Comparative Analysis of Impact Strength among Various Polymeric Materials for Orthotic Production

Abstract

1. Introduction

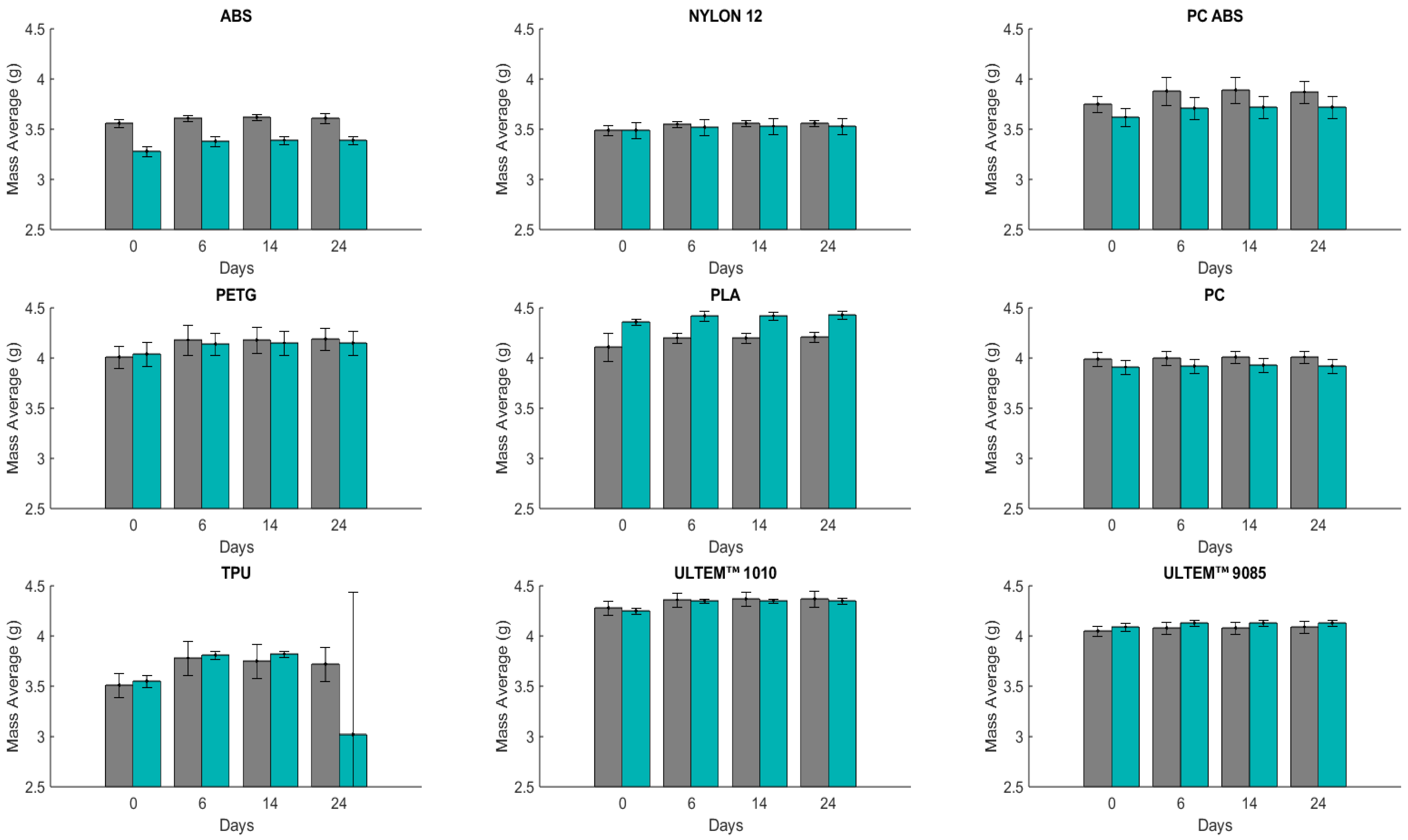

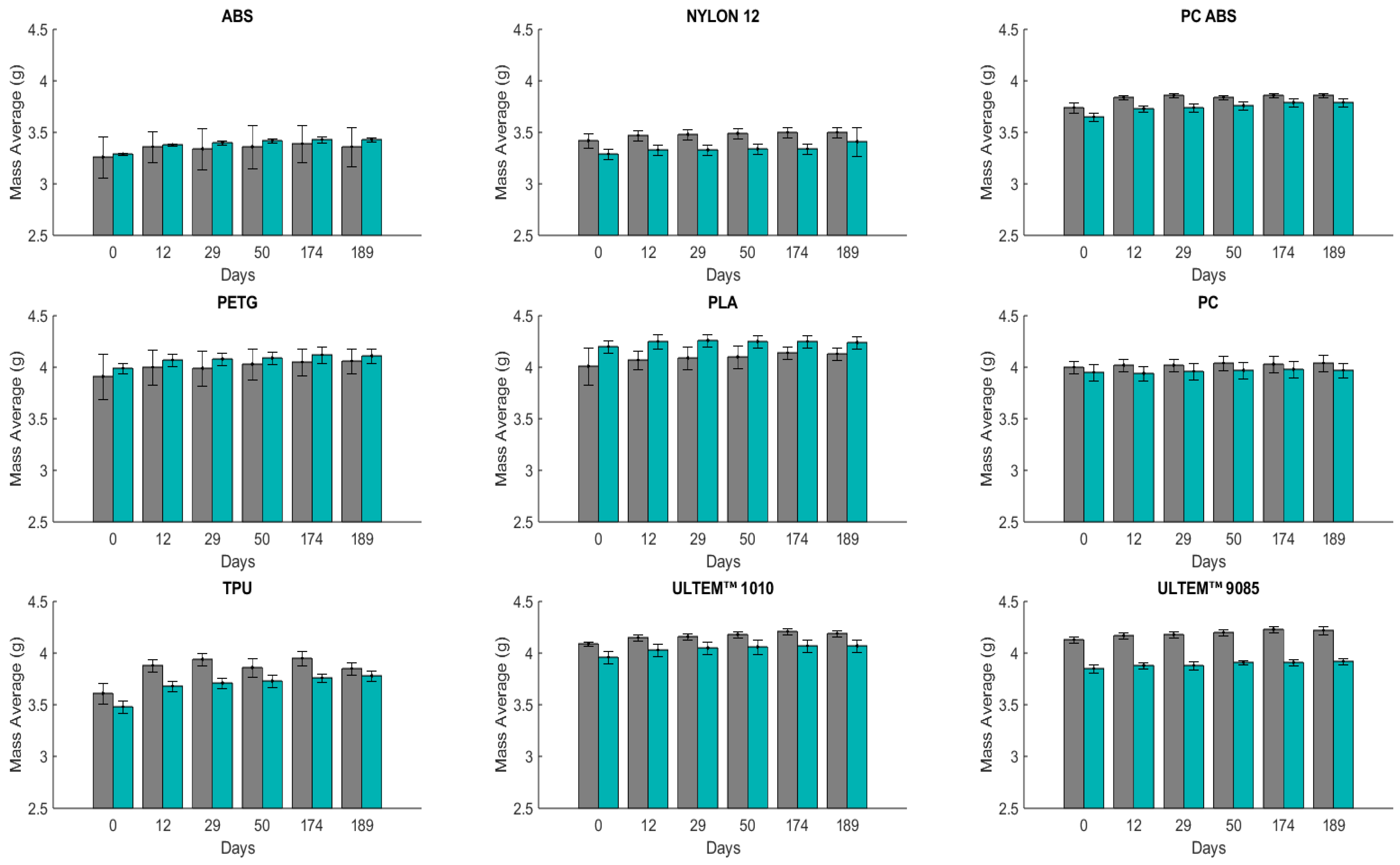

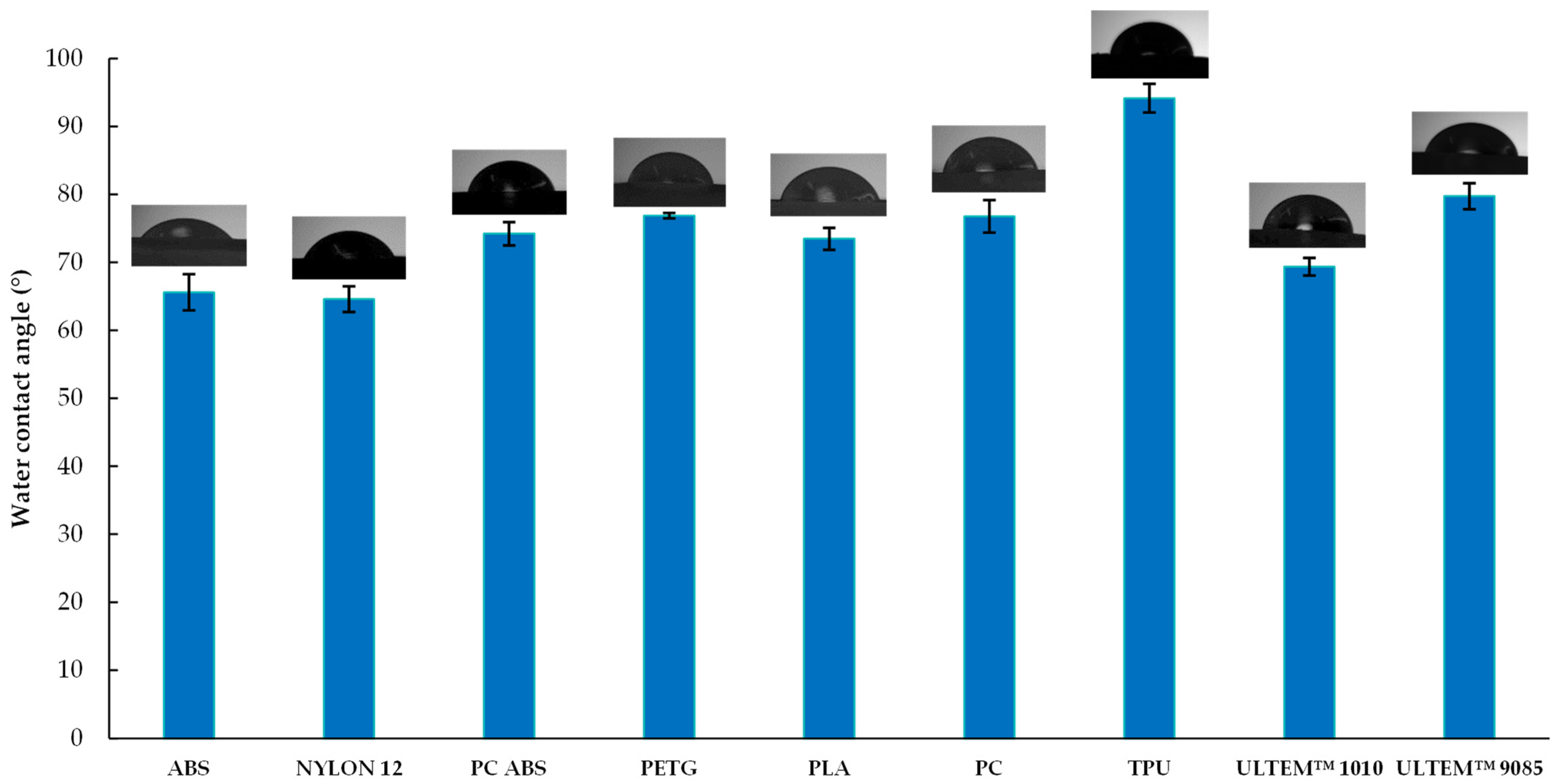

- It is important to understand sweat’s influence on polymeric materials’ mechanical properties. The materials were subjected to artificial sweat with a pH of 6.3, simulating physiological conditions. By analyzing the changes in mechanical behavior resulting from exposure to sweat, the present study aimed to gain insights into the suitability of these materials for applications involving contact with human skin;

