The Influence of Environmental Factors on the Degradation of PLA/Diatomaceous Earth Composites

Abstract

:1. Introduction

2. Materials and Methods

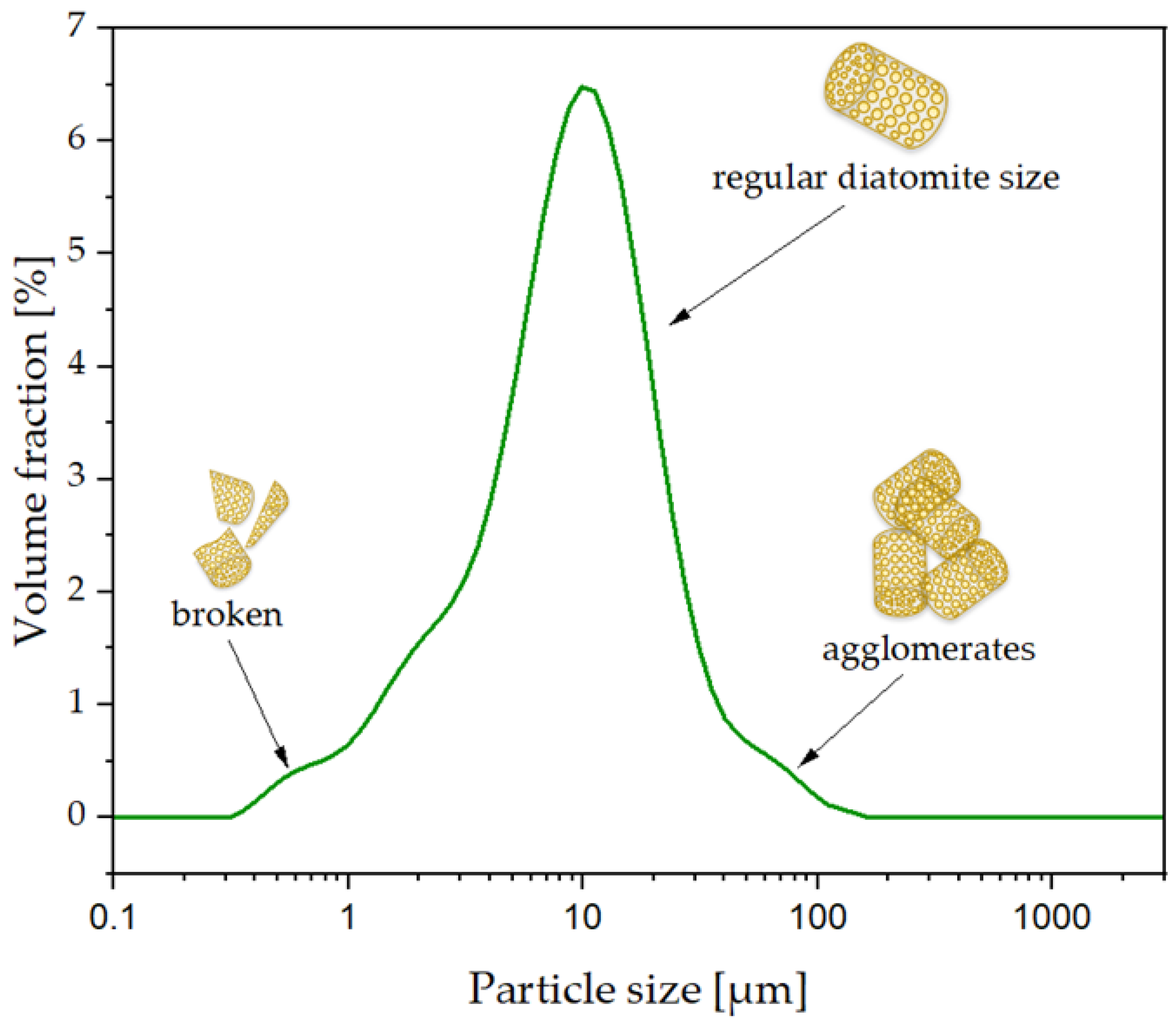

2.1. Materials

2.2. Preparation of Modified Diamaceous Earth

2.3. Preparation of Granulates

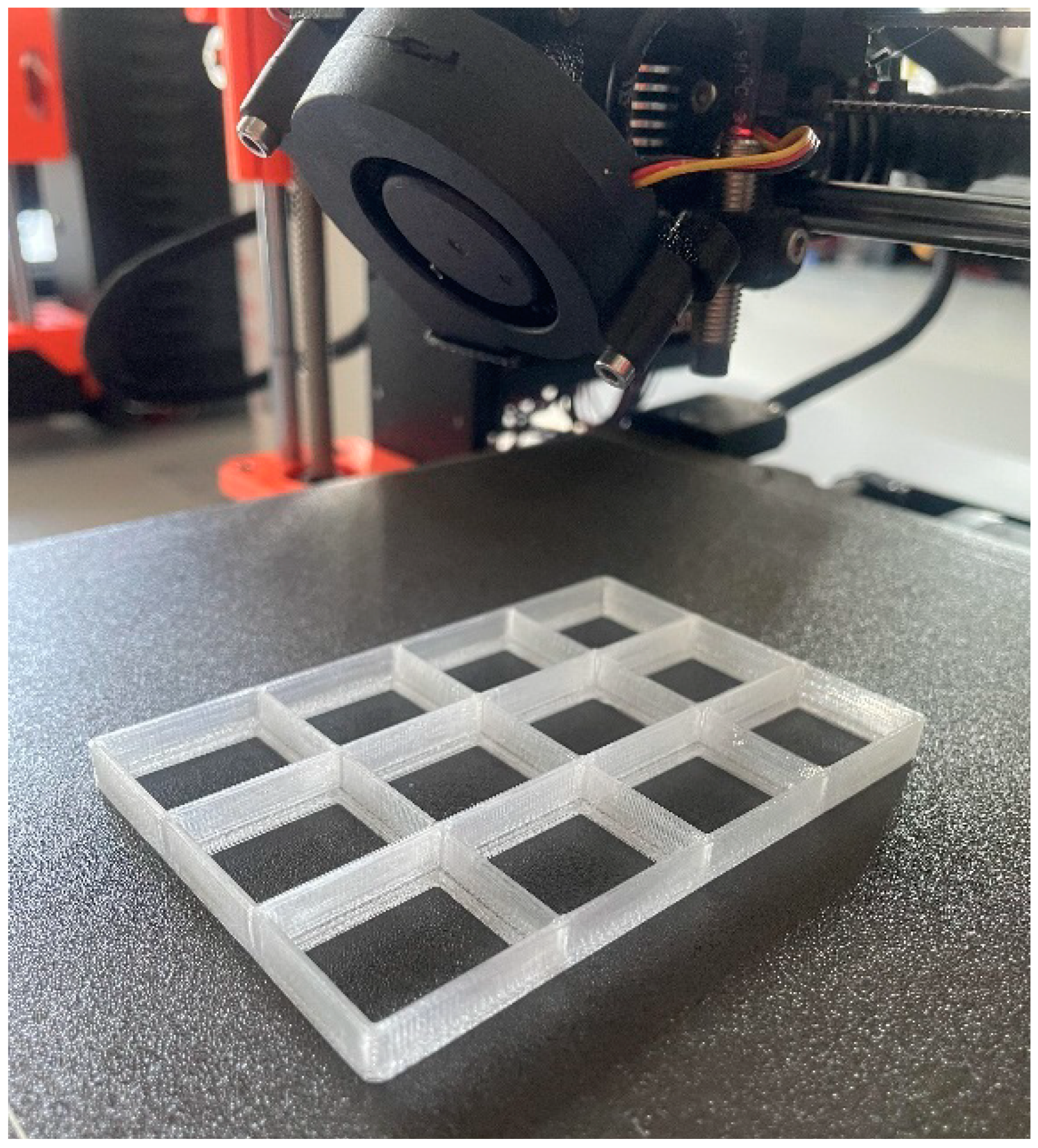

2.4. Preparation of Samples for Measurements

2.5. Characterization Methods

- − UV irradiation—intensity of radiation 0.71 W/m2, 60 °C—4 h (light segment);

- − condensation 50 °C—4 h (dark segment).

