-Reinforced 3D-Printed PLA Composites

Abstract

:1. Introduction

2. Materials and Methods

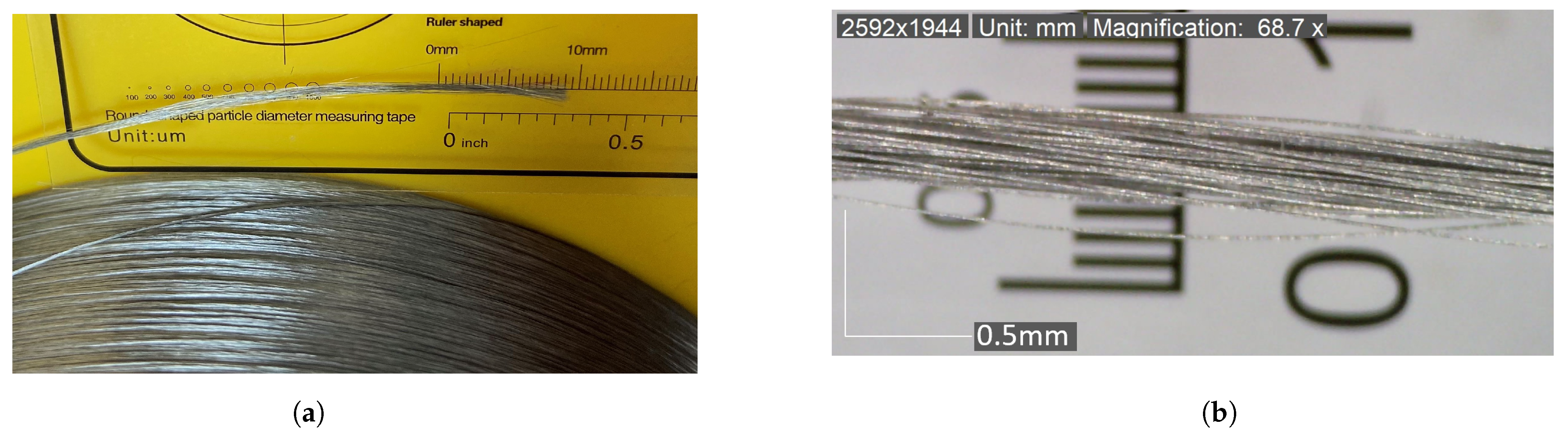

2.1. Materials

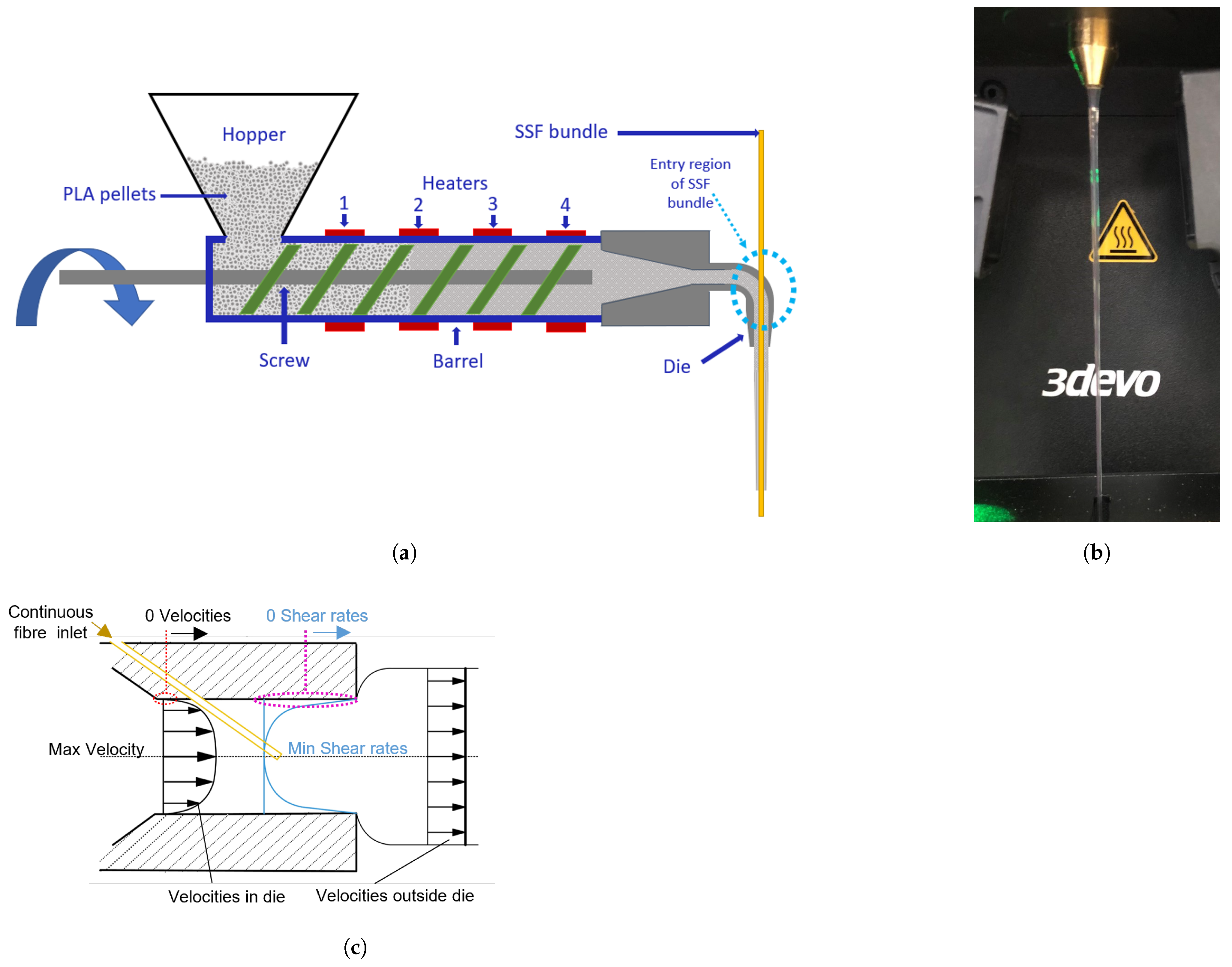

2.1.1. PLA-Reinforced SSF Filament

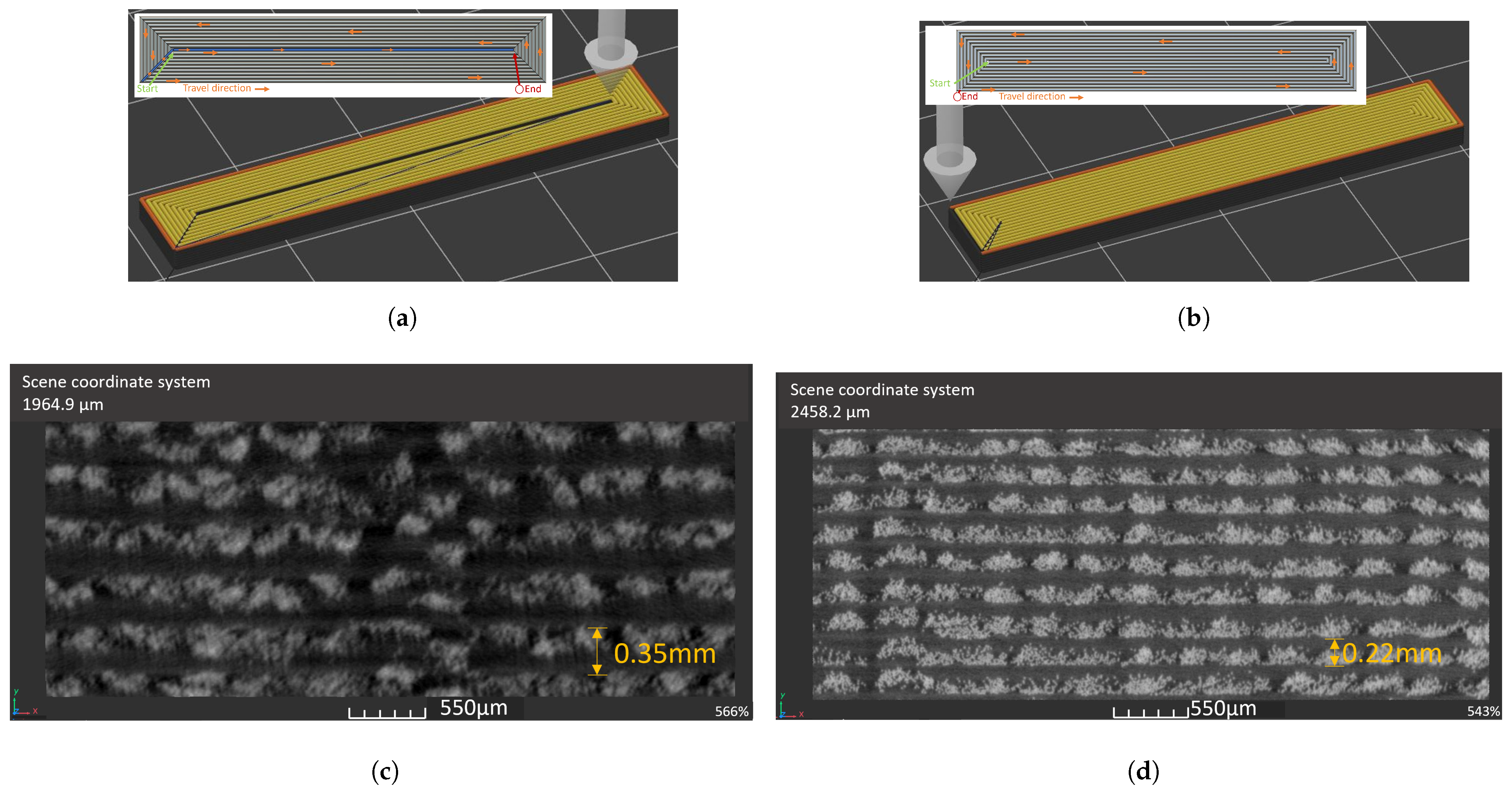

2.1.2. Three-Dimensional Printing Continuous PLA-SSF Composite Components

2.2. Composite Characterisation

2.2.1. Polymer-SSF Filament

2.2.2. Three-Dimensional Printed Composites

2.3. Mechanical Performance

2.3.1. Interlaminar Shear Strength

2.3.2. Tensile Testing

3. Results and Discussion

3.1. Filament Characterisation

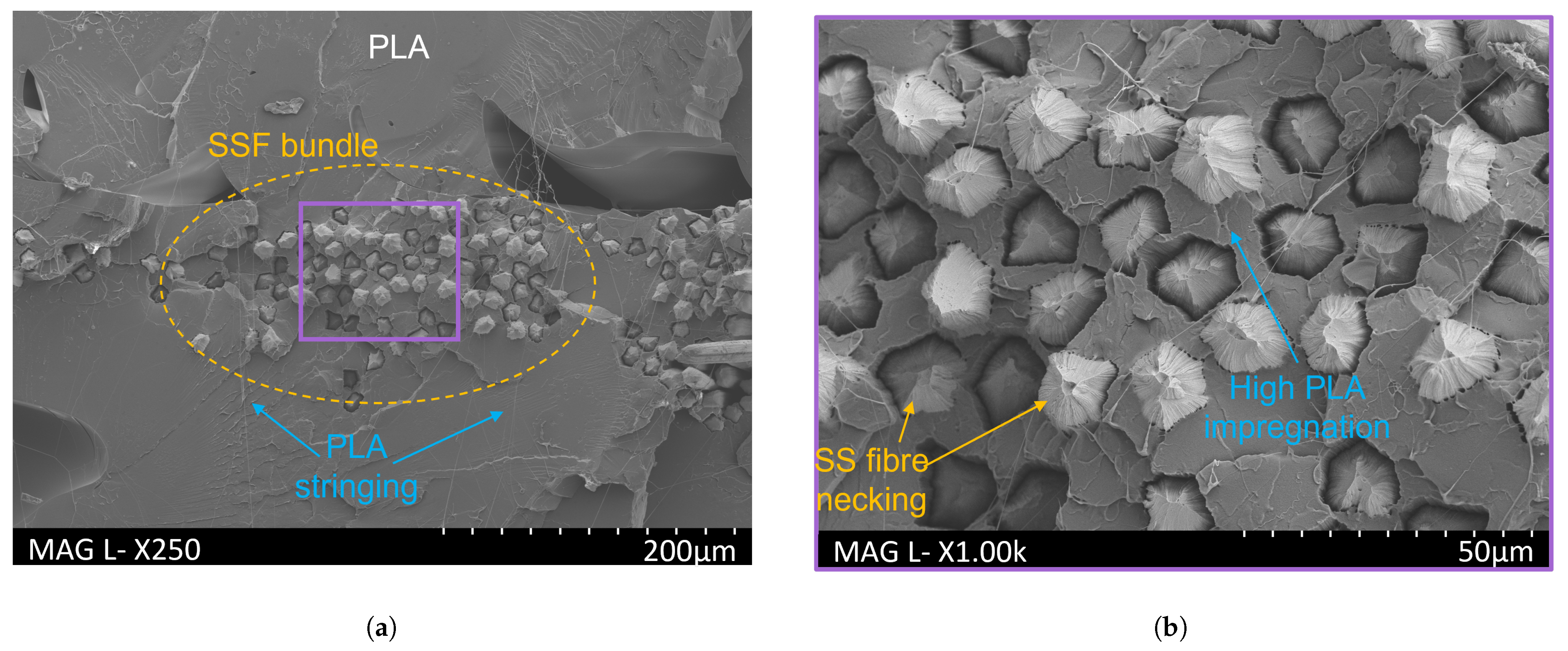

3.2. Printed Composite Evaluation

3.3. Mechanical Testing

