Fibrous Structures: An Overview of Their Responsiveness to External Stimuli towards Intended Application

Abstract

:1. Introduction

2. Responsive Fibrous Structures

2.1. Responsiveness to External Stimuli

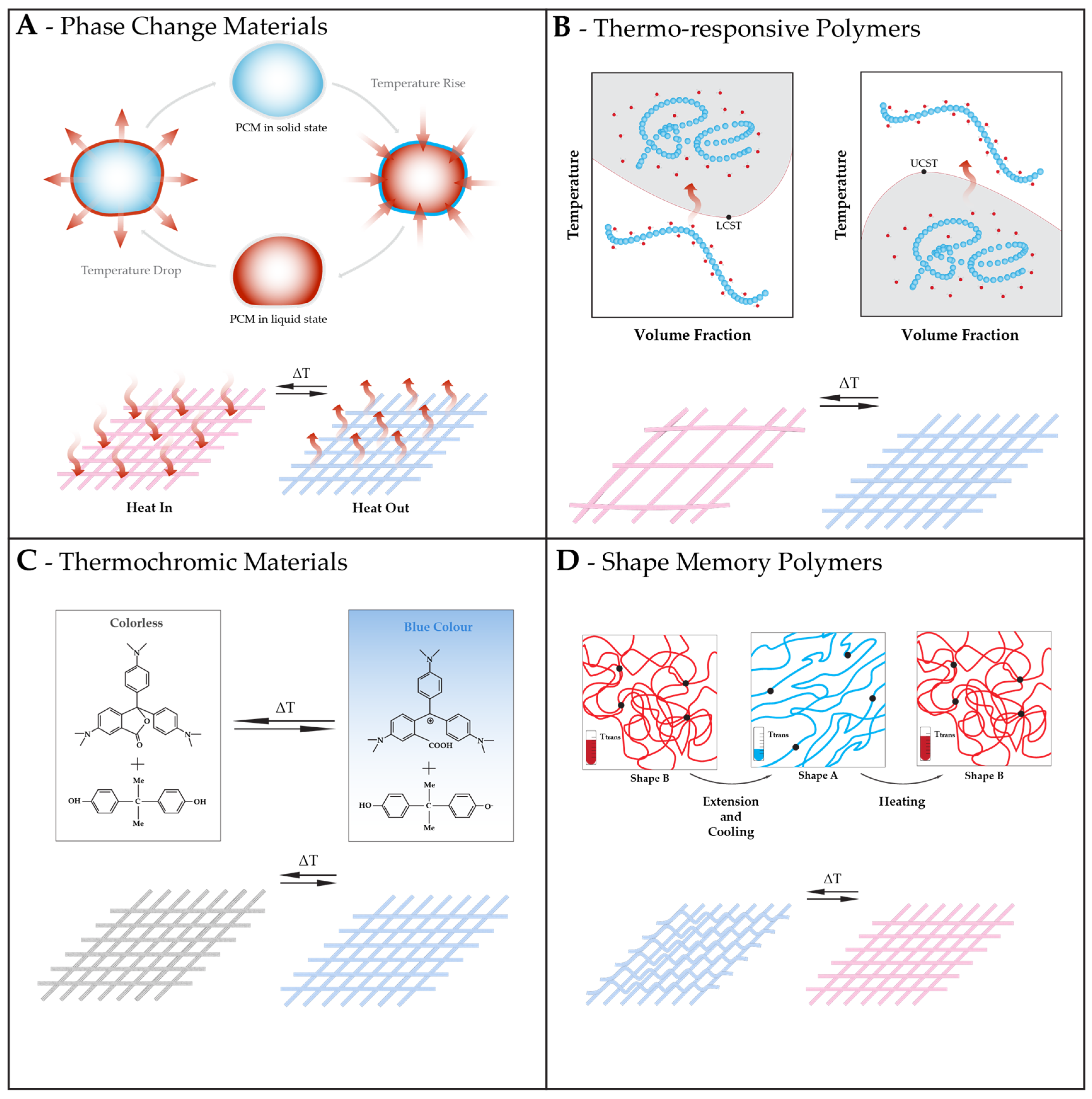

2.1.1. Temperature

Phase Change Materials

Shape Memory Materials

Thermo-Responsive Polymers

Thermochromic Materials

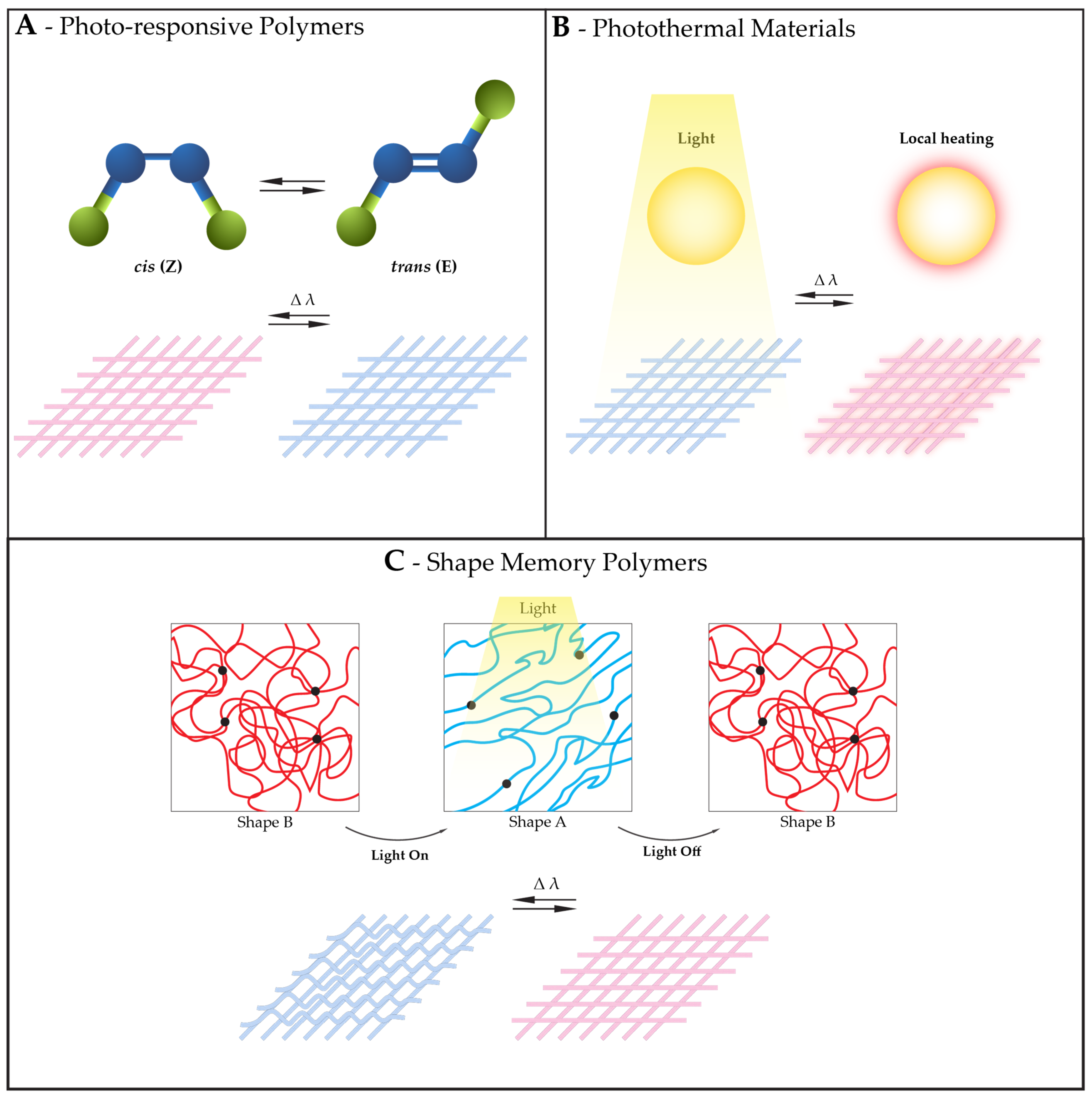

2.1.2. Light

Photo-Responsive Polymers

Photothermal Materials

2.1.3. pH

pH-Responsive Polymers

Halochromic Materials

3. Production of Responsive Fibrous Structures

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mishra, R.; Militky, J. Nanotechnology in Textiles—Theory and Application, 2nd ed.; Woodhead Publishing: Kidlington, UK, 2019; ISBN 9781782424581. [Google Scholar]

- Miao, M.; Xin, J.H. Engineering of High-Performance Textiles; Woodhead Publishing: Kidlington, UK, 2018; ISBN 9780081012734. [Google Scholar]

- Briggs-Goode, A.; Townsend, K. Textile Design: Principles, Advances and Applications; Woodhead Publishing: Cambridge, UK, 2011; ISBN 978-0-85709-256-4. [Google Scholar]

