Quality Analysis of Micro-Holes Made by Polymer Jetting Additive Manufacturing

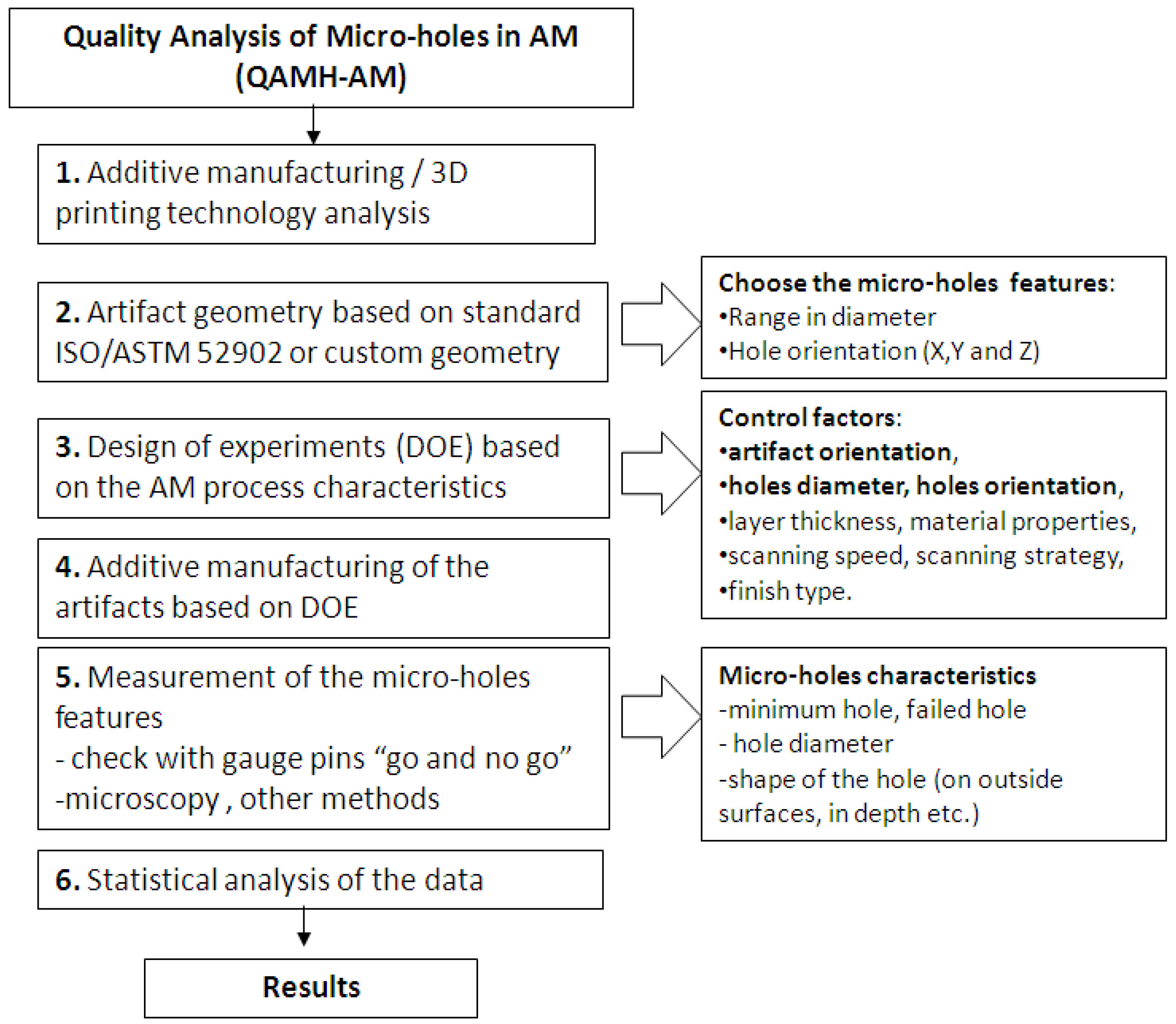

Abstract

:1. Introduction

2. Materials and Methods

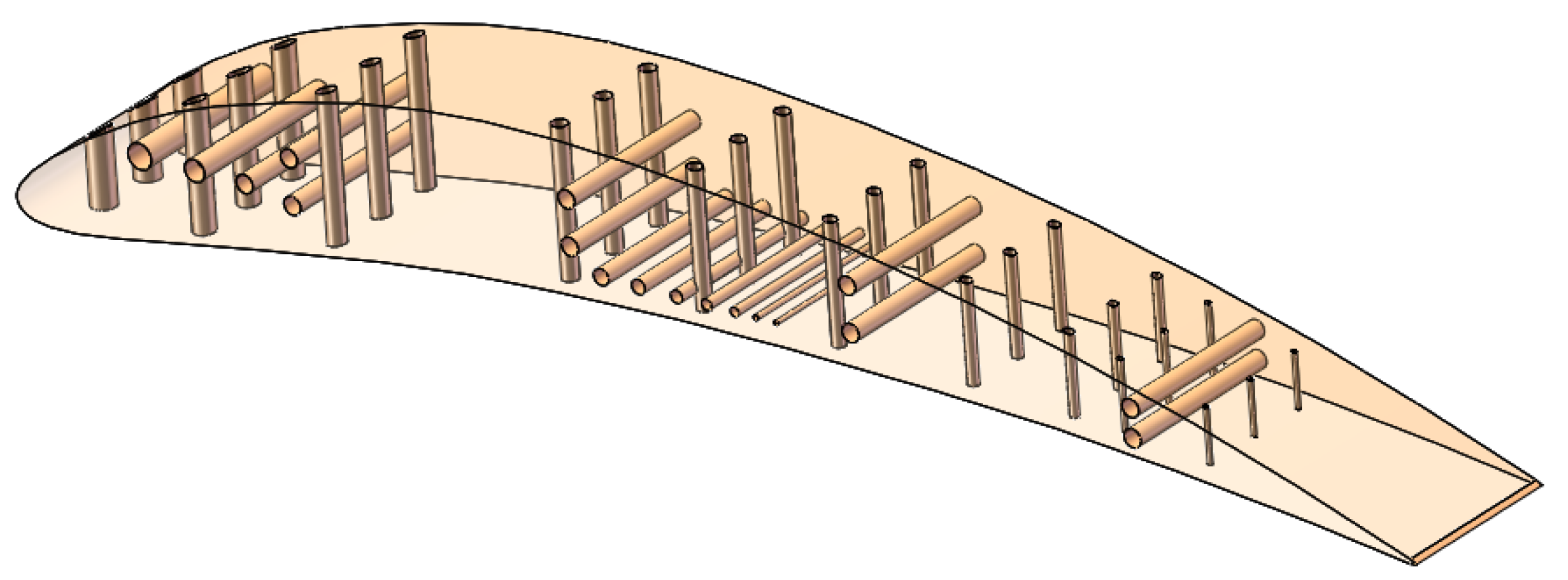

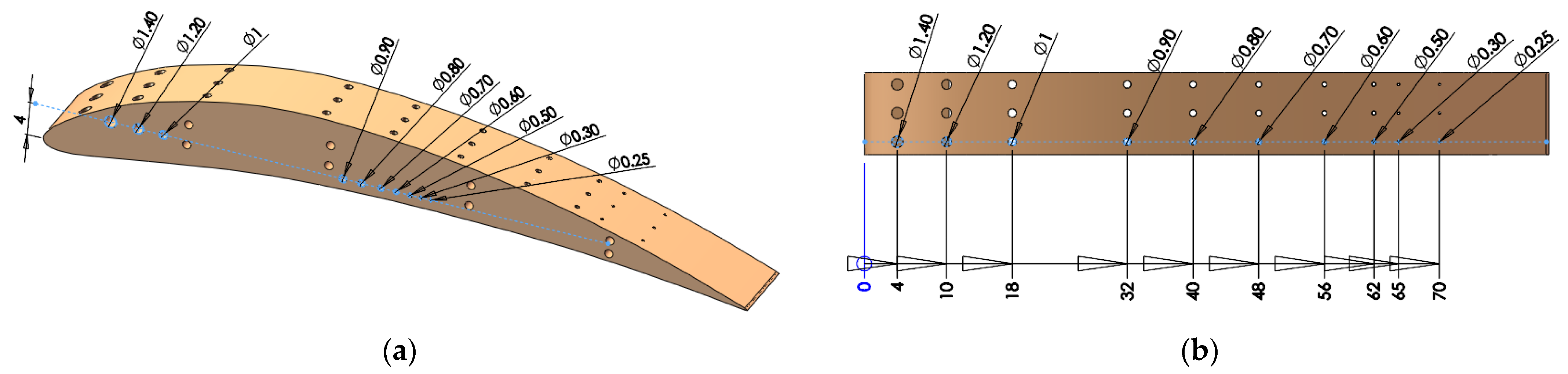

