Exploring the Future of Polyhydroxyalkanoate Composites with Organic Fillers: A Review of Challenges and Opportunities

Abstract

1. Introduction

2. PHA Composites

3. Biodegradable Polymer Composites with Natural Waste Fillers

4. Applications and Properties

5. Current Developments

6. Challenges and Future Aspects

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tumu, K.; Vorst, K.; Curtzwiler, G. Global Plastic Waste Recycling and Extended Producer Responsibility Laws. J. Environ. Manag. 2023, 348, 119242. [Google Scholar] [CrossRef] [PubMed]

- Xu, Q.; Zhang, M.; Han, S. Reflections on the European Union’s Participation in Negotiations of the Global Plastic Pollution Instrument under International Environmental Law. Front. Mar. Sci. 2024, 11, 1388975. [Google Scholar] [CrossRef]

- Andrady, A.L. Assessment of Environmental Biodegradation of Synthetic Polymers. J. Macromol. Sci. Part C Polym. Rev. 1994, 34, 25–76. [Google Scholar] [CrossRef]

- Saleh Alghamdi, S.; John, S.; Roy Choudhury, N.; Dutta, N.K. Additive Manufacturing of Polymer Materials: Progress, Promise and Challenges. Polymers 2021, 13, 753. [Google Scholar] [CrossRef]

- Bhong, M.; Khan, T.K.; Devade, K.; Krishna, B.V.; Sura, S.; Eftikhaar, H.K.; Thethi, H.P.; Gupta, N. Review of Composite Materials and Applications. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Zaaba, N.F.; Ismail, H. Thermoplastic/Natural Filler Composites: A Short Review. J. Phys. Sci. 2019, 30, 81–99. [Google Scholar] [CrossRef]

- Philip, S.; Keshavarz, T.; Roy, I. Polyhydroxyalkanoates: Biodegradable Polymers with a Range of Applications. J. Chem. Technol. Biotechnol. Int. Res. Process Environ. Clean Technol. 2007, 82, 233–247. [Google Scholar] [CrossRef]

- Mukherjee, A.; Koller, M. Microbial polyHydroxyAlkanoate (PHA) Biopolymers—Intrinsically Natural. Bioengineering 2023, 10, 855. [Google Scholar] [CrossRef]

- Cinelli, P.; Mallegni, N.; Gigante, V.; Montanari, A.; Seggiani, M.; Coltelli, M.B.; Bronco, S.; Lazzeri, A. Biocomposites Based on Polyhydroxyalkanoates and Natural Fibres from Renewable Byproducts. Appl. Food Biotechnol. 2019, 6, 35–43. [Google Scholar]

- Mohit, H.; Mavinkere Rangappa, S.; Siengchin, S.; Gorbatyuk, S.; Manimaran, P.; Alka Kumari, C.; Khan, A.; Doddamani, M. A Comprehensive Review on Performance and Machinability of Plant Fiber Polymer Composites. Polym. Compos. 2022, 43, 608–623. [Google Scholar] [CrossRef]

- Dacko, P.; Kowalczuk, M.; Janeczek, H.; Sobota, M. Physical Properties of the Biodegradable Polymer Compositions Containing Natural Polyesters and Their Synthetic Analogues. In Macromolecular Symposia; Wiley Online Library: Weinheim, Germany, 2006; Volume 239, pp. 209–216. [Google Scholar]

- Das, P.P.; Chaudhary, V. Moving towards the Era of Bio Fibre Based Polymer Composites. Clean. Eng. Technol. 2021, 4, 100182. [Google Scholar] [CrossRef]

