Evaluating Effectiveness of Multi-Component Waste Plastic Bags on Bitumen Properties: Physical, Rheological, and Aging

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Plan and Statistical Data Processing

2.2. Materials

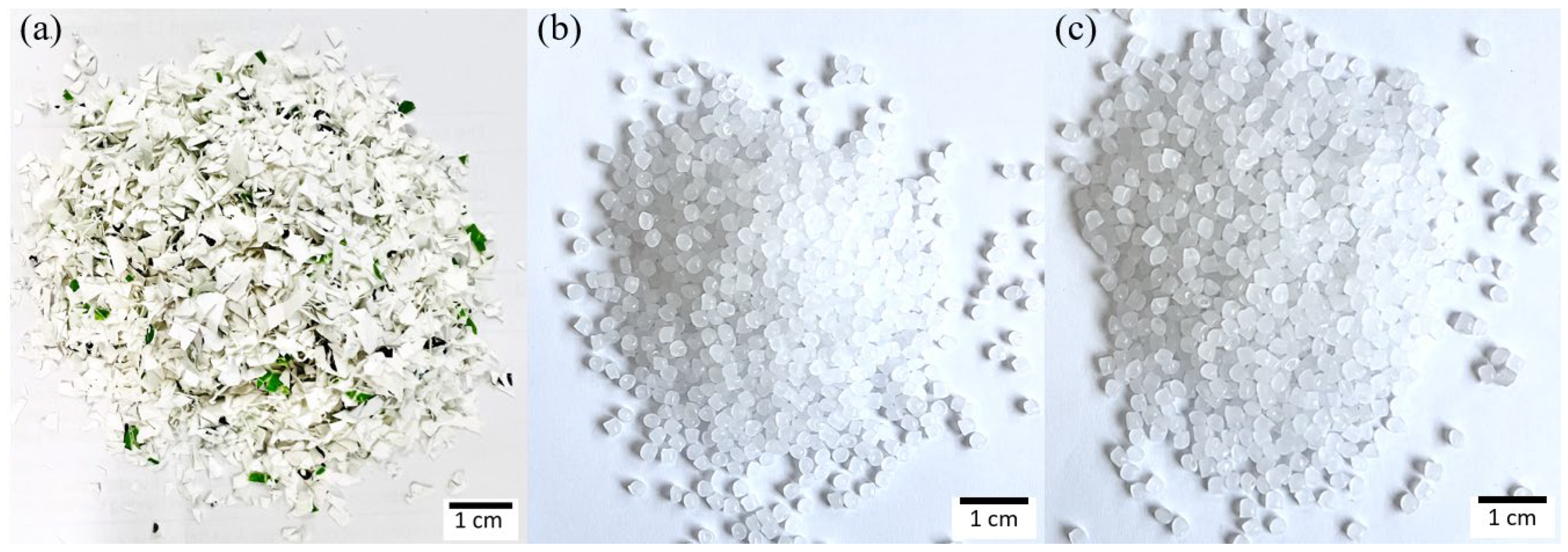

2.3. Characterization of the Waste Plastic Bags

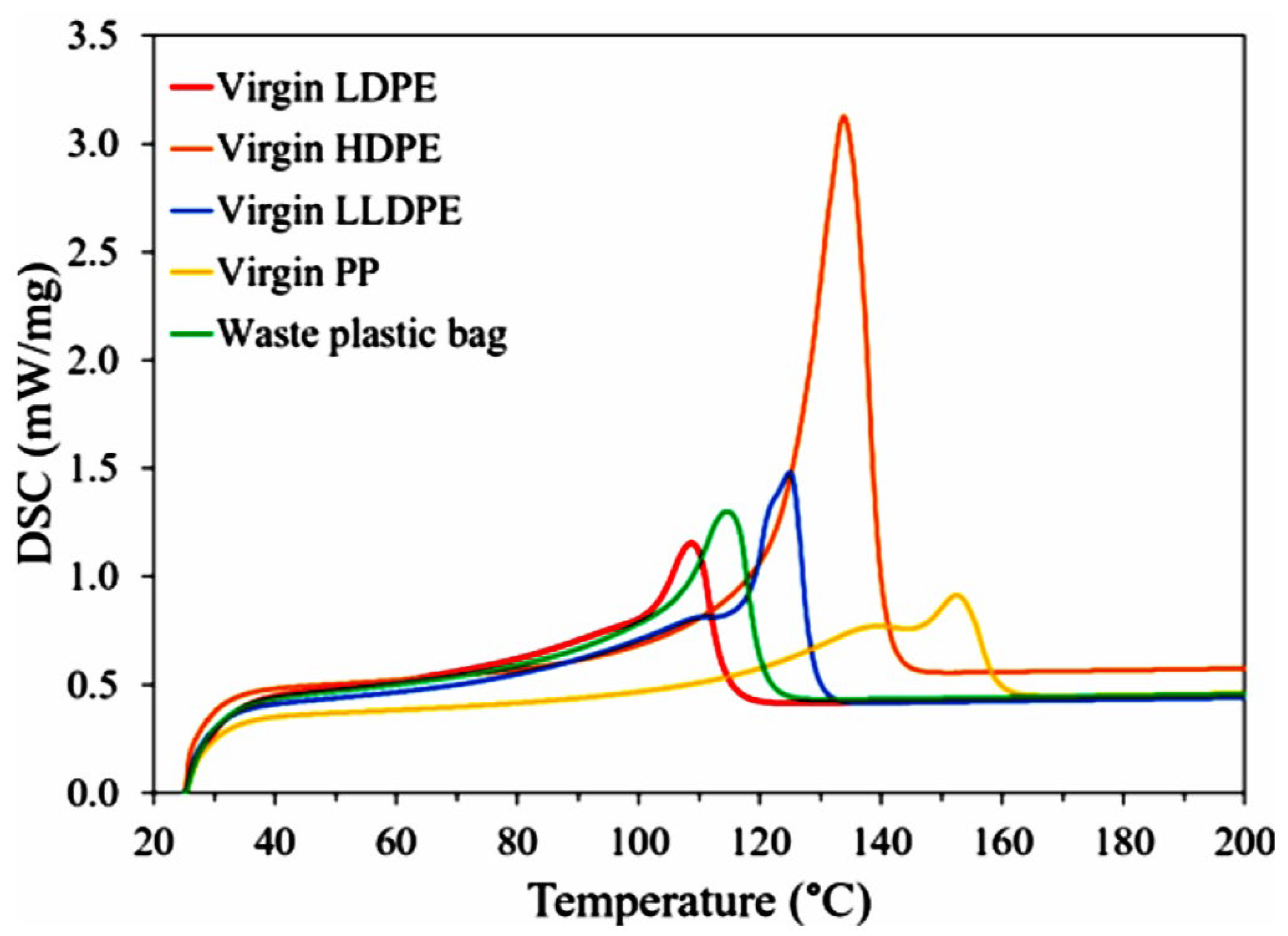

2.3.1. Thermal Behavior Analysis

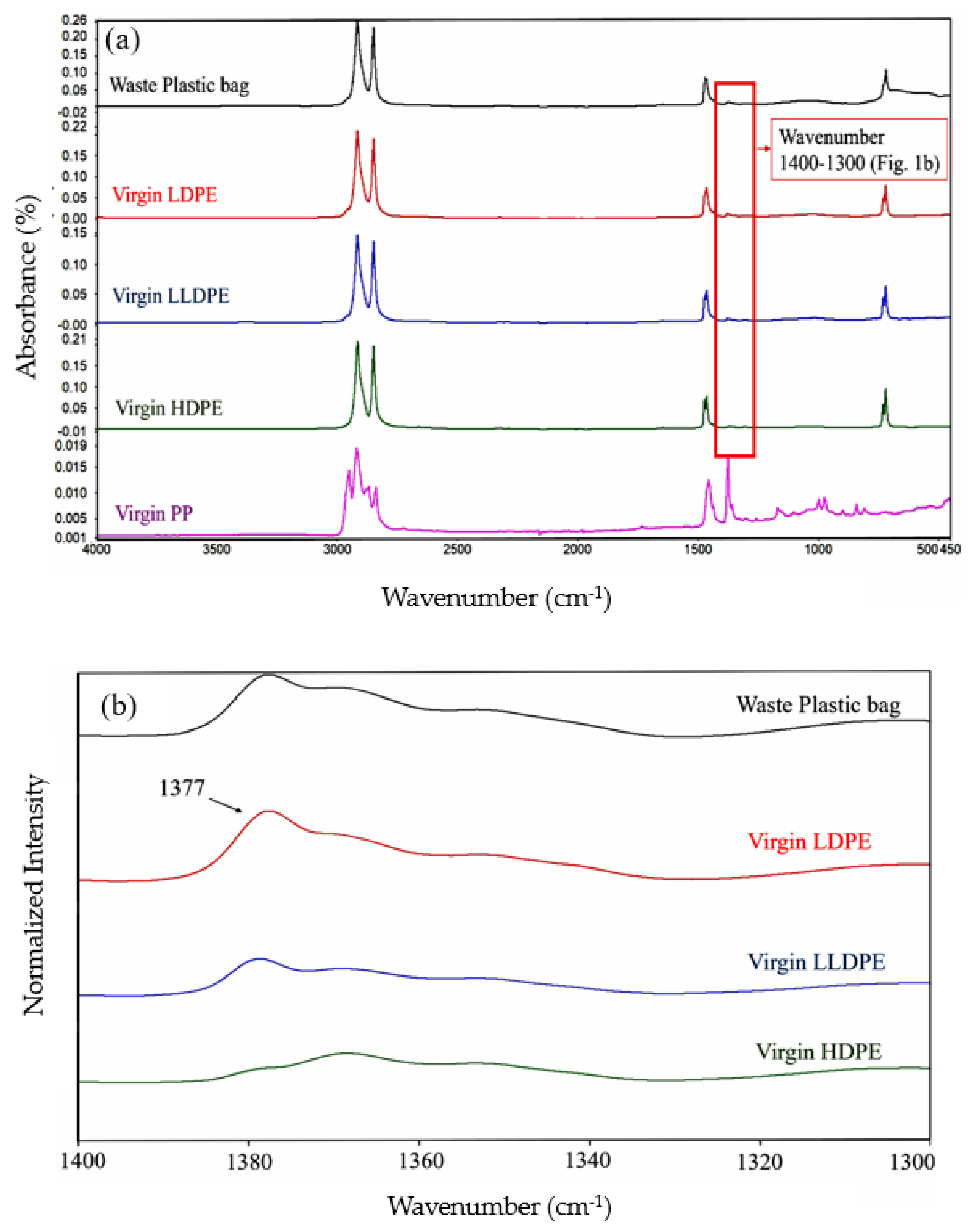

