The Influence of Citrus Pectin and Polyacrylamide Modified with Plant-Derived Additives on the Properties of α-TCP-Based Bone Cements

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Synthesis of α-TCP

2.1.2. Synthesis of Polyacrylamide Hydrogels (PAAMs)

2.1.3. Synthesis of Sago Starch/Neem Flower/Rambutan Peel-Modified Polyacrylamide Hydrogels

2.1.4. Bone Cements Preparation

2.2. Methods

2.2.1. Phase Composition

2.2.2. Setting Times

2.2.3. Mechanical Strength

2.2.4. Microstructure

2.2.5. In Vitro Bioactivity and Chemical Stability

2.2.6. Evaluation of Cytotoxicity

Evaluation of Cytotoxicity

Live/Dead Fluorescent Staining

3. Results and Discussion

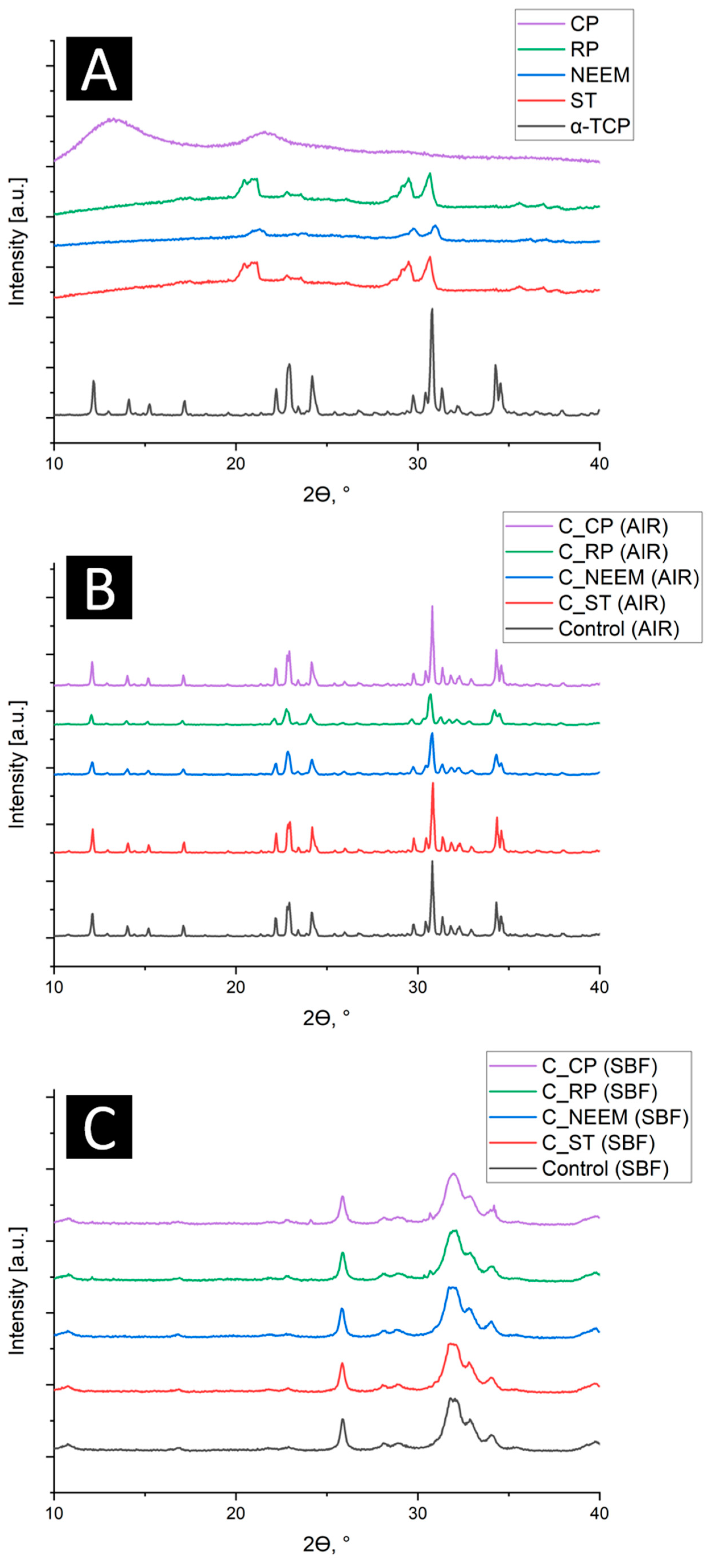

3.1. Phase Composition

