Review of Recent Progress on Silicone Rubber Composites for Multifunctional Sensor Systems

Abstract

1. Introduction

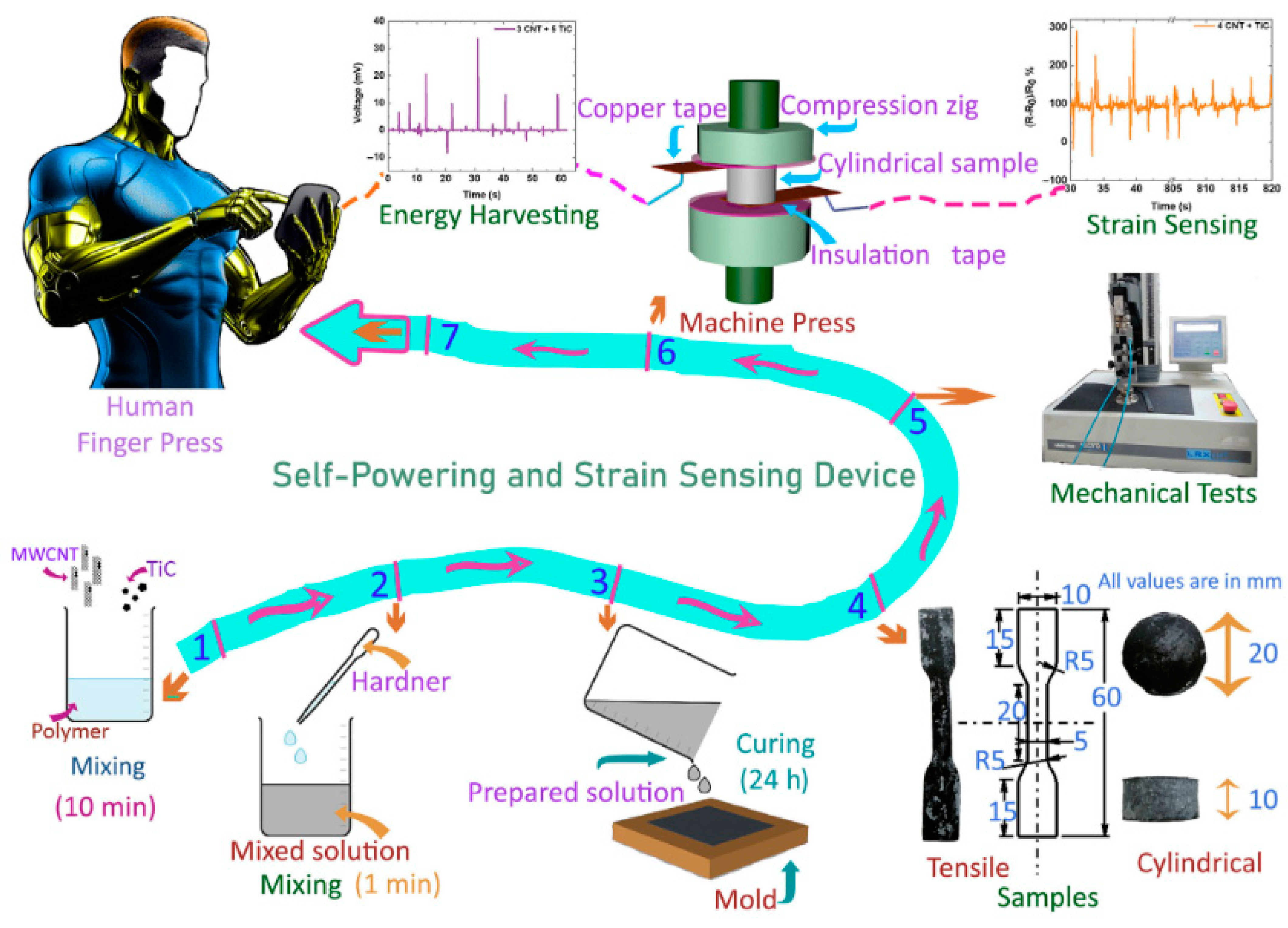

2. Fabrication and Testing Methods

- Steps 1 and 2: Optimized mixing of a known amount of silicone rubber solution with a known amount of fillers, like titanium carbide and MWCNT, was reported. It was performed through solution mixing for 10 min. Then, the known amount of vulcanizing agent was added and mixed for 1 min before pouring them into the mold.

- Steps 3 and 4: The desired shape and size of the molds were used for pouring the composite after mixing the vulcanizing agent. These molds were then pressed manually and kept at room temperature for 24 h for vulcanizing. The samples with desired dimensions were prepared and made ready for testing

- Steps 5 and 6: The cylindrical and dumbbell samples were used to test mechanical and electro-mechanical properties through a universal testing machine and a multimeter. The cylindrical samples were used to study the compressive modulus. The dumbbell sample was used to study the tensile modulus, tensile strength, elongation at break, and fracture toughness.

- Step 7: Finally, the real-time monitoring for strain sensors and self-powered devices was performed through finger bending, wrist bending, thumb pressing, and finger pressing.

