Parametric Optimization of FDM Process for PA12-CF Parts Using Integrated Response Surface Methodology, Grey Relational Analysis, and Grey Wolf Optimization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Printing Process Parameters and Experimental Design

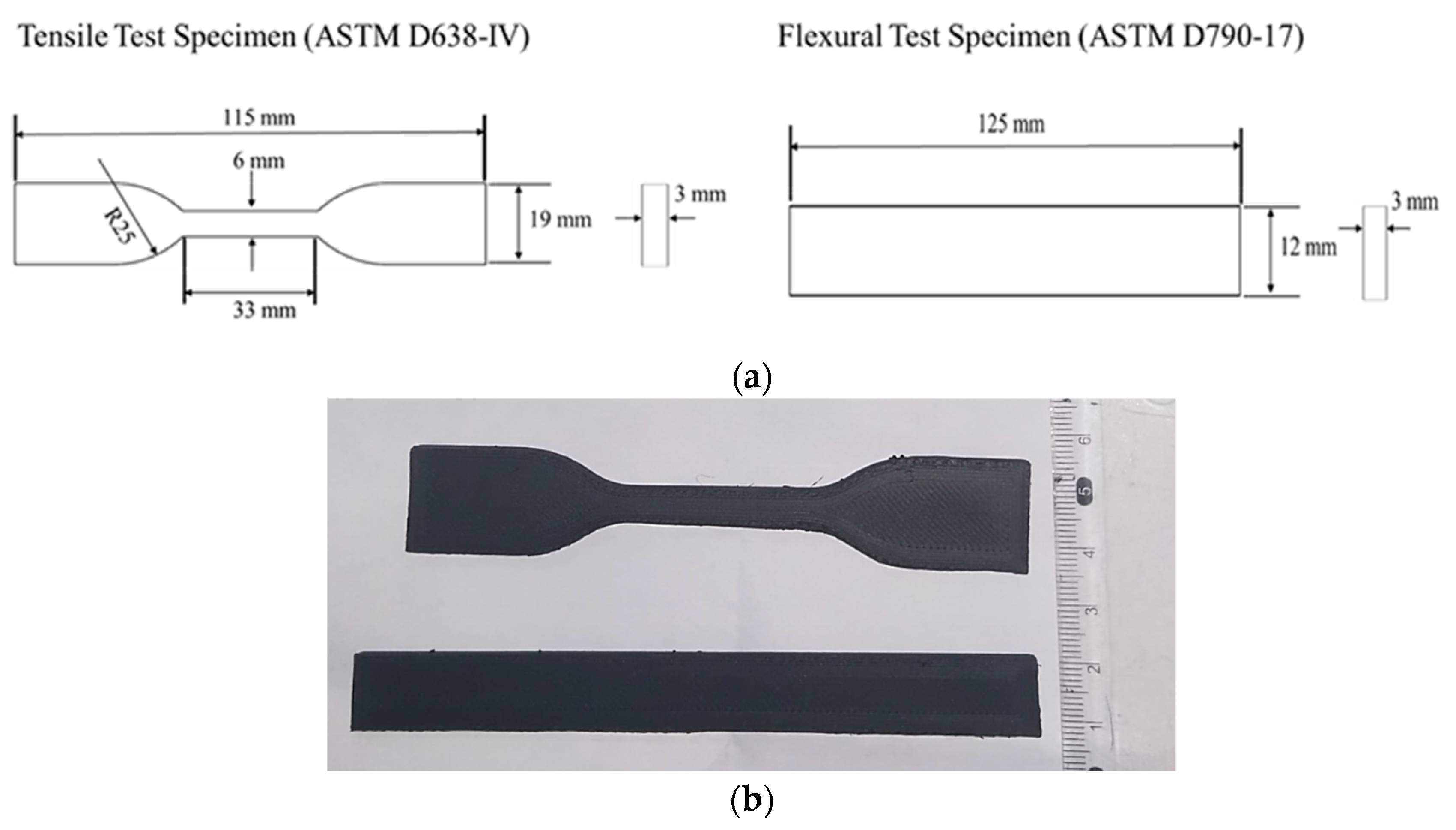

2.2. Responses

2.3. Multi-Response Optimization

2.4. Grey Relational Analysis

2.5. Grey Wolf Optimization (GWO)

3. Results and Discussions

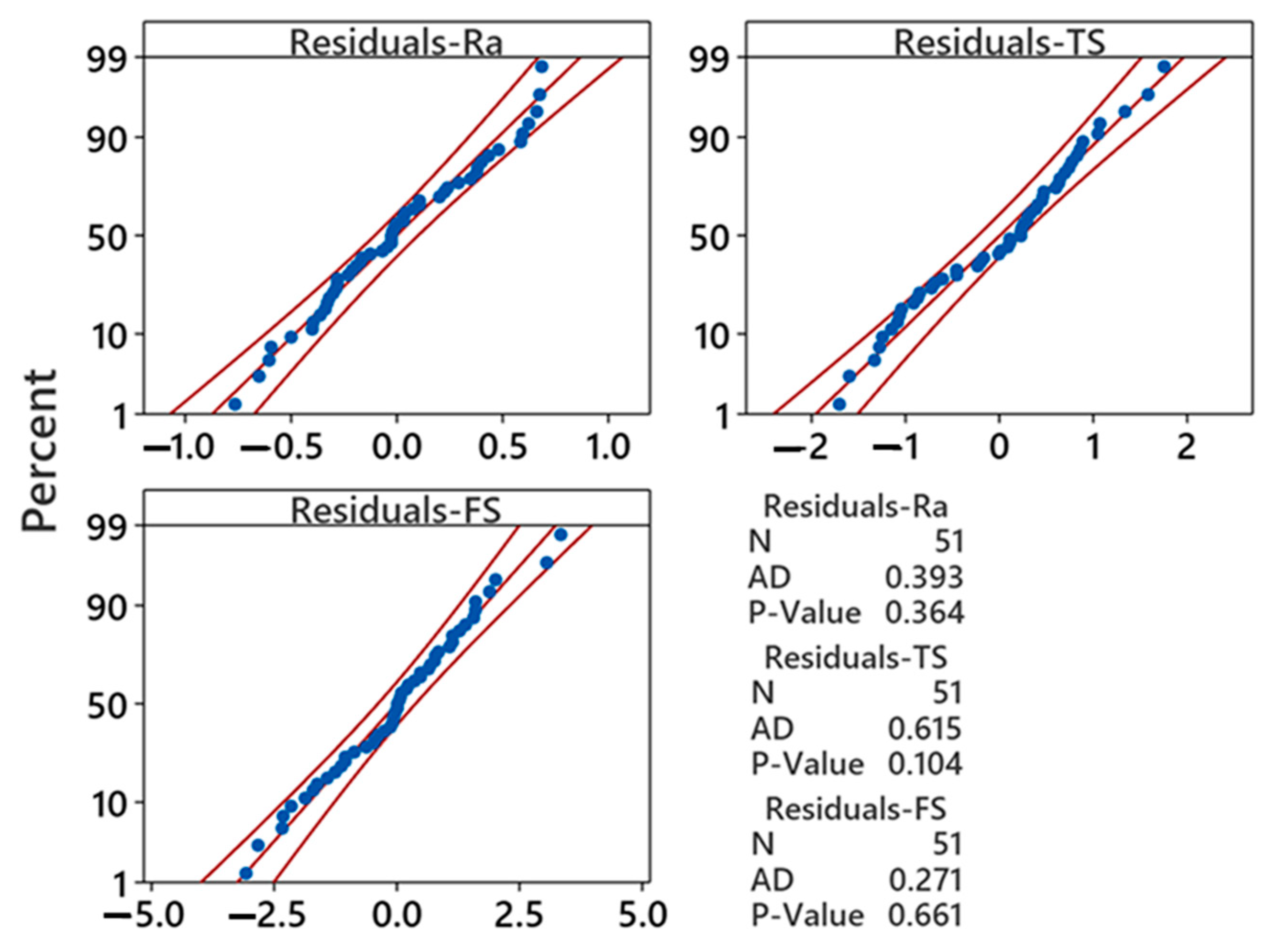

3.1. Regression Analysis of Variance (ANOVA)

3.2. Effects of Process Parameters on Responses

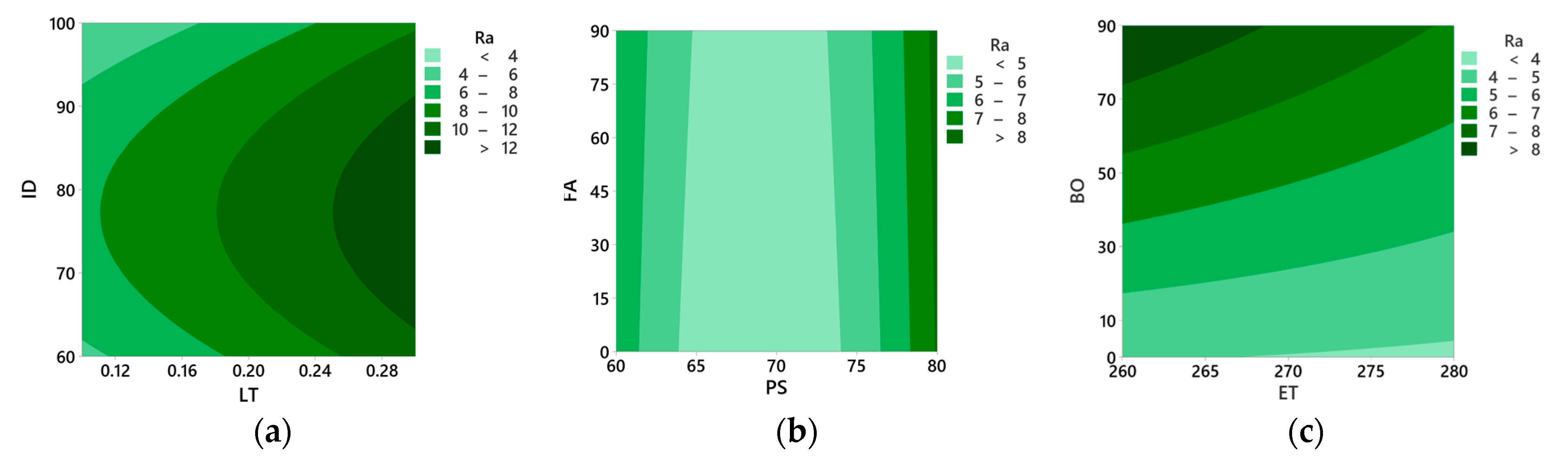

3.2.1. Effects of Process Parameters on Ra

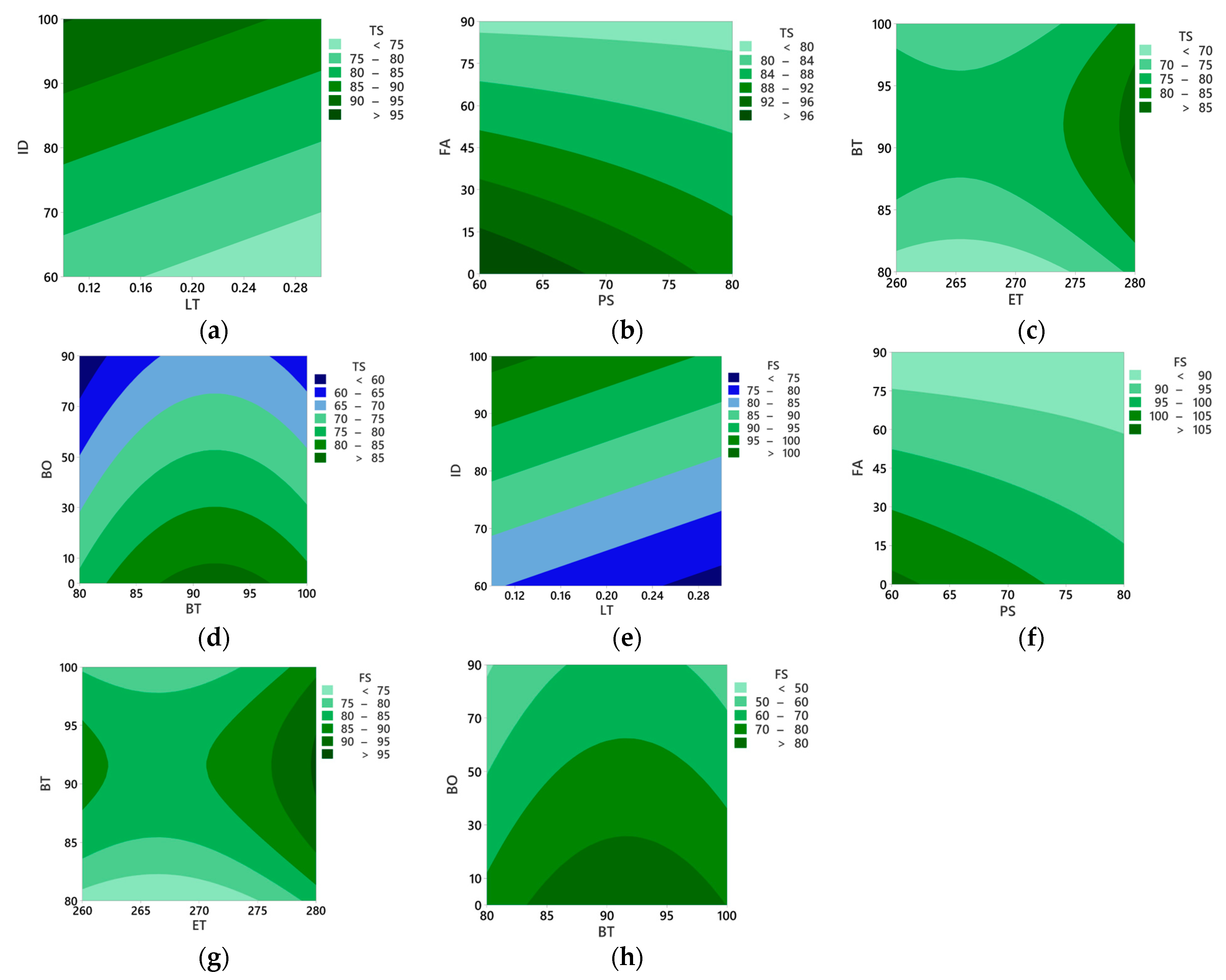

3.2.2. Effects of Process Parameters on Tensile and Flexural Strengths

3.3. Optimization Using Grey Relational Analysis (GRA)

3.4. Regression Model Based on Grey Relational Grade (GRG) Values

3.5. Grey Wolf Optimization

4. Practical Implications and Limitations of GWO

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Karimi, A.; Rahmatabadi, D.; Baghani, M. Various FDM Mechanisms Used in the Fabrication of Continuous-Fiber Reinforced Composites: A Review. Polymers 2024, 16, 831. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Singh, H.; Singh, I.; Bharti, S.; Kumar, D.; Siebert, G.; Koloor, S.S.R. A Comprehensive Review of FDM Printing in Sensor Applications: Advancements and Future Perspectives. J. Manuf. Process. 2024, 113, 152–170. [Google Scholar] [CrossRef]