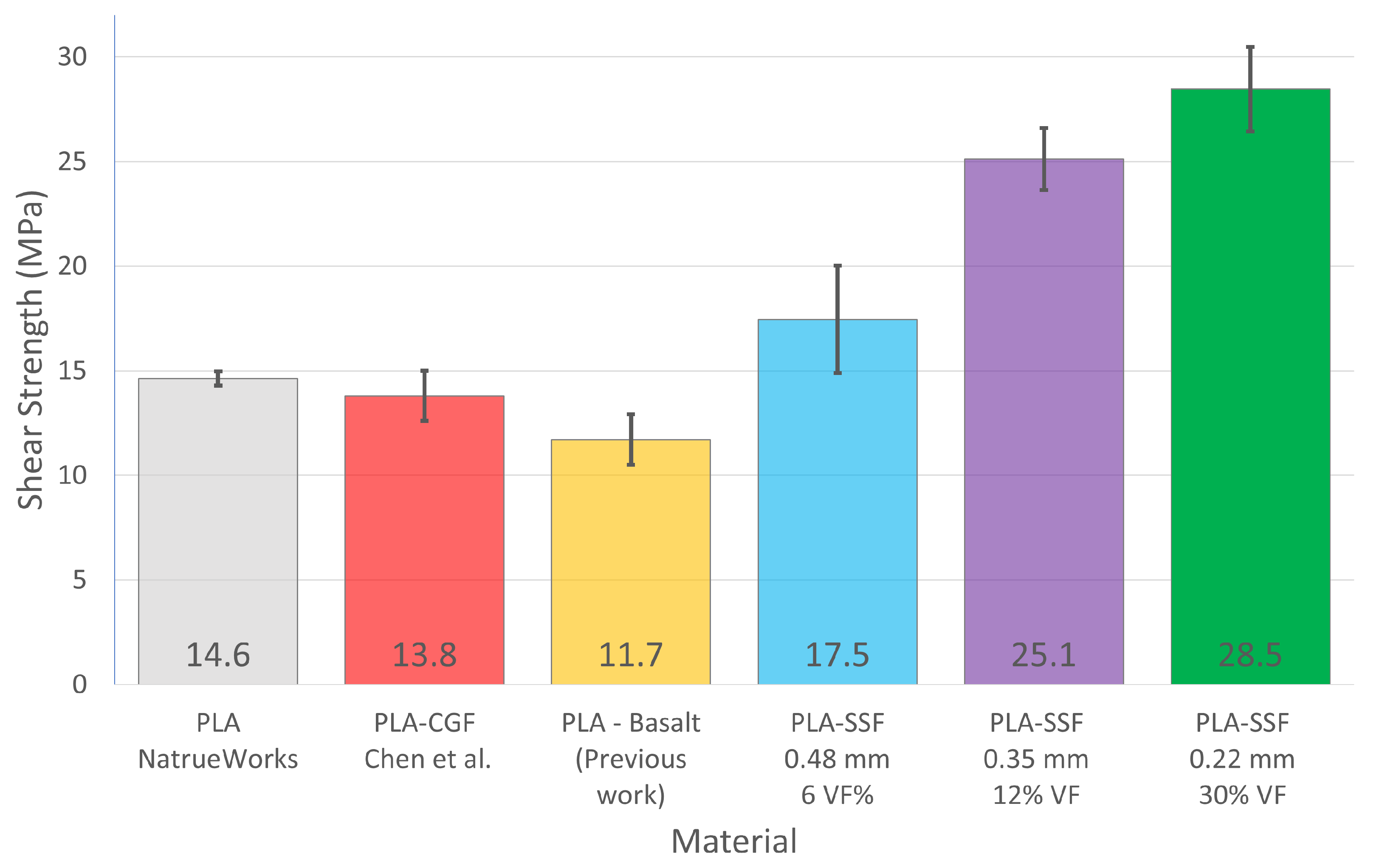

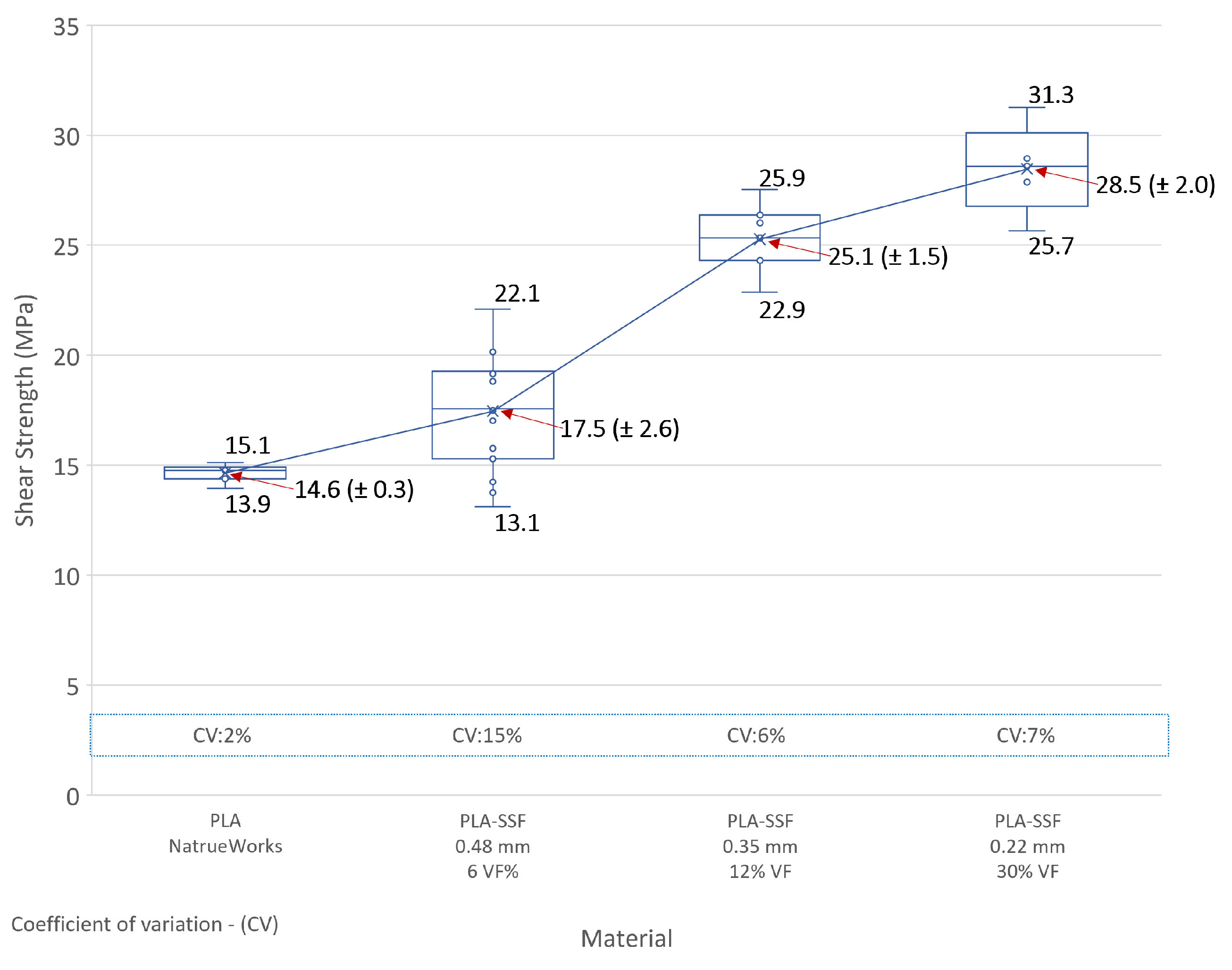

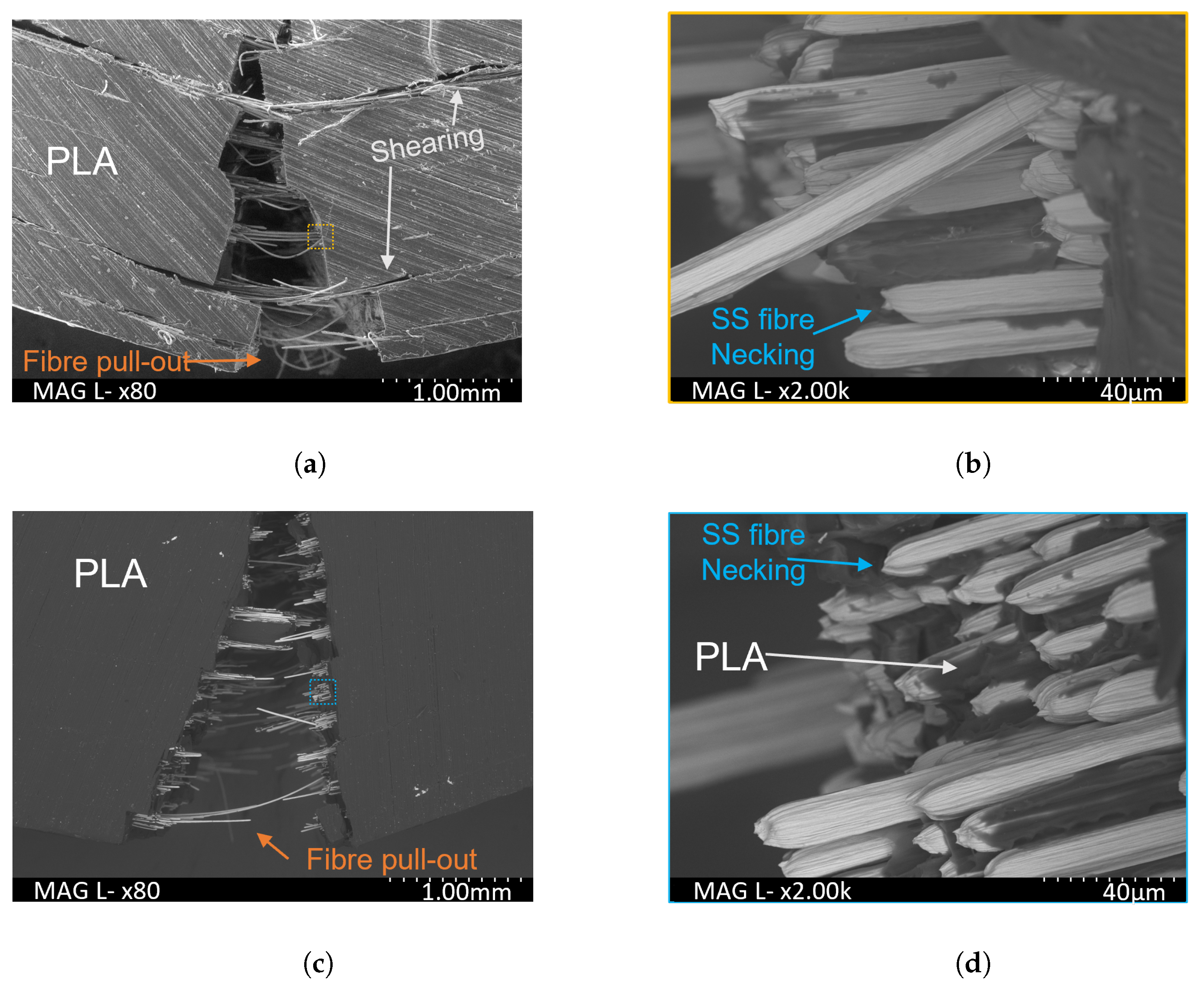

3.3.1. Interlaminar Shear Strength

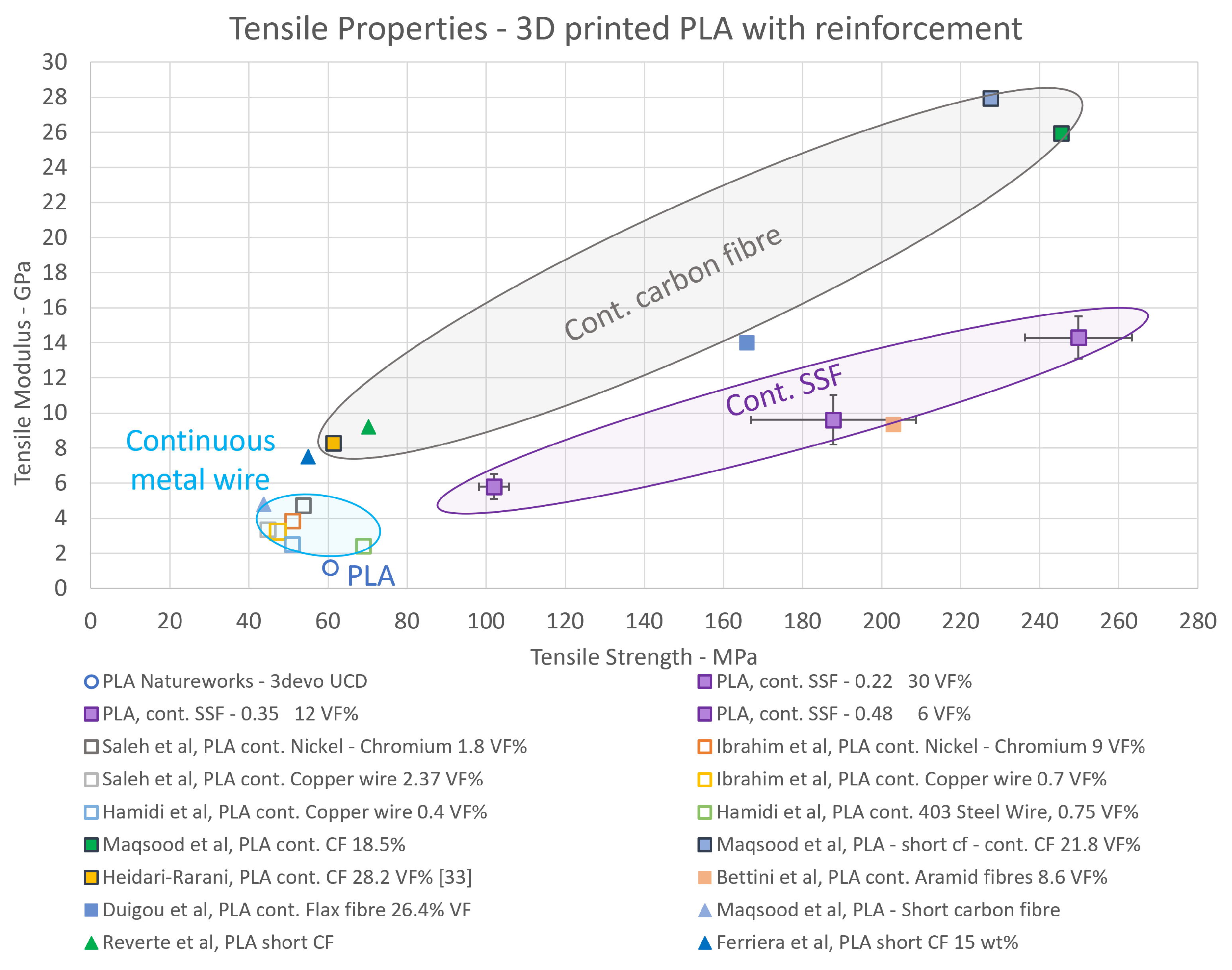

3.3.2. Tensile Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| 3D | Three-dimensional |

| °C | Degrees Centigrade |

| b | Specimen width |

| h | Specimen thickness |

| kN | Kilonewton |

| CT | Micro computed tomography |

| μm | Micrometer |

| mm | Millimeter |

| mm/s | Millimeters Per second |

| wt% | Weight percent |

| Tensile strength | |

| or | Maximum load or failure |

| rpm | Revolutions per minute |

| 1st Extrusion barrel heater temperature | |