3. Properties

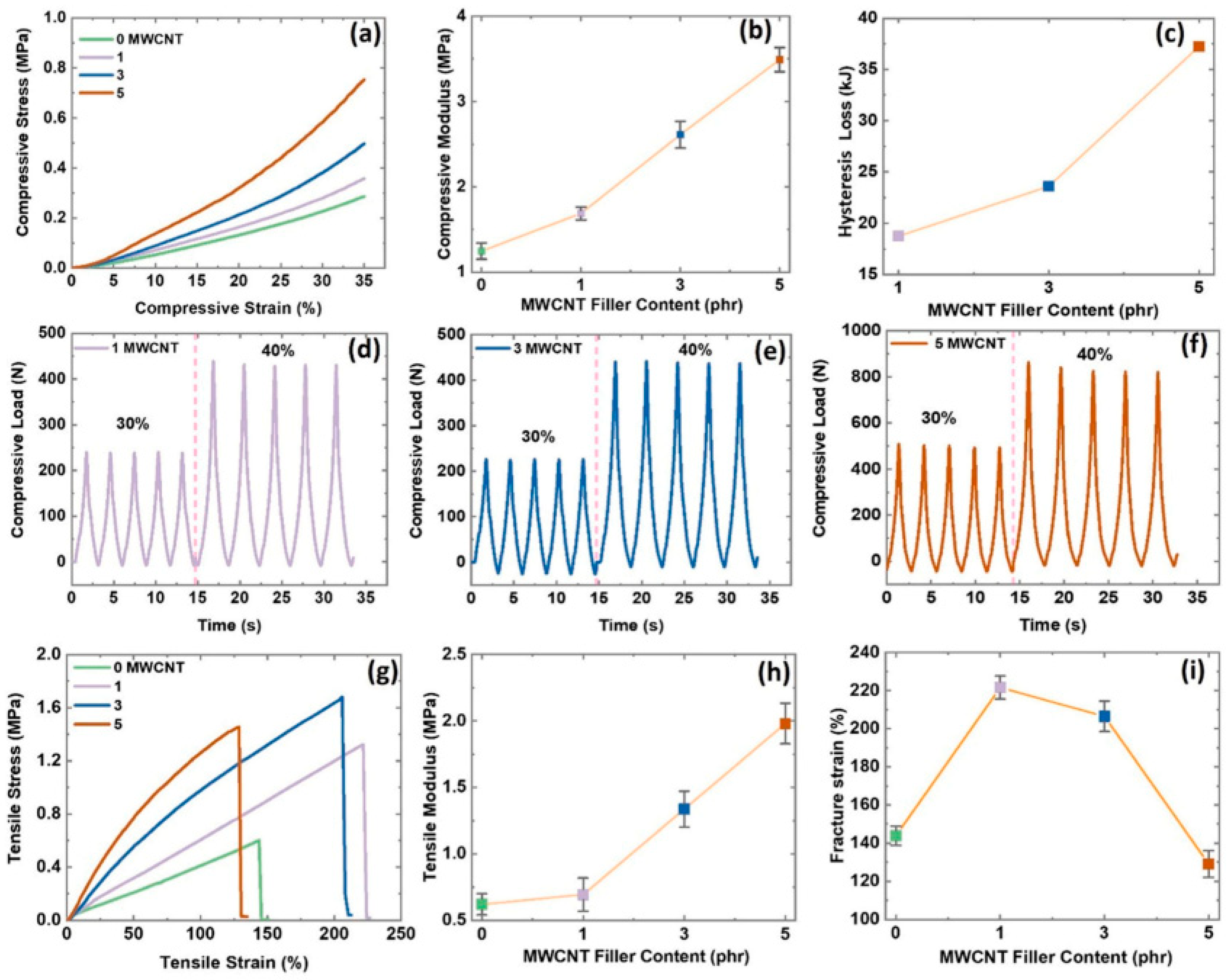

3.1. Mechanical Properties

3.2. Response Time, Linearity, and Gauge Factor of Sensors Based on Composites

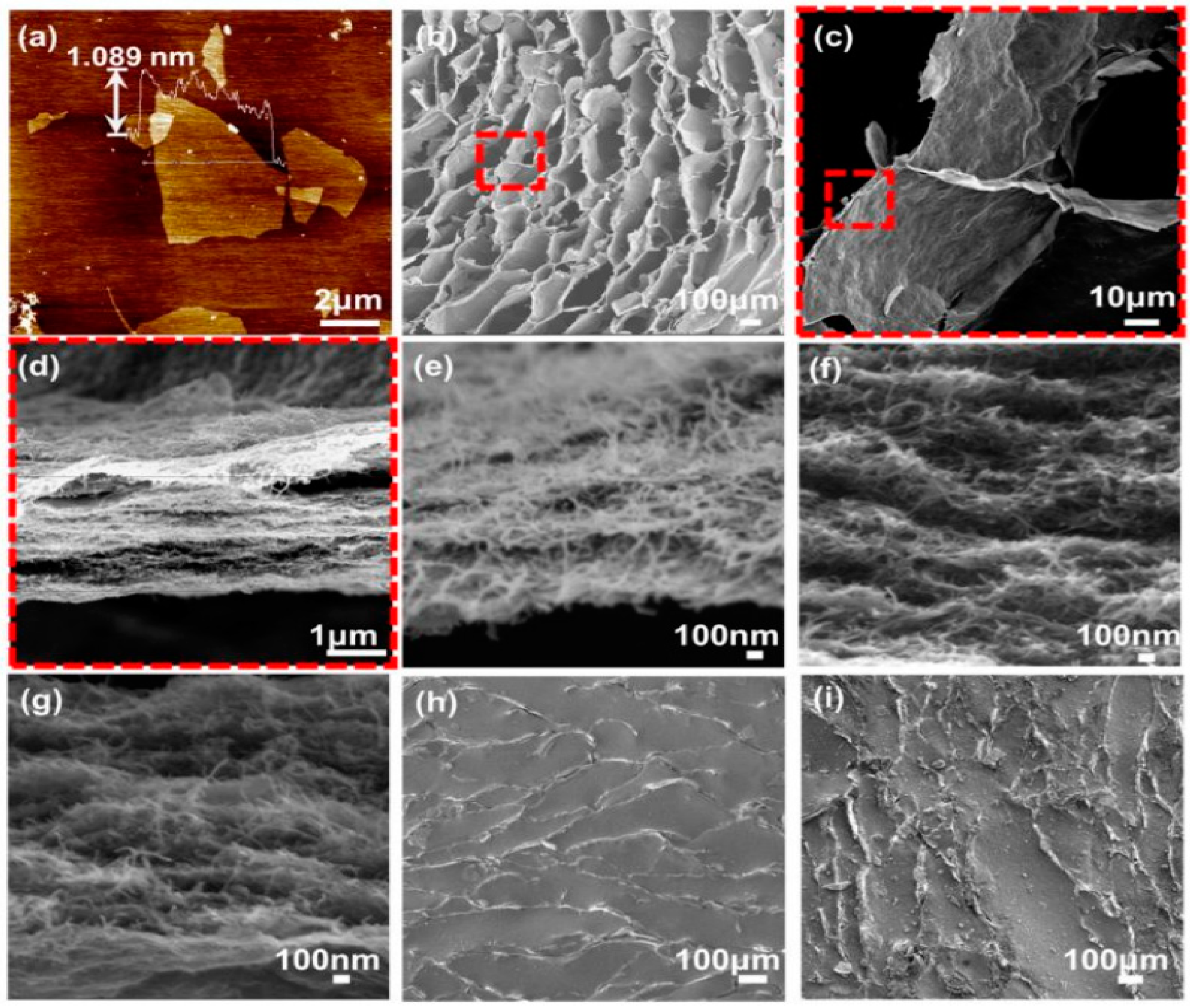

3.3. Filler Dispersion and Morphology by AFM and SEM

4. Applications

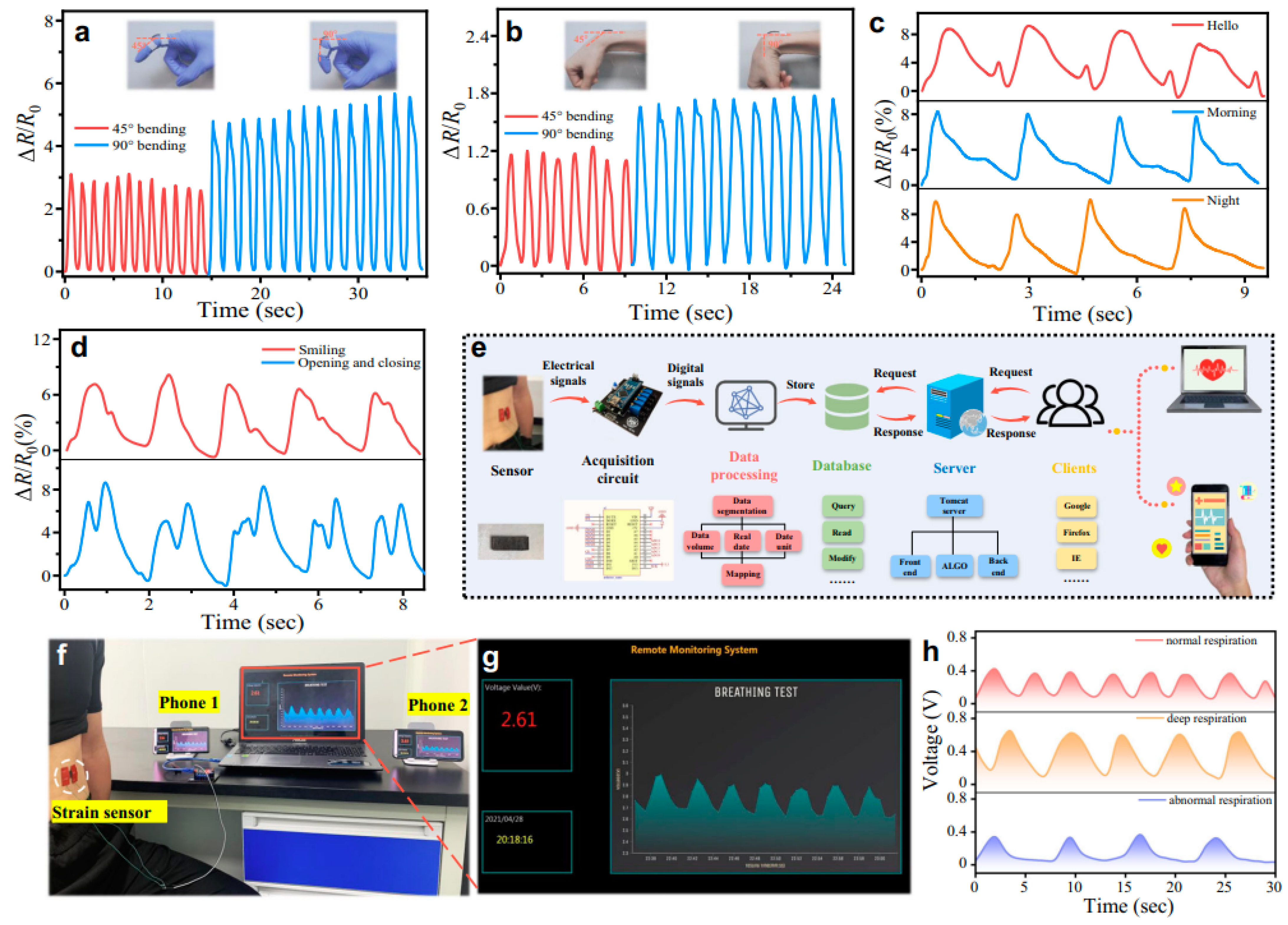

4.1. Real-Time Monitoring of Strain Sensor through Relative Resistance

4.2. Sensing Different Real-Time Human Monitoring through Capacitance

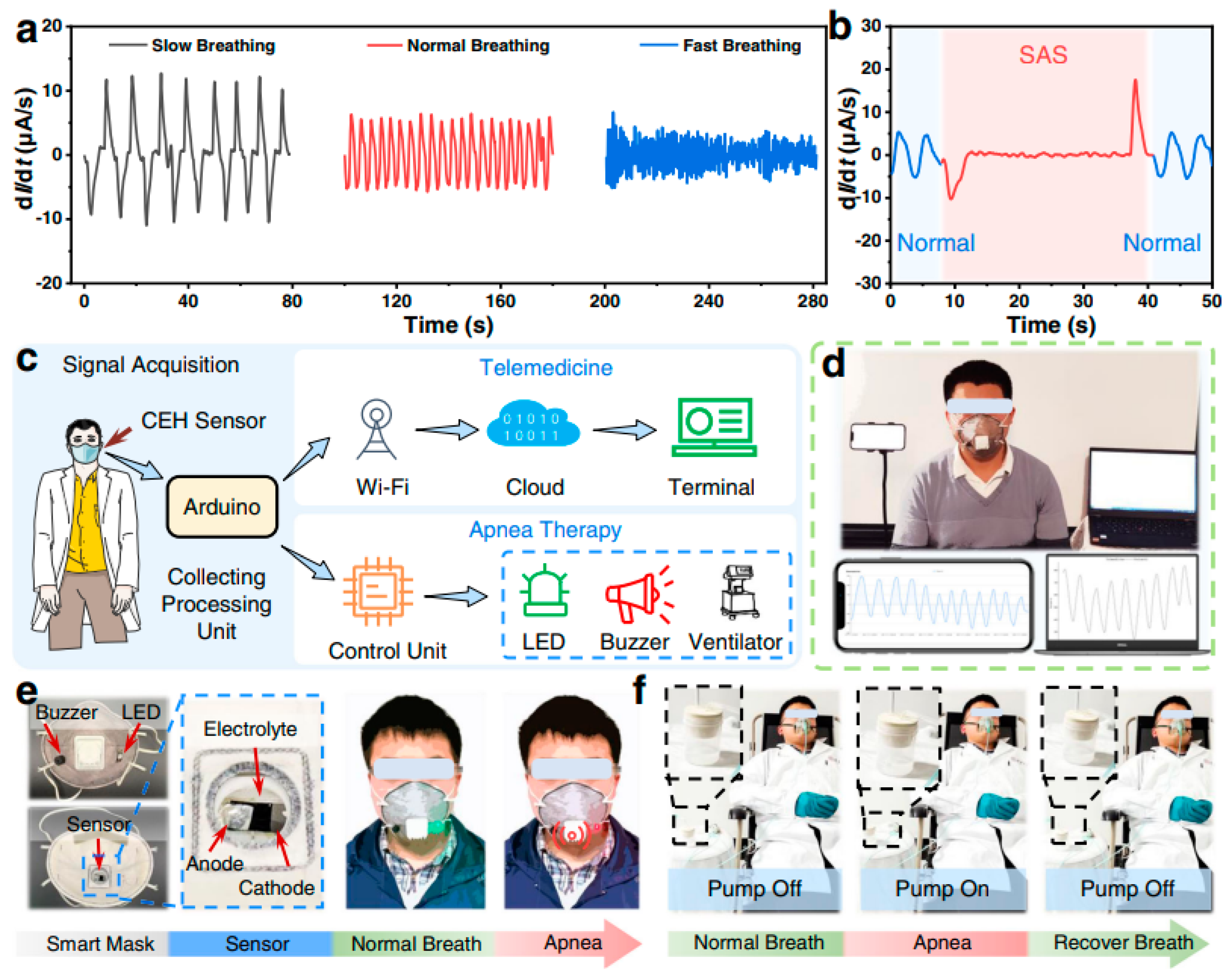

4.3. Sensor for Breathing through Relative Current Change

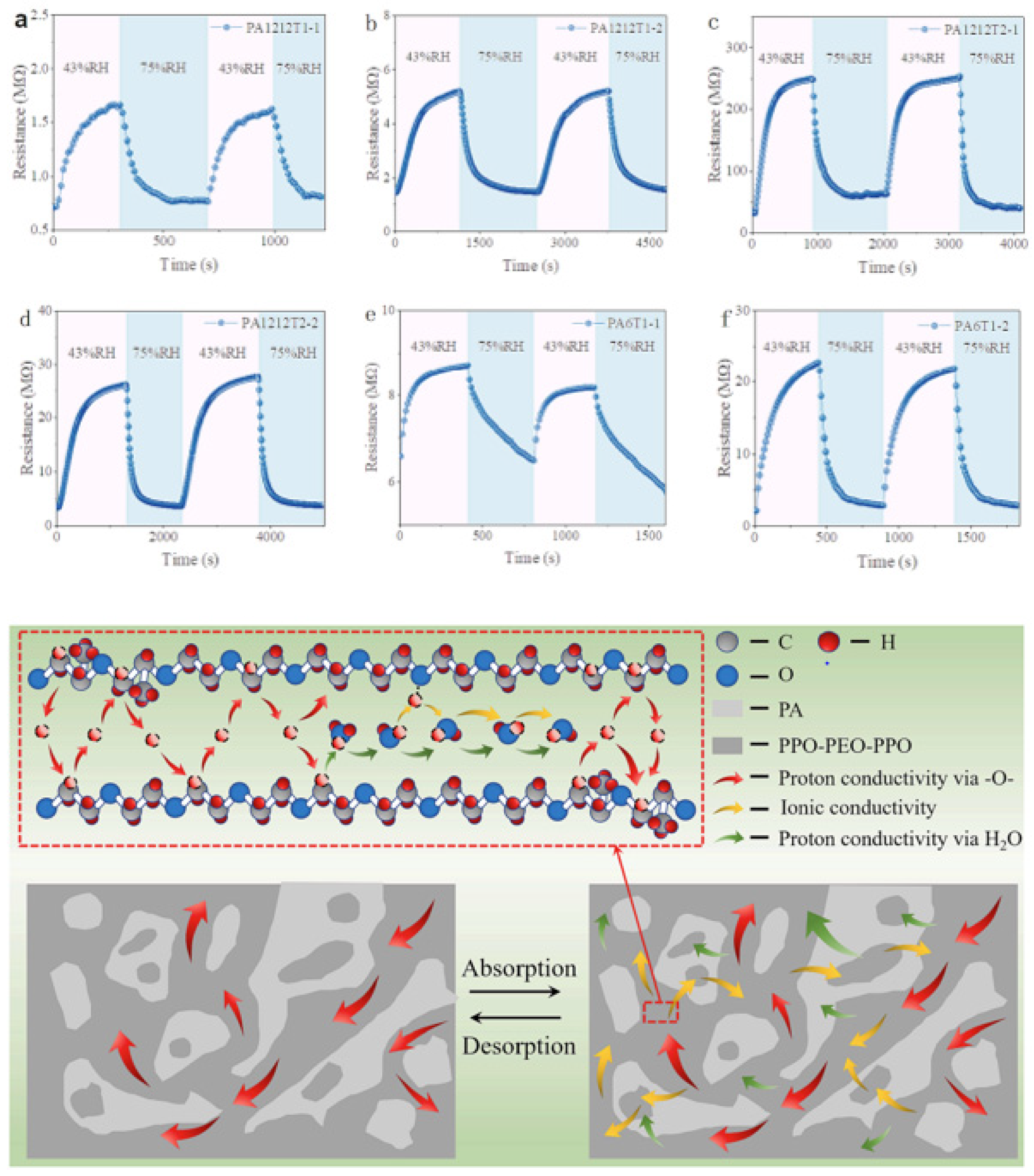

4.4. Sensor for Monitoring under Different Humidity Conditions

4.5. Sensor for Different Organic Gas Sensing

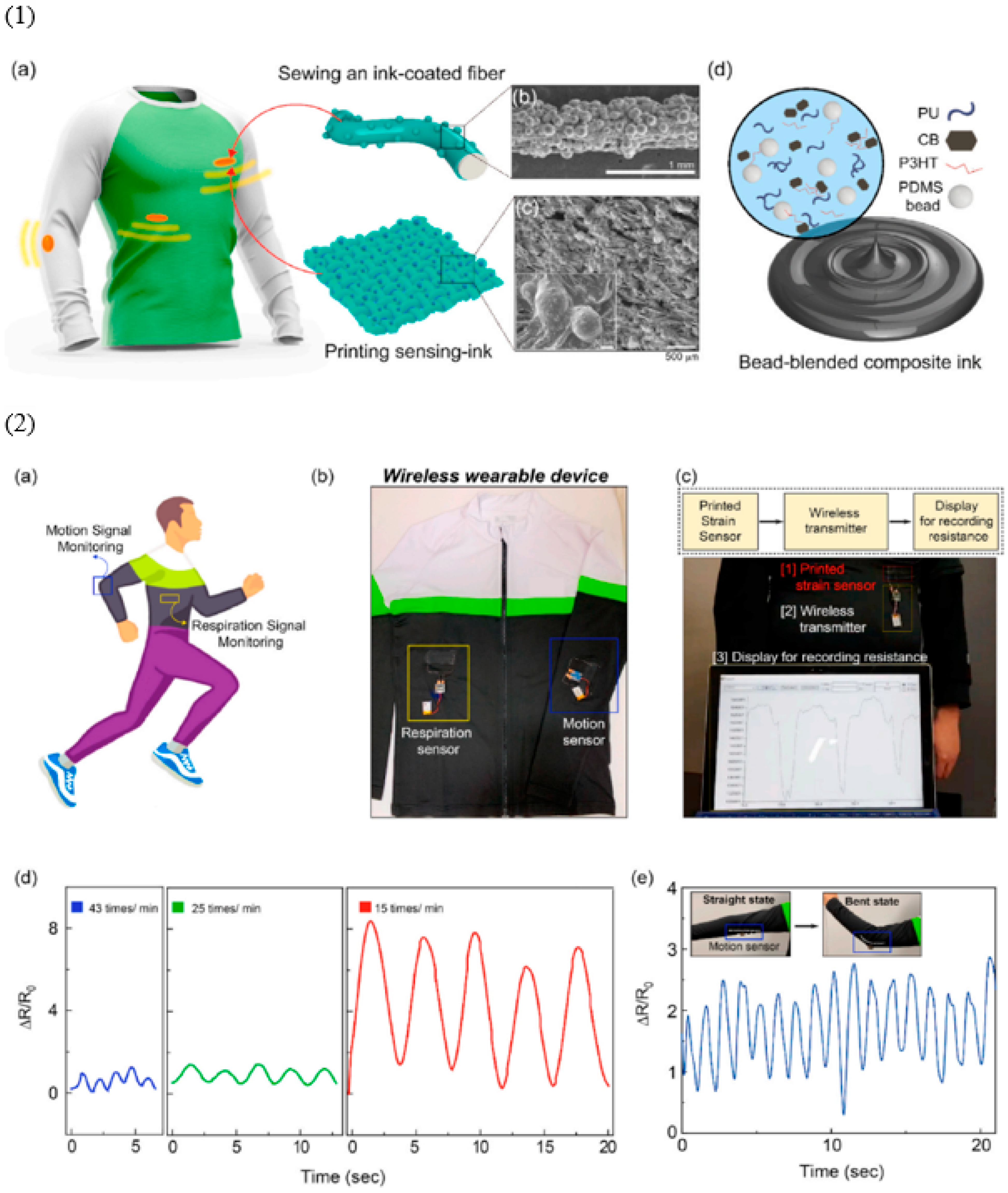

4.6. Wearable Smart Textile Sensor

