Cellulose-Based Polyurethane Foams of Low Flammability

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Polyol Using Phosphoric(III) Acid Esters

2.2.1. Synthesis 1

2.2.2. Synthesis 2

2.3. Analytical Methods

2.4. Physical Properties of Polyol

2.5. Polyurethane Foams

2.6. Properties of Foams

2.7. Flammability of Foams

3. Results and Discussion

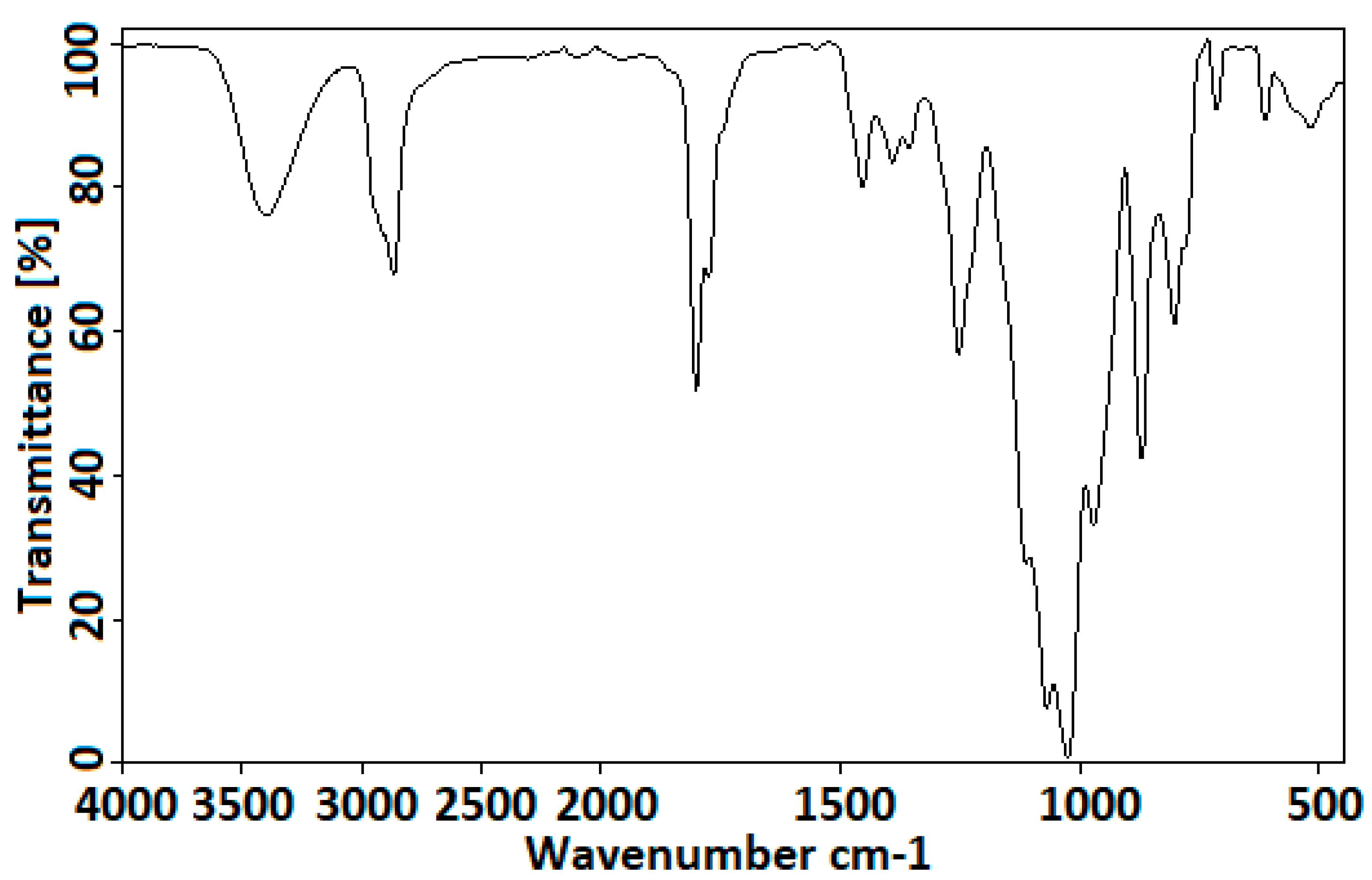