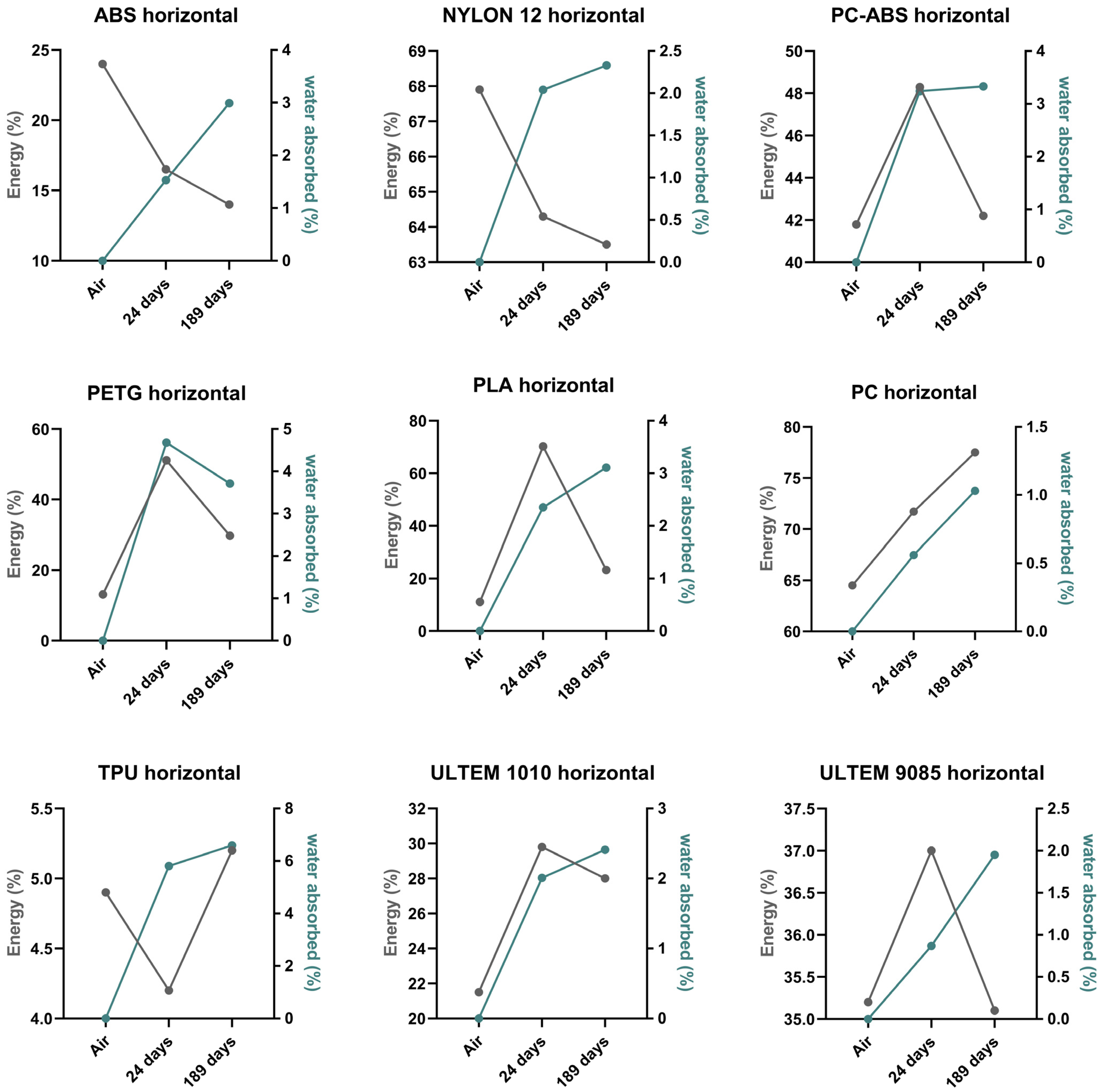

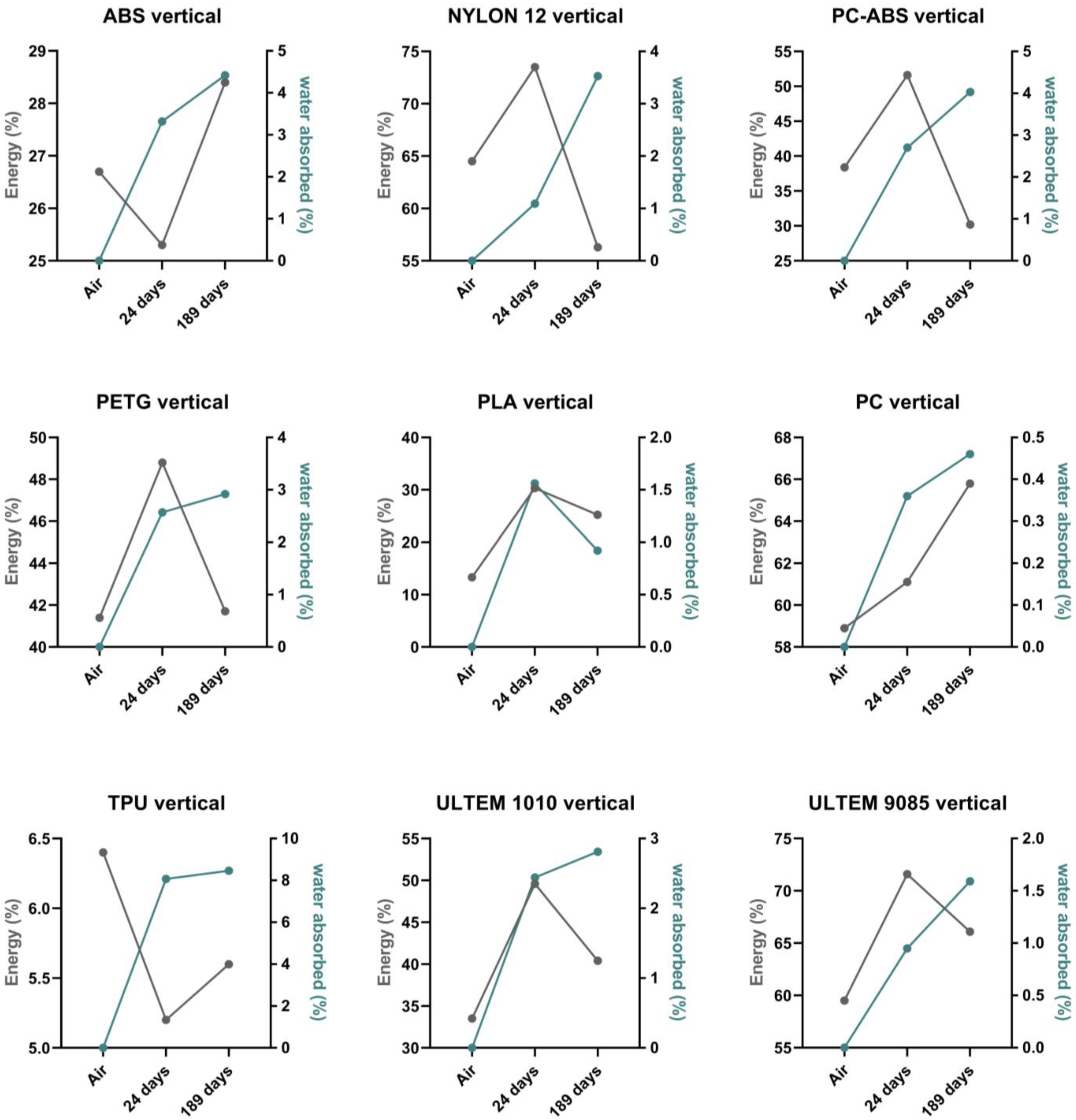

- The impact strength of the samples was evaluated in different printing orientations (vertical and horizontal) and under varying environmental conditions, including exposure to air and immersion in artificial sweat. The purpose of conducting these tests was to determine the materials’ ability to withstand impact forces and identify any variations in their performance based on different orientations (i.e., determining which orientation results in optimal mechanical properties and performance) and environmental exposures. This