5. Conclusions

Current Challenges and Future Prospects

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Guo, Y.; Wei, X.; Gao, S.; Yue, W.; Li, Y.; Shen, G. Recent advances in carbon material-based multifunctional sensors and their applications in electronic skin systems. Adv. Funct. Mater. 2021, 31, 2104288. [Google Scholar] [CrossRef]

- Sun, Q.J.; Lai, Q.T.; Tang, Z.; Tang, X.G.; Zhao, X.H.; Roy, V.A. Advanced functional composite materials toward E-skin for health monitoring and artificial intelligence. Adv. Mater. Technol. 2023, 8, 2201088. [Google Scholar] [CrossRef]

- Alam, M.N.; Kumar, V.; Lee, D.J.; Choi, J. Synergistically toughened silicone rubber nanocomposites using carbon nanotubes and molybdenum disulfide for stretchable strain sensors. Compos. Part B Eng. 2023, 259, 110759. [Google Scholar] [CrossRef]

- Norizan, M.N.; Moklis, M.H.; Demon, S.Z.N.; Halim, N.A.; Samsuri, A.; Mohamad, I.S.; Knight, V.F.; Abdullah, N. Carbon nanotubes: Functionalisation and their application in chemical sensors. RSC Adv. 2020, 10, 43704–43732. [Google Scholar] [CrossRef] [PubMed]

- Rocha, H.; Semprimoschnig, C.; Nunes, J.P. Sensors for process and structural health monitoring of aerospace composites: A review. Eng. Struct. 2021, 237, 112231. [Google Scholar] [CrossRef]

- Kumar, V.; Alam, M.N.; Yewale, M.A.; Lee, D.J.; Park, S.S. Mimicking Self-Powered Piezoelectric Energy-Generating Behavior in Silicone Rubber Composites under Compressive and Tensile Strains. ACS Appl. Electron. Mater. 2024, 6, 1638–1650. [Google Scholar] [CrossRef]