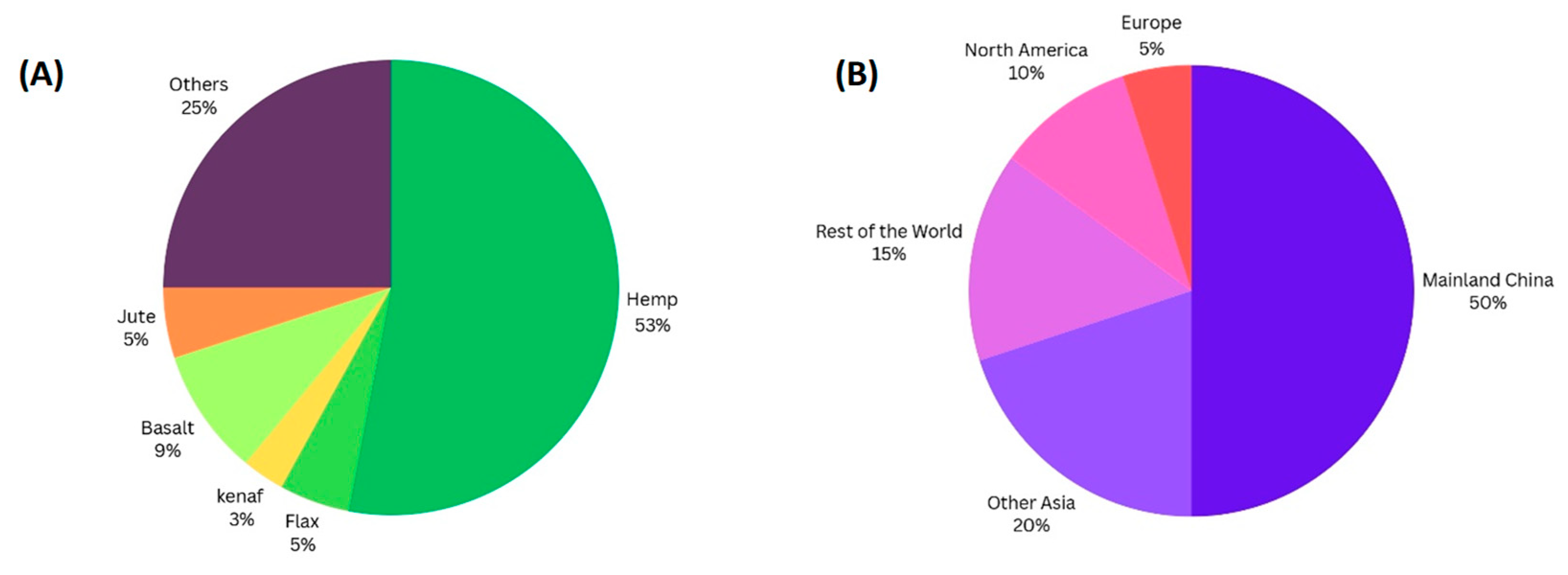

- Thapliyal, D.; Verma, S.; Sen, P.; Kumar, R.; Thakur, A.; Tiwari, A.K.; Singh, D.; Verros, G.D.; Arya, R.K. Natural Fibers Composites: Origin, Importance, Consumption Pattern, and Challenges. J. Compos. Sci. 2023, 7, 506. [Google Scholar] [CrossRef]

- Ramu, S.; Senthilkumar, N. Approaches of Material Selection, Alignment and Methods of Fabrication for Natural Fiber Polymer Composites: A Review. J. Appl. Nat. Sci. 2022, 14, 490–499. [Google Scholar] [CrossRef]

- Townsend, T. 1B—World Natural Fibre Production and Employment. In Handbook of Natural Fibres, 2nd ed.; Kozłowski, R.M., Mackiewicz-Talarczyk, M., Eds.; Woodhead Publishing Series in Textiles; Woodhead Publishing: Cambridge, UK, 2020; pp. 15–36. ISBN 978-0-12-818398-4. [Google Scholar]

- Akinmulewo, A.B.; Nwinyi, O.C. Polyhydroxyalkanoate: A Biodegradable Polymer (a Mini Review). J. Phys. Conf. Ser. 2019, 1378, 042007. [Google Scholar] [CrossRef]

- Vannini, M.; Marchese, P.; Sisti, L.; Saccani, A.; Mu, T.; Sun, H.; Celli, A. Integrated Efforts for the Valorization of Sweet Potato By-Products within a Circular Economy Concept: Biocomposites for Packaging Applications Close the Loop. Polymers 2021, 13, 1048. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Shen, J.; Chen, S.; Cooper, M.A.; Fu, H.; Wu, D.; Yang, Z. Nanofiller Reinforced Biodegradable PLA/PHA Composites: Current Status and Future Trends. Polymers 2018, 10, 505. [Google Scholar] [CrossRef] [PubMed]