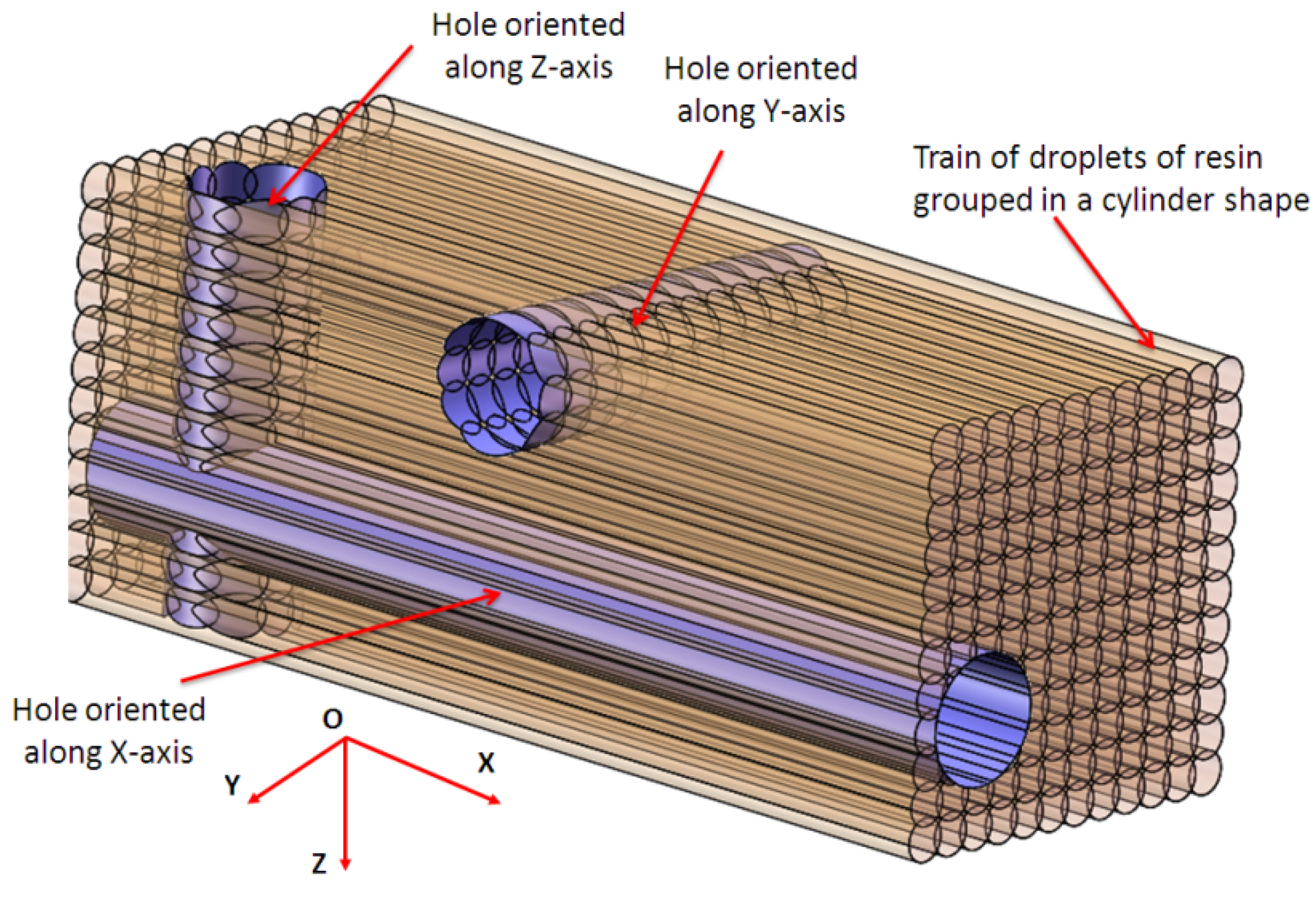

2.1. Artifact Geometry

2.2. Design of the Experiments and Statistical Analysis

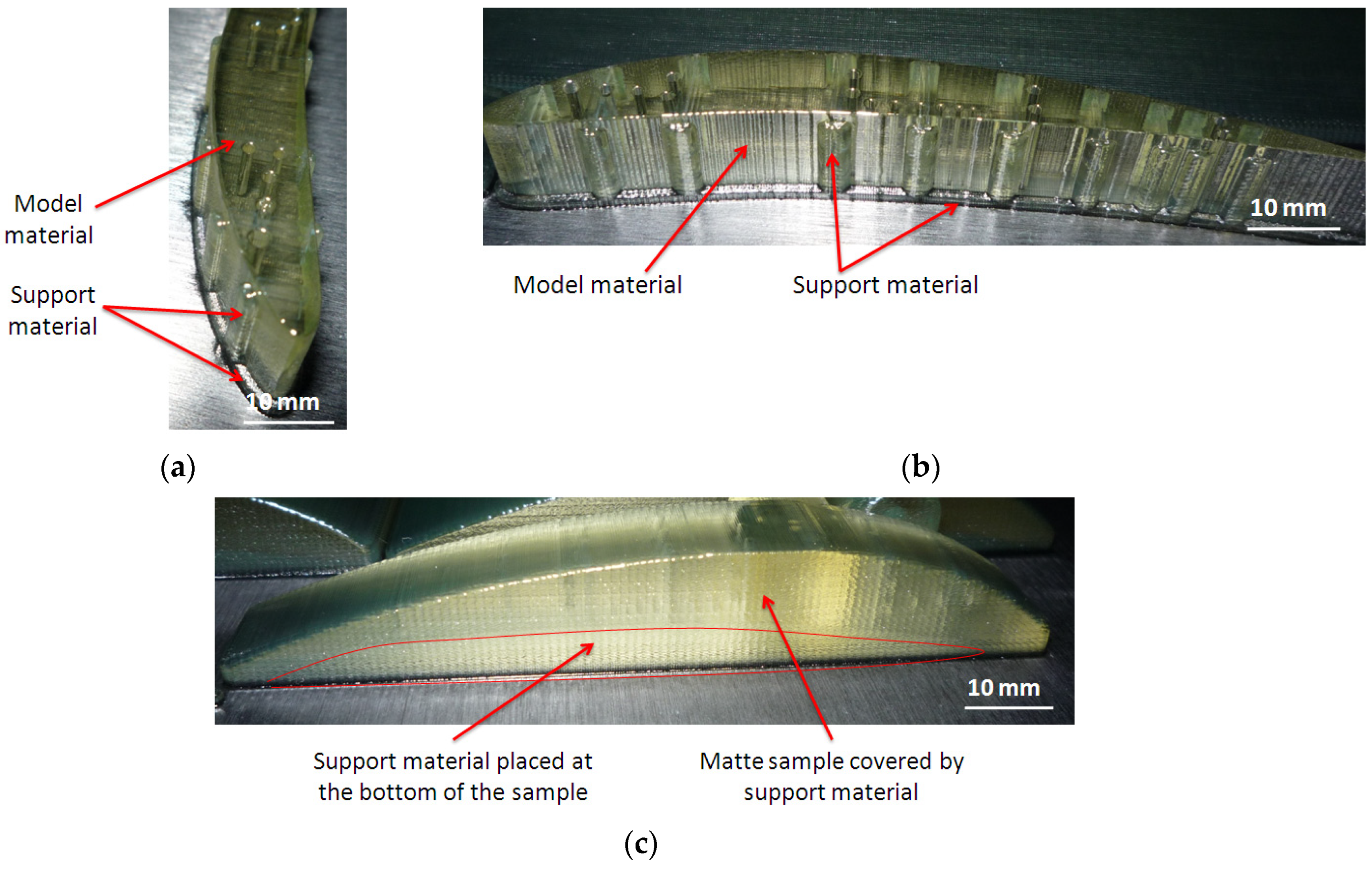

2.3. Manufacturing Process Specification and Quality Analysis

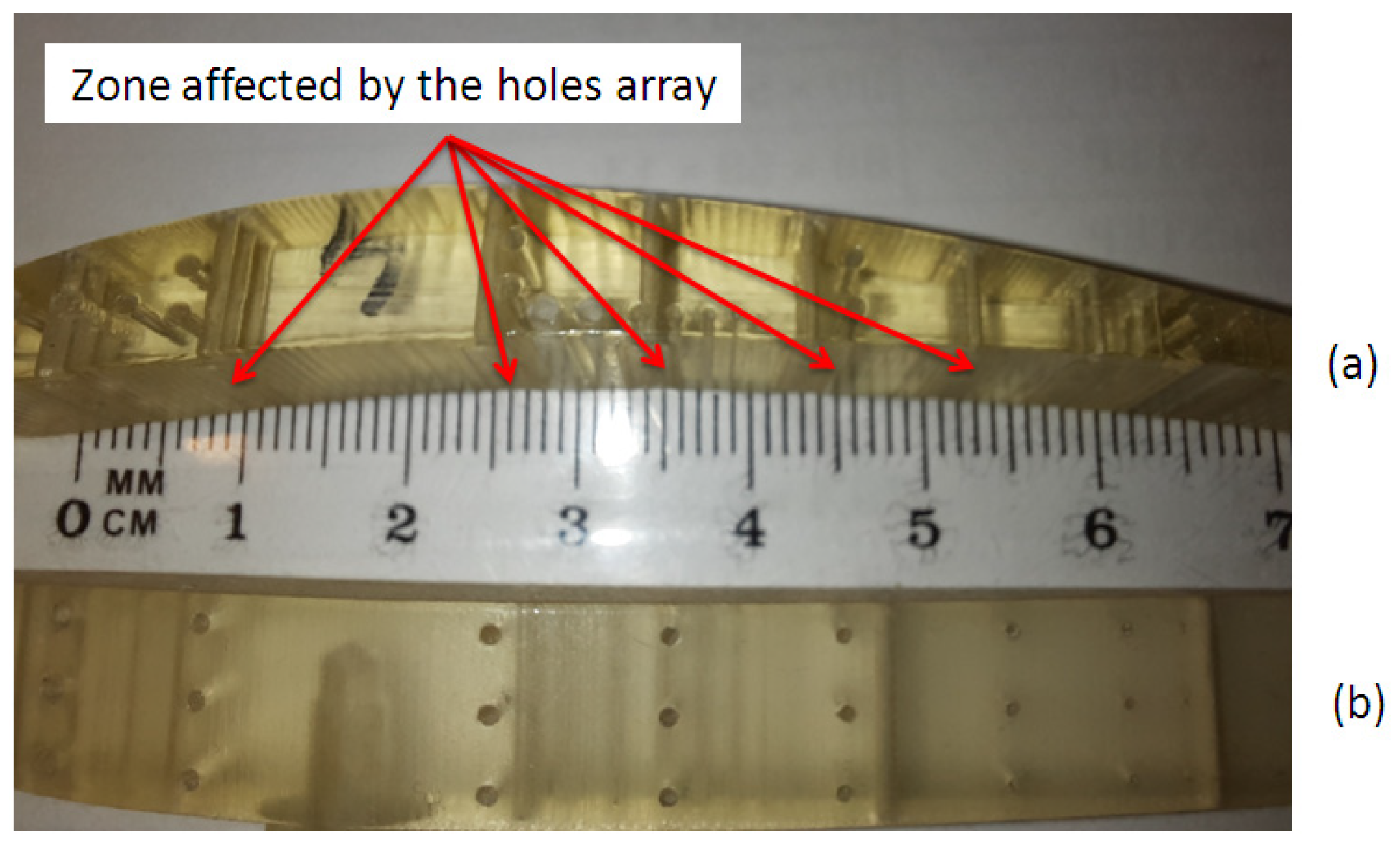