- Qureshi, Y.; Tarfaoui, M.; Lafdi, K.K.; Lafdi, K. Real-time strain monitoring and damage detection of composites in different directions of the applied load using a microscale flexible Nylon/Ag strain sensor. Struct. Health Monit. 2020, 19, 885–901. [Google Scholar] [CrossRef]

- Lu, Q.; Wang, P.; Liu, C. An analytical and experimental study on adaptive active vibration control of sandwich beam. Int. J. Mech. Sci. 2022, 232, 107634. [Google Scholar] [CrossRef]

- Farahpour, H.; Hejazi, F. Development of integrated semi-active adaptive vibration control system for bridges subjected to traffic loads. In Structures; Elsevier: Amsterdam, The Netherlands, 2023; Volume 51, pp. 1773–1794. [Google Scholar]

- Khoshmanesh, F.; Thurgood, P.; Pirogova, E.; Nahavandi, S.; Baratchi, S. Wearable sensors: At the frontier of personalised health monitoring, smart prosthetics and assistive technologies. Biosens. Bioelectron. 2021, 176, 112946. [Google Scholar] [CrossRef]

- Tai, H.; Duan, Z.; Wang, Y.; Wang, S.; Jiang, Y. based sensors for gas, humidity, and strain detections: A review. ACS Appl. Mater. Interfaces 2020, 12, 31037–31053. [Google Scholar] [CrossRef]

- Ma, Z.; Fei, T.; Zhang, T. An overview: Sensors for low humidity detection. Sens. Actuators B Chem. 2023, 376, 133039. [Google Scholar] [CrossRef]

- Dhall, S.; Mehta, B.R.; Tyagi, A.K.; Sood, K. A review on environmental gas sensors: Materials and technologies. Sens. Int. 2021, 2, 100116. [Google Scholar] [CrossRef]

- Lei, D.; Liu, N.; Su, T.; Zhang, Q.; Wang, L.; Ren, Z.; Gao, Y. Roles of MXene in pressure sensing: Preparation, composite structure design, and mechanism. Adv. Mater. 2022, 34, 2110608. [Google Scholar] [CrossRef]

- Yuan, L.; Fan, W.; Yang, X.; Ge, S.; Xia, C.; Foong, S.Y.; Liew, R.K.; Wang, S.; Le, Q.V.; Lam, S.S. Piezoelectric PAN/BaTiO3 nanofiber membranes sensor for structural health monitoring of real-time damage detection in composite. Compos. Commun. 2021, 25, 100680. [Google Scholar] [CrossRef]

- Giordano, M.R.; Malings, C.; Pandis, S.N.; Presto, A.A.; McNeill, V.F.; Westervelt, D.M.; Beekmann, M.; Subramanian, R. From low-cost sensors to high-quality data: A summary of challenges and best practices for effectively calibrating low-cost particulate matter mass sensors. J. Aerosol Sci. 2021, 158, 105833. [Google Scholar] [CrossRef]

- Dai, J.; Li, K.; Li, Z.; Zheng, L.; Wen, X.; Cai, G.; Yin, X. Enhanced Interface between Conductive Fillers and Elastomeric Ionomers for Highly Sensitive and Stretchable Strain Sensors toward Human Motion Detection. ACS Appl. Polym. Mater. 2023, 5, 6441–6451. [Google Scholar] [CrossRef]

- Kumar, V.; Alam, M.N.; Yewale, M.A.; Park, S.S. Stretchable rubber composites with lower hysteresis losses, improved magnetic effect, and a robust magnetic sensitivity. Sens. Actuators A Phys. 2024, 373, 115425. [Google Scholar] [CrossRef]

- Mehmood, A.; Mubarak, N.M.; Khalid, M.; Walvekar, R.; Abdullah, E.C.; Siddiqui, M.T.H.; Baloch, H.A.; Nizamuddin, S.; Mazari, S. Graphene based nanomaterials for strain sensor application—A review. J. Environ. Chem. Eng. 2020, 8, 103743. [Google Scholar] [CrossRef]

- Alam, M.N.; Kumar, V.; Lee, D.J.; Park, S.S. Styrene–butadiene rubber-based nanocomposites toughened by carbon nanotubes for wide and linear electromechanical sensing applications. Polym. Compos. 2024, 45, 2485–2499. [Google Scholar] [CrossRef]

- Kumar, V.; Tang, X. New Horizons in Nanofiller-Based Polymer Composites II. Polymers 2023, 15, 4259. [Google Scholar] [CrossRef]

- Manikkavel, A.; Kumar, V.; Alam, M.N.; Kim, U.; Park, S.S. The electro-mechanical energy harvesting configurations in different modes from machine to self-powered wearable electronics. ACS Appl. Electron. Mater. 2023, 5, 5537–5554. [Google Scholar] [CrossRef]

- Wu, Q.; Liu, L.; Meng, J.; Liu, S.; Hui, J.; Wang, X.; Xu, L.; Zhang, L. Microstructure and performance of green Tire tread based on epoxidized solution polymerized styrene butadiene rubber and epoxidized natural rubber. Ind. Eng. Chem. Res. 2023, 62, 5582–5593. [Google Scholar] [CrossRef]

- Chacon, L.A.; Deaton, B.; Bessire, B.K.; Poovathingal, S.J. Chemical and structural degradation of room temperature vulcanizing (RTV) silicone at high temperatures. Polym. Degrad. Stab. 2024, 220, 110661. [Google Scholar] [CrossRef]

- Deng, Y.; Peng, B.; Liu, Z.; Du, Y.; Zhou, S.; Liu, J.; Yu, X.; Zhou, J. Hygrothermal ageing performance of high temperature vulcanised silicone rubber and its degradation mechanism. High Volt. 2023, 8, 1196–1205. [Google Scholar] [CrossRef]

- Kumar, V.; Lee, G.; Choi, J.; Lee, D.J. Studies on composites based on HTV and RTV silicone rubber and carbon nanotubes for sensors and actuators. Polymer 2020, 190, 122221. [Google Scholar] [CrossRef]

- Kumar, V.; Mandal, T.K.; Parvin, N.; Joo, S.W.; Park, S.S. The multifunctional composites based on new generation carbon microsphere and their hybrids with robust interfacial mechanical strength. Surf. Interfaces 2023, 42, 103378. [Google Scholar] [CrossRef]

- Parvin, N.; Kumar, V.; Park, S.S.; Mandal, T.K.; Joo, S.W. Enhanced piezoelectric energy harvesting using hybrid composites of MWCNTs and partially-reduced GO in RTV-SR for stable voltage generation. Surf. Interfaces 2024, 44, 103681. [Google Scholar] [CrossRef]

- Yang, Y.; Kong, L.; Lu, J.; Lin, B.; Fu, L.; Xu, C. A highly conductive MXene-based rubber composite with relatively stable conductivity under small deformation and high sensing sensitivity at large strain. Compos. Part A Appl. Sci. Manuf. 2023, 170, 107545. [Google Scholar] [CrossRef]

- Li, W.D.; Ke, K.; Jia, J.; Pu, J.H.; Zhao, X.; Bao, R.Y.; Liu, Z.Y.; Bai, L.; Zhang, K.; Yang, M.B.; et al. Recent advances in multiresponsive flexible sensors towards E-skin: A delicate design for versatile sensing. Small 2022, 18, 2103734. [Google Scholar] [CrossRef] [PubMed]

- Zhu, T.; Cheng, Y.; Cao, C.; Mao, J.; Li, L.; Huang, J.; Lai, Y. A semi-interpenetrating network ionic hydrogel for strain sensing with high sensitivity, large strain range, and stable cycle performance. Chem. Eng. J. 2020, 385, 123912. [Google Scholar] [CrossRef]

- Huang, H.; Su, S.; Wu, N.; Wan, H.; Wan, S.; Bi, H.; Sun, L. Graphene-based sensors for human health monitoring. Front. Chem. 2019, 7, 399. [Google Scholar] [CrossRef]