2.3.2. Chemical Characterization Analysis

2.3.3. Thermal Stability Analysis

2.4. Preparation of Polymer Modified Bitumen Samples

2.5. Aging Procedure of the Samples

2.6. Conventional Properties of Asphalt Binders

2.7. Rheological Analysis of Asphalt Binders

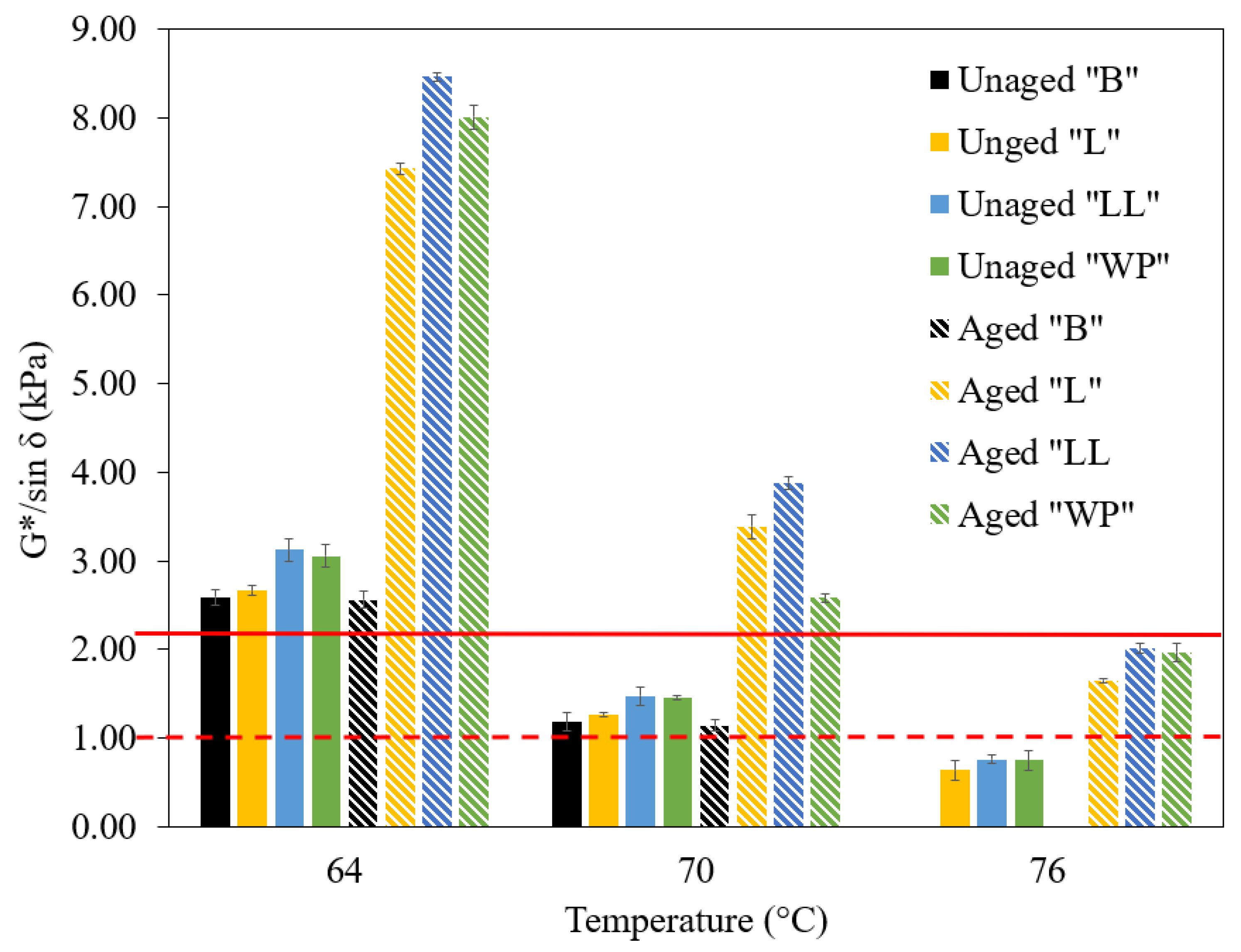

2.7.1. High-Temperature Rutting Resistance of Asphalt Binders

- Superpave rutting parameter

- 2.