- Anerao, P.; Kulkarni, A.; Munde, Y. A Review on Exploration of the Mechanical Characteristics of 3D-Printed Biocomposites Fabricated by Fused Deposition Modelling (FDM). Rapid Prototyp. J. 2024, 30, 430–440. [Google Scholar] [CrossRef]

- Abas, M.; Habib, T.; Noor, S.; Zimon, D.; Woźniak, J. Application of Multi-Criteria Decision-Making Methods in the Selection of Additive Manufacturing Materials for Solid Ankle Foot Orthoses. J. Eng. Des. 2023, 34, 616–643. [Google Scholar] [CrossRef]

- Mallikarjuna, B.; Bhargav, P.; Hiremath, S.; Jayachristiyan, K.G.; Jayanth, N. A Review on the Melt Extrusion-Based Fused Deposition Modeling (FDM): Background, Materials, Process Parameters and Military Applications. Int. J. Interact. Des. Manuf. 2023. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Soltanmohammadi, K.; Pahlavani, M.; Aberoumand, M.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; Baghani, M. Shape Memory Performance Assessment of FDM 3D Printed PLA-TPU Composites by Box-Behnken Response Surface Methodology. Int. J. Adv. Manuf. Technol. 2023, 127, 935–950. [Google Scholar] [CrossRef]

- Khan, I.; Yaseen, M.; Ahmad, M.M.; Abas, M.; Shah, M.I.; Hussain, H.; Hira, F. Integrating Resistance-Based Sensing into Fused Filament Fabricated Mechanical Metamaterial Structure. Prog. Addit. Manuf. 2024. [Google Scholar] [CrossRef]

- Abas, M.; Habib, T.; Noor, S. Design and Analysis of Solid Ankle Foot Orthosis by Employing Mechanical Characterization and a Low-Cost Scanning Approach for Additive Manufacturing. Rapid Prototyp. J. 2024, 30, 782–797. [Google Scholar] [CrossRef]