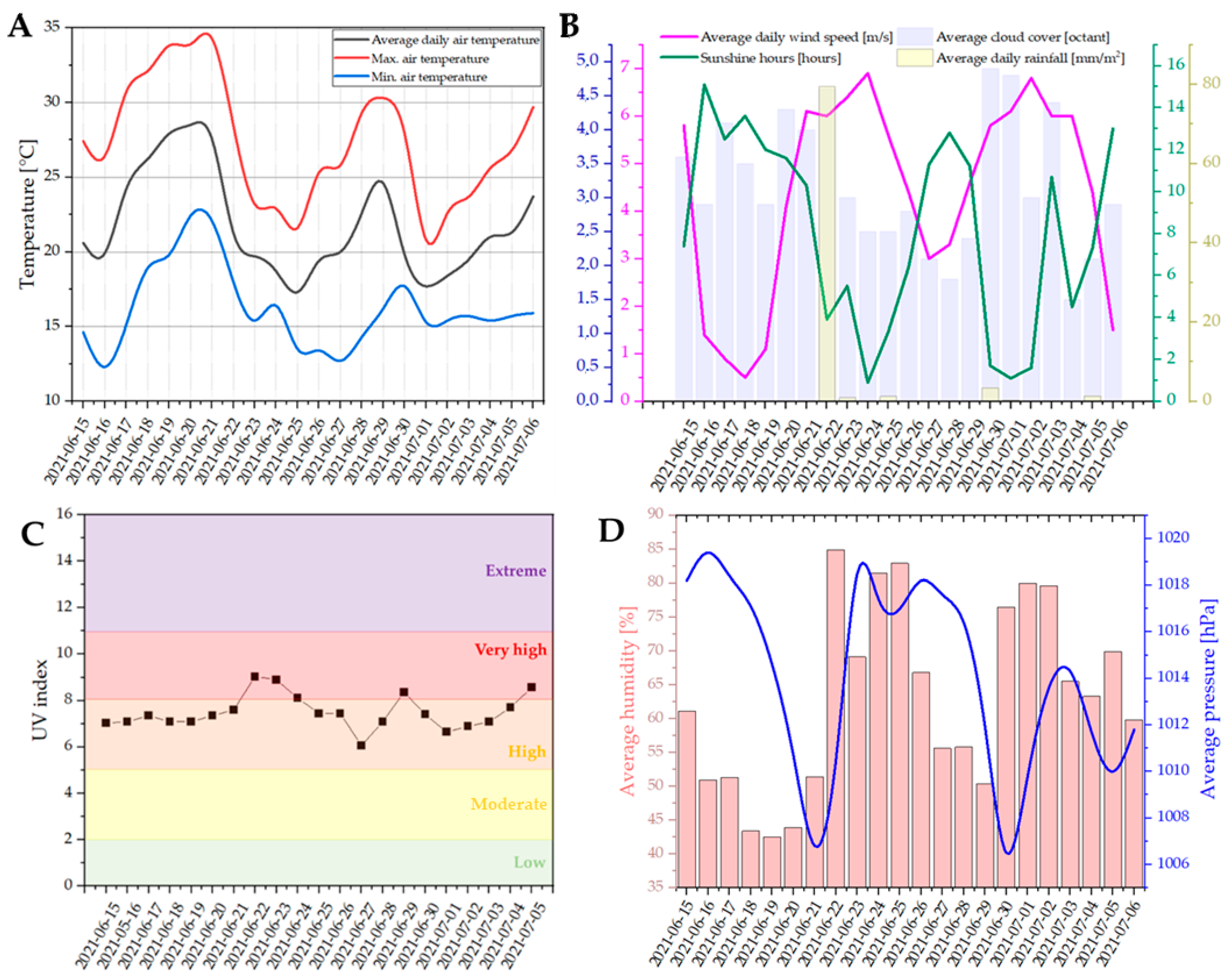

3. Results

3.1. Mechanical Tests

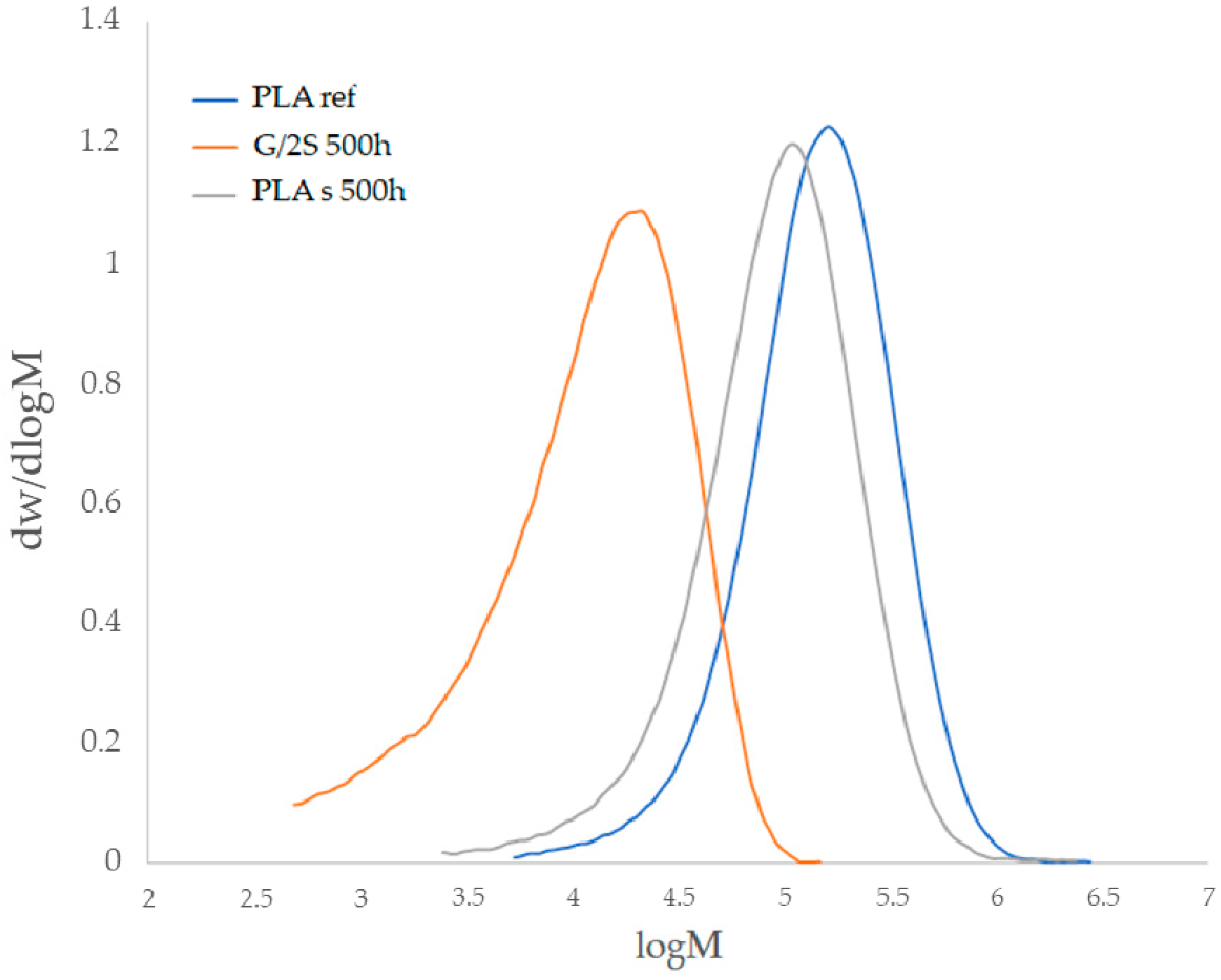

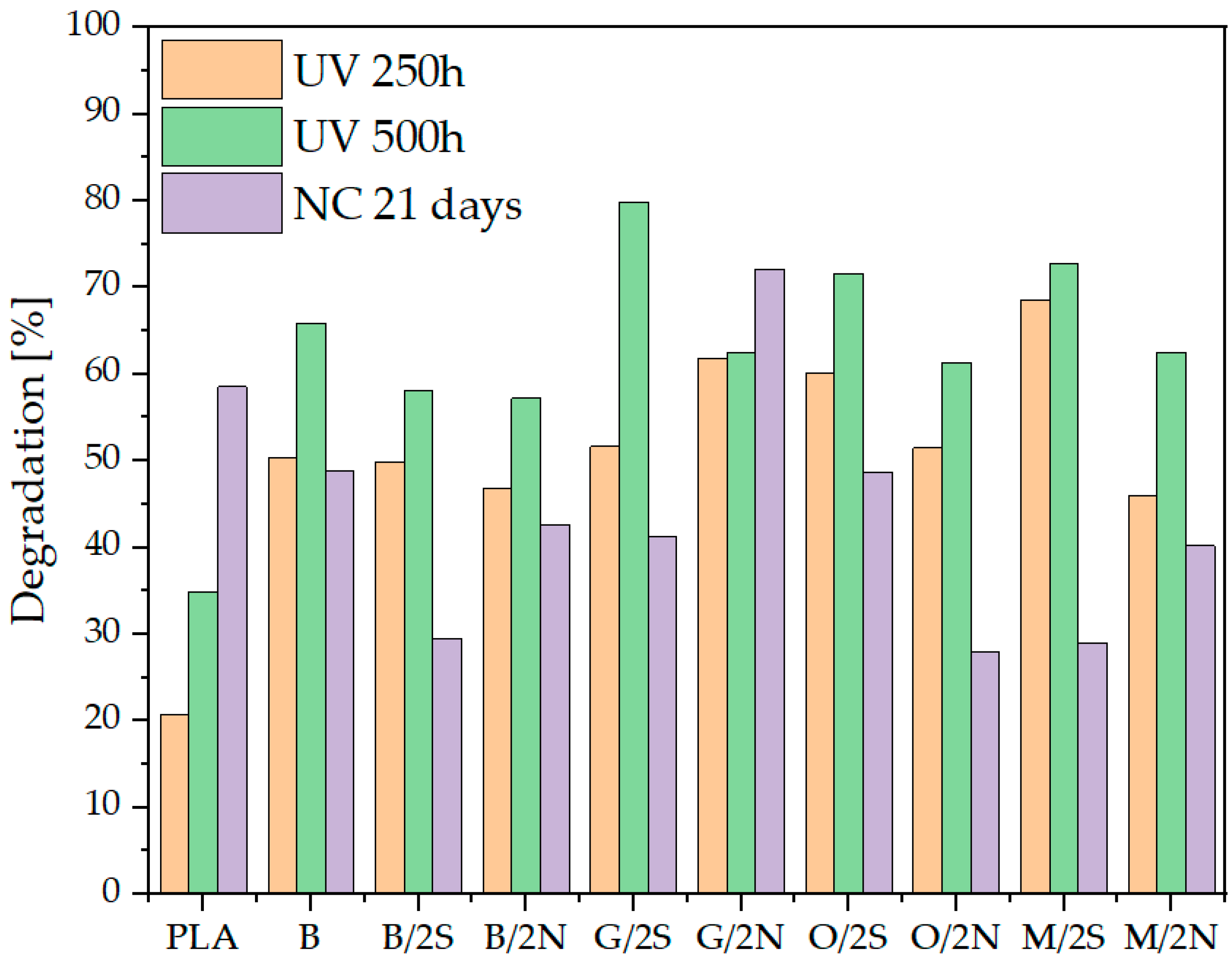

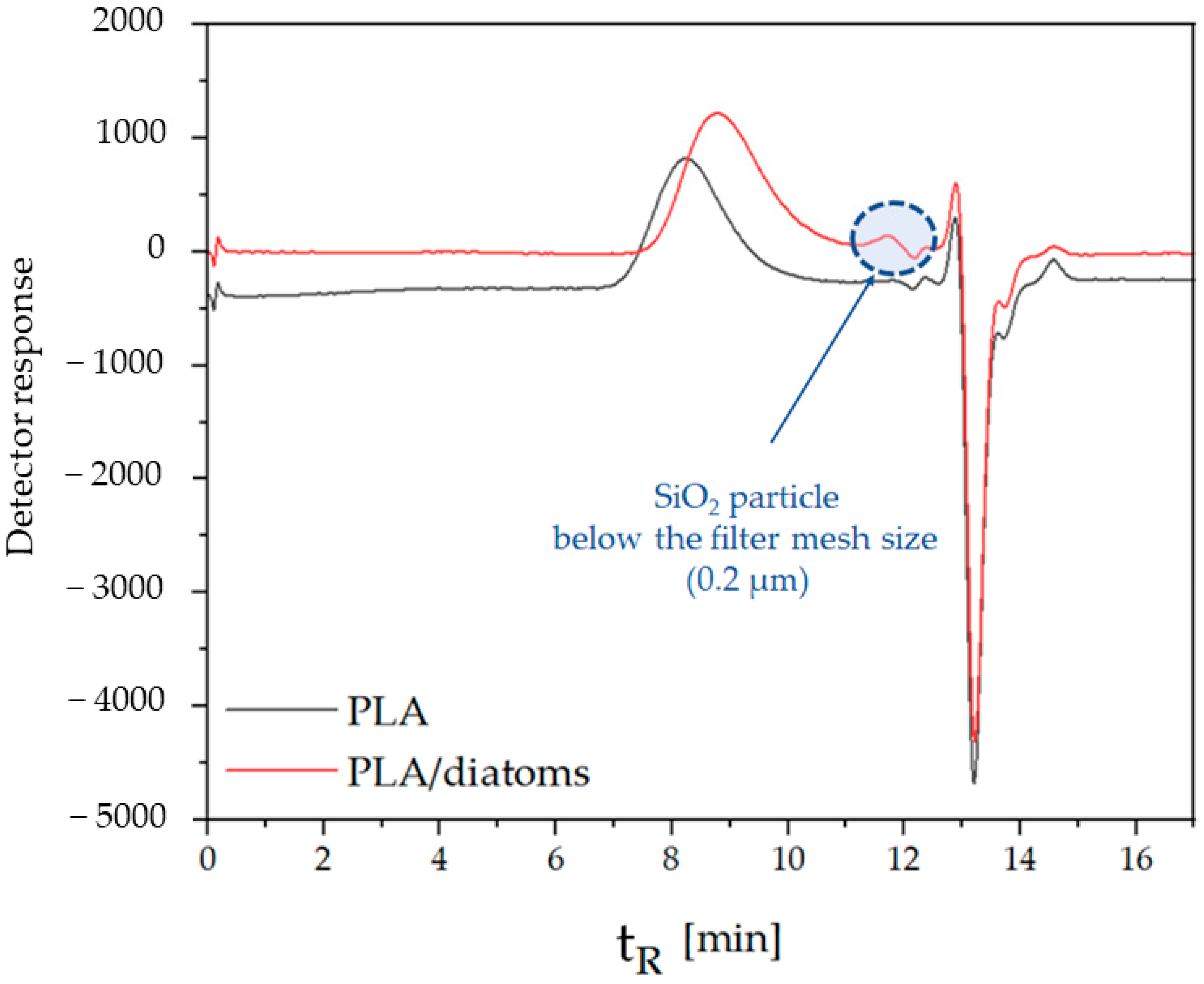

3.2. Degradation of PLA Macromolecular Structure

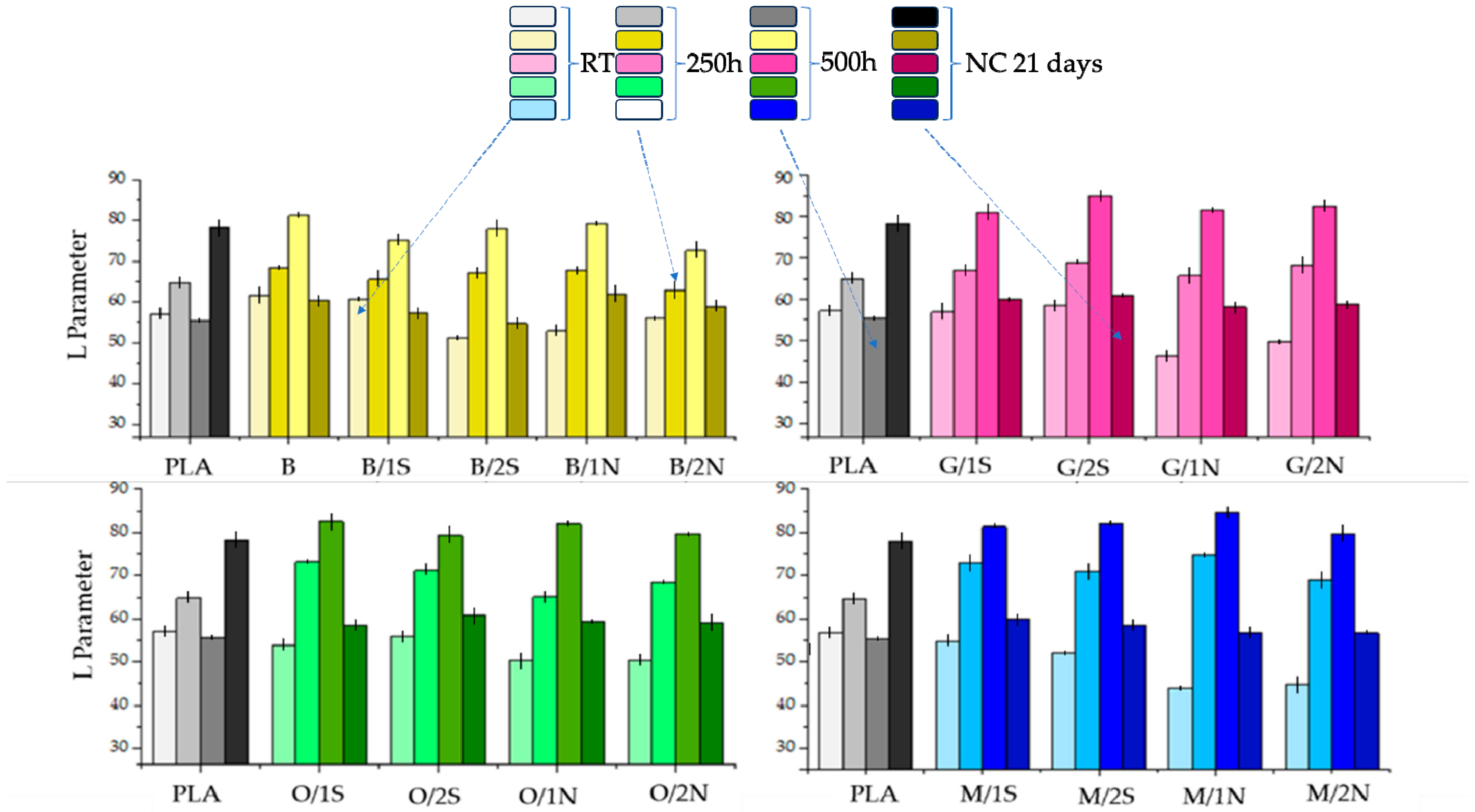

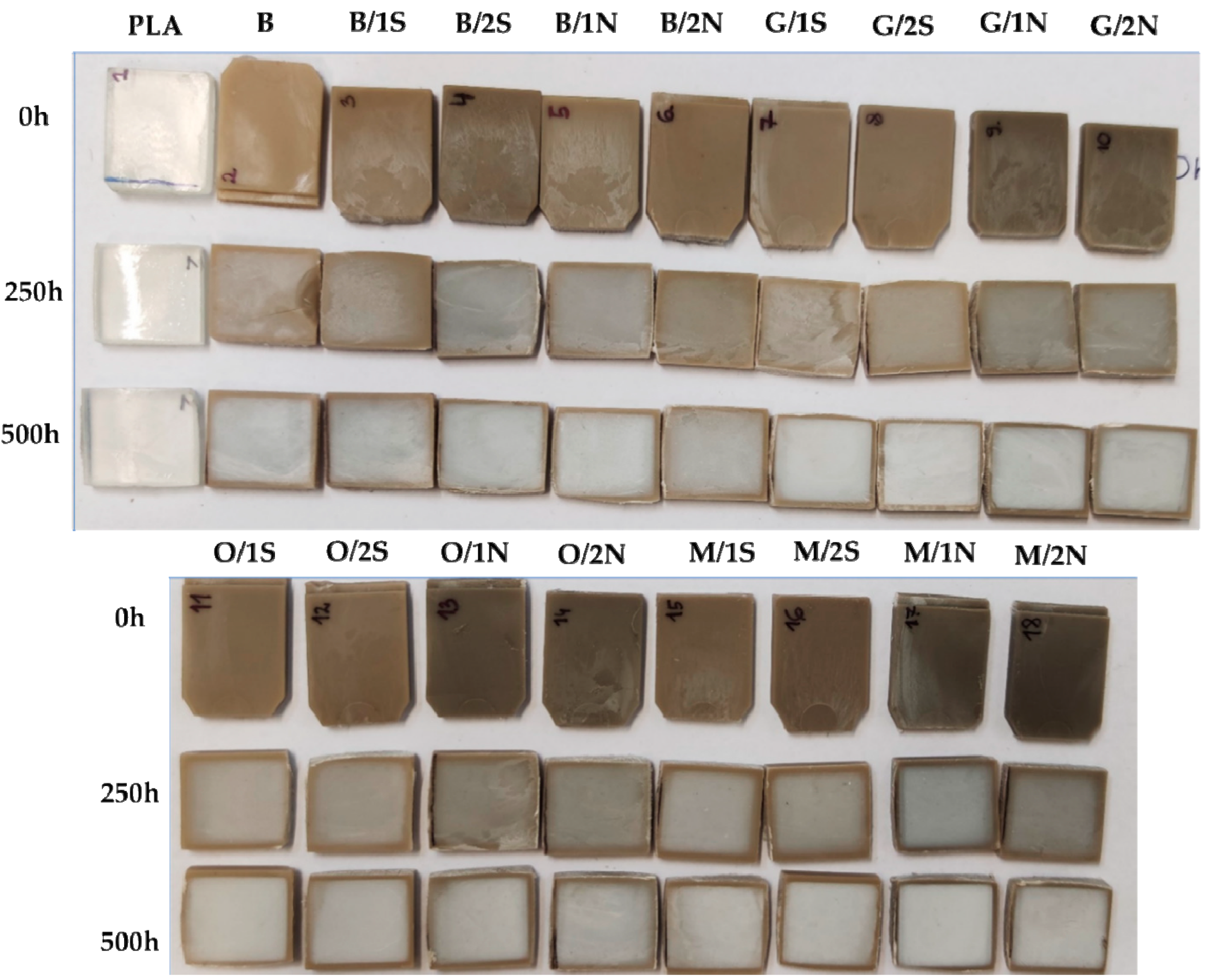

3.3. Color Testing after UV Irradiaton

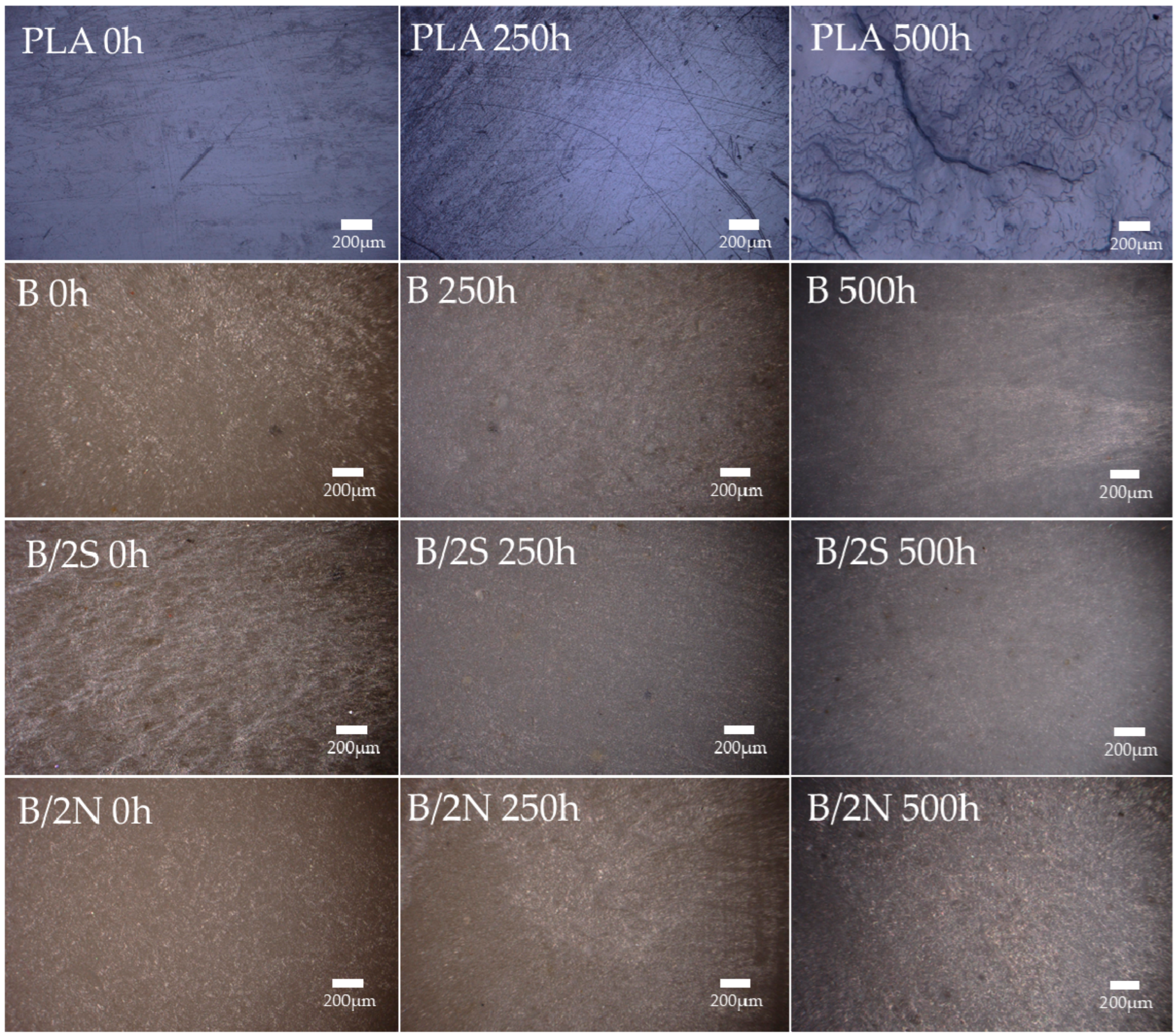

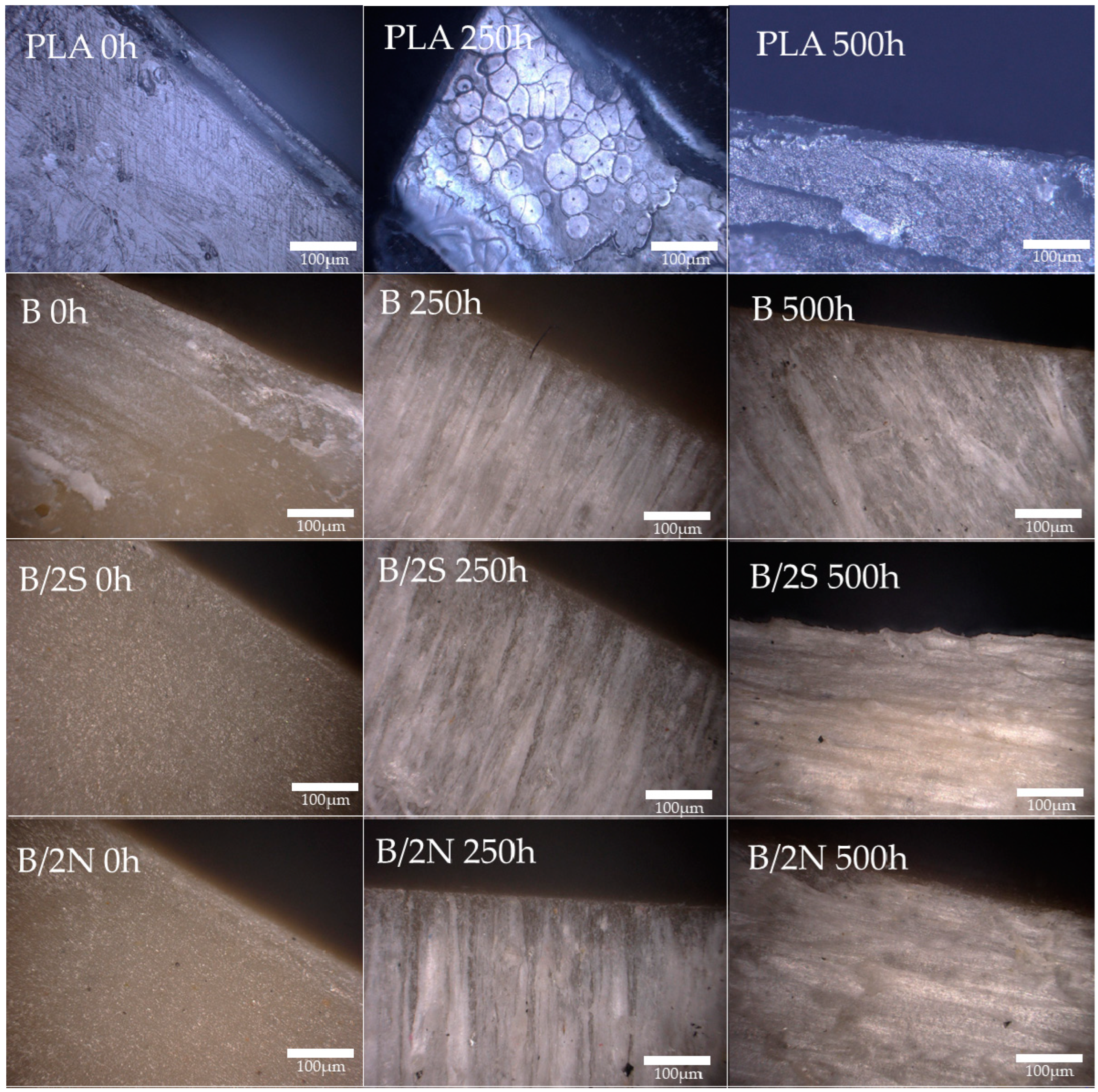

3.4. Microscopy Analysis of the Composites’ Structure after UV Irradiaton