3.2. Setting Times

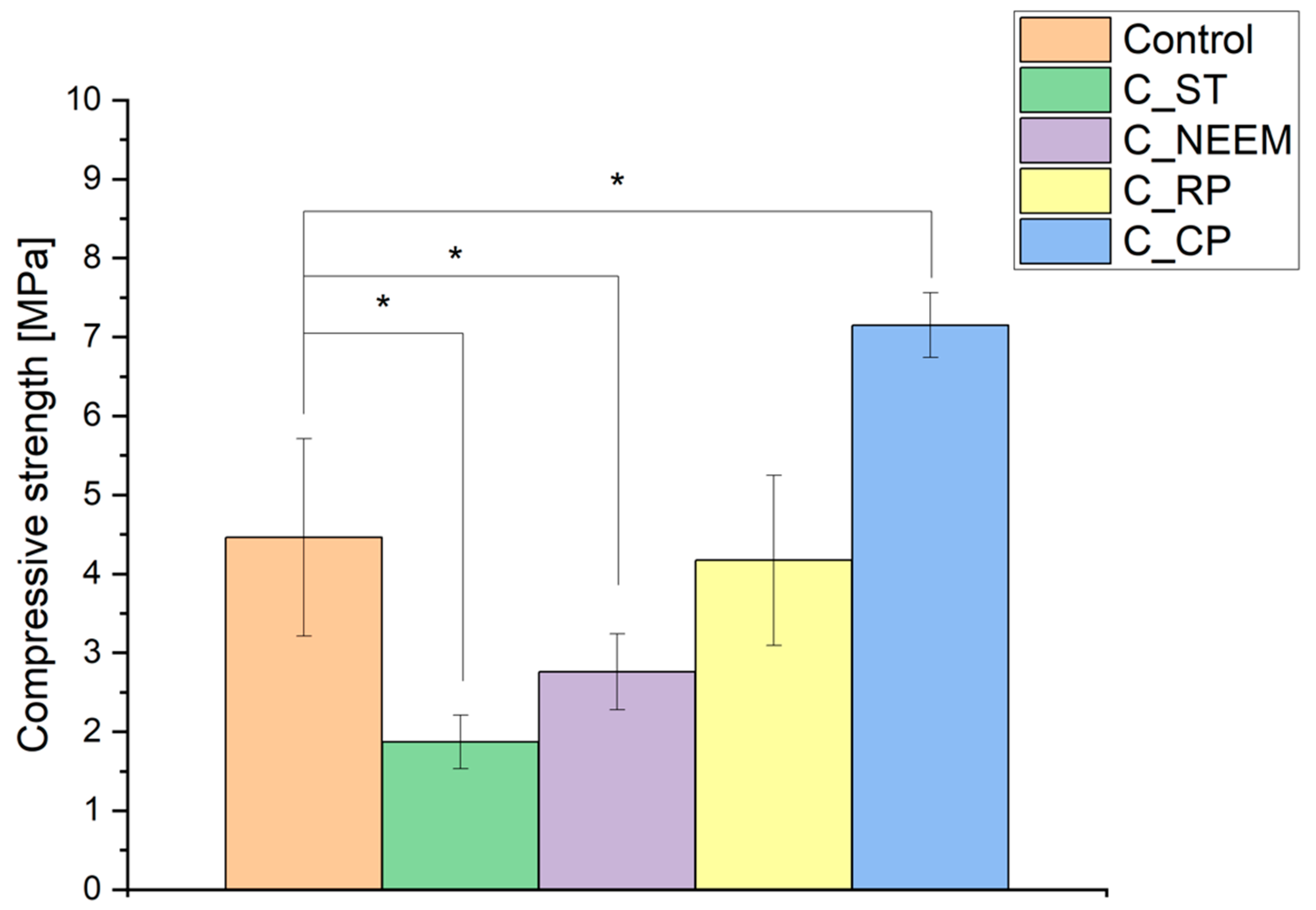

3.3. Mechanical Strength

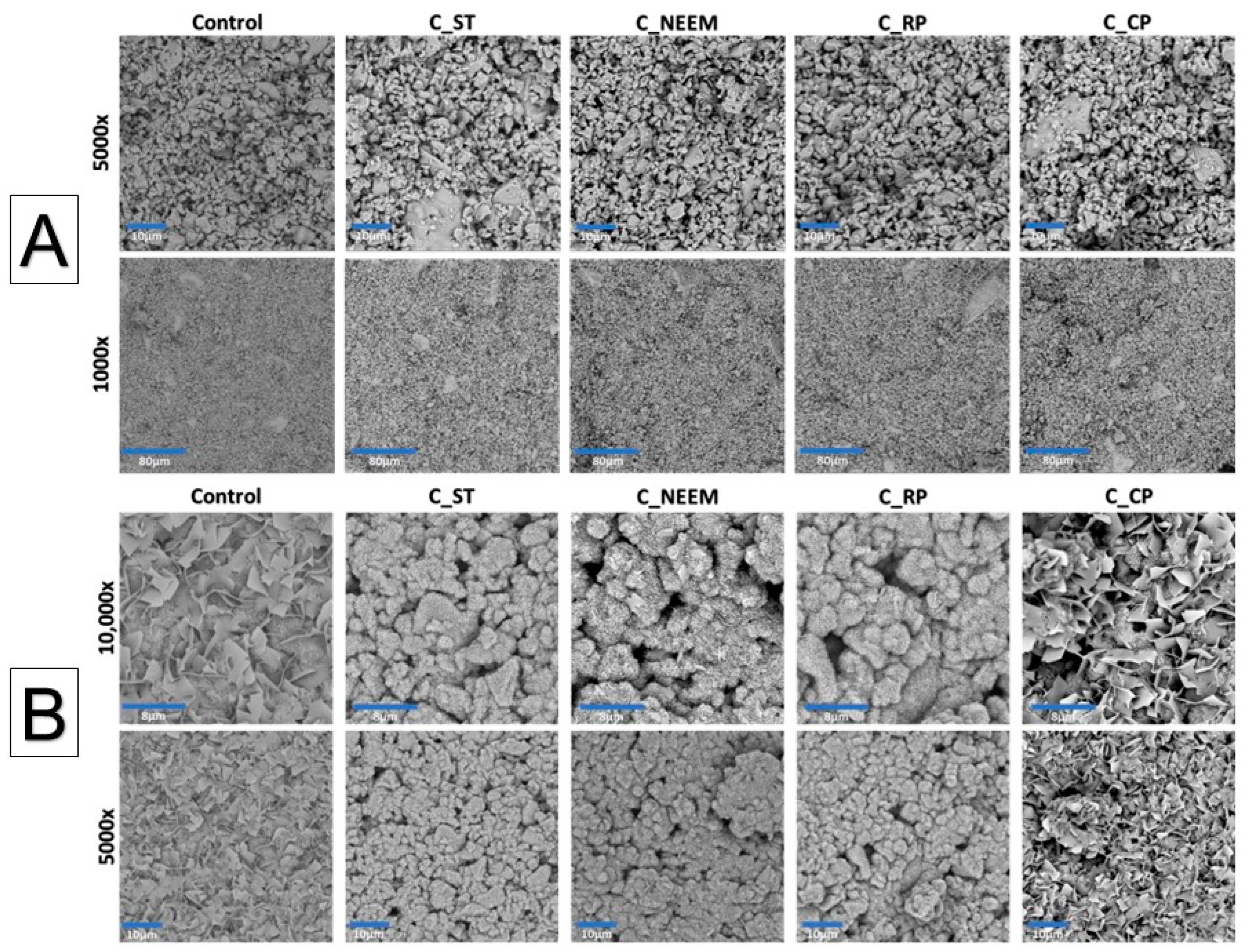

3.4. Microstructure

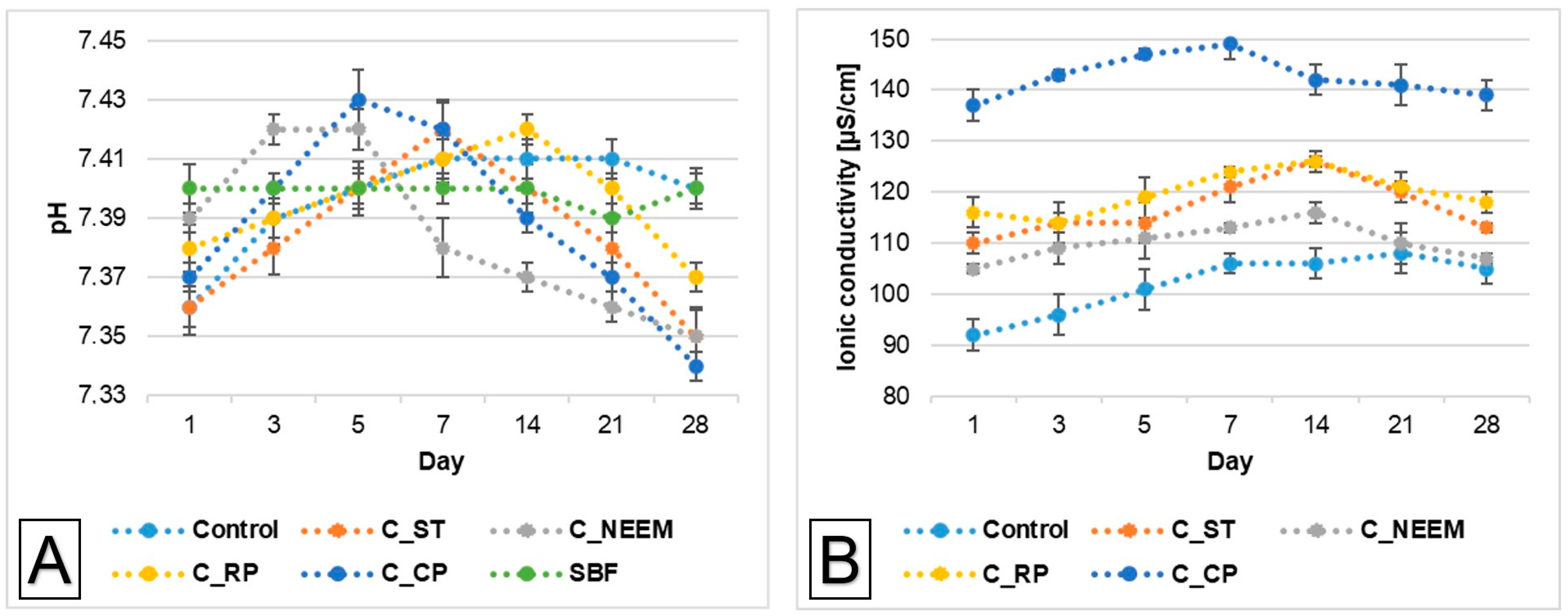

3.5. Chemical Stability and Bioactivity

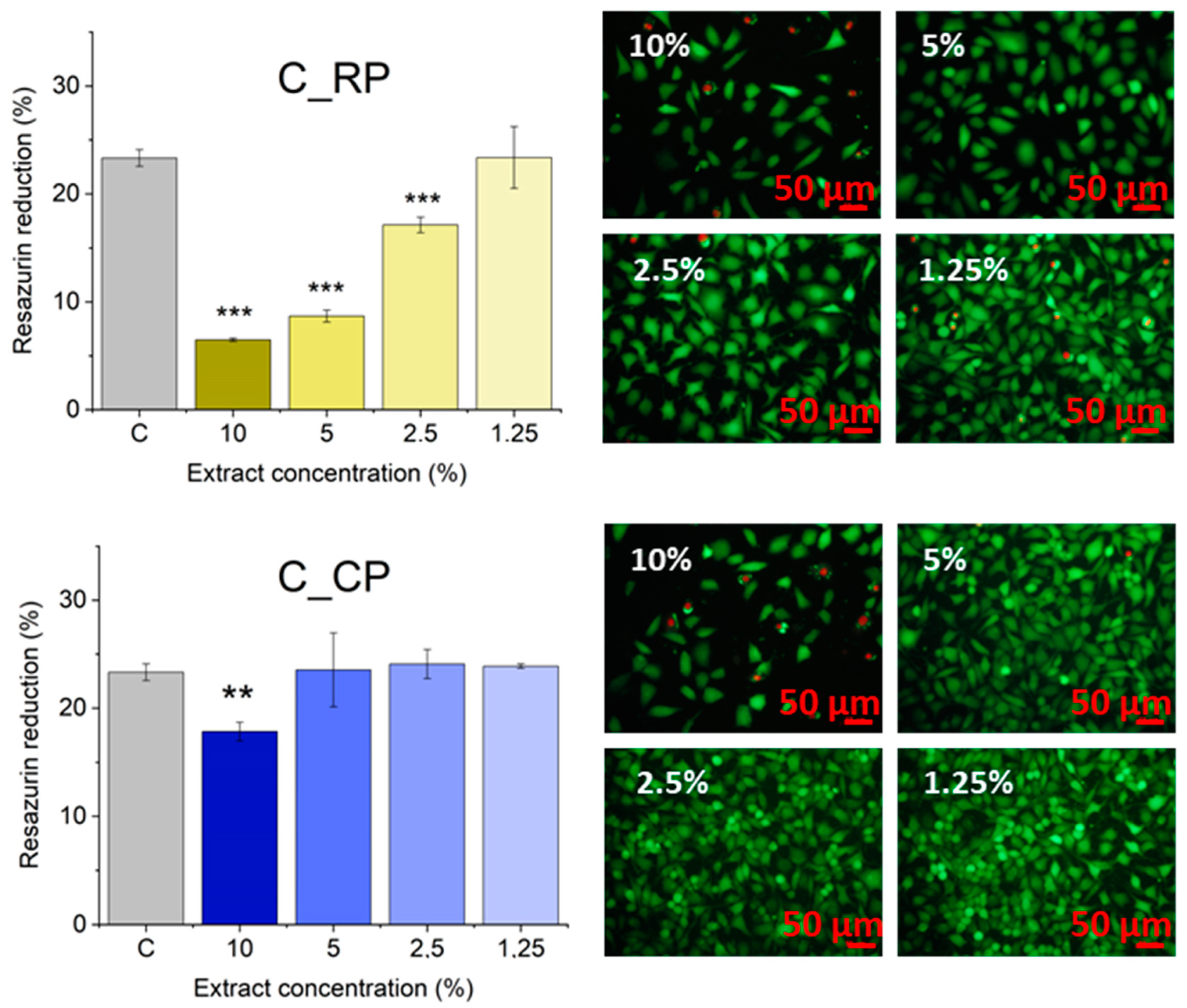

3.6. Evaluation of Cytotoxicity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, H.H.; Wang, P.; Wang, L.; Bao, C.; Chen, Q.; Weir, M.D.; Chow, L.C.; Zhao, L.; Zhou, X.; Reynolds, M.A. Calcium Phosphate Cements for Bone Engineering and Their Biological Properties. Bone Res. 2017, 5, 17056. [Google Scholar] [CrossRef] [PubMed]

- Ambard, A.J.; Mueninghoff, L. Calcium Phosphate Cement: Review of Mechanical and Biological Properties. J. Prosthodont. 2006, 15, 321–328. [Google Scholar] [CrossRef] [PubMed]