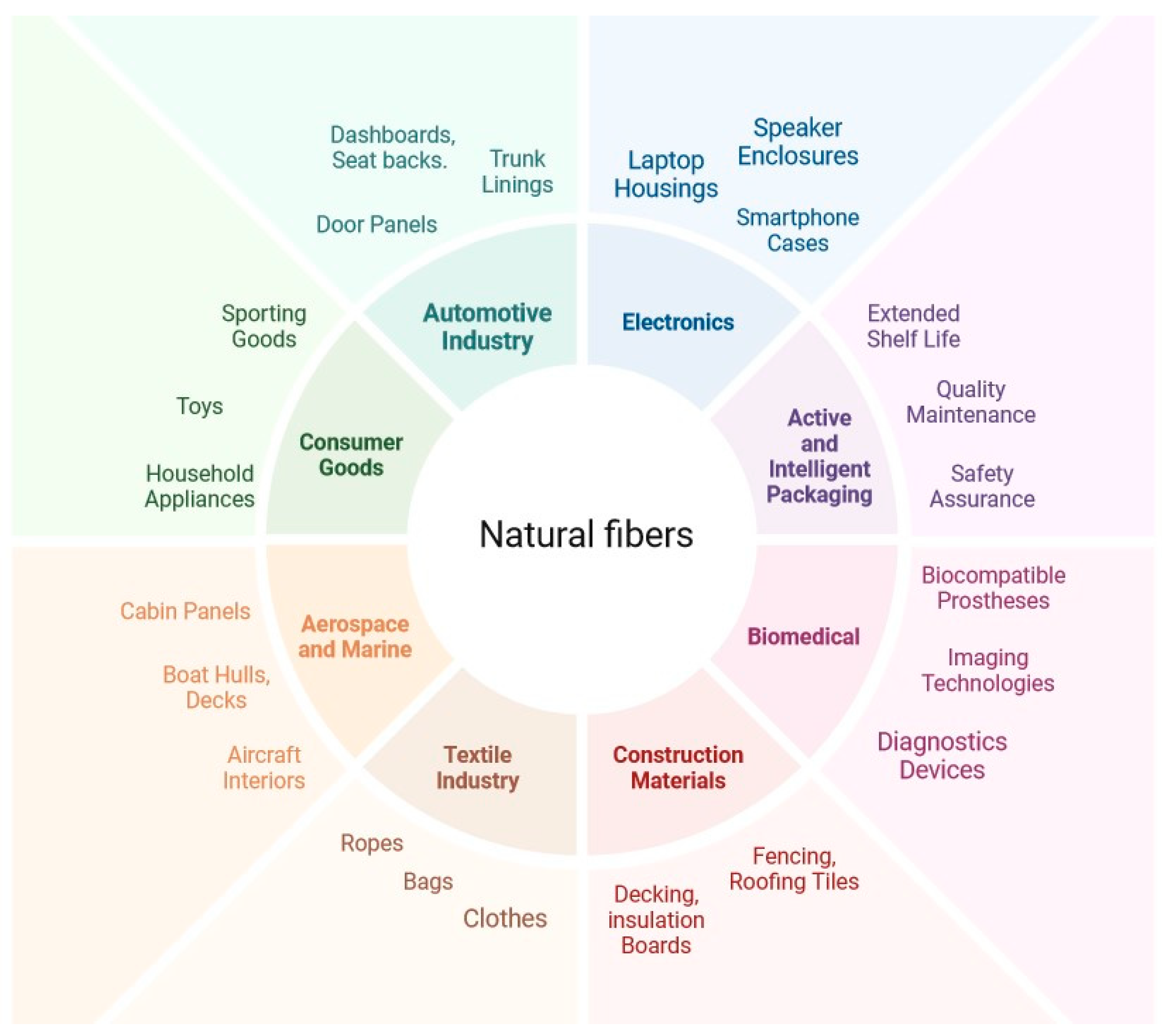

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef]