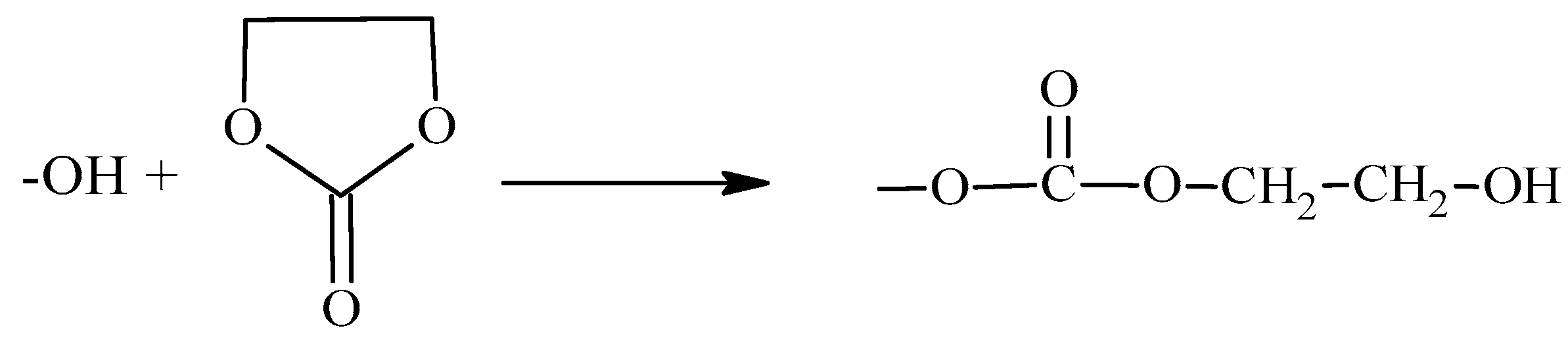

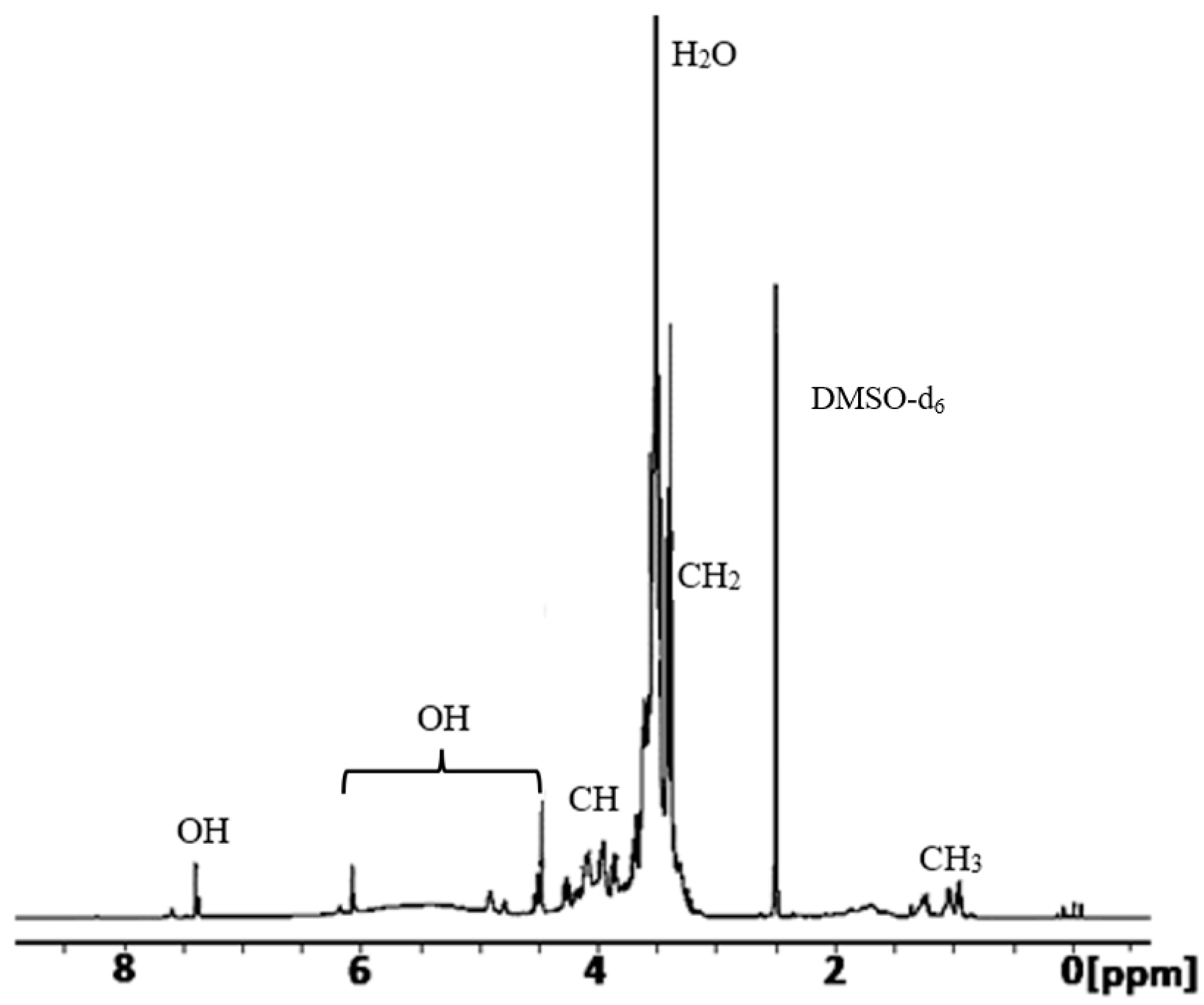

3.1. Synthesis of Polyol

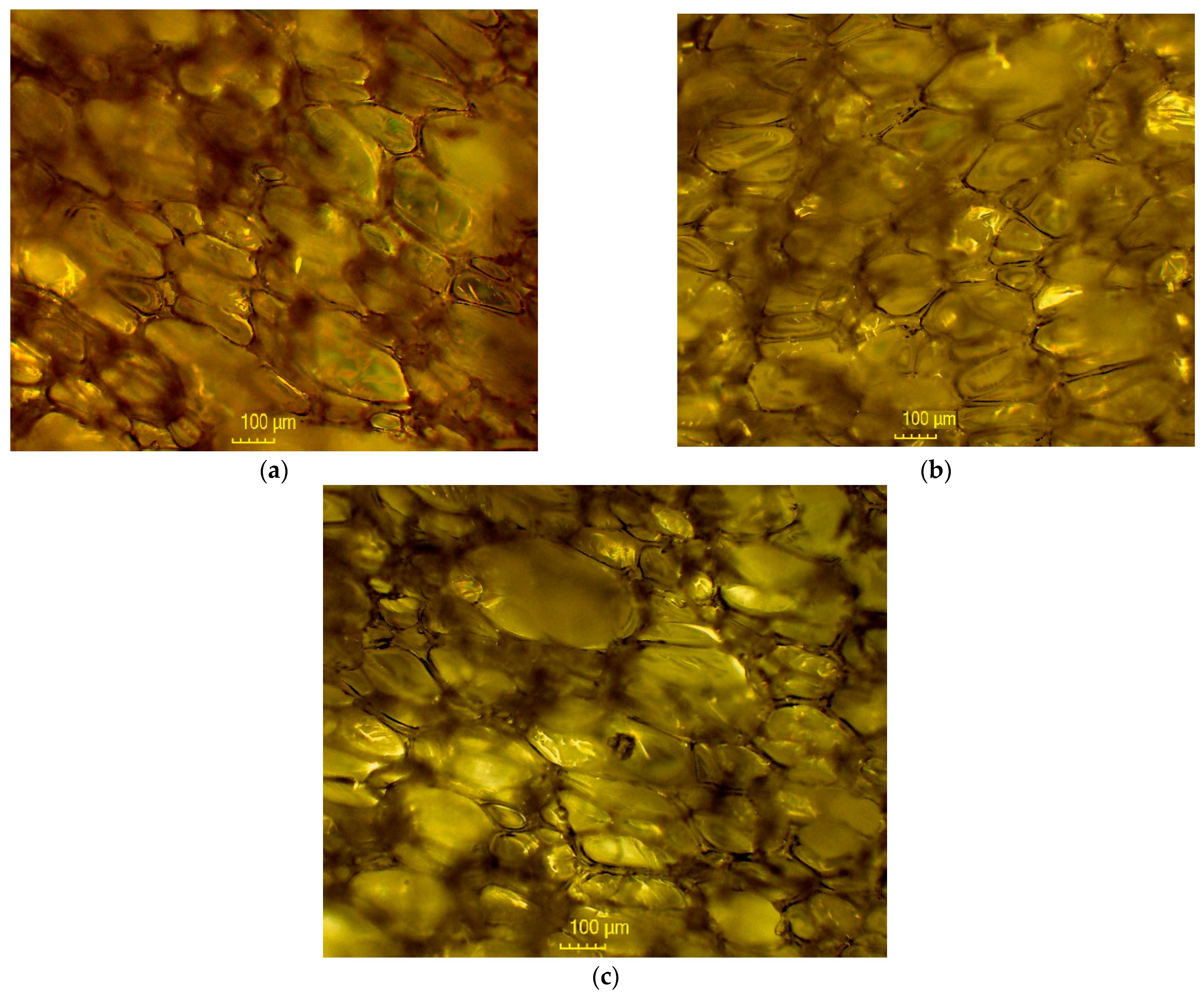

3.2. Polyurethane Foams

4. Summary and Conclusions

- In the reaction between phosphoric(III) acid and diethylene glycol, the ester with terminal hydroxyl groups was obtained, which was further dissolved in HPC. It was hydroxyalkylated with glycidol and ethylene carbonate to give polyol with phosphorus atoms incorporated into the polyol;

- The obtained polyol was reacted with polymeric diphenylmethane diisocyanate and water to obtain the rigid polyurethane foam. In the foaming process, melamine was also added as an additive flame retardant. The presence of incorporated phosphorus and added melamine led to the material of clearly reduced flammability, compared to foams based on HPC;

- Obtained polyurethane foam had considerably higher thermal stability and lower polymerization shrink than other HPC-based polyurethane foams not modified with flame retardants. On the other hand, the obtained PUF had a higher apparent density, water uptake, and lower thermal resistance;