- Tronco, M.C.; Cassel, J.B.; Dos Santos, L.A. α-TCP-Based Calcium Phosphate Cements: A Critical Review. Acta Biomater. 2022, 151, 70–87. [Google Scholar] [CrossRef] [PubMed]

- Ding, L.; Wang, H.; Zhang, W.; Li, J.; Liu, D.; Han, F.; Chen, S.; Li, B. Calcium Phosphate Bone Cement with Enhanced Physicochemical Properties via in Situ Formation of an Interpenetrating Network. J. Mater. Chem. B 2021, 9, 6802–6810. [Google Scholar] [CrossRef] [PubMed]

- Voronova, M.I.; Surov, O.V.; Afineevskii, A.V.; Zakharov, A.G. Properties of Polyacrylamide Composites Reinforced by Cellulose Nanocrystals. Heliyon 2020, 6, e05529. [Google Scholar] [CrossRef] [PubMed]

- Low, Z.W.; Chee, P.L.; Kai, D.; Loh, X.J. The Role of Hydrogen Bonding in Alginate/Poly(Acrylamide-Co-Dimethylacrylamide) and Alginate/Poly(Ethylene Glycol) Methyl Ether Methacrylate-Based Tough Hybrid Hydrogels. RSC Adv. 2015, 5, 57678–57685. [Google Scholar] [CrossRef]

- Li, Z.; Wen, T.; Su, Y.; Wei, X.; He, C.; Wang, D. Hollow Hydroxyapatite Spheres Fabrication with Three-Dimensional Hydrogel Template. CrystEngComm 2014, 16, 4202–4209. [Google Scholar] [CrossRef]

- Fang, J.; Li, P.; Lu, X.; Fang, L.; Lü, X.; Ren, F. A Strong, Tough, and Osteoconductive Hydroxyapatite Mineralized Polyacrylamide/Dextran Hydrogel for Bone Tissue Regeneration. Acta Biomater. 2019, 88, 503–513. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Cai, B.; Ni, D.; Sun, Y.; Wang, G.; Jiang, H. A Novel Antibacterial and Antifouling Nanocomposite Coated Endotracheal Tube to Prevent Ventilator-Associated Pneumonia. J. Nanobiotechnol. 2022, 20, 112. [Google Scholar] [CrossRef]

- Xia, Q.; Zhou, Z.; Zhao, X.; Zhang, M.; Wu, C.; Yu, S.; Liu, G. Effects of Calcium Ions on Anionic Polyacrylamide Fouling of Ion-Exchange Membranes in Desalination of Polymer-Flooding Wastewater by Electrodialysis. Desalination 2022, 535, 115846. [Google Scholar] [CrossRef]

- Chuenkaek, T.; Nakajima, K.; Kobayashi, T. Water-Soluble Pectin Films Prepared with Extracts from Citrus Maxima Wastes under Acidic Conditions and Their Moisturizing Characteristics. Biomass Conv. Bioref. 2023. [Google Scholar] [CrossRef]

