Influence of Yarn and Fabric Properties on Mechanical Behavior of Polymer Materials and Its Retention over Time

Abstract

:1. Introduction

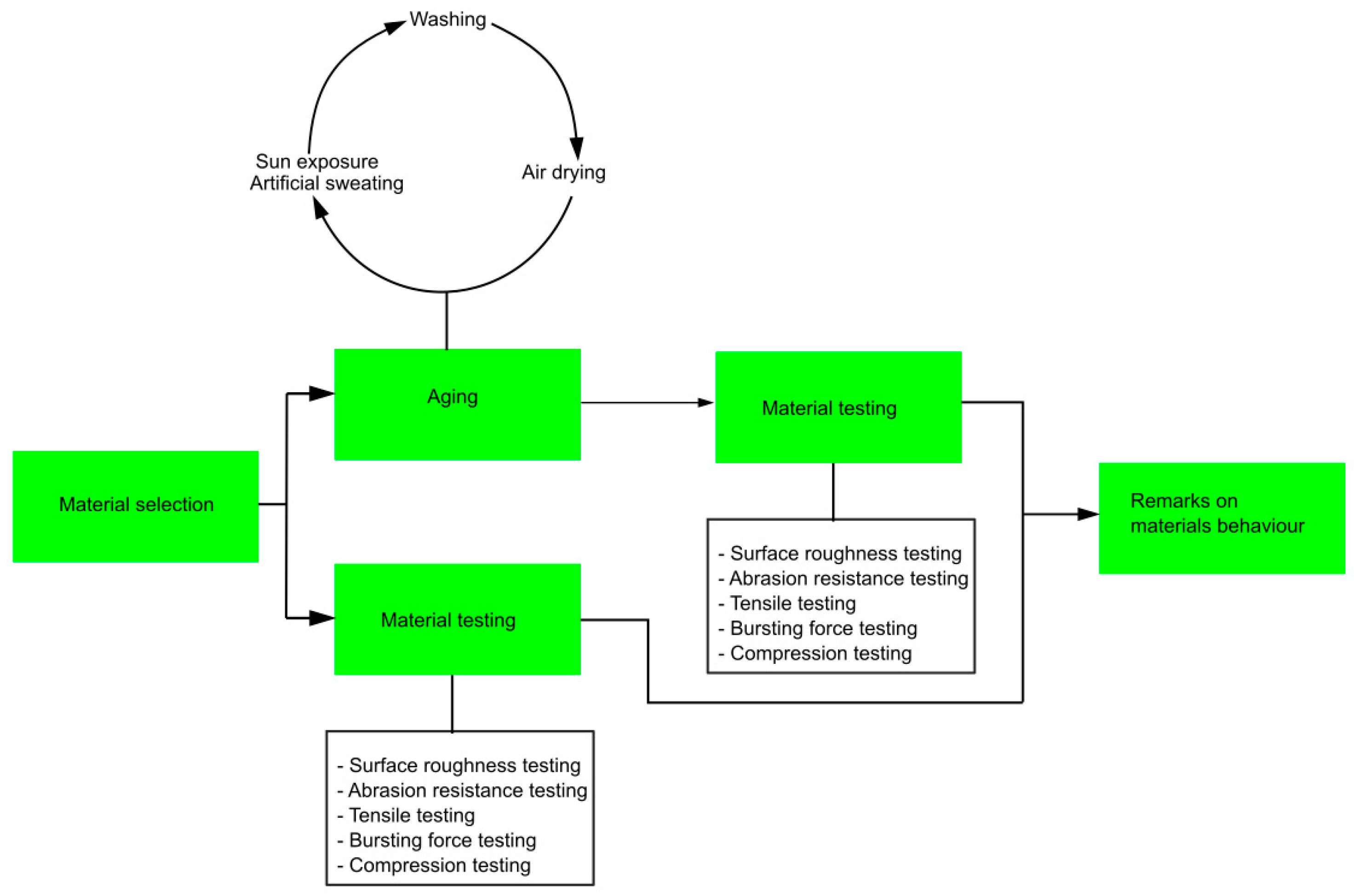

2. Materials and Methods

2.1. Materials

2.2. Methods of Measurement

