Comprehensive Review of Geotechnical Engineering Properties of Recycled Polyethylene Terephthalate Fibers and Strips for Soil Stabilization

Abstract

:1. Introduction

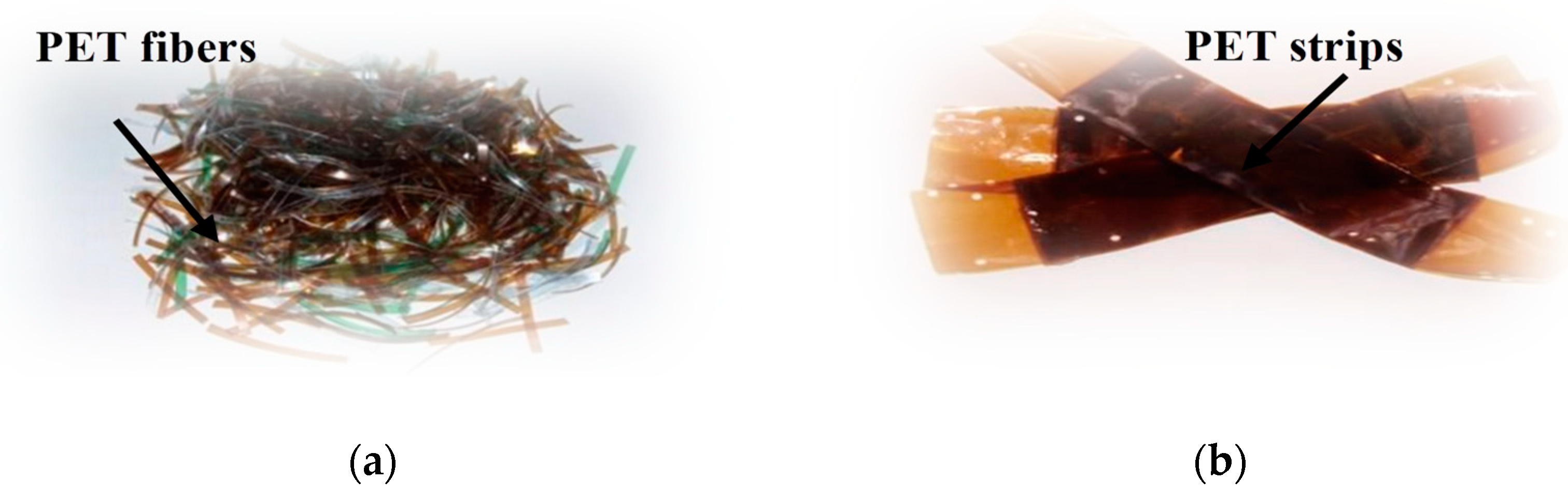

2. Materials and Methods

3. Properties of PET

3.1. Structural Properties of PET

3.2. Thermal, Mechanical, and Physiochemical Properties of PET

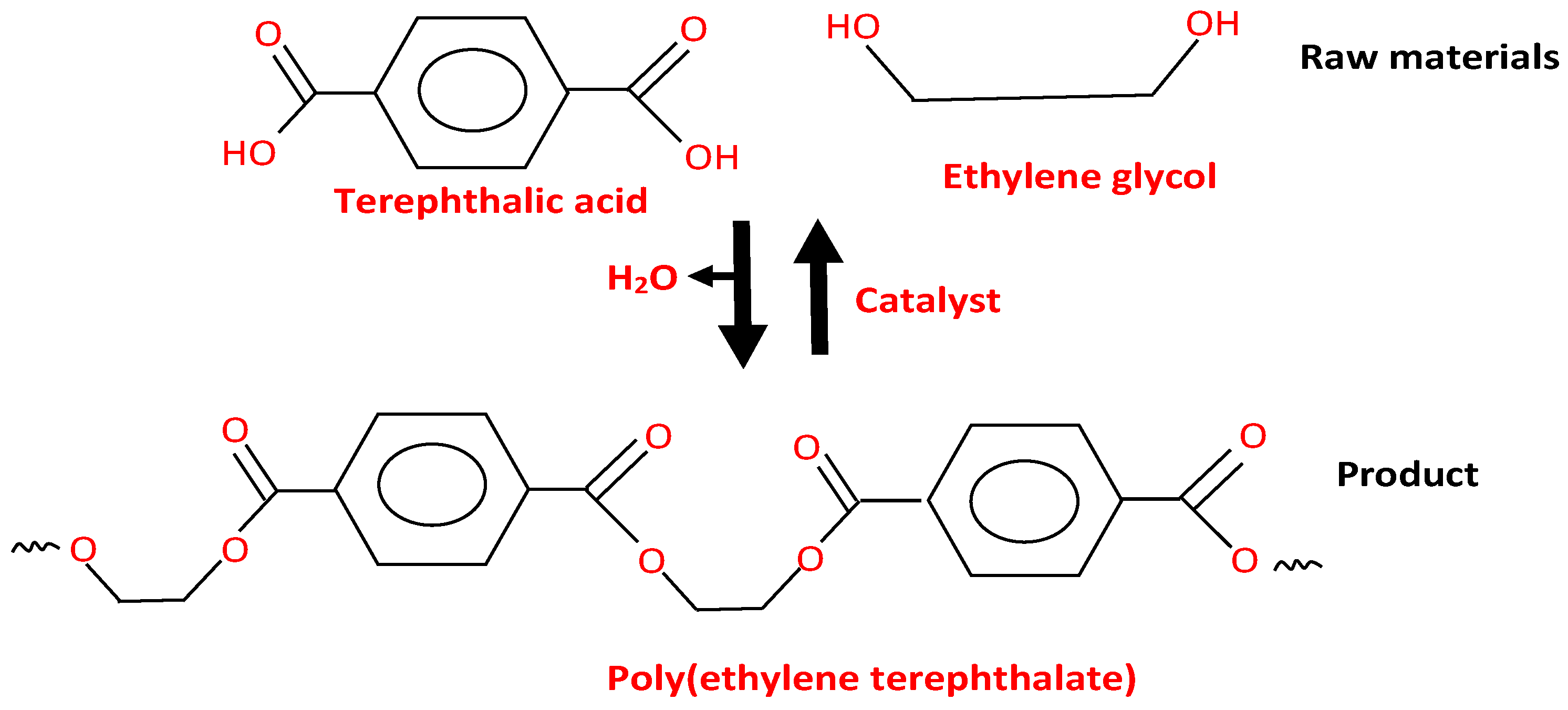

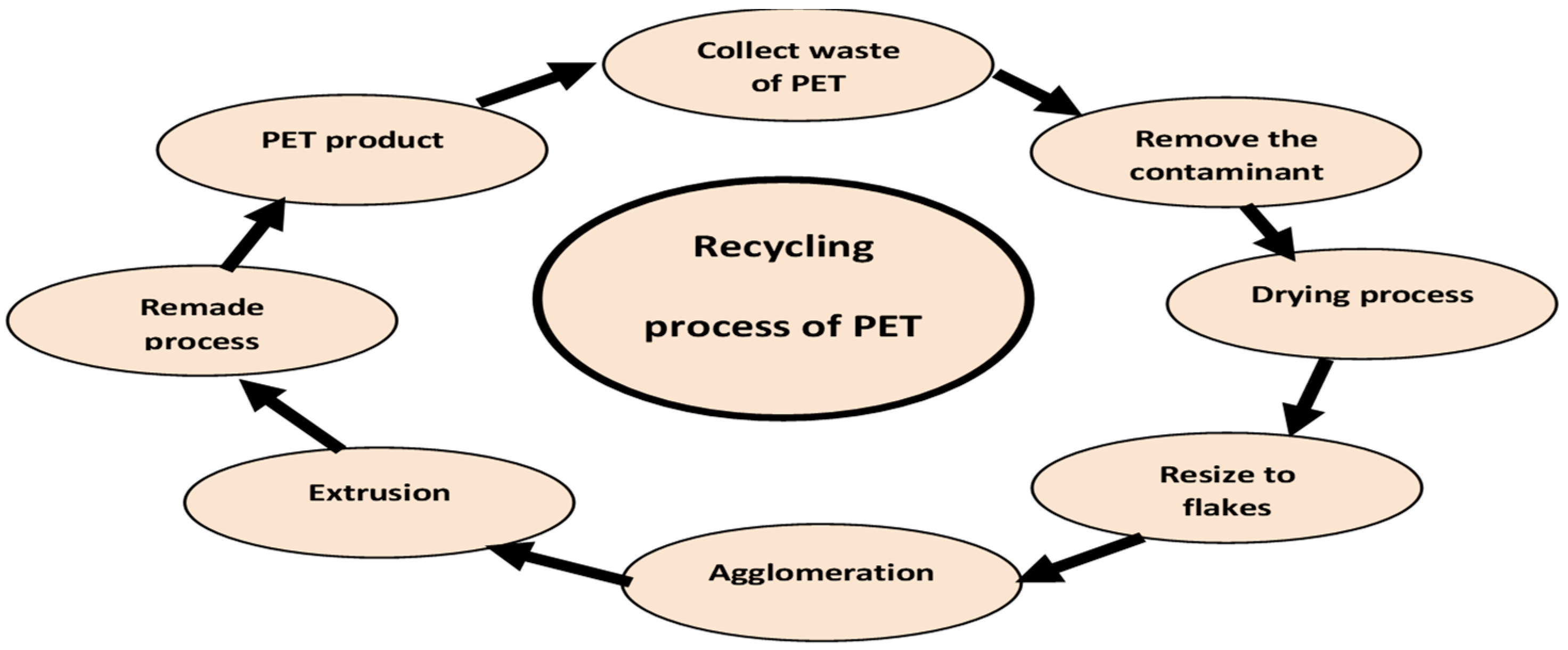

4. Polymerization and Conventional Recycling Process of PET

4.1. Polymerization Process of PET

4.2. Conventional PET Recycling Process

5. Distribution and Placement of Recycled PET in Soil

6. Applications of Recycled PET Fibers in Soil Stabilization