- Pańtak, P.; Czechowska, J.P.; Cichoń, E.; Zima, A. Novel Double Hybrid-Type Bone Cements Based on Calcium Phosphates, Chitosan and Citrus Pectin. Int. J. Mol. Sci. 2023, 24, 13455. [Google Scholar] [CrossRef] [PubMed]

- Munarin, F.; Guerreiro, S.G.; Grellier, M.A.; Tanzi, M.C.; Barbosa, M.A.; Petrini, P.; Granja, P.L. Pectin-Based Injectable Biomaterials for Bone Tissue Engineering. Biomacromolecules 2011, 12, 568–577. [Google Scholar] [CrossRef] [PubMed]

- Silva, M.A.D.; Bierhalz, A.C.K.; Kieckbusch, T.G. Alginate and Pectin Composite Films Crosslinked with Ca2+ Ions: Effect of the Plasticizer Concentration. Carbohydr. Polym. 2009, 77, 736–742. [Google Scholar] [CrossRef]

- Alzohairy, M.A. Therapeutics Role of Azadirachta indica (Neem) and Their Active Constituents in Diseases Prevention and Treatment. Evid.-Based Complement. Altern. Med. 2016, 2016, 7382506. [Google Scholar] [CrossRef]

- Afzaal, M.; Saeed, F.; Bibi, M.; Ejaz, A.; Shah, Y.A.; Faisal, Z.; Ateeq, H.; Akram, N.; Asghar, A.; Shah, M.A. Nutritional, Pharmaceutical, and Functional Aspects of Rambutan in Industrial Perspective: An Updated Review. Food Sci. Nutr. 2023, 11, 3675–3685. [Google Scholar] [CrossRef] [PubMed]

- Kolmas, J.; Kaflak, A.; Zima, A.; Ślósarczyk, A. Alpha-Tricalcium Phosphate Synthesized by Two Different Routes: Structural and Spectroscopic Characterization. Ceram. Int. 2015, 41, 5727–5733. [Google Scholar] [CrossRef]

- Vedaiyan, J.; Kandaswamy, R.; Dasaien, L.M. Starch Modified Tough Biocompatible Polyurethane/Acrylamide Bio Composites: Physicochemical Properties and Biodegradation Studies. Mater. Plast. 2023, 60, 98–111. [Google Scholar] [CrossRef]

- ASTM C266-20; Test Method for Time of Setting of Hydraulic-Cement Paste by Gillmore Needles. ASTM International: West Conshohocken, PA, USA, 2020.

- Kokubo, T. (Ed.) Bioceramics and Their Clinical Applications; Woodhead publishing in materials; 1. publ.; CRC Press: Boca Raton, FL, USA, 2008; ISBN 978-1-84569-204-9. [Google Scholar]

- ISO 10993-5:2009; Biological Evaluation of Medical Devices—Part 5: Tests for In Vitro Cytotoxicity. International Organization for Standardization: Geneva, Switzerland, 2009.

- Stephen, A.M.; Cummings, J.H. Water-Holding by Dietary Fibre In Vitro and Its Relationship to Faecal Output in Man. Gut 1979, 20, 722–729. [Google Scholar] [CrossRef]

- Boulos, N.N.; Greenfield, H.; Wills, R.B.H. Water Holding Capacity of Selected Soluble and Insoluble Dietary Fibre. Int. J. Food Prop. 2000, 3, 217–231. [Google Scholar] [CrossRef]

- Czechowska, J.; Zima, A.; Paszkiewicz, Z.; Lis, J.; Ślósarczyk, A. Physicochemical Properties and Biomimetic Behaviour of α-TCP-Chitosan Based Materials. Ceram. Int. 2014, 40, 5523–5532. [Google Scholar] [CrossRef]

- Şahin, E. Calcium Phosphate Bone Cements. In Cement Based Materials; Saleh, H.E.-D.M., Rahman, R.O.A., Eds.; InTech: Rijeka, Croatia, 2018; ISBN 978-1-78984-153-4. [Google Scholar]

- Durucan, C.; Brown, P.W. Reactivity of α-Tricalcium Phosphate. J. Mater. Sci. 2002, 37, 963–969. [Google Scholar] [CrossRef]

- He, Z.; Zhai, Q.; Hu, M.; Cao, C.; Wang, J.; Yang, H.; Li, B. Bone Cements for Percutaneous Vertebroplasty and Balloon Kyphoplasty: Current Status and Future Developments. J. Orthop. Transl. 2015, 3, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Rabiee, S.M.; Baseri, H. Prediction of the Setting Properties of Calcium Phosphate Bone Cement. Comput. Intell. Neurosci. 2012, 2012, 809235. [Google Scholar] [CrossRef]