- Ahmed, U.; Hussain, T.; Abid, S. Role of Knitted Techniques in Recent Developments of Biomedical Applications: A Review. J Eng. Fiber Fabr. 2023, 18, 1–18. [Google Scholar] [CrossRef]

- Hasan, K.M.F.; Horváth, P.G.; Alpár, T. Potential Fabric-Reinforced Composites: A Comprehensive Review. J. Mater. Sci. 2021, 56, 14381–14415. [Google Scholar] [CrossRef]

- Stolyarov, O.; Quadflieg, T.; Gries, T. Effects of Fabric Structures on the Tensile Properties of Warp-Knitted Fabrics Used as Concrete Reinforcements. Text. Res. J. 2015, 85, 1934–1945. [Google Scholar] [CrossRef]

- He, Z.; Xuan, H.; Bai, C.; Song, M.; Zhu, Z. Containment of Soft Wall Casing Wrapped with Kevlar Fabric. Chin. J. Aeronaut. 2019, 32, 954–966. [Google Scholar] [CrossRef]

- Stránská, E.; Neděla, D. Reinforcing Fabrics as the Mechanical Support of Ion Exchange Membranes. J. Ind. Text. 2018, 48, 432–447. [Google Scholar] [CrossRef]

- Choudhury, A.K.R. Principles of Textile Finishing; Woodhead Publishing: Kidlington, UK, 2017; ISBN 978-0-08-100646-7. [Google Scholar]

- Sharma, D.; Ziegler, G.R.; Harte, F.M. Ethanol-Mediated Electrospinning of Casein-Only Bead-Free Nanofibers. Food Hydrocoll. 2024, 148, 109503. [Google Scholar] [CrossRef]

- Fawal, G.F.E. Polymer Nanofibers Electrospinning: A Review. Egypt J. Chem. 2020, 63, 1279–1303. [Google Scholar] [CrossRef]

- Antunes, J.C.; Moreira, I.P.; Gomes, F.; Cunha, F.; Henriques, M.; Fangueiro, R. Recent Trends in Protective Textiles against Biological Threats: A Focus on Biological Warfare Agents. Polymers 2022, 14, 1599. [Google Scholar] [CrossRef] [PubMed]

- Haider, A.; Haider, S.; Kang, I.K. A Comprehensive Review Summarizing the Effect of Electrospinning Parameters and Potential Applications of Nanofibers in Biomedical and Biotechnology. Arab. J. Chem. 2018, 11, 1165–1188. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, Y.; Zhang, M.; Feng, Z.; Yu, D.G.; Wang, K. Electrospun Nanofiber Membranes for Air Filtration: A Review. Nanomaterials 2022, 12, 1077. [Google Scholar] [CrossRef]

- Zhuo, T.; Xin, B.; Chen, Z.; Xu, Y.; Zhou, X.; Yu, J. Enhanced Thermal Insulation Properties of PI Nanofiber Membranes Achieved by Doping with SiO2 Nanoparticles. Eur. Polym. J. 2021, 153, 110489. [Google Scholar] [CrossRef]

- Rossin, A.R.S.; Spessato, L.; da Silva Lima Cardoso, F.; Caetano, J.; Caetano, W.; Radovanovic, E.; Dragunski, D.C. Electrospinning in Personal Protective Equipment for Healthcare Work. Polym. Bull. 2023, 81, 1957–1980. [Google Scholar] [CrossRef]

- Halicka, K.; Cabaj, J. Electrospun Nanofibers for Sensing and Biosensing Applications—A Review. Int. J. Mol. Sci. 2021, 22, 6357. [Google Scholar] [CrossRef]

- Chen, K.; Hu, H.; Zeng, Y.; Pan, H.; Wang, S.; Zhang, Y.; Shi, L.; Tan, G.; Pan, W.; Liu, H. Recent Advances in Electrospun Nanofibers for Wound Dressing. Eur. Polym. J. 2022, 178, 111490. [Google Scholar] [CrossRef]

- Flores-Rojas, G.G.; Gómez-Lazaro, B.; López-Saucedo, F.; Vera-Graziano, R.; Bucio, E.; Mendizábal, E. Electrospun Scaffolds for Tissue Engineering: A Review. Macromol 2023, 3, 31. [Google Scholar] [CrossRef]

- Dang, T.; Zhao, M. The Application of Smart Fibers and Smart Textiles. J. Phys. Conf. Ser. 2021, 1790, 012084. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Y.; Liang, X.; Zhang, Y. Smart Fibers and Textiles for Personal Health Management. ACS Nano 2021, 15, 12497–12508. [Google Scholar] [CrossRef]

- Agra-Kooijman, D.M.; Mostafa, M.; Krifa, M.; Ohrn-McDaniel, L.; West, J.L.; Jákli, A. Liquid Crystal Coated Yarns for Thermo-Responsive Textile Structures. Fibers 2023, 11, 3. [Google Scholar] [CrossRef]

- Ramesh, S.; Davis, J.; Roros, A.; Zhou, C.; He, N.; Gao, W.; Khan, S.; Genzer, J.; Menegatti, S. Nonwoven Membranes with Infrared Light-Controlled Permeability. ACS Appl. Mater. Interfaces 2022, 14, 42558–42567. [Google Scholar] [CrossRef]

- Jia, J.; Liu, W.; Xiao, Q.; Yang, Y.; Chen, J.; Li, H.; Fang, X.; Li, Y. Smart PH Indicating Functional Fabric Based on Reversible Acidichromic Self-Colored Microparticles. Prog. Org. Coat. 2023, 185, 107894. [Google Scholar] [CrossRef]

- Meng, X.; Yang, J.; Liu, W.; Ramakrishna, S.; Sun, Y.; Dai, Y. Stimulus-Responsive Graphene with Periodical Wrinkles on Grooved Microfiber Arrays: Simulation, Programmable Shape-Shifting, and Catalytic Applications. ACS Appl. Mater. Interfaces 2021, 13, 26561–26572. [Google Scholar] [CrossRef] [PubMed]

- Xu, R.; Wu, G.; Jiang, M.; Cao, S.; Panahi-Sarmad, M.; Kamkar, M.; Xiao, X. Multi-Stimuli Dually-Responsive Intelligent Woven Structures with Local Programmability for Biomimetic Applications. Small 2023, 19, 2207900. [Google Scholar] [CrossRef] [PubMed]

- Nadi, A.; Jamoudi Sbai, S.; Bentiss, A.; Belaiche, M.; Briche, S.; Gmouh, S. Application of Fe3O4 Nanoparticles on Cotton Fabrics by the Pad-Dry-Cure Process for the Elaboration of Magnetic and Conductive Textiles. IOP Conf. Ser. Mater. Sci. Eng. 2020, 827, 012021. [Google Scholar] [CrossRef]

- Quartinello, F.; Tallian, C.; Auer, J.; Schön, H.; Vielnascher, R.; Weinberger, S.; Wieland, K.; Weihs, A.M.; Herrero-Rollett, A.; Lendl, B.; et al. Smart Textiles in Wound Care: Functionalization of Cotton/PET Blends with Antimicrobial Nanocapsules. J. Mater. Chem. B 2019, 7, 6592–6603. [Google Scholar] [CrossRef]

- Li, Y.; Jia, J.; Yu, H.; Wang, S.; Jin, Z.Y.; Zhang, Y.H.; Ma, H.Z.; Zhang, K.; Ke, K.; Yin, B.; et al. Macromolecule Relaxation Directed 3D Nanofiber Architecture in Stretchable Fibrous Mats for Wearable Multifunctional Sensors. ACS Appl. Mater. Interfaces 2022, 14, 15678–15686. [Google Scholar] [CrossRef] [PubMed]

- Drikvand, H.N.; Golgoli, M.; Zargar, M.; Ulbricht, M.; Nejati, S.; Mansourpanah, Y. Thermo-Responsive Hydrophilic Support for Polyamide Thin-Film Composite Membranes with Competitive Nanofiltration Performance. Polymers 2022, 14, 3376. [Google Scholar] [CrossRef] [PubMed]

- Liao, X.; Xiang, Z.; Lei, Y.; Zhu, Z.; Guo, J.; Lin, S.; Shang, J. Facile Fabrication of PH-Controlled Drug Release Mat via Engineering 3D Reversible Gel-like Nanofibers. Polymers 2022, 252, 124925. [Google Scholar] [CrossRef]

- Choe, A.; Kwon, Y.; Shin, Y.E.; Yeom, J.; Kim, J.; Ko, H. Adaptive IR- and Water-Gating Textiles Based on Shape Memory Fibers. ACS Appl. Mater. Interfaces 2022, 14, 55217–55226. [Google Scholar] [CrossRef]