6.1. Influence of Recycled PET Fibers on Soil’s Stress–Strain Characteristics

6.2. Influence of Recycled PET Fibers on Soil’s Liquid, Plastic, and Shrinkage Limits

6.3. Influence of Recycled PET Fibers on Soil’s Dry Density

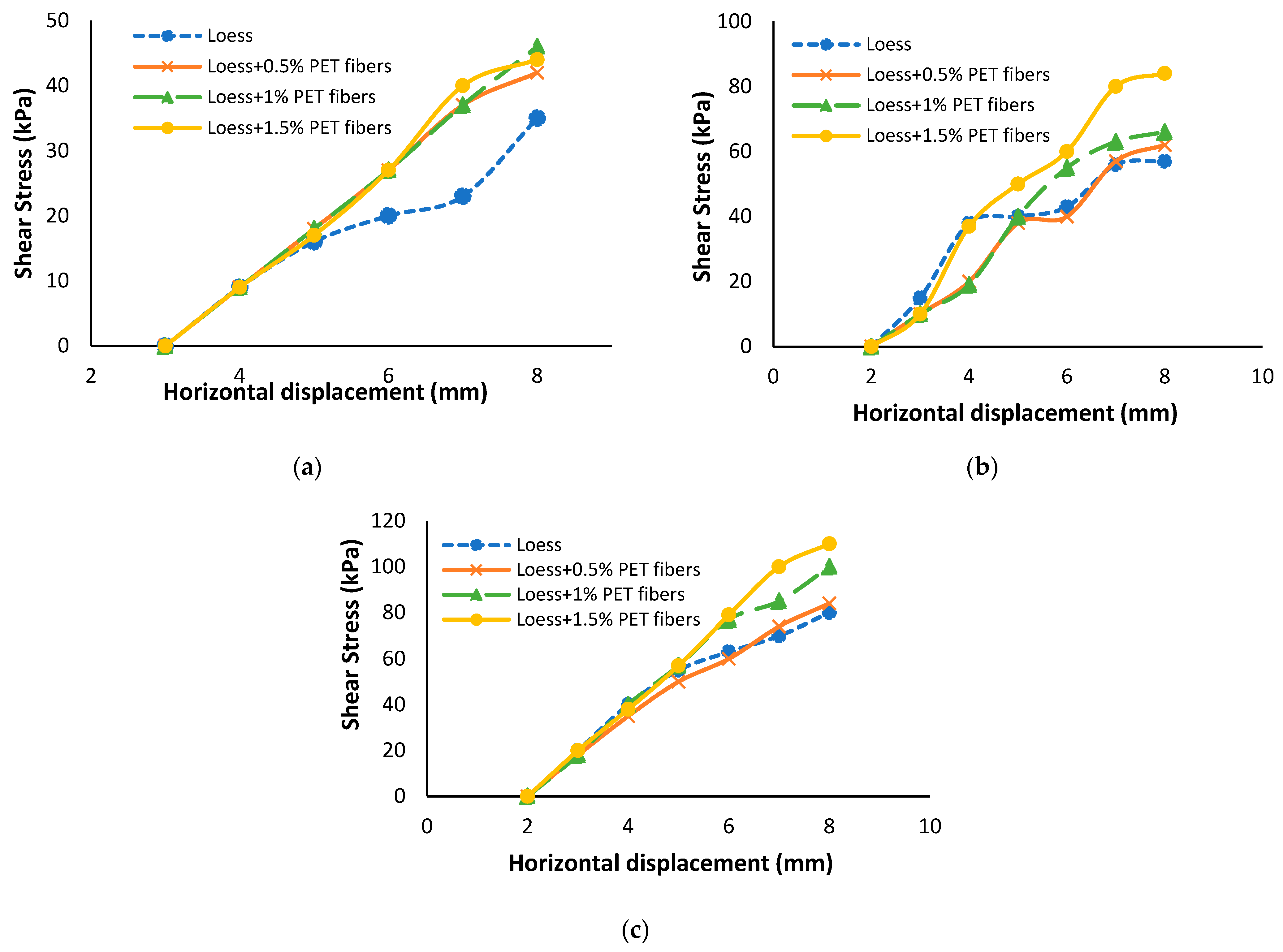

6.4. Influence of Recycled PET Fibers on Soil’s Normal–Shear Stress Characteristics

6.5. Influence of Recycled PET Fibers on Soil’s California Bearing Ratio

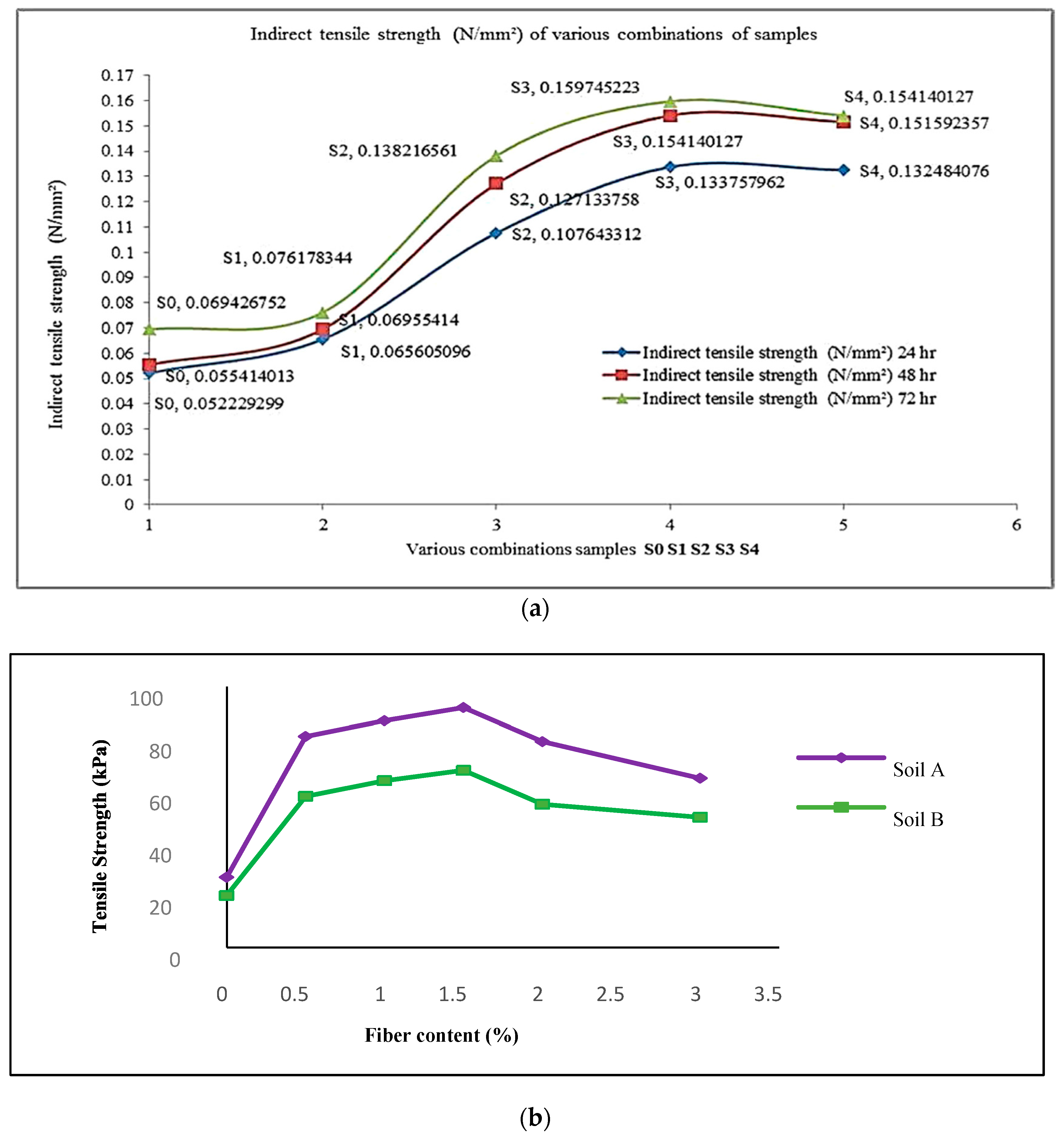

6.6. Influence of Recycled PET Fibers on Soil’s Indirect Tensile Strength

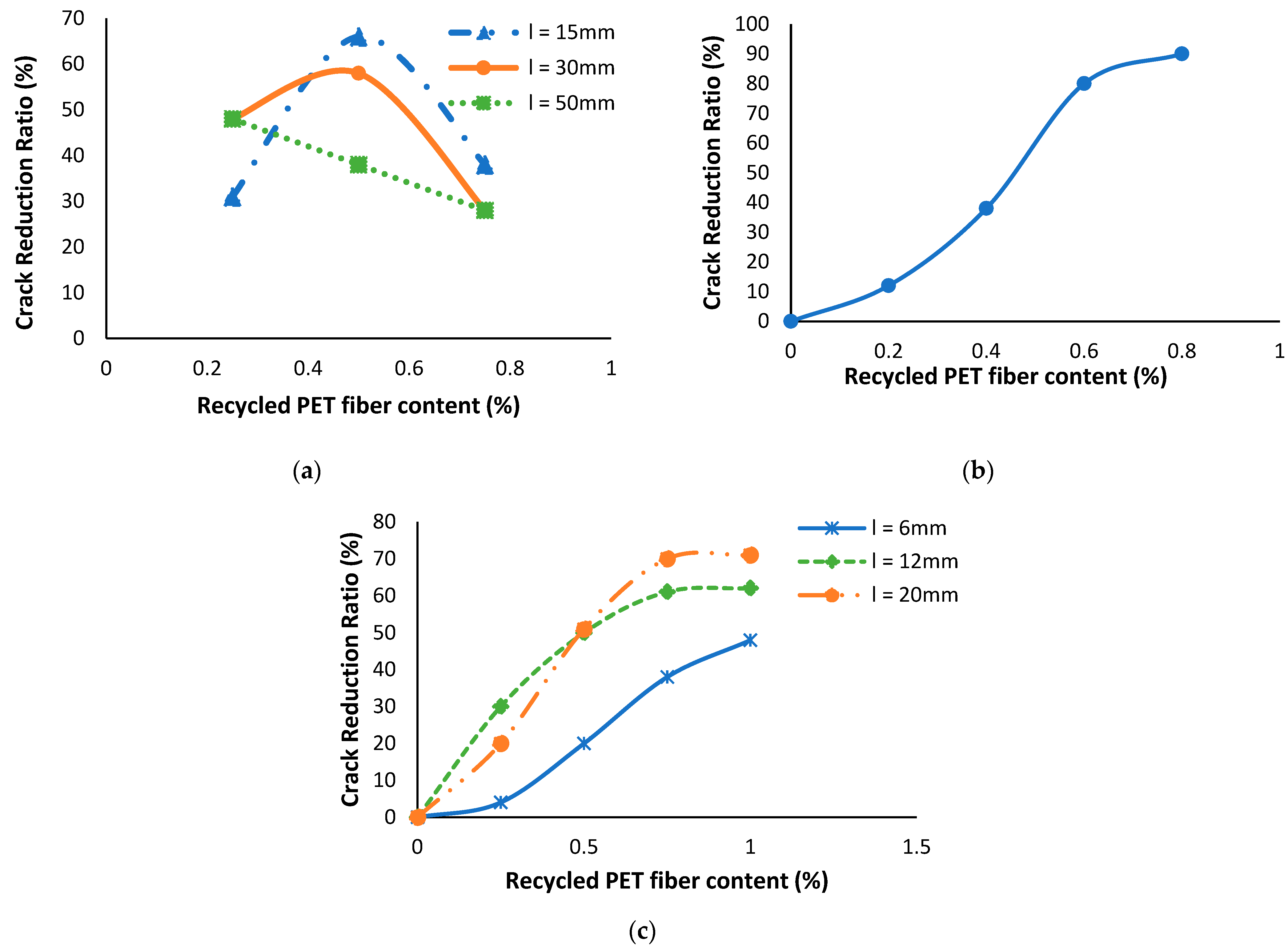

6.7. Influence of Recycled PET Fibers on Soil’s Crack Reduction Ratio

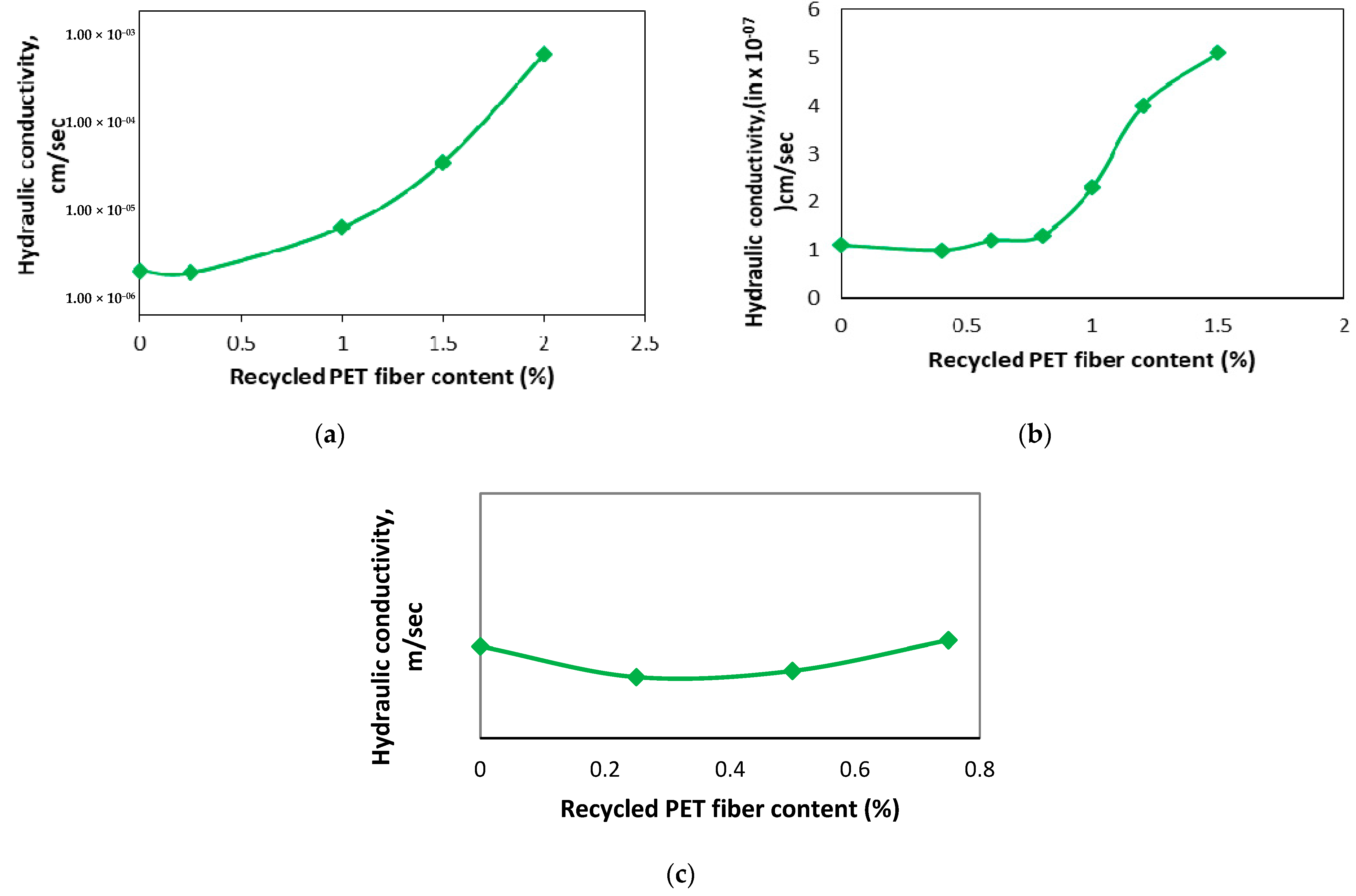