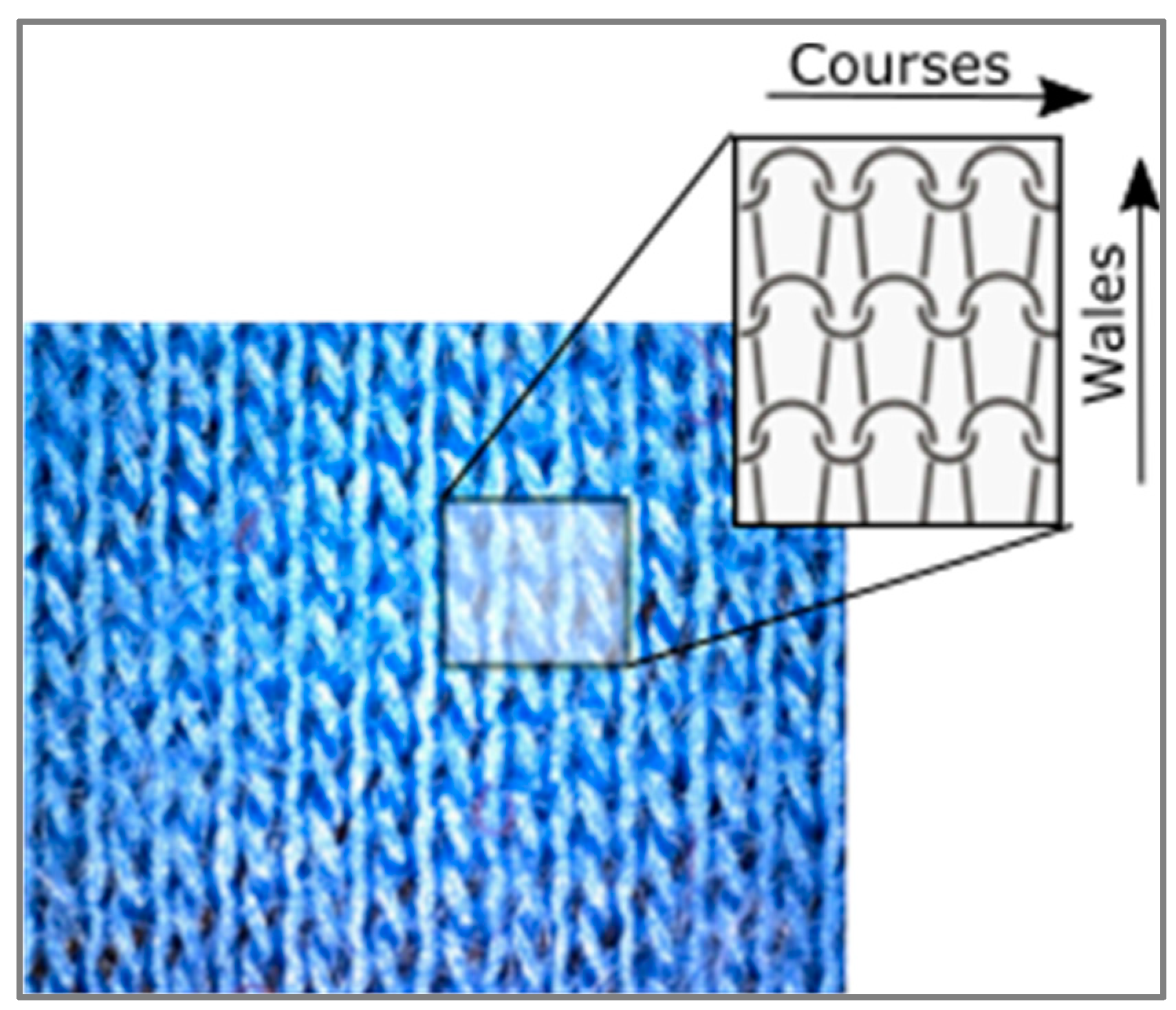

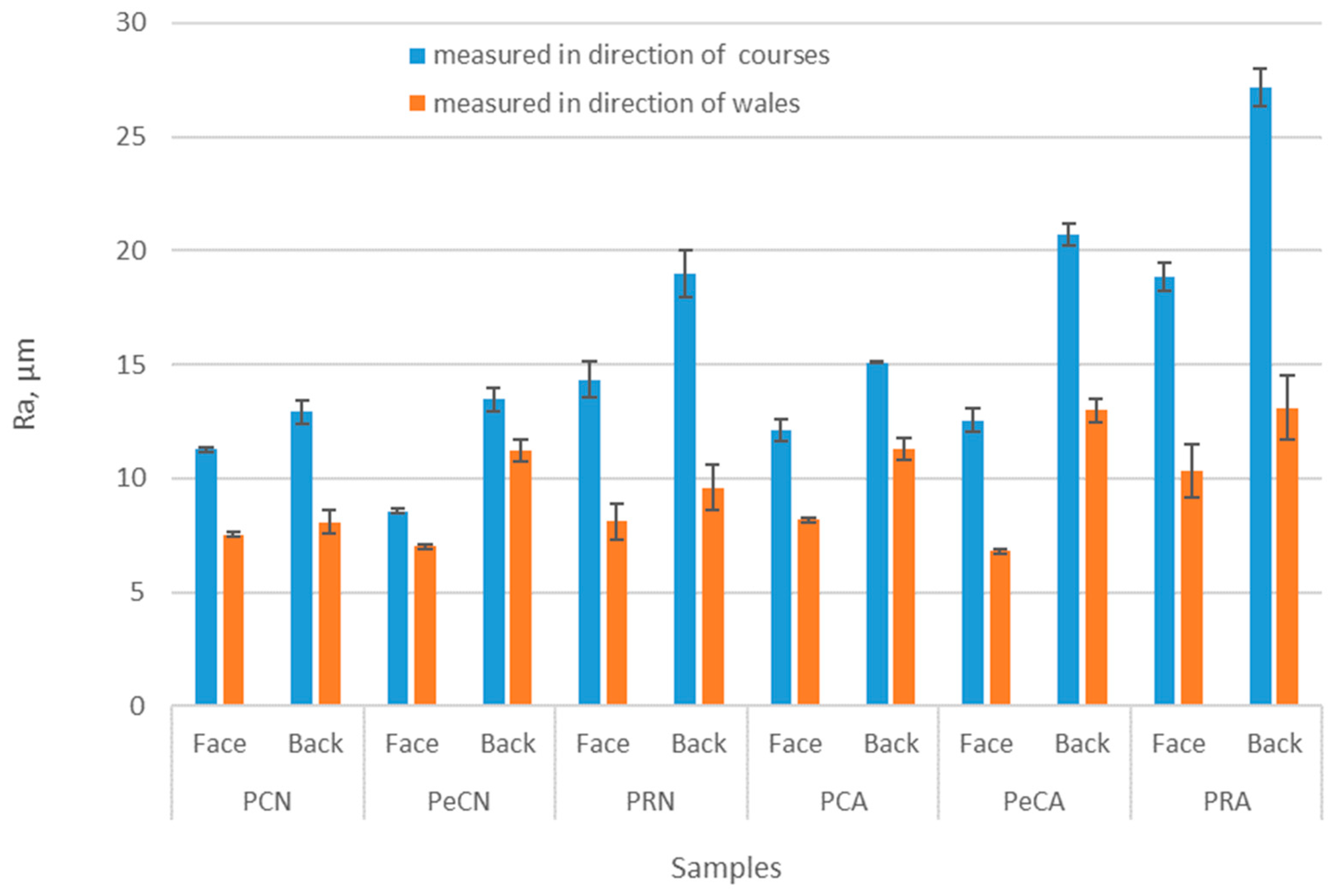

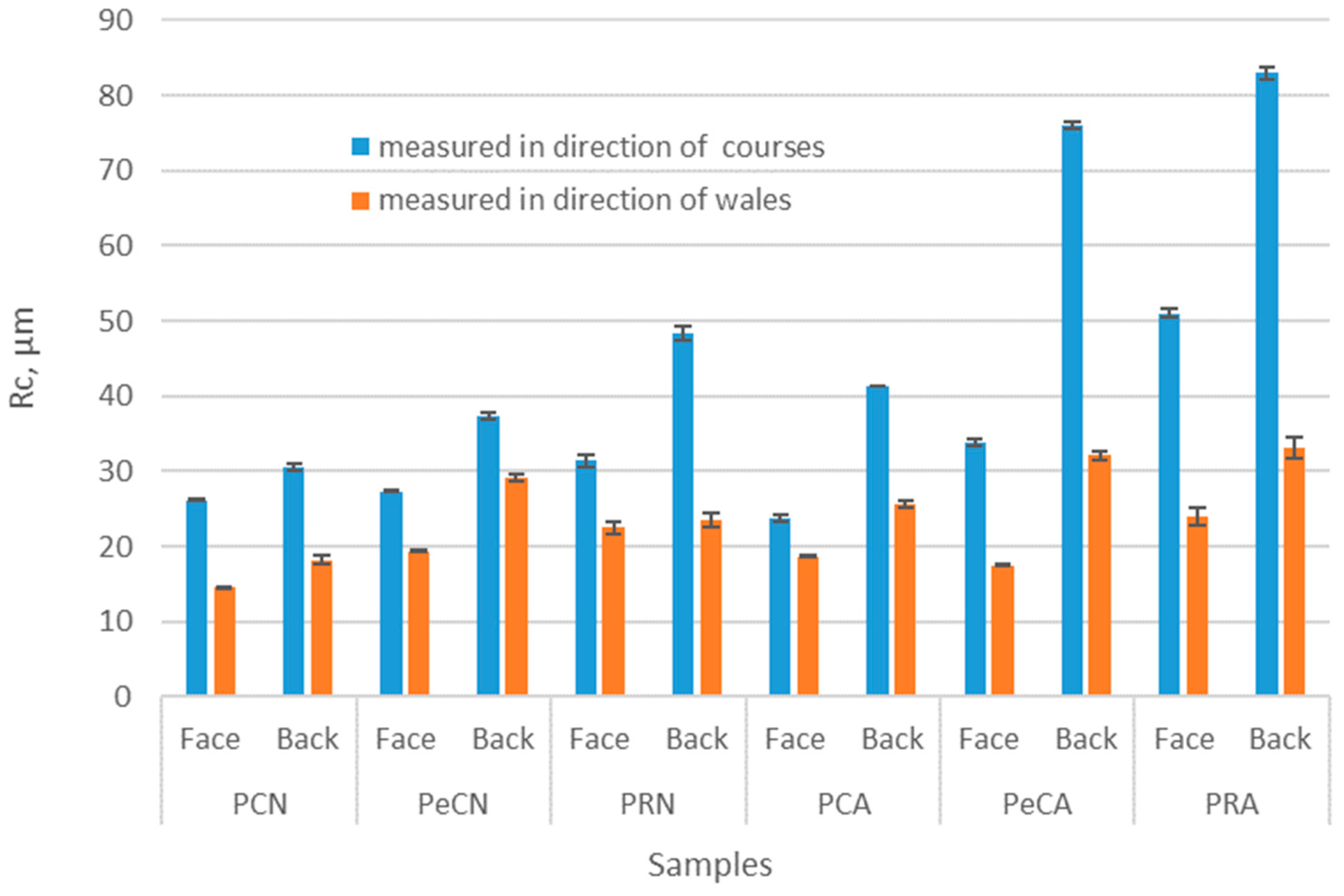

2.2.1. Surface Roughness Testing

- Mean height of profile elements (Rc), and

- Arithmetical mean deviation of assessed profile (Ra).