- Jin, Y.; Liu, Y.; Li, X.; Zhong, T. Self-Cleaning and Antifouling Properties of Silica/Octadecylamine-Coated Cotton Fabrics. Fibers Polym. 2023, 24, 3879–3887. [Google Scholar] [CrossRef]

- Çelikel, D.C. Smart E-Textile Materials. In Advanced Functional Materials; Tasaltin, N., Nnamchi, P.S., Saud, S., Eds.; IntechOpen: Rijeka, Croatia, 2020; pp. 1–17. ISBN 978-1-83962-480-3. [Google Scholar]

- Šubrová, T.; Wiener, J.; Khan, M.Z.; Šlamborová, I.; Mullerová, S. Development of Novel Eco-Friendly Polyvinyl Alcohol-Based Coating for Antibacterial Textiles. Colloids Surf. A Physicochem. Eng. Asp. 2024, 680, 132719. [Google Scholar] [CrossRef]

- Wicaksono, I.; Tucker, C.I.; Sun, T.; Guerrero, C.A.; Liu, C.; Woo, W.M.; Pence, E.J.; Dagdeviren, C. A Tailored, Electronic Textile Conformable Suit for Large-Scale Spatiotemporal Physiological Sensing in Vivo. NPJ Flex. Electron. 2020, 4, 5. [Google Scholar] [CrossRef]

- Ganesh, V.A.; Baji, A.; Ramakrishna, S. Smart Functional Polymers—A New Route towards Creating a Sustainable Environment. RSC Adv. 2014, 4, 53352–53364. [Google Scholar] [CrossRef]

- Williams, M.W.; Wimberly, J.A.; Stwodah, R.M.; Nguyen, J.; D’Angelo, P.A.; Tang, C. Temperature-Responsive Structurally Colored Fibers via Blend Electrospinning. ACS Appl. Polym. Mater. 2023, 5, 3065–3078. [Google Scholar] [CrossRef]

- Józefczak, A.; Kaczmarek, K.; Bielas, R.; Procházková, J.; Šafařík, I. Magneto-Responsive Textiles for Non-Invasive Heating. Int. J. Mol. Sci. 2023, 24, 11744. [Google Scholar] [CrossRef]

- Ning, D.; Lu, Z.; Liu, J.; Ji, X.; Geng, B.; Tian, C.; Songfeng, E. pH-Responsive BNNS/PAA Nanofiltration Membrane for Tunable Water Permeance and Efficient Dye Separation. Sep. Purif. Technol. 2024, 328, 125023. [Google Scholar] [CrossRef]

- Ziai, Y.; Petronella, F.; Rinoldi, C.; Nakielski, P.; Zakrzewska, A.; Kowalewski, T.A.; Augustyniak, W.; Li, X.; Calogero, A.; Sabała, I.; et al. Chameleon-Inspired Multifunctional Plasmonic Nanoplatforms for Biosensing Applications. NPG Asia Mater. 2022, 14, 18. [Google Scholar] [CrossRef]

- Min, T.; Zhou, L.; Sun, X.; Du, H.; Bian, X.; Zhu, Z.; Wen, Y. Enzyme-Responsive Food Packaging System Based on Pectin-Coated Poly (Lactic Acid) Nanofiber Films for Controlled Release of Thymol. Food. Res. Int. 2022, 157, 111256. [Google Scholar] [CrossRef]

- Genç, S.D.; Alay Aksoy, S.; Alkan, C. A Smart Cotton Fabric with Adaptive Moisture Management through Temperature Sensitive Poly(2-Hydroxyethyl-6-(Vinyl Amino)Hexanoate) Finishing. Cellulose 2023, 30, 2467–2481. [Google Scholar] [CrossRef]

- Li, S.; Yang, H.; Chen, G.; Zheng, J.; Wang, W.; Ren, J.; Zhu, C.; Yang, Y.; Cong, Y.; Fu, J. 4D Printing of Biomimetic Anisotropic Self-Sensing Hydrogel Actuators. Chem. Eng. J. 2023, 473, 145444. [Google Scholar] [CrossRef]

- Wei, M.; Gao, Y.; Li, X.; Serpe, M.J. Stimuli-Responsive Polymers and Their Applications. Polym. Chem. 2017, 8, 127–143. [Google Scholar] [CrossRef]

- Liu, T.; Bao, B.; Li, Y.; Lin, Q.; Zhu, L. Photo-responsive polymers based on o-Nitrobenzyl derivatives: From structural design to applications. Prog. Polym. Sci. 2023, 146, 101741. [Google Scholar] [CrossRef]

- Genç, S.D.; Aksoy, S.A. Development of Temperature and PH Responsive Smart Cotton Fabrics by P(NIPAM-Co-MAM) Copolymer Finishing. Tekst. Konfeksiyon 2022, 32, 193–207. [Google Scholar]

- Jocić, D. Polymer-Based Smart Coatings for Comfort in Clothing. Tekstilec 2016, 59, 107–114. [Google Scholar] [CrossRef]

- Saadat, Y.; Kim, K.; Foudazi, R. Two-Step Thermoresponsive Ultrafiltration Membranes from Polymerization of Lyotropic Liquid Crystals. ACS Appl. Polym. Mater. 2022, 4, 8156–8165. [Google Scholar] [CrossRef]

- Weng, L.; Xie, J. Smart Electrospun Nanofibers for Controlled Drug Release: Recent Advances and New Perspectives. Curr. Pharm. Des. 2015, 21, 1944–1959. [Google Scholar] [CrossRef] [PubMed]

- Mondal, S. Phase Change Materials for Smart Textiles—An Overview. Appl. Therm. Eng. 2008, 28, 1536–1550. [Google Scholar] [CrossRef]

- De Castro, P.F.; Minko, S.; Vinokurov, V.; Cherednichenko, K.; Shchukin, D.G. Long-Term Autonomic Thermoregulating Fabrics Based on Microencapsulated Phase Change Materials. ACS Appl. Energy Mater. 2021, 4, 12789–12797. [Google Scholar] [CrossRef]

- Sarier, N.; Onder, E. The Manufacture of Microencapsulated Phase Change Materials Suitable for the Design of Thermally Enhanced Fabrics. Thermochim. Acta 2007, 452, 149–160. [Google Scholar] [CrossRef]

- Kumar, A.; Kebaili, I.; Boukhris, I.; Vaish, R.; Kumar, A.; Park, H.K.B.; Joo, Y.H.; Sung, T.H. Cotton Functionalized with Polyethylene Glycol and Graphene Oxide for Dual Thermoregulating and UV-Protection Applications. Sci. Rep. 2023, 13, 5923. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Y.; Zhu, Z.; Zhu, J.; Luo, J.; Peng, F.; Sun, X. Thermal Comfort in a Building with Trombe Wall Integrated with Phase Change Materials in Hot Summer and Cold Winter Region without Air Conditioning. Energy Built. Environ. 2024, 5, 58–69. [Google Scholar] [CrossRef]

- Qu, J.G.; Liu, Y.; Zhang, J.F.; Jin, Z.G.; Chen, Y.S.; Zhao, X. Experimental Study on Heat Transfer during Melting in Metal and Carbon Foam Saturated with Phase-Change Materials for Temperature Control in Electronic Devices. Appl. Therm. Eng. 2024, 236, 121681. [Google Scholar] [CrossRef]

- Ma, Q.; Wang, X.; Chen, Y.; Chen, L.; Zhang, L.; Zhao, X.; Bing, N.; Yu, W.; Xie, H. Poly(Vinyl Alcohol)-Based Nanofibers with Improved Thermal Conductivity and Efficient Photothermal Response for Wearable Thermal Management. ACS Appl. Nano. Mater. 2023, 6, 14733–14744. [Google Scholar] [CrossRef]

- El Majd, A.; Younsi, Z.; Youssef, N.; Belouaggadia, N.; El Bouari, A. Experimental Study of Thermal Characteristics of Bio-Based Textiles Integrating Microencapsulated Phase Change Materials. Energy Build. 2023, 297, 113465. [Google Scholar] [CrossRef]

- Reghunadhan, A.; Jibin, K.P.; Kaliyathan, A.V.; Velayudhan, P.; Strankowski, M.; Thomas, S. Shape Memory Materials from Rubbers. Materials 2021, 14, 7216. [Google Scholar] [CrossRef] [PubMed]

- Hornbogen, E. Comparison of Shape Memory Metals and Polymers. Adv. Eng. Mater. 2006, 8, 101–106. [Google Scholar] [CrossRef]

- Leng, J.; Lan, X.; Liu, Y.; Du, S. Shape-Memory Polymers and Their Composites: Stimulus Methods and Applications. Prog. Mater. Sci. 2011, 56, 1077–1135. [Google Scholar] [CrossRef]

- Behl, M.; Lendlein, A. Shape-Memory Polymers. Mater. Today 2007, 10, 20–28. [Google Scholar] [CrossRef]