6.8. Influence of Recycled PET Fibers on Soil’s Hydraulic Conductivity

6.9. Influence of Recycled PET Fibers on Soil’s Elastic Modulus

6.10. Influence of Recycled PET Fibers on Soil’s Unconfined Compressive Strength

6.11. Influence of Recycled PET Fibers on Soil’s Cohesion and Frictional Angle

7. Applications of Recycled PET Strips in Soil Stabilization

7.1. Influence of Recycled PET Strips on Soil’s Dry Density

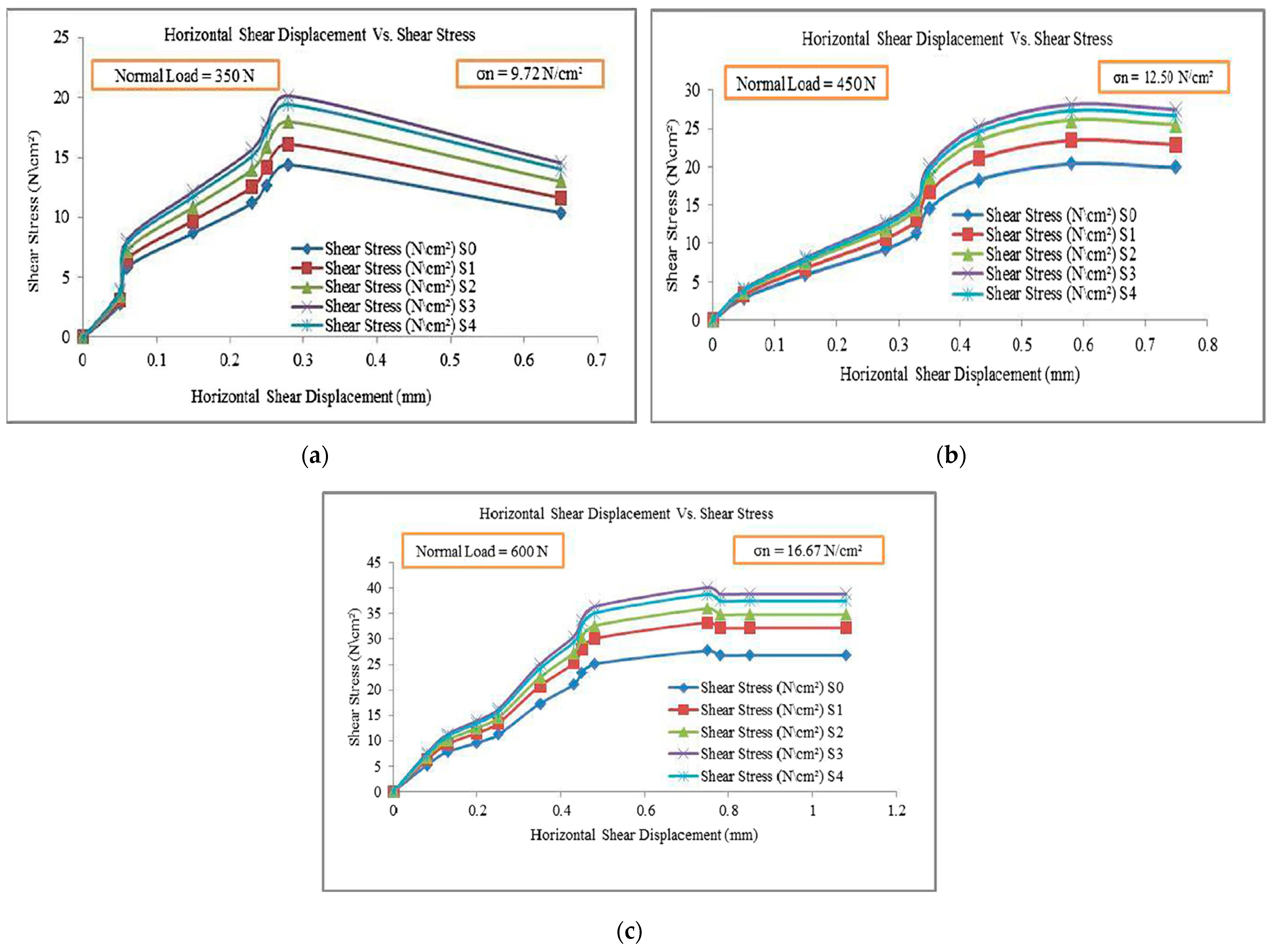

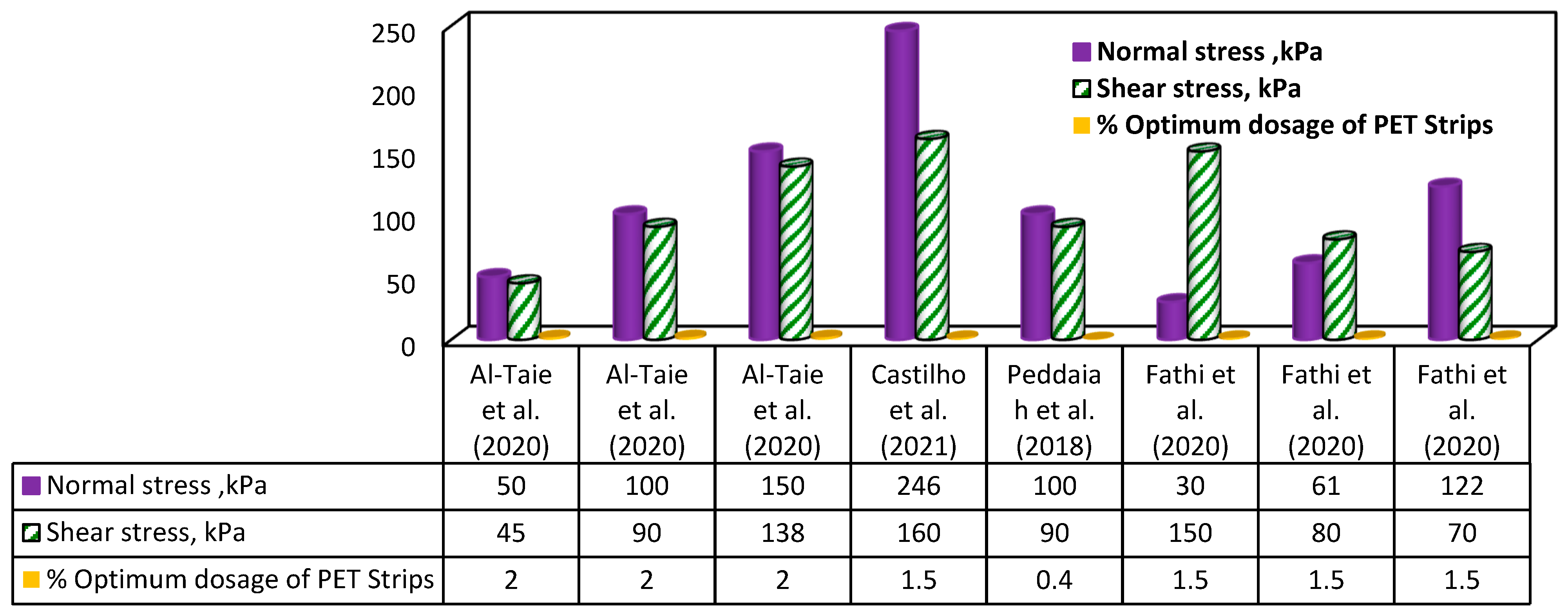

7.2. Influence of Recycled PET Strips on Soil’s Normal–Shear Stress Characteristics

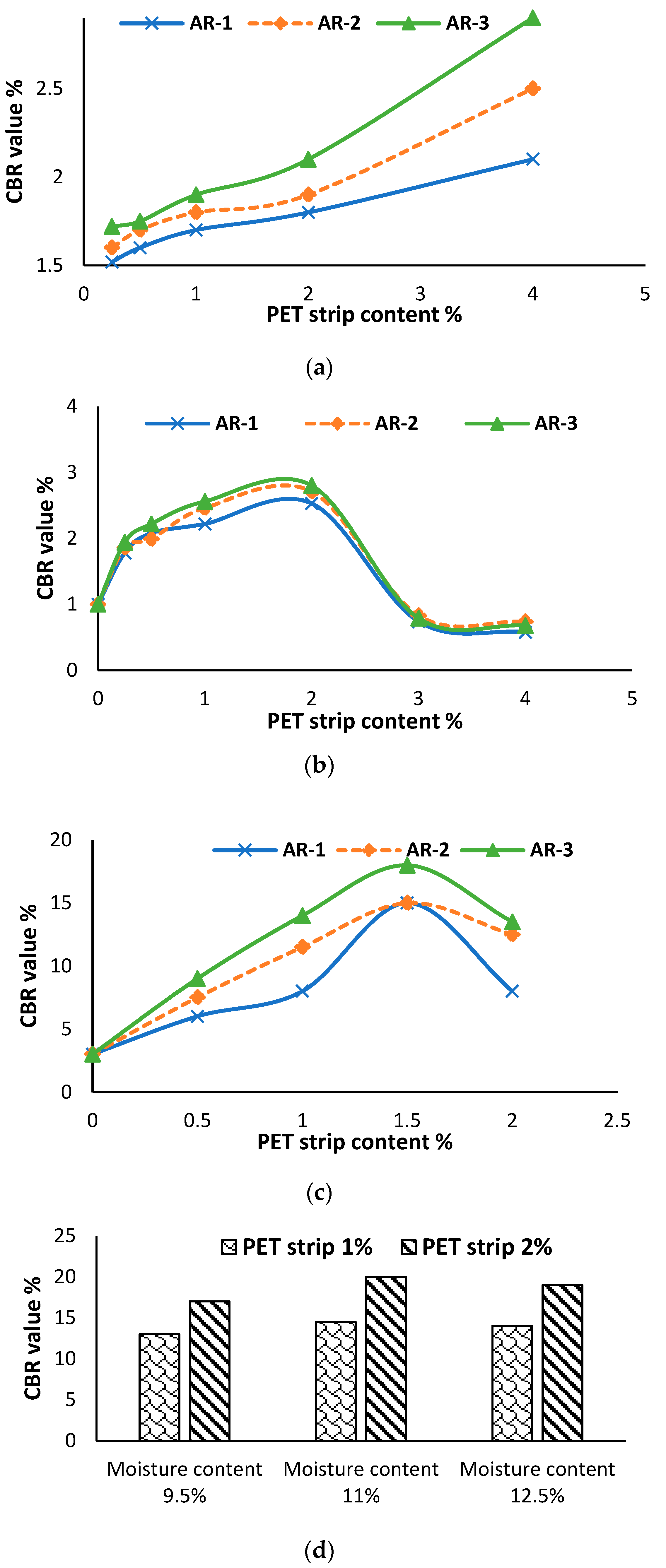

7.3. Influence of Recycled PET Strips on Soil’s CBR