- Freitas, C.M.P.; Coimbra, J.S.R.; Souza, V.G.L.; Sousa, R.C.S. Structure and Applications of Pectin in Food, Biomedical, and Pharmaceutical Industry: A Review. Coatings 2021, 11, 922. [Google Scholar] [CrossRef]

- Singhal, S.; Swami Hulle, N.R. Citrus Pectins: Structural Properties, Extraction Methods, Modifications and Applications in Food Systems—A Review. Appl. Food Res. 2022, 2, 100215. [Google Scholar] [CrossRef]

- Tho, I.; Arne Sande, S.; Kleinebudde, P. Cross-Linking of Amidated Low-Methoxylated Pectin with Calcium during Extrusion/Spheronisation: Effect on Particle Size and Shape. Chem. Eng. Sci. 2005, 60, 3899–3907. [Google Scholar] [CrossRef]

- Ginebra, M.-P.; Montufar, E.B. Cements as Bone Repair Materials. In Bone Repair Biomaterials; Elsevier: Amsterdam, The Netherlands, 2019; pp. 233–271. ISBN 978-0-08-102451-5. [Google Scholar]

- Samavedi, S.; Poindexter, L.K.; Van Dyke, M.; Goldstein, A.S. Synthetic Biomaterials for Regenerative Medicine Applications. In Regenerative Medicine Applications in Organ Transplantation; Elsevier: Amsterdam, The Netherlands, 2014; pp. 81–99. ISBN 978-0-12-398523-1. [Google Scholar]

- Dziadek, M.; Dziadek, K.; Salagierski, S.; Drozdowska, M.; Serafim, A.; Stancu, I.-C.; Szatkowski, P.; Kopec, A.; Rajzer, I.; Douglas, T.E.L.; et al. Newly Crosslinked Chitosan- and Chitosan-Pectin-Based Hydrogels with High Antioxidant and Potential Anticancer Activity. Carbohydr. Polym. 2022, 290, 119486. [Google Scholar] [CrossRef]

- Dziadek, M.; Zima, A.; Cichoń, E.; Czechowska, J.; Ślósarczyk, A. Biomicroconcretes Based on the Hybrid HAp/CTS Granules, α-TCP and Pectins as a Novel Injectable Bone Substitutes. Mater. Lett. 2020, 265, 127457. [Google Scholar] [CrossRef]

- Pańtak, P.; Cichoń, E.; Czechowska, J.; Zima, A. Influence of Natural Polysaccharides on Properties of the Biomicroconcrete-Type Bioceramics. Materials 2021, 14, 7496. [Google Scholar] [CrossRef]

- Gerhardt, L.-C.; Boccaccini, A.R. Bioactive Glass and Glass-Ceramic Scaffolds for Bone Tissue Engineering. Materials 2010, 3, 3867–3910. [Google Scholar] [CrossRef] [PubMed]

- Moreno, D.; Vargas, F.; Ruiz, J.; López, M.E. Solid-State Synthesis of Alpha Tricalcium Phosphate for Cements Used in Biomedical Applications. Boletín De La Soc. Española De Cerámica Y Vidr. 2020, 59, 193–200. [Google Scholar] [CrossRef]

- Kokubo, T.; Takadama, H. How Useful Is SBF in Predicting in Vivo Bone Bioactivity? Biomaterials 2006, 27, 2907–2915. [Google Scholar] [CrossRef] [PubMed]

- Czechowska, J.; Zima, A.; Siek, D.; Ślósarczyk, A. Influence of Sodium Alginate and Methylcellulose on Hydrolysis and Physicochemical Properties of α-TCP Based Materials. Ceram. Int. 2018, 44, 6533–6540. [Google Scholar] [CrossRef]

- Ma, X.; Wang, W.; Wang, D.; Ding, T.; Ye, X.; Liu, D. Degradation Kinetics and Structural Characteristics of Pectin under Simultaneous Sonochemical-Enzymatic Functions. Carbohydr. Polym. 2016, 154, 176–185. [Google Scholar] [CrossRef] [PubMed]

- Klinchongkon, K.; Khuwijitjaru, P.; Adachi, S. Degradation Kinetics of Passion Fruit Pectin in Subcritical Water. Biosci. Biotechnol. Biochem. 2017, 81, 712–717. [Google Scholar] [CrossRef] [PubMed]

- Xiong, B.; Loss, R.D.; Shields, D.; Pawlik, T.; Hochreiter, R.; Zydney, A.L.; Kumar, M. Polyacrylamide Degradation and Its Implications in Environmental Systems. NPJ Clean Water 2018, 1, 17. [Google Scholar] [CrossRef]