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Andrusiv, L. Experimental Study of Reinforcing Mechanical Properties of Nylon-11 by Selective Laser Sintering. Phys. Sci. Forum 2022, 4, 22. [Google Scholar] [CrossRef]

- Zgłobicka, I.; Joka-Yildiz, M.; Molak, R.; Kawalec, M.; Dubicki, A.; Wróblewski, J.; Dydek, K.; Boczkowska, A.; Kurzydłowski, K.J. Poly(lactic acid) Matrix Reinforced with Diatomaceous Earth. Materials 2022, 15, 18. [Google Scholar] [CrossRef]

- Pilla, S.; Gong, S.; O’Neill, E.; Rowell, R.M.; Krzysik, A.M. Polylactide-pine wood flour composites. Polym. Eng. Sci. 2008, 48, 578–587. [Google Scholar] [CrossRef]

- Sanivada, U.K.; Mármol, G.; Brito, F.P.; Fangueiro, R. PLA Composites Reinforced with Flax and Jute Fibers—A Review of Recent Trends, Processing Parameters and Mechanical Propertie. Polymers 2020, 12, 237. [Google Scholar] [CrossRef]

- Haddou, G.; Dandurand, J.; Dantras, E.; Maiduc, H.; Thai, H.; Vu Giang, N.; Trung, T.H.; Ponteins, P.; Lacabanne, C. Mechanical properties of continuous bamboo fiber-reinforced biobased polyamide 11 composites. Inc. J. Appl. Polym. Sci. 2019, 136, 4762. [Google Scholar] [CrossRef]