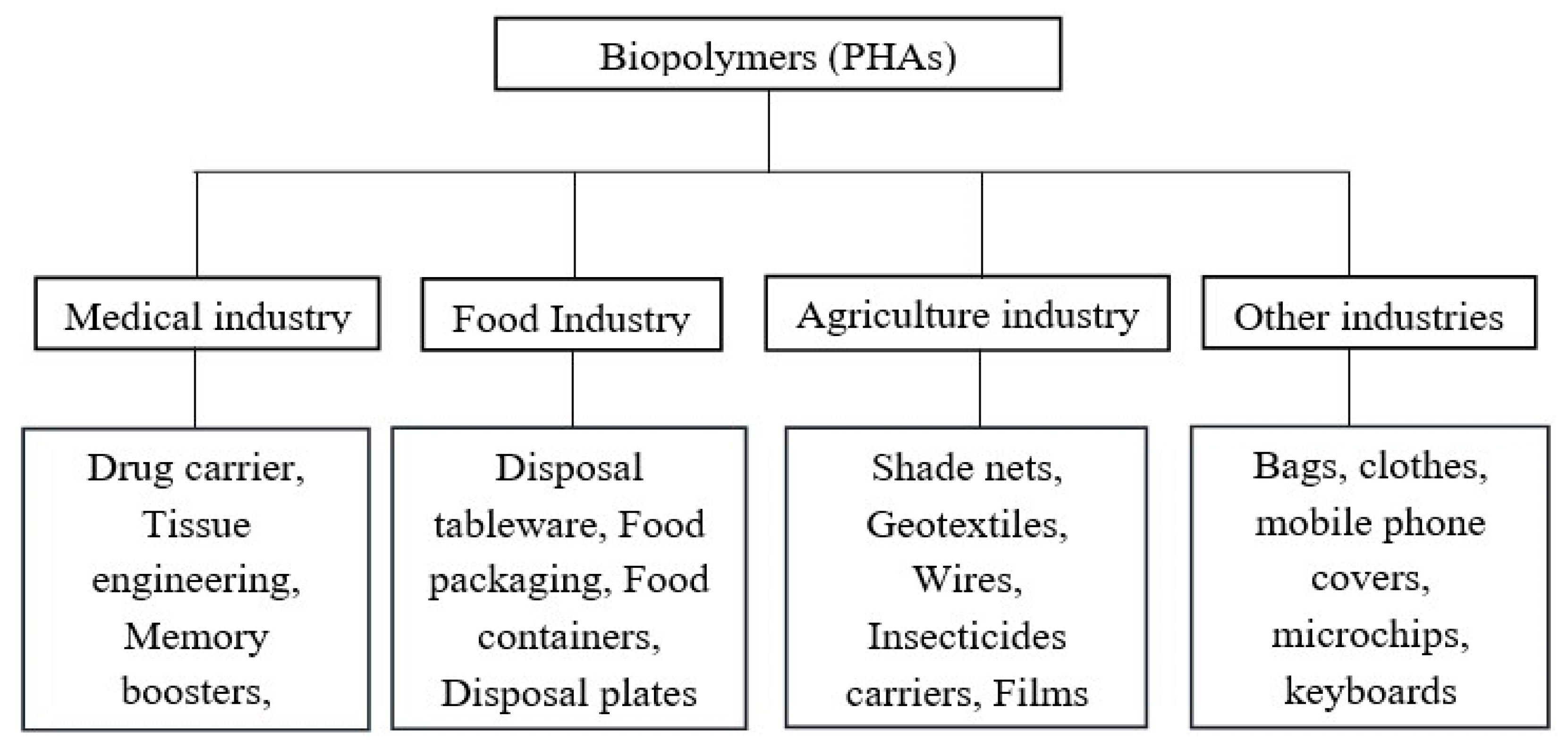

- Poltronieri, P.; Kumar, P. Polyhydroxyalkanoates (PHAs) in Industrial Applications. Handb. Ecomater. 2017, 4, 2843–2872. [Google Scholar]

- Raj, H.; Tripathi, S.; Bauri, S.; Choudhary, A.; Mandal, S.; Maiti, P. Green Composites Using Naturally Occurring Fibers: A Comprehensive Review. Sustain. Polym. Energy 2023, 1, 10010. [Google Scholar] [CrossRef]

- Dobrogojski, J.; Spychalski, M.; Luciński, R.; Borek, S. Transgenic Plants as a Source of Polyhydroxyalkanoates. Acta Physiol. Plant. 2018, 40, 162. [Google Scholar] [CrossRef]

- Chodak, I. Polyhydroxyalkanoates: Origin, Properties and Applications. In Monomers, Polymers and Composites from Renewable Resources; Elsevier: Amsterdam, The Netherlands, 2008; pp. 451–477. [Google Scholar]

- Maiti, S.; Islam, M.R.; Uddin, M.A.; Afroj, S.; Eichhorn, S.J.; Karim, N. Sustainable Fiber-reinforced Composites: A Review. Adv. Sustain. Syst. 2022, 6, 2200258. [Google Scholar] [CrossRef]

- Abd El-malek, F.; Khairy, H.; Farag, A.; Omar, S. The Sustainability of Microbial Bioplastics, Production and Applications. Int. J. Biol. Macromol. 2020, 157, 319–328. [Google Scholar] [CrossRef] [PubMed]

- Aeschelmann, F.; Carus, M. Bio-Based Building Blocks and Polymers in the World. Ind. Biotechnol. 2015, 11, 150514132956000. [Google Scholar]

- Vandi, L.-J.; Chan, C.M.; Werker, A.; Richardson, D.; Laycock, B.; Pratt, S. Wood-PHA Composites: Mapping Opportunities. Polymers 2018, 10, 751. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Tian, S.; Tao, F.; Yu, W. A Review of Artificial Neural Networks in the Constitutive Modeling of Composite Materials. Compos. Part B Eng. 2021, 224, 109152. [Google Scholar] [CrossRef]

- Fang, J.; Xie, M.; He, X.; Zhang, J.; Hu, J.; Chen, Y.; Yang, Y.; Jin, Q. Machine Learning Accelerates the Materials Discovery. Mater. Today Commun. 2022, 33, 104900. [Google Scholar] [CrossRef]

- Kibrete, F.; Trzepieciński, T.; Gebremedhen, H.S.; Woldemichael, D.E. Artificial Intelligence in Predicting Mechanical Properties of Composite Materials. J. Compos. Sci. 2023, 7, 364. [Google Scholar] [CrossRef]

- Luna, M.F.; Ochsner, A.M.; Amstutz, V.; von Blarer, D.; Sokolov, M.; Arosio, P.; Zinn, M. Modeling of Continuous PHA Production by a Hybrid Approach Based on First Principles and Machine Learning. Processes 2021, 9, 1560. [Google Scholar] [CrossRef]