2.2.2. Abrasion Resistance Testing

2.2.3. Tensile Testing

2.2.4. Bursting Force Testing

2.2.5. Compression Testing

3. Results and Discussion

3.1. Results of Surface Roughness Testing

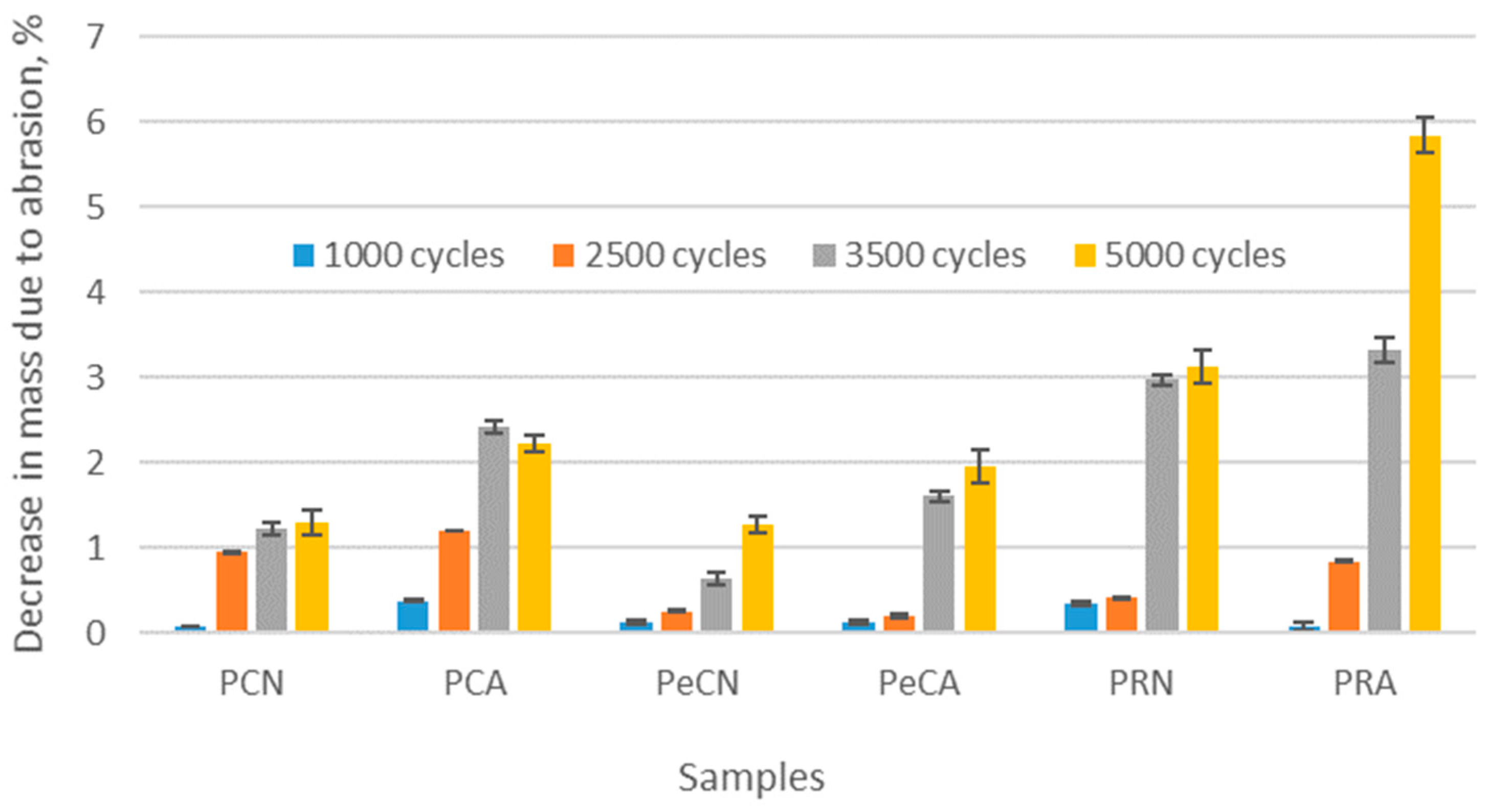

3.2. Results of Abrasion Resistance

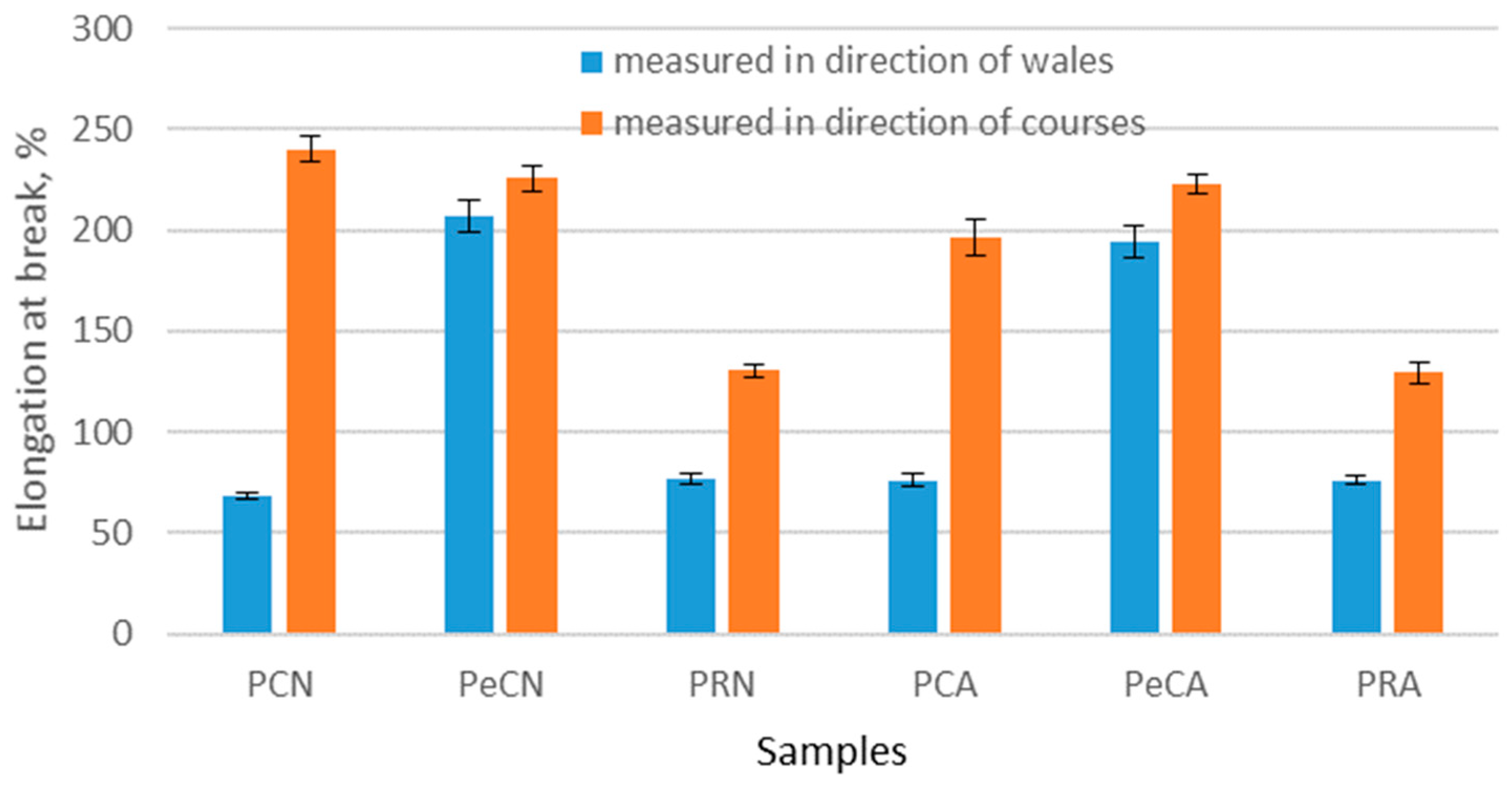

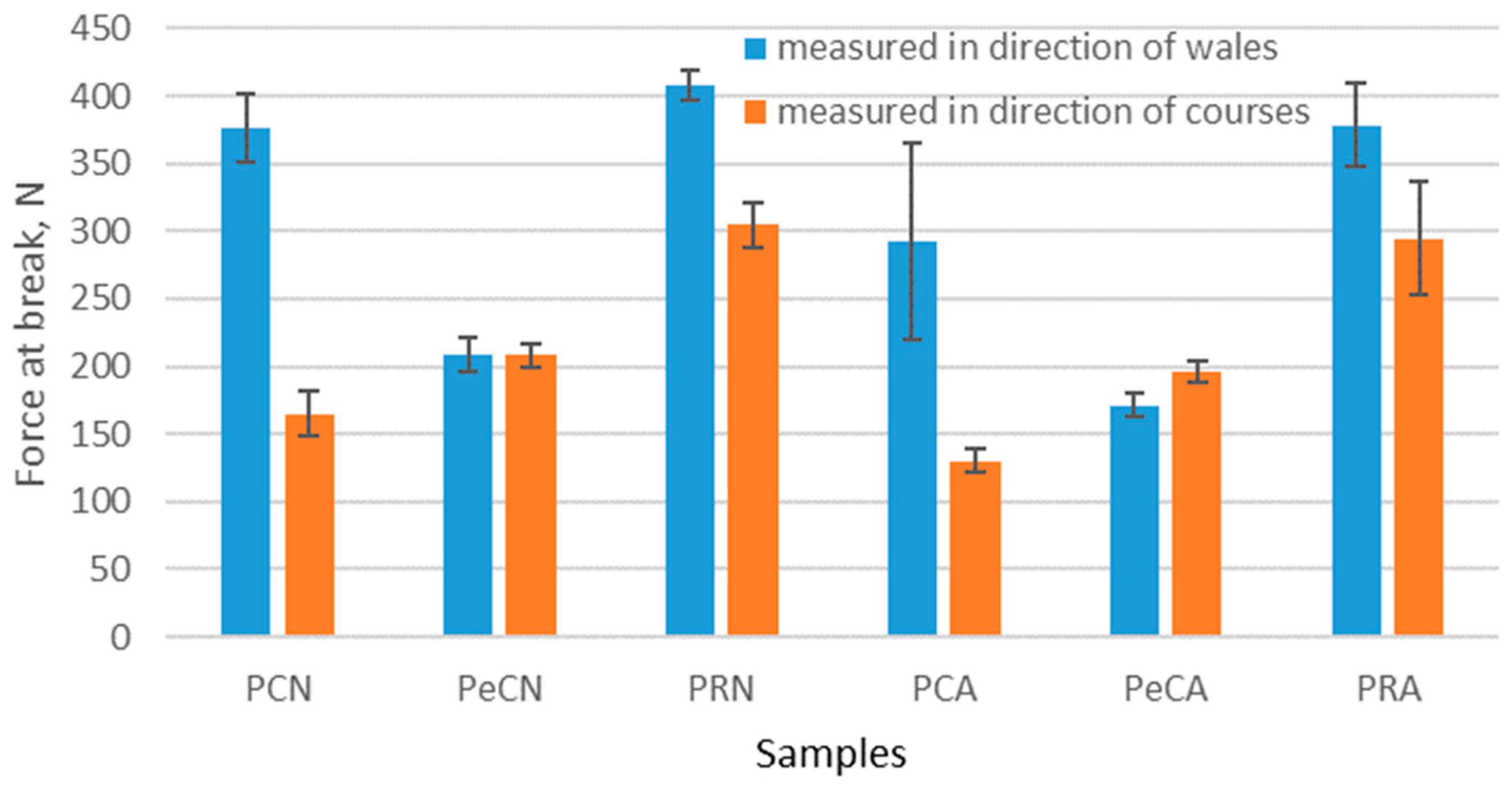

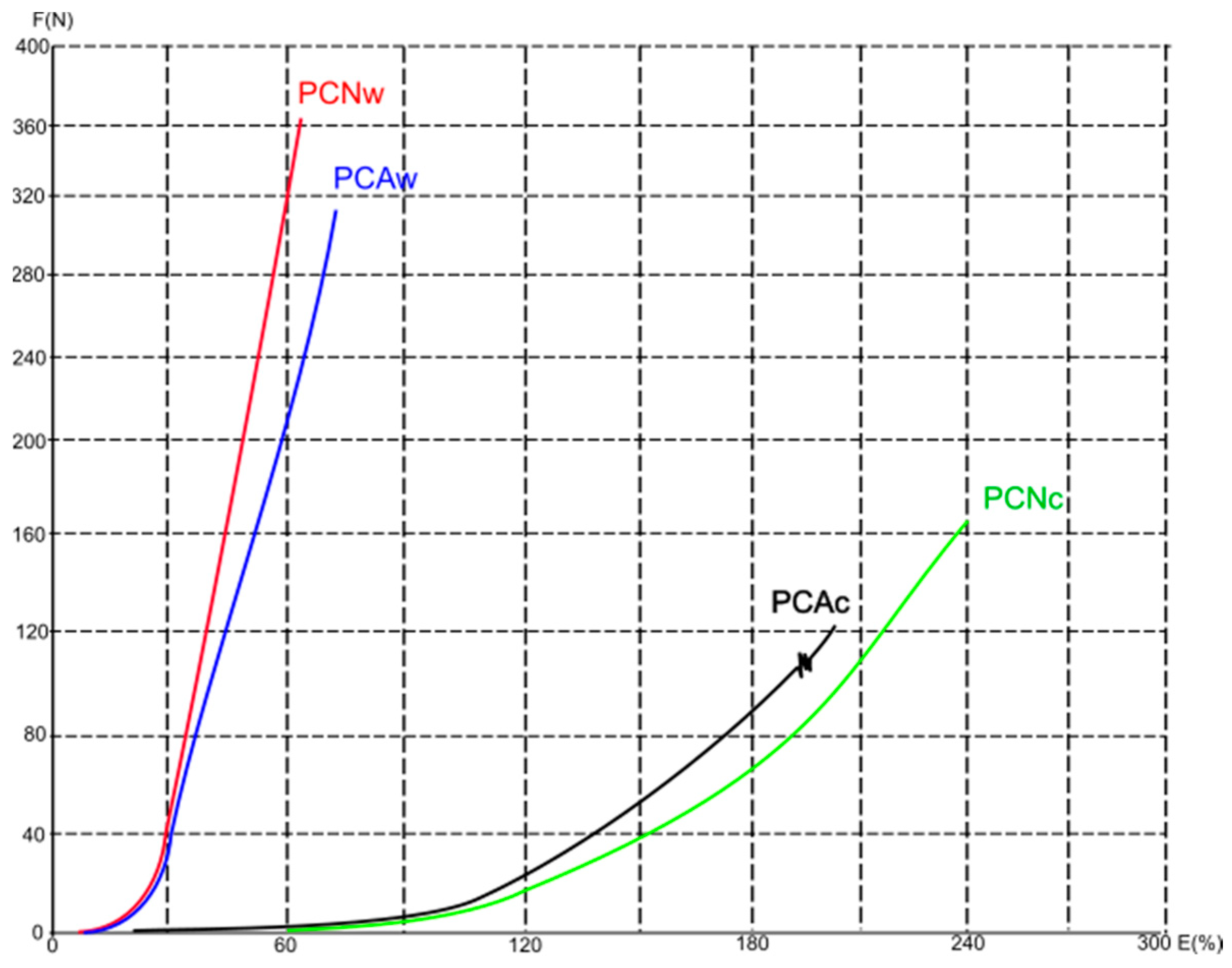

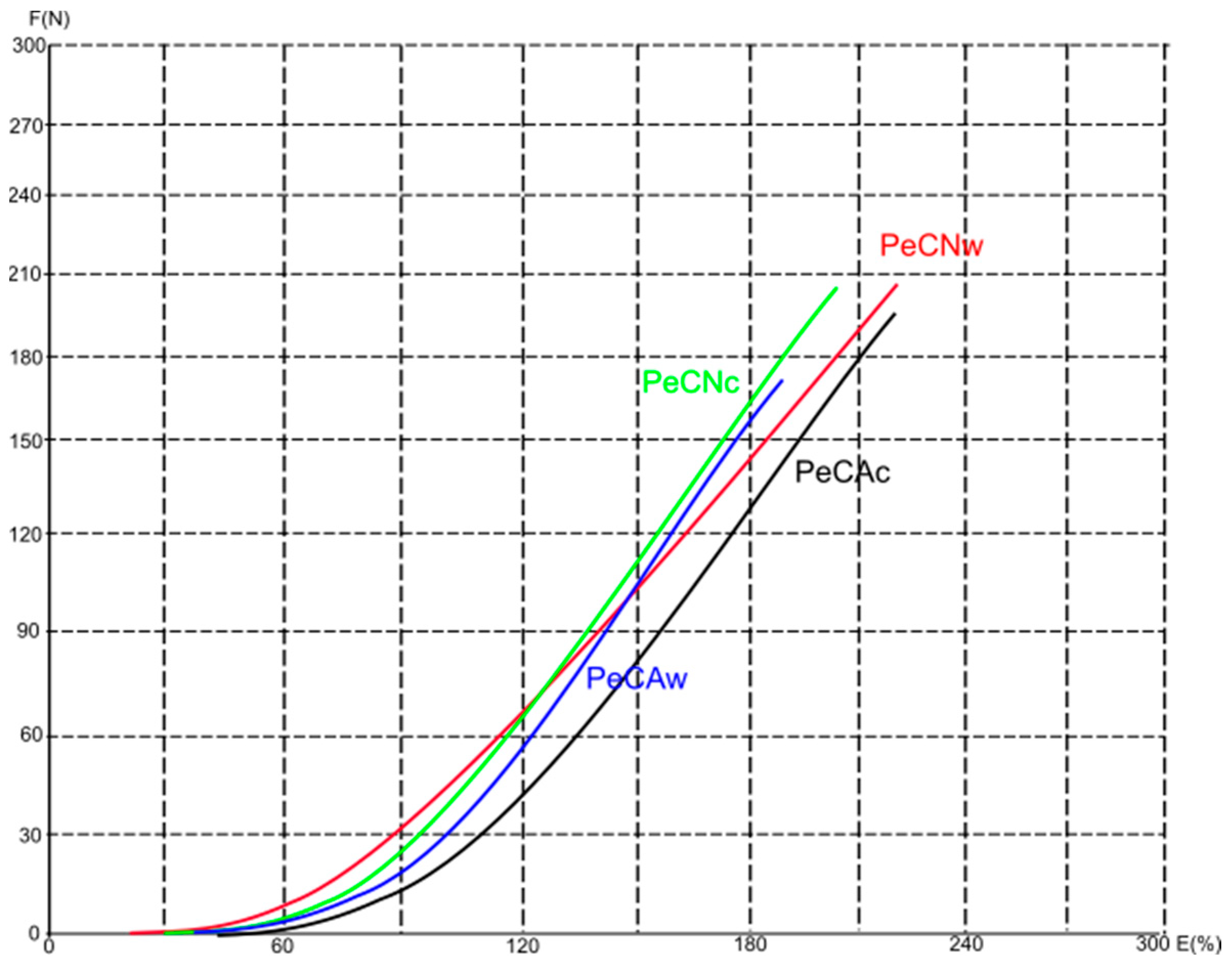

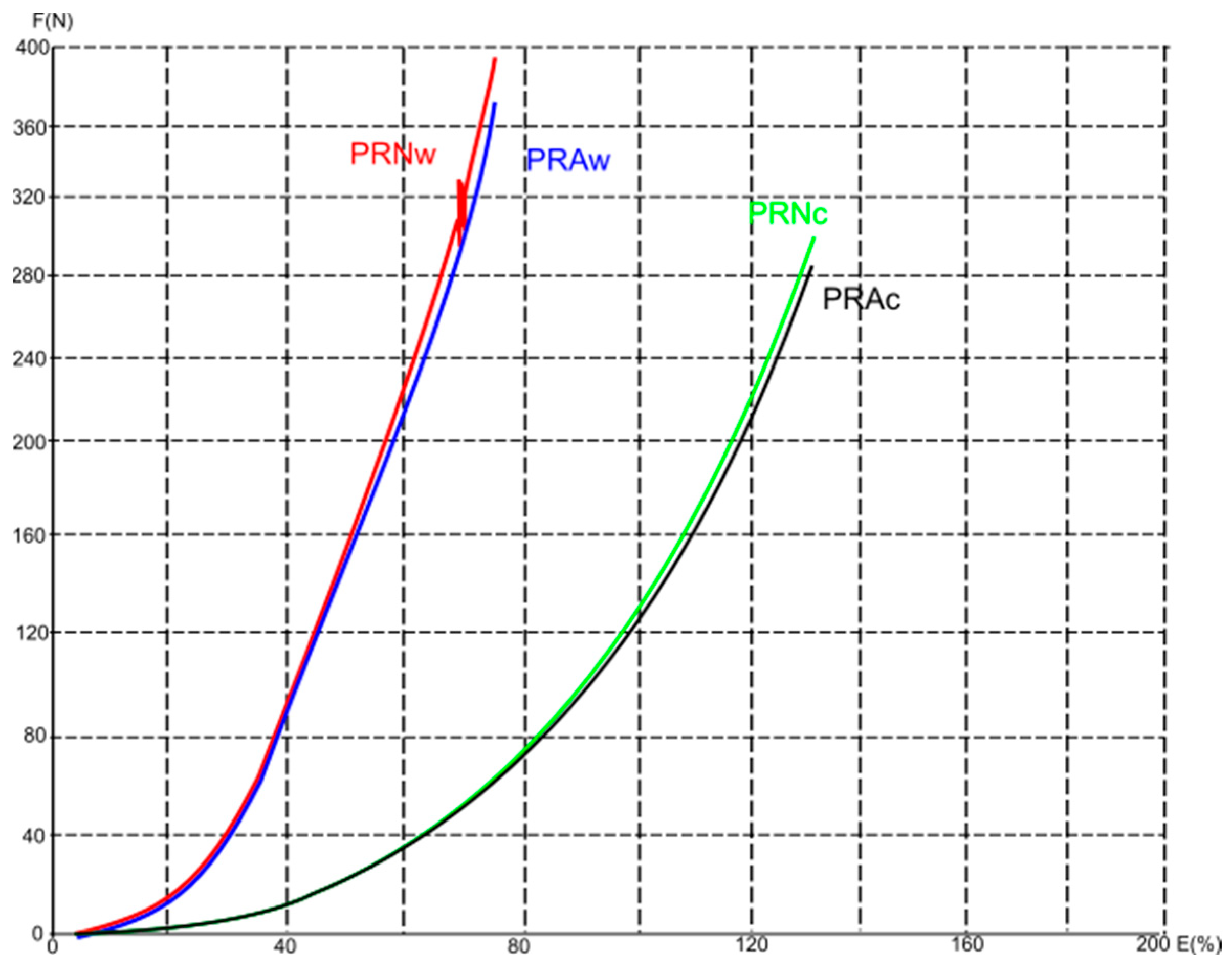

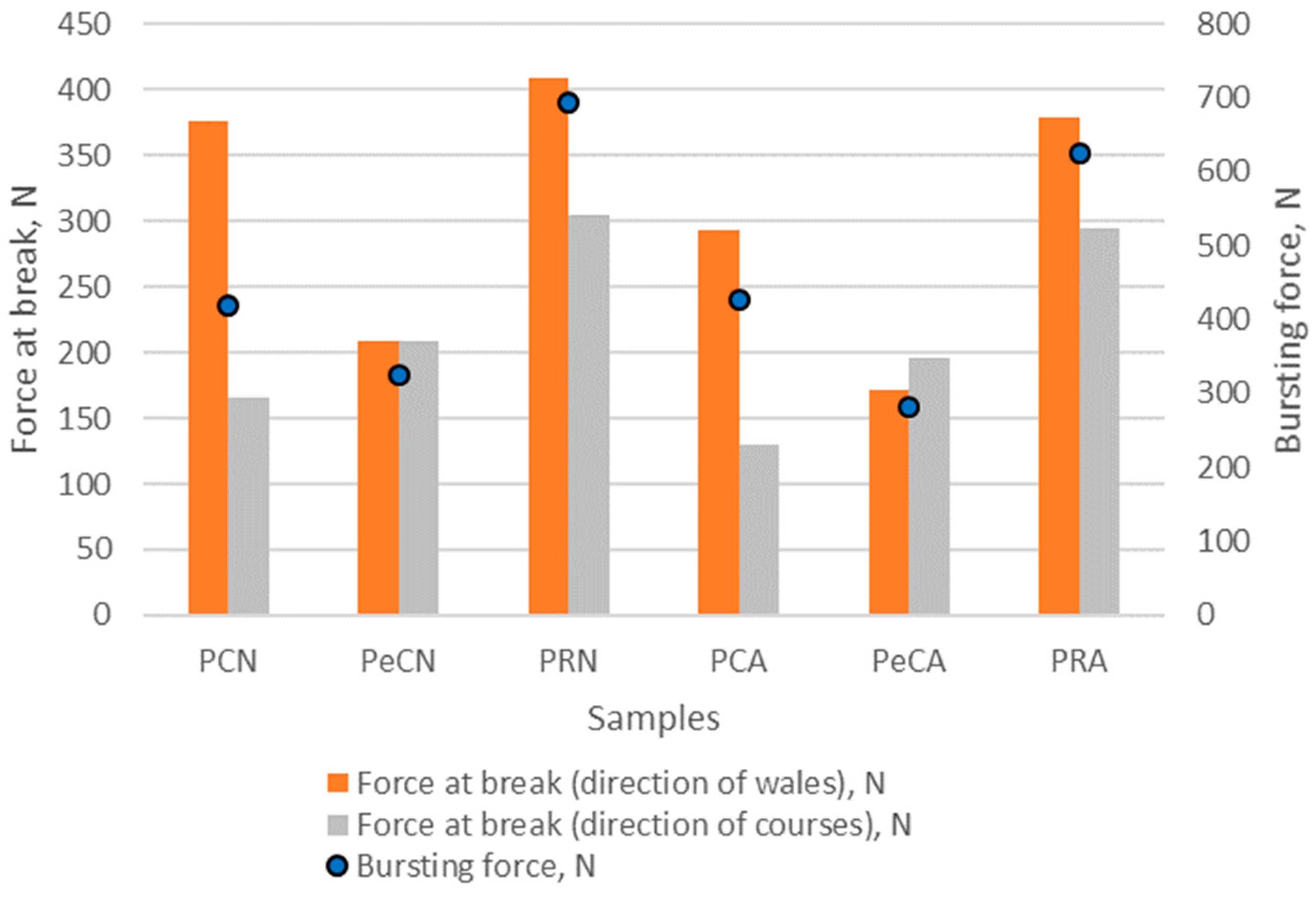

3.3. Results of Tensile Testing

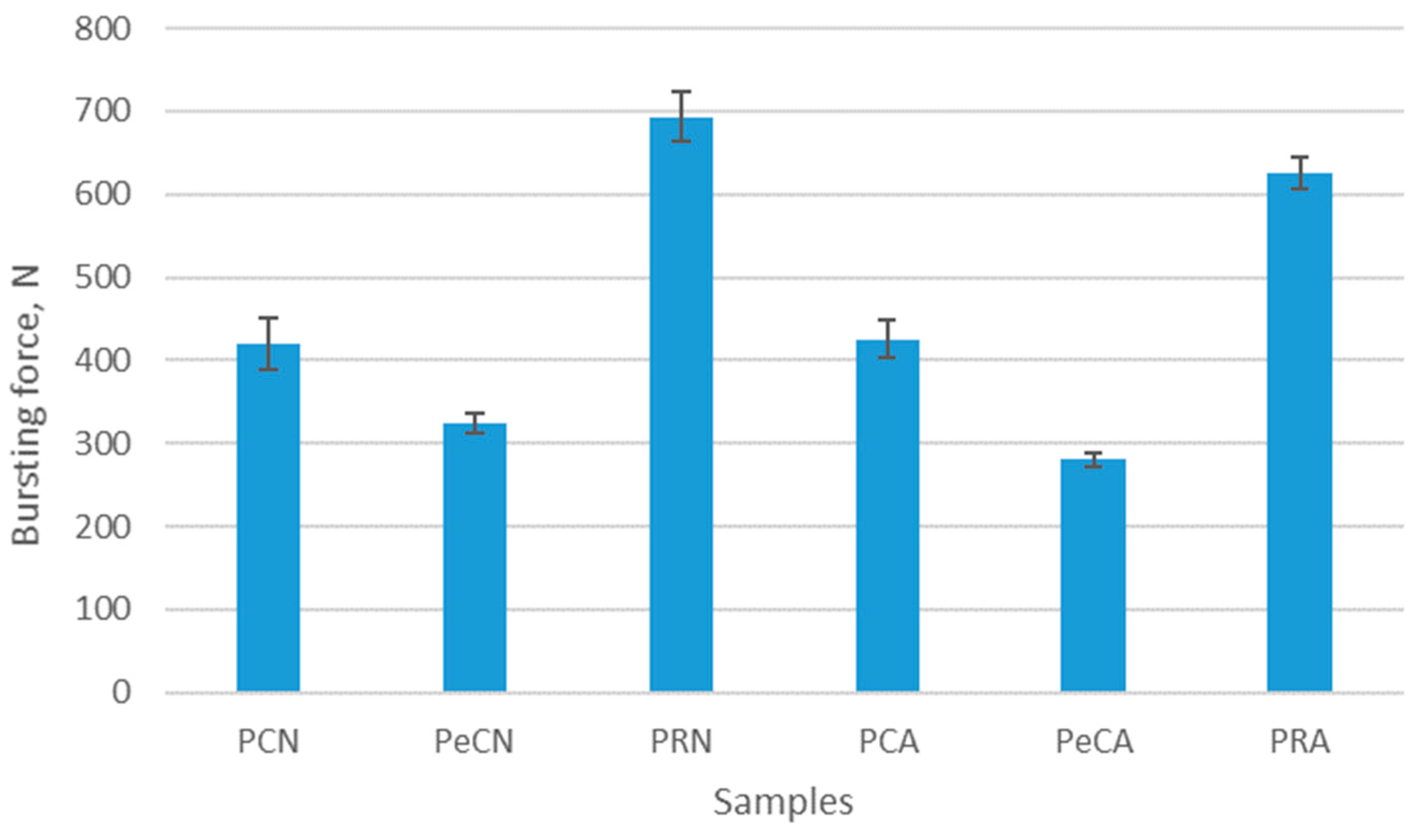

3.4. Results of Bursting Force Testing

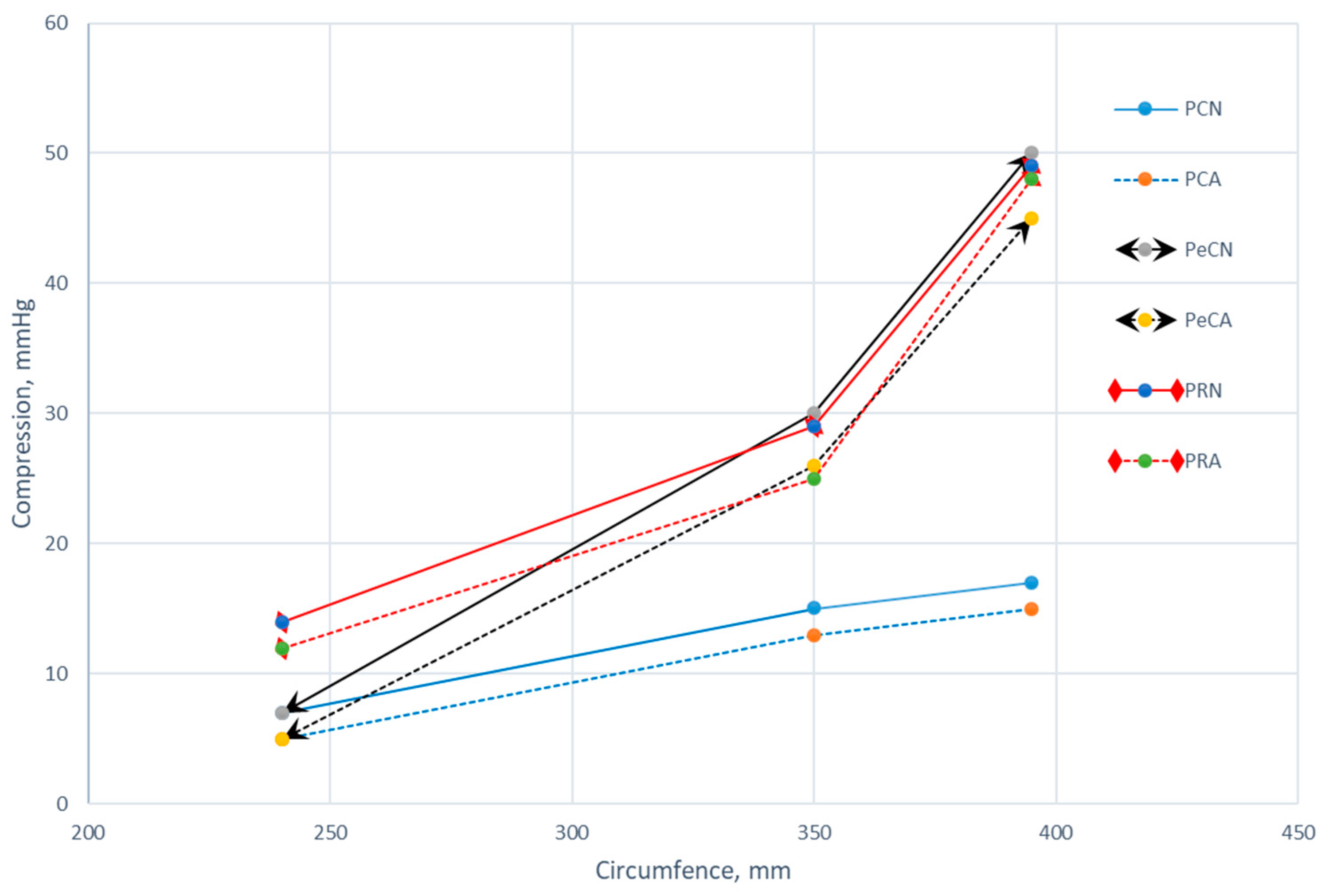