2.4. Case Study as Confirmatory Experiment

3. Results

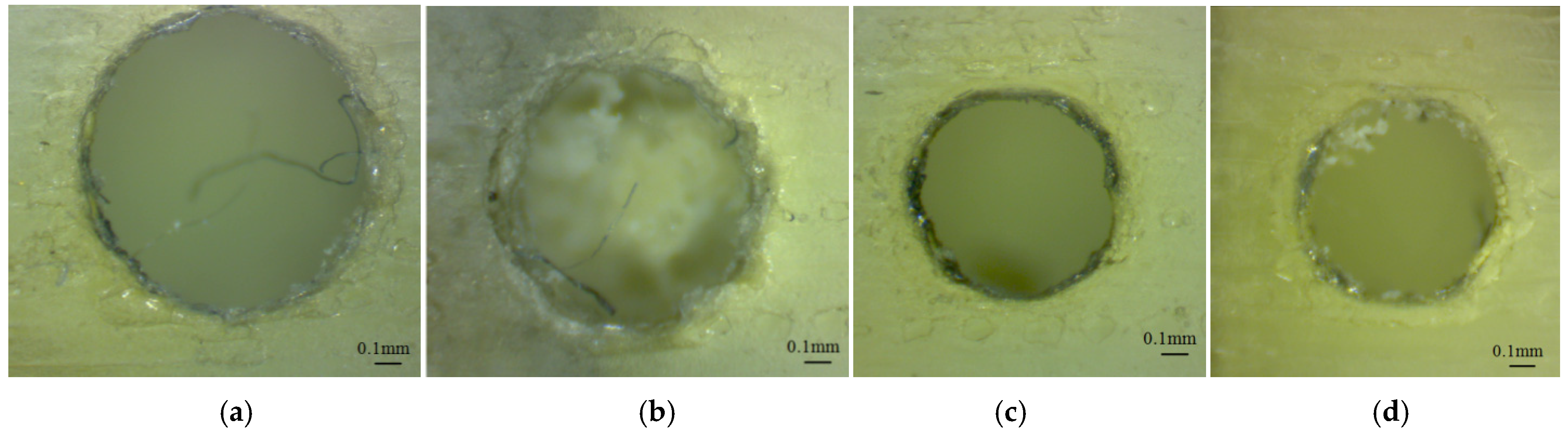

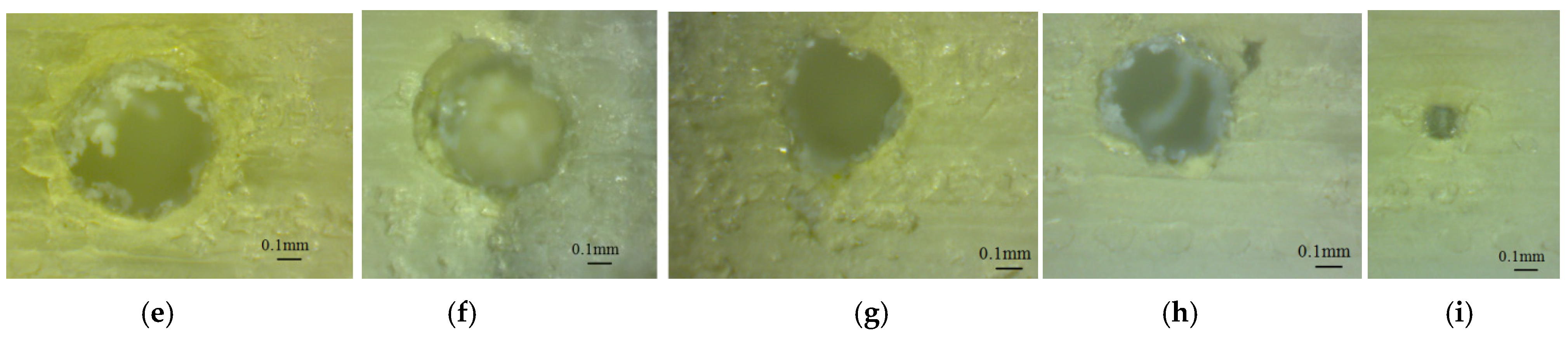

3.1. Quality Analysis of the Micro-Hole Features

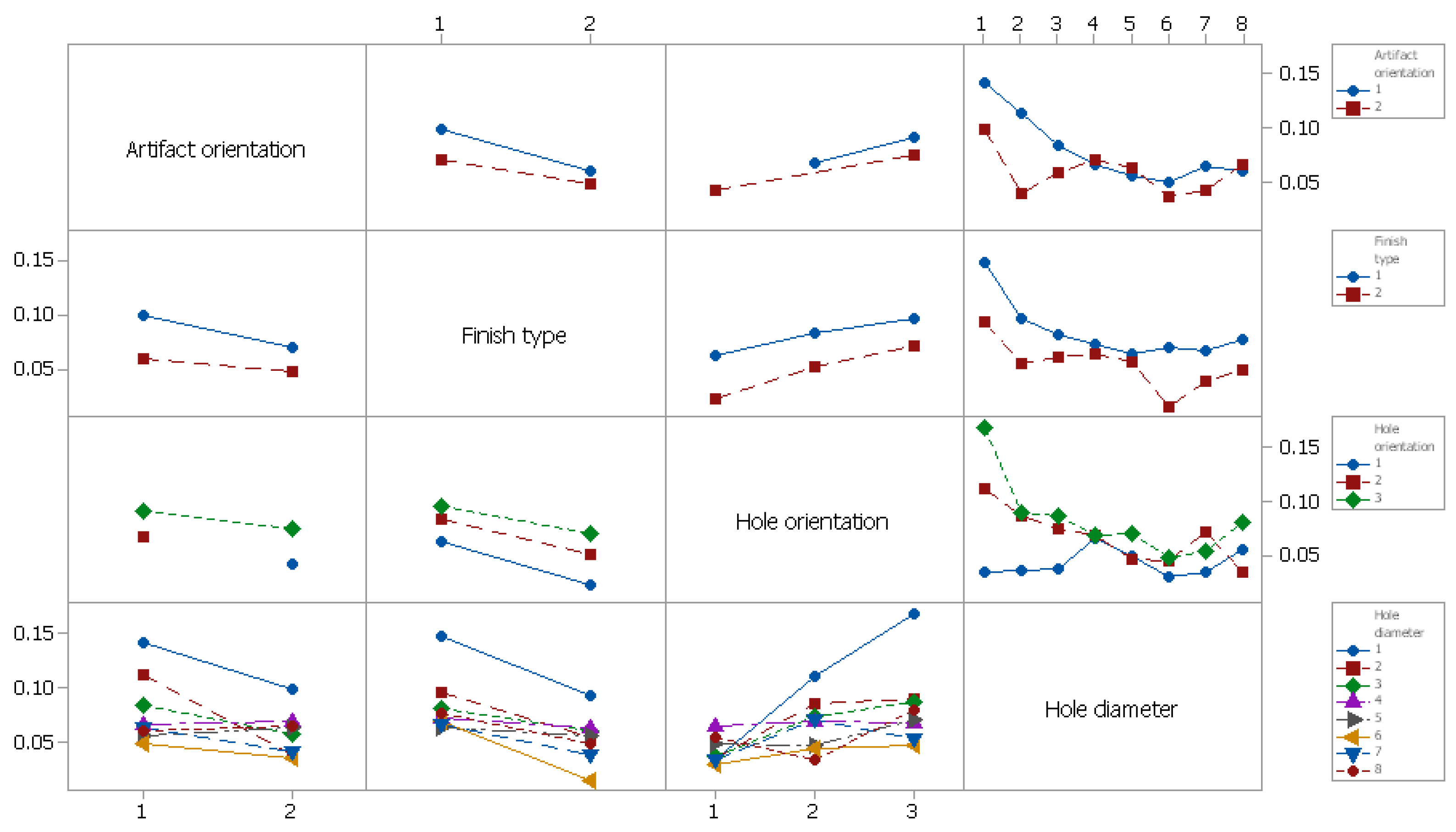

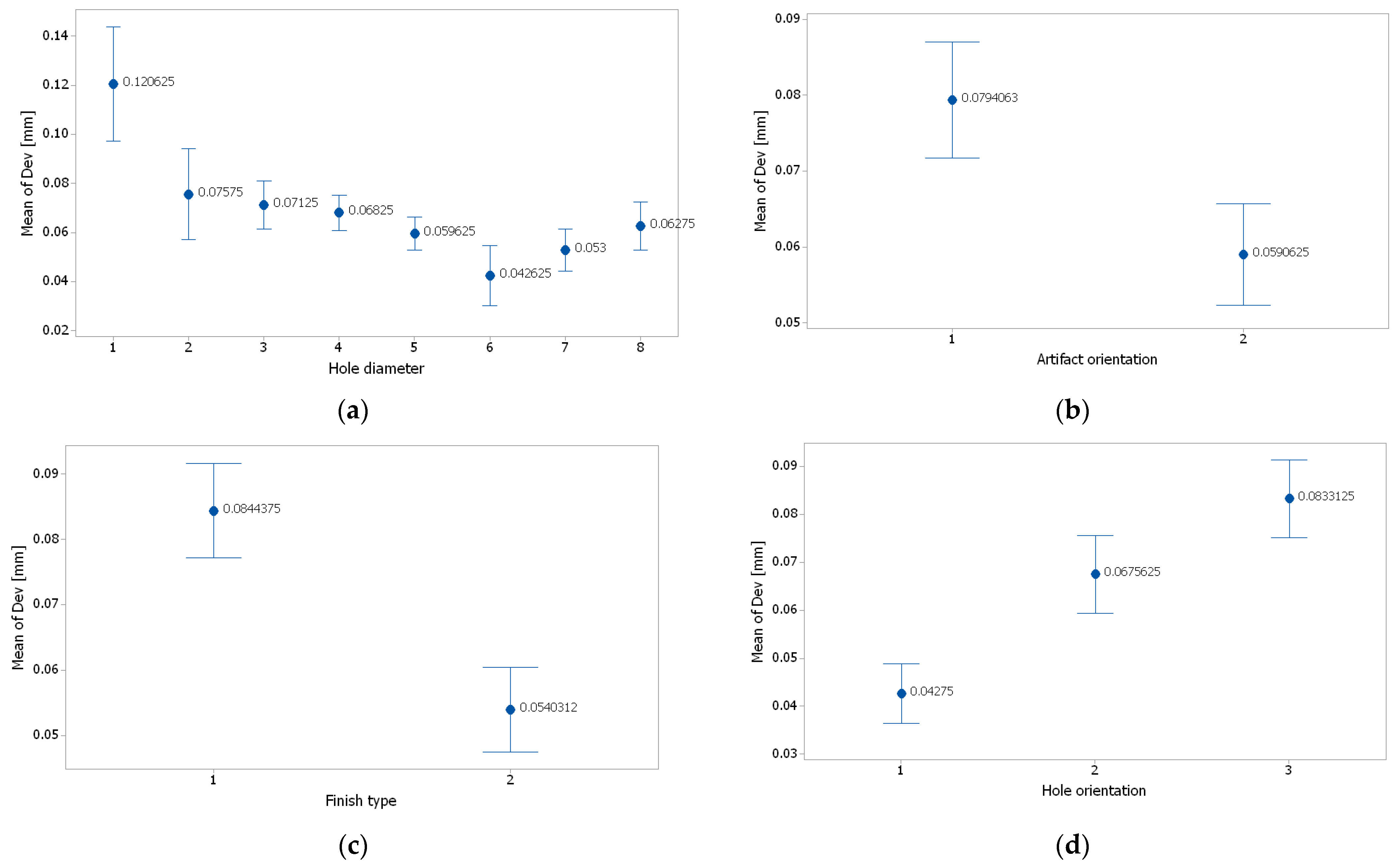