- Tekay, E. Low-Voltage Triggered Electroactive and Heat-Responsive Thermoplastic Elastomer/Carbon Nanotube Polymer Blend Composites. Mater. Today Commun. 2023, 35, 106443. [Google Scholar] [CrossRef]

- Bertran, J.G.; Ardanuy, M.; González, M.; Rodriguez, R.; Jovančić, P. Design and Characterization of Reversible Thermodynamic SMPU-Based Fabrics with Improved Comfort Properties. J. Ind. Text. 2023, 53, 15280837231166390. [Google Scholar] [CrossRef]

- Zhang, P.; Cai, F.; Wang, G.J.; Yu, H.F. UV-Vis-NIR Light-Deformable Shape-Memory Polyurethane Doped with Liquid-Crystal Mixture and GO towards Biomimetic Applications. Chin. J. Polym. Sci. (Engl. Ed.) 2022, 40, 166–174. [Google Scholar] [CrossRef]

- Mohr, R.; Kratz, K.; Weigel, T.; Lucka-Gabor, M.; Moneke, M.; Lendlein, A. Initiation of Shape-Memory Effect by Inductive Heating of Magnetic Nanoparticles in Thermoplastic Polymers. PNAS 2006, 7, 3540–3545. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Wang, Y.; Wang, S.; Liu, Z.; Liu, Z.; Jiang, J. A Thermo- and Moisture-Responsive Zwitterionic Shape Memory Polymer for Novel Self-Healable Wound Dressing Applications. Macromol. Mater. Eng. 2019, 304, 1800603. [Google Scholar] [CrossRef]

- Song, Q.; Chen, H.; Zhou, S.; Zhao, K.; Wang, B.; Hu, P. Thermo- and PH-Sensitive Shape Memory Polyurethane Containing Carboxyl Groups. Polym. Chem. 2016, 7, 1739–1746. [Google Scholar] [CrossRef]

- Li, J.; Duan, Q.; Zhang, E.; Wang, J. Applications of Shape Memory Polymers in Kinetic Buildings. Adv. Mater. Sci. Eng. 2018, 2018, 7453698. [Google Scholar] [CrossRef]

- Xie, T. Recent Advances in Polymer Shape Memory. Polymer 2011, 52, 4985–5000. [Google Scholar] [CrossRef]

- Yang, X.; Han, Z.; Jia, C.; Wang, T.; Wang, X.; Hu, F.; Zhang, H.; Zhao, J.; Zhang, X. Preparation and Characterization of Body-Temperature-Responsive Thermoset Shape Memory Polyurethane for Medical Applications. Polymers 2023, 15, 3193. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Song, X.; Chen, Y.; Xin, W.; Zhu, C.; Huang, Y.; Tian, N.; Huang, Y. Self-Healing of Poly(Vinyl Alcohol)/Poly(Acrylic Acid)-Polytetrahydrofuran-Poly(Acrylic Acid) Blend Boosted via Shape Memory. Langmuir 2023, 39, 14811–14821. [Google Scholar] [CrossRef]

- Emmanuel, K.D.C.; Jeewantha, L.H.J.; Herath, H.M.C.M.; Epaarachchi, J.A.; Aravinthan, T. Shape Memory Polymer Composite Circular and Square Hollow Members for Deployable Structures. Compos. Part. A Appl. Sci. Manuf. 2023, 171, 107559. [Google Scholar] [CrossRef]

- An, S.C.; Lim, Y.; Jun, Y.C. Rapid and Selective Actuation of 3D-Printed Shape-Memory Composites via Microwave Heating. Sci. Rep. 2023, 13, 18179. [Google Scholar] [CrossRef]

- Peng, S.; Cao, X.; Sun, Y.; Chen, L.; Ma, C.; Yang, L.; Zhao, H.; Liu, Q.; Liu, Z.; Ma, C. Polyurethane Shape Memory Polymer/pH-Responsive Hydrogel Hybrid for Bi-Function Synergistic Actuations. Gels 2023, 9, 428. [Google Scholar] [CrossRef]

- Yang, F.T.; Chen, Y.M.; Rwei, S.P. Synthesis and Characterization of the Temperature Controllable Shape Memory of Polycaprolactone/Poly(Ethylene Terephthalate) Copolyester. Fibers Polym. 2022, 23, 2526–2538. [Google Scholar] [CrossRef]

- de Castro, P.B.; Salmoria, G.V.; de Mello Roesler, C.R.; da Rosa, E.; Fancello, E.A. A Study on the Response of PLGA 85/15 under Compression and Heat-Treatment Testing Cycles. Mech. Time Depend. Mater. 2021, 25, 411–427. [Google Scholar] [CrossRef]

- Ranganatha Swamy, M.K.; Mallikarjun, U.S.; Udayakumar, V. Cyclic Thermomechanical Analysis of Polyethylene Glycol Based Shape Memory Polymers. J. Mines Met. Fuels 2022, 70, 282–289. [Google Scholar] [CrossRef]

- Rolińska, K.; Bakhshi, H.; Balk, M.; Blocki, A.; Panwar, A.; Puchalski, M.; Wojasiński, M.; Mazurek-Budzyńska, M. Electrospun Poly(Carbonate-Urea-Urethane)s Nonwovens with Shape-Memory Properties as a Potential Biomaterial. ACS Biomater. Sci. Eng. 2023, 9, 6683–6697. [Google Scholar] [CrossRef]

- Leonés, A.; Sonseca, A.; López, D.; Fiori, S.; Peponi, L. Shape Memory Effect on Electrospun PLA-Based Fibers Tailoring Their Thermal Response. Eur. Polym. J. 2019, 117, 217–226. [Google Scholar] [CrossRef]

- Qi, Y.; Sun, B.; Gu, B.; Zhang, W. Electrothermally Actuated Properties of Fabric-Reinforced Shape Memory Polymer Composites Based on Core–Shell Yarn. Compos. Struct. 2022, 292, 115681. [Google Scholar] [CrossRef]

- Shi, Y.; Chen, H.; Guan, X. High Shape Memory Properties and High Strength of Shape Memory Polyurethane Nanofiber-Based Yarn and Coil. Polym. Test 2021, 101, 107277. [Google Scholar] [CrossRef]

- Liu, L.; Xu, W.; Ding, Y.; Agarwal, S.; Greiner, A.; Duan, G. A Review of Smart Electrospun Fibers toward Textiles. Compos. Commun. 2020, 22, 100506. [Google Scholar] [CrossRef]

- Kotova, S.; Kostjuk, S.; Rochev, Y.; Efremov, Y.; Frolova, A.; Timashev, P. Phase Transition and Potential Biomedical Applications of Thermoresponsive Compositions Based on Polysaccharides, Proteins and DNA: A Review. Int. J. Biol. Macromol. 2023, 249, 126054. [Google Scholar] [CrossRef]

- Wu, C.; Wang, X. Globule-to-Coil Transition of a Single Homopolymer Chain in Solution. Phys. Rev. Lett. 1998, 80, 4092–4094. [Google Scholar] [CrossRef]

- Wang, X.; Qiu, X.; Wu, C. Comparison of the Coil-to-Globule and the Globule-to-Coil Transitions of a Single Poly(N-Isopropylacrylamide) Homopolymer Chain in Water. Macromolecules 1998, 31, 2972–2976. [Google Scholar] [CrossRef]

- Khrystonko, O.; Rimpelová, S.; Burianová, T.; Švorčík, V.; Lyutakov, O.; Elashnikov, R. Smart Multi Stimuli-Responsive Electrospun Nanofibers for on-Demand Drug Release. J. Colloid. Interface Sci. 2023, 648, 338–347. [Google Scholar] [CrossRef]

- Li, W.; Zhao, Y.; Sun, W.; Dong, T.; Saldaña, M.D.A.; Sun, W. Multi-Responsive Poly N-Isopropylacrylamide/Poly N-Tert-Butylacrylamide Nanocomposite Hydrogel with the Ability to Be Adsorbed on the Chitosan Film as an Active Antibacterial Material. Int. J. Biol. Macromol. 2022, 208, 1019–1028. [Google Scholar] [CrossRef]

- Zhang, Z.; Tan, S.; Bao, Z.; Wu, Y.; Wang, C. Thermal Conductivity of PNIPAm Hydrogels and Heat Management as Smart Windows. Macromol. Mater. Eng. 2023, 308, 2200566. [Google Scholar] [CrossRef]

- Sim, H.J.; Noh, J.H.; Choi, C. Bio-Inspired Shape-Morphing Actuator with a Large Stroke at Low Temperatures. Sens. Actuators B Chem. 2023, 378, 133185. [Google Scholar] [CrossRef]