- Nabavizadeh, M.; Moazami, F.; Gholami, A.; Mehrabi, V.; Ghahramani, Y. Cytotoxic Effect of Nano Fast Cement and ProRoot Mineral Trioxide Aggregate on L-929 Fibroblast Cells: An In Vitro Study. J. Dent. 2022, 23, 13–19. [Google Scholar] [CrossRef]

- Reza, F.; Omar, N.; Mahshim, N. Physical Properties and Cytotoxicity Comparison of Experimental Gypsum-Based Biomaterials with Two Current Dental Cement Materials on L929 Fibroblast Cells. J. Conserv. Dent. 2013, 16, 331. [Google Scholar] [CrossRef]

| Label | Powder Phase | Liquid Phase | L/P [g/g] |

|---|---|---|---|

| Control | α-TCP | 2 wt.% Na2HPO4 solution in distilled water | 0.45 |

| C_ST | α-TCP + 3.0 wt.% sago starch modified PAAM | ||

| C_NEEM | α-TCP + 3.0 wt.% neem flower modified PAAM | ||

| C_RP | α-TCP + 3.0 wt.% rambutan peel modified PAAM | ||

| C_CP | α-TCP + 3.0 wt.% citrus pectin |

| Material | 7 Days in Air | 7 Days in SBF | ||

|---|---|---|---|---|

| α-TCP, wt.% | Hydroxyapatite, wt.% | α-TCP, wt.% | Hydroxyapatite, wt.% | |

| Control | 86 ± 1 | 14 ± 1 | 2 ± 1 | 98 ± 1 |

| C_ST | 90 ± 1 | 10 ± 1 | 5 ± 1 | 95 ± 1 |

| C_NEEM | 88 ± 1 | 12 ± 1 | 4 ± 1 | 96 ± 1 |

| C_RP | 86 ± 1 | 14 ± 1 | 4 ± 1 | 96 ± 1 |

| C_CP | 88 ± 1 | 12 ± 1 | 3 ± 1 | 97 ± 1 |

| Material | Initial Setting Time, min | Final Setting Time, min |

|---|---|---|

| Control | 6.0 ± 0.5 | 14.0 ± 1.0 |

| C_ST | 2.5 ± 1.0 | 10.0 ± 1.5 |

| C_NEEM | 3.0 ± 1.0 | 11.5 ± 0.5 |

| C_RP | 3.0 ± 0.5 | 8.0 ± 0.5 |

| C_CP | 12.5 ± 1.0 | 21.0 ± 1.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Czechowska, J.P.; Pańtak, P.; Kowalska, K.J.; Vedaiyan, J.; Balasubramanian, M.; Ganesan, S.M.; Kwiecień, K.; Pamuła, E.; Kandaswamy, R.; Zima, A. The Influence of Citrus Pectin and Polyacrylamide Modified with Plant-Derived Additives on the Properties of α-TCP-Based Bone Cements. Polymers 2024, 16, 1711. https://doi.org/10.3390/polym16121711

Czechowska JP, Pańtak P, Kowalska KJ, Vedaiyan J, Balasubramanian M, Ganesan SM, Kwiecień K, Pamuła E, Kandaswamy R, Zima A. The Influence of Citrus Pectin and Polyacrylamide Modified with Plant-Derived Additives on the Properties of α-TCP-Based Bone Cements. Polymers. 2024; 16(12):1711. https://doi.org/10.3390/polym16121711

Chicago/Turabian StyleCzechowska, Joanna P., Piotr Pańtak, Kinga J. Kowalska, Jeevitha Vedaiyan, Mareeswari Balasubramanian, Sundara Moorthi Ganesan, Konrad Kwiecień, Elżbieta Pamuła, Ravichandran Kandaswamy, and Aneta Zima. 2024. "The Influence of Citrus Pectin and Polyacrylamide Modified with Plant-Derived Additives on the Properties of α-TCP-Based Bone Cements" Polymers 16, no. 12: 1711. https://doi.org/10.3390/polym16121711

APA StyleCzechowska, J. P., Pańtak, P., Kowalska, K. J., Vedaiyan, J., Balasubramanian, M., Ganesan, S. M., Kwiecień, K., Pamuła, E., Kandaswamy, R., & Zima, A. (2024). The Influence of Citrus Pectin and Polyacrylamide Modified with Plant-Derived Additives on the Properties of α-TCP-Based Bone Cements. Polymers, 16(12), 1711. https://doi.org/10.3390/polym16121711