- MSCR

2.7.2. Frequency Sweep Test

3. Results and Discussion

3.1. Characterization of the Waste Plastic Bags

3.1.1. Chemical Characterization Analysis Using FTIR

3.1.2. Thermal Behavior Analysis Using DSC

3.1.3. Thermal Stability Analysis Using TGA

3.2. Size Distribution

3.3. Conventional Properties of Asphalt Binders

3.4. Rutting Resistance Analysis

3.4.1. Superpave Rutting Parameter

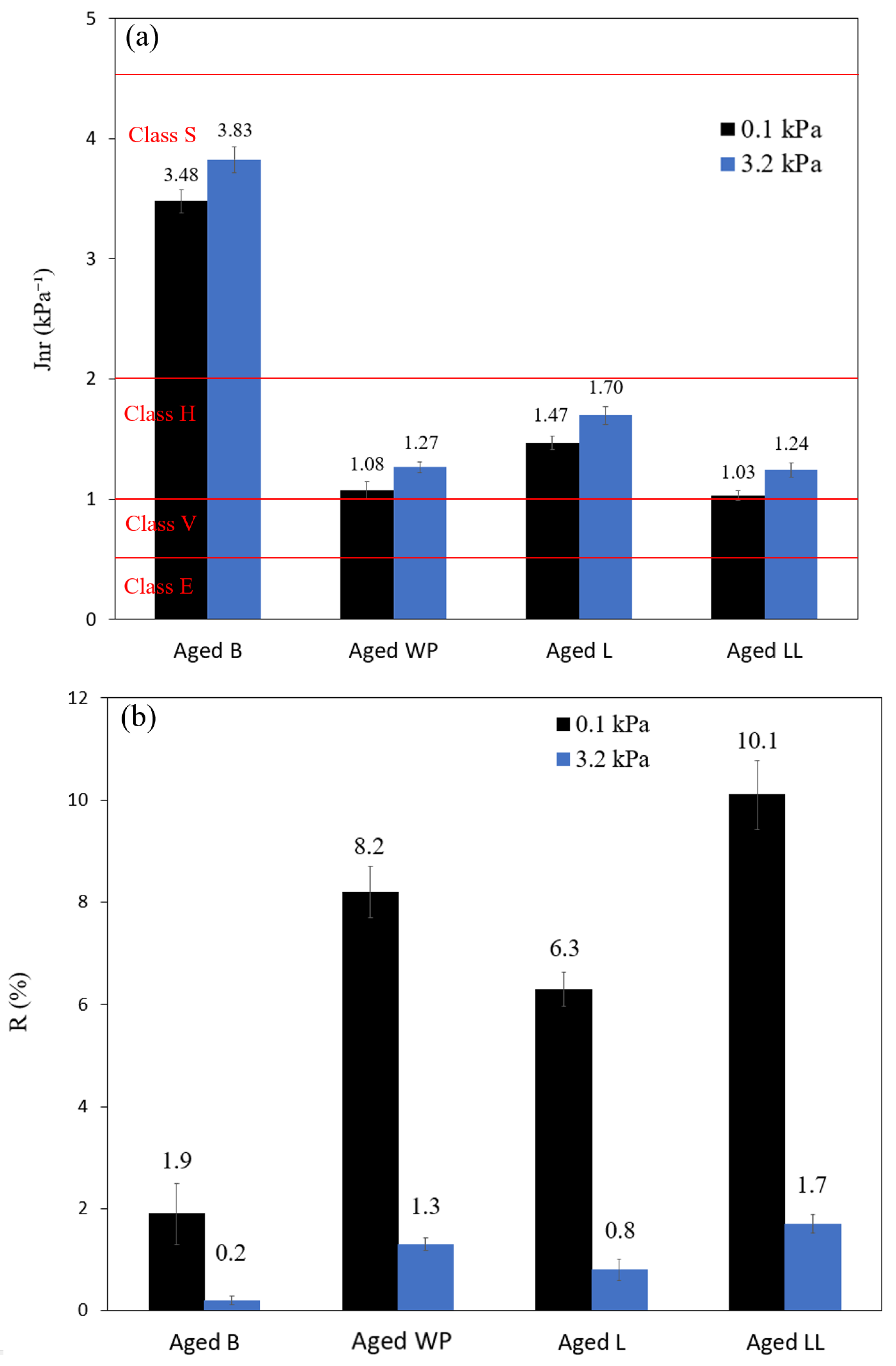

3.4.2. MSCR

3.5. Rheological Analysis Using Frequency Sweep Test

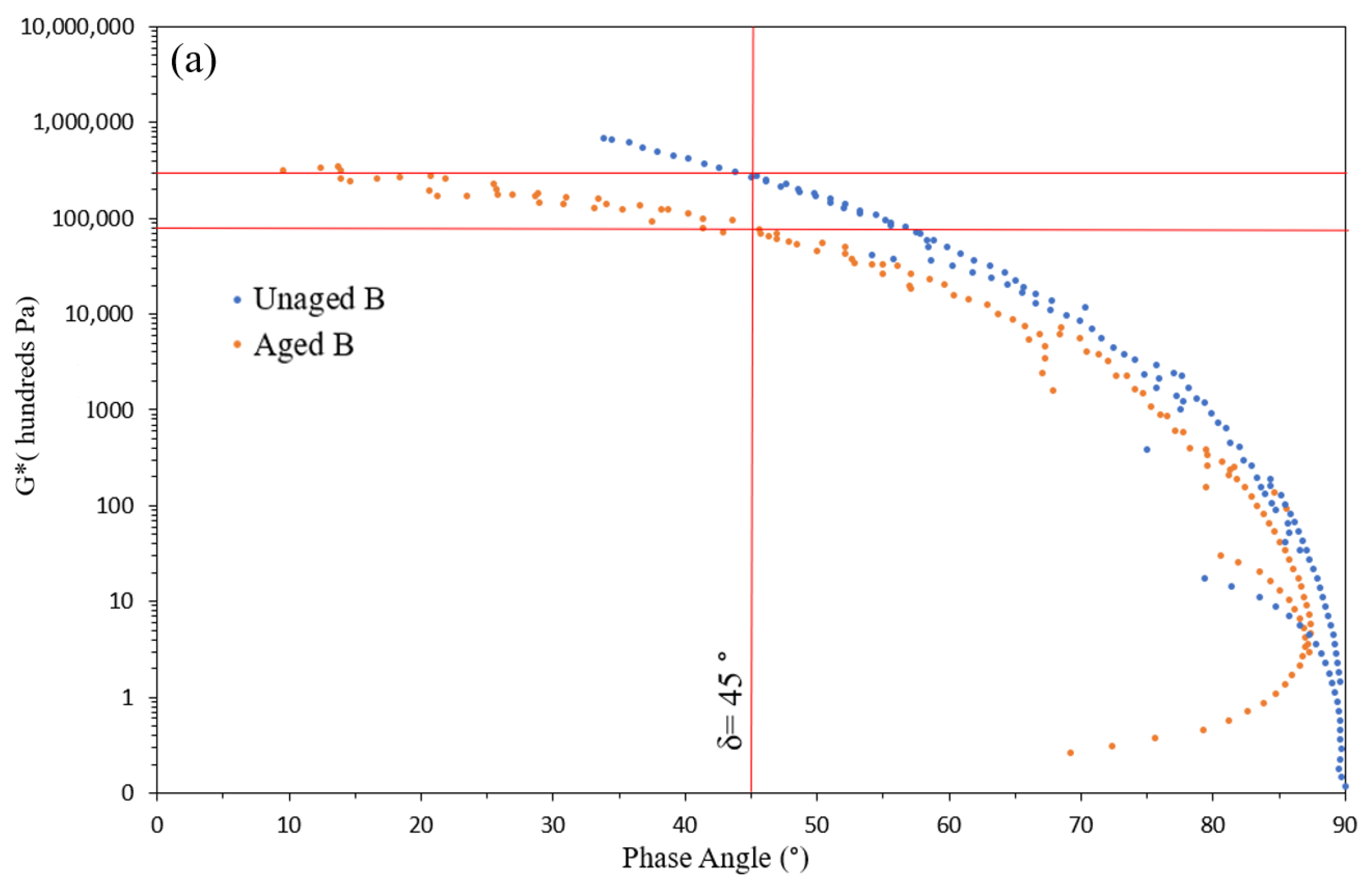

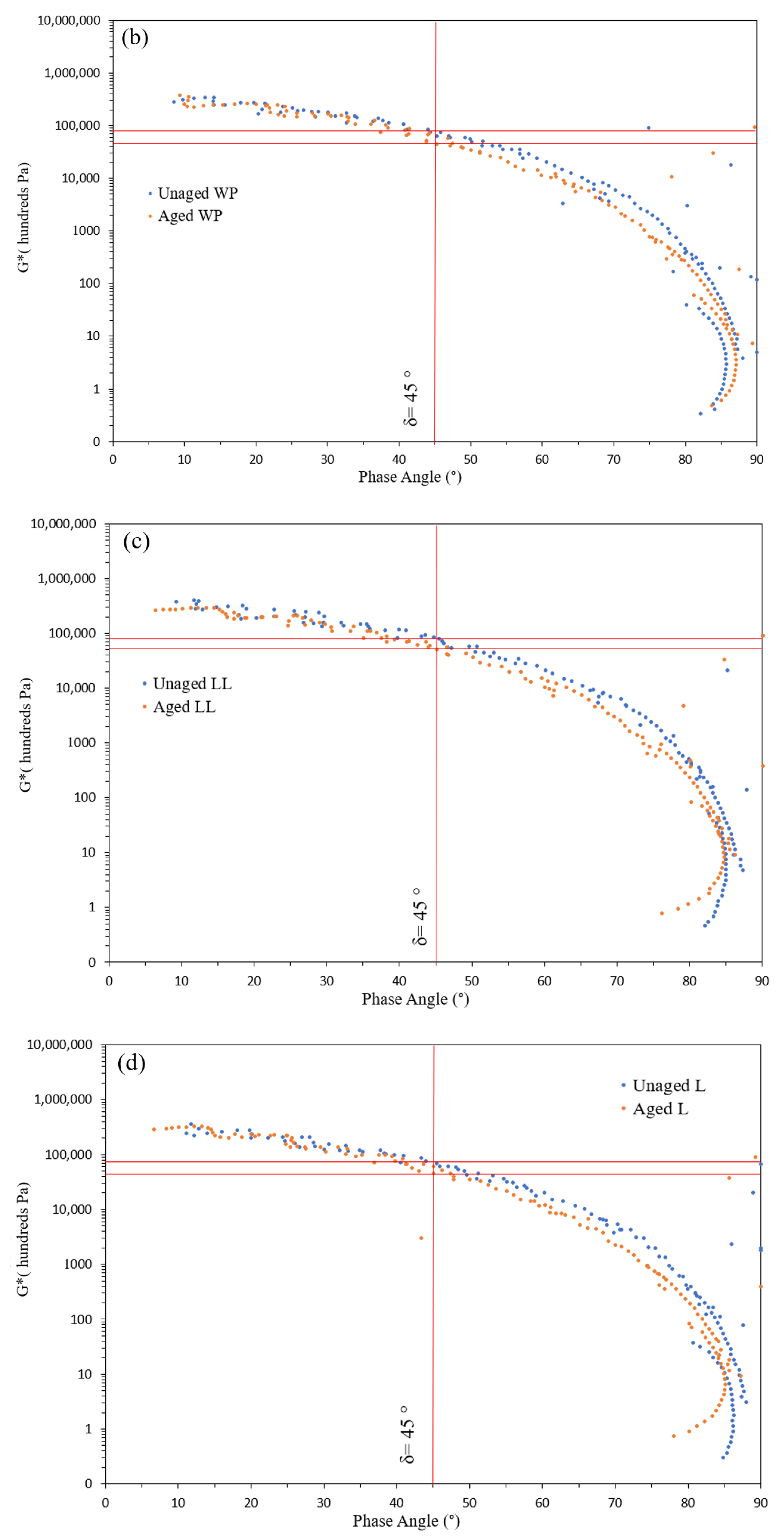

3.5.1. Black Diagram

3.5.2. Cole–Cole Diagram

3.6. Effect of Short-Term Aging on Rheological Properties

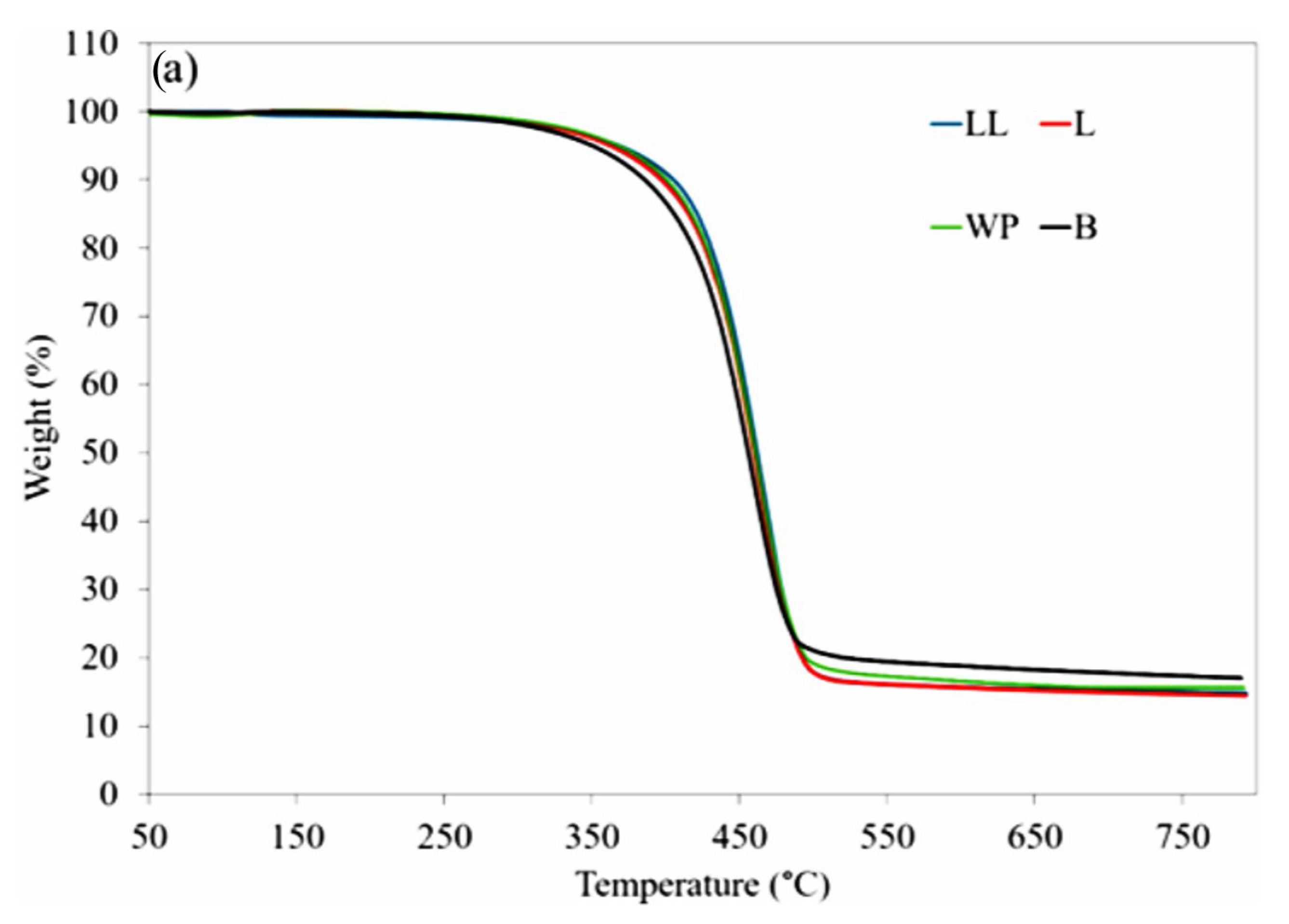

3.7. Thermal Stability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. Available online: https://www.science.org (accessed on 12 February 2024). [CrossRef] [PubMed]

- Sakthipriya, N. Plastic waste management: A road map to achieve circular economy and recent innovations in pyrolysis. Sci. Total Environ. 2022, 809, 151160. [Google Scholar] [CrossRef] [PubMed]

- United Nations Environment Programme. Single-Use Plastics, a Roadmap for Sustainability; United Nations Environment Programme: Nairobi, Kenya, 2018. [Google Scholar]

- Gómez, I.D.L.; Escobar, A.S. The dilemma of plastic bags and their substitutes: A review on LCA studies. Sustain. Prod. Consum. 2022, 30, 107–116. [Google Scholar] [CrossRef]

- Thomas, J.; Patil, R.S.; Patil, M.; John, J. Addressing the Sustainability Conundrums and Challenges within the Polymer Value Chain. Sustainability 2023, 15, 15758. [Google Scholar] [CrossRef]

- da Silva, T.R.; de Azevedo, A.R.G.; Cecchin, D.; Marvila, M.T.; Amran, M.; Fediuk, R.; Vatin, N.; Karelina, M.; Klyuev, S.; Szelag, M. Application of plastic wastes in construction materials: A review using the concept of life-cycle assessment in the context of recent research for future perspectives. Materials 2021, 14, 3549. [Google Scholar] [CrossRef] [PubMed]