- Xu, R.; Ma, S.; Wu, Y.; Lee, H.; Zhou, F.; Liu, W. Adaptive Control in Lubrication, Adhesion, and Hemostasis by Chitosan-Catechol-PNIPAM. Biomater. Sci. 2019, 7, 3599–3608. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhou, K.; Jiang, H.; Zhang, S.; Zhang, B.; Guo, M.; He, G. Poly(NIPAM-Co-Thienoviologen) for Multi-Responsive Smart Windows and Thermo-Controlled Photodynamic Antimicrobial Therapy. J. Mater. Chem. A Mater. 2021, 9, 18369–18376. [Google Scholar] [CrossRef]

- Cerda-Sumbarda, Y.D.; Domínguez-González, C.; Zizumbo-López, A.; Licea-Claverie, A. Thermoresponsive Nanocomposite Hydrogels with Improved Properties Based on Poly(N-Vinylcaprolactam). Mater. Today. Commun. 2020, 24, 101041. [Google Scholar] [CrossRef]

- Karjalainen, E.; Aseyev, V.; Tenhu, H. Influence of Hydrophobic Anion on Solution Properties of PDMAEMA. Macromolecules 2014, 47, 2103–2111. [Google Scholar] [CrossRef]

- Silva, J.B.; Haddow, P.; Bruschi, M.L.; Cook, M.T. Thermoresponsive Poly(Di(Ethylene Glycol) Methyl Ether Methacrylate)-Ran-(Polyethylene Glycol Methacrylate) Graft Copolymers Exhibiting Temperature-Dependent Rheology and Self-Assembly. J. Mol. Liq. 2022, 346, 117906. [Google Scholar] [CrossRef]

- Hegazy, M. PVCL-Grafted Mesoporous Silica Nanocontainers for Thermo-Responsive Controlled Release and Their Antifungal Activity Study. Mater. Today Commun. 2023, 35, 105585. [Google Scholar] [CrossRef]

- Seuring, J.; Agarwal, S. Polymers with Upper Critical Solution Temperature in Aqueous Solution. Macromol. Rapid Commun. 2012, 33, 1898–1920. [Google Scholar] [CrossRef]

- Liang, J.; Ding, L.; Yu, Z.; Zhang, X.; Chen, S.; Wang, Y. Smart and Programmed Thermo-Wetting Yarns for Scalable and Customizable Moisture/Heat Conditioning Textiles. J. Colloid Interface Sci. 2023, 651, 612–621. [Google Scholar] [CrossRef] [PubMed]

- Qi, B.; Fan, B.; Xu, B.; Zhou, M.; Yu, Y.; Cui, L.; Wang, Q.; Wang, P. Enzymatic Construction of Temperature-Responsive PDMAPS-Decorated Textiles for Oil-Water Separation. Colloids Surf. A Physicochem. Eng. Asp. 2023, 656, 130340. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, Y.N.; Chong, J.Y.; Wang, R. Thermo-Responsive Nonionic Amphiphilic Copolymers as Draw Solutes in Forward Osmosis Process for High-Salinity Water Reclamation. Water. Res. 2022, 221, 18768. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Bao, X.; Wang, Q.; Wang, P.; Zhou, M.; Yu, Y. Thermo-Responsive Cotton Fabric Prepared by Enzyme-Initiated “Graft from” Polymerization for Moisture/Thermal Management. Cellulose 2021, 28, 1795–1808. [Google Scholar] [CrossRef]

- Genç, S.D.; Alay-Aksoy, S. Production of CS-g-PNIPAM Copolymer and Stimuli Responsive and Antibacterial Cotton Fabric. Int. J. Cloth. Sci. Technol. 2022, 34, 852–868. [Google Scholar] [CrossRef]

- Genç, S.D.; Aksoy, S.A. Synthesis of Poly(N-Isopropylacrylamide) Polymer for Fabrication of Thermo-Responsive Cotton Fabric. Indian J. Fibre Text. Res. 2021, 46, 385–397. [Google Scholar] [CrossRef]

- Ghasemi, H.; Abu-Zahra, N.; Baig, N.; Abdulazeez, I.; Aljundi, I.H. Enhancing Fouling Resistance and Separation Performance of Polyethersulfone Membrane through Surface Grafting with Copolymerized Thermo-Responsive Polymer and Copper Oxide Nanoparticles. Chem. Eng. J. Adv. 2023, 16, 100528. [Google Scholar] [CrossRef]

- Lin, Y.; Cheng, N.; Meng, N.; Wang, C.; Wang, X.; Yu, J.; Ding, B. A Patterned Knitted Fabric with Reversible Gating Stability for Dynamic Moisture Management of Human Body. Adv. Funct. Mater. 2023, 33, 2304109. [Google Scholar] [CrossRef]

- Hakami, A.; Srinivasan, S.S.; Biswas, P.K.; Krishnegowda, A.; Wallen, S.L.; Stefanakos, E.K. Review on Thermochromic Materials: Development, Characterization, and Applications. J. Coat. Technol. Res. 2022, 19, 377–402. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, Z.; He, F.; Chen, Z.; Li, X.; Wang, P.; He, G.; Zhu, X.; Yang, W. Reversible Thermochromic Microcapsules with SiO2 Shell for Indicating Temperature and Thermoregulation. J. Energy Storage 2023, 72, 108674. [Google Scholar] [CrossRef]

- Pareja-Rivera, C.; Solis-Ibarra, D. Reversible and Irreversible Thermochromism in Copper-Based Halide Perovskites. Adv. Opt. Mater. 2021, 9, 2100633. [Google Scholar] [CrossRef]

- Nguyen, D.K.; Lee, H.; Kim, I.T. Synthesis and Thermochromic Properties of Cr-Doped Al2O3 for a Reversible Thermochromic Sensor. Materials 2017, 10, 476. [Google Scholar] [CrossRef] [PubMed]

- Nataraj, L.; Burke, R.; Wilson, A.; Hanrahan, B.; Knick, C.; Walck, S.; Phillips, F. Simultaneous Multi-Domain Transformation of Vanadium Dioxide for Reconfigurable Metamaterial Architectures. Appl. Phys. A Mater. Sci. Process. 2022, 128, 506. [Google Scholar] [CrossRef]

- Xiang, W.; Le Drogoff, B.; Koch, D.; Margot, J.; Chaker, M. High-Quality VO2 Films Synthesized on Polymer Substrates Using Room-Temperature Pulsed Laser Deposition and Annealing. Ceram. Int. 2023, 50, 838–846. [Google Scholar] [CrossRef]

- Sahebkar, K.; Indrakar, S.; Srinivasan, S.; Thomas, S.; Stefanakos, E. Electrospun Microfibers with Embedded Leuco Dye-Based Thermochromic Material for Textile Applications. J. Ind. Text. 2022, 51, 3188S–3200S. [Google Scholar] [CrossRef]

- White, M.A.; LeBlanc, M. Thermochromism in Commercial Products. J. Chem. Educ. 1999, 76, 1201–1205. [Google Scholar] [CrossRef]

- Hanzer, S.J.; Kulčar, R.; Vukoje, M.; Marošević, A.; Dolovski, M. Assessment of Thermochromic Packaging Prints’ Resistance to UV Radiation and Various Chemical Agents. Polymers 2023, 15, 1208. [Google Scholar] [CrossRef]

- Babazadeh-Mamaqani, M.; Mohammadi-Jorjafki, M.; Alipour-Fakhri, S.; Mardani, H.; Roghani-Mamaqani, H. Thermal-Induced Chromism and Fluorescence Emission of Rhodamine B-Containing Polymers with Different Polarities: Tracking Temperature and Development of Thermochromic Labels. Macromolecules 2023, 56, 5843–5853. [Google Scholar] [CrossRef]

- Liu, J.; Tan, J.; Liu, H.; Yin, Y.; Wang, C. Multicolor-Tunable Biomass Thermochromic Dyes Utilizing Tea Polyphenols Color Developer for Temperature-Controlled Linen Fabric. Ind. Crops Prod. 2023, 204, 117254. [Google Scholar] [CrossRef]

- Badour, Y.; Danto, S.; Albakour, S.; Mornet, S.; Penin, N.; Hirsch, L.; Gaudon, M. Low-Cost WO3 Nanoparticles/PVA Smart Photochromic Glass Windows for Sustainable Building Energy Savings. Sol. Energy Mater. Sol. Cells 2023, 255, 112291. [Google Scholar] [CrossRef]

- Li, H.; Zhang, X.; Tian, L.; Jia, M.; Xie, N.; Han, Y.; Yuan, X.; Li, K.; Qian, S. Experimental Investigation on Performance of Composite Thermochromic and Ice-Melting Coatings for Dynamic Pavement Temperature Control. Constr. Build Mater. 2023, 409, 133787. [Google Scholar] [CrossRef]

- Zhou, L.; Ye, J.; Cai, Q.; Liu, G.; Dadgar, M.; Zhu, G.; Zhang, G. Study on Preparation, Characterization and Application of Mixed-Colorants Thermochromic Microcapsules. Particuology 2024, 88, 89–97. [Google Scholar] [CrossRef]