- Bejagam, K.K.; Lalonde, J.; Iverson, C.N.; Marrone, B.L.; Pilania, G. Machine Learning for Melting Temperature Predictions and Design in Polyhydroxyalkanoate-Based Biopolymers. J. Phys. Chem. B 2022, 126, 934–945. [Google Scholar] [CrossRef]

- Kalak, T. Potential Use of Industrial Biomass Waste as a Sustainable Energy Source in the Future. Energies 2023, 16, 1783. [Google Scholar] [CrossRef]

- Jaffur, N.; Kumar, G.; Jeetah, P.; Ramakrishna, S.; Bhatia, S.K. Current Advances and Emerging Trends in Sustainable Polyhydroxyalkanoate Modification from Organic Waste Streams for Material Applications. Int. J. Biol. Macromol. 2023, 253, 126781. [Google Scholar] [CrossRef] [PubMed]

- Said, Z.; Sharma, P.; Nhuong, Q.T.B.; Bora, B.J.; Lichtfouse, E.; Khalid, H.M.; Luque, R.; Nguyen, X.P.; Hoang, A.T. Intelligent Approaches for Sustainable Management and Valorisation of Food Waste. Bioresour. Technol. 2023, 377, 128952. [Google Scholar] [CrossRef] [PubMed]

- Pagliari, P.; Wilson, M.; He, Z. Animal Manure Production and Utilization: Impact of Modern Concentrated Animal Feeding Operations. Anim. Manure: Prod. Charact. Environ. Concerns Manag. 2020, 67, 1–14. [Google Scholar]

- Ogbu, C.C.; Okey, S.N. Agro-Industrial Waste Management: The Circular and Bioeconomic Perspective. In Agricultural Waste-New Insights; IntechOpen: Rijeka, Croatia, 2023. [Google Scholar]

- He, D.; Hu, H.; Jiao, F.; Zuo, W.; Liu, C.; Xie, H.; Dong, L.; Wang, X. Thermal Separation of Heavy Metals from Municipal Solid Waste Incineration Fly Ash: A Review. Chem. Eng. J. 2023, 467, 143344. [Google Scholar] [CrossRef]

- Abdellatief, M.; Al-Tam, S.M.; Elemam, W.E.; Alanazi, H.; Elgendy, G.M.; Tahwia, A.M. Development of Ultra-High-Performance Concrete with Low Environmental Impact Integrated with Metakaolin and Industrial Wastes. Case Stud. Constr. Mater. 2023, 18, e01724. [Google Scholar] [CrossRef]

- Bagheri, M.; Bauer, T.; Burgman, L.E.; Wetterlund, E. Fifty Years of Sewage Sludge Management Research: Mapping Researchers’ Motivations and Concerns. J. Environ. Manag. 2023, 325, 116412. [Google Scholar] [CrossRef]

- Tripathi, N.; Hills, C.D.; Singh, R.S.; Atkinson, C.J. Biomass Waste Utilisation in Low-Carbon Products: Harnessing a Major Potential Resource. NPJ Clim. Atmos. Sci. 2019, 2, 35. [Google Scholar] [CrossRef]

- EPA. National Overview: Facts and Figures on Materials, Wastes and Recycling. Retrieved Novemb. 2020, 15, 2020. [Google Scholar]

- Mavugara, R.; Matsa, M.M. Resource Recovery from Municipal Wastewater Treatment Plants: The Zimbabwean Perspective. Circ. Econ. Sustain. 2024, 4, 363–386. [Google Scholar] [CrossRef]

- Singh, N.; Singhania, R.R.; Nigam, P.S.; Dong, C.-D.; Patel, A.K.; Puri, M. Global Status of Lignocellulosic Biorefinery: Challenges and Perspectives. Bioresour. Technol. 2022, 344, 126415. [Google Scholar] [CrossRef]

- Acharjee, S.A.; Bharali, P.; Gogoi, B.; Sorhie, V.; Walling, B.; Alemtoshi. PHA-Based Bioplastic: A Potential Alternative to Address Microplastic Pollution. Water Air Soil Pollut. 2023, 234, 21. [Google Scholar] [CrossRef] [PubMed]

- Musioł, M.; Rydz, J.; Janeczek, H.; Kordyka, A.; Andrzejewski, J.; Sterzyński, T.; Jurczyk, S.; Cristea, M.; Musioł, K.; Kampik, M. (Bio) Degradable Biochar Composites–Studies on Degradation and Electrostatic Properties. Mater. Sci. Eng. B 2022, 275, 115515. [Google Scholar] [CrossRef]

- Battista, F.; Frison, N.; Pavan, P.; Cavinato, C.; Gottardo, M.; Fatone, F.; Eusebi, A.L.; Majone, M.; Zeppilli, M.; Valentino, F. Food Wastes and Sewage Sludge as Feedstock for an Urban Biorefinery Producing Biofuels and Added-value Bioproducts. J. Chem. Technol. Biotechnol. 2020, 95, 328–338. [Google Scholar] [CrossRef]