- Gu, L.; Ozbakkaloglu, T. Use of recycled plastics in concrete: A critical review. Waste Manag. 2016, 51, 19–42. [Google Scholar] [CrossRef] [PubMed]

- Lamba, P.; Kaur, D.P.; Raj, S.; Sorout, J. Recycling/reuse of plastic waste as construction material for sustainable development: A review. Environ. Sci. Pollut. Res. 2022, 29, 86156–86179. [Google Scholar] [CrossRef]

- Nyika, J.; Dinka, M. Recycling plastic waste materials for building and construction Materials: A minireview. Mater. Today Proc. 2022, 62, 3257–3262. [Google Scholar] [CrossRef]

- Tang, Z.; Li, W.; Tam, V.W.Y.; Xue, C. Advanced progress in recycling municipal and construction solid wastes for manufacturing sustainable construction materials. Resour. Conserv. Recycl. X 2020, 6, 100036. [Google Scholar] [CrossRef]

- Huang, Y.; Bird, R.N.; Heidrich, O. A review of the use of recycled solid waste materials in asphalt pavements. Resour. Conserv. Recycl. 2007, 52, 58–73. [Google Scholar] [CrossRef]

- Ma, J.; Nawarathna, H.M.C.; Hesp, S.A.M. On the sustainable use of recycled plastics in flexible asphalt pavements. J. Clean. Prod. 2022, 359, 132081. [Google Scholar] [CrossRef]

- Xu, F.; Zhao, Y.; Li, K. Using waste plastics as asphalt modifier: A review. Materials 2022, 15, 110. [Google Scholar] [CrossRef] [PubMed]

- Al-Abdul Wahhab, H.I.; Dalhat, M.A.; Habib, M.A. Storage stability and high-temperature performance of asphalt binder modified with recycled plastic. Road Mater. Pavement Des. 2017, 18, 1117–1134. [Google Scholar] [CrossRef]

- Heydari, S.; Hajimohammadi, A.; Javadi, N.H.; Khalili, N. The use of plastic waste in asphalt: A critical review on asphalt mix design and Marshall properties. Constr. Build. Mater. 2021, 309, 125185. [Google Scholar] [CrossRef]

- Köfteci, S.; Ahmedzade, P.; Kultayev, B. Performance evaluation of bitumen modified by various types of waste plastics. Constr. Build. Mater. 2014, 73, 592–602. [Google Scholar] [CrossRef]