| 2st Extrusion barrel heater temperature | |

| 3st Extrusion barrel heater temperature | |

| 4st Extrusion barrel heater temperature | |

| ABS | Acrylonitrile butadiene styrene |

| CAD | Computer-aided design |

| cCF | Continuous carbon fibre |

| EDAX | Energy-dispersive X-ray spectroscopy |

| ILSS or | Interlaminar shear strength |

| L | Loop 3D print geometry |

| GPa | Gigapascal |

| MEX | Material extrusion |

| MPa | Megapascal |

| PC | Polyamide or nylon |

| PC | Polycarbonate |

| PLA | Polylactic acid |

| PLA-cCF | Polylactic acid containing continuous carbon fibre |

| PLA-cGF | Polylactic acid containing continuous glass fibre |

| PLA-SCF-cCF | Polylactic acid containing short carbon fibres and continuous carbon fibre |

| PLA-SSF | Polylactic acid containing continuous stainless steel fibre bundle composite |

| SEM | Scanning electron 255 microscope |

| SSF | 316 L stainless steel fibre bundle |

| ATL | Stereolithography |

| TEX | Decitex |

| Volume fraction | |

| Volume of continuous stainless steel fibre | |

| Overall volume |

References

- NatureWorks. Ingeo™ Biopolymer 3D850 Technical Data Sheet 3D Printing Monofilament—General Purpose Grade; Technical Report 4; NatureWorks LLC: Fridley, MN, USA, 2018. [Google Scholar]

- Luo, M.; Tian, X.; Shang, J.; Yun, J.; Zhu, W.; Li, D.; Qin, Y. Bi-scale interfacial bond behaviors of CCF/PEEK composites by plasma-laser cooperatively assisted 3D printing process. Compos. Part A Appl. Sci. Manuf. 2020, 131, 105812. [Google Scholar] [CrossRef]

- Dutra, T.; Ferreira, R.T.L.; Resende, H. Interlaminar shear strength of continuous carbon fiber reinforced thermoplastic composites manufactured by 3D printing. In Proceedings of the 24th ABCM International Congress of Mechanical Engineering, Lisbon, Portugal, 17–19 September 2018. [Google Scholar] [CrossRef]

- Xu, X.; Mi, G.; Luo, Y.; Jiang, P.; Shao, X.; Wang, C. Morphologies, microstructures, and mechanical properties of samples produced using laser metal deposition with 316 L stainless steel wire. Opt. Lasers Eng. 2017, 94, 1–11. [Google Scholar] [CrossRef]