- Khan, A.; Saxena, K.K. A Review on Enhancement of Mechanical Properties of Fiber Reinforcement Polymer Composite under Different Loading Rates. Mater. Today Proc. 2022, 56, 2316–2322. [Google Scholar] [CrossRef]

- Kordi, M.; Farrokhi, N.; Pech-Canul, M.I.; Ahmadikhah, A. Rice Husk at a Glance: From Agro-Industrial to Modern Applications. Rice Sci. 2023, 31, 14–32. [Google Scholar] [CrossRef]

- Jabu, M.A.; Alugongo, A.A.; Nkomo, N.Z. Application of Natural Fibre Composites in Interior Panels in the Automotive Industry: A Review. Int. J. Eng. Trends Technol. 2024, 72, 91–98. [Google Scholar] [CrossRef]

- Mohammed, L.; Ansari, M.N.; Pua, G.; Jawaid, M.; Islam, M.S. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. Int. J. Polym. Sci. 2015, 2015, 243947. [Google Scholar] [CrossRef]

- Nikodinovic-Runic, J.; Guzik, M.; Kenny, S.T.; Babu, R.; Werker, A.; Connor, K.E. Carbon-Rich Wastes as Feedstocks for Biodegradable Polymer (Polyhydroxyalkanoate) Production Using Bacteria. Adv. Appl. Microbiol. 2013, 84, 139–200. [Google Scholar]

- Coats, E.R.; Loge, F.J.; Wolcott, M.P.; Englund, K.; McDonald, A.G. Synthesis of Polyhydroxyalkanoates in Municipal Wastewater Treatment. Water Environ. Res. 2007, 79, 2396–2403. [Google Scholar] [CrossRef]

- Jiang, G.; Hill, D.J.; Kowalczuk, M.; Johnston, B.; Adamus, G.; Irorere, V.; Radecka, I. Carbon Sources for Polyhydroxyalkanoates and an Integrated Biorefinery. Int. J. Mol. Sci. 2016, 17, 1157. [Google Scholar] [CrossRef]

- Chirdon, W.M. Utilization of Biorefinery Waste Proteins as Feed, Glues, Composites, and Other Co-Products. In Algal Biorefineries: Volume 2: Products and Refinery Design; Springer: Cham, Switzerland, 2015; pp. 367–392. [Google Scholar]

- Brebu, M. Environmental Degradation of Plastic Composites with Natural Fillers—A Review. Polymers 2020, 12, 166. [Google Scholar] [CrossRef] [PubMed]

- La Mantia, F.P.; Morreale, M. Green Composites: A Brief Review. Compos. Part A: Appl. Sci. Manuf. 2011, 42, 579–588. [Google Scholar] [CrossRef]

- Dina, I.A.; Gimba, C.E.; Hamza, A.; Ekwumemgbo, P. The Study of using Natural Fillers on the Biodegradation Properties of Virgin/Waste low Density Polyethylene and Virgin/Waste High Density Polyethylene Composites. J. Chem. Soc. Niger. 2023, 48, 536–577. [Google Scholar] [CrossRef]

- Kaniuk, Ł.; Stachewicz, U. Development and Advantages of Biodegradable PHA Polymers Based on Electrospun PHBV Fibers for Tissue Engineering and Other Biomedical Applications. ACS Biomater. Sci. Eng. 2021, 7, 5339–5362. [Google Scholar] [CrossRef]

- Mohapatra, S.; Vishwakarma, K.; Joshi, N.C.; Maity, S.; Kumar, R.; Ramchander, M.; Pattnaik, S.; Samantaray, D.P. A Review on PHAs: The Future Biopolymer. In Environmental and Agricultural Microbiology, Applications for Sustainability; Scrivener Publishing LLC: Beverly, MA, USA, 2021; pp. 83–100. [Google Scholar]

- Saber, D.; Abdelnaby, A.H. Recent Developments in Natural Fiber as Reinforcement in Polymeric Composites: A Review. Asian J. Appl. Sci. Technol. (AJAST) 2022, 6, 56–75. [Google Scholar] [CrossRef]

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garnier, C. A Comprehensive Review of Natural Fibers and Their Composites: An Eco-Friendly Alternative to Conventional Materials. Results Eng. 2023, 19, 101271. [Google Scholar] [CrossRef]

- Koohestani, B.; Darban, A.K.; Mokhtari, P.; Yilmaz, E.; Darezereshki, E. Comparison of Different Natural Fiber Treatments: A Literature Review. Int. J. Environ. Sci. Technol. 2019, 16, 629–642. [Google Scholar] [CrossRef]

- Kolya, H.; Kang, C.W. Next-Generation Water Treatment: Exploring the Potential of Biopolymer-Based Nanocomposites in Adsorption and Membrane Filtration. Polymers 2023, 15, 3421. [Google Scholar] [CrossRef]