- Nouali, M.; Ghorbel, E.; Derriche, Z. Phase separation and thermal degradation of plastic bag waste modified bitumen during high temperature storage. Constr. Build. Mater. 2020, 239, 117872. [Google Scholar] [CrossRef]

- Özkan, K.; Ergin, S.; Işik, S.; Işikli, I. A new classification scheme of plastic wastes based upon recycling labels. Waste Manag. 2015, 35, 29–35. [Google Scholar] [CrossRef]

- Abdel-Raheem, A.; Dulaimi, A.; Mohamed, A.S.; Moussa, G.S.; Özkılıç, Y.O.; Mashaan, N.; Jaya, R.P.; Abdel-Wahed, T. Investigating the Potential of High-Density Polyethylene and Nano Clay Asphalt-Modified Binders to Enhance the Rutting Resistance of Asphalt Mixture. Sustainability 2023, 15, 13992. [Google Scholar] [CrossRef]

- Al-Hadidy, A.I.; Yi-Qiu, T. Effect of polyethylene on life of flexible pavements. Constr. Build. Mater. 2009, 23, 1456–1464. [Google Scholar] [CrossRef]

- Desidery, L.; Lanotte, M.; Devasahayam, S. Effect of Waste Polyethylene and Wax-Based Additives on Bitumen Performance. Polymers 2021, 13, 3733. [Google Scholar] [CrossRef]

- Wang, D.; Zhu, J.; Porot, L.; Falchetto, A.C.; Damen, S. Multiple stress creep and recovery test for bituminous binders–influence of several key experimental parameters. Road Mater. Pavement Des. 2023, 24, 290–308. [Google Scholar] [CrossRef]

- Piromanski, B.; Chegenizadeh, A.; Mashaan, N.; Nikraz, H. Study on HDPE effect on rutting resistance of binder. Buildings 2020, 10, 156. [Google Scholar] [CrossRef]

- Cheng, S.Y.; Hassan, A.; Ghazali, M.I.H.; Ismail, A.F. Heat sealability of laminated films with LLDPE and LDPE as the sealant materials in bar sealing application. J. Appl. Polym. Sci. 2007, 104, 3736–3745. [Google Scholar] [CrossRef]

- Taylor, J.; Baik, J.J. Benefits of coextruded LLDPE/LDPE film vs. blended LLDPE/LDPE film. J. Plast. Film Sheeting 2000, 16, 223–236. [Google Scholar] [CrossRef]

- Alam, O.; Billah, M.; Yajie, D. Characteristics of plastic bags and their potential environmental hazards. Resour. Conserv. Recycl. 2018, 132, 121–129. [Google Scholar] [CrossRef]