- Muhamedagic, K.; Berus, L.; Potočnik, D.; Cekic, A.; Begic-Hajdarevic, D.; Cohodar Husic, M.; Ficko, M. Effect of Process Parameters on Tensile Strength of FDM Printed Carbon Fiber Reinforced Polyamide Parts. Appl. Sci. 2022, 12, 6028. [Google Scholar] [CrossRef]

- Fountas, N.A.; Zaoutsos, S.; Chaidas, D.; Kechagias, J.D.; Vaxevanidis, N.M. Statistical Modelling and Optimization of Mechanical Properties for PLA and PLA/Wood FDM Materials. Mater. Today Proc. 2023, 93, 824–830. [Google Scholar] [CrossRef]

- Nagendra, J.; Prasad, M.S.G. FDM Process Parameter Optimization by Taguchi Technique for Augmenting the Mechanical Properties of Nylon–Aramid Composite Used as Filament Material. J. Inst. Eng. Ser. C 2020, 101, 313–322. [Google Scholar] [CrossRef]

- Balaji, N.S.; Velmurugan, C.; Saravana Kumar, M.; Sivakumar, M.; Asokan, P. Experimental Investigation on Mechanical Properties of Fdm-Based Nylon Carbon Parts Using Ann Approach. Surf. Rev. Lett. 2023, 30, 2350028. [Google Scholar] [CrossRef]

- Kumar, P.; Gupta, P.; Singh, I. Parametric Optimization of FDM Using the ANN-Based Whale Optimization Algorithm. AI EDAM 2022, 36, e27. [Google Scholar] [CrossRef]

- Saad, M.S.; Nor, A.M.; Baharudin, M.E.; Zakaria, M.Z.; Aiman, A.F. Optimization of Surface Roughness in FDM 3D Printer Using Response Surface Methodology, Particle Swarm Optimization, and Symbiotic Organism Search Algorithms. Int. J. Adv. Manuf. Technol. 2019, 105, 5121–5137. [Google Scholar] [CrossRef]

- Chinchanikar, S.; Shinde, S.; Shaikh, A.; Gaikwad, V.; Ambhore, N.H. Multi-Objective Optimization of FDM Using Hybrid Genetic Algorithm-Based Multi-Criteria Decision-Making (MCDM) Techniques. J. Inst. Eng. Ser. D 2023, 105, 49–63. [Google Scholar] [CrossRef]