3.5. Results of Compression Testing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Militky, J.; Mazal, M. Image Analysis Method of Surface Roughness Evaluation. Int. J. Cloth. Sci. Technol. 2007, 19, 186–193. [Google Scholar] [CrossRef]

- Mooneghi, S.A.; Saharkhiz, S.; Varkiani, S.M.H. Surface Roughness Evaluation of Textile Fabrics: A Literature Review. J. Eng. Fiber. Fabrics 2014, 9, 1–18. [Google Scholar] [CrossRef]

- Salopek Čubrić, I.; Čubrić, G.; Majumdar, A. Sensory attributes of knitted fabrics intended for next-to-skin clothing. J. Text. Inst. 2023, 114, 757–762. [Google Scholar] [CrossRef]

- Čubrić, I.S.; Čubrić, G.; Perry, P. Assessment of Knitted Fabric Smoothness and Softness Based on Paired Comparison. Fibers Polym. 2019, 20, 656–667. [Google Scholar] [CrossRef]

- Chae, Y. Color appearance shifts depending on surface roughness, illuminants, and physical colors. Sci. Rep. 2022, 12, 1371. [Google Scholar] [CrossRef] [PubMed]

- Lee, S. Study of superhydrophobicity according to surface structure of knitted fabrics. Text. Res. J. 2022, 92, 4357–4373. [Google Scholar] [CrossRef]

- Šaravanja, A.; Dekanić, T.; Pušić, T.; Kaurin, T. Primary sensory indices of polyester fabric exposed to aging. In Proceedings of the 5th Scientific–Professional Symposium TZG 2023, Zagreb, Croatia, 26 January 2023. [Google Scholar]