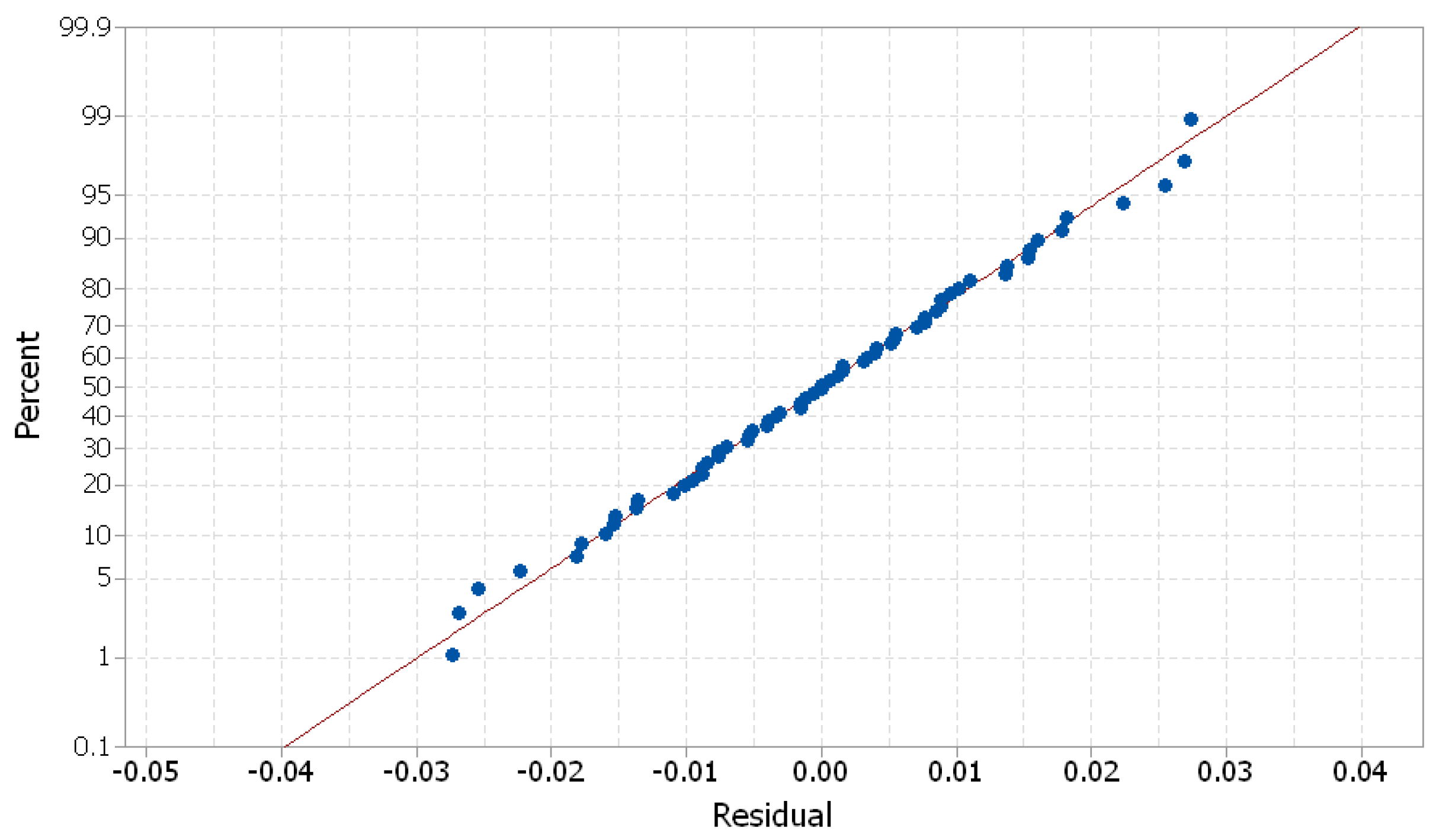

3.2. Results of Statistical Analysis

3.3. Case Study as Confirmatory Experiment

4. Conclusions

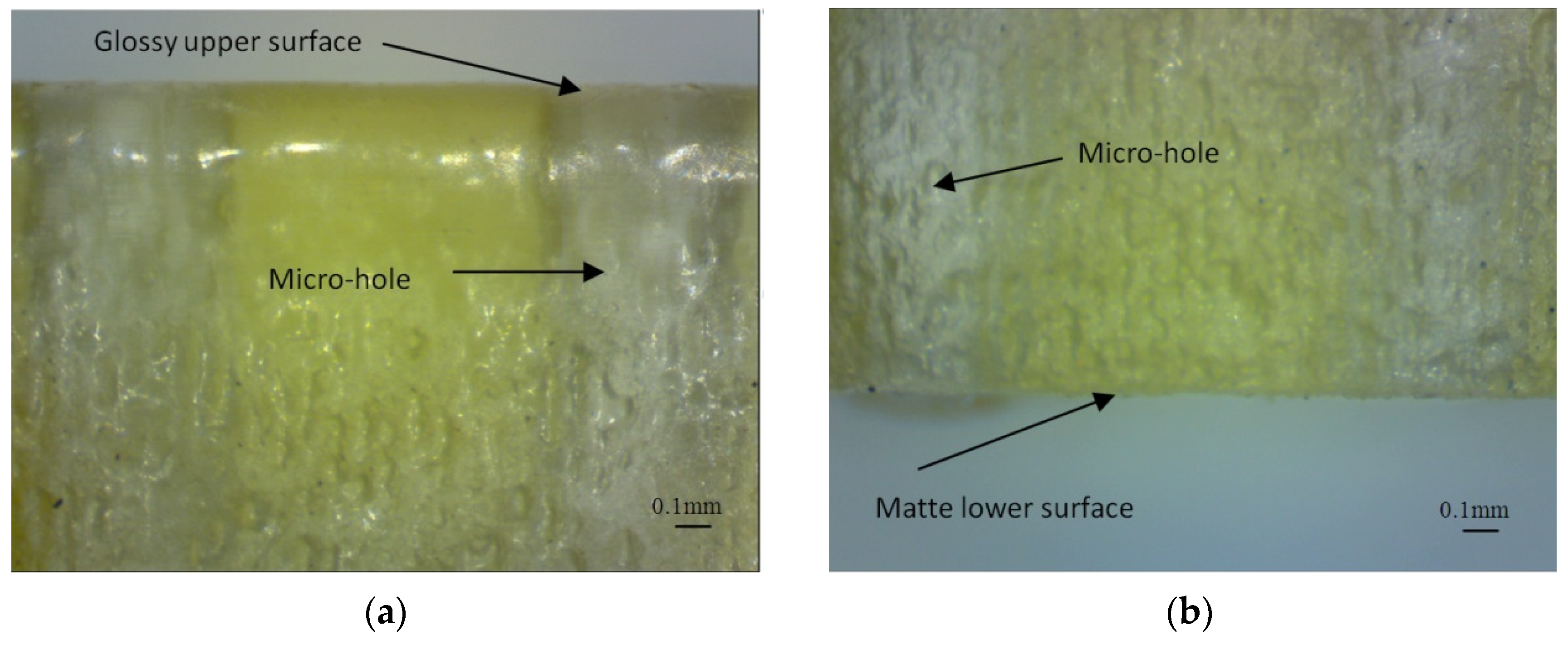

- An artifact made by translucent polymer resin allows a facile investigation (by microscopy) of