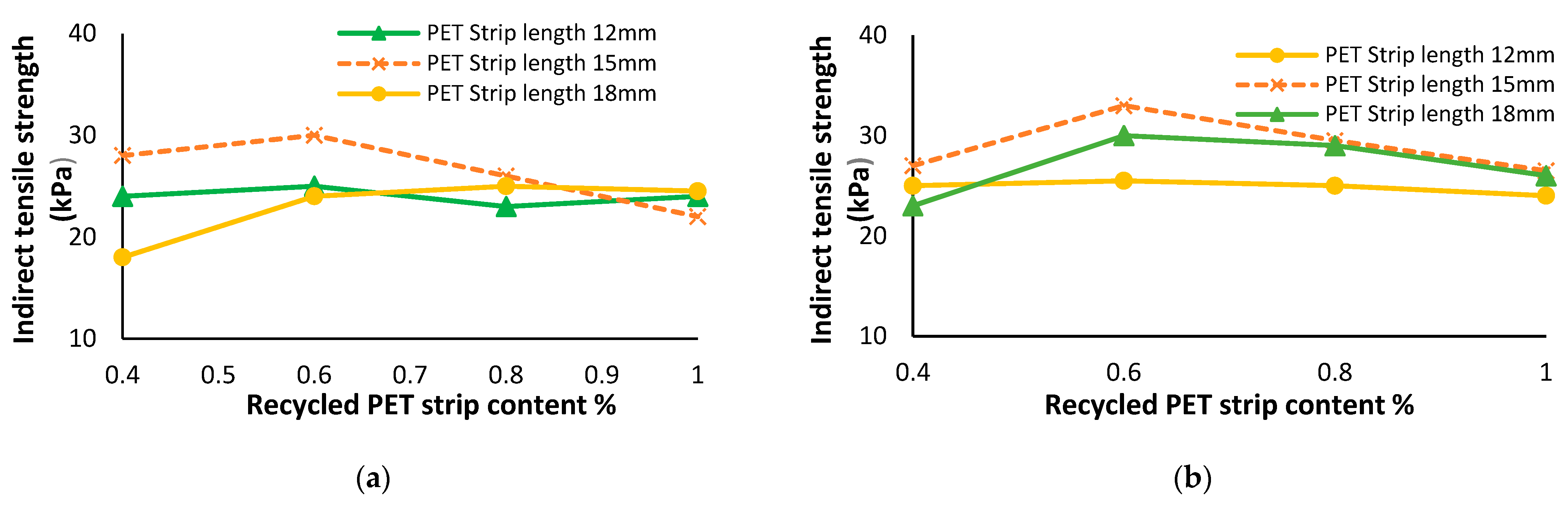

7.4. Influence of Recycled PET Strips on Soil’s Indirect Tensile Strength

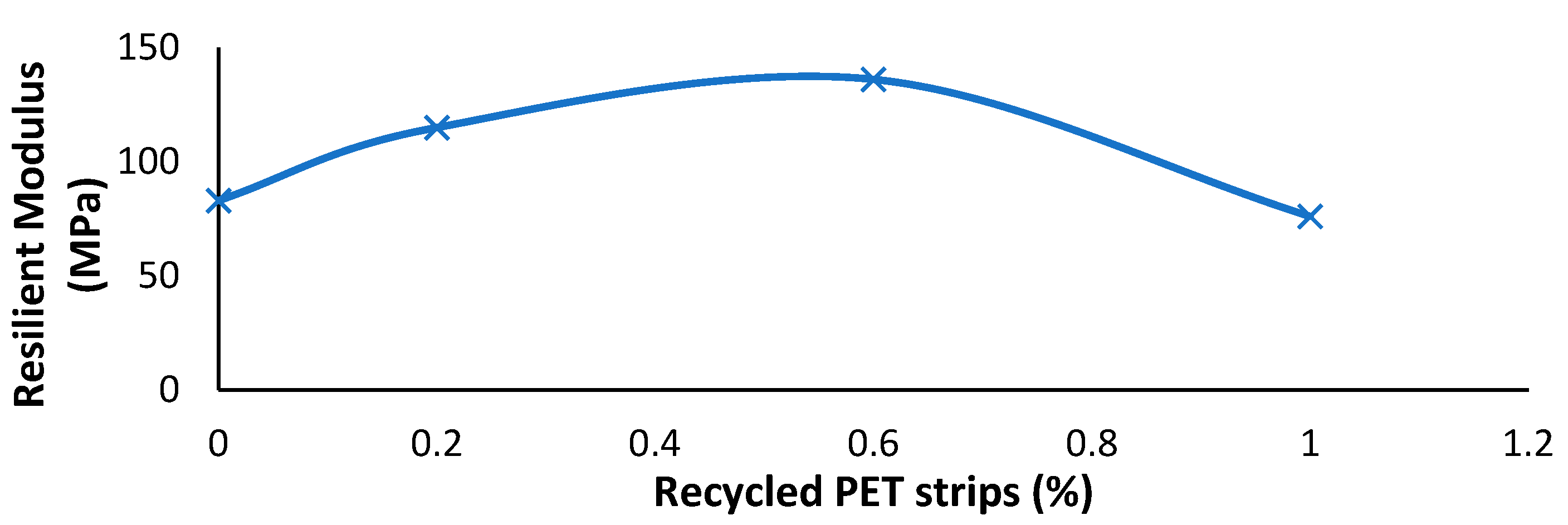

7.5. Influence of Recycled PET Strips on Soil’s Resilience Modulus

7.6. Influence of Recycled PET Strips on Soil’s UCS Value

7.7. Influence of Recycled PET Strips on Soil’s Cohesion and Internal Frictional Angle

8. Environmental Implication of PET Addition to Soil

9. Economic Implication of PET Addition to Soil

10. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Makusa, G.P. Soil Stabilization Methods and Materials in Engineering Practice: State of the Art Review; Luleå University of Technology: Luleå, Sweden, 2013; pp. 1–35. [Google Scholar]