- Mikučioniene, D.; Čepukone, L.; Milašiene, D. Investigation on mechanical and thermal properties of knits from peat fibers and their combination with other natural fibers. Text. Res. J. 2018, 88, 1660–1670. [Google Scholar] [CrossRef]

- Balci Kilic, G.; Okur, A. Effect of yarn characteristics on surface properties of knitted fabrics. Text. Res. J. 2019, 89, 2476–2489. [Google Scholar] [CrossRef]

- Tomljenović, A.; Skenderi, Z.; Kraljević, I. Evaluation of usage quality and thermal comfort of male socks. In Proceedings of the 8th International Textile Conference, Tirana, Albania, 18 November 2018. [Google Scholar]

- Gupta, S.K.; Goswami, K.K.; Majumdar, A. Optimization of durability of Persian hand-knotted wool carpets by using desirability functions. Text. Res. J. 2018, 88, 89–98. [Google Scholar] [CrossRef]

- Jabbar, A.; Palacios-Marín, A.V.; Ghanbarzadeh, A.; Yang, D.; Tausif, M. Impact of conventional and modified ring-spun yarn structures on the generation and release of fragmented fibers (microfibers) during abrasive wear and laundering. Text. Res. J. 2023, 93, 1099–1112. [Google Scholar] [CrossRef]

- Shi, Q.Q.; Jiao, J.; Shin, K.; Chow, H.K.; Lau, N. Study of cyclists’ skin deformation for compression skinsuit design. Text. Res. J. 2023, 93, 4548–4561. [Google Scholar] [CrossRef]