- Zazoum, B.; Batoo, K.M.; Khan, M.A.A. Recent advances in flexible sensors and their applications. Sensors 2022, 22, 4653. [Google Scholar] [CrossRef]

- Li, S.; Xu, R.; Wang, J.; Yang, Y.; Fu, Q.; Pan, C. Ultra-stretchable, super-hydrophobic and high-conductive composite for wearable strain sensors with high sensitivity. J. Colloid Interface Sci. 2022, 617, 372–382. [Google Scholar] [CrossRef]

- Ahmed, O.; Wang, X.; Tran, M.V.; Ismadi, M.Z. Advancements in fiber-reinforced polymer composite materials damage detection methods: Towards achieving energy-efficient SHM systems. Compos. Part B Eng. 2021, 223, 109136. [Google Scholar] [CrossRef]

- Majumder; Deb, B.; Roy, J.K.; Padhee, S. Recent advances in multifunctional sensing technology on a perspective of multi-sensor system: A review. IEEE Sens. J. 2018, 19, 1204–1214. [Google Scholar] [CrossRef]

- Alarifi, I.M. A comprehensive review on advancements of elastomers for engineering applications. Adv. Ind. Eng. Polym. Res. 2023, 6, 451–464. [Google Scholar] [CrossRef]

- Dolui, T.; Natarajan, T.S.; Chanda, J.; Ghosh, P.; Mukhopadhyay, R.; Wießner, S.; Heinrich, G.; Das, A.; Banerjee, S.S. Stimuli–responsive Mechanoadaptive elastomeric composite materials: Challenges, opportunities, and new approaches. Adv. Eng. Mater. 2023, 25, 2300584. [Google Scholar] [CrossRef]

- Luo, L.; Zhang, F.; Wang, L.; Liu, Y.; Leng, J. Recent Advances in Shape Memory Polymers: Multifunctional Materials, Multiscale Structures, and Applications. Adv. Funct. Mater. 2024, 34, 2312036. [Google Scholar] [CrossRef]

- Kumar, V.; Alam, M.N.; Yewale, M.A.; Park, S.S. Robust performance for composites using silicone rubber with different prospects for wearable electronics. Polym. Adv. Technol. 2024, 35, e6264. [Google Scholar] [CrossRef]

- Jin, J.; Noordermeer, J.W.; Blume, A.; Dierkes, W.K. Effect of SBR/BR elastomer blend ratio on filler and vulcanization characteristics of silica filled tire tread compounds. Polym. Test. 2021, 99, 107212. [Google Scholar] [CrossRef]

- Zhang, H.; Li, Y.; Zhang, Y.; Wu, J.; Li, S.; Li, L. A disposable electrochemical sensor for lead ion detection based on in situ polymerization of conductive polypyrrole coating. J. Electron. Mater. 2023, 52, 1819–1828. [Google Scholar] [CrossRef]

- Yu, H.; Zhang, R.; Jia, Y.G.; Chen, Y.; Shi, X. Tuning Dry and Wet Adhesion with a Branched Supramolecular Polymer Solution. Small Sci. 2023, 3, 2300044. [Google Scholar] [CrossRef]

- Yang, D.; Stimpson, T.C.; Soucy, J.; Esser, A.; Pelton, R.H. Increasing wet adhesion between cellulose surfaces with polyvinylamine. Cellulose 2019, 26, 341–353. [Google Scholar] [CrossRef]

- Manikkavel, A.; Kumar, V.; Park, S.S. Multifunctionality of MWCNT and TiC hybrid filler silicone composite for energy harvesting and strain sensing. Polym. Compos. 2024, 45, 6629–6643. [Google Scholar] [CrossRef]

- Kumar, V.; Lee, D.J.; Park, S.S. Multi-functionality prospects in functionalized and pristine graphene nanosheets reinforced silicone rubber composites: A focused review. FlatChem 2023, 41, 100535. [Google Scholar] [CrossRef]

- Kumar, V.; Parvin, N.; Manikkavel, A.; Lee, D.Y.; Mandal, T.K.; Joo, S.W.; Park, S.S. Improved interfacial mechanical strength and synergy in properties of nano-carbon black reinforced rubber composites containing functionalized graphite nanoplatelets. Surf. Interfaces 2023, 39, 102941. [Google Scholar] [CrossRef]

- Vishvanathperumal, S.; Anand, G. Effect of nanoclay/nanosilica on the mechanical properties, abrasion and swelling resistance of EPDM/SBR composites. Silicon 2020, 12, 1925–1941. [Google Scholar] [CrossRef]

- Manikkavel, A.; Kumar, V.; Park, S.S. MWCNT-reinforced Silicone’s Dual Response to Human and Mechanical Motion: Exploring Strain Sensing Behavior and Practical Applications. Colloids Surf. A Physicochem. Eng. Asp. 2024, 688, 133536. [Google Scholar] [CrossRef]

- Kumar, V.; Alam, M.N.; Park, S.S. Soft composites filled with iron oxide and graphite nanoplatelets under static and cyclic strain for different industrial applications. Polymers 2022, 14, 2393. [Google Scholar] [CrossRef]

- Wen, Y.; Chen, C.; Ye, Y.; Xue, Z.; Liu, H.; Zhou, X.; Mai, Y.W. Advances on thermally conductive epoxy-based composites as electronic packaging underfill materials—A review. Adv. Mater. 2022, 34, 2201023. [Google Scholar] [CrossRef]

- Hu, Y.; Chen, C.; Wen, Y.; Xue, Z.; Zhou, X.; Shi, D.; Hu, G.H.; Xie, X. Novel micro-nano epoxy composites for electronic packaging application: Balance of thermal conductivity and processability. Compos. Sci. Technol. 2021, 209, 108760. [Google Scholar] [CrossRef]

- Bokobza, L. Elastomer Nanocomposites: Effect of Filler–Matrix and Filler–Filler Interactions. Polymers 2023, 15, 2900. [Google Scholar] [CrossRef]

- Vieira, L.D.S.; dos Anjos, E.G.R.; Verginio, G.E.A.; Oyama, I.C.; Braga, N.F.; da Silva, T.F.; Montagna, L.S.; Passador, F.R. A review concerning the main factors that interfere in the electrical percolation threshold content of polymeric antistatic packaging with carbon fillers as antistatic agent. Nano Sel. 2022, 3, 248–260. [Google Scholar] [CrossRef]

- Kumar, V.; Azam, S.; Alam, M.N.; Hong, W.B.; Park, S.S. Novel rubber composites based on copper particles, multi-wall carbon nanotubes and their hybrid for stretchable devices. Polymers 2022, 14, 3744. [Google Scholar] [CrossRef]

- Wan, B.; Yang, Y.; Guo, R.; Fan, Z.; Deng, P.; Zhang, S. Effect of Vulcanization on the Electro-Mechanical Sensing Characteristics of Multi-Walled Carbon Nanotube/Silicone Rubber Composites. Polymers 2023, 15, 1412. [Google Scholar] [CrossRef]

- Zhao, J.; Shi, Y. Boosting the durability of triboelectric nanogenerators: A critical review and prospect. Adv. Funct. Mater. 2023, 33, 2213407. [Google Scholar] [CrossRef]

- Zhang, C.; Chi, Q.; Dong, J.; Cui, Y.; Wang, X.; Liu, L.; Lei, Q. Enhanced dielectric properties of poly (vinylidene fluoride) composites filled with nano iron oxide-deposited barium titanate hybrid particles. Sci. Rep. 2016, 6, 33508. [Google Scholar] [CrossRef]

