Preparation and Properties of PA10T/PPO Blends Compatibilized with SEBS-g-MAH

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of PA10T/PPO Blends

2.3. Characterization

3. Results

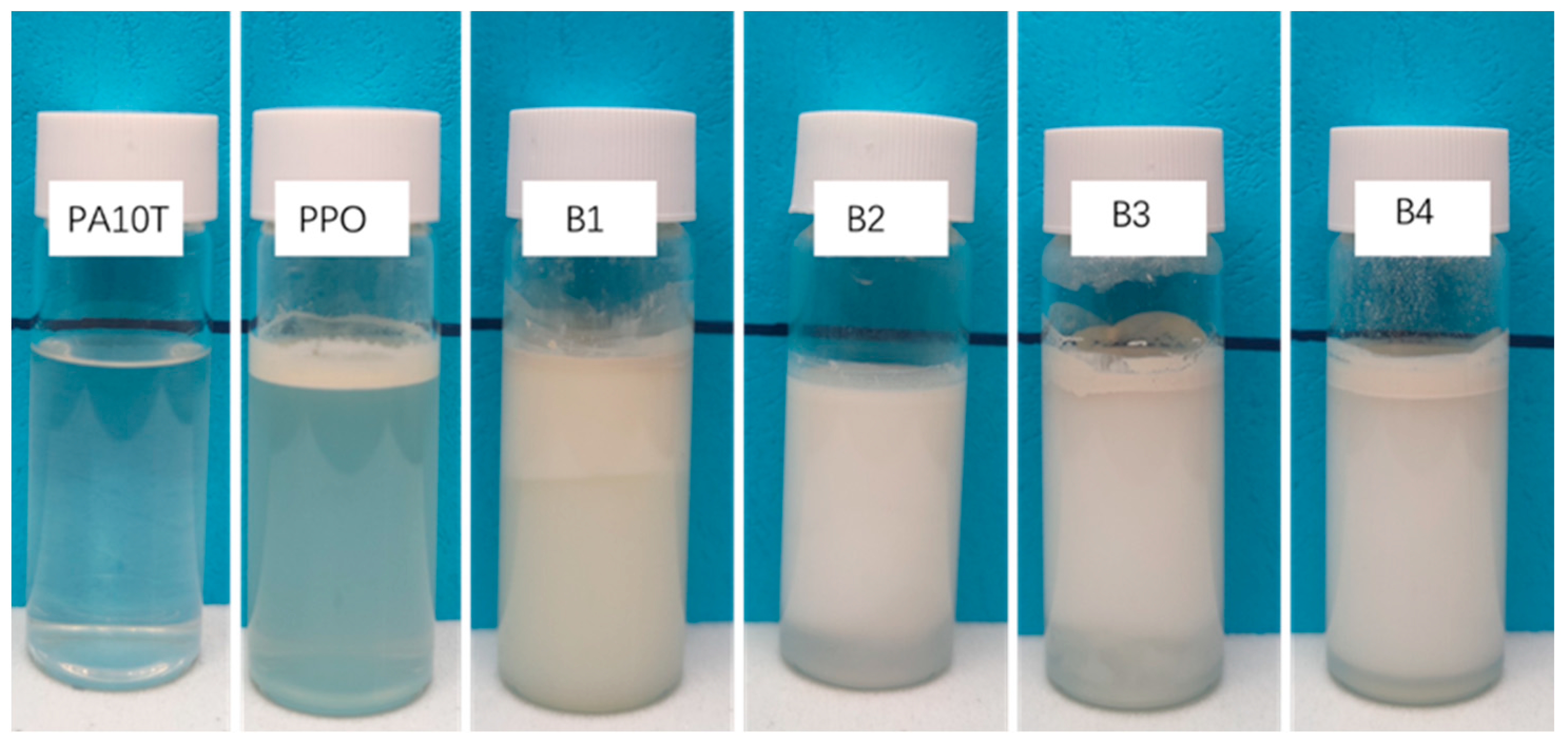

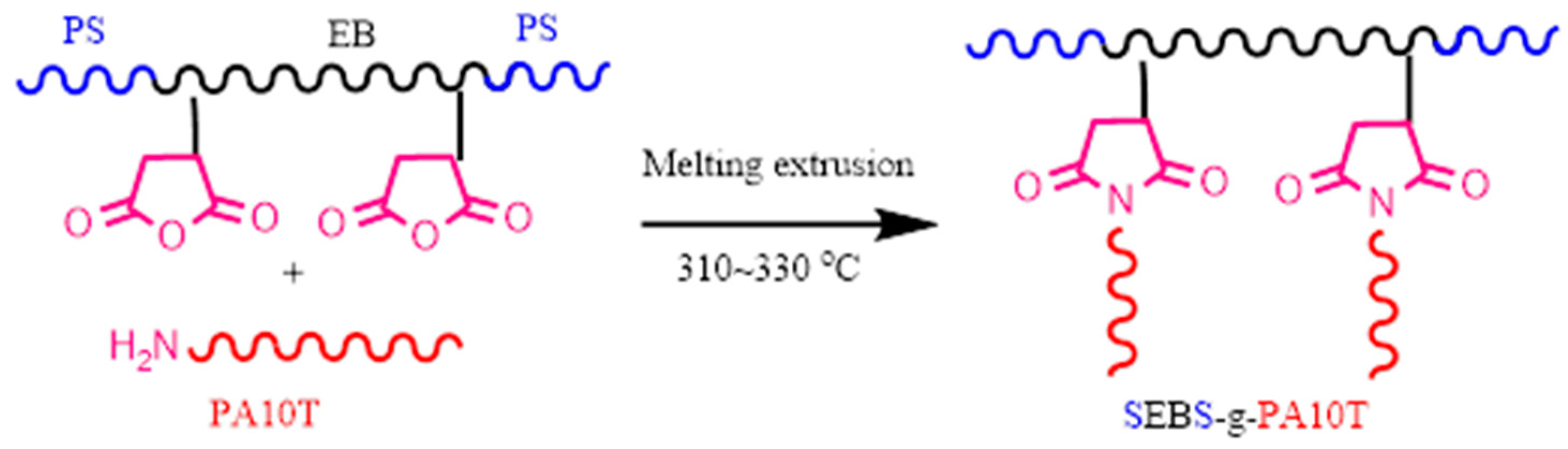

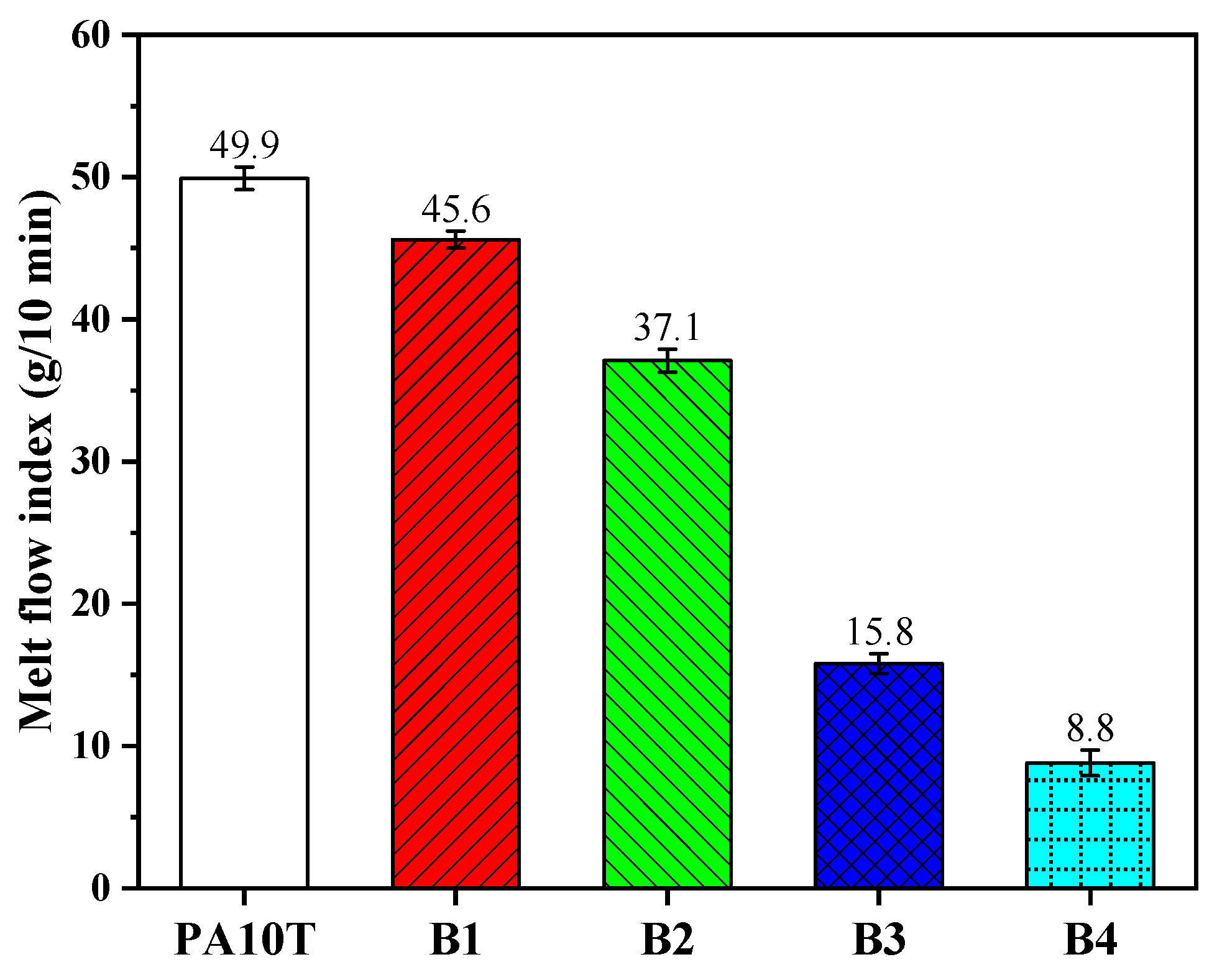

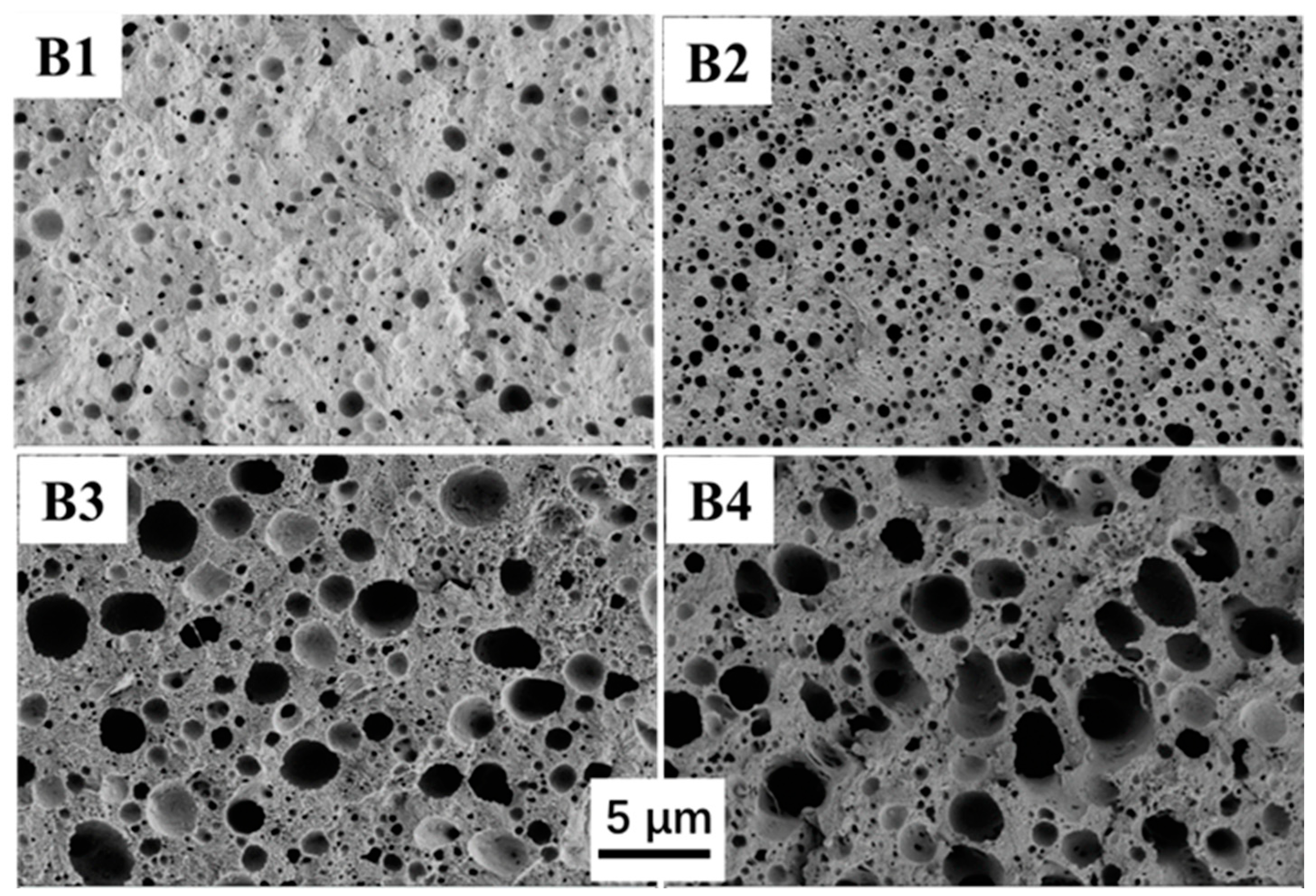

3.1. Compatiblizing Effect of SEBS-g-MAH on PA10T/PPO Blend

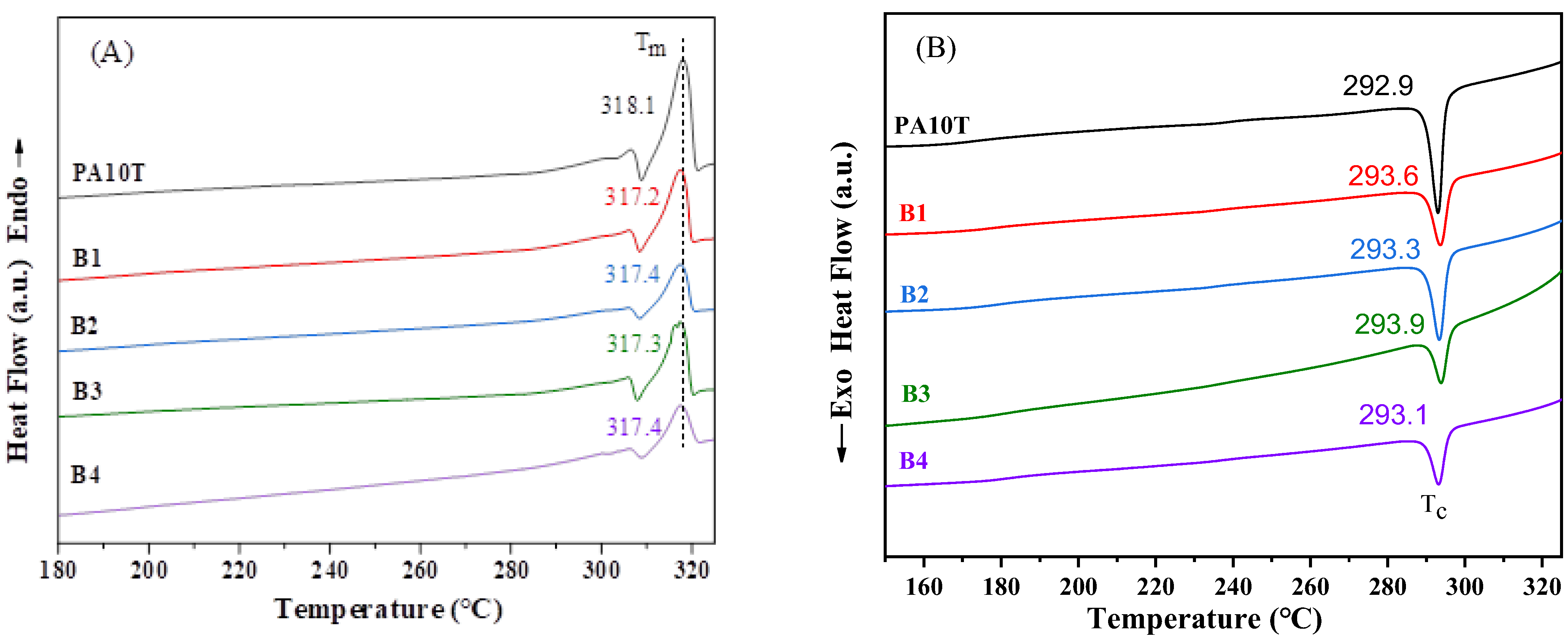

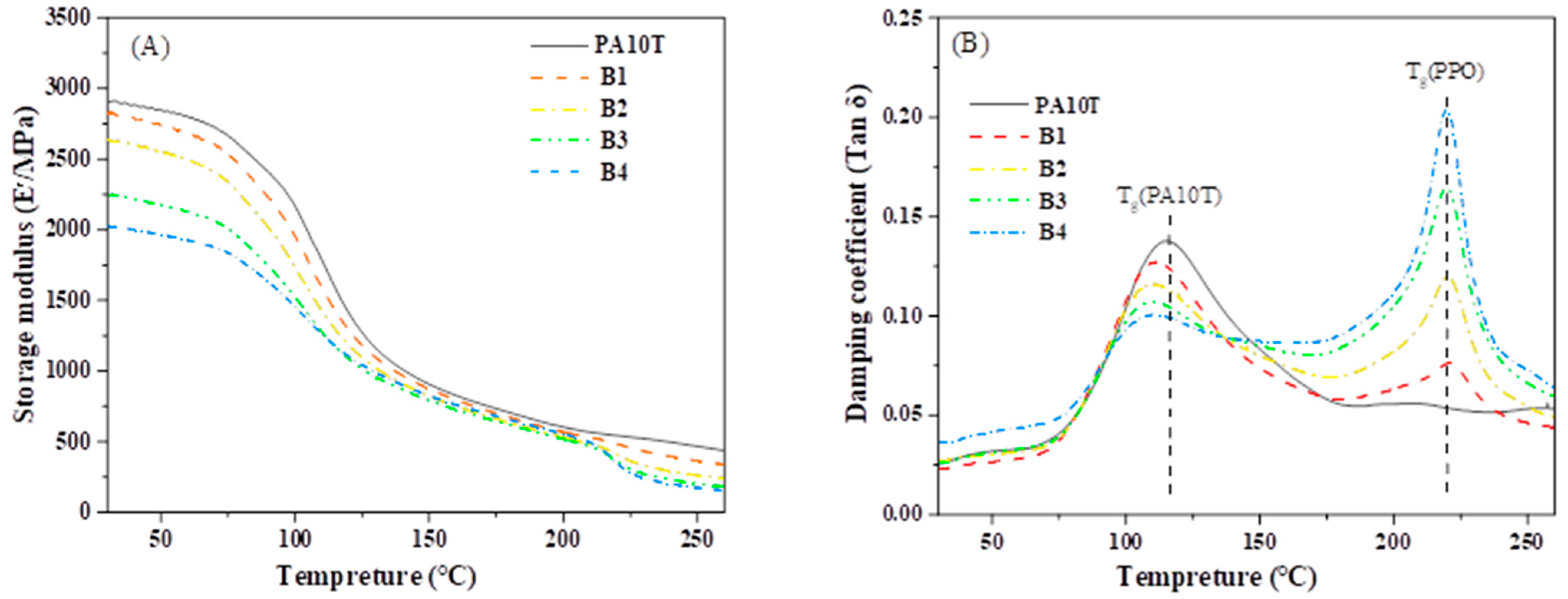

3.2. Thermal Properties

3.3. Water Absorption Properties

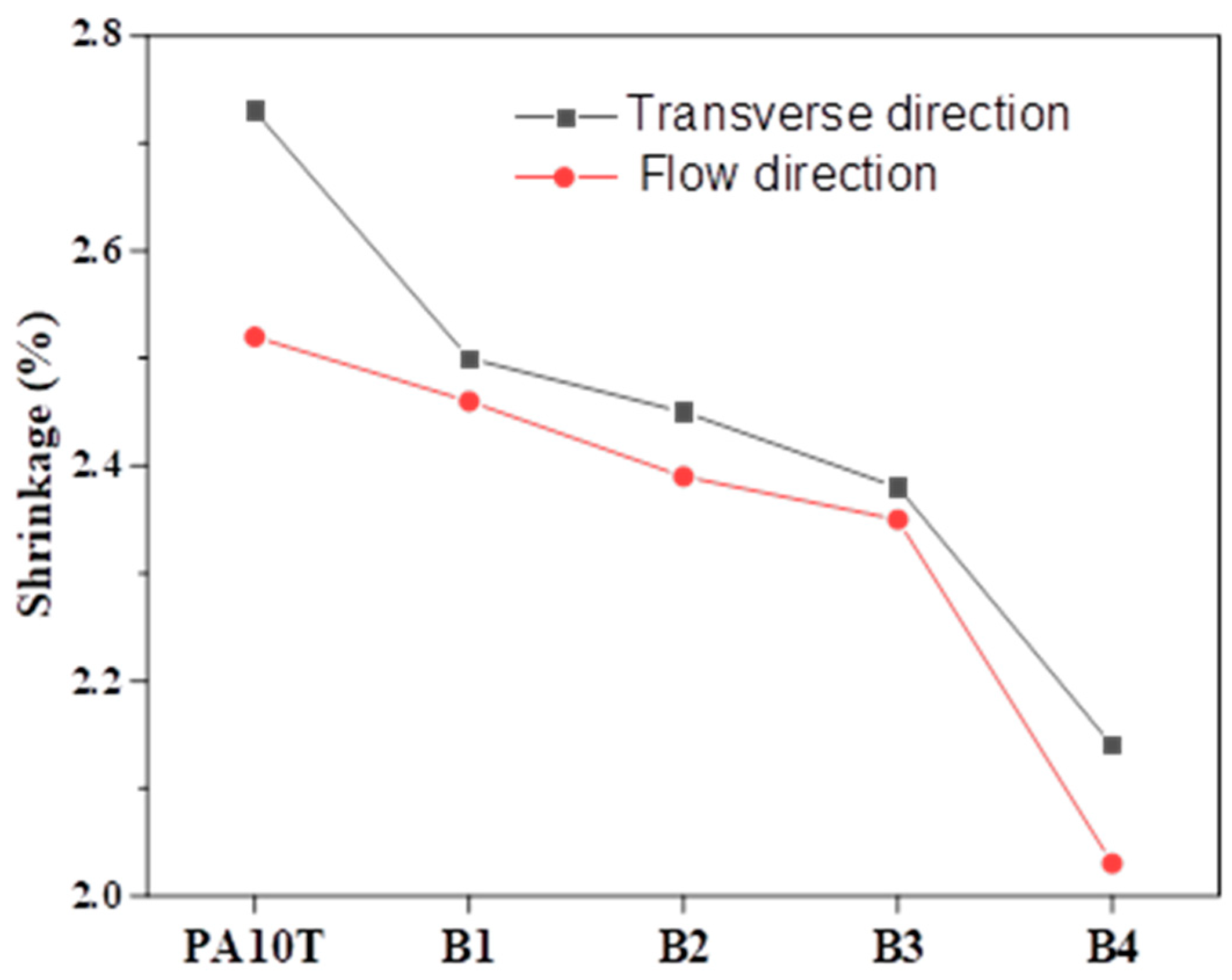

3.4. Dimensional Accuracy