information can help select the most suitable material and orientation for the specific application;

- The use of additively manufactured polymeric materials for medical orthotics is attracting the interest of the scientific world nowadays; by understanding the mechanical behavior of these materials in different environmental conditions, including exposure to sweat, their suitability for orthotic applications can be determined and improved. This knowledge is crucial for developing orthotic devices that offer the necessary support and durability while maintaining comfort for the wearer.

2. Materials and Methods

3. Results and Discussion

4. Conclusions

- ULTEMTM 9085 samples showed an anisotropy behavior during the impact test. This reveals an important consideration in the choice of printing orientation.

- Vertically printed samples displayed higher energy absorption than those printed horizontally. Materials like PC and NYLON 12 consistently displayed strong impact strength.

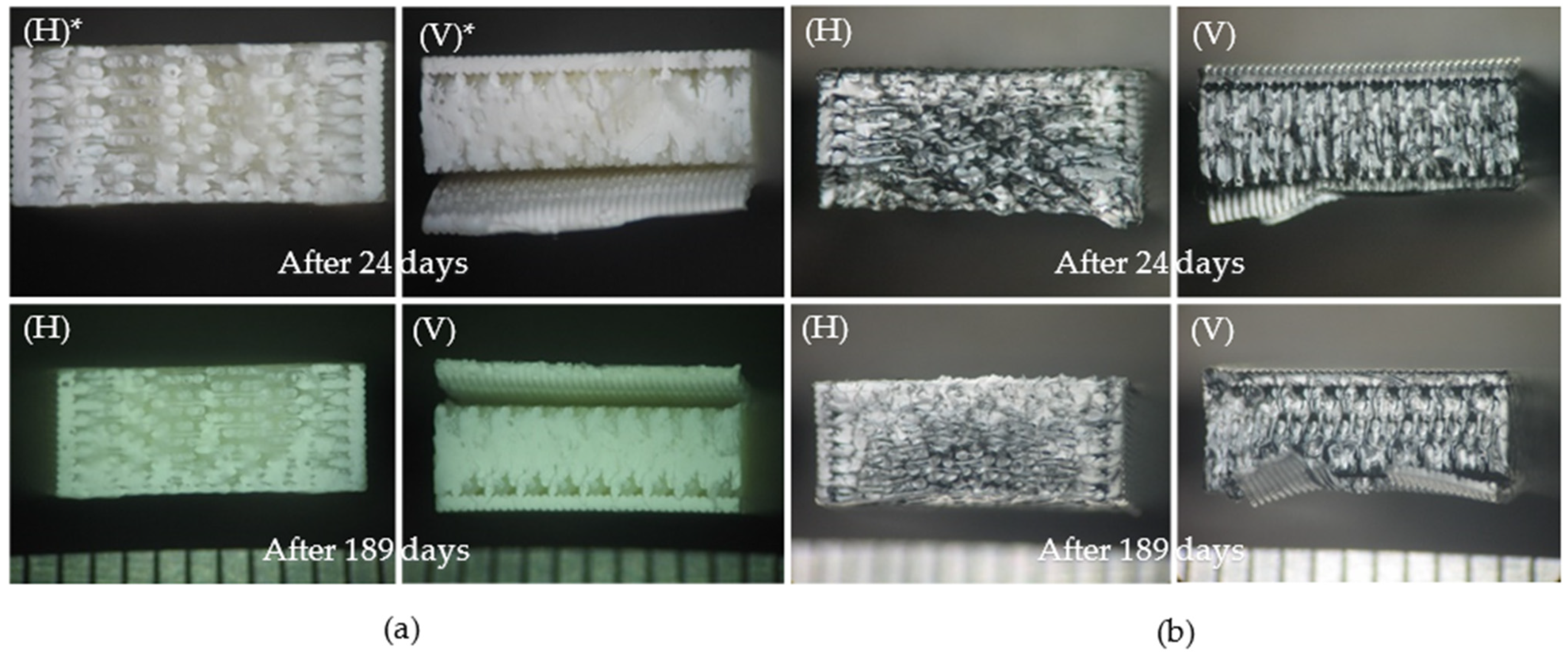

- For a long-term use, PC would be a good choice as a material for the manufacturing of orthotics because of its resistance to liquid penetration and its good energy absorption.