- Wang, D.-C.; Lei, S.-N.; Zhong, S.; Xiao, X.; Guo, Q.-H. Cellulose-Based Conductive Materials for Energy and Sensing Applications. Polymers 2023, 15, 4159. [Google Scholar] [CrossRef]

- Eissenberger, K.; Ballesteros, A.; De Bisschop, R.; Bugnicourt, E.; Cinelli, P.; Defoin, M.; Demeyer, E.; Fürtauer, S.; Gioia, C.; Gómez, L. Approaches in Sustainable, Biobased Multilayer Packaging Solutions. Polymers 2023, 15, 1184. [Google Scholar] [CrossRef]

- Musioł, M.; Janeczek, H.; Jurczyk, S.; Kwiecień, I.; Sobota, M.; Marcinkowski, A.; Rydz, J. (Bio) Degradation Studies of Degradable Polymer Composites with Jute in Different Environments. Fibers Polym. 2015, 16, 1362–1369. [Google Scholar] [CrossRef]

- Anwajler, B.; Zdybel, E.; Tomaszewska-Ciosk, E. Innovative Polymer Composites with Natural Fillers Produced by Additive Manufacturing (3D Printing)—A Literature Review. Polymers 2023, 15, 3534. [Google Scholar] [CrossRef] [PubMed]

- Jurczyk, S.; Musioł, M.; Sobota, M.; Klim, M.; Hercog, A.; Kurcok, P.; Janeczek, H.; Rydz, J. (Bio) Degradable Polymeric Materials for Sustainable Future—Part 2: Degradation Studies of P (3HB-Co-4HB)/Cork Composites in Different Environments. Polymers 2019, 11, 547. [Google Scholar] [CrossRef] [PubMed]

- Musioł, M.; Jurczyk, S.; Sobota, M.; Klim, M.; Sikorska, W.; Zięba, M.; Janeczek, H.; Rydz, J.; Kurcok, P.; Johnston, B. (Bio) Degradable Polymeric Materials for Sustainable Future—Part 3: Degradation Studies of the PHA/Wood Flour-Based Composites and Preliminary Tests of Antimicrobial Activity. Materials 2020, 13, 2200. [Google Scholar] [CrossRef] [PubMed]

- Kamarudin, S.H.; Mohd Basri, M.S.; Rayung, M.; Abu, F.; Ahmad, S.; Norizan, M.N.; Osman, S.; Sarifuddin, N.; Desa, M.S.Z.M.; Abdullah, U.H. A Review on Natural Fiber Reinforced Polymer Composites (NFRPC) for Sustainable Industrial Applications. Polymers 2022, 14, 3698. [Google Scholar] [CrossRef]

- Markevičiūtė, Z.; Varžinskas, V. Smart Material Choice: The Importance of Circular Design Strategy Applications for Bio-Based Food Packaging Preproduction and End-of-Life Life Cycle Stages. Sustainability 2022, 14, 6366. [Google Scholar] [CrossRef]

- Jan-Georg, R.; Langer, R.; Giovanni, T. Bioplastics for a Circular Economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar]

- Phiri, R.; Rangappa, S.M.; Siengchin, S.; Oladijo, O.P.; Dhakal, H.N. Development of Sustainable Biopolymer-Based Composites for Lightweight Applications from Agricultural Waste Biomass: A Review. Adv. Ind. Eng. Polym. Res. 2023, 6, 436–450. [Google Scholar] [CrossRef]

- Naser, A.Z.; Deiab, I.; Darras, B.M. Poly (Lactic Acid)(PLA) and Polyhydroxyalkanoates (PHAs), Green Alternatives to Petroleum-Based Plastics: A Review. RSC Adv. 2021, 11, 17151–17196. [Google Scholar] [CrossRef]

- Melendez-Rodriguez, B.; Torres-Giner, S.; Aldureid, A.; Cabedo, L.; Lagaron, J.M. Reactive Melt Mixing of Poly (3-Hydroxybutyrate)/Rice Husk Flour Composites with Purified Biosustainably Produced Poly (3-Hydroxybutyrate-Co-3-Hydroxyvalerate). Materials 2019, 12, 2152. [Google Scholar] [CrossRef]

- Zhang, K.; Misra, M.; Mohanty, A.K. Toughened Sustainable Green Composites from Poly (3-Hydroxybutyrate-Co-3-Hydroxyvalerate) Based Ternary Blends and Miscanthus Biofiber. ACS Sustain. Chem. Eng. 2014, 2, 2345–2354. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Julian, F.; Espinach, F.X.; Tarrés, Q.; Ardanuy, M.; Mutjé, P. Research on the Use of Lignocellulosic Fibers Reinforced Bio-Polyamide 11 with Composites for Automotive Parts: Car Door Handle Case Study. J. Clean. Prod. 2019, 226, 64–73. [Google Scholar] [CrossRef]