- Consoli, N.C.; da Silva Lopes, L., Jr.; Heineck, K.S. Key parameters for the strength control of lime stabilized soils. J. Mater. Civ. Eng. 2009, 21, 210–216. [Google Scholar] [CrossRef]

- Lu, D.; Ma, C.; Du, X.; Jin, L.; Gong, Q. Development of a new nonlinear unified strength theory for geomaterials based on the characteristic stress concept. Int. J. Geomech. 2017, 17, 04016058. [Google Scholar] [CrossRef]

- Lu, D.; Liang, J.; Du, X.; Ma, C.; Gao, Z. Fractional elastoplastic constitutive model for soils based on a novel 3D fractional plastic flow rule. Comput. Geotech. 2019, 105, 277–290. [Google Scholar] [CrossRef]

- Tang, C.-S.; Shi, B.; Zhao, L.-Z. Interfacial shear strength of fiber reinforced soil. Geotext. Geomembr. 2010, 28, 54–62. [Google Scholar] [CrossRef]

- Khodabandeh, M.A.; Nagy, G.; Török, Á. Stabilization of collapsible soils with nanomaterials, fibers, polymers, industrial waste, and microbes: Current trends. Constr. Build. Mater. 2023, 368, 130463. [Google Scholar] [CrossRef]

- Ahmed, G.H.; Askandar, N.H.; Jumaa, G.B. A review of largescale 3DCP: Material characteristics, mix design, printing process, and reinforcement strategies. Structures 2022, 43, 508–532. [Google Scholar] [CrossRef]

- Tingle, J.S.; Newman, J.K.; Larson, S.L.; Weiss, C.A.; Rushing, J.F. Stabilization mechanisms of nontraditional additives. Transp. Res. Rec. 2007, 1989, 59–67. [Google Scholar] [CrossRef]

- Onyelowe Ken, C.; Okafor, F. A comparative review of soil modification methods. ARPN J. Earth Sci. 2006, 1, 36–41. [Google Scholar]

- El Ouni, M.H.; Raza, A.; Khalid, B.; Ahmed, A.; Jameel, M.S.; Alashker, Y. Axial strength of FRP-reinforced geopolymeric concrete members: A step towards sustainable construction. Struct. Eng. Mech. 2023, 86, 687–704. [Google Scholar]

- Harbottle, M.J.; Al-Tabbaa, A.; Evans, C. A comparison of the technical sustainability of in situ stabilisation/solidification with disposal to landfill. J. Hazard. Mater. 2007, 141, 430–440. [Google Scholar] [CrossRef]

- Oelofse, S.; Godfrey, L. Defining waste in South Africa: Moving beyond the age of ‘waste’: Science policy. S. Afr. J. Sci. 2008, 104, 242–246. [Google Scholar]

- Chavan, R. Environmental sustainability through textile recycling. J. Text. Sci. Eng. 2014, S2, 1–5. [Google Scholar]

- Mishra, B.; Gupta, M.K. Use of randomly oriented polyethylene terephthalate (PET) fiber in combination with fly ash in subgrade of flexible pavement. Constr. Build. Mater. 2018, 190, 95–107. [Google Scholar] [CrossRef]

- Arulrajah, A.; Perera, S.; Wong, Y.C.; Maghool, F.; Horpibulsuk, S. Stabilization of PET plastic-demolition waste blends using fly ash and slag-based geopolymers in light traffic road bases/subbases. Constr. Build. Mater. 2021, 284, 122809. [Google Scholar] [CrossRef]

- Mohee, R.; Unmar, G.; Mudhoo, A.; Khadoo, P. Biodegradability of biodegradable/degradable plastic materials under aerobic and anaerobic conditions. Waste Manag. 2008, 28, 1624–1629. [Google Scholar] [CrossRef]

- Gopinath, K.P.; Nagarajan, V.M.; Krishnan, A.; Malolan, R. A critical review on the influence of energy, environmental and economic factors on various processes used to handle and recycle plastic wastes: Development of a comprehensive index. J. Clean. Prod. 2020, 274, 123031. [Google Scholar] [CrossRef]

- Vaverková, M.D. Landfill impacts on the environment. Geosciences 2019, 9, 431. [Google Scholar] [CrossRef]

- Alabi, O.A.; Ologbonjaye, K.I.; Awosolu, O.; Alalade, O.E. Public and environmental health effects of plastic wastes disposal: A review. J. Toxicol. Risk Assess. 2019, 5, 21. [Google Scholar]

- Hua, N.; Wang, W.; Wang, Q.; Ye, Y.; Lin, S.; Zhang, L.; Guo, Q.; Brechtl, J.; Liaw, P.K. Mechanical, corrosion, and wear properties of biomedical Ti–Zr–Nb–Ta–Mo high entropy alloys. J. Alloys Compd. 2021, 861, 157997. [Google Scholar] [CrossRef]

- Schweitzer, P.A. Mechanical and Corrosion-Resistant Properties of Plastics and Elastomers; Informa UK Limited: Colchester, UK, 2000. [Google Scholar]

- Wong, S.; Ngadi, N.; Abdullah, T.A.T.; Inuwa, I.M. Current state and future prospects of plastic waste as source of fuel: A review. Renew. Sustain. Energy Rev. 2015, 50, 1167–1180. [Google Scholar] [CrossRef]

- Evode, N.; Qamar, S.A.; Bilal, M.; Barceló, D.; Iqbal, H.M. Plastic waste and its management strategies for environmental sustainability. Case Stud. Chem. Environ. Eng. 2021, 4, 100142. [Google Scholar] [CrossRef]

- Khalid, B.; Alshawmar, F. Exploring the feasibility of using recycled PET strips with palm leaf ash for sustainable soil stabilization. Sustainability 2023, 15, 13542. [Google Scholar] [CrossRef]

- Barisoglu, E.N.; Meeusen, J.; Snoeck, D.; Verástegui-Flores, R.D.; Di Emidio, G. Feasibility of using recycled construction and demolition materials for deep soil mixing. Sustainability 2023, 15, 5223. [Google Scholar] [CrossRef]

- Barnard, E.; Arias, J.J.R.; Thielemans, W. Chemolytic depolymerisation of PET: A review. Green. Chem. 2021, 23, 3765–3789. [Google Scholar] [CrossRef]

- Shahidan, S. Concrete incorporated with optimum percentages of recycled polyethylene terephthalate (PET) bottle fiber. Int. J. Integr. Eng. 2018, 10, 1–8. [Google Scholar] [CrossRef]

- Nikles, D.E.; Farahat, M.S. New motivation for the depolymerization products derived from poly (ethylene terephthalate)(PET) waste: A review. Macromol. Mater. Eng. 2005, 290, 13–30. [Google Scholar] [CrossRef]

- Shmyh, R.; Bilozir, V.; Vysochenko, A.; Bilozir, V. Carrying capacity of bending concrete elements reinforced by fibro and stripes taken from used polyethylene terephthalate bottles. In Proceedings of the International Scientific and Practical Conference World Science, Lviv, Ukraine, 9–12 October 2018; pp. 88–93. [Google Scholar]

- ASTM D4767-11; Standard Test Method for Unconsolidated-Undrained Triaxial Compression Test on Cohesive Soils. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D4318; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D2166; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D1883; Standard Test Method for California Bearing Ratio (CBR) of Laboratory-Compacted Soils. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D5084; Standard Test Methods for Measurement of Hydraulic Conductivity of Saturated Porous Materials Using a Flexible Wall Permeameter. ASTM International: West Conshohocken, PA, USA, 2010.

- Mandal, S.; Dey, A. PET chemistry. In Recycling of Polyethylene Terephthalate Bottles, 1st ed.; Thomas, S., Rane, A.V., Kanny, K., Abitha, V.K., Thomas, M.G., Eds.; William Andrew: Norwich, NY, USA, 2018; pp. 1–22. ISBN 9780128113615. [Google Scholar]

- Campanelli, J.R.; Kamal, M.; Cooper, D. A kinetic study of the hydrolytic degradation of polyethylene terephthalate at high temperatures. J. Appl. Polym. Sci. 1993, 48, 443–451. [Google Scholar] [CrossRef]

- Maurya, A.; Bhattacharya, A.; Khare, S.K. Enzymatic remediation of polyethylene terephthalate (PET)–based polymers for effective management of plastic wastes: An overview. Front. Bioeng. Biotechnol. 2020, 8, 602325. [Google Scholar] [CrossRef]

- Fernández-Menéndez, T.; García-López, D.; Argüelles, A.; Fernández, A.; Viña, J. Industrially produced PET nanocomposites with enhaced properties for food packaging applications. Polym. Test. 2020, 90, 106729. [Google Scholar] [CrossRef]

- Mousavi, M.; Fini, E.H. Preventing emissions of hazardous organic compounds from bituminous composites. J. Clean. Prod. 2022, 344, 131067. [Google Scholar] [CrossRef]

- De Araújo, M. Natural and man-made fibres: Physical and mechanical properties. In Fibrous and Composite Materials for Civil Engineering Applications; Woodhead Publishing: Sawston, UK, 2011; pp. 3–28. [Google Scholar]

- Demirel, B.; Yaraş, A.; Elçiçek, H. Crystallization behavior of PET materials. BAÜ Fen Bil. Enst. Dergisi Cilt 2021, 13, 26–35. [Google Scholar]

- Nisticò, R. Polyethylene terephthalate (PET) in the packaging industry. Polym. Test. 2020, 90, 106707. [Google Scholar] [CrossRef]

- Hinrichsen, G.; Adam, H.; Krebs, H.; Springer, H. On nonorientation drawing of polyethyleneterephthalate (PET). Colloid. Polym. Sci. 1980, 258, 232–240. [Google Scholar] [CrossRef]