- Salunkhe, S.; Jatti, D.V.S.; Tamboli, S.; Shaikh, S.; Solke, N.; Gulia, V.; Jatti, V.S.; Khedkar, N.K.; Pagac, M.; Abouel Nasr, E. Optimization of Tensile Strength in 3D Printed PLA Parts via Meta-Heuristic Approaches: A Comparative Study. Front. Mater. 2023, 10, 1336837. [Google Scholar]

- Boppana, V.C.; Ali, F. Improvement of Tensile Strength of Fused Deposition Modelling (FDM) Part Using Artificial Neural Network and Genetic Algorithm Techniques. Int. J. Ind. Eng. Oper. Manag. 2024, 6, 117–142. [Google Scholar] [CrossRef]

- Mohanty, A.; Nag, K.S.; Bagal, D.K.; Barua, A.; Jeet, S.; Mahapatra, S.S.; Cherkia, H. Parametric Optimization of Parameters Affecting Dimension Precision of FDM Printed Part Using Hybrid Taguchi-MARCOS-Nature Inspired Heuristic Optimization Technique. Mater. Today Proc. 2022, 50, 893–903. [Google Scholar] [CrossRef]

- Chandrashekarappa, M.P.G.; Chate, G.R.; Parashivamurthy, V.; Kumar, B.S.; Bandukwala, M.A.N.; Kaisar, A.; Giasin, K.; Pimenov, D.Y.; Wojciechowski, S. Analysis and Optimization of Dimensional Accuracy and Porosity of High Impact Polystyrene Material Printed by FDM Process: PSO, JAYA, Rao, and Bald Eagle Search Algorithms. Materials 2021, 14, 7479. [Google Scholar] [CrossRef] [PubMed]

- Raju, M.; Gupta, M.K.; Bhanot, N.; Sharma, V.S. A Hybrid PSO–BFO Evolutionary Algorithm for Optimization of Fused Deposition Modelling Process Parameters. J. Intell. Manuf. 2019, 30, 2743–2758. [Google Scholar] [CrossRef]

- Shirmohammadi, M.; Goushchi, S.J.; Keshtiban, P.M. Optimization of 3D Printing Process Parameters to Minimize Surface Roughness with Hybrid Artificial Neural Network Model and Particle Swarm Algorithm. Prog. Addit. Manuf. 2021, 6, 199–215. [Google Scholar] [CrossRef]

- Feng, R.; Jiang, J.; Sun, Z.; Thakur, A.; Wei, X. A Hybrid of Genetic Algorithm and Particle Swarm Optimization for Reducing Material Waste in Extrusion-Basedadditive Manufacturing. Rapid Prototyp. J. 2021, 27, 1872–1885. [Google Scholar] [CrossRef]

- Seyedzavvar, M. A Hybrid ANN/PSO Optimization of Material Composition and Process Parameters for Enhancement of Mechanical Characteristics of 3D-Printed Sample. Rapid Prototyp. J. 2023, 29, 1270–1288. [Google Scholar] [CrossRef]

- Sai, T.; Pathak, V.K.; Srivastava, A.K. Modeling and Optimization of Fused Deposition Modeling (FDM) Process through Printing PLA Implants Using Adaptive Neuro-Fuzzy Inference System (ANFIS) Model and Whale Optimization Algorithm. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 617. [Google Scholar] [CrossRef]

- Fountas, N.A.; Vaxevanidis, N.M. Optimization of Fused Deposition Modeling Process Using a Virus-Evolutionary Genetic Algorithm. Comput. Ind. 2021, 125, 103371. [Google Scholar] [CrossRef]

- Negi, G.; Kumar, A.; Pant, S.; Ram, M. GWO: A Review and Applications. Int. J. Syst. Assur. Eng. Manag. 2021, 12, 1–8. [Google Scholar] [CrossRef]

- Hatta, N.M.; Zain, A.M.; Sallehuddin, R.; Shayfull, Z.; Yusoff, Y. Recent Studies on Optimisation Method of Grey Wolf Optimiser (GWO): A Review (2014–2017). Artif. Intell. Rev. 2019, 52, 2651–2683. [Google Scholar] [CrossRef]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 1998. Available online: https://www.astm.org/d0638-14.html (accessed on 10 June 2023).

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 1997. Available online: https://www.astm.org/d0790-17.html (accessed on 10 June 2023).

- Jones, B.; Nachtsheim, C.J. A Class of Three-Level Designs for Definitive Screening in the Presence of Second-Order Effects. J. Qual. Technol. 2011, 43, 1–15. [Google Scholar] [CrossRef]

- Jones, B.; Nachtsheim, C.J. Effective Design-Based Model Selection for Definitive Screening Designs. Technometrics 2017, 59, 319–329. [Google Scholar] [CrossRef]

- Abas, M.; Habib, T.; Noor, S.; Salah, B.; Zimon, D. Parametric Investigation and Optimization to Study the Effect of Process Parameters on the Dimensional Deviation of Fused Deposition Modeling of 3D Printed Parts. Polymers 2022, 14, 3667. [Google Scholar] [CrossRef]

- Abas, M.; Habib, T.; Noor, S.; Khan, K.M. Comparative Study of I-Optimal Design and Definitive Screening Design for Developing Prediction Models and Optimization of Average Surface Roughness of PLA Printed Parts Using Fused Deposition Modeling. Int. J. Adv. Manuf. Technol. 2022, 125, 689–700. [Google Scholar] [CrossRef]

- Luzanin, O.; Guduric, V.; Ristic, I.; Muhic, S. Investigating Impact of Five Build Parameters on the Maximum Flexural Force in FDM Specimens—A Definitive Screening Design Approach. Rapid Prototyp. J. 2017, 23, 1088–1098. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Influence of Processing Parameters on Creep and Recovery Behavior of FDM Manufactured Part Using Definitive Screening Design and ANN. Rapid Prototyp. J. 2017, 23, 998–1010. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Modeling, Analysis, and Optimization of Dimensional Accuracy of FDM-Fabricated Parts Using Definitive Screening Design and Deep Learning Feedforward Artificial Neural Network. Adv. Manuf. 2021, 9, 115–129. [Google Scholar] [CrossRef]

- Abas, M.; Habib, T.; Khan, I.; Noor, S. Definitive Screening Design for Mechanical Properties Enhancement in Extrusion-Based Additive Manufacturing of Carbon Fiber-Reinforced PLA Composite. Prog. Addit. Manuf. 2024. [Google Scholar] [CrossRef]

- ISO 21920-2:2021; Geometrical Product Specifications (GPS)—Surface Texture: Profile—Part 2: Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2021. Available online: https://www.iso.org/standard/72226.html (accessed on 20 December 2023).