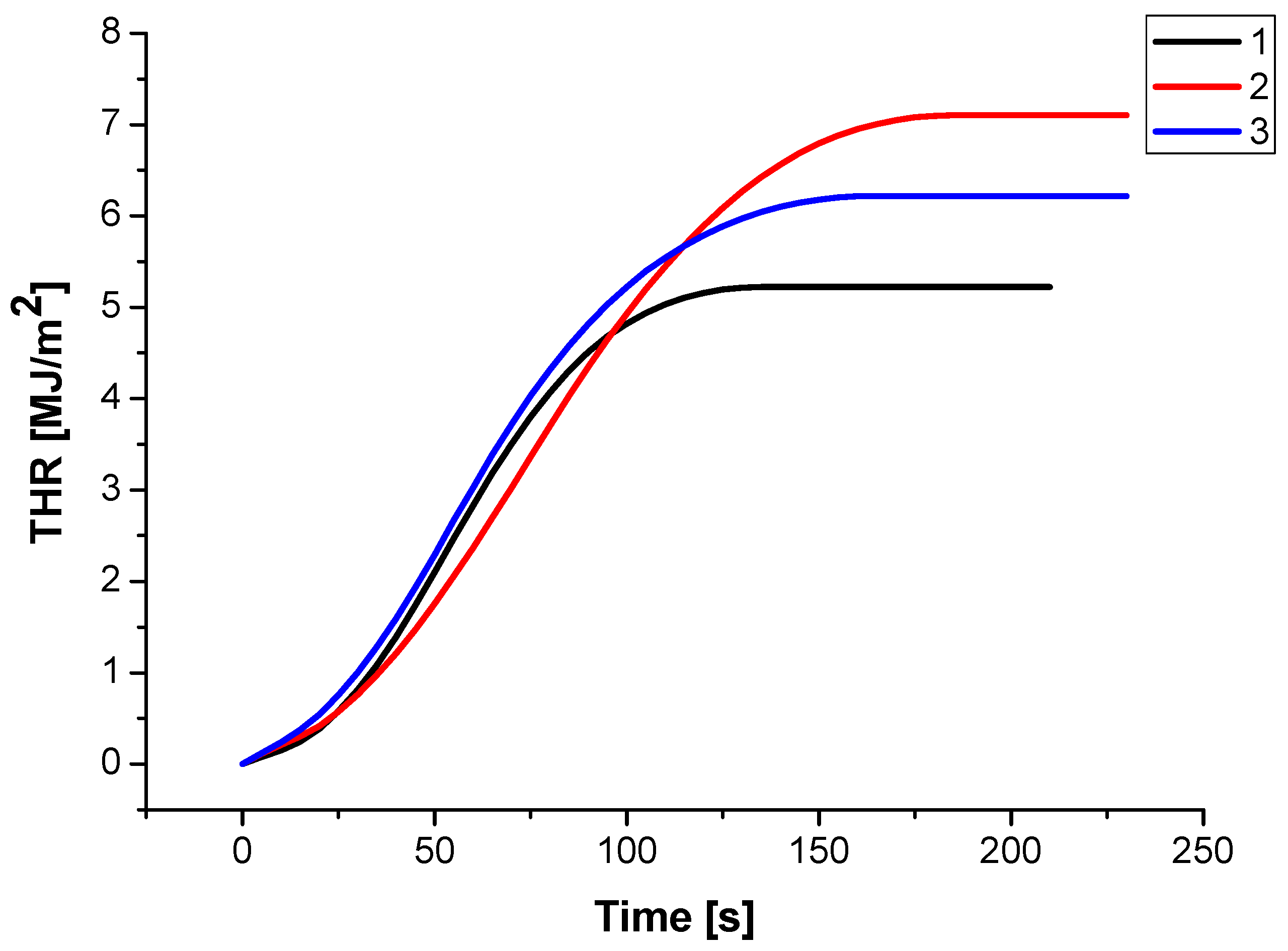

- Foam modified with phosphorus atoms and melamine has a similar burning rate to unmodified foam obtained from HPC-based polyol in a diethylene glycol environment. Modified foam shows lower total heat release than non-modified one, which is its advantageous utility feature.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Akindoyo, J.O.; Beg MD, H.; Ghazali, S.; Islam, M.R.; Jeyaratnam, N.; Yuvaraj, A.R. Polyurethane types, synthesis and applications—A review. RSC Adv. 2016, 6, 114453–114482. [Google Scholar] [CrossRef]

- Prociak, A.; Rokicki, G.; Ryszkowska, J. Polyurethane Materials. Państwowe Wydawnictwo Naukowe:: Warsaw, Poland, 2014. [Google Scholar]

- Ryszkowska, J. Polyurethane Materials Manufactured Using Renewable Raw Materials; Publishing House of the Warsaw University of Technology: Warsaw, Poland, 2019. [Google Scholar]

- Macedo, V.; Zimmermann, M.; Koester, L.; Scienza, L.; Zattera, A. Flexible polyurethane foams filled with Pinnus elliotti cellulose. Polímeros 2017, 27, 27–34. [Google Scholar] [CrossRef]

- Prociak, A.; Malewska, E.; Bąk, S. Influence of Isocyanate Index on Selected Properties of Flexible Polyurethane Foams Modified with Various Bio-Components. J. Renew. Mater. 2016, 4, 78–85. [Google Scholar] [CrossRef]