- Zierdt, P.; Theumer, T.; Kulkarni, G.; Däumlich, V.; Klehm, J.; Hirsch, U.; Weber, A. Sustainable wood-plastic composites from bio-based polyamide 11 and chemically modified beech fibers. Sustain. Mater. Technol. 2015, 6, 6–14. [Google Scholar] [CrossRef]

- Dobrosielska, M.; Przekop, R.E.; Sztorch, B.; Brząkalski, D.; Zgłobicka, I.; Łępicka, M.; Dobosz, R.; Kurzydłowski, K.J. Biogenic Composite Filaments Based on Polylactide and Diatomaceous Earth for 3D Printing. Materials 2020, 13, 4632. [Google Scholar] [CrossRef]

- Dobrosielska, M.; Dobrucka, R.; Brząkalski, D.; Frydrych, M.; Kozera, P.; Jałbrzykowski, M.; Kurzydłowski, K.J.; Przekop, R.E. Influence of Diatomaceous Earth Particle Size on Mechanical Properties of PLA/Diatomaceous earth Composites. Materials 2022, 15, 3607. [Google Scholar] [CrossRef]

- Dobrosielska, M.; Dobrucka, R.; Kozera, P.; Kozera, R.; Kołodziejczak, M.; Gabriel, E.; Głowacka, J.; Jałbrzykowski, M.; Kurzydłowski, K.J.; Przekop, R.E. Biocomposites Based on Polyamide 11/Diatoms with Different Sized Frustules. Polymers 2022, 14, 3153. [Google Scholar] [CrossRef]