- Bhandari, S.; Lopez-Anido, R.A.; Gardner, D.J. Enhancing the interlayer tensile strength of 3D printed short carbon fiber reinforced PETG and PLA composites via annealing. Addit. Manuf. 2019, 30, 100922. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, D.; Huang, T.; Hu, Q.; Lammer, H. Three-dimensional printing of continuous flax fiber-reinforced thermoplastic composites by five-axis machine. Materials 2020, 13, 1678. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Durandet, Y.; Huang, X.; Sun, G.; Ruan, D. Additively manufactured fiber-reinforced composites: A review of mechanical behavior and opportunities. J. Mater. Sci. Technol. 2022, 119, 219–244. [Google Scholar] [CrossRef]

- Hao, W.; Liu, Y.; Zhou, H.; Chen, H.; Fang, D. Preparation and characterization of 3D printed continuous carbon fiber reinforced thermosetting composites. Polym. Test. 2018, 65, 29–34. [Google Scholar] [CrossRef]

- Sodeifian, G.; Ghaseminejad, S.; Yousefi, A.A. Preparation of polypropylene/short glass fiber composite as Fused Deposition Modeling (FDM) filament. Results Phys. 2019, 12, 205–222. [Google Scholar] [CrossRef]

- Mirabedini, A.; Foroughi, J. Carbon Nanotube-Graphene Composites Fibers; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; pp. 61–86. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Rafiee, M.; Farahani, R.D.; Therriault, D. Multi-Material 3D and 4D Printing: A Survey. Adv. Sci. 2020, 7, 1902307. [Google Scholar] [CrossRef]

- Dickson, A.; Abourayana, H.; Dowling, D. 3D Printing of Fibre Reinforced Thermoplastic Composites Using Fused Filament Fabrication—A Review; Technical report; University College Dublin: Dublin, Ireland, 2020. [Google Scholar]

- Dickson, A.N.; Ross, K.A.; Dowling, D.P. Additive manufacturing of woven carbon fibre polymer composites. Compos. Struct. 2018, 206, 637–643. [Google Scholar] [CrossRef]

- Dowling, D.P.; Abourayana, H.M.; Brantseva, T.; Antonov, A.; Dobbyn, P.J. Enhancing the mechanical performance of 3D-printed basalt fiber-reinforced composites using in-line atmospheric plasma pretreatments. Plasma Process. Polym. 2020, 17. [Google Scholar] [CrossRef]

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.A.; Ozcan, S. Highly oriented carbon fiber-polymer composites via additive manufacturing. Compos. Sci. Technol. 2014, 105, 144–150. [Google Scholar] [CrossRef]

- Reverte, J.M.; Caminero, M.á.; Chacón, J.M.; García-Plaza, E.; Núñez, P.J.; Becar, J.P. Mechanical and geometric performance of PLA-based polymer composites processed by the fused filament fabrication additive manufacturing technique. Materials 2020, 13, 1924. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, Y. 3D Printing of Continuous Wire Polymer Composite for Mechanical and Thermal Applications. Ph.D. Thesis, York University, York, UK, 2019. [Google Scholar]

- Saleh, M.A.; Kempers, R.; Melenka, G.W. 3D printed continuous wire polymer composites strain sensors for structural health monitoring. Smart Mater. Struct. 2019, 28, 105041. [Google Scholar] [CrossRef]

- Le Duigou, A.; Chabaud, G.; Matsuzaki, R.; Castro, M. Tailoring the mechanical properties of 3D-printed continuous flax/PLA biocomposites by controlling the slicing parameters. Compos. Part B Eng. 2020, 203, 108474. [Google Scholar] [CrossRef]

- Hine, P.J.; Rudolf Lusti, H.; Gusev, A.A. Numerical simulation of the effects of volume fraction, aspect ratio and fibre length distribution on the elastic and thermoelastic properties of short fibre composites. Compos. Sci. Technol. 2002, 62, 1445–1453. [Google Scholar] [CrossRef]

- Materials, P.; Materials, E.I.; Matrix, P.; Materials, C.; Specimens, P. Standard Test Method for Tensile Properties of Plastics 1; Technical Report January 2004; ASTM International: West Conshohocken, PA, USA, 2006. [Google Scholar]

- Beckman, I.P.; Lozano, C.; Freeman, E.; Riveros, G. Fiber selection for reinforced additive manufacturing. Polymers 2021, 13, 2231. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Ueda, M.; Namiki, M.; Jeong, T.K.; Asahara, H.; Horiguchi, K.; Nakamura, T.; Todoroki, A.; Hirano, Y. Three-dimensional printing of continuous-fiber composites by in-nozzle impregnation. Sci. Rep. 2016, 6, 23058. [Google Scholar] [CrossRef]

- Goh, G.D.; Dikshit, V.; Nagalingam, A.P.; Goh, G.L.; Agarwala, S.; Sing, S.L.; Wei, J.; Yeong, W.Y. Characterization of mechanical properties and fracture mode of additively manufactured carbon fiber and glass fiber reinforced thermoplastics. Mater. Des. 2018, 137, 79–89. [Google Scholar] [CrossRef]

- Botelho, E.C.; Figiel, Ł.; Rezende, M.C.; Lauke, B. Mechanical behavior of carbon fiber reinforced polyamide composites. Compos. Sci. Technol. 2003, 63, 1843–1855. [Google Scholar] [CrossRef]

- Hu, Q.; Duan, Y.; Zhang, H.; Liu, D.; Yan, B.; Peng, F. Manufacturing and 3D printing of continuous carbon fiber prepreg filament. J. Mater. Sci. 2018, 53, 1887–1898. [Google Scholar] [CrossRef]

- Pandelidi, C.; Bateman, S.; Piegert, S.; Hoehner, R.; Kelbassa, I.; Brandt, M. The technology of continuous fibre-reinforced polymers: A review on extrusion additive manufacturing methods. Int. J. Adv. Manuf. Technol. 2021, 113, 3057–3077. [Google Scholar] [CrossRef]

- Zhuo, P.; Li, S.; Ashcroft, I.A.; Jones, A.I. Material extrusion additive manufacturing of continuous fibre reinforced polymer matrix composites: A review and outlook. Compos. Part Eng. 2021, 224, 109143. [Google Scholar] [CrossRef]

- Ibrahim, Y.; Melenka, G.W.; Kempers, R. Fabrication and tensile testing of 3D printed continuous wire polymer composites. Rapid Prototyp. J. 2018, 24, 1131–1141. [Google Scholar] [CrossRef]

- Mahltig, B. Introduction to Inorganic Fibers; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; pp. 1–29. [Google Scholar] [CrossRef]