the inner structure of the micro-holes.

- The experimental research demonstrated that hole diameter, finish type, and hole orientation were the most influential factors on diameter deviation of the micro-holes.

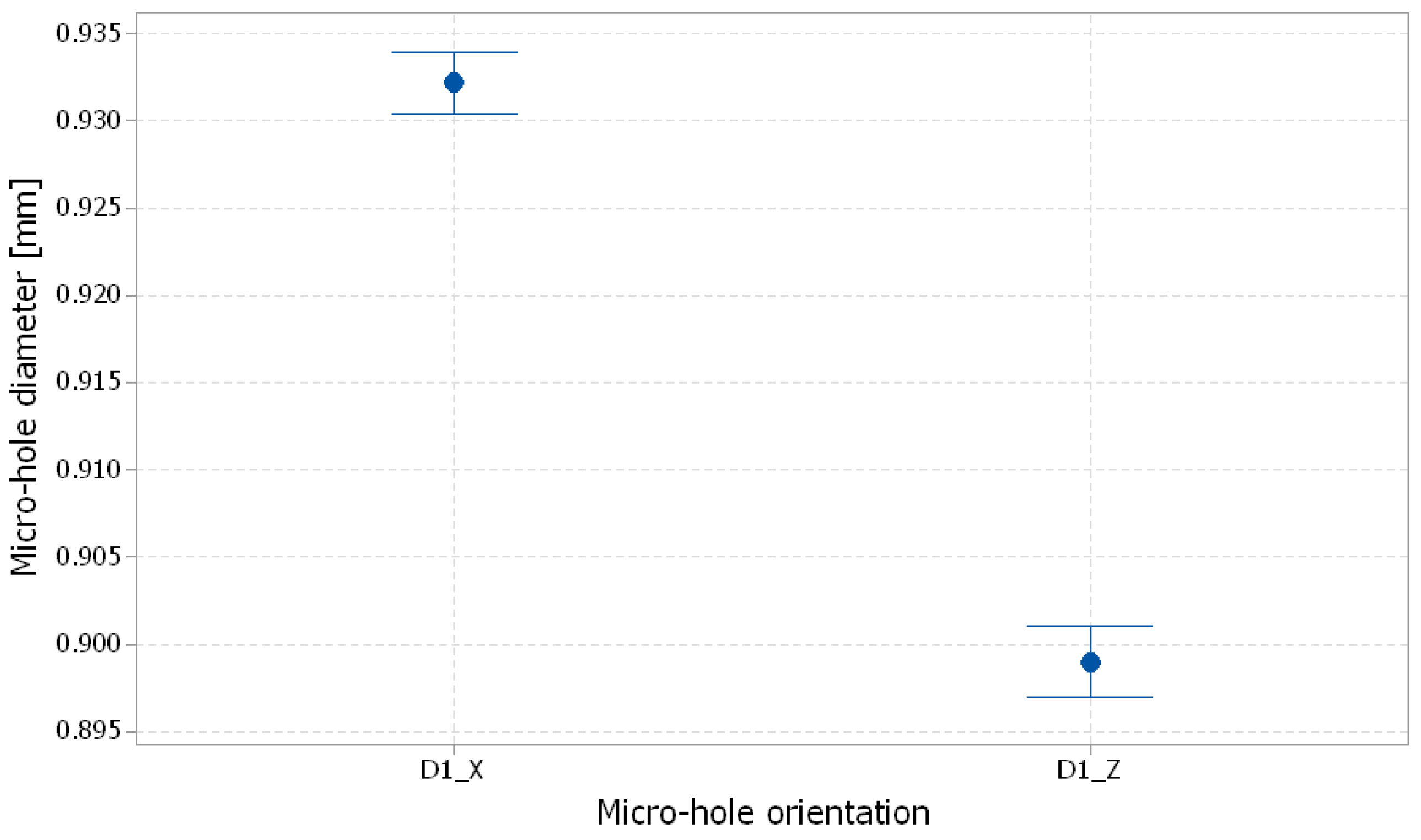

- Micro-holes are smaller than nominal. The micro-holes made by the PolyJet technology that are oriented along the x-axis are more accurate than the micro-holes along the y-axis and z-axis, and have an average deviation of 0.042 mm, compared with 0.067 mm and 0,083 mm, respectively.