- Li, T.; Sun, H.; Wu, B.; Han, H.; Li, D.; Wang, J.-K.; Zhang, J.; Huang, J.; Sun, D. High-performance polylactic acid composites reinforced by artificially cultured diatom frustules. Mater. Des. 2020, 195, 109003. [Google Scholar] [CrossRef]

- Nair, N.R.; Sekhar, V.C.; Nampoothiri, K.M.; Pandey, A. 32-Biodegradation of Biopolymers. In Current Developments in Biotechnology and Bioengineering; Pandey, A., Negi, S., Soccol, C.R., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 739–755. [Google Scholar]

- Zaaba, N.F.; Jaafar, M. A review on degradation mechanisms of polylactic acid: Hydrolytic, photodegradative, microbial, and enzymatic degradation. Polym. Eng. Sci. 2020, 60, 2061–2075. [Google Scholar] [CrossRef]

- Siparsky, G.L.; Voorhees, K.J.; Miao, F. Hydrolysis of Polylactic Acid (PLA) and Polycaprolactone (PCL) in Aqueous Acetonitrile, Solutions: Autocatalysis. J. Polym. Environ. 1998, 6, 31–41. [Google Scholar] [CrossRef]

- Hirao, K.; Nakatsuchi, Y.; Ohara, H. Alcoholysis of Poly(l-lactic acid) under microwave irradiation. Polym. Degrad. Stab. 2010, 95, 925–928. [Google Scholar] [CrossRef]

- Iñiguez-Franco, F.; Auras, R.; Burgess, G.; Holmes, D.; Fang, X.; Rubino, M.; Soto-Valdez, H. Concurrent solvent induced crystallization and hydrolytic degradation of PLA by water-ethanol solutions. Polymer 2016, 99, 315–323. [Google Scholar] [CrossRef]

- Castro-Aguirre, E.; Iñiguez-Franco, F.; Samsudin, H.; Fang, X.; Auras, R. Poly(lactic acid)—Mass production, processing, industrial applications, and end of life. Adv. Drug Deliv. Rev. 2016, 107, 333–366. [Google Scholar] [CrossRef]

- Qi, X.; Ren, Y.; Wang, X. New advances in the biodegradation of Poly(lactic) acid. Int. Biodeterior. Biodegrad. 2017, 117, 215–223. [Google Scholar] [CrossRef]

- Teixeira, S.; Morawa-Eblagon, K.; Miranda, F.; Pereira, M.F.R.; Figueiredo, J.L. Towards Controlled Degradation of Poly(lactic) Acid in Technical Applications. C 2021, 7, 42. [Google Scholar] [CrossRef]

- Zhang, C.; Sun, J.; Lyu, S.; Lu, Z.; Li, T.; Yang, Y.; Li, B.; Han, H.; Wu, B.; Sun, H.; et al. Poly(lactic acid)/artificially cultured diatom frustules nanofibrous membranes with fast and controllable degradation rates for air filtration. Adv. Compos. Hybrid Mater. 2022, 5, 1221–1232. [Google Scholar] [CrossRef]

- Drohsler, P.; Yasir, M.; Cruz, F.D.R.; Cisar, J.; Yadollahi, Z.; Sedlarik, V. Comparative degradation study of a biodegradable composite based on polylactide with halloysite nanotubes and a polyacrylic acid copolymer. Mater. Today Commun. 2022, 33, 104400. [Google Scholar] [CrossRef]

- Qin, Q.; Yang, Y.; Yang, C.; Zhang, L.; Yin, H.; Yu, F.; Ma, J. Degradation and adsorption behavior of biodegradable plastic PLA under conventional weathering conditions. Sci. Total Environ. 2022, 84210, 156775. [Google Scholar] [CrossRef]

- PN-EN ISO 20753:2019-01; Plastics—Test Specimens. ISO: Geneva, Switzerland, 2019.

- EN ISO 527:2012; Standard—Plastics—Determination of Tensile Properties. ISO: Geneva, Switzerland, 2012.

- EN ISO 178:2006; Plastics—Determination of Flexural Properties. ISO: Geneva, Switzerland, 2006.

- ISO 4892-3; Methods of Exposure To Laboratory Light Sources—Part 3: Fluorescent UV Lamps. ISO: Geneva, Switzerland, 2006.

- ASTM G154; Standard Practice for Operating Fluorescent Light Apparatus for UV Exposure of Nonmetallic Materials. American Society for Testing and Materials: West Conshohocken, PA, USA, 2016.

- PN-EN ISO 16474-3; Paints and Varnishes—Methods of Exposure to Laboratory Light Sources—Part 3: UV Fluorescent Lamps. Polish Norm, International Organization for Standardization: Warsaw, Poland, 2014.

- Dobrosielska, M.; Dobrucka, R.; Pajewska-Szmyt, M.; Kozera, P.; Gabriel, E.; Głowacka, J.; Brząkalski, D.; Kurzydłowski, K.J.; Przekop, R.E. Effect of Wax Additives and Silanization of Diatom Surfaces on Thermomechanical Properties of Polylactide Composites. Polymers 2022, 14, 5511. [Google Scholar] [CrossRef]

- Dobrosielska, M.; Dobrucka, R.; Kozera, P.; Brząkalski, D.; Gabriel, E.; Głowacka, J.; Jałbrzykowski, M.; Kurzydłowski, K.J.; Przekop, R.E. Beeswax as a natural alternative to synthetic waxes for fabrication of PLA/diatomaceous earth composites. Sci. Rep. 2023, 13, 1161. [Google Scholar] [CrossRef]

- Ho, K.L.G.; Pometto, A.L.; Hinz, P.N. Effects of Temperature and Relative Humidity on Polylactic Acid Plastic Degradation. J. Environ. Polym. Degrad. 1999, 7, 83–92. [Google Scholar] [CrossRef]

- Badarinath, K.V.S.; Kumar Kharol, S.; Krishna Prasad, V.; Rani Sharma, A.; Reddi, E.U.B.; Kambezidis, H.D.; Kaskaoutis, D.G. Influence of natural and anthropogenic activities on UV Index variations—A study over tropical urban region using ground based observations and satellite data. J. Atmos. Chem. 2008, 59, 219–236. [Google Scholar] [CrossRef]

- Leccese, F.; Salvadori, G.; Lista, D.; Burattini, C. Outdoor Workers Exposed to UV Radiation: Comparison of UV Index Forecasting Methods. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Palermo, Italy, 12–15 June 2008. [Google Scholar] [CrossRef]

- Trifol, J.; Plackett, D.; Szabo, P.; Daugaard, A.E.; Giacinti Baschetti, M. Effect of Crystallinity on Water Vapor Sorption, Diffusion, and Permeation of PLA-Based Nanocomposites. ACS Omega 2020, 5, 15362–15369. [Google Scholar] [CrossRef]