- Suleman, R.; Amjad, A.; Ismail, A.; Javed, S.; Ghafoor, U.; Fahad, S. Impact of plastic bags usage in food commodities: An irreversible loss to environment. Environ. Sci. Pollut. Res. 2022, 29, 49483–49489. [Google Scholar] [CrossRef] [PubMed]

- Ge, C.; Lei, K.; Aldi, R. Barrier, mechanical, and thermal properties of the three-layered co-extruded blown polyethylene/ethylene-vinyl alcohol/low density polyethylene film without tie layers. J. Thermoplast. Compos. Mater. 2017, 30, 794–807. [Google Scholar] [CrossRef]

- Baskaran, S.; Sathiavelu, M. Application of Attenuated Total Reflection-Fourier Transform Infrared spectroscopy to characterize the degradation of littered multilayer food packaging plastics. Vib. Spectrosc. 2020, 109, 103105. [Google Scholar] [CrossRef]

- Qabur, A.; Baaj, H.; El-Hakim, M. Incorporation of the Multi-Layer Plastic Packaging in the Asphalt Binders: Physical, Thermal, Rheological, and Storage Properties Evaluation. Polymers 2022, 14, 5396. [Google Scholar] [CrossRef]

- de Mello Soares, C.T.; Ek, M.; Östmark, E.; Gällstedt, M.; Karlsson, S. Recycling of multi-material multilayer plastic packaging: Current trends and future scenarios. Resour. Conserv. Recycl. 2022, 176, 10590. [Google Scholar] [CrossRef]

- Otsyina, H.R.; Nguhiu-Mwangi, J.; Mogoa, E.G.M.; Mbuthia, P.G.; Ogara, W.O. Knowledge, attitude, and practices on usage, disposal, and effect of plastic bags on sheep and goats. Trop. Anim. Health Prod. 2018, 50, 997–1003. [Google Scholar] [CrossRef] [PubMed]

- State Asphalts NSW. Available online: https://www.stateasphalts.com.au/ (accessed on 18 January 2024).

- TfNSW. QA Specification 3253, Bitumen for Pavements, Transport for NSW; NSW Government: Sydney, Australia, 2020.

- Scoppio, A.; Cavallo, D.; Müller, A.J.; Tranchida, D. Temperature modulated DSC for composition analysis of recycled polyolefin blends. Polym. Test. 2022, 113, 107656. [Google Scholar] [CrossRef]

- Othman, N. Thermal Properties of Polyvinyl Alcohol (PVOH)/Corn Starch Blend Film. Malays. Polym. J. 2011, 6, 147–154. [Google Scholar]

- Wong, A.C.-Y.; Lam, F. Study of selected thermal characteristics of polypropylene/polyethylene binary blends using DSC and TGA. Polym. Test. 2002, 21, 691–696. [Google Scholar] [CrossRef]

- Kong, Y.; Hay, J.N. The measurement of the crystallinity of polymers by DSC. Polymer 2002, 43, 3873–3878. [Google Scholar] [CrossRef]

- Yu, F.; Wu, Z.; Wang, J.; Li, Y.; Chu, R.; Pei, Y.; Ma, J. Effect of landfill age on the physical and chemical characteristics of waste plastics/microplastics in a waste landfill sites. Environ. Pollut. 2022, 306, 119366. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Tang, X.; Li, L. Origins of Baseline Drift and Distortion in Fourier Transform Spectra. Molecules 2022, 27, 4287. [Google Scholar] [CrossRef] [PubMed]

- Gao, R.; Liu, R.; Sun, C. A marine fungus Alternaria alternata FB1 efficiently degrades polyethylene. J. Hazard. Mater. 2022, 431, 128617. [Google Scholar] [CrossRef] [PubMed]

- Mourad, A.H.I.; Akkad, R.O.; Soliman, A.A.; Madkour, T.M. Characterisation of thermally treated and untreated polyethylene- polypropylene blends using DSC, TGA and IR techniques. Plast. Rubber Compos. 2009, 38, 265–278. [Google Scholar] [CrossRef]

- Babalghaith, A.M.; Koting, S.; Ramli Sulong, N.H.; Karim, M.R. Optimization of mixing time for polymer modified asphalt. IOP Conf. Ser. Mater. Sci. Eng. 2019, 512, 012030. [Google Scholar] [CrossRef]

- Pérez-Lepe, A.; Martínez-Boza, F.J.; Gallegos, C.; González, O.; Muñoz, M.E.; Santamaría, A. Influence of the processing conditions on the rheological behaviour of polymer-modified bitumen. Fuel 2003, 82, 1339–1348. [Google Scholar] [CrossRef]

- Abouelsaad, A.; White, G. Comparing the Effect of Thermal-Oxidation and Photo-Oxidation of Asphalt Mixtures on the Rheological and Chemical Properties of Extracted Bituminous Binder. Materials 2022, 15, 6793. [Google Scholar] [CrossRef] [PubMed]

- Heydari, S.; Hajimohammadi, A.; Javadi, N.H.; Ng, J.J.; Kypreos, J.E.; Khalili, N. Modified asphalt by coffee cup Fibres: An optimum mix design using response surface method. Constr. Build. Mater. 2023, 401, 133005. [Google Scholar] [CrossRef]

- Zhang, D.; Birgisson, B.; Luo, X.; Onifade, I. A new short-term aging model for asphalt binders based on rheological activation energy. Mater. Struct. Mater. Constr. 2019, 52, 68. [Google Scholar] [CrossRef]

- AASHTO T240; Standard Method of Test for Effect of Heat and Air on a Moving Film of Asphalt Binder (Rolling Thin-Film Oven Test). AASHTO: Washington, DC, USA, 2021.

- Lu, Q.; Xin, C.; Alamri, M.; Alharthai, M. Development of porous asphalt mixture with bio-based epoxy asphalt. J. Clean. Prod. 2021, 317, 128404. [Google Scholar] [CrossRef]

- AS 2341.12; Australian Standard—Method of Testing Bitumen and Related Roadmaking Products-Method 12: Determination of Penetration-AS 2341.12. Standards Australia Committee: Sydney, Australia, 1993.

- Mashaan, N.S.; Ali, A.H.; Karim, M.R.; Abdelaziz, M. An overview of crumb rubber modified asphalt. Int. J. Phys. Sci. 2012, 7, 166–170. [Google Scholar] [CrossRef]

- Zoorob, S.E.; Castro-Gomes, J.P.; Pereira Oliveira, L.A. Assessing low shear viscosity as the new bitumen Softening Point test. Constr. Build. Mater. 2012, 27, 357–367. [Google Scholar] [CrossRef]

- Vargas, C.; Hanandeh, A.E. The Utilisation of Polyethylene Waste Pyrolytic Wax as an Additive to Enhance the Performance of Virgin and Polypropylene-Modified Bitumen. Int. J. Pavement Res. Technol. 2023. [Google Scholar] [CrossRef]

- AS 2341.18; Methods of Testing Bitumen and Related Roadmaking Products-Method 18: Determination of Softening Point. Standards Australia Committee: Sydney, Australia, 2015; Volume 7, pp. 37–72.

- AS 2341.4; Methods of Testing Bitumen and Related Roadmaking Products-Method 4: Determination of Dynamic Viscosity by Rotational Viscometer. Standards Australia Committee: Sydney, Australia, 2015.