- Chae, H.G.; Kumar, S. Rigid-rod polymeric fibers. J. Appl. Polym. Sci. 2006, 100, 791–802. [Google Scholar] [CrossRef]

- Korycki, A.; Garnier, C.; Irusta, S.; Chabert, F. Evaluation of Fatigue Life of Recycled Opaque PET from Household Milk Bottle Wastes. Polymers 2022, 14, 3466. [Google Scholar] [CrossRef]

- Eisa, M.; Alfedeel, A. Simulation properties of thin films of indium tin oxide deposited on polymer substrates. Dig. J. Nanomater. Biostructures (DJNB) 2020, 15, 59–65. [Google Scholar] [CrossRef]

- Shields, R.; Bhattacharyya, D.; Fakirov, S. Oxygen permeability analysis of microfibril reinforced composites from PE/PET blends. Compos. Part A Appl. Sci. Manuf. 2008, 39, 940–949. [Google Scholar] [CrossRef]

- Ahmed, A.M.; Kainulainen, T.P.; Heiskanen, J.P. Furfural-based modification of PET for UV-blocking copolymers with decreased oxygen permeability. Ind. Eng. Chem. Res. 2021, 60, 7495–7504. [Google Scholar] [CrossRef]

- Miao, D.; Jiang, S.; Shang, S.; Chen, Z. Highly transparent and infrared reflective AZO/Ag/AZO multilayer film prepared on PET substrate by RF magnetron sputtering. Vacuum 2014, 106, 1–4. [Google Scholar] [CrossRef]

- Dudem, B.; Ko, Y.H.; Leem, J.W.; Lee, S.H.; Yu, J.S. Highly transparent and flexible triboelectric nanogenerators with subwavelength-architectured polydimethylsiloxane by a nanoporous anodic aluminum oxide template. ACS Appl. Mater. Interfaces 2015, 7, 20520–20529. [Google Scholar] [CrossRef]

- Pang, J.; Zheng, M.; Sun, R.; Wang, A.; Wang, X.; Zhang, T. Synthesis of ethylene glycol and terephthalic acid from biomass for producing PET. Green. Chem. 2016, 18, 342–359. [Google Scholar] [CrossRef]

- Olewnik, E.; Czerwiński, W.; Nowaczyk, J.; Sepulchre, M.-O.; Tessier, M.; Salhi, S.; Fradet, A. Synthesis and structural study of copolymers of L-lactic acid and bis (2-hydroxyethyl terephthalate). Eur. Polym. J. 2007, 43, 1009–1019. [Google Scholar] [CrossRef]

- Vouyiouka, S.; Karakatsani, E.; Papaspyrides, C. Solid state polymerization. Prog. Polym. Sci. 2005, 30, 10–37. [Google Scholar] [CrossRef]

- Chokshi, R.; Zia, H. Hot-melt extrusion technique: A review. Iran. J. Pharm. Res. 2004, 3, 3–16. [Google Scholar]

- Coelho, T.M.; Castro, R.; Gobbo, J., Jr. PET containers in Brazil: Opportunities and challenges of a logistics model for post-consumer waste recycling. Resour. Conserv. Recycl. 2011, 55, 291–299. [Google Scholar] [CrossRef]

- Pohlen, T.L.; Theodore Farris, M. Reverse logistics in plastics recycling. Int. J. Phys. Distrib. Logist. Manag. 1992, 22, 35–47. [Google Scholar] [CrossRef]

- Feil, A.; Pretz, T. Mechanical recycling of packaging waste. In Plastic Waste and Recycling; Elsevier: Amsterdam, The Netherlands, 2020; pp. 283–319. [Google Scholar]

- Zimmermann, J.; Reifler, F.A.; Fortunato, G.; Gerhardt, L.C.; Seeger, S. A simple, one-step approach to durable and robust superhydrophobic textiles. Adv. Funct. Mater. 2008, 18, 3662–3669. [Google Scholar] [CrossRef]

- Seebaluck, V.; Koussa, W.B. Prospects for recycling of waste PET bottles in Mauritius. Univ. Maurit. Res. J. 2009, 15, 334–349. [Google Scholar]

- Soong, Y.-H.V.; Sobkowicz, M.J.; Xie, D. Recent advances in biological recycling of polyethylene terephthalate (PET) plastic wastes. Bioengineering 2022, 9, 98. [Google Scholar] [CrossRef]

- Subramanian, K.; Sarkar, M.K.; Wang, H.; Qin, Z.-H.; Chopra, S.S.; Jin, M.; Kumar, V.; Chen, C.; Tsang, C.-W.; Lin, C.S.K. An overview of cotton and polyester, and their blended waste textile valorisation to value-added products: A circular economy approach–research trends, opportunities and challenges. Crit. Rev. Environ. Sci. Technol. 2022, 52, 3921–3942. [Google Scholar] [CrossRef]

- Damayanti; Wu, H.-S. Strategic possibility routes of recycled PET. Polymers 2021, 13, 1475. [Google Scholar] [CrossRef]

- Shukla, S.K. Applications of fibre-reinforced soil. In Fundamentals of Fibre-Reinforced Soil Engineering; Developments in Geotechnical Engineering, Springer: Singapore, 2017; pp. 145–180. [Google Scholar]

- Suthar, L.; Meena, S.; Kumar, U. Utilization of plastic waste in reinforcing sandy soil for sustainable engineering applications. J. Eng. Sci. 2024, 11, H1–H8. [Google Scholar] [CrossRef]

- Tanasă, F.; Nechifor, M.; Ignat, M.-E.; Teacă, C.-A. Geotextiles—A versatile tool for environmental sensitive applications ingeotechnical engineering. Textiles 2022, 2, 189–208. [Google Scholar] [CrossRef]

- Wu, H.; Yao, C.; Li, C.; Miao, M.; Zhong, Y.; Lu, Y.; Liu, T. Review of application and innovation of geotextiles in geotechnical engineering. Materials 2020, 13, 1774. [Google Scholar] [CrossRef] [PubMed]

- Waldschläger, K.; Schüttrumpf, H. Erosion behavior of different microplastic particles in comparison to natural sediments. Environ. Sci. Technol. 2019, 53, 13219–13227. [Google Scholar] [CrossRef]

- Mishra, M.; Maheshwari, U.; Saxena, N. Improving strength of soil using fiber and fly ash—A review. Int. Res. J. Eng. Technol. IRJET 2016, 3, 1262–1266. [Google Scholar]

- Hafez, M.; Mousa, R.; Awed, A.; El-Badawy, S. Soil reinforcement using recycled plastic waste for sustainable pavements. In Proceedings of the International Congress and Exhibition on Sustainable Civil Infrastructures: Innovative Infrastructure Geotechnology; Springer: Cham, Switzerland, 2019; pp. 7–20. [Google Scholar]

- Botero, E.; Ossa, A.; Sherwell, G.; Ovando-Shelley, E. Stress–strain behavior of a silty soil reinforced with polyethylene terephthalate (PET). Geotext. Geomembr. 2015, 43, 363–369. [Google Scholar] [CrossRef]

- Mariri, M.; Ziaie Moayed, R.; Kordnaeij, A. Stress–strain behavior of loess soil stabilized with cement, zeolite, and recycled polyester fiber. J. Mater. Civ. Eng. 2019, 31, 04019291. [Google Scholar] [CrossRef]

- Changizi, F.; Haddad, A. Strength properties of soft clay treated with mixture of nano-SiO2 and recycled polyester fiber. J. Rock. Mech. Geotech. Eng. 2015, 7, 367–378. [Google Scholar] [CrossRef]

- Valipour, M.; Shourijeh, P.T.; Mohammadinia, A. Application of recycled tire polymer fibers and glass fibers for clay reinforcement. Transp. Geotech. 2021, 27, 100474. [Google Scholar] [CrossRef]

- Zhao, J.-J.; Lee, M.-L.; Lim, S.-K.; Tanaka, Y. Unconfined compressive strength of PET waste-mixed residual soils. Geomech. Eng. 2015, 8, 53–66. [Google Scholar] [CrossRef]

- Kinjal, S.; Desai, A.; Solanki, C. Experimental study on the Atterberg limits of expansive soil reinforced with polyester triangular fibers. Int. J. Eng. Res. Appl. 2012, 2, 636–639. [Google Scholar]

- Changizi, F.; Haddad, A. Stabilization of subgrade soil for highway by recycled polyester fiber. J. Rehabil. Civ. Eng. 2014, 2, 93–105. [Google Scholar]

- Arya, P.; Patel, S.B.; Bharti, G.; Shukla, B.K.; Hurukadli, P. Impact of using a blend of bagasse ash and polyester fiber in black cotton soil for improvement of mechanical and geotechnical properties of soil. Mater. Today Proc. 2023, 78, 738–743. [Google Scholar] [CrossRef]

- Fauzi, A.; Rahman, W.M.N.W.A.; Jauhari, Z. Utilization waste material as stabilizer on kuantan clayey soil stabilization. Procedia Eng. 2013, 53, 42–47. [Google Scholar] [CrossRef]

- Harianto, T.; Hayashi, S.; Du, Y.-J.; Suetsugu, D. Effects of fiber additives on the desiccation crack behavior of the compacted Akaboku soil as a material for landfill cover barrier. Water Air Soil. Pollut. 2008, 194, 141–149. [Google Scholar] [CrossRef]

- Miller, C.J.; Rifai, S. Fiber reinforcement for waste containment soil liners. J. Environ. Eng. 2004, 130, 891–895. [Google Scholar] [CrossRef]

- Sarli, J.M.; Hadadi, F.; Bagheri, R.-A. Stabilizing geotechnical properties of loess soil by mixing recycled polyester fiber and nano-SiO2. Geotech. Geol. Eng. 2020, 38, 1151–1163. [Google Scholar] [CrossRef]

- Yadav, J.; Tiwari, S. Evaluation of the strength characteristics of cement-stabilized clay–crumb rubber mixtures for its sustainable use in geotechnical applications. Environ. Dev. Sustain. 2018, 20, 1961–1985. [Google Scholar] [CrossRef]

- Malicki, K.; Górszczyk, J.; Dimitrovová, Z. Recycled polyester geosynthetic influence on improvement of road and railway subgrade bearing capacity—Laboratory investigations. Materials 2021, 14, 7264. [Google Scholar] [CrossRef]