- Julong, D. Introduction to Grey System Theory. J. grey Syst. 1989, 1, 1–24. [Google Scholar]

- Jayant, A.; Giri, V.; Singh, P.K.; Luthra, S. A State-of the-Art Literature Survey of Grey Relational Analysis Applications in Competitive Business Environment. Int. J. Ind. Syst. Eng. 2018, 30, 425–448. [Google Scholar] [CrossRef]

- Chakraborty, S.; Datta, H.N.; Chakraborty, S. Grey Relational Analysis-Based Optimization of Machining Processes: A Comprehensive Review. Process Integr. Optim. Sustain. 2023, 7, 609–639. [Google Scholar] [CrossRef]

- Xuemei, L.; Cao, Y.; Wang, J.; Dang, Y.; Kedong, Y. A Summary of Grey Forecasting and Relational Models and Its Applications in Marine Economics and Management. Mar. Econ. Manag. 2019, 2, 87–113. [Google Scholar] [CrossRef]

- Prakash, S.; Agrawal, A.; Singh, R.; Singh, R.K.; Zindani, D. A Decade of Grey Systems: Theory and Application–Bibliometric Overview and Future Research Directions. Grey Syst. Theory Appl. 2023, 13, 14–33. [Google Scholar] [CrossRef]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

- Mathew, A.; Kishore, S.R.; Tomy, A.T.; Sugavaneswaran, M.; Scholz, S.G.; Elkaseer, A.; Wilson, V.H.; John Rajan, A. Vapour Polishing of Fused Deposition Modelling (FDM) Parts: A Critical Review of Different Techniques, and Subsequent Surface Finish and Mechanical Properties of the Post-Processed 3D-Printed Parts. Prog. Addit. Manuf. 2023, 8, 1161–1178. [Google Scholar] [CrossRef]

- Lalegani Dezaki, M.; Ariffin, M.K.; Serjouei, A.; Zolfagharian, A.; Hatami, S.; Bodaghi, M. Influence of Infill Patterns Generated by CAD and FDM 3D Printer on Surface Roughness and Tensile Strength Properties. Appl. Sci. 2021, 11, 7272. [Google Scholar] [CrossRef]

- Bakhtiari, H.; Nikzad, M.; Tolouei-Rad, M. Influence of Three-Dimensional Printing Parameters on Compressive Properties and Surface Smoothness of Polylactic Acid Specimens. Polymers 2023, 15, 3827. [Google Scholar] [CrossRef] [PubMed]

- Kumar, M.S.; Farooq, M.U.; Ross, N.S.; Yang, C.-H.; Kavimani, V.; Adediran, A.A. Achieving Effective Interlayer Bonding of PLA Parts during the Material Extrusion Process with Enhanced Mechanical Properties. Sci. Rep. 2023, 13, 6800. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Domínguez-Fernández, A.; Durán-Llucià, R. Influence of Print Orientation on Surface Roughness in Fused Deposition Modeling (FDM) Processes. Materials 2019, 12, 3834. [Google Scholar] [CrossRef] [PubMed]

- Gordelier, T.J.; Thies, P.R.; Turner, L.; Johanning, L. Optimising the FDM Additive Manufacturing Process to Achieve Maximum Tensile Strength: A State-of-the-Art Review. Rapid Prototyp. J. 2019, 25, 953–971. [Google Scholar] [CrossRef]

- Karad, A.S.; Sonawwanay, P.D.; Naik, M.; Thakur, D.G. Experimental Study of Effect of Infill Density on Tensile and Flexural Strength of 3D Printed Parts. J. Eng. Appl. Sci. 2023, 70, 104. [Google Scholar] [CrossRef]

- Liaw, C.-Y.; Tolbert, J.W.; Chow, L.W.; Guvendiren, M. Interlayer Bonding Strength of 3D Printed PEEK Specimens. Soft Matter 2021, 17, 4775–4789. [Google Scholar] [CrossRef]

- Durgun, I.; Ertan, R. Experimental Investigation of FDM Process for Improvement of Mechanical Properties and Production Cost. Rapid Prototyp. J. 2014, 20, 228–235. [Google Scholar] [CrossRef]

- Syrlybayev, D.; Zharylkassyn, B.; Seisekulova, A.; Akhmetov, M.; Perveen, A.; Talamona, D. Optimisation of Strength Properties of FDM Printed Parts—A Critical Review. Polymers 2021, 13, 1587. [Google Scholar] [CrossRef] [PubMed]

- Snapp, K.L.; Gongora, A.E.; Brown, K.A. Increasing Throughput in Fused Deposition Modeling by Modulating Bed Temperature. J. Manuf. Sci. Eng. 2021, 143, 94502. [Google Scholar] [CrossRef]

- Patadiya, N.H.; Dave, H.K.; Rajpurohit, S.R. Effect of Build Orientation on Mechanical Strength of FDM Printed PLA BT—Advances in Additive Manufacturing and Joining; Shunmugam, M.S., Kanthababu, M., Eds.; Springer: Singapore, 2020; pp. 301–307. [Google Scholar]

- Popescu, D.; Zapciu, A.; Amza, C.; Baciu, F.; Marinescu, R. FDM Process Parameters Influence over the Mechanical Properties of Polymer Specimens: A Review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

- Agushaka, J.O.; Ezugwu, A.E.; Abualigah, L.; Alharbi, S.K.; Khalifa, H.A.E.-W. Efficient Initialization Methods for Population-Based Metaheuristic Algorithms: A Comparative Study. Arch. Comput. Methods Eng. 2023, 30, 1727–1787. [Google Scholar] [CrossRef]

- Wang, B.; Liu, L.; Li, Y.; Khishe, M. Robust Grey Wolf Optimizer for Multimodal Optimizations: A Cross-Dimensional Coordination Approach. J. Sci. Comput. 2022, 92, 110. [Google Scholar] [CrossRef]

- Makhadmeh, S.N.; Al-Betar, M.A.; Doush, I.A.; Awadallah, M.A.; Kassaymeh, S.; Mirjalili, S.; Zitar, R.A. Recent Advances in Grey Wolf Optimizer, Its Versions and Applications: Review. IEEE Access 2024, 12, 22991–23028. [Google Scholar] [CrossRef]