- For a short-term use, NYLON 12 would be recommended because of its high energy absorption percentage after 24 days of immersion.

- Failure was associated with the presence of voids or pores along with crack propagation. PC, which exhibited the greatest energy absorption, showed a melted fracture surface.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Faustini, M.C.; Neptune, R.R.; Crawford, R.H.; Stanhope, S.J. Manufacture of Passive Dynamic Ankle–Foot Orthoses Using Selective Laser Sintering. IEEE Trans. Biomed. Eng. 2008, 55, 784–790. [Google Scholar] [CrossRef] [PubMed]

- Paterson, A.M.J.; Bibb, R.J.; Campbell, R.I. A Review of Existing Anatomical Data Capture Methods to Support the Mass Customisation of Wrist Splints. Virtual Phys. Prototyp. 2010, 5, 201–207. [Google Scholar] [CrossRef]

- Baronio, G.; Harran, S.; Signoroni, A. A Critical Analysis of a Hand Orthosis Reverse Engineering and 3D Printing Process. Appl. Bionics Biomech. 2016, 2016, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Cazon, A.; Kelly, S.; Paterson, A.M.; Bibb, R.J.; Campbell, R.I. Analysis and Comparison of Wrist Splint Designs Using the Finite Element Method: Multi-Material Three-Dimensional Printing Compared to Typical Existing Practice with Thermoplastics. Proc. Inst. Mech. Eng. H 2017, 231, 881–897. [Google Scholar] [CrossRef] [PubMed]

- Volonghi, P.; Baronio, G.; Signoroni, A. 3D Scanning and Geometry Processing Techniques for Customised Hand Orthotics: An Experimental Assessment. Virtual Phys. Prototyp. 2018, 13, 105–116. [Google Scholar] [CrossRef]

- Prata Bagulho Santos, S. Desenvolvimento de Novos Produtos Para Medicina de Reabilitação Com Recurso à Fabricação Aditiva: Design Customizado de Uma Ortótese de Posicionamento de Joelho. Master’s Dissertation, Técnico Lisboa, Lisbon, Portugal, 2015. [Google Scholar]

- Yan, T.; Cempini, M.; Oddo, C.M.; Vitiello, N. Review of Assistive Strategies in Powered Lower-Limb Orthoses and Exoskeletons. Rob. Auton. Syst. 2015, 64, 120–136. [Google Scholar] [CrossRef]

- Liaw, C.-Y.; Guvendiren, M. Current and Emerging Applications of 3D Printing in Medicine. Biofabrication 2017, 9, 024102. [Google Scholar] [CrossRef] [PubMed]

- Santos, S.; Soares, B.; Leite, M.; Jacinto, J. Design and Development of a Customised Knee Positioning Orthosis Using Low Cost 3D Printers. Virtual Phys. Prototyp. 2017, 12, 322–332. [Google Scholar] [CrossRef]

- Leopoldino De Brito, C.; Neto, G.; Alves, D.; Nagem, P.; Roberto, H.; Karilany, H.; Coutinho, D.; Alexsandro, R.; Valentim, M. Tecnologia 3D NA SAÚDE Uma Visão Sobre Órteses e Próteses, Tecnologias Assistivas e Modelagem 3D; Sedisufrn: Lagoa Nova, Brazil, 2018; ISBN 9788593839535. [Google Scholar]

- Puppi, D.; Chiellini, F. Biodegradable Polymers for Biomedical Additive Manufacturing. Appl. Mater. Today 2020, 20, 100700. [Google Scholar] [CrossRef]

- Singh, N.; Singh, G. Advances in Polymers for Bio-Additive Manufacturing: A State of Art Review. J. Manuf. Process 2021, 72, 439–457. [Google Scholar] [CrossRef]

- Arif, Z.U.; Khalid, M.Y.; Noroozi, R.; Hossain, M.; Shi, H.H.; Tariq, A.; Ramakrishna, S.; Umer, R. Additive Manufacturing of Sustainable Biomaterials for Biomedical Applications. Asian J. Pharm. Sci. 2023, 18, 100812. [Google Scholar] [CrossRef] [PubMed]

- Regina Alves da Silva, J. Avaliação e Certificação de Dispositivos Protéticos e Ortéticos Para Membro Inferior. Master ‘s Thesis, University of Porto, Porto, Portugal, 2014. [Google Scholar]

- Berge, J.; Lerneryd, E. Spring Orthosis Analysis Finite Element Modelling and Optimization of a Composite Material. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2010. [Google Scholar]