- Chen, K.; Yu, L.; Cui, Y.; Jia, M.; Pan, K. Optimization of printing parameters of 3D-printed continuous glass fiber reinforced polylactic acid composites. Thin-Walled Struct. 2021, 164, 107717. [Google Scholar] [CrossRef]

- Heidari-Rarani, M.; Rafiee-Afarani, M.; Zahedi, A.M. Mechanical characterization of FDM 3D printing of continuous carbon fiber reinforced PLA composites. Compos. Part B Eng. 2019, 175, 107147. [Google Scholar] [CrossRef]

- Li, N.; Li, Y.; Liu, S. Rapid prototyping of continuous carbon fiber reinforced polylactic acid composites by 3D printing. J. Mater. Process. Technol. 2016, 238, 218–225. [Google Scholar] [CrossRef]

- Rimašauskas, M.; Kuncius, T.; Rimašauskienė, R. Processing of carbon fiber for 3D printed continuous composite structures. Mater. Manuf. Process. 2019, 34, 1528–1536. [Google Scholar] [CrossRef]

- Maqsood, N.; Rimašauskas, M. Characterization of carbon fiber reinforced PLA composites manufactured by fused deposition modeling. Compos. Part C Open Access 2021, 4, 100112. [Google Scholar] [CrossRef]

- Caminero, M.A.; Chacón, J.M.; García-Moreno, I.; Reverte, J.M. Interlaminar bonding performance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling. Polym. Test. 2018, 68, 415–423. [Google Scholar] [CrossRef]

- Kabir, S.M.; Mathur, K.; Seyam, A.F.M. A critical review on 3D printed continuous fiber-reinforced composites: History, mechanism, materials and properties. Compos. Struct. 2020, 232, 111476. [Google Scholar] [CrossRef]

- Ibrahim, Y.; Melenka, G.W.; Kempers, R. Additive manufacturing of Continuous Wire Polymer Composites. Manuf. Lett. 2018, 16, 49–51. [Google Scholar] [CrossRef]

- Sugiyama, K.; Matsuzaki, R.; Malakhov, A.V.; Polilov, A.N.; Ueda, M.; Todoroki, A.; Hirano, Y. 3D printing of optimized composites with variable fiber volume fraction and stiffness using continuous fiber. Compos. Sci. Technol. 2020, 186, 107905. [Google Scholar] [CrossRef]

- Bettini, P.; Alitta, G.; Sala, G.; Di Landro, L. Fused Deposition Technique for Continuous Fiber Reinforced Thermoplastic. J. Mater. Eng. Perform. 2017, 26, 843–848. [Google Scholar] [CrossRef]

- Liu, G.; Xiong, Y.; Zhou, L. Additive manufacturing of continuous fiber reinforced polymer composites: Design opportunities and novel applications. Compos. Commun. 2021, 27, 100907. [Google Scholar] [CrossRef]

- Quan, D.; Flynn, S.; Artuso, M.; Murphy, N.; Rouge, C.; Ivanković, A. Interlaminar fracture toughness of CFRPs interleaved with stainless steel fibres. Compos. Struct. 2019, 210, 49–56. [Google Scholar] [CrossRef]

- Hamidi, A.; Tadesse, Y. Single step 3D printing of bioinspired structures via metal reinforced thermoplastic and highly stretchable elastomer. Compos. Struct. 2019, 210, 250–261. [Google Scholar] [CrossRef]

- Gunes, M.; Cayiroglu, I. Mechanical Behaviour of 3D Printed Parts with Continuous Steel Wire Reinforcement. El-Cezeri J. Sci. Eng. 2022, 9, 276–289. [Google Scholar] [CrossRef]

- Bekaert. Metal Fiber Composite Reinforcement; Technical report; Bekaert: Zwevegem, Belgium, 2018. [Google Scholar]

- Küster, K.; Barburski, M.; Lomov, S.V.; Vanclooster, K. Metal Fibers-Steel. In Inorganic and Composite Fibers: Production, Properties, and Applications; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; pp. 219–241. [Google Scholar] [CrossRef]

- Verlinden, B.; Driver, J.; Samajdar, I.; Doherty, R. Thermo-Mechanical Processing of Metallic Materials; Pergamon Materials Series; Pergamon: Bergama, Turkey, 2007; Volume 11, pp. 7–30. [Google Scholar] [CrossRef]

- 3devo. Composer 350; Technical report; 3devo: Utrecht, The Netherlands, 2020. [Google Scholar]

- Lafleur, P.G.; Vergnes, B. Wire Coating and Cable Insulation. In Polymer Extrusion; John Wiley & Sons, Incorporated: Somerset, UK, 2014; Volume 1, pp. 305–333. [Google Scholar] [CrossRef]

- Rauwendaal, D.C. Die Design Handbook, 5th ed.; Carl Hanser Verlag GmbH & Co. KG: Munich, Germany, 2014; Volume 65, pp. 1–17. [Google Scholar]

- McCullough, K. US6863729B2 Nozzle Insert for Long Fiber Compounding. 2005. Available online: https://worldwide.espacenet.com/patent/original-document?channel=espacenet_channel-c9b6335c-1fad-438a-ac13-c4c4532c2a05 (accessed on 22 November 2023).

- Fang, Q.; Hanna, M.A. Rheological properties of amorphous and semicrystalline polylactic acid polymers. Ind. Crop. Prod. 1999, 10, 47–53. [Google Scholar] [CrossRef]

- Fratte, E.D.; D’hooge, D.R.; Eeckhout, M.; Cardon, L. Principles and Guidelines for In-Line Viscometry in Cereal Extrusion. Polymers 2022, 14, 2316. [Google Scholar] [CrossRef]

- Hussain, A.; Ameer, S.; Javed, F.; Malik, M.Y. Rheological analysis on non-Newtonian wire coating. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 115. [Google Scholar] [CrossRef]

- Skelland, A.H.P. Non-Newtonian Flow and Heat Transfer; Wiley: New York, NY, USA, 1967; pp. 12–14. [Google Scholar]

- Shah, R.A.; Islam, S.; Siddiqui, A.M.; Haroon, T. Heat transfer by laminar flow of a third grade fluid in wire coating analysis with temperature dependent and independent viscosity. Anal. Math. Phys. 2011, 1, 147–166. [Google Scholar] [CrossRef]

- Rauwendaal, C. Extruder Screw Design. In Polymer Extrusion; Carl Hanser Verlag GmbH & Co. KG: Munchen, Germany, 2014; pp. 509–652. [Google Scholar] [CrossRef]

- Yao, Y.; Li, M.; Lackner, M.; Herfried, L. A continuous fiber-reinforced additive manufacturing processing based on PET fiber and PLA. Materials 2020, 13, 3044. [Google Scholar] [CrossRef] [PubMed]

- Naranjo-Lozada, J.; Ahuett-Garza, H.; Orta-Castañón, P.; Verbeeten, W.M.; Sáiz-González, D. Tensile properties and failure behavior of chopped and continuous carbon fiber composites produced by additive manufacturing. Addit. Manuf. 2019, 26, 227–241. [Google Scholar] [CrossRef]

- ASTM D2344; ASTM D2344/D2344M: Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates. In Annual Book ASTM Standard; ASTM: West Conshohocken, PA, USA, 2003; Volume 3, pp. 136–140.