- Meidani, K.; Hemmasian, A.; Mirjalili, S.; Barati Farimani, A. Adaptive Grey Wolf Optimizer. Neural Comput. Appl. 2022, 34, 7711–7731. [Google Scholar] [CrossRef]

| Printing Parameters | Symbol | Units | Levels | ||

|---|---|---|---|---|---|

| −1 | 0 | 1 | |||

| Layer thickness | LT | mm | 0.1 | 0.2 | 0.3 |

| Number of perimeters | NP | - | 2 | 4 | 6 |

| Infill density | ID | % | 60 | 80 | 100 |

| Fill angle | FA | ° | 0 | 45 | 90 |

| Printing Speed | PS | mm/s | 60 | 70 | 80 |

| Extrusion temperature | ET | °C | 260 | 270 | 280 |

| Bed temperature | BT | °C | 80 | 90 | 100 |

| Build orientation | BO | ͦ | 0 | 45 | 90 |

| Exp. No | LT | NP | ID | FA | PS | ET | BT | BO | Exp. No | LT | NP | ID | FA | PS | ET | BT | BO |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.2 | 6 | 100 | 90 | 80 | 280 | 100 | 90 | 27 | 0.2 | 2 | 60 | 0 | 60 | 260 | 80 | 0 |

| 2 | 0.1 | 2 | 100 | 90 | 80 | 270 | 80 | 0 | 28 | 0.1 | 4 | 60 | 90 | 60 | 280 | 100 | 0 |

| 3 | 0.3 | 6 | 60 | 90 | 80 | 260 | 90 | 0 | 29 | 0.3 | 6 | 100 | 45 | 60 | 280 | 80 | 0 |

| 4 | 0.1 | 6 | 80 | 90 | 60 | 260 | 80 | 90 | 30 | 0.1 | 2 | 100 | 90 | 80 | 270 | 80 | 0 |

| 5 | 0.3 | 6 | 100 | 45 | 60 | 280 | 80 | 0 | 31 | 0.2 | 4 | 80 | 45 | 70 | 270 | 90 | 45 |

| 6 | 0.3 | 6 | 60 | 0 | 60 | 270 | 100 | 90 | 32 | 0.2 | 2 | 60 | 0 | 60 | 260 | 80 | 0 |

| 7 | 0.3 | 6 | 60 | 90 | 80 | 260 | 90 | 0 | 33 | 0.1 | 6 | 100 | 0 | 70 | 260 | 100 | 0 |

| 8 | 0.1 | 2 | 100 | 0 | 60 | 280 | 90 | 90 | 34 | 0.3 | 2 | 100 | 90 | 60 | 260 | 100 | 45 |

| 9 | 0.3 | 2 | 60 | 90 | 70 | 280 | 80 | 90 | 35 | 0.3 | 6 | 100 | 45 | 60 | 280 | 80 | 0 |

| 10 | 0.3 | 6 | 60 | 0 | 60 | 270 | 100 | 90 | 36 | 0.3 | 4 | 100 | 0 | 80 | 260 | 80 | 90 |

| 11 | 0.1 | 2 | 100 | 0 | 60 | 280 | 90 | 90 | 37 | 0.3 | 4 | 100 | 0 | 80 | 260 | 80 | 90 |

| 12 | 0.1 | 6 | 100 | 0 | 70 | 260 | 100 | 0 | 38 | 0.2 | 6 | 100 | 90 | 80 | 280 | 100 | 90 |

| 13 | 0.1 | 2 | 60 | 45 | 80 | 260 | 100 | 90 | 39 | 0.3 | 2 | 100 | 90 | 60 | 260 | 100 | 45 |

| 14 | 0.1 | 6 | 60 | 0 | 80 | 280 | 80 | 45 | 40 | 0.1 | 4 | 60 | 90 | 60 | 280 | 100 | 0 |

| 15 | 0.1 | 6 | 60 | 0 | 80 | 280 | 80 | 45 | 41 | 0.2 | 6 | 100 | 90 | 80 | 280 | 100 | 90 |

| 16 | 0.1 | 2 | 100 | 90 | 80 | 270 | 80 | 0 | 42 | 0.3 | 2 | 80 | 0 | 80 | 280 | 100 | 0 |

| 17 | 0.1 | 6 | 100 | 0 | 70 | 260 | 100 | 0 | 43 | 0.1 | 6 | 80 | 90 | 60 | 260 | 80 | 90 |

| 18 | 0.3 | 2 | 80 | 0 | 80 | 280 | 100 | 0 | 44 | 0.2 | 2 | 60 | 0 | 60 | 260 | 80 | 0 |

| 19 | 0.1 | 6 | 60 | 0 | 80 | 280 | 80 | 45 | 45 | 0.3 | 2 | 100 | 90 | 60 | 260 | 100 | 45 |

| 20 | 0.1 | 2 | 100 | 0 | 60 | 280 | 90 | 90 | 46 | 0.1 | 2 | 60 | 45 | 80 | 260 | 100 | 90 |

| 21 | 0.1 | 2 | 60 | 45 | 80 | 260 | 100 | 90 | 47 | 0.2 | 4 | 80 | 45 | 70 | 270 | 90 | 45 |

| 22 | 0.1 | 6 | 80 | 90 | 60 | 260 | 80 | 90 | 48 | 0.3 | 6 | 60 | 0 | 60 | 270 | 100 | 90 |

| 23 | 0.2 | 4 | 80 | 45 | 70 | 270 | 90 | 45 | 49 | 0.3 | 2 | 60 | 90 | 70 | 280 | 80 | 90 |

| 24 | 0.1 | 4 | 60 | 90 | 60 | 280 | 100 | 0 | 50 | 0.3 | 4 | 100 | 0 | 80 | 260 | 80 | 90 |

| 25 | 0.3 | 2 | 80 | 0 | 80 | 280 | 100 | 0 | 51 | 0.3 | 2 | 60 | 90 | 70 | 280 | 80 | 90 |