- Roussel, L.E. Experimental Investigation of Stick-Slip Behavior in Granular Materials. Master’s Thesis, Louisiana State University and Agricultural & Mechanical College, Baton Rouge, LA, USA, 2005. [Google Scholar]

- Lieou, C.K.; Elbanna, A.E.; Langer, J.S.; Carlson, J.M. Stick-slip instabilities in sheared granular flow: The role of friction and acoustic vibrations. Phys. Rev. E 2015, 92, 022209. [Google Scholar] [CrossRef]

- Kholghifard, M.; Amini Behbahani, B. Shear strength of clayey sand treated by nanoclay mixed with recycled polyester fiber. J. Cent. South. Univ. 2022, 29, 259–269. [Google Scholar] [CrossRef]

- Al-Taie, A.J.; Al-Obaidi, A.; Alzuhairi, M. Utilization of depolymerized recycled polyethylene terephthalate in improving poorly graded soil. Transp. Infrastruct. Geotechnol. 2020, 7, 206–223. [Google Scholar] [CrossRef]

- Bhardwaj, A. Influence of Cement and Polyester Fibres on Compaction and CBR Value of Clayey Soil. Master’s Thesis, Punjab Technical University, Punjab, India, 2016. [Google Scholar]

- Naeini, S.; Ziaei, M.R. Effect of plasticity index and reinforcement on the CBR value of soft clay. Int. J. Civ. Eng. 2009, 7, 124–130. [Google Scholar]

- Tafti, M.F.; Emadi, M.Z. Impact of using recycled tire fibers on the mechanical properties of clayey and sandy soils. Electron. J. Geotech. Eng. 2016, 21, 7113–7225. [Google Scholar]

- Tang, C.-S.; Shi, B.; Liu, C.; Gao, L.; Inyang, H.I. Experimental investigation of the desiccation cracking behavior of soil layers during drying. J. Mater. Civ. Eng. 2011, 23, 873–878. [Google Scholar] [CrossRef]

- Al-Jeznawi, D.; Sanchez, M.; Al-Taie, A.J. Using image analysis technique to study the effect of boundary and environment conditions on soil cracking mechanism. Geotech. Geol. Eng. 2021, 39, 25–36. [Google Scholar] [CrossRef]

- Tang, C.-S.; Shi, B.; Cui, Y.-J.; Liu, C.; Gu, K. Desiccation cracking behavior of polypropylene fiber–reinforced clayey soil. Can. Geotech. J. 2012, 49, 1088–1101. [Google Scholar] [CrossRef]

- Chaduvula, U.; Viswanadham, B.; Kodikara, J. A study on desiccation cracking behavior of polyester fiber-reinforced expansive clay. Appl. Clay Sci. 2017, 142, 163–172. [Google Scholar] [CrossRef]

- Olgun, M. Effects of polypropylene fiber inclusion on the strength and volume change characteristics of cement-fly ash stabilized clay soil. Geosynth. Int. 2013, 20, 263–275. [Google Scholar] [CrossRef]

- Balaguru, P. Contribution of fibers to crack reduction of cement composites during the initial and final setting period. Mater. J. 1994, 91, 280–288. [Google Scholar]

- Lixon, C.; Delpouve, N.; Saiter, A.; Dargent, E.; Grohens, Y. Evidence of cooperative rearranging region size anisotropy for drawn PET. Eur. Polym. J. 2008, 44, 3377–3384. [Google Scholar] [CrossRef]

- Gupta, S.; Rao, V.K.; Sengupta, J. Evaluation of polyester fiber reinforced concrete for use in cement concrete pavement works. Road Mater. Pavement Des. 2008, 9, 441–461. [Google Scholar] [CrossRef]

- Maurya, R.; Umesh, K.; Gupta, M. Hydraulic conductivity for silty soil added with plastic wastes. In Proceedings of the International Seminar on Sources of Planet Energy, Environmental and Disaster Science: Challenges and Strategies, Lucknow, India, 19–20 November 2016. SPEEDS-16. [Google Scholar]

- Divya, P.; Viswanadham, B.; Gourc, J. Hydraulic conductivity behaviour of soil blended with geofiber inclusions. Geotext. Geomembr. 2018, 46, 121–130. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, F.; Li, X. Effects of polyester microfibers on soil physical properties: Perception from a field and a pot experiment. Sci. Total Environ. 2019, 670, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Battu, A.K.; Varga, T.; Denny, A.C.; Zahid, T.M.; Chowdhury, I.; Flury, M. Minimalimpacts of microplastics on soil physical properties under environmentally relevant concentrations. Environ. Sci. Technol. 2023, 57, 5296–5304. [Google Scholar] [CrossRef] [PubMed]

- Mulliken, A.D.; Boyce, M.C. Mechanics of the rate-dependent elastic–plastic deformation of glassy polymers from low to high strain rates. Int. J. Solids Struct. 2006, 43, 1331–1356. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, W.; Jiang, P.; Li, C. The elastic modulus and damage stress–strain model of polypropylene fiber and nano clay modified lime treated soil under axiall oad. Polymers 2022, 14, 2606. [Google Scholar] [CrossRef] [PubMed]

- Hassan, H.J.A.; Rasul, J.; Samin, M. Effects of plastic waste materials on geotechnical properties of clayey soil. Transp. Infrastruct. Geotechnol. 2021, 8, 390–413. [Google Scholar] [CrossRef]

- Kumar, A.; Walia, B.S.; Mohan, J. Compressive strength of fiber reinforced highly compressible clay. Constr. Build. Mater. 2006, 20, 1063–1068. [Google Scholar] [CrossRef]

- Ramesh, A.; Nageshwar Rao, C.; Kumar, M. Experimental study on geocell and of fibre reinforced soil sub-grade under static and repetitive load. In Geotechnics for Transportation Infrastructure: Recent Developments, Upcoming Technologies and New Concepts; Springer: Singapore, 2019; Volume 29, pp. 139–149. [Google Scholar]

- Emmanuel, E.; Yong, L.L.; Fogne Appiah, N.; Gawu, S. Response surface methodology: A tool to optimise the contents of lime and polyethylene terephthalate (PET) fiber for stabilising a residual soil. Geomech. Geoengin. 2022, 17, 1516–1535. [Google Scholar] [CrossRef]

- Kumar, A.; Walia, B.S.; Bajaj, A. Influence of fly ash, lime, and polyester fibers on compaction and strength properties of expansive soil. J. Mater. Civ. Eng. 2007, 19, 242–248. [Google Scholar] [CrossRef]

- Alvarez, A.; Sosa, J.; Duran, G.; Pacheco, L. Improved mechanical properties of a high plasticity clay soil by adding recycled PET. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Sanya, China, 2020; Volume 758, p. 012075. [Google Scholar]

- Tiu, B.D.B.; Delparastan, P.; Ney, M.R.; Gerst, M.; Messersmith, P.B. Enhanced adhesion and cohesion of bioinspired dry/wet pressure-sensitive adhesives. ACS Appl. Mater. Interfaces 2019, 11, 28296–28306. [Google Scholar] [CrossRef] [PubMed]

- dos Santos Ferreira, J.W.; Senez, P.C.; Casagrande, M.D.T. Pet fiber reinforced sand performance under triaxial and plate load tests. Case Stud. Constr. Mater. 2021, 15, e00741. [Google Scholar]

- Chebbi, M.; Guiras, H.; Jamei, M. Tensile behaviour analysis of compacted clayey soil reinforced with natural and synthetic fibers: Effect of initial compaction conditions. Eur. J. Environ. Civ. Eng. 2020, 24, 354–380. [Google Scholar] [CrossRef]

- Ahmadi, H.; Janati, S.; Jamshidi Chenari, R. Strength parameters of stabilized clay using polypropylene fibers and nano-MgO: An experimental study. Geotech. Geol. Eng. 2020, 38, 2845–2858. [Google Scholar] [CrossRef]

- Peddaiah, S.; Burman, A.; Sreedeep, S. Experimental study on effect of waste plastic bottle strips in soil improvement. Geotech. Geol. Eng. 2018, 36, 2907–2920. [Google Scholar] [CrossRef]

- Ahmed, A.; Ugai, K.; Kamei, T. Investigation of recycled gypsum in conjunction with waste plastic trays for ground improvement. Constr. Build. Mater. 2011, 25, 208–217. [Google Scholar] [CrossRef]

- Shah, A.; Modha, H. Improving the soil subgrade with plastic waste reinforcement—An experimental study. In Proceedings of the EECE 2020, St. Petersburg, Russia, 19–20 November 2020; pp. 153–161. [Google Scholar]

- Sidle, R.C.; Ziegler, A.D.; Negishi, J.N.; Nik, A.R.; Siew, R.; Turkelboom, F. Erosion processes in steep terrain—Truths, myths, and uncertainties related to forest management in Southeast Asia. For. Ecol. Manag. 2006, 224, 199–225. [Google Scholar] [CrossRef]

- Amena, S.; Kabeta, W.F. Mechanical behavior of plastic strips-reinforced expansive soils stabilized with waste marble dust. Adv. Civ. Eng. 2022, 2022, 1–8. [Google Scholar] [CrossRef]

- Foti, D. Recycled waste PET for sustainable fiber-reinforced concrete. In Use of Recycled Plastics in Eco-Efficient Concrete; Elsevier: Amsterdam, The Netherlands, 2019; pp. 387–410. [Google Scholar]

- Zulkernain, N.H.; Gani, P.; Chuan, N.C.; Uvarajan, T. Utilisation of plastic waste as aggregate in construction materials: A review. Constr. Build. Mater. 2021, 296, 123669. [Google Scholar] [CrossRef]

- Kromp, B. Carabid beetles in sustainable agriculture: A review on pest control efficacy, cultivation impacts and enhancement. Agric. Ecosyst. Environ. 1999, 74, 187–228. [Google Scholar] [CrossRef]

- Birle, E.; Heyer, D.; Vogt, N. Influence of the initial water content and dry density on the soil–water retention curve and the shrinkage behavior of a compacted clay. Acta Geotech. 2008, 3, 191–200. [Google Scholar] [CrossRef]

- Chim Jin, D.J.P. Laboratory Investigation of Soil Reinforcement Using Shredded Waste Plastic Bottles. Master’s Thesis, University of Cape Town, Cape Town, South Africa, 2018. [Google Scholar]

- Tatlisoz, N.; Edil, T.B.; Benson, C.H. Interaction between reinforcing geosynthetics and soil-tire chip mixtures. J. Geotech. Geoenviron. Eng. 1998, 124, 1109–1119. [Google Scholar] [CrossRef]