- Pan, X.; Saddler, J. Effect of replacing polyol by organosolv and kraft lignin on the property and structure of rigid polyurethane foam. Biotechnol. Biofuels 2013, 6, 12. [Google Scholar] [CrossRef]

- Kosmela, P.; Hejna, A.; Formela, K.; Haponiuk, J.; Piszczyk, Ł. The Study on Application of Biopolyols Obtained by Cellulose Biomass Liquefaction Performed with Crude Glycerol for the Synthesis of Rigid Polyurethane Foams. J. Polym. Environ. 2018, 26, 2546–2554. [Google Scholar] [CrossRef]

- Szpiłyk, M.; Lubczak, R.; Lubczak, J. Polyetherols and polyurethane foams with cellulose subunits. Polym-Plast. Technol. Mater. 2021, 60, 440–452. [Google Scholar] [CrossRef]

- Szpiłyk, M.; Lubczak, R.; Walczak, M.; Lubczak, J. Polyol and polyurethane foam from cellulose hydrolysate. J. Chem. Technol. Biotechnol. 2021, 96, 881–889. [Google Scholar] [CrossRef]

- Szpiłyk, M.; Lubczak, R.; Lubczak, J. The biodegradable cellulose-derived polyol and polyurethane foam products. Polym. Test. 2021, 100, 107250. [Google Scholar] [CrossRef]

- Goodman, H. Handbook of Thermoset Plastics, 2nd ed.; William Andrew Pulishing/Noyes: Norwich, NY, USA, 1999. [Google Scholar]

- Hilado, C.J. Flammability Handbook for Plastics. Technomic Publishing C. Company, Inc.: Lancaster, PA, USA, 1998. [Google Scholar]

- Żuchowska, D. Construction Polymers; WNT: Warsaw, Poland, 2000. [Google Scholar]

- Brzozowski, Z.; Kijeńska, D.; Zatorski, W. Flammability of polymers, part 2.Methods of reducing the flammability of plastics. Plast. Rev. 2001, 9, 65–67. [Google Scholar]

- Gijsman, P.; Steenbakkers, R.; Furst, C.; Kersjes, J. Differences in the flame retardant mechanism of melamine cyanurate in polyamide 6 and polyamide 66. Polym. Degrad. Stab. 2002, 78, 219–224. [Google Scholar] [CrossRef]

- Cichy, B.; Łuczkowska, D.; Nowak, M.; Władyka-Przybylak, M. Polyphosphate Flame Retardants with Increased Heat Resistance. Ind. Eng. Chem. Res. 2003, 42, 2897–2905. [Google Scholar] [CrossRef]

- Zatorski, W.; Brzozowski, Z.K.; Łebek, K. Production of PUR and PUR-PIR foams with red phosphorus as a flame retardant. Polimery 2005, 50, 686–689. [Google Scholar] [CrossRef]

- Green, J. Mechanisms for Flame Retardancy and Smoke Suppression—A Review. J. Fire Sci. 1996, 14, 426–442. [Google Scholar] [CrossRef]

- Prociak, A.; Pielichowski, J.; Modesti, M.; Simoni, F.; Checchin, M. Influence of different phosphorus flame retardants on fire behaviour of rigid polyurethane foams blown with pentane. Polimery 2002, 10, 692–696. [Google Scholar] [CrossRef]

- Brojer, Z.; Hertz, Z.; Penczek, P. Epoxy Resins. WNT: Warsaw, Poland, 1972. [Google Scholar]

- Kijowska, D.; Wołowiec, S.; Lubczak, J. Kinetics and mechanism of initial steps of synthesis of polyetherols from melamine and ethylene carbonate. J. Appl. Polym. Sci. 2004, 93, 294–300. [Google Scholar] [CrossRef]

- Kastierina, T.; Kalinina, L. Chemical Analysis of Plastics; WNT: Warsaw, Poland, 1965. [Google Scholar]

- PN-EN ISO 845-2000; Cellular Plastics and Rubbers. Determination of Apparent (Bulk) Density, Polish (European) Standards Ed. Polish Committee for Standardization: Warsaw, Poland, 2000.