- Wang, X.Q.; Chow, C.L.; Lau, D. Topology-controlled thermomechanical properties of diamond nanothread enhanced polymeric materials. Appl. Mater. Today 2023, 32, 101822. [Google Scholar] [CrossRef]

- Shin, J.Y.; Kim, K.S.; Yoon, M.C.; Lim, J.M.; Yoon, Z.S.; Osuka, A.; Kim, D. Aromaticity and photophysical properties of various topology-controlled expanded porphyrins. Chem. Soc. Rev. 2010, 39, 2751–2767. [Google Scholar] [CrossRef] [PubMed]

- Cai, L.; Fan, J.; Ding, S.; He, D.; Zeng, X.; Sun, R.; Ren, L.; Hu, J.; Zeng, X. Soft composite gels with high toughness and low thermal resistance through lengthening polymer strands and controlling filler. Adv. Funct. Mater. 2023, 33, 2207143. [Google Scholar] [CrossRef]

- Hottin, A.; Naït-Abdelaziz, M.; Talha, A.; Charrier, P. An attempt to predict the heat build-up of filled elastomers under multiaxial fatigue. Polym. Test. 2023, 128, 108239. [Google Scholar] [CrossRef]

- Alam, M.N.; Kumar, V.; Jo, C.R.; Ryu, S.R.; Lee, D.J.; Park, S.S. Mechanical and magneto-mechanical properties of styrene-butadiene-rubber-based magnetorheological elastomers conferred by novel filler-polymer interactions. Compos. Sci. Technol. 2022, 229, 109669. [Google Scholar] [CrossRef]

- Yousefi, A.; Jolaiy, S.; Lalegani Dezaki, M.; Zolfagharian, A.; Serjouei, A.; Bodaghi, M. 3D-Printed Soft and Hard Meta-Structures with Supreme Energy Absorption and Dissipation Capacities in Cyclic Loading Conditions. Adv. Eng. Mater. 2023, 25, 2201189. [Google Scholar] [CrossRef]

- Birčáková, Z.; Kollár, P.; Füzer, J.; Bureš, R.; Fáberová, M.; Jakubčin, M. Energy loss and hysteresis of reversible magnetization processes in iron-based soft magnetic composites. J. Magn. Magn. Mater. 2023, 587, 171291. [Google Scholar] [CrossRef]

- Kumar, V.; Alam, M.N.; Manikkavel, A.; Song, M.; Lee, D.J.; Park, S.S. Silicone rubber composites reinforced by carbon nanofillers and their hybrids for various applications: A review. Polymers 2021, 13, 2322. [Google Scholar] [CrossRef] [PubMed]

- Abubakre, O.K.; Medupin, R.O.; Akintunde, I.B.; Jimoh, O.T.; Abdulkareem, A.S.; Muriana, R.A.; James, J.A.; Ukoba, K.O.; Jen, T.C.; Yoro, K.O. Carbon nanotube-reinforced polymer nanocomposites for sustainable biomedical applications: A review. J. Sci. Adv. Mater. Devices 2023, 8, 100557. [Google Scholar] [CrossRef]

- Aguiar, V.O.; Maru, M.M.; Soares, I.T.; Kapps, V.; Almeida, C.M.; Perez, G.; Archanjo, B.S.; Pita, V.J.R.R.; Marques, M.D.F.V. Effect of incorporating multi-walled carbon nanotube and graphene in UHMWPE matrix on the enhancement of thermal and mechanical properties. J. Mater. Sci. 2022, 57, 21104–21116. [Google Scholar] [CrossRef]

- Arrigo, R.; Malucelli, G. Rheological behavior of polymer/carbon nanotube composites: An overview. Materials 2020, 13, 2771. [Google Scholar] [CrossRef]

- Liu, Z.; Zheng, Y.; Jin, L.; Chen, K.; Zhai, H.; Huang, Q.; Chen, Z.; Yi, Y.; Umar, M.; Xu, L.; et al. Highly breathable and stretchable strain sensors with insensitive response to pressure and bending. Adv. Funct. Mater. 2021, 31, 2007622. [Google Scholar] [CrossRef]

- Wang, A.; Wang, Y.; Zhang, B.; Wan, K.; Zhu, J.; Xu, J.; Zhang, C.; Liu, T. Hydrogen-bonded network enables semi-interpenetrating ionic conductive hydrogels with high stretchability and excellent fatigue resistance for capacitive/resistive bimodal sensors. Chem. Eng. J. 2021, 411, 128506. [Google Scholar] [CrossRef]

- Kim, K.H.; Hong, S.K.; Ha, S.H.; Li, L.; Lee, H.W.; Kim, J.M. Enhancement of linearity range of stretchable ultrasensitive metal crack strain sensor via superaligned carbon nanotube-based strain engineering. Mater. Horiz. 2020, 7, 2662–2672. [Google Scholar] [CrossRef]

- Pyo, S.; Lee, J.; Bae, K.; Sim, S.; Kim, J. Recent progress in flexible tactile sensors for human-interactive systems: From sensors to advanced applications. Adv. Mater. 2021, 33, 2005902. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Zhao, Y.; Xu, X.; Chen, D.; Zhang, X.; Yang, G.; Qiao, W.; Feng, R.; Zhang, X.; Wu, J.; et al. Biomimetic flexible strain sensor with high linearity using double conducting layers. Compos. Sci. Technol. 2021, 213, 108908. [Google Scholar] [CrossRef]

- Araromi, O.A.; Graule, M.A.; Dorsey, K.L.; Castellanos, S.; Foster, J.R.; Hsu, W.H.; Wood, R.J. Ultra-Sensitive Resilient Compliant Strain Gauges Soft Mach. Nature 2020, 587, 219–224. [Google Scholar] [CrossRef] [PubMed]

- Kumar, V.; Alam, M.N.; Manikkavel, A.; Choi, J.; Lee, D.J. Investigation of silicone rubber composites reinforced with carbon nanotube, nanographite, their hybrid, and applications for flexible devices. J. Vinyl Addit. Technol. 2021, 27, 254–263. [Google Scholar] [CrossRef]

- Tang, Z.H.; Li, Y.Q.; Huang, P.; Wang, H.; Hu, N.; Fu, S.Y. Comprehensive evaluation of the piezoresistive behavior of carbon nanotube-based composite strain sensors. Compos. Sci. Technol. 2021, 208, 108761. [Google Scholar] [CrossRef]

- de Bomfim, A.S.C.; de Oliveira, D.M.; Benini, K.C.C.D.C.; Cioffi, M.O.H.; Voorwald, H.J.C.; Rodrigue, D. Effect of Spent Coffee Grounds on the Crystallinity and Viscoelastic Behavior of Polylactic Acid Composites. Polymers 2023, 15, 2719. [Google Scholar] [CrossRef] [PubMed]

- Wei, B.; Chen, M.; Jiang, L.; Yu, Y.; Min, H. Equivalence of Bilinear Hysteresis and Viscous Damping Energy Dissipation. J. Test. Eval. 2024, 52, JTE20230207. [Google Scholar] [CrossRef]

- Yan, X.; Alam, M.S.; Shu, G.; Qin, Y. A novel self-centering viscous damper for improving seismic resilience: Its development, experimentation, and system response. Eng. Struct. 2023, 279, 115632. [Google Scholar] [CrossRef]

- He, Z.; Shi, F.; Lin, Z.; Zhang, C.; Zhou, Y.; Zhao, F. Experimental characterization on cyclic stability behavior of a high-damping viscoelastic damper. Constr. Build. Mater. 2023, 371, 130749. [Google Scholar] [CrossRef]

- Huang, X.; Peng, S.; Zheng, L.; Zhuo, D.; Wu, L.; Weng, Z. 3D Printing of High Viscosity UV-Curable Resin for Highly Stretchable and Resilient Elastomer. Adv. Mater. 2023, 35, 2304430. [Google Scholar] [CrossRef]