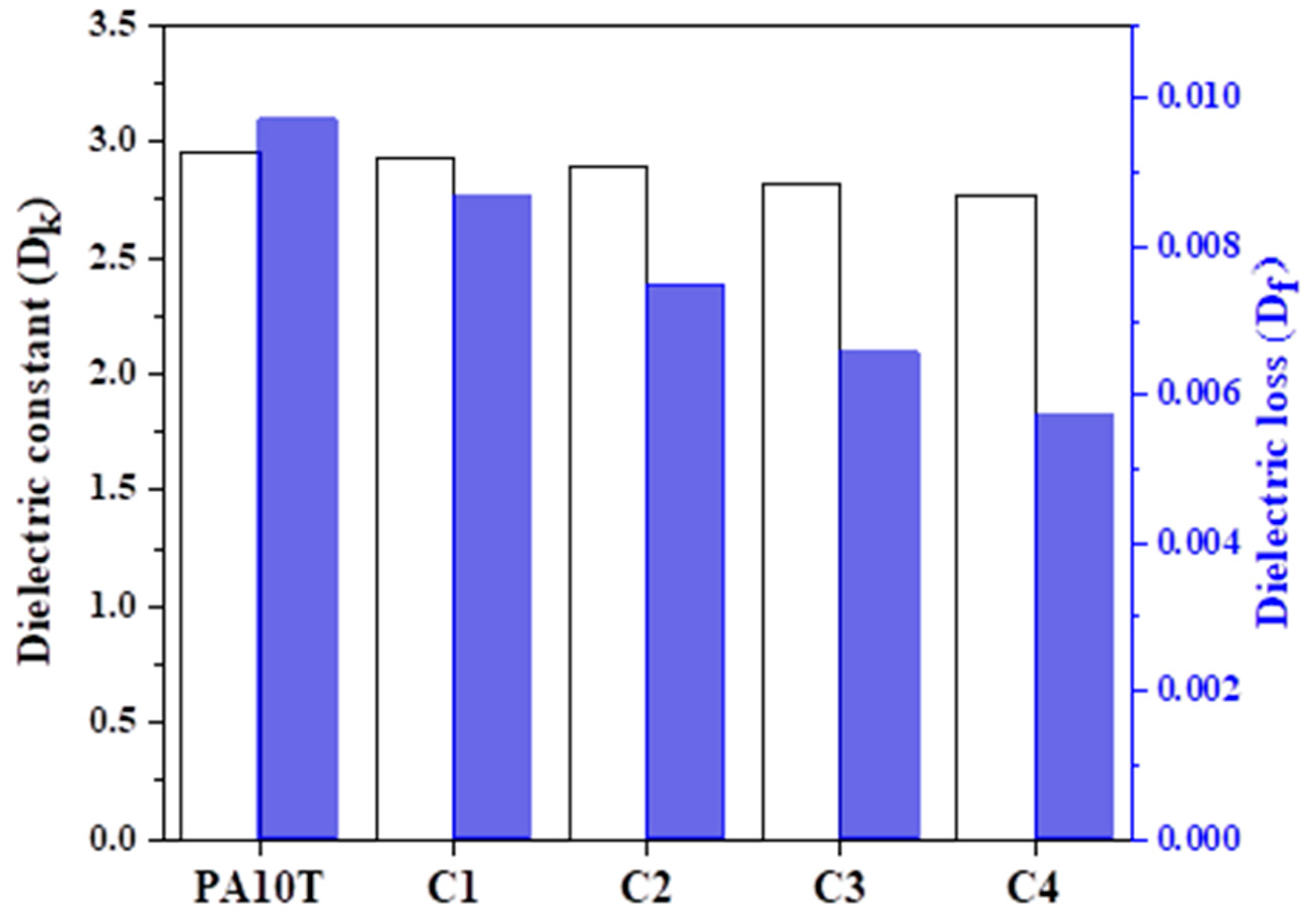

3.5. Dielectric Properties

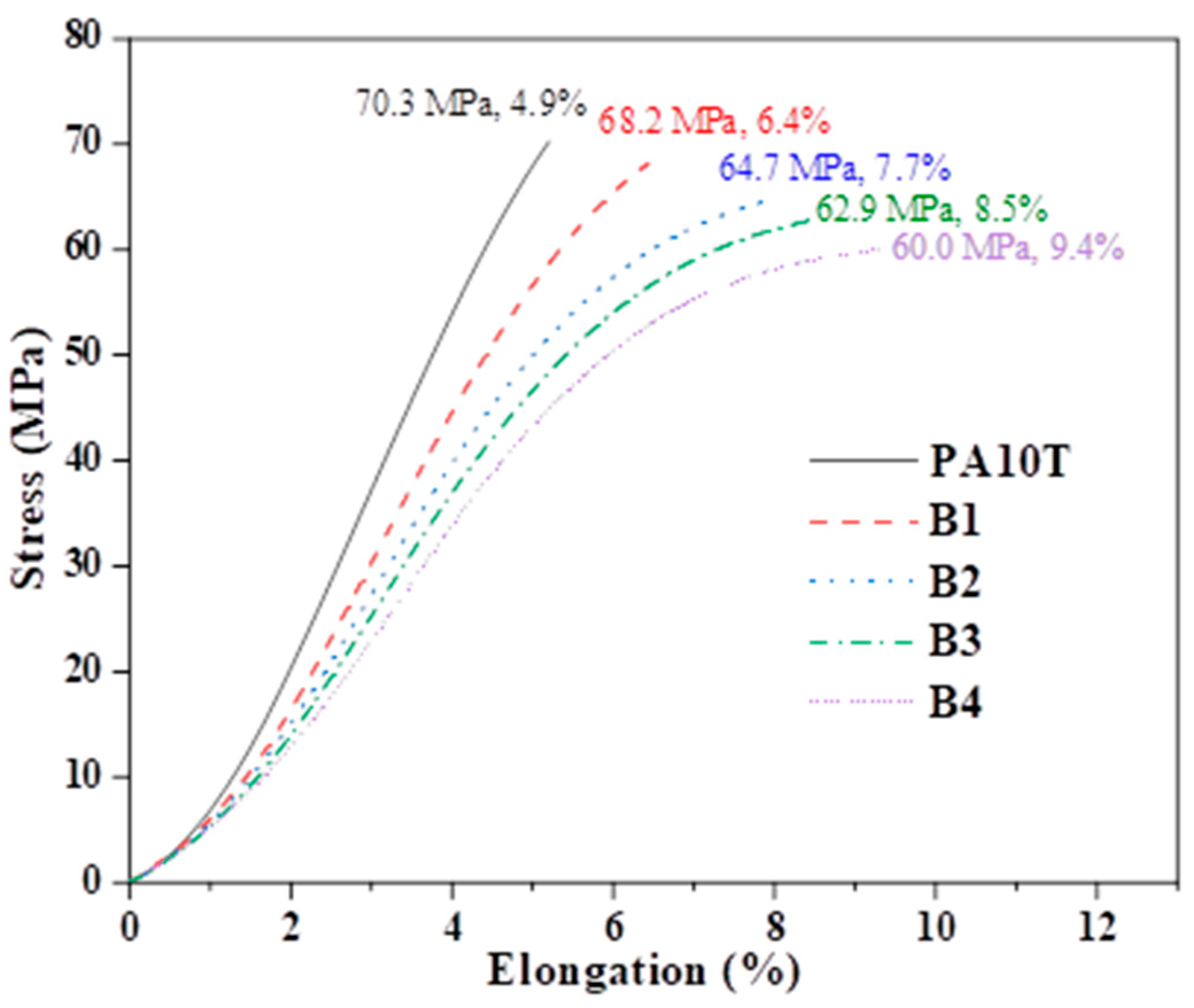

3.6. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiang, J.; Wang, Z.; Sun, Y.; Qian, Z.; Cao, Z.; Wang, Z.; Zhou, G. Amorphous Poly (Aryl Ether Ketones) Containing Methylene Groups with Excellent Thermal Resistance, Dielectric Properties and Mechanical Performance. Polymers 2023, 15, 4330. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Peng, Z.; Zhang, X.; Pan, Q.; Liu, S.; Cao, B.; Zhao, J. Soluble liquid crystalline poly(ester imide)s with high glass transition temperatures and improved dielectric properties. ACS Appl. Polym. Mater. 