- Berzin, F.; Vergnes, B. Thermoplastic Natural Fiber Based Composites. In Fiber Reinforced Composites; Elsevier: Amsterdam, The Netherlands, 2021; pp. 113–139. [Google Scholar]

- Halley, P.J.; Dorgan, J.R. Next-Generation Biopolymers: Advanced Functionality and Improved Sustainability. MRS Bull. 2011, 36, 687–691. [Google Scholar] [CrossRef]

- Khamkong, T.; Penkhrue, W.; Lumyong, S. Optimization of Production of Polyhydroxyalkanoates (PHAs) from Newly Isolated Ensifer Sp. Strain HD34 by Response Surface Methodology. Processes 2022, 10, 1632. [Google Scholar] [CrossRef]

- Suhaily, S.S.; Khalil, H.A.; Nadirah, W.W.; Jawaid, M. Bamboo Based Biocomposites Material, Design and Applications. In Materials Science-Advanced Topics; IntechOpen: Rijeka, Croatia, 2013; ISBN 953-51-1140-X. [Google Scholar]

- Lange, J.-P. Managing Plastic Waste—Sorting, Recycling, Disposal, and Product Redesign. ACS Sustain. Chem. Eng. 2021, 9, 15722–15738. [Google Scholar] [CrossRef]

- Mishra, T.; Mandal, P.; Rout, A.K.; Sahoo, D. A State-of-the-Art Review on Potential Applications of Natural Fiber-Reinforced Polymer Composite Filled with Inorganic Nanoparticle. Compos. Part C Open Access 2022, 9, 100298. [Google Scholar] [CrossRef]

- Marciniak, P.; Możejko-Ciesielska, J. What Is New in the Field of Industrial Wastes Conversion into Polyhydroxyalkanoates by Bacteria? Polymers 2021, 13, 1731. [Google Scholar] [CrossRef] [PubMed]

- Mohanty, A.K.; Misra, M.; Hinrichsen, G.I. Biofibres, Biodegradable Polymers and Biocomposites: An Overview. Macromol. Mater. Eng. 2000, 276–277, 1–24. [Google Scholar] [CrossRef]

- Wang, C.; Yu, J.; Lu, Y.; Hua, D.; Wang, X.; Zou, X. Biodegradable Microplastics (BMPs): A New Cause for Concern? Environ. Sci. Pollut. Res. 2021, 28, 66511–66518. [Google Scholar] [CrossRef]

- Malafeev, K.V.; Apicella, A.; Incarnato, L.; Scarfato, P. Understanding the Impact of Biodegradable Microplastics on Living Organisms Entering the Food Chain: A Review. Polymers 2023, 15, 3680. [Google Scholar] [CrossRef]

| Waste Substrate | Commercial Volume (Million Tons/Year) | Applications | References |

|---|---|---|---|

| Food waste | 931 | Bio-gas | [35] |

| Animal waste | 1400 | Fertilizers, bio-energy | [36] |

| Agriculture waste | 2500 | Recycling materials | [37] |

| Municipal waste | 2240 | Energy resource | [38] |

| Industrial waste | 84.5 | Coal Combustion products | [39] |

| Sewage waste | 10.4 | Fertilizer, soil improver | [40] |

| Forest residue | 4600 | Bio-fuel production | [41] |

| Paper waste | 67.4 | Newspapers, towels | [42] |

| Wastewater | 0.264–0.600 | Treated wastewater | [43] |

| Lignocellulosic waste | 2009 | Animal feed | [44] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thakur, A.; Musioł, M.; Duale, K.; Kowalczuk, M. Exploring the Future of Polyhydroxyalkanoate Composites with Organic Fillers: A Review of Challenges and Opportunities. Polymers 2024, 16, 1768. https://doi.org/10.3390/polym16131768

Thakur A, Musioł M, Duale K, Kowalczuk M. Exploring the Future of Polyhydroxyalkanoate Composites with Organic Fillers: A Review of Challenges and Opportunities. Polymers. 2024; 16(13):1768. https://doi.org/10.3390/polym16131768

Chicago/Turabian StyleThakur, Abhishek, Marta Musioł, Khadar Duale, and Marek Kowalczuk. 2024. "Exploring the Future of Polyhydroxyalkanoate Composites with Organic Fillers: A Review of Challenges and Opportunities" Polymers 16, no. 13: 1768. https://doi.org/10.3390/polym16131768

APA StyleThakur, A., Musioł, M., Duale, K., & Kowalczuk, M. (2024). Exploring the Future of Polyhydroxyalkanoate Composites with Organic Fillers: A Review of Challenges and Opportunities. Polymers, 16(13), 1768. https://doi.org/10.3390/polym16131768