- Airey, G.D.; Collop, A.C. Viscoelastic linearity limits for bituminous materials. Mater. Struct. Mattriaux Constr. 2003, 36, 643–647. [Google Scholar] [CrossRef]

- Hainin, M.R.; Aziz, M.M.A.; Adnan, A.M.; Hassan, N.A.; Jaya, R.P.; Liu, H.Y. Performance of modified asphalt binder with tire rubber powder. J. Teknol. 2015, 73, 55–60. [Google Scholar] [CrossRef][Green Version]

- Airey, G.D.; Grenfell, J.R.A.; Apeagyei, A.; Subhy, A.; Lo Presti, D. Time dependent viscoelastic rheological response of pure, modified and synthetic bituminous binders. Mech. Time-Depend. Mater. 2016, 20, 455–480. [Google Scholar] [CrossRef]

- Li, C.; Liu, H.; Xiao, Y.; Li, J.; Wang, T.; Peng, L. Modification and Enhancing Contribution of Fiber to Asphalt Binders and Their Corresponding Mixtures: A Study of Viscoelastic Properties. Materials 2023, 16, 5727. [Google Scholar] [CrossRef]

- AASHTO T315; Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). AASHTO: Washington, DC, USA, 2015.

- AASHTO M320; Standard Specification for Performance-Graded Asphalt Binder. AASHTO: Washington, DC, USA, 2015.

- Domingos, M.D.I.; Faxina, A.L. Susceptibility of Asphalt Binders to Rutting: Literature Review. J. Mater. Civil Eng. 2016, 28, 04015134. [Google Scholar] [CrossRef]

- Zhang, J.; Walubita, L.F.; Faruk AN, M.; Karki, P.; Simate, G.S. Use of the MSCR test to characterize the asphalt binder properties relative to HMA rutting performance—A laboratory study. Constr. Build. Mater. 2015, 94, 218–227. [Google Scholar] [CrossRef]

- AASHTO M332; Standard Specification for Performance-Graded Asphalt Binder Using Multiple Stress Creep Recovery (MSCR) Test. AASHTO: Washington, DC, USA, 2015.

- Jamal, M.; Giustozzi, F. Low-content crumb rubber modified bitumen for improving Australian local roads condition. J. Clean. Prod. 2020, 271, 122484. [Google Scholar] [CrossRef]

- Wu, W.; Jiang, W.; Xiao, J.; Yuan, D.; Wang, T.; Xing, C. Analysis of thermal susceptibility and rheological properties of asphalt binder modified with microwave activated crumb rubber. J. Clean. Prod. 2022, 377, 134488. [Google Scholar] [CrossRef]

- da Silva, D.J.; Wiebeck, H. ATR-FTIR Spectroscopy Combined with Chemometric Methods for the Classification of Polyethylene Residues Containing Different Contaminants. J. Polym. Environ. 2022, 30, 3031–3044. [Google Scholar] [CrossRef]

- Fang, J.; Zhang, L.; Sutton, D.; Wang, X.; Lin, T. Needleless melt-electrospinning of polypropylene nanofibres. J. Nanomater. 2012, 2012, 382639. [Google Scholar] [CrossRef]

- Chapke, K.; Gandhi, K.; Lata, K.; Sharma, R.; Mann, B.; Singh, N. Migration study of chemical additives from low density polyethylene (LDPE) into dahi. J. Food Sci. Technol. 2022, 59, 3283–3295. [Google Scholar] [CrossRef]

- Chércoles Asensio, R.; San Andrés Moya, M.; De La Roja, J.M.; Gómez, M. Analytical characterization of polymers used in conservation and restoration by ATR-FTIR spectroscopy. Anal. Bioanal. Chem. 2009, 395, 2081–2096. [Google Scholar] [CrossRef]

- Fu, Y.; Lim, L.T. Investigation of multiple-component diffusion through LLDPE film using an FTIR-ATR technique. Polym. Test. 2012, 31, 56–67. [Google Scholar] [CrossRef]

- Karlsson, T.M.; Kärrman, A.; Rotander, A.; Hassellöv, M. Comparison between manta trawl and in situ pump filtration methods, and guidance for visual identification of microplastics in surface waters. Environ. Sci. Pollut. Res. 2020, 27, 5559–5571. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.H.; Pan, Y.J.; Liu, C.F.; Huang, C.L.; Hsieh, C.T.; Chen, C.K.; Lin, Z.I.; Lou, C.W. Preparation and compatibility evaluation of polypropylene/high density polyethylene polyblends. Materials 2015, 8, 8850–8859. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez Lamar, Y.; Noboa, J.; Torres Miranda, A.S.; Almeida Streitwieser, D. Conversion of PP, HDPE and LDPE Plastics into Liquid Fuels and Chemical Precursors by Thermal Cracking. J. Polym. Environ. 2021, 29, 3842–3853. [Google Scholar] [CrossRef]

- Fang, Y.; Carreau, P.J.; Lafleur, P.G. Thermal and rheological properties of mLLDPE/LDPE blends. Polym. Eng. Sci. 2005, 45, 1254–1264. [Google Scholar] [CrossRef]

- Abbas-Abadi, M.S. The effect of process and structural parameters on the stability, thermo-mechanical and thermal degradation of polymers with hydrocarbon skeleton containing PE, PP, PS, PVC, NR, PBR and SBR. J. Therm. Anal. Calorim. 2021, 143, 2867–2882. [Google Scholar] [CrossRef]

- Giustozzi, F.; Xuan, D.L.; Enfrin, M.; Masood, H.; Audy, R.; Jia Boom, Y. Use of Road-Grade Recycled Plastics for Sustainable Asphalt Pavements: Towards the Selection of Road-Grade Plastics—An Evaluation Framework and Preliminary Experimental Results; RMIT University: Melbourne, Australia, 2021. [Google Scholar]

- Juan, R.; Domínguez, C.; Robledo, N.; Paredes, B.; Galera, S.; García-Muñoz, R.A. Challenges and opportunities for recycled polyethylene fishing nets: Towards a circular economy. Polymers 2021, 13, 3155. [Google Scholar] [CrossRef] [PubMed]

- Prasad, A. A quantitative analysis of low density polyethylene and linear low density polyethylene blends by differential scanning calorimetery and fourier transform infrared spectroscopy methods. Polym. Eng. Sci. 1998, 38, 1716–1728. [Google Scholar] [CrossRef]

- Singh, B.; Kumar, P. Effect of polymer modification on the ageing properties of asphalt binders: Chemical and morphological investigation. Constr. Build. Mater. 2019, 205, 633–641. [Google Scholar] [CrossRef]

- Wu, X.; Chen, J.; Zeng, X. The application of DSC in identification of LDPE/LLDPE blends mulching film. Die Angew. Makromol. Chem. 1991, 189, 183–193. [Google Scholar] [CrossRef]

- Laukkanen, O.V.; Soenen, H.; Pellinen, T.; Heyrman, S.; Lemoine, G. Creep-recovery behavior of bituminous binders and its relation to asphalt mixture rutting. Mater. Struct. Mater. Constr. 2015, 48, 4039–4053. [Google Scholar] [CrossRef]

- Kataware, A.V.; Singh, D. A study on rutting susceptibility of asphalt binders at high stresses using MSCR test. Innov. Infrastruct. Solut. 2017, 2, 4. [Google Scholar] [CrossRef]

- Airey, G.D. Use of Black Diagrams to Identify Inconsistencies in Rheological Data. Road Mater. Pavement Des. 2002, 3, 403–424. [Google Scholar] [CrossRef]

- Joohari, I.B.; Giustozzi, F. Chemical and high-temperature rheological properties of recycled plastics-polymer modified hybrid bitumen. J. Clean. Prod. 2020, 276, 123064. [Google Scholar] [CrossRef]

- Airey, G.D. Styrene butadiene styrene polymer modification of road bitumens. J. Mater. Sci. 2004, 39, 951–959. [Google Scholar] [CrossRef]