- Ye, Q.; Wang, R.; Yan, S.; Chen, B.; Zhu, X. Bioinspired Photo-Responsive Membrane Enhanced with “Light-Cleaning” Feature for Controlled Molecule Release. J. Mater. Chem. B 2021, 10, 2617–2627. [Google Scholar] [CrossRef] [PubMed]

- Lu, C. The Design and Development of Photochromic Jacquard Woven Fabric. J. Text. Sci. Fash. Technol. 2021, 9, 2641-192X. [Google Scholar] [CrossRef]

- Li, Y.L.; Chen, C.Y. Near-Infrared Light-Remote Localized Drug Delivery Systems Based on Zwitterionic Polymer Nanofibers for Combination Therapy. Polymers 2022, 14, 1860. [Google Scholar] [CrossRef] [PubMed]

- Aguilar, M.R.; Román, J.S. Smart Polymers and Their Applications, 2nd ed.; Woodhead Publishing: Kidlington, UK, 2019; ISBN 978-0-08-102417-1. [Google Scholar]

- Bertrand, O.; Gohy, J.F. Photo-Responsive Polymers: Synthesis and Applications. Polym. Chem. 2017, 8, 52–73. [Google Scholar] [CrossRef]

- Chen, J.; Chen, X.; Azhar, U.; Yang, X.; Zhou, C.; Yan, M.; Li, H.; Zong, C. Flexible and Photo-Responsive Superwetting Surfaces Based on Porous Materials Coated with Mussel-Inspired Azo-Copolymer. Chem. Eng. J. 2023, 466, 143176. [Google Scholar] [CrossRef]

- Miao, S.; Xiong, Z.; Zhang, J.; Wu, Y.; Gong, X. Polydopamine/SiO2Hybrid Structured Superamphiphobic Fabrics with Good Photothermal Behavior. Langmuir 2022, 38, 9431–9440. [Google Scholar] [CrossRef]

- Xiao, L.; Chen, X.; Yang, X.; Sun, J.; Geng, J. Recent Advances in Polymer-Based Photothermal Materials for Biological Applications. ACS Appl. Polym. Mater. 2020, 2, 4273–4288. [Google Scholar] [CrossRef]

- Tian, B.; Wang, C.; Zhang, S.; Feng, L.; Liu, Z. Photothermally Enhanced Photodynamic Therapy Delivered by Nano-Graphene Oxide. ACS Nano 2011, 5, 7000–7009. [Google Scholar] [CrossRef]

- Petryayeva, E.; Krull, U.J. Localized Surface Plasmon Resonance: Nanostructures, Bioassays and Biosensing-A Review. Anal. Chim. Acta 2011, 706, 8–24. [Google Scholar] [CrossRef]

- Liz-Marzán, L.M. Tailoring Surface Plasmons through the Morphology and Assembly of Metal Nanoparticles. Langmuir 2006, 22, 32–41. [Google Scholar] [CrossRef]

- Rodrigues, M.S.; Borges, J.; Lopes, C.; Pereira, R.M.S.; Vasilevskiy, M.I.; Vaz, F. Gas Sensors Based on Localized Surface Plasmon Resonances: Synthesis of Oxide Films with Embedded Metal Nanoparticles, Theory and Simulation, and Sensitivity Enhancement Strategies. Appl. Sci. 2021, 11, 5388. [Google Scholar] [CrossRef]

- Zhu, Z.; Qi, D.; Yang, Z.; Wang, Y.; Müller-Buschbaum, P.; Zhong, Q. Nanogels Containing Gold Nanoparticles on Cotton Fabrics for Comfort Control via Localized Surface Plasmon Resonance. ACS Appl. Nano. Mater. 2024, 7, 1222–1232. [Google Scholar] [CrossRef]

- Gorjanc, M.; Gerl, A.; Kert, M. Screen Printing of pH-Responsive Dye to Textile. Polymers 2022, 14, 447. [Google Scholar] [CrossRef]

- Chi, H.; Xu, Z.; Zhang, T.; Li, X.; Wu, Z.; Zhao, Y. Randomly Heterogeneous Oleophobic/pH-Responsive Polymer Coatings with Reversible Wettability Transition for Multifunctional Fabrics and Controllable Oil–Water Separation. J. Colloid. Interface Sci. 2021, 594, 122–130. [Google Scholar] [CrossRef]

- Li, T.T.; Li, S.; Sun, F.; Shiu, B.C.; Ren, H.T.; Lou, C.W.; Lin, J.H. pH-Responsive Nonwoven Fabric with Reversibly Wettability for Controllable Oil-Water Separation and Heavy Metal Removal. Environ. Res. 2022, 215, 114355. [Google Scholar] [CrossRef]

- Zhang, Y.; Gong, X. Smart and Durable pH-Responsive Superhydrophobic Fabrics with Switchable Surface Wettability for High-Efficiency and Complex Oil/Water Separation. Giant 2023, 14, 100157. [Google Scholar] [CrossRef]

- Kocak, G.; Tuncer, C.; Bütün, V. pH-Responsive Polymers. Polym. Chem. 2017, 8, 144–176. [Google Scholar] [CrossRef]

- Inthanusorn, W.; Rutnakornpituk, M.; Rutnakornpituk, B. Reusable Poly(2-Acrylamido-2-Methylpropanesulfonic Acid)-Grafted Magnetic Nanoparticles as Anionic Nano-Adsorbents for Antibody and Antigen. Int. J. Polym. Mater. Polym. Biomater. 2023, 72, 636–645. [Google Scholar] [CrossRef]

- Salehi, H.; Shakeri, A.; Mahdavi, H.; Lammertink, R.G.H. Improved Performance of Thin-Film Composite Forward Osmosis Membrane with Click Modified Polysulfone Substrate. Desalination 2020, 496, 114731. [Google Scholar] [CrossRef]

- González, N.; Elvira, C.; Román, J.S. Novel Dual-Stimuli-Responsive Polymers Derived from Ethylpyrrolidine. Macromolecules 2005, 38, 9298–9303. [Google Scholar] [CrossRef]

- Anbardan, M.A.; Alipour, S.; Mahdavinia, G.R.; Rezaei, P.F. Synthesis of Magnetic Chitosan/Hyaluronic Acid/κ-Carrageenan Nanocarriers for Drug Delivery. Int. J. Biol. Macromol. 2023, 253, 126805. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Wang, Z.; Yan, M.; Xin, J.; Yang, Y. One-Pot Three-Step Synthesis of PDMAEMA-b-PMMA-b-PNIPAM Triblock Block Copolymer for Preparing PH and Thermal Dual-Responsive PVDF Blend Membranes. Polym. Eng. Sci. 2023, 63, 3343–3352. [Google Scholar] [CrossRef]

- Ren, X.; Lin, X. Switchable Hydrophilic/Hydrophobic Antibacterial Fibrous Composites for Biomedical Application. Compos. Commun. 2023, 43, 101728. [Google Scholar] [CrossRef]

- Li, L.; Cen, J.; Huang, L.; Luo, L.; Jiang, G. Fabrication of a Dual pH-Responsive and Photothermal Microcapsule Pesticide Delivery System for Controlled Release of Pesticides. Pest. Manag. Sci. 2023, 79, 969–979. [Google Scholar] [CrossRef] [PubMed]

- Yousefi, P.; Dini, G.; Movahedi, B.; Vaezifar, S.; Mehdikhani, M. Polycaprolactone/Chitosan Core/Shell Nanofibrous Mat Fabricated by Electrospinning Process as Carrier for Rosuvastatin Drug. Polym. Bull. 2022, 79, 1627–1645. [Google Scholar] [CrossRef]

- Steyaert, I.; Vancoillie, G.; Hoogenboom, R.; De Clerck, K. Dye Immobilization in Halochromic Nanofibers through Blend Electrospinning of a Dye-Containing Copolymer and Polyamide-6. Polym. Chem. 2015, 6, 2685–2694. [Google Scholar] [CrossRef]

- Hassabo, A.G.; Bakr, M.; Zayed, M.; Othman, H.A. Chromic Dyes for SMART Textile: A Review. Lett. Appl. NanoBioSci. 2023, 12, 161. [Google Scholar]

- Atav, R.; Akkuş, E.; Ergünay, U. Investigation of the Dyeability of Cotton Fabrics with a Halochromic Dye According to Exhaust and Padding Methods. J. Nat. Fibers 2022, 19, 9125–9138. [Google Scholar] [CrossRef]

- Lim, T.; Lee, J.H.; Yang, K.H.; Ju, S.; Jeong, S.M. Highly Elastic Halochromic Fibers Capable of Reversible Sensing of Acidic/Basic Vapor for Use in Wearable Textiles. AIP Adv. 2022, 12, 105011. [Google Scholar] [CrossRef]