- Castilho, T.W.; Rodrigues, R.A.; Lodi, P.C. Use of recycled polyethylene terephthalate strips in soil improvement. Geotech. Geol. Eng. 2021, 39, 5943–5955. [Google Scholar] [CrossRef]

- Fathi, H.; Jamshidi Chenari, R.; Vafaeian, M. Shaking table study on PET strips-sand mixtures using laminar box modelling. Geotech. Geol. Eng. 2020, 38, 683–694. [Google Scholar] [CrossRef]

- Choudhary, A.; Jha, J.; Gill, K. A study on CBR behavior of waste plastic strip reinforced soil. Emir. J. Eng. Res. 2010, 15, 51–57. [Google Scholar]

- Sinha, A.K.; Jha, J.; Choudhary, A.K. A study on CBR behaviour of waste pet strip reinforced stone dust. In Proceedings of the 1st International Conference on Sustainable Waste Management through Design: IC_SWMD, Ludhiana, India, 2–3 November 2018; Springer: Cham, Switzerland, 2019; pp. 302–312. [Google Scholar]

- Rawat, P.; Kumar, A. Study of CBR behaviour of soil reinforced with HDPE strips. Methodology 2016, 2, x10–x14. [Google Scholar]

- Niyomukiza, J.; Bitekateko, A.; Nsemerirwe, J.; Kawiso, B.; Kiwanuka, M. Investigating the effect of PET plastic bottle strips on the strength and compressibility properties of clayey soil. In IOP Conference Series: Earth and Environmental Science; Surakarta, Indonesia, 24–25 August 2021; IOP Publishing: Bristol, UK, 2021; p. 012021. [Google Scholar]

- Marçal, R.; Lodi, P.C.; Correia, N.d.S.; Giacheti, H.L.; Rodrigues, R.A.; McCartney, J.S. Reinforcing effect of polypropylene waste strips on compacted lateritic soils. Sustainability 2020, 12, 9572. [Google Scholar] [CrossRef]

- Kassa, R.B.; Workie, T.; Abdela, A.; Fekade, M.; Saleh, M.; Dejene, Y. Soil stabilization using waste plastic materials. Open J. Civ. Eng. 2020, 10, 55–68. [Google Scholar] [CrossRef]

- Gangwar, P.; Tiwari, S. Stabilization of soil with waste plastic bottles. Mater. Today Proc. 2021, 47, 3802–3806. [Google Scholar] [CrossRef]

- Sobhan, K.; Mashnad, M. Tensile strength and toughness of soil–cement–fly-ash composite reinforced with recycled high-density polyethylene strips. J. Mater. Civ. Eng. 2002, 14, 177–184. [Google Scholar] [CrossRef]

- Khoury, N.; Khoury, C.; Abousleiman, Y. Soil fused with recycled plastic bottles for various geo-engineering applications. In GeoCongress 2008: Geotechnics of Waste Management and Remediation; ASCE: Reston, VA, USA, 2008; pp. 336–343. [Google Scholar]

- Roustaei, M.; Tavana, J.; Bayat, M. Influence of adding waste polyethylene terephthalate plastic strips on uniaxial compressive and tensile strength of cohesive soil. Geopersia 2022, 12, 39–51. [Google Scholar]

- Ameri, M.; Shaker, H.; Badarloo, B.; Jafari, F. Numerical and experimental investigation on the modified of hot mix asphalt concrete containing crumb rubber and waste pet. Teh. Vjesn. 2020, 27, 1186–1193. [Google Scholar]

- El-Badawy, S.; Valentin, J. (Eds.) Sustainable Solutions for Railways and Transportation Engineering: Proceedings of the 2nd GeoMEast International Congress and Exhibition on Sustainable Civil Infrastructures, Egypt 2018–The Official International Congress of the Soil-Structure Interaction Group in Egypt (SSIGE); Springer: Cham, Switzerland, 2018. [Google Scholar]

- Kabeta, W.F. Study on some of the strength properties of soft clay stabilized with plastic waste strips. Arch. Civ. Eng. 2022, 68, 385–395. [Google Scholar]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A simple review of soil reinforcement by using natural and synthetic fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

- Silveira, M.R.; Lodi, P.C.; Correia, N.d.S.; Rodrigues, R.A.; Giacheti, H.L. Effect of recycled polyethylene terephthalate strips on the mechanical properties of cement-treated lateritic sandy soil. Sustainability 2020, 12, 9801. [Google Scholar] [CrossRef]

- Acharyya, R.; Lahiri, A.; Mukherjee, S.; Raghu, P.; Acharyya, R.; Lahiri, A.; Mukherjee, S.; Raghu, P. Improvement of undrained shear strength of clayey soil with PET bottle strips. In Proceedings of the Indian Geotechnical Conference, Roorkee, India, 22–24 December 2013; p. 2013. [Google Scholar]

- Sajjad, M.; Huang, Q.; Khan, S.; Khan, M.A.; Liu, Y.; Wang, J.; Lian, F.; Wang, Q.; Guo, G. Microplastics in the soil environment: A critical review. Environ. Technol. Innov. 2022, 27, 102408. [Google Scholar]

- Zhang, S.; Wang, J.; Yan, P.; Hao, X.; Xu, B.; Wang, W.; Aurangzeib, M. Non-biodegradable microplastics in soils: A brief review and challenge. J. Hazard. Mater. 2021, 409, 124525. [Google Scholar] [CrossRef]

- Kumar, R.; Verma, A.; Shome, A.; Sinha, R.; Sinha, S.; Jha, P.K.; Kumar, R.; Kumar, P.; Shubham; Das, S. Impacts of plastic pollution on ecosystem services, sustainable development goals, and need to focus on circular economy and policy interventions. Sustainability 2021, 13, 9963. [Google Scholar] [CrossRef]

- Luwalaga, J.G. Analysing the Behaviour of Soil Reinforced with Polyethylene Terephthalate (PET) Plastic Waste. Ph.D. Dissertation, Stellenbosch University, Stellenbosch, South Africa, 2016. [Google Scholar]

- Dlamini, T.U. The Feasibility of Wood Plastic Composites as Building Material for RDP Houses in South Africa. Master’s Thesis, Stellenbosch University, Stellenbosch, South Africa, 2020. [Google Scholar]

- da Silva, T.R.; de Azevedo, A.R.G.; Cecchin, D.; Marvila, M.T.; Amran, M.; Fediuk, R.; Vatin, N.; Karelina, M.; Klyuev, S.; Szelag, M. Application of plastic wastes in construction materials: A review using the concept of life-cycle assessment in the context of recent research for future perspectives. Materials 2021, 14, 3549. [Google Scholar] [CrossRef] [PubMed]

- Gherman, I.-E.; Lakatos, E.-S.; Clinci, S.D.; Lungu, F.; Constandoiu, V.V.; Cioca, L.I.; Rada, E.C. Circularity outlines in the construction and demolition waste management: A literature review. Recycling 2023, 8, 69. [Google Scholar] [CrossRef]

- Cadenazzi, T.; Dotelli, G.; Rossini, M.; Nolan, S.; Nanni, A. Cost and environmental analyses of reinforcement alternatives for a concrete bridge. Struct. Infrastruct. Eng. 2020, 16, 787–802. [Google Scholar] [CrossRef]

| PET | |||

|---|---|---|---|

| Semi-Crystalline | Amorphous | ||

| Thermal properties | |||

| Tg (°C) | 68–80 | 60–84 | |

| Tmax (°C) | 115–120 | 55–65 | |

| Tmould (°C) | 125–145 | 20–30 | |

| Tm (°C) | 255–265 | - | |

| Mechanical properties | |||

| E (GPa) | 2.8–3.1 | 2.8–3.0 | |

| εb (%) | 65–75 | 280–320 | |

| σmax (MPa) | 70–75 | 55–60 | |

| Physiochemical properties | |||

| Density (g/cm3) | 1.37–1.40 | 1.29–1.39 | |

| Permeability, 25 °C (cm3 mm) | CO2 | 14.0 | 15.7 |

| O2 | 1.2–2.8 | 1.2–2.8 | |

| Transparency | Opaque | Transparent | |

| References | Specimen | 1 | 2 | 3 | 4 |

|---|---|---|---|---|---|

| Silty clayey [81] | PET fiber content (%) | 0 | 0.5 | 1 | 1.5 |

| Cohesion, c, (kPa) | 11 | 18 | 24 | 32 | |

| Angle of internal friction, ϕ, (°) | 24 | 26 | 28 | 31 | |

| Fat clay [72] | PET fiber content (%) | 0 | 0.1 | 0.3 | 0.5 |

| Cohesion, c, (kPa) | 38 | 56 | 59 | 64 | |

| Angle of internal friction, ϕ, (°) | 13.5 | 14.6 | 19.3 | 23.3 | |

| Clayey sand [86] | PET fiber content (%) | 0 | 0.1 | 0.3 | 0.5 |

| Cohesion, c, (kPa) | 30.92 | 39.93 | 43.05 | 46.88 | |

| Angle of internal friction, ϕ, (°) | 27.04 | 32.85 | 34.51 | 35.9 | |

| Clay [114] | PET fiber content (%) | 0 | 0.2 | 0.5 | 1 |

| Cohesion, c, (kPa) | 62 | 72.4 | 95.2 | 97.4 | |

| Angle of internal friction, ϕ, (°) | 17.2 | 21.8 | 25.2 | 27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khalid, B.; Alshawmar, F. Comprehensive Review of Geotechnical Engineering Properties of Recycled Polyethylene Terephthalate Fibers and Strips for Soil Stabilization. Polymers 2024, 16, 1764. https://doi.org/10.3390/polym16131764

Khalid B, Alshawmar F. Comprehensive Review of Geotechnical Engineering Properties of Recycled Polyethylene Terephthalate Fibers and Strips for Soil Stabilization. Polymers. 2024; 16(13):1764. https://doi.org/10.3390/polym16131764

Chicago/Turabian StyleKhalid, Bisma, and Fahad Alshawmar. 2024. "Comprehensive Review of Geotechnical Engineering Properties of Recycled Polyethylene Terephthalate Fibers and Strips for Soil Stabilization" Polymers 16, no. 13: 1764. https://doi.org/10.3390/polym16131764

APA StyleKhalid, B., & Alshawmar, F. (2024). Comprehensive Review of Geotechnical Engineering Properties of Recycled Polyethylene Terephthalate Fibers and Strips for Soil Stabilization. Polymers, 16(13), 1764. https://doi.org/10.3390/polym16131764