| 26 | 0.3 | 6 | 60 | 90 | 80 | 260 | 90 | 0 |

| Exp. No | Ra | TS | FS | Exp. No | Ra | TS | FS |

|---|---|---|---|---|---|---|---|

| 1 | 15.00 | 45.02 | 53.22 | 27 | 11.26 | 49.28 | 57.39 |

| 2 | 8.07 | 56.25 | 64.39 | 28 | 8.06 | 50.93 | 59.74 |

| 3 | 15.33 | 43.79 | 54.28 | 29 | 12.93 | 65.98 | 77.38 |

| 4 | 14.56 | 38.24 | 43.96 | 30 | 7.70 | 56.51 | 67.53 |

| 5 | 12.20 | 64.29 | 72.69 | 31 | 13.39 | 52.86 | 61.99 |

| 6 | 19.95 | 46.26 | 52.12 | 32 | 10.99 | 50.73 | 59.49 |

| 7 | 15.90 | 43.10 | 53.15 | 33 | 3.85 | 71.16 | 83.46 |

| 8 | 9.14 | 71.12 | 80.57 | 34 | 16.78 | 48.73 | 57.15 |

| 9 | 17.06 | 32.33 | 37.92 | 35 | 11.96 | 64.55 | 75.70 |

| 10 | 20.60 | 45.10 | 50.22 | 36 | 20.36 | 36.62 | 42.95 |

| 11 | 8.82 | 69.56 | 80.00 | 37 | 20.55 | 35.81 | 42.00 |

| 12 | 4.37 | 73.72 | 86.46 | 38 | 15.49 | 44.98 | 49.04 |

| 13 | 14.55 | 42.52 | 49.72 | 39 | 15.80 | 48.58 | 56.98 |

| 14 | 10.93 | 49.28 | 57.79 | 40 | 8.45 | 50.24 | 58.92 |

| 15 | 11.22 | 50.30 | 55.34 | 41 | 14.67 | 43.29 | 50.77 |

| 16 | 8.69 | 55.05 | 62.17 | 42 | 17.16 | 62.44 | 73.23 |

| 17 | 4.51 | 73.16 | 85.79 | 43 | 16.00 | 36.16 | 42.40 |

| 18 | 17.16 | 61.78 | 72.32 | 44 | 10.66 | 51.20 | 60.05 |

| 19 | 10.54 | 50.97 | 59.78 | 45 | 15.62 | 47.89 | 56.16 |

| 20 | 9.80 | 72.48 | 84.96 | 46 | 14.32 | 43.55 | 50.51 |

| 21 | 14.42 | 41.13 | 46.60 | 47 | 12.50 | 54.50 | 63.91 |

| 22 | 15.91 | 37.19 | 42.75 | 48 | 19.95 | 46.42 | 51.68 |

| 23 | 12.94 | 51.14 | 60.32 | 49 | 16.38 | 31.50 | 36.63 |

| 24 | 7.63 | 49.32 | 57.84 | 50 | 20.72 | 35.29 | 41.38 |

| 25 | 17.17 | 62.01 | 72.72 | 51 | 16.79 | 31.93 | 36.64 |

| 26 | 15.22 | 45.14 | 54.29 |

| Hyperparameters | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 |

|---|---|---|---|---|---|

| Number of iterations | 100 | 150 | 200 | 250 | 300 |

| Number of wolves | 10 | 20 | 30 | 40 | 50 |

| Source | F-Value | p-Value | Contribution |

|---|---|---|---|

| Linear | 781.58 | <0.001 | 86.79% |

| LT | 2829.41 | <0.001 | 52.36% |

| ID | 150.11 | <0.001 | 2.78% |

| FA | 3.98 | 0.053 | 0.07% |

| PS | 107.67 | <0.001 | 1.99% |

| ET | 72.89 | <0.001 | 1.35% |

| BO | 1525.44 | <0.001 | 28.23% |

| Square | 137.65 | <0.001 | 10.87% |

| ID2 | 189.39 | <0.001 | 3.70% |

| PS2 | 234.1 | <0.001 | 7.17% |

| Two-way Interactions | 43.39 | <0.001 | 1.61% |

| LT × BO | 40.88 | <0.001 | 1.15% |

| ET × BO | 24.62 | <0.001 | 0.46% |

| Error | 0.74% | ||

| Lack-of-Fit | 0.72 | 0.634 | 0.08% |

| Pure Error | 0.66% | ||

| Total | 100.00% |

| Source | F-Value | p-Value | Contribution |

|---|---|---|---|

| Linear | 886.5 | <0.001 | 87.43% |

| LT | 494.9 | <0.001 | 6.97% |

| ID | 1409.17 | <0.001 | 19.85% |

| FA | 1332.43 | <0.001 | 18.77% |

| PS | 252.2 | <0.001 | 3.55% |

| ET | 439.95 | <0.001 | 6.20% |

| BT | 359.87 | <0.001 | 5.07% |

| BO | 1917.01 | <0.001 | 27.01% |

| Square | 139.26 | <0.001 | 4.72% |

| ET2 | 125.7 | <0.001 | 0.15% |

| BT2 | 220.75 | <0.001 | 4.57% |

| Two-way Interactions | 173.05 | <0.001 | 7.31% |

| ID × BO | 302.79 | <0.001 | 5.45% |

| FA × PS | 117.63 | <0.001 | 1.10% |

| FA × ET | 54.29 | <0.001 | 0.76% |

| Error | 0.54% | ||

| Lack-of-Fit | 0.56 | 0.696 | 0.03% |

| Pure Error | 0.50% | ||

| Total | 100.00% |

| Source | F-Value | p-Value | Contribution |

|---|---|---|---|

| Linear | 433.52 | <0.001 | 86.21% |

| LT | 217.19 | <0.001 | 6.17% |

| ID | 679.03 | <0.001 | 19.29% |

| FA | 596.98 | <0.001 | 16.96% |

| PS | 102.08 | <0.001 | 2.90% |

| ET | 172.14 | <0.001 | 4.89% |

| BT | 177.29 | <0.001 | 5.04% |

| BO | 1089.92 | <0.001 | 30.96% |

| Square | 94.12 | <0.001 | 6.07% |

| ET2 | 81.38 | <0.001 | 0.03% |

| BT2 | 152.09 | <0.001 | 6.05% |

| Two-way Interactions | 77.85 | <0.001 | 6.64% |

| ID×BO | 148.46 | <0.001 | 5.25% |

| FA×PS | 44.12 | <0.001 | 0.84% |

| FA× ET | 19.18 | <0.001 | 0.54% |

| Error | 1.08% | ||

| Lack-of-Fit | 0.47 | 0.761 | 0.06% |

| Pure Error | 1.02% | ||

| Total | 100.00% |

| Exp. No | GRCRa | GRCTS | GRCFS | GRG | Exp. No | GRCRa | GRCTS | GRCFS | GRG |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.142 | 0.140 | 0.141 | 0.141 | 27 | 0.176 | 0.153 | 0.152 | 0.160 |