- Wach, A. Mechanical Characterization of Carbon Fiber and Thermoplastic Ankle Foot Orthoses. Master’s Thesis, Marquette University, Milwaukee, WI, USA, 2009. [Google Scholar]

- Saharan, L.; Sharma, A.; Jung de Andrade, M.; Baughman, R.H.; Tadesse, Y. Design of a 3D Printed Lightweight Orthotic Device Based on Twisted and Coiled Polymer Muscle: IGrab Hand Orthosis. In Active and Passive Smart Structures and Integrated Systems 2017; SPIE: Bellingham, WA, USA, 2017; Volume 10164, p. 1016428. [Google Scholar]

- Yu, H.Z.; Cross, S.R.; Schuh, C.A. Mesostructure Optimization in Multi-Material Additive Manufacturing: A Theoretical Perspective. J. Mater. Sci. 2017, 52, 4288–4298. [Google Scholar] [CrossRef]

- Paterson, A.M.; Bibb, R.J.; Campbell, R.I. Evaluation of a Digitised Splinting Approach with Multiple-Material Functionality Using Additive Manufacturing Technologies; University of Loughborough: Leicestershire, UK, 2012. [Google Scholar]

- Walbran, M.; Turner, K.; McDaid, A.J. Customized 3D Printed Ankle-Foot Orthosis with Adaptable Carbon Fibre Composite Spring Joint. Cogent Eng. 2016, 3, 1227022. [Google Scholar] [CrossRef]

- Habiba, R.; Amaro, A.; Moura, C.; Silva, R.; Trindade, D.; Antão, A.; Martins, R.; Malça, C.; Branco, R. Impact Resistance of Additively Manufactured Polymeric Materials for Biomedical Applications. In Proceedings of the 10th Congress of the Portuguese Society of Biomechanics; Lecture Notes in Bioengineering; Springer: Cham, Switzerland, 2023; pp. 333–341. [Google Scholar] [CrossRef]

- Kumar, A.; Chhabra, D. Adopting Additive Manufacturing as a Cleaner Fabrication Framework for Topologically Optimized Orthotic Devices: Implications over Sustainable Rehabilitation. Clean. Eng. Technol. 2022, 10, 100559. [Google Scholar] [CrossRef]

- Russell, E.; Koren, G.; Rieder, M.; Van Uum, S.H.M. The Detection of Cortisol in Human Sweat. Ther. Drug Monit. 2014, 36, 30–34. [Google Scholar] [CrossRef]

- Jadoon, S.; Karim, S.; Akram, M.R.; Kalsoom Khan, A.; Zia, M.A.; Siddiqi, A.R.; Murtaza, G. Recent Developments in Sweat Analysis and Its Applications. Int. J. Anal. Chem. 2015, 2015, 1–7. [Google Scholar] [CrossRef] [PubMed]

- ISO 179; Plastics—Determination of Charpy Impact Properties. International Organization for Standardization (ISO): Geneva, Switzerland, 2000.

- Chen, S.-C.; Su, H.; Mathew, J.J.; Gunawan, H.; Huang, C.-W.; Feng, C.-T. An Investigation to Reduce the Effect of Moisture on Injection-Molded Parts through Optimization of Plasticization Parameters. Appl. Sci. 2022, 12, 1410. [Google Scholar] [CrossRef]

- Boubakri, A.; Elleuch, K.; Guermazi, N.; Ayedi, H.F. Investigations on Hygrothermal Aging of Thermoplastic Polyurethane Material. Mater. Des. 2009, 30, 3958–3965. [Google Scholar] [CrossRef]

- Boubakri, A.; Haddar, N.; Elleuch, K.; Bienvenu, Y. Impact of Aging Conditions on Mechanical Properties of Thermoplastic Polyurethane. Mater. Des. 2010, 31, 4194–4201. [Google Scholar] [CrossRef]

- Palencia, M. Surface Free Energy of Solids by Contact Angle Measurements. J. Sci. Technol. Appl. 2017, 2, 84–93. [Google Scholar] [CrossRef]

- Chodkowski, M.; Sulym, I.Y.; Terpiłowski, K.; Sternik, D. Surface Properties of Silica–MWCNTs/PDMS Composite Coatings Deposited on Plasma Activated Glass Supports. Appl. Sci. 2021, 11, 9256. [Google Scholar] [CrossRef]

- Chodkowski, M.P. Significance of the Receding Contact Angle in the Determination of Surface Free Energy. Ann. Univ. Mariae Curie-Sklodowska Sect. AA—Chem. 2019, 73, 61. [Google Scholar] [CrossRef]