- PN-EN ISO 2896-1986; Cellular Plastics, Rigid. Determination of Water Absorption, Polish (European) Standards Ed. Polish Committee for Standardization: Warsaw, Poland, 1986.

- PN-EN ISO 2796-1986; Cellular Plastics, Rigid. Test of Dimensional Stability, Polish (European) Standards Ed. Polish Committee for Standardization: Warsaw, Poland, 1986.

- PN-EN ISO 844-1978; Cellular Plastics, Compression Test for Rigid Materials, Polish (European) Standards Ed. Polish Committee for Standardization: Warsaw, Poland, 1978.

- PN-EN ISO 3582-2002; Flexible Cellular Polymeric Materials—Laboratory Characteristics of Small Specimens Subject to a Small Flame, Polish (European) Standards Ed. Polish Committee for Standardization: Warsaw, Poland, 2002.

- EN-ISO 13927:2015-05; Plastics—Simple Heat Release Test Using a Conical Radiant Heater and a Thermopile Detector. European Standards: Geneva, Switzerland, 2015.

- Wirpsza, Z. Polyurethanes: Chemistry, Technology, Application; WNT: Warsaw, Poland, 1991. [Google Scholar]

- Jiao, L.; Xiao, H.; Wang, Q.; Sun, J. Thermal degradation characteristics of rigid poly-urethane foam and the volatile products analysis with TG-FTIR-MS. Polym. Degrad. Stab. 2013, 98, 2687–2696. [Google Scholar] [CrossRef]

- Ketata, N.; Sanglar, C.; Waton, H.; Alamercery, S.; Delolme, F.; Raffin, G.; Grenier-Loustalot, M.F. Thermal Degradation of Polyurethane Bicomponent Systems in Control-led Atmospheres. Polym. Polym. Compos. 2005, 13, 1–26. [Google Scholar] [CrossRef]

- Urbas, J. Effects of retainer frame, irradiance level and specimen thickness on cone calorimeter test results. Fire Mater. 2005, 29, 1–13. [Google Scholar] [CrossRef]

) and foam exposed to temperatures 150 °C (

) and foam exposed to temperatures 150 °C ( ) and 175 °C (

) and 175 °C ( ).

).

| Hydroxypropyl Derivative of Cellulose | %C | %H | %O |

|---|---|---|---|

| HPC | 53.21 | 8.44 | 38.35 |

| monosubstituted | 49.09 | 7.27 | 43.64 |

| disubstituted | 51.80 | 7.91 | 40.29 |

| trisubstituted | 53.57 | 8.33 | 38.10 |

| Composition [g/100 g of Polyol] | Notes | ||||

|---|---|---|---|---|---|

| pMDI | Water | TEA | Silicon L-6900 | Melamine | |

| 180 | 3 | 7.8 | 3.9 | - | Slowly self-extinguishing |

| 180 | 2 | 7.8 | 3.9 | - | Slowly self-extinguishing |

| 180 | 2 | 7.8 | 3.9 | 20 | self-extinguishing |

| No | Composition [g/100 g of Polyol] | Isocyanate Index | Foaming Process | Notes | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| pMDI | Water [%] | TEA | Silicon L-6900 | Melamine | Cream Time [s] | Rise Time | Tack-Free Time [s] | |||

| 1 | 180 | 2 | 4.6 | 2.6 | 20 | 1.8 | 20 | 23 | 1 | Viscous surface |

| 2 | 180 | 2 | 5.8 | 2.6 | 20 | 1.8 | 15 | 10 | 1 | Large pores |

| 3 | 180 | 2 | 8.9 | 2.7 | 20 | 1.8 | 13 | 9 | 1 | Small pores, fragile foam |

| 4 * | 180 | 2 | 7.8 | 2.7 | 20 | 1.8 | 18 | 9 | 1 | Small pores, rigid foam |

| Foam Obtained from Poyol | Density [kg/m3] | Absorption Of Water [% vol.] | Dimensional Stability of Foams [%] At 150 °C Temperature | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Length Change After | Width Change After | Height Change After | ||||||||