- The experimental deviations of the diameter of the micro-holes manufactured by PolyJet technology in the glossy finish mode were lower than those obtained in the matte finish mode. After uniform surface and the quality issues of glossy mode were taken into account, the micro-holes printed in matte finishing gave the best results.

- Three situations of micro-holes construction by the AM systems can be noted, names of holes that appear properly built, holes that appear partially filled, and holes that appear absent. The smallest diameter of the properly-built micro-holes obtained by PolyJet technology using the EDEN 350 machine was 0.5 mm. After facile post-processing is taken into account, it is recommended that 1 mm diameter micro-holes should be chosen for industrial application.

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- ISO/ASTM 52900-15; Standard Terminology for Additive Manufacturing—General Principles—Terminology. ISO: Geneva, Switzerland, 2015.

- Yap, Y.L.; Wang, C.; Sing, S.L.; Dikshit, V.; Yeong, W.Y.; Wei, J. Material jetting additive manufacturing: An experimental study using designed metrological benchmarks. Precis. Eng. 2017, 50, 275–285. [Google Scholar] [CrossRef]

- Gülcan, O.; Günaydın, K.; Tamer, A. The State of the Art of Material Jetting—A Critical Review. Polymers 2021, 13, 2829. [Google Scholar] [CrossRef] [PubMed]

- Udroiu, R. New Methodology for Evaluating Surface Quality of Experimental Aerodynamic Models Manufactured by Polymer Jetting Additive Manufacturing. Polymers 2022, 14, 371. [Google Scholar] [CrossRef] [PubMed]

- Leach, R. Metrology for additive manufacturing. Meas. Control 2016, 49, 132–135. [Google Scholar] [CrossRef]

- Umaras, E.; Tsuzuki, M.S.G. Additive manufacturing-considerations on geometric accuracy and factors of influence. IFAC-PapersOnLine 2017, 50, 14940–14945. [Google Scholar] [CrossRef]

- Świderski, J.; Makieła, W.; Dobrowolski, T.; Stępień, K.; Zuperl, U. The study of the roundness and cylindricity deviations of parts produced with the use of the additive manufacturing. Int. J. Adv. Manuf. Technol. 2022, 121, 7427. [Google Scholar] [CrossRef]

- Kim, G.D.; Oh, Y.T. A benchmark study on rapid prototyping processes and machines: Quantitative comparisons of mechanical properties, accuracy, roughness, speed, and material cost. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2008, 222, 201–215. [Google Scholar] [CrossRef]

- Mueller, J.; Shea, K.; Daraio, C. Mechanical properties of parts fabricated with inkjet 3D printing through efficient experimental design. Mater. Des. 2015, 86, 902–912. [Google Scholar] [CrossRef]

- Geier, N.; Patra, K.; Shankar Anand, R.; Ashworth, S.; Blasz, B.; Davim, P. A critical review on mechanical micro-drilling of glass and carbon fibre reinforced polymer (GFRP and CFRP) composites. Compos. Part B 2023, 254, 110589. [Google Scholar] [CrossRef]

- Kara, A.; Vassiliadou, A.; Ongoren, B.; Keeble, W.; Hing, R.; Lalatsa, A.; Serrano, D.R. Engineering 3D Printed Microfluidic Chips for the Fabrication of Nanomedicines. Pharmaceutics 2021, 13, 2134. [Google Scholar] [CrossRef] [PubMed]

- Gonzaleza, G.; Roppoloa, I.; Pirria, C.F.; Chiapponed, A. Current and emerging trends in polymeric 3D printed microfluidic devices. Addit. Manuf. 2022, 55, 102867. [Google Scholar] [CrossRef]

- Endo, H.; Marui, E. Small-hole drilling in engineering plastics sheet and its accuracy estimation. Int. J. Mach. Tools Manuf. 2006, 46, 575–579. [Google Scholar] [CrossRef]

- Singh, M.; Singh, S.; Arora, J.K.; Antil, P.; Oza, A.D.; Burduhos-Nergis, D.D.; Burduhos-Nergis, D.P. Multi Response Optimization of ECDM Process for Generating Micro Holes in CFRP Composite Using TOPSIS Methodology. Polymers 2022, 14, 5291. [Google Scholar] [CrossRef] [PubMed]

- Gomez-Gras, G.; Pérez, M.A.; Fabregas-Moreno, J.; Reyes-Pozo, G. Experimental study on the accuracy and surface quality of printed versus machined holes in PEI Ultem 9085 FDM specimens. Rapid Prototyp. J. 2021, 27, 1–12. [Google Scholar] [CrossRef]

- Tiwary, V.K.; Arunkumar, P.; Vinayak, R.M. An overview on joining/welding as post-processing technique to circumvent the build volume limitation of an FDM-3D printer. Rapid Prototyp. J. 2021, 27, 808–821. [Google Scholar] [CrossRef]

- Popescu, D.; Amza, C.G.; Marinescu, R.; Iacob, M.C.; Căruţaşu, N.L. Investigations on Factors Affecting 3D-Printed Holes Dimensional Accuracy and Repeatability. Appl. Sci. 2023, 13, 41. [Google Scholar] [CrossRef]

- Zhang, W.; Lin, X.; Jiang, J. Dimensional accuracy of 3D printing navigation templates of chemical-based sterilization. Sci. Rep. 2022, 12, 1253. [Google Scholar] [CrossRef]

- Olasek, K.; Wiklak, P. Application of 3D printing technology in aerodynamic study. J. Phys. Conf. Ser. 2014, 530, 012009. [Google Scholar] [CrossRef]

- Junka, S.; Schröder, W.; Schrock, S. Design of additively manufactured wind tunnel models for use with UAVs. Procedia CIRP 2017, 60, 241–246. [Google Scholar] [CrossRef]

- Beltrán, N.; Carriles, F.; Álvarez, B.J.; Blanco, D.; Rico, J.C. Characterization of factors influencing dimensional and geometric errors in PolyJet manufacturing of cylindrical features. Procedia Eng. 2015, 132, 62–69. [Google Scholar] [CrossRef]

- Nagendra, K.M.; Rastogi, V.; Singh, P. Comparative Study and Measurement of Form Errors for the Component Printed by FDM and PolyJet Process. Instrum. Mes. Métrologie. 2019, 18, 353–359. [Google Scholar] [CrossRef]

- Pilipović, A.; Baršić, G.; Katić, M.; Rujnić Havstad, M. Repeatability and Reproducibility Assessment of a PolyJet Technology Using X-ray Computed Tomography. Appl. Sci. 2020, 10, 7040. [Google Scholar] [CrossRef]

- Tee, Y.L.; Tran, P.; Leary, M.; Pille, P.; Brandt, M. 3D Printing of polymer composites with material jetting: Mechanical and fractographic analysis. Addit. Manuf. 2020, 36, 101558. [Google Scholar] [CrossRef]

- ISO/ASTM 52902-15; Additive Manufacturing—Test Artifacts—Geometric Capability Assessment of Additive Manufacturing Systems. ISO: Geneva, Switzerland, 2019.