- Murphy, M.; O’mahony, M.; Lycett, C.; Jamieson, I. Recycled polymers for use as bitumen modifiers. J. Mater. Civ. Eng. 2001, 13, 306–314. [Google Scholar] [CrossRef]

- Kaya, D.; Topal, A.; McNally, T. Relationship between processing parameters and aging with the rheological behaviour of SBS modified bitumen. Constr. Build. Mater. 2019, 221, 345–350. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Jamal, M.; Biligiri, K.P.; Giustozzi, F. Effect of Various Compatibilizers on the Storage Stability, Thermochemical and Rheological Properties of Recycled Plastic-Modified Bitumen. Int. J. Pavement Res. Technol. 2023. [Google Scholar] [CrossRef]

- Jing, R.; Varveri, A.; Liu, X.; Scarpas, A.; Erkens, S. Rheological, fatigue and relaxation properties of aged bitumen. Int. J. Pavement Eng. 2020, 21, 1024–1033. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, Y.; Omairey, E.L.; Al-Malaika, S.; Sheena, H. Influence of anti-ageing compounds on rheological properties of bitumen. J. Clean. Prod. 2021, 318, 12855. [Google Scholar] [CrossRef]

- Villegas-Villegas, R.E.; Baldi, A.; Aguiar-Moya, J.P.; Loria-Salazar, L.; Miranda Arguello, F. Relationship between crossover modulus and asphalt chemistry to oxidation process based on the RHEO+ method. Road Mater. Pavement Des. 2023. [Google Scholar] [CrossRef]

- Liu, F.; Zhou, Z.; Wang, Y. Predict the rheological properties of aged asphalt binders using a universal kinetic model. Constr. Build. Mater. 2019, 195, 283–291. [Google Scholar] [CrossRef]

- Faisal Kabir, S.; Fini, E.H. Investigating Aging and Rejuvenation Mechanism of Biomodified Rubberized Bitumen. J. Mater. Civil Eng. 2021, 33, 04021142. [Google Scholar] [CrossRef]

- Zhang, X.; Hoff, I. Comparative study of thermal-oxidative aging and salt solution aging on bitumen performance. Materials 2021, 14, 1174. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Xu, T.; Shi, H.; Wang, L. Physicochemical and pyrolysis properties of SARA fractions separated from asphalt binder. J. Therm. Anal. Calorim. 2015, 122, 241–249. [Google Scholar] [CrossRef]

- Fernandes, S.R.M.; Silva, H.M.R.D.; Oliveira, J.R.M. Developing enhanced modified bitumens with waste engine oil products combined with polymers. Constr. Build. Mater. 2018, 160, 714–724. [Google Scholar] [CrossRef]

| Plastic Type | Grade | Density at 25° C (g/cm3) | Melting Point (°C) |

|---|---|---|---|

| PP | SM598 | 0.9 | 160 |

| LDPE | LD2426K | 0.924 | 110 |

| HDPE | HD1010J | 0.956 | 127 |

| LLDPE | LL7410D | 0.921 | 121 |

| Binder Name | Modifier Content per Weight of Bitumen (%) | Modifier Composition (wt.%) | ||

|---|---|---|---|---|

| Virgin LLDPE | Virgin LDPE | Waste Plastic Bag | ||

| B | 0 | 0 | 0 | 0 |

| LL | 5 | 100 | 0 | 0 |

| L | 5 | 0 | 100 | 0 |

| WP | 5 | 0 | 0 | 100 |

| Plastic Type | Wavenumber (cm−1) | Chemical Group and Vibrational Mode | Reference |

|---|---|---|---|

| PP | 2950 | asymmetrical stretching vibrations of CH3 | [67,68] |

| 2917 | asymmetrical stretching vibrations of CH2 | [67,68] | |

| 2869 | stretching vibrations of CH3 | [67,68] | |

| 1456 | symmetrical bending vibrations of CH3 | [67,68] | |

| 1376 | symmetrical bending vibrations of CH3 | [67,68] | |

| 1166 | wagging vibrations of CH | [67,68] | |

| rocking vibrations of CH3 | [67,68] | ||

| stretching vibrations of C-C | [67,68] | ||

| 996 | rocking vibrations of CH3 | [67,68] | |

| 973 | rocking vibrations of CH3 | [67,68] | |

| stretching vibrations of C-C | [67,68] | ||

| 840 | rocking vibrations of CH | [67,68] | |

| 808 | stretching vibrations of C-C | [67,68] | |

| LDPE/LLDPE | 2917 | asymmetric stretching vibrations of CH2 | [69,70,71] |

| 2848 | symmetric stretching vibrations of CH2 | [69,70,71] | |

| 1471 | bending deformation vibration of CH2 (crystalline domains) | [69,70,71] | |

| 1463 | bending deformation vibration of CH2 (amorphous domains) | [69,70,71] | |

| 1377 | symmetric deformation vibration of CH3 | [69,70,71] | |

| 1369 | wagging deformation vibration of CH2 | [69,70,71] | |

| 729 | rocking deformation vibrations of CH2 in crystalline domains | [69,70,71] | |

| 718 | rocking deformation vibrations of CH2 in amorphous domains | [69,70,71] | |

| HDPE | 2917 | asymmetric stretching vibrations of CH2 | [67,72] |

| 2848 | symmetric stretching vibrations of CH2 | [67,72] | |

| 1471 | bending deformation vibration of CH2 in crystalline domains | [67,72] | |

| 1463 | bending deformation vibration of CH2 in amorphous domains | [67,72] | |

| 729 | rocking deformation vibrations of CH2 in crystalline domains | [67,72] | |

| 718 | rocking deformation vibrations of CH2 in amorphous domains | [67,72] |

| Binder Name | Crossover Modulus (MPa) | Crossover Changes after Aging (%) | |

|---|---|---|---|

| before Aging | after Aging | ||

| B | 27 | 8 | −70.4 |

| WPE | 8 | 4.5 | −43.7 |

| L | 7.5 | 4.5 | −40 |

| LL | 8 | 5.2 | −35 |

| Binder Name | Tmax | Residue at 750 °C (%) |

|---|---|---|

| B | 459.3 | 16.9 |

| L | 462.2 | 14.9 |

| LL | 464.9 | 14.6 |

| WP | 462.8 | 15.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haji Seyed Javadi, N.; Heydari, S.; Hajimohammadi, A. Evaluating Effectiveness of Multi-Component Waste Plastic Bags on Bitumen Properties: Physical, Rheological, and Aging. Polymers 2024, 16, 1669. https://doi.org/10.3390/polym16121669

Haji Seyed Javadi N, Heydari S, Hajimohammadi A. Evaluating Effectiveness of Multi-Component Waste Plastic Bags on Bitumen Properties: Physical, Rheological, and Aging. Polymers. 2024; 16(12):1669. https://doi.org/10.3390/polym16121669

Chicago/Turabian StyleHaji Seyed Javadi, Nioushasadat, Soheil Heydari, and Ailar Hajimohammadi. 2024. "Evaluating Effectiveness of Multi-Component Waste Plastic Bags on Bitumen Properties: Physical, Rheological, and Aging" Polymers 16, no. 12: 1669. https://doi.org/10.3390/polym16121669

APA StyleHaji Seyed Javadi, N., Heydari, S., & Hajimohammadi, A. (2024). Evaluating Effectiveness of Multi-Component Waste Plastic Bags on Bitumen Properties: Physical, Rheological, and Aging. Polymers, 16(12), 1669. https://doi.org/10.3390/polym16121669