2022, 4, 4234–4243. [Google Scholar] [CrossRef]

- Hasegawa, M.; Fukuda, T.; Ishii, J. Poly(ester imide)s with Low Linear Coefficients of Thermal Expansion and Low Water Uptake (VII): A Strategy to Achieve Ultra-Low Dissipation Factors at 10 GHz. Polymers 2024, 16, 653. [Google Scholar] [CrossRef] [PubMed]

- Zhu, R.; Pu, Z.; He, G.; Peng, Q.; Zheng, P.; Wu, F.; Yu, X.; Wang, D.; Hou, H.; Li, X.; et al. Effect of addition of 1,6-hexanediamine on thermal properties and crystallization behaviors of biobased PA10T polyamides. J. Polym. Res. 2023, 30, 188. [Google Scholar] [CrossRef]

- Wang, W.; Wang, X.; Li, R.; Liu, B.; Wang, E.; Zhang, Y. Environment-friendly synthesis of long chain semiaromatic polyamides with high heat resistance. J. Appl. Polym. Sci. 2009, 114, 2036–2042. [Google Scholar] [CrossRef]

- Shang, Y.; Lou, H.; Zhao, W.; Zhang, Y.; Cui, Z.; Fu, P.; Pang, X.; Zhang, X.; Liu, M. The Structural Evolu-tion and Mechanical Properties of Semi-Aromatic Polyamide 12T after Stretching. Polymers 2022, 14, 4805. [Google Scholar] [CrossRef]

- Zhu, R.; Pu, Z.; Zheng, L.; Zheng, P.; Wu, F.; Yu, D.; Wang, X.; Yue, M.; Yang, Y.; Yang, K.; et al. Effect of addition of