- Udroiu, R.; Braga, I.C.; Nedelcu, A. Evaluating the Quality Surface Performance of Additive Manufacturing Systems: Methodology and a Material Jetting Case Study. Materials 2019, 12, 995. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Lu, J. RP Part Surface quality versus build orientation: When the layers are getting thinner. Int. J. Adv. Manuf. Technol. 2013, 67, 377–385. [Google Scholar] [CrossRef]

- Udroiu, R.; Braga, I.C. System Performance and Process Capability in Additive Manufacturing: Quality Control for Polymer Jetting. Polymers 2020, 12, 1292. [Google Scholar] [CrossRef]

- Moylan, S. Progress toward standardized additive manufacturing test artifacts. In Proceedings of the ASPE 2015 Spring Topical Meeting Achieving Precision Tolerances in Additive Manufacturing, Raleigh, NC, USA, 26–29 April 2015; pp. 100–105. [Google Scholar]

- Krolczyk, G.; Raos, P.; Legutko, S. Experimental analysis of surface roughness and surface texture of machined and fused deposition modelled parts. Teh. Vjesn. 2014, 21, 217–221. [Google Scholar]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2017; ISBN 9781119113478. [Google Scholar]

- Minitab. Getting Started with Minitab 17. Available online: https://www.minitab.com (accessed on 15 March 2022).

- Objet Geometries. Eden 500V/350V/350 3-D Printer System. In User Guide; Objet Geometries Ltd.: Rehovot, Israel, 2007. [Google Scholar]

- ISO/ASTM 52921-13; Standard Terminology for Additive Manufacturing—Coordinate Systems and Test Methodologies. ISO: Geneva, Switzerland, 2013.

- Stratasys. PolyJet Materials Data Sheet. Available online: http://www.stratasys.com (accessed on 10 September 2015).

- Kepler, J. Investigation of Acrilic Based Systems for 3D Polyjet Printing. Master’s Thesis, University of Linz, Linz, Austria, 2018. [Google Scholar]

- Derby, B. The inkjet printing of functional and structural materials: Fluid property requirements, feature stability, and resolution. Annu. Rev. Mater. Res. 2010, 40, 395–414. [Google Scholar] [CrossRef]

| Level | Target | Artifact Orientation | Finish Type | Hole Orientation | Hole Diameter | ||||

|---|---|---|---|---|---|---|---|---|---|

| Symbol | Symbol | Value (°) | Symbol | Value | Symbol | Value | Symbol | Value [mm] | |

| 1 | Deviation | 1 | 0 | 1 | Matte | 1 | X | 1 | 1.4 |

| 2 | 2 | 90 | 2 | Glossy | 2 | Y | 2 | 1.2 | |

| 3 | - | - | - | - | 3 | Z | 3 | 1 | |

| 4 | - | - | - | - | - | - | 4 | 0.9 | |

| 5 | - | - | - | - | - | - | 5 | 0.8 | |

| 6 | - | - | - | - | - | - | 6 | 0.7 | |

| 7 | - | - | - | - | - | - | 7 | 0.6 | |

| 8 | - | -- | - | - | - | - | 8 | 0.5 | |

| Notation | Micro-Hole Diameter [mm] | Artifact Orientation and Finish Type | Micro-Hole Orientation | Position of the Micro-Hole End |

|---|---|---|---|---|

| Dval_GX_Z_Up | Dval | GX (X, glossy) | Z (along z-axis) | Up (on the upper surface) |

| Dval_GX_Z_Low | Dval | GX (X, glossy) | Z (along z-axis) | Low (on the lower surface) |

| Dval_GX_Y | Dval | GX (X, glossy) | Y (along y-axis) | - |

| Dval_GY_Z_Up | Dval | GY (Y, glossy) | Z (along z-axis) | Up (on the upper surface) |

| Dval_GY_Z_Low | Dval | GY (Y, glossy) | Z (along z-axis) | Low (on the lower surface) |

| Dval_GY_X | Dval | GY (Y, glossy) | X (along x-axis) | - |

| Dval_MX_Y | Dval | MX (X, matte) | Y (along y-axis) | - |

| Dval_MX_Z | Dval | MX (X, matte) | Z (along z-axis) | - |

| Dval_MY_X | Dval | MY (Y, matte) | X (along x-axis) | - |

| Dval_MY_Z | Dval | MY (Y matte) | Z (along z-axis) | - |

| Source | DF | Seq SS | Seq MS | Fexp | F0.1% | p | PC (%) |

|---|---|---|---|---|---|---|---|

| Artifact orientation | 1 | 0.006622 | 0.006622 | 19.97 | 17.14 | 0.001 | 6.10% |

| Finish type | 1 | 0.014793 | 0.014793 | 44.61 | 17.14 | <0.001 | 13.64% |

| Hole orientation | 2 | 0.013004 | 0.006502 | 19.61 | 9.72 | <0.001 | 11.99% |

| Hole diameter | 7 | 0.030356 | 0.004337 | 13.08 | 7.07 | <0.001 | 27.98% |

| Artifact orientation * Finish type | 1 | 0.001131 | 0.001131 | 3.41 | 17.14 | 0.086 | 1.04% |

| Artifact orientation * Hole diameter | 7 | 0.010874 | 0.001553 | 4.69 | 7.07 | 0.007 | 10.02% |

| Finish type * Hole orientation | 2 | 0.00267 | 0.001335 | 4.03 | 9.72 | 0.042 | 2.46% |

| Finish type * Hole diameter | 7 | 0.004573 | 0.000653 | 1.97 | 7.07 | 0.133 | 4.22% |

| Hole orientation * Hole diameter | 14 | 0.017266 | 0.001233 | 3.72 | 5.92 | 0.01 | 15.91% |

| Artifact orientation * Finish type * Hole diameter | 7 | 0.002562 | 0.000366 | 1.1 | 7.07 | 0.412 | 2.36% |

| Error | 14 | 0.004642 | 0.000332 | 4.28% | |||

| Total | 63 | 0.108491 | 100.00% |

| Micro-Hole Orientation | Mean Value [mm] | Standard Deviation [mm] | Coefficient of Variation [%] |

|---|---|---|---|

| X | 0.932 | 0.01129 | 1.21 |

| Z | 0.899 | 0.01274 | 1.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Udroiu, R. Quality Analysis of Micro-Holes Made by Polymer Jetting Additive Manufacturing. Polymers 2024, 16, 32. https://doi.org/10.3390/polym16010032

Udroiu R. Quality Analysis of Micro-Holes Made by Polymer Jetting Additive Manufacturing. Polymers. 2024; 16(1):32. https://doi.org/10.3390/polym16010032

Chicago/Turabian StyleUdroiu, Razvan. 2024. "Quality Analysis of Micro-Holes Made by Polymer Jetting Additive Manufacturing" Polymers 16, no. 1: 32. https://doi.org/10.3390/polym16010032

APA StyleUdroiu, R. (2024). Quality Analysis of Micro-Holes Made by Polymer Jetting Additive Manufacturing. Polymers, 16(1), 32. https://doi.org/10.3390/polym16010032