| 2 | 0.220 | 0.181 | 0.175 | 0.192 | 28 | 0.220 | 0.159 | 0.159 | 0.179 |

| 3 | 0.140 | 0.136 | 0.144 | 0.140 | 29 | 0.159 | 0.242 | 0.242 | 0.214 |

| 4 | 0.145 | 0.123 | 0.122 | 0.130 | 30 | 0.227 | 0.182 | 0.188 | 0.199 |

| 5 | 0.166 | 0.228 | 0.213 | 0.202 | 31 | 0.155 | 0.166 | 0.166 | 0.162 |

| 6 | 0.113 | 0.143 | 0.139 | 0.132 | 32 | 0.179 | 0.158 | 0.158 | 0.165 |

| 7 | 0.136 | 0.135 | 0.141 | 0.137 | 33 | 0.330 | 0.294 | 0.295 | 0.306 |

| 8 | 0.203 | 0.294 | 0.267 | 0.255 | 34 | 0.130 | 0.151 | 0.152 | 0.144 |

| 9 | 0.129 | 0.111 | 0.112 | 0.117 | 35 | 0.168 | 0.230 | 0.230 | 0.210 |

| 10 | 0.111 | 0.140 | 0.134 | 0.128 | 36 | 0.112 | 0.120 | 0.120 | 0.117 |

| 11 | 0.208 | 0.276 | 0.262 | 0.248 | 37 | 0.111 | 0.118 | 0.119 | 0.116 |

| 12 | 0.311 | 0.330 | 0.330 | 0.324 | 38 | 0.139 | 0.140 | 0.132 | 0.137 |

| 13 | 0.145 | 0.133 | 0.133 | 0.137 | 39 | 0.137 | 0.151 | 0.151 | 0.146 |

| 14 | 0.179 | 0.153 | 0.153 | 0.162 | 40 | 0.214 | 0.156 | 0.157 | 0.176 |

| 15 | 0.176 | 0.156 | 0.147 | 0.160 | 41 | 0.145 | 0.135 | 0.136 | 0.138 |

| 16 | 0.210 | 0.175 | 0.167 | 0.184 | 42 | 0.128 | 0.215 | 0.216 | 0.186 |

| 17 | 0.306 | 0.321 | 0.321 | 0.316 | 43 | 0.135 | 0.119 | 0.119 | 0.124 |

| 18 | 0.128 | 0.211 | 0.213 | 0.183 | 44 | 0.183 | 0.160 | 0.160 | 0.167 |

| 19 | 0.184 | 0.159 | 0.159 | 0.167 | 45 | 0.138 | 0.148 | 0.149 | 0.145 |

| 20 | 0.194 | 0.312 | 0.311 | 0.272 | 46 | 0.147 | 0.136 | 0.135 | 0.139 |

| 21 | 0.146 | 0.130 | 0.127 | 0.134 | 47 | 0.163 | 0.173 | 0.173 | 0.170 |

| 22 | 0.136 | 0.121 | 0.120 | 0.125 | 48 | 0.113 | 0.144 | 0.138 | 0.132 |

| 23 | 0.159 | 0.159 | 0.161 | 0.160 | 49 | 0.133 | 0.110 | 0.110 | 0.118 |

| 24 | 0.228 | 0.153 | 0.154 | 0.178 | 50 | 0.110 | 0.117 | 0.118 | 0.115 |

| 25 | 0.128 | 0.212 | 0.213 | 0.184 | 51 | 0.130 | 0.111 | 0.110 | 0.117 |

| 26 | 0.141 | 0.140 | 0.144 | 0.142 |

| Process Parameters | Levels | Optimal Levels | ||

|---|---|---|---|---|

| −1 | 0 | 1 | ||

| Layer thickness | 0.196 | 0.156 | 0.149 | −1 (0.1 mm) |

| Number of perimeters | 0.171 | 0.153 | 0.175 | 1 (6) |

| Infill density | 0.147 | 0.158 | 0.196 | 1 (100%) |

| Fill angle | 0.190 | 0.170 | 0.148 | −1 (0°) |

| Print speed | 0.173 | 0.199 | 0.153 | 0 (70 mm/s) |

| Extrusion temperature | 0.163 | 0.162 | 0.178 | 1 (280 °C) |

| Bed temperature | 0.155 | 0.187 | 0.176 | 0 (90 °C) |

| Build orientation | 0.197 | 0.157 | 0.146 | −1 (0°) |

| S. No | No of Wolves | No of Iterations | Objective Function Values |

|---|---|---|---|

| 1 | 10 | 100 | 0.323 |

| 2 | 10 | 150 | 0.336 |

| 3 | 10 | 200 | 0321 |

| 4 | 10 | 250 | 0.336 |

| 5 | 10 | 300 | 0.316 |

| 6 | 20 | 100 | 0.316 |

| 7 | 20 | 150 | 0.316 |

| 8 | 20 | 200 | 0.316 |

| 9 | 20 | 250 | 0.319 |

| 10 | 20 | 300 | 0.316 |

| 11 | 30 | 100 | 0.316 |

| 12 | 30 | 150 | 0.320 |

| 13 | 30 | 200 | 0.316 |

| 14 | 30 | 250 | 0.337 |

| 15 | 30 | 300 | 0.336 |

| 16 | 40 | 100 | 0.316 |

| 17 | 40 | 150 | 0.337 |

| 18 | 40 | 200 | 0.337 |

| 19 | 40 | 250 | 0.337 |

| 20 | 40 | 300 | 0.337 |

| 21 | 50 | 100 | 0.320 |

| 22 | 50 | 150 | 0.337 |

| 23 | 50 | 200 | 0.340 |

| 24 | 50 | 250 | 0.337 |

| 25 | 50 | 300 | 0.337 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almuflih, A.S.; Abas, M.; Khan, I.; Noor, S. Parametric Optimization of FDM Process for PA12-CF Parts Using Integrated Response Surface Methodology, Grey Relational Analysis, and Grey Wolf Optimization. Polymers 2024, 16, 1508. https://doi.org/10.3390/polym16111508

Almuflih AS, Abas M, Khan I, Noor S. Parametric Optimization of FDM Process for PA12-CF Parts Using Integrated Response Surface Methodology, Grey Relational Analysis, and Grey Wolf Optimization. Polymers. 2024; 16(11):1508. https://doi.org/10.3390/polym16111508

Chicago/Turabian StyleAlmuflih, Ali Saeed, Muhammad Abas, Imran Khan, and Sahar Noor. 2024. "Parametric Optimization of FDM Process for PA12-CF Parts Using Integrated Response Surface Methodology, Grey Relational Analysis, and Grey Wolf Optimization" Polymers 16, no. 11: 1508. https://doi.org/10.3390/polym16111508

APA StyleAlmuflih, A. S., Abas, M., Khan, I., & Noor, S. (2024). Parametric Optimization of FDM Process for PA12-CF Parts Using Integrated Response Surface Methodology, Grey Relational Analysis, and Grey Wolf Optimization. Polymers, 16(11), 1508. https://doi.org/10.3390/polym16111508