fillers (MoS2 and PFA) on the tribological and mechanical properties of biobased semi-aromatic polyamide (PA10T). Polym. Compos. 2024, 45, 3713–3723. [Google Scholar] [CrossRef]

- Apeldorn, T.; Keilholz, C.; Wolff-Fabris, F.; Altstädt, V. Dielectric properties of highly filled thermoplastics for printed circuit boards. J. Appl. Polym. Sci. 2013, 128, 3758–3770. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, D.; Jin, B.; Zhang, B.; Gong, P.; Zhang, B.; Park, C.; Li, G. Ultrahigh electromagnetic wave transmitting polyphenylene sulfide microcellular foams based on molecular structure design for 5G communication. Ind. Eng. Chem. Res. 2023, 62, 5850–5863. [Google Scholar] [CrossRef]

- Liu, B.; Long, J.; Chen, L.; Xiao, X.; Lin, X.; Wang, Y. Semi-aromatic polyamides containing fluorenyl pendent toward excellent thermal stability, mechanical properties and dielectric performance. Polymer 2021, 224, 123757. [Google Scholar] [CrossRef]

- Ning, J.; Tian, C.; Yang, Y.; Huang, L.; Lv, J.; Zeng, F.; Liu, Q.; Zhao, F.; Kong, W.; Cai, X. A novel intrinsic semi-aromatic polyamide dielectric toward excellent thermal stability, mechanical robustness and dielectric performance. Polymer 2021, 234, 124233. [Google Scholar] [CrossRef]