- Kert, M.; Skoko, J. Formation of pH-Responsive Cotton by the Adsorption of Methyl Orange Dye. Polymers 2023, 15, 1783. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Li, X.; Nagao, M.; Elias, A.L.; Narain, R.; Chung, H.J. A PH-Indicating Colorimetric Tough Hydrogel Patch towards Applications in a Substrate for Smart Wound Dressings. Polymers 2017, 9, 558. [Google Scholar] [CrossRef] [PubMed]

- Khanjanzadeh, H.; Park, B.D. Covalent Immobilization of Bromocresol Purple on Cellulose Nanocrystals for Use in pH-Responsive Indicator Films. Carbohydr. Polym. 2021, 273, 118550. [Google Scholar] [CrossRef] [PubMed]

- Grassi, P.; Drumm, F.C.; Spannemberg, S.S.; Georgin, J.; Tonato, D.; Mazutti, M.A.; Gonçalves, J.O.; Oliveira, M.L.S.; Dotto, G.L.; Jahn, S.L. Solid Wastes from the Enzyme Production as a Potential Biosorbent to Treat Colored Effluents Containing Crystal Violet Dye. Environ. Sci. Pollut. Res. 2020, 27, 10484–10494. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, R.; Ejaz, M.O. Efficient Adsorption of Crystal Violet (CV) Dye onto Benign Chitosan-Modified L-Cysteine/Bentonite (CS-Cys/Bent) Bionanocomposite: Synthesis, Characterization and Experimental Studies. Dyes Pigments 2023, 216, 111305. [Google Scholar] [CrossRef]

- Devarayan, K.; Kim, B.S. Reversible and Universal PH Sensing Cellulose Nanofibers for Health Monitor. Sens. Actuators B Chem. 2015, 209, 281–286. [Google Scholar] [CrossRef]

- Adamu, B.F.; Gao, J.; Gebeyehu, E.K.; Beyene, K.A.; Tadesse, M.G.; Liyew, E.Z. Self-Responsive Electrospun Nanofibers Wound Dressings: The Future of Wound Care. Adv. Mater. Sci. Eng. 2022, 2022, 2025170. [Google Scholar] [CrossRef]

- Alsahag, M.; Alisaac, A.; Al-Hazmi, G.A.A.; Pashameah, R.A.; Attar, R.M.S.; Saad, F.A.; El-Metwaly, N.M. Preparation of Carboxymethyl Cellulose/Polyvinyl Alcohol Wound Dressing Composite Immobilized with Anthocyanin Extract for Colorimetric Monitoring of Wound Healing and Prevention of Wound Infection. Int. J. Biol. Macromol. 2023, 224, 233–242. [Google Scholar] [CrossRef] [PubMed]

- Leite, L.; Pais, V.; Silva, C.; Boticas, I.; Bessa, J.; Cunha, F.; Relvas, C.; Ferreira, N.; Fangueiro, R. Halochromic Textiles for Real-Time Sensing of Hazardous Chemicals and Personal Protection. Materials 2023, 16, 2938. [Google Scholar] [CrossRef] [PubMed]

- Celebioglu, A.; Saporito, A.F.; Uyar, T. Green Electrospinning of Chitosan/Pectin Nanofibrous Films by the Incorporation of Cyclodextrin/Curcumin Inclusion Complexes: pH-Responsive Release and Hydrogel Features. ACS Sustain. Chem. Eng. 2022, 10, 4758–4769. [Google Scholar] [CrossRef]

- He, Y.; Liu, Q.; Tian, M.; Zhang, X.; Qu, L.; Fan, T.; Miao, J. Highly Conductive and Elastic Multi-Responsive Phase Change Smart Fiber and Textile. Compos. Commun. 2023, 44, 101772. [Google Scholar] [CrossRef]

- Gupta, P.; Mohanty, J.; Garg, H.; Kumar, B. Memory Behaviour of Polyester Knitted Fabric Integrated with Temperature-Responsive Shape Memory Polymer Filament. J. Ind. Text. 2022, 51, 5952S–5972S. [Google Scholar] [CrossRef]

- Khadse, N.; Ruckdashel, R.; Macajoux, S.; Sun, H.; Park, J.H. Temperature Responsive PBT Bicomponent Fibers for Dynamic Thermal Insulation. Polymers 2022, 14, 2757. [Google Scholar] [CrossRef]

- Iqbal, M.I.; Sun, F.; Fei, B.; Xia, Q.; Wang, X.; Hu, J. Knit Architecture for Water-Actuating Woolen Knitwear and Its Personalized Thermal Management. ACS Appl. Mater. Interfaces 2021, 13, 6298–6308. [Google Scholar] [CrossRef]

- Baniasadi, H.; Madani, Z.; Mohan, M.; Vaara, M.; Lipponen, S.; Vapaavuori, J.; Seppälä, J.V. Heat-Induced Actuator Fibers: Starch-Containing Biopolyamide Composites for Functional Textiles. ACS Appl. Mater. Interfaces 2023, 15, 48584–48600. [Google Scholar] [CrossRef]

| Polymer | Tg (°C) | Tm (°C) | Tprog (°C) | Rr (%) | Rf (%) | Applications | Ref. |

|---|---|---|---|---|---|---|---|

| PCUU | −13–18 | 48–51 | 50 | 99 | 96 | Tissue engineering | [79] |

| PLA | 21–60 | 142–149 | 40–60 | 61–100 | 74–100 | Smart textiles | [80] |

| PLA/PU | 55 | - | 80 | - | - | Smart textiles | [32] |

| PU | 45 | - | 80 | 91–98 | 76–80 | Smart textiles | [64] |

| 45 | 149 | >45 | 99 | - | Intelligent structures | [81] | |

| 65 | - | 70 | 50–99 | 93–99 | Smart textiles | [82] |

| Polymer | Type | Ttrans (°C) | Applications | Ref. |

|---|---|---|---|---|

| PDMAPS | UCST | 33 | Smart textiles | [98] |

| 28 | Smart oil–water separation fabric | [99] | ||

| PEO–PPO–PEO | LCST | 35 | Ultrafiltration membrane | [49] |

| 29–98 | Forward osmosis membrane | [100] | ||

| PHEVAH | LCST | 34 | Smart textiles | [43] |

| P(MEO2MA-co-OEGMA500) | LCST | 29 | Smart textiles | [101] |

| PNIPAM | LCST | 39 (VPTT) | NWFs for processing temperature-sensitive bioactive ingredients or for use in remote-controlled bioreactors | [23] |

| 32 | Thermo-responsive membrane | [30] | ||

| 32 | Smart textiles | [98] | ||

| 31–32 | Smart textiles | [102] | ||

| 31 | Smart textiles | [103] | ||

| P(NIPAM-co-AAm) | LCST | 33–37 | Smart membrane for water treatment | [104] |

| P(NIPAM-co-MAM) | LCST | 33–41 | Smart textiles | [47] |

| SBMA | UCST | 26–27 | Smart textiles | [105] |

| Polymer | Responsive Group | Applications | Ref. |

|---|---|---|---|

| CS | Amine | Controlled drug release | [145] |

| P(DEAEMA-co-MMA-co-ABP) | Tertiary amine | Controlled drug release | [31] |

| PDMAEMA-b-PMMA | Amine | Oil–water separation fabric | [135] |

| P(NIPAM-co-MAM) | Amine | Smart textile | [47] |

| PNIPAM-g-CS | Amine | Antibacterial thermoregulating textile | [102] |

| Polymer containing 2VP | Pyridine | Smart textile, oil–water separation | [134] |

| UA-co-VTMS | Carboxyl | Oil–water separation fabric | [136] |

| Stimulus | Material | Structure | Methodology | Application | Ref. |

|---|---|---|---|---|---|

| Temperature | N-octadecane | Woven | Microencapsulation of the PCM (N-octadecane) with ODMA-MAA copolymer as shell using suspension-like polymerization; wet spinning of fibers containing PCM, CNTs, graphene and PU; dip-coating of the CNTs-graphene-PCM@PU fibers in a conductive ink of CNTs-graphene/PEDOT:PSS; weaving with the obtained fibers | Smart textiles and wearable electronics | [160] |

| Temperature | Cholesteryl ester | Nonwoven mat | Formulation of thermochromic LC through the heating at 80–90 °C of ternary mixtures of COC, CB, and CP; electrospinning of blends of LC and polycaprolactone or polystyrene, with chloroform as a solvent | Smart face masks | [38] |

| Temperature | SFXC and Hallcrest | Knitted and woven fabrics | Coating of yarns (100% PES) with LC inks (SFXC and Hallcrest), by looping the yarns through pulleys and ink barrels, followed by drying and collection; weaving and knitting with the coated yarns | Smart textiles | [22] |