- ASTM. Standard Test Method for Tensile Properties of Reinforced Thermosetting Plastics; ASTM Standards: West Conshohocken, PA, USA, 2002; pp. 1–9. [Google Scholar]

- Callens, M.G.; Gorbatikh, L.; Verpoest, I. Ductile steel fibre composites with brittle and ductile matrices. Compos. Part A Appl. Sci. Manuf. 2014, 61, 235–244. [Google Scholar] [CrossRef]

- Ferreira, R.T.L.; Amatte, I.C.; Dutra, T.A.; Bürger, D. Experimental characterization and micrography of 3D printed PLA and PLA reinforced with short carbon fibers. Compos. Part B Eng. 2017, 124, 88–100. [Google Scholar] [CrossRef]

- Ahmad, N.D.; Kusmono; Wildan, M.W.; Herianto. Preparation and properties of cellulose nanocrystals-reinforced Poly (lactic acid) composite filaments for 3D printing applications. Results Eng. 2023, 17, 100842. [Google Scholar] [CrossRef]

- Callens, M.G.; Gorbatikh, L.; Bertels, E.; Goderis, B.; Smet, M.; Verpoest, I. Tensile behaviour of stainless steel fibre/epoxy composites with modified adhesion. Compos. Part A Appl. Sci. Manuf. 2015, 69, 208–218. [Google Scholar] [CrossRef]

| Element | Fe | Cr | Ni | Mo | Si | Al |

|---|---|---|---|---|---|---|

| Weight % | 69.6 | 17.9 | 5.6 | 2.1 | 0.5 | 0.4 |

| Filament | Filament | Fans | Extruder | ||||

|---|---|---|---|---|---|---|---|

| Diameter | (%) | Speed | (°C) | (°C) | (°C) | (°C) | |

| (mm) | (rpm) | ||||||

| PLA-SSF | 0.90 | 45 | 2.7 | 177 | 187 | 186 | 177 |

| PLA-SSF | 0.60–0.70 | 20 | 2.6 | 177 | 187 | 186 | 170 |

| PLA-SSF | 0.50–0.65 | 33 | 2.2 | 179 | 186 | 193 | 191 |

| Sample Set | Hatch | Filament | Speed | T | T |

|---|---|---|---|---|---|

| Layer Height (h) | Spacing (w) | Diameter | (mm/s) | (°C) | (°C) |

| (mm) | (mm) | (mm) | |||

| 0.48 | 0.60 | 0.50–0.65 | 3 | 209 | 40 |

| 0.35 | 0.40 | 0.50–0.65 | 6 | 209 | 40 |

| 0.22 | 0.40 | 0.50–0.65 | 4 | 215 | 55 |

| Sample Set | Volume | Porosity |

|---|---|---|

| Layer Height | Fraction () | (%) |

| (mm) | (%) | |

| 0.48 | 6 | 21 |

| 0.35 | 12 | 6 |

| 0.22 | 30 | 2 |

| PLA Reinforcement | (%) | Tensile Strength (MPa) | Reference |

|---|---|---|---|

| Continuous Stainless steel fibre bundle 0.22 mm | 30 | 249.8 | This work |

| Continuous Stainless steel fibre bundle 0.35 mm | 12 | 187.8 | This work |

| Continuous Stainless steel fibre bundle 0.48 mm | 7 | 102.0 | This work |

| Continuous Nickel-Chromium wire | |||

| Wire diameter = 75 μm | 9.0 | 51.2 | [30] |

| Continuous nickel-chromium wire | |||

| Wire diameter = 75 μm | 1.8 | 53.8 | [19] |

| Continuous copper wire | |||

| Wire diameter = 75 μm | 2.4 | 44.9 | [19] |

| Continuous copper wire | |||

| Wire diameter = 75 μm | 0.7 | 47.5 | [30] |

| Continuous copper wire | |||

| Wire diameter = 0.127 mm | 0.4 | 59.0 | [44] |

| Continuous spring-back 304 stainless steel wire | |||

| Wire diameter = 0.1778 mm | 0.8 | 61.0 | [44] |

| Continuous carbon fibre | 18.5 | 245.4 | [36] |

| Continuous carbon fibre, (short CF PLA matrix) | 21.8 | 227.6 | [36] |

| Continuous carbon fibre | 28.2 | 61.4 | [33] |

| Continuous carbon fibre | 34.0 | 80.0 | [34] |

| Continuous aramid fibre | 8.6 | 203 | [41] |

| Continuous flax fibre | 26.4 | 166.0 | [20] |

| Short carbon fibre, ColorFabb XT-CF20 | 20 wt% | 43.6 | [36] |

| Short carbon fibre, CarbonX™ filament | - | 70.3 | [17] |

| Short carbon fibre, Proto-Pasta filament | 15 wt% | 53.4 | [64] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Clarke, A.J.; Dickson, A.; Dowling, D.P. Fabrication and Performance of Continuous 316 Stainless Steel Fibre-Reinforced 3D-Printed PLA Composites. Polymers 2024, 16, 63. https://doi.org/10.3390/polym16010063

Clarke AJ, Dickson A, Dowling DP. Fabrication and Performance of Continuous 316 Stainless Steel Fibre-Reinforced 3D-Printed PLA Composites. Polymers. 2024; 16(1):63. https://doi.org/10.3390/polym16010063

Chicago/Turabian StyleClarke, Alison J., Andrew Dickson, and Denis P. Dowling. 2024. "Fabrication and Performance of Continuous 316 Stainless Steel Fibre-Reinforced 3D-Printed PLA Composites" Polymers 16, no. 1: 63. https://doi.org/10.3390/polym16010063

APA StyleClarke, A. J., Dickson, A., & Dowling, D. P. (2024). Fabrication and Performance of Continuous 316 Stainless Steel Fibre-Reinforced 3D-Printed PLA Composites. Polymers, 16(1), 63. https://doi.org/10.3390/polym16010063