- Kizhakkinan, U.; Rosen, D.W.; Raghavan, N. Experimental Investigation of Fracture Toughness of Fused Deposition Modeling 3D-Printed PLA Parts. Mater. Today Proc. 2022, 70, 631–637. [Google Scholar] [CrossRef]

| Material | Filament Diameter (mm) | Ultimate Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|---|

| ABS | 1.75 | 28.1 | 8.1 |

| NYLON 12 | 1.75 | 49.3 | 6.1 |

| PC ABS | 1.75 | 36.5 | 3.0 |

| PETG | 1.75 | 29 | 140 |

| PLA | 1.75 | 65.5 | 4.3 |

| PC | 1.75 | 57.9 | 4.9 |

| TPU | 1.75 | 15.6 | 552 |

| ULTEM™ 1010 | 1.75 | 79.2 | 4.0 |

| ULTEM™ 9085 | 1.75 | 68.1 | 5.4 |

| Materials | Dry Environment (%) | Wet Environment (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| After 24 Days | After 189 Days | ||||||||

| (H) | (V) | p-Value | (H) | (V) | p-Value | (H) | (V) | p-Value | |

| ABS | 24.0 ± 2.2 | 26.7 ± 1.7 | NS | 16.5 ± 1.0 | 25.3 ± 3.3 | NS | 14.0 ± 3.8 | 28.4 ± 3.1 | ** |

| - | - | - | # | NS | - | # | NS | - | |

| NYLON 12 | 67.9 ± 3.0 | 64.5 ± 0.1 | NS | 64.3 ± 1.4 | 73.5 ± 20.5 | NS | 63.5 ± 3.7 | 56.3 ± 3.8 | NS |

| - | - | - | NS | NS | - | NS | NS | - | |

| PC ABS | 41.8 ± 15.5 | 38.4 ± 1.6 | NS | 48.3 ± 3.6 | 51.6 ± 16.0 | NS | 42.2 ± 2.3 | 30.2 ± 1.2 | ** |

| - | - | - | NS | NS | - | NS | ## | - | |

| PETG | 13.1 ± 6.3 | 41.4 ± 3.6 | ** | 51.1 ± 35.0 | 48.8 ± 21.1 | NS | 29.7 ± 10.5 | 41.7 ± 15.0 | NS |

| - | - | - | NS | NS | - | NS | NS | - | |

| PLA | 11.1 ± 0.6 | 13.3 ± 3.2 | NS | 70.2 ± 40.2 | 30.3 ± 3.6 | NS | 23.2 ± 9.0 | 25.2 ± 5.0 | NS |

| - | - | - | NS | ## | - | NS | # | - | |

| PC | 64.5 ± 4.7 | 58.9 ± 4.3 | NS | 71.7 ± 20.0 | 61.1 ± 2.7 | NS | 77.5 ± 7.0 | 65.8 ± 1.2 | NS |

| - | - | - | NS | NS | - | NS | NS | - | |

| TPU | 4.9 ± 0.2 | 6.4 ± 0.3 | ** | 4.2 ± 0.3 | 5.2 ± 0.1 | ** | 5.2 ± 0.6 | 5.6 ± 1.2 | NS |

| - | - | - | # | # | - | NS | NS | - | |

| ULTEM™ 1010 | 21.5 ± 2.1 | 33.5 ± 10.0 | NS | 29.8 ± 4.7 | 49.6 ± 9.6 | NS | 28.0 ± 3. 6 | 40.4 ± 11.0 | NS |

| - | - | - | NS | NS | - | NS | NS | - | |

| ULTEM™ 9085 | 35.2 ± 3.5 | 59.5 ± 16.4 | NS | 37.0 ± 5.2 | 71.6 ± 1.8 | *** | 35.1 ± 2.6 | 66.1 ± 6.7 | ** |

| - | - | - | NS | NS | - | NS | NS | - | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Habiba, R.; Amaro, A.; Trindade, D.; Moura, C.; Silva, R.; Antão, A.; Martins, R.F.; Malça, C.; Branco, R. Comparative Analysis of Impact Strength among Various Polymeric Materials for Orthotic Production. Polymers 2024, 16, 1843. https://doi.org/10.3390/polym16131843

Habiba R, Amaro A, Trindade D, Moura C, Silva R, Antão A, Martins RF, Malça C, Branco R. Comparative Analysis of Impact Strength among Various Polymeric Materials for Orthotic Production. Polymers. 2024; 16(13):1843. https://doi.org/10.3390/polym16131843

Chicago/Turabian StyleHabiba, Rachel, Ana Amaro, Daniela Trindade, Carla Moura, Rui Silva, André Antão, Rui F. Martins, Cândida Malça, and Ricardo Branco. 2024. "Comparative Analysis of Impact Strength among Various Polymeric Materials for Orthotic Production" Polymers 16, no. 13: 1843. https://doi.org/10.3390/polym16131843

APA StyleHabiba, R., Amaro, A., Trindade, D., Moura, C., Silva, R., Antão, A., Martins, R. F., Malça, C., & Branco, R. (2024). Comparative Analysis of Impact Strength among Various Polymeric Materials for Orthotic Production. Polymers, 16(13), 1843. https://doi.org/10.3390/polym16131843