| Temperature | PNIPAM | Nonwoven | Nonwoven PET scaffold filled with NIPAAm hydrogel; UV irradiation; reactive pore-filling with NIPAAm, MBA as the cross-linker, and APS as the initiator; cross-linking polymerization; PA thin layer obtained by interfacial polymerization; addition of PEG as a pore-forming agent | Thin film composite membranes | [30] |

| Temperature | Cratin and Hytreal (polymers with different coefficient of thermal expansion) | Nonwoven battings | Side-by-side melt coextrusion of Crastin and Hytrel to form a bicomponent fiber (50–50 composition), where two melt-pump-controlled extruders with pineapple mixers are used for melting the resins, with temperature zones maintained at 230, 240, 250 and 260 °C; fibers transformed into nonwoven battings | Wearable insulation | [162] |

| Temperature | PEO–PPO–PEO | Nonwoven membrane | Preparation of LLC by mixing and centrifugation of PEO-PPO-PEO, APS, nBA and EGDMA; LLC sandwiched between Mylar films and glass plates; casting on nonwoven polyester sheet under pressure and thermal polymerization at 65 °C | Ultrafiltration membrane | [49] |

| Temperature | Wool fibers | Knitted fabric | Descaling of raw wool fibers using nanoparticles of calcium carbonate, sodium hypochlorite, and hydrochloric acid; production of double-plied ring-spun dyed woollen yarns using conventional yarn and dyeing technologies; fabrication of single jersey, tuck knit, miss knit, and double-knit structures in a flat-bed knitting machine | Smart textiles | [163] |

| Temperature | PHA, MDI and BDO | Knitted fabric | Melt spinning of SMP filament using PHA, MDI and BDO; production of knitted fabric using SMP filament and PES yarn on a V-bed knitting machine; shape memory behavior programming by heating up to the transition temperature, deforming up to the required strain, cooling to fix the temporary deformation below 20 °C, releasing the strain, and re-heating to activate the recovery process | Smart textiles | [161] |

| Temperature | SBMA | Knitted fabric | Spray coating of one side of a knitted cotton fabric with a solution containing a thermo-responsive polymer (SBMA), MBA and TPO-Li; covering of the coated fabric with a tape mask with hole patterns, followed by UV cross-linking | Smart textiles | [105] |

| Temperature | Bio-based low-melting-point polyamide | Woven 3D fabric | Copolymerization of PA11coPA1218 using the monomers 11-aminoundecanoic acid, 1,12-diaminododecane, and octadecanedioic acid, and sodium hypophosphite monohydrate as a catalyst; surface treatment of starch particles with OSA to make them compatible with the biopolyamide matrix; melt-blending of OSA-treated starch with PA11coPA1218; production of filaments from the copolymer and OSA-treated starch composites; coiling and thermosetting of filaments to form actuators; integration of thermo-responsive coiled actuators into a woven 3D fabric comprised of 100% cotton warp and wefts consisting of linen-tencel, cotton, glow-in-the-dark yarn, and actuators | Smart textiles | [164] |

| Temperature | PLA and PU | Woven fabric | Wet spinning of PLA/PU/GO fibers using PLA, PU, GO and DMF as solvent; weaving of the fibers using the plain weaving method; spray-coating of one side of the fibers with AgNWs; programming of the SMP textile by stretching deformation at 80 °C, cooling to room temperature and releasing of the stretch force | Smart textiles | [32] |

| Temperature and light | PNIPAM and GONPs | Nonwoven fiber mat | Synthesis of P(NIPAm-co-HEA-co-AA) microgels by precipitation polymerization of NIPAm, AA, and HEA in water, using SDS as surfactant and BIS as cross-linker; synthesis of P(NIPAm-co-BPAm) via free radical polymerization using NIPAm and BPAm; synthesis of GO sheets and GONPs from graphite; fabrication of GO NWFs via sequential deposition and UV photo-cross-linking of colloidal suspensions of P(NIPAM-co-HEA-co-AA) microgels, P(NIPAM-co-BPAm) and GONPs, onto PP NWFs | Membranes for processing temperature-sensitive bioactive ingredients or remote-controlled bioreactors | [23] |

| Temperature | PNIPAM and PDMAPS | Woven fabric | Preparation of LCST polymer coating solutions by mixing monomers (NIPAM), EGDMA, and initiator (DEAP) in ethanol, and of UCST polymer coating solutions by mixing monomers (DMAPS), EGDMA and Irgacure D-2959 in DI water/trifluoroethanol; hydrophobic monomer (LMA) or hydrophilic monomer (HEMA) added to the LCST and UCST polymer coating solutions; dipping of cotton yarns in the polymer coating solutions; weaving of textiles with LCST warp yarns, hydrophobic PET yarns, and UCST weft yarns | Smart textiles | [98] |

| Temperature | LA | Nanofibers | Preparation of ZnO@MWCNT composite materials by dispersion of MWCNTs in deionized water, mixing with Zn(NO3)·6H2O, and reaction at 140 °C; preparation of phase change nanofibers by electrospinning using LA as a PCM, PVA as a supporting material, SDS as an emulsifier, and ZnO@MWCNT for thermal conductivity; coating of the resultant nanofibers with polydimethylsiloxane and a curing agent, to obtain the resultant hydrophobic, self-cleaning, thermoregulated nanofibers | Wearable systems and protective fabrics | [57] |

| Temperature and pH | P(NIPAM-co-MAM) | Woven fabric | Synthesis of P(NIPAM-co-MAM) through free radical addition polymerization, using NIPAM and MAM as monomers, at 80 °C; application of the P(NIPAM-co-MAM) copolymer to a 100% cotton plain weaved fabric using a double-bath impregnation method, with the first bath containing the BTCA cross-linker and the SHP catalyst, and the second bath containing an aqueous polymer solution; drying and curing of the fabric | Smart textile | [47] |

| Temperature | PHEVAH | Woven fabric | VCL monomer was hydrolyzed with EG to produce HEVAH; synthesis of PHEVAH through free radical polymerization, using HEVAH and AIBN in toluene; application of the PHEVAH to a 100% cotton plain weaved fabric using a double bath impregnation, with the first bath containing the BTCA cross-linker and the SHP catalyst, and the second bath containing a polymer solution; drying and curing of the fabric | Smart textile | [43] |

| Temperature | P(MEO2MA-co-OEGMA500 | Fabric | Graft copolymerization of a cotton fabric with TMSPMA; grafting of P(MEO2MA-co-OEGMA500) from TMSPMA-cotton using free-radical polymerization, at 37 °C, using HRP, the monomers MEO2MA and OEGMA500, ACAC, ethanol/phosphate buffer and H2O2; washing and air-drying of the fabric | Smart textile | [101] |

| Temperature | PDMAPS | Woven fabric | BN and KH-570 were applied to a twill patterned cotton fabric to improve its hydrophobicity and reactivity; temperature-responsive cotton fabric prepared enzymatically through HRP-catalyzed graft polymerization of PDMAPS, at 37 °C, using HRP, H2O2, ACAC, DMAPS, MBA, and phosphate buffer; washing and air-drying of the fabric | Smart oil–water separation fabric | [99] |

| pH | Chitosan and pectin | Nanofibrous films | Electrospinning of solutions with different combinations of polymers (chitosan and pectin), and HPγCD; preparation of inclusion complexes of curcumin and HPγCD using the freeze-drying method; incorporation of the complexes into chitosan/pectin systems, followed by electrospinning | Biomedical | [159] |

| pH | P(DEAEMA-co-MMA-co-ABP) (same as PDMA) | Nanofiber mats | Synthesis of PDMA through radical polymerization, at 70 °C, using DEAEMA and MMA as monomers, ABP as cross-linking agents, and AIBN as the thermal initiator, followed by dialysis; electrospinning of solutions containing PDMA, DMF, THF and amoxicillin; UV irradiation and drying of the nanofiber mats | Biomedical | [31] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferreira, M.P.S.; Gonçalves, A.S.; Antunes, J.C.; Bessa, J.; Cunha, F.; Fangueiro, R. Fibrous Structures: An Overview of Their Responsiveness to External Stimuli towards Intended Application. Polymers 2024, 16, 1345. https://doi.org/10.3390/polym16101345

Ferreira MPS, Gonçalves AS, Antunes JC, Bessa J, Cunha F, Fangueiro R. Fibrous Structures: An Overview of Their Responsiveness to External Stimuli towards Intended Application. Polymers. 2024; 16(10):1345. https://doi.org/10.3390/polym16101345

Chicago/Turabian StyleFerreira, Mónica P. S., Afonso S. Gonçalves, Joana C. Antunes, João Bessa, Fernando Cunha, and Raúl Fangueiro. 2024. "Fibrous Structures: An Overview of Their Responsiveness to External Stimuli towards Intended Application" Polymers 16, no. 10: 1345. https://doi.org/10.3390/polym16101345