- Ge, Z.; Yang, S.; Tao, Z.; Liu, J.; Fan, L. Synthesis and characterization of novel soluble fluorinated aromatic polyamides derived from fluorinated isophthaloyl dichlorides and aromatic diamines. Polymer 2004, 45, 3627–3635. [Google Scholar] [CrossRef]

- Gnanasekaran, D.; Ajit Walter, P.; Reddy, B. Influence of moieties on morphology, thermal, and dielectric properties in polyamide-polyhedral oligomeric silsequioxanes nanocomposites. Polym. Eng. Sci. 2013, 53, 1637–1644. [Google Scholar] [CrossRef]

- Gnanasekaran, D.; Thomas, P. Enhanced dielectric and thermal performance of bio-polyamide polyhedral oligomeric silsesquioxane (PA-POSS) nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 398–405. [Google Scholar] [CrossRef]

- Luo, K.; Song, G.; Wang, Y.; Yu, J.; Zhu, J.; Hu, Z. Low-k and recyclable high-performance POSS/polyamide composites based on Diels−Alder reaction. ACS Appl. Polym. Mater. 2019, 1, 944–952. [Google Scholar] [CrossRef]

- Koning, C.; Martin, V.; Pagnoulle, C.; Jerome, R. Strategies for compatibilization of polymer blends. Prog. Polym. Sci. 1998, 23, 707–757. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, M.; Zhang, D.; Wang, Y.; Wang, L.; Qiu, Y.; Wang, L.; Chen, T.; Zhao, L. Crystallization and Performance of Polyamide Blends Comprising Polyamide 4, Polyamide 6, and Their Copolymers. Polymers 2023, 15, 3399. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Dai, X.; Yang, D.; Guo, S.; Yang, J. Polyamide 66/poly(2,6-dimethyl-1,4-phenylene oxide) compatibilization with styrene-acrylonitrile-glycidyl methacrylate: Rheology, morphology, and mechanical properties. Int. J. Polym. Anal. Charact. 2024, 29, 98–108. [Google Scholar] [CrossRef]

- Guo, Z.; Shen, Y.; Fang, Z. Compatibilization of polyamide 6/poly(2,6-dimethyl-1,4-phenylene oxide) blends by poly(styrene-co-maleic anhydride). J. Polym. Eng. 2014, 34, 193–199. [Google Scholar] [CrossRef]

- Zhang, Z.; Cai, K.; Liu, S.; Guo, W.; Zhang, B.; Yang, M.; Liu, W. The effect of HIPS-g-MAH on the mechanical properties of PA66/PPO alloy. Polym. Bull. 2022, 79, 7939–7951. [Google Scholar] [CrossRef]

- Jeziorska, R.; Szadkowska, A.; Studzinski, M. Morphology and properties of poly(2,6-dimethyl-1,4-phenylene oxide)/polyamide 11 hybrid nanocomposites: Effect of silica surface modification. Materials 2022, 15, 3421. [Google Scholar] [CrossRef]

- Ai, T.; Feng, W.; Ren, Z.; Li, F.; Wang, P.; Zou, G.; Ji, J. Simultaneous enhancement of mechanical performance and thermal conductivity for polyamide 10T by nanodiamond compositing. J. Appl. Polym. Sci. 2022, 139, 52098. [Google Scholar] [CrossRef]

- Xia, H.; Jiang, Z.; Zhou, J.; Yang, Z.; Cao, Y.; Wan, Z.; Niu, J. Green synthesis of reactive copolymers in molten ε-caprolactam solvent and their compatibilizing effects in PA10T/PPO blends. J. Appl. Polym. Sci. 2023, 140, e54604. [Google Scholar] [CrossRef]

- Wang, S.; Li, B.; Zhang, Y. Reactive compatibilisation and toughening of poly(2,6-dimethyl-1,4-phenylene oxide)/polyamide 6 blends by maleic grafted styrene ethylene butadiene styrene copolymer and styrene maleic anhydride copolymer. Plast. Rubber Compos. 2010, 39, 379–384. [Google Scholar] [CrossRef]

- Li, B.; Wan, C.; Zhang, Y.; Ji, J.; Su, Y. Reactive compatibilization and elastomer toughening of poly(2,6-dimethyl-1,4-phenylene oxide)/polyamide 6 blends. Polym. Polym. Compos. 2010, 18, 219–226. [Google Scholar] [CrossRef]

- Ryu, Y.; Sohn, J.; Yun, C.; Cha, S. Shrinkage and warpage minimization of glass-fiber-reinforced polyamide 6 parts by microcellular foam injection molding. Polymers 2020, 12, 889. [Google Scholar] [CrossRef]

- ISO 62; Plastics—Determination of Water Absorption. International Organization for Standardization: Geneva, Switzerland, 2008.

- Aparna, S.; Purnima, D.; Adusumalli, R. Effect of short carbon fiber content and water absorption on tensile and impact properties of PA6/PP blend based composites. Polym. Compos. 2020, 41, 5167–5181. [Google Scholar] [CrossRef]

- ISO 527; Plastics—Determination of Tensile Properties. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO 178; Plastics—Determination of Flexural Properties. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 180; Plastics—Determination of Izod Impact Strength. International Organization for Standardization: Geneva, Switzerland, 2019.