| After 5 min | After 3 h | After 24 h | 20 h | 40 h | 20 h | 40 h | 20 h | 40 h | ||

| H3PO3-DEG-HPC-GL-EC | 74.4 | 1.67 | 2.50 | 4.79 | −1.15 | −1.22 | −1.34 | −1.76 | −0.50 | −1.64 |

| HPC-GL-GE-EC | 61.6 | 1.30 | 1.76 | 3.62 | +3.51 | +3.12 | +6.72 | +6.09 | +1.19 | +1.01 |

| HPC-GL-TEG-EC | 58.1 | 0.25 | 0.89 | 2.12 | 3.13 | +4.56 | −5.07 | −4.16 | −3.53 | −2.89 |

| Foam Obtained from Poyol | Thermal Conductivity Coefficient [W/m·K] | Mass Loss [%] after Exposure to Temperature | Compressive Strength [MPa] | |||||

|---|---|---|---|---|---|---|---|---|

| Before Exposure | After Exposure to Temperature | |||||||

| 150 °C | 175 °C | 200 °C | 150 °C | 175 °C | 200 °C | |||

| H3PO3-DEG-HPC-GL-EC | 0.0361 | 19.0 | 31.7 | - | 0.237 | 0.350 | 0.173 | - |

| HPC-GL-GE-EC | 0.0358 | 12.4 | 28.9 | 45.3 | 0.475 | 0.499 | 0.533 | 0.606 |

| HPC-GL-TEG-EC | 0.0354 | 9.8 | 29.3 | 44.5 | 0.279 | 0.350 | 0.549 | 0.725 |

| Foam Obtained From Polyol | Larger Dia-Meter [μm] | Smaller Dia-Meter [µm] | Thickness of Cell Wall [µm] |

|---|---|---|---|

| H3PO3-DEG-HPC-GL-EC | 234 ± 36 | 99 ± 20 | 8 ± 1 |

| HPC-GL-EG-EC | 216 ± 37 | 111 ± 36 | 9 ± 2 |

| HPC-GL-TEG-EC | 284 ± 57 | 155 ± 37 | 10 ± 2 |

| Foam Obtained From Polyol | Extent of Burning [mm] | Flame Rate [mm/s] | Mass Loss Upon Flaming [%] | Oxygen Index [%] |

|---|---|---|---|---|

| H3PO3-DEG-HPC-GL-EC | 30–40 | 0.5 | 5.1 | 21.7 |

| HPC-EG-GL-EC | 150 | 4.3 | 68.4 | 19.0 |

| HPC-TEG-GL-EC | 150 | 4.4 | 67.5 | 19.0 |

| Foam Obtained From Polyol | TTI [s] | TTF [s] | PML [%] | HRR [kW/m2] | THR [MJ/m2] | EHC [MJ/kg] |

|---|---|---|---|---|---|---|

| H3PO3-DEG-HPC-GL-EC | 5 | 90 | 77.5 | 74.12 | 5.1 | 46.30 |

| HPC-GL-EG-EC | 8 | 158 | 79.5 | 67.67 | 7.1 | 64.29 |

| HPC-GL-TEG-WE | 5 | 149 | 82.5 | 74.03 | 6.2 | 60.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szpiłyk, M.; Lubczak, R.; Lubczak, J. Cellulose-Based Polyurethane Foams of Low Flammability. Polymers 2024, 16, 1438. https://doi.org/10.3390/polym16101438

Szpiłyk M, Lubczak R, Lubczak J. Cellulose-Based Polyurethane Foams of Low Flammability. Polymers. 2024; 16(10):1438. https://doi.org/10.3390/polym16101438

Chicago/Turabian StyleSzpiłyk, Marzena, Renata Lubczak, and Jacek Lubczak. 2024. "Cellulose-Based Polyurethane Foams of Low Flammability" Polymers 16, no. 10: 1438. https://doi.org/10.3390/polym16101438

APA StyleSzpiłyk, M., Lubczak, R., & Lubczak, J. (2024). Cellulose-Based Polyurethane Foams of Low Flammability. Polymers, 16(10), 1438. https://doi.org/10.3390/polym16101438