- Hakala, T.; Puolakka, A.; Nousiainen, P.; Vuorela, T.; Vanhala, J. Application of air bladders for medical compression hosieries. Text. Res. J. 2018, 88, 2169–2181. [Google Scholar] [CrossRef]

- Lozo, M.; Lovričević, I.; Pavlović, Ž.; Vrljičak, Z. Designing compression of preventive compression stockings. J. Eng. Fiber. Fabrics 2021, 16, 1–12. [Google Scholar] [CrossRef]

- Liu, T.; Gao, Y.; Fan, W.; Gao, X.; Ma, J. Predictions of the axial tensile property of the unidirectional composite influenced by microfiber breakage defects. Text. Res. J. 2022, 92, 15–29. [Google Scholar] [CrossRef]

- Xie, Z.; Li, J.; Liu, Y.; Liu, K.; Li, W. Effect of structural parameters on tensile properties of alumina fabrics. Text. Res. J. 2023, 93, 2095–2210. [Google Scholar] [CrossRef]

- Shi, Y.; Liu, R.; Wong, C.; Ye, C.; Lv, J. Prediction of tensile behavior of compression therapeutic biomedical materials by mesoscale laid-in loop model. Polymer 2024, 302, 127094. [Google Scholar] [CrossRef]

- Huang, Y.; Song, X. Study on an innovative knitting technology of spacer fabrics and the low-velocity impact properties of its composites. Text. Res. J. 2023, 93, 1142–1152. [Google Scholar] [CrossRef]

- Li, X.; Jiang, G.; Nie, X.; Ma, P.; Gao, Z. Knitting Technologies And Tensile Properties Of A Novel Curved Flat-Knitted Three-Dimensional Spacer Fabrics. Autex Res. J. 2015, 15, 191–197. [Google Scholar] [CrossRef]

- Cionek, C.A.; Nunes, C.; Freitas, A.; Homem, N.; Muniz, E.; Amorim, T. Degradation study of polyester fiber in swimming pool water. Text. Res. J. 2021, 91, 51–61. [Google Scholar] [CrossRef]

- Sørensen, L.; Groven, A.S.; Hovsbakken, I.-A.; Del Puerto, O.; Krause, D.F.; Sarno, A.; Booth, A.M. UV degradation of natural and synthetic microfibers causes fragmentation and release of polymer degradation products and chemical additives. Sci. Total Environ. 2021, 755, 143170. [Google Scholar] [CrossRef]

- Arhant, M.; Le Gall, M.; Le Gac, P.Y.; Davies, P.D. Impact of hydrolytic degradation on mechanical properties of PET—Towards an understanding of microplastics formation. Polym. Degrad. Stab. 2019, 161, 175–182. [Google Scholar] [CrossRef]

- Petrov, A.; Salopek Čubrić, I.; Čubrić, G. Influence of Aging on the Physical Properties of Knitted Polymeric Materials. Polymers 2024, 16, 513. [Google Scholar] [CrossRef]

- Salopek Čubrić, I.; Čubrić, G.; Katić Križmančić, I.; Kovačević, M. Evaluation of Changes in Polymer Material Properties Due to Aging in Different Environments. Polymers 2022, 14, 1682. [Google Scholar] [CrossRef] [PubMed]

- Salopek Čubrić, I.; Čubrić, G.; Potočić Matković, V.M. Behavior of Polymer Materials Exposed to Aging in the Swimming Pool: Focus on Properties That Assure Comfort and Durability. Polymers 2021, 13, 2414. [Google Scholar] [CrossRef] [PubMed]

- Katić Križmančić, I.; Salopek Čubrić, I.; Potočić Matković, V.M.; Čubrić, G. Changes in Mechanical Properties of Fabrics Made of Standard and Recycled Polyester Yarns Due to Aging. Polymers 2023, 15, 4511. [Google Scholar] [CrossRef] [PubMed]

- ISO 3274:1996; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Nominal Characteristics of Contact (stylus) Instruments. International Organization for Standardization: Geneva, Switzerland, 1996.

- ISO 13934-1:2013; Textiles—Tensile Properties of Fabrics—Part 1: Determination of Maximum Force and Elongation at Maximum Force Using the Strip Method. International Organization for Standardization: Geneva, Switzerland, 2013.

- ASTM D3787; Textile Ball Burst Testing. ADMET, Inc.: Norwood, MA, USA, 2020.

- Pušić, T.; Vojnović, B.; Flinčec Grgac, S.; Čurlin, M.; Malinar, R. Particle Shedding from Cotton and Cotton-Polyester Fabrics in the Dry State and in Washes. Polymers 2023, 15, 3201. [Google Scholar] [CrossRef]

| Material Designation | Composition | Yarn Type | Aging |

|---|---|---|---|

| PCN | 100% polyester | conventional yarn | unaged |

| PeCN | 87% polyester + 13% elastane | conventional yarn | unaged |

| PRN | 100% polyester | recycled yarn | unaged |

| PCA | 100% polyester | conventional yarn | aged |

| PeCA | 87% polyester + 13% elastane | conventional yarn | aged |

| PRA | 100% polyester | recycled yarn | aged |

| Direction of Courses | Direction of Wales | |

|---|---|---|

| Mean | 13.2533 | 8.5983 |

| Variance | 12.0555 | 2.4075 |

| Observations | 6 | 6 |

| Pearson Correlation | 0.9277 | 0.8631 |

| Hypothesized Mean Difference | 0 | 0 |

| df | 5 | 5 |

| t Stat | −3.8961 | −3.1228 |

| P(T ≤ t) one-tail | 0.0057 | 0.0131 |

| t Critical one-tail | 2.0150 | 2.0150 |

| P(T ≤ t) two-tail | 0.0114 | 0.0262 |

| t Critical two-tail | 2.5706 | 2.5706 |

| t-Test: Paired Two Sample for Means | |

|---|---|

| Pearson Correlation | 0.9876 |

| Hypothesized Mean Difference | 0 |

| df | 5 |

| t Stat | 3.9908 |

| P(T ≤ t) one-tail | 0.0052 |

| t Critical one-tail | 2.0150 |

| P(T ≤ t) two-tail | 0.0104 |

| t Critical two-tail | 2.5706 |

| t-Test: Paired Two Sample for Means | |

|---|---|

| Pearson Correlation | 0.9972 |

| Hypothesized Mean Difference | 0 |

| df | 8 |

| t Stat | 6.0474 |

| P(T ≤ t) one-tail | 0.0002 |

| t Critical one-tail | 1.8596 |

| P(T ≤ t) two-tail | 0.0003 |

| t Critical two-tail | 2.3060 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salopek Čubrić, I.; Čubrić, G. Influence of Yarn and Fabric Properties on Mechanical Behavior of Polymer Materials and Its Retention over Time. Polymers 2024, 16, 1725. https://doi.org/10.3390/polym16121725

Salopek Čubrić I, Čubrić G. Influence of Yarn and Fabric Properties on Mechanical Behavior of Polymer Materials and Its Retention over Time. Polymers. 2024; 16(12):1725. https://doi.org/10.3390/polym16121725

Chicago/Turabian StyleSalopek Čubrić, Ivana, and Goran Čubrić. 2024. "Influence of Yarn and Fabric Properties on Mechanical Behavior of Polymer Materials and Its Retention over Time" Polymers 16, no. 12: 1725. https://doi.org/10.3390/polym16121725

APA StyleSalopek Čubrić, I., & Čubrić, G. (2024). Influence of Yarn and Fabric Properties on Mechanical Behavior of Polymer Materials and Its Retention over Time. Polymers, 16(12), 1725. https://doi.org/10.3390/polym16121725