- Zhang, Z.; Yang, M.; Cai, K.; Chen, Y.; Liu, S.; Liu, W.; Liu, J. Effect of the flame retardants and glass fiber on the polyamide 66/polyphenylene oxide composites. Materials 2022, 15, 813. [Google Scholar] [CrossRef]

- Yang, C.; Huang, Y.; Dong, J.; Li, N. Anion-conductive poly(2,6-dimethyl-1,4-phenylene oxide) grafted with tailored polystyrene chains for alkaline fuel cells. J. Membr. Sci. 2019, 573, 247–256. [Google Scholar] [CrossRef]

- Wang, S.; Li, B.; Zhang, Y. Compatibilization of poly(2,6-dimethyl-1,4-phenylene oxide)/polyamide 6 blends with styrene-maleic anhydride copolymer: Mechanical properties, morphology, crystallization, and melting behavior. J. Appl. Polym. Sci. 2010, 118, 3545–3551. [Google Scholar] [CrossRef]

- Luna, C.; Filho, E.; Siqueira, D.; Araújo, E.; Nascimento, E.; Melo, T. Influence of small amounts of ABS and ABS-MA on PA6 properties: Evaluation of torque rheometry, mechanical, thermomechanical, thermal, morphological, and water absorption kinetics characteristics. Materials 2022, 15, 2502. [Google Scholar] [CrossRef]

- Li, Y.; Shimizu, H. Novel morphologies of poly(phenylene oxide) (PPO)/polyamide 6 (PA6) blend nanocomposites. Polymer 2004, 45, 7381–7388. [Google Scholar] [CrossRef]

- Nakano, A.; Kubota, Y.; Osaka, N.; Higashimura, H. Enzyme model-catalyzed, oxidative copolymerization of phenol while continuously adding an endcap to multi-branched poly(phenylene oxide) showing low dielectric constant. Chem. Lett. 2022, 51, 420–423. [Google Scholar] [CrossRef]

- Zhu, W.; Weil, E. Influence of the molecular weight of PPO resins and char-forming behavior of polymeric additives on the flame retardancy of EPDM formulations. J. Appl. Polym. Sci. 1998, 67, 1405–1414. [Google Scholar] [CrossRef]

- Li, M. Study on melting and polymorphic behavior of poly(decamethylene terephthalamide). J. Appl. Polym. Sci. 2019, 57, 465–472. [Google Scholar] [CrossRef]

- Yang, K.; Xin, C.; Huang, Y.; Jiang, L.; He, Y. Effects of extensional flow on properties of polyamide-66/poly(2,6-dimethyl-1,4-phenylene oxide) blends: A study of morphology, mechanical properties, and rheology. Polym. Eng. Sci. 2017, 57, 1090–1098. [Google Scholar] [CrossRef]

- Capone, C.; Di Landro, L.; Inzoli, F.; Penco, M.; Sartore, L. Thermal, and mechanical degradation during polymer extrusion processing. Polym. Eng. Sci. 2007, 47, 1813–1819. [Google Scholar] [CrossRef]

- Pekdemir, M.; Tukur, A.; Coskun, M. Thermal and dielectric investigation of magnetic nanoparticles functionalized with PVC via click chemistry. Polym. Bull. 2021, 78, 6047–6057. [Google Scholar] [CrossRef]

- Rosa, A.; Ursan, G.; Aradoaei, M.; Ursan, M.; Schreiner, C. Susceptor assisted microwave processing of polymers for adhesive production. In Proceedings of the 2018 International Conference and Exposition on Electrical And Power Engineering (EPE), Iasi, Romania, 18–19 October 2018; pp. 0662–0665. [Google Scholar] [CrossRef]

- Li, M.; Bijleveld, J.; Dingemans, T. Synthesis and properties of semi-crystalline poly(decamethylene terephthalamide) thermosets from reactive side-group copolyamides. Eur. Polym. J. 2018, 98, 273–284. [Google Scholar] [CrossRef]

- Ai, T.; Feng, W.; Zou, G.; Ren, Z.; Wang, P.; Ji, J.; Zhang, W. High-performances biobased semi-aromatic polyamide 10T copolymerized with silicone monomers. J. Appl. Polym. Sci. 2020, 138, 50266. [Google Scholar] [CrossRef]

| Designation | Base Resin | Additive SEBS-g-MAH (phr) * | |

|---|---|---|---|

| PA10T (%) | PPO (%) | ||

| PA10T | 100 | -- | -- |

| B1 | 90 | 10 | 2 |

| B2 | 80 | 20 | 4 |

| B3 | 70 | 30 | 6 |

| B4 | 60 | 40 | 8 |

| Samples | Tensile Strength (MPa) | Flexural Strength (MPa) | Flexural Modulus (MPa) | Notched Izod Impact Strength (kJ/m2) |

|---|---|---|---|---|

| PA10T | 70.3 | 132.3 | 2670 | 7.9 |

| B1 | 68.2 | 117.0 | 2430 | 8.2 |

| B2 | 64.7 | 108.7 | 2310 | 9.7 |

| B3 | 62.9 | 104.4 | 2220 | 10.6 |

| B4 | 60.0 | 96.7 | 2040 | 13.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, H.; Jiang, Z.; Tang, J.; Tang, J.; Zhou, J.; Yang, Z.; Zheng, R.; Niu, J. Preparation and Properties of PA10T/PPO Blends Compatibilized with SEBS-g-MAH. Polymers 2024, 16, 1598. https://doi.org/10.3390/polym16111598

Xia H, Jiang Z, Tang J, Tang J, Zhou J, Yang Z, Zheng R, Niu J. Preparation and Properties of PA10T/PPO Blends Compatibilized with SEBS-g-MAH. Polymers. 2024; 16(11):1598. https://doi.org/10.3390/polym16111598

Chicago/Turabian StyleXia, Housheng, Zhen Jiang, Jiaxiang Tang, Jiao Tang, Jianping Zhou, Zize Yang, Rongbo Zheng, and Junfeng Niu. 2024. "Preparation and Properties of PA10T/PPO Blends Compatibilized with SEBS-g-MAH" Polymers 16, no. 11: 1598. https://doi.org/10.3390/polym16111598

APA StyleXia, H., Jiang, Z., Tang, J., Tang, J., Zhou, J., Yang, Z., Zheng, R., & Niu, J. (2024). Preparation and Properties of PA10T/PPO Blends Compatibilized with SEBS-g-MAH. Polymers, 16(11), 1598. https://doi.org/10.3390/polym16111598