- Copinet, A.; Bertrand, C.; Govindin, S.; Coma, V.; Couturier, Y. Effects of ultraviolet light (315 nm), temperature and relative humidity on the degradation of polylactic acid plastic films. Chemosphere 2004, 55, 763–773. [Google Scholar] [CrossRef]

- Gallet, G.; Lempiäinen, R.; Karlsson, S. Characterisation by solid phase microextraction–gas chromatography–mass spectrometry of matrix changes of poly(l-lactide) exposed to outdoor soil environment. Polym. Degrad. Stab. 2000, 71, 147–151. [Google Scholar] [CrossRef]

- Li, T.; Sun, H.; Han, H.; Zhang, C.; Li, B.; Huang, J.; Sun, D. Ultrafast bulk degradation of polylactic acid by artificially cultured diatom frustules. Compos. Sci. Technol. 2022, 22326, 109410. [Google Scholar] [CrossRef]

| Temperature [°C] | Mold | Die | Zone 3 | Zone 2 | Zone 1 | Feed |

| 80 | 190 | 195 | 200 | 185 | 40 | |

| Holding pressure | t [s] | 0.0 | 9.0 | |||

| P [bar] | 500 | 1500 | ||||

| Clamping force [kN] | Holding time [s] | Coolig time [s] | Screw diameter [mm] | |||

| 800 | 9.0 | 50.0 | 25.0 | |||

| Full Name | Short Name |

|---|---|

| PLA | PLA |

| PLA/DE | B |

| PLA/DE + 1% wt. SW | B/1S |

| PLA/DE + 2% wt. SW | B/2S |

| PLA/DE + 1% wt. NW | B/1N |

| PLA/DE + 2% wt. NW | B/2N |

| PLA/DE + 1% wt. GPTMOS + 1% wt. SW | G/1S |

| PLA/DE + 1% wt. GPTMOS + 2% wt. SW | G/2S |

| PLA/DE + 1% wt. GPTMOS + 1% wt. NW | G/1N |

| PLA/DE + 1% wt. GPTMOS + 2% wt. NW | G/2N |

| PLA/DE + 1% wt. OTES + 1% wt. SW | O/1S |

| PLA/DE + 1% wt. OTES + 2% wt. SW | O/2S |

| PLA/DE + 1% wt. OTES + 1% wt. NW | O/1N |

| PLA/DE + 1% wt. OTES + 2% wt. NW | O/2N |

| PLA/DE + 1% wt. MTMOS + 1% wt. SW | M/1S |

| PLA/DE + 1% wt. MTMOS + 2% wt. SW | M/2S |

| PLA/DE + 1% wt. MTMOS + 1% wt. NW | M/1N |

| PLA/DE + 1% wt. MTMOS + 2% wt. NW | M/2N |

| Sample Name | Mn (250 h) | Mn (500 h) | Mn (NC) | Mw (250 h) | Mw (500 h) | Mw (NC) | %Degradation 250 h [a] | %Degradation 500 h [a] | %Degradation NC [a] |

|---|---|---|---|---|---|---|---|---|---|

| PLA | 82,600 | 55,100 | 26,000 | 148,500 | 126,000 | 84,100 | 20.7 | 34.9 | 58.5 |

| B | 27,000 | 37,600 | 28,800 | 63,700 | 96,000 | 103,400 | 50.4 | 65.9 | 48.9 |

| B/1S | 71,400 | 46,900 | 33,600 | 116,400 | 105,900 | 108,400 | 37.8 | 45.3 | 46.5 |

| B/2S | 40,900 | 34,500 | 56,900 | 93,700 | 81,200 | 143,000 | 49.9 | 58.1 | 29.4 |

| B/1N | 45,100 | 36,400 | 38,300 | 94,800 | 82,800 | 9100 | 49.4 | 57.2 | 95.5 |

| B/2N | 43,100 | 36,300 | 33,300 | 99,600 | 82,800 | 116,300 | 46.8 | 57.2 | 42.6 |

| G/1S | 47,500 | 20,600 | 44,300 | 99,300 | 52,500 | 133,200 | 47.0 | 72.9 | 34.2 |

| G/2S | 35,100 | 16,400 | 45,700 | 90,500 | 39,200 | 119,000 | 51.6 | 79.8 | 41.3 |

| G/1N | 43,500 | 20,900 | 39,700 | 82,600 | 64,800 | 90,100 | 55.9 | 66.5 | 55.5 |

| G/2N | 31,500 | 31,600 | 18,400 | 70,300 | 74,000 | 56,600 | 61.8 | 62.5 | 72.1 |

| O/1S | 28,600 | 22,200 | 27,700 | 65,400 | 54,700 | 110,300 | 65.1 | 71.8 | 45.5 |

| O/2S | 33,000 | 25,100 | 17,300 | 74,600 | 54,900 | 103,800 | 60.1 | 71.6 | 48.7 |

| O/1N | 47,200 | 30,600 | 65,700 | 109,400 | 75,500 | 121,000 | 41.5 | 61.0 | 40.3 |

| O/2N | 61,100 | 27,300 | 75,500 | 90,800 | 74,900 | 146,100 | 51.5 | 61.3 | 27.9 |

| M/1S | 29,100 | 19,400 | 67,400 | 73,300 | 53,600 | 111,400 | 60.8 | 72.3 | 45.0 |

| M/2S | 24,500 | 17,600 | 42,000 | 58,800 | 52,800 | 143,800 | 68.6 | 72.7 | 29.0 |

| M/1N | 25,600 | 22,500 | 39,200 | 60,900 | 56,300 | 118,700 | 67.5 | 70.9 | 41.4 |

| M/2N | 44,300 | 24,500 | 43,100 | 101,300 | 72,600 | 120,400 | 45.9 | 62.5 | 40.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dobrosielska, M.; Dobrucka, R.; Brząkalski, D.; Pajewska-Szmyt, M.; Kurzydłowski, K.J.; Przekop, R.E. The Influence of Environmental Factors on the Degradation of PLA/Diatomaceous Earth Composites. Polymers 2024, 16, 1450. https://doi.org/10.3390/polym16111450

Dobrosielska M, Dobrucka R, Brząkalski D, Pajewska-Szmyt M, Kurzydłowski KJ, Przekop RE. The Influence of Environmental Factors on the Degradation of PLA/Diatomaceous Earth Composites. Polymers. 2024; 16(11):1450. https://doi.org/10.3390/polym16111450

Chicago/Turabian StyleDobrosielska, Marta, Renata Dobrucka, Dariusz Brząkalski, Martyna Pajewska-Szmyt, Krzysztof J. Kurzydłowski, and Robert E. Przekop. 2024. "The Influence of Environmental Factors on the Degradation of PLA/Diatomaceous Earth Composites" Polymers 16, no. 11: 1450. https://doi.org/10.3390/polym16111450

APA StyleDobrosielska, M., Dobrucka, R., Brząkalski, D., Pajewska-Szmyt, M., Kurzydłowski, K. J., & Przekop, R. E. (2024). The Influence of Environmental Factors on the Degradation of PLA/Diatomaceous Earth Composites. Polymers, 16(11), 1450. https://doi.org/10.3390/polym16111450