- Zhang, H.; Li, H.; Li, Y. Biomimetic Electronic Skin for Robots Aiming at Superior Dynamic-Static Perception and Material Cognition Based on Triboelectric-Piezoresistive Effects. Nano Lett. 2024, 24, 4002–4011. [Google Scholar] [CrossRef] [PubMed]

- Schönlein, R.; Fernández, M.; Calafel, I.; Azkune, M.; Liu, G.; Müller, A.J.; Ugartemendia, J.M.; Aguirresarobe, R. Flow-induced crystallization of piezoelectric poly (L-lactide) fibers by a one-step melt-spinning process. Mater. Des. 2024, 237, 112525. [Google Scholar] [CrossRef]

- Alam, M.N.; Kumar, V.; Jeong, T.; Park, S.S. Nanocarbon Black and Molybdenum Disulfide Hybrid Filler System for the Enhancement of Fracture Toughness and Electromechanical Sensing Properties in the Silicone Rubber-Based Energy Harvester. Polymers 2023, 15, 2189. [Google Scholar] [CrossRef] [PubMed]

- Kumar, V.; Kumar, A.; Han, S.S.; Park, S.S. RTV silicone rubber composites reinforced with carbon nanotubes, titanium-di-oxide and their hybrid: Mechanical and piezoelectric actuation performance. Nano Mater. Sci. 2021, 3, 233–240. [Google Scholar] [CrossRef]

- Zarei Darani, S.; Naghdabadi, R. An experimental study on multiwalled carbon nanotube nanocomposite piezoresistivity considering the filler agglomeration effects. Polym. Compos. 2021, 42, 4707–4716. [Google Scholar] [CrossRef]

- Kumar, V.; Park, S.J.; Lee, D.J.; Park, S.S. Mechanical and magnetic response of magneto-rheological elastomers with different types of fillers and their hybrids. J. Appl. Polym. Sci. 2021, 138, 50957. [Google Scholar] [CrossRef]

- Kumar, V.; Wu, R.R.; Lee, D.J. Morphological aspects of carbon nanofillers and their hybrids for actuators and sensors. Polym. Compos. 2019, 40 (Suppl. S1), E373–E382. [Google Scholar] [CrossRef]

- Kumar, V.; Kumar, A.; Lee, D.J.; Park, S.S. Estimation of number of graphene layers using different methods: A focused review. Materials 2021, 14, 4590. [Google Scholar] [CrossRef]

- Kumar, V.; Kumar, A.; Song, M.; Lee, D.J.; Han, S.S.; Park, S.S. Properties of silicone rubber-based composites reinforced with few-layer graphene and iron oxide or titanium dioxide. Polymers 2021, 13, 1550. [Google Scholar] [CrossRef]

- Liu, D.; Kong, Q.Q.; Jia, H.; Xie, L.J.; Chen, J.; Tao, Z.; Wang, Z.; Jiang, D.; Chen, C.M. Dual-functional 3D multi-wall carbon nanotubes/graphene/silicone rubber elastomer: Thermal management and electromagnetic interference shielding. Carbon 2021, 183, 216–224. [Google Scholar] [CrossRef]

- Manikkavel, A.; Kumar, V.; Kim, J.; Lee, D.J.; Park, S.S. Investigation of high temperature vulcanized and room temperature vulcanized silicone rubber based on flexible piezo-electric energy harvesting applications with multi-walled carbon nanotube reinforced composites. Polym. Compos. 2022, 43, 1305–1318. [Google Scholar] [CrossRef]

- Sun, F.; Liu, L.; Liu, T.; Wang, X.; Qi, Q.; Hang, Z.; Fu, J. Vascular smooth muscle-inspired architecture enables soft yet tough self-healing materials for durable capacitive strain-sensor. Nat. Commun. 2023, 14, 130. [Google Scholar] [CrossRef] [PubMed]

- Mora-Barrantes, I.; Rodríguez, A.; Ibarra, L.; González, L.; Valentín, J.L. Overcoming the disadvantages of fumed silica as filler in elastomer composites. J. Mater. Chem. 2011, 21, 7381–7392. [Google Scholar] [CrossRef]

- Gao, Z.; Xiao, X.; Carlo, A.D.; Yin, J.; Wang, Y.; Huang, L.; Chen, J. Advances in wearable strain sensors based on electrospun fibers. Adv. Funct. Mater. 2023, 33, 2214265. [Google Scholar] [CrossRef]

- Golhin, A.P.; Tonello, R.; Frisvad, J.R.; Grammatikos, S.; Strandlie, A. Surface roughness of as-printed polymers: A comprehensive review. Int. J. Adv. Manuf. Technol. 2023, 127, 987–1043. [Google Scholar] [CrossRef]

- Rao, R.K.; Sindu, B.S.; Sasmal, S. Real-time monitoring of structures under extreme loading using smart composite-based embeddable sensors. J. Intell. Mater. Syst. Struct. 2023, 34, 1073–1096. [Google Scholar] [CrossRef]

- Ku, C.A.; Chung, C.K. Advances in humidity nanosensors and their application. Sensors 2023, 23, 2328. [Google Scholar] [CrossRef] [PubMed]

- Parvin, N.; Kumar, V.; Manikkavel, A.; Park, S.S.; Mandal, T.K.; Joo, S.W. Great new generation carbon microsphere-based composites: Facile synthesis, properties and their application in piezo-electric energy harvesting. Appl. Surf. Sci. 2023, 613, 156078. [Google Scholar] [CrossRef]

- Nocera, A.; Sbrollini, A.; Romagnoli, S.; Morettini, M.; Gambi, E.; Burattini, L. Physiological and biomechanical monitoring in American football players: A scoping review. Sensors 2023, 23, 3538. [Google Scholar] [CrossRef]

- McDevitt, S.; Hernandez, H.; Hicks, J.; Lowell, R.; Bentahaikt, H.; Burch, R.; Ball, J.; Chander, H.; Anderson, B. Wearables for biomechanical performance optimization and risk assessment in industrial and sports applications. Bioengineering 2022, 9, 33. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Long, X.; Huang, J.; Jiang, C.; Zhuo, F.; Guo, C.; Li, H.; Fu, Y.Q.; Duan, H. Multiscale and hierarchical wrinkle enhanced graphene/Ecoflex sensors integrated with human-machine interfaces and cloud-platform. NPJ Flex. Electron. 2022, 6, 55. [Google Scholar] [CrossRef] [PubMed]

- Beringer III, C.R.; Mansouri, M.; Fisher, L.E.; Collinger, J.L.; Munin, M.C.; Boninger, M.L.; Gaunt, R.A. The effect of wrist posture on extrinsic finger muscle activity during single joint movements. Sci. Rep. 2020, 10, 8377. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Liu, G.; Li, R.; Li, Q.; Zhao, Y.; Huang, M.; Zhang, M.; Yin, S.; Zhou, Y.; Tang, H.; et al. Contact-resistance-free stretchable strain sensors with high repeatability and linearity. ACS Nano 2021, 16, 541–553. [Google Scholar] [CrossRef] [PubMed]

- Duan, L.; D’hooge, D.R.; Cardon, L. Recent progress on flexible and stretchable piezoresistive strain sensors: From design to application. Prog. Mater. Sci. 2020, 114, 100617. [Google Scholar] [CrossRef]

- Homayounfar, S.Z.; Andrew, T.L. Wearable sensors for monitoring human motion: A review on mechanisms, materials, and challenges. Slas Technol. Transl. Life Sci. Innov. 2020, 25, 9–24. [Google Scholar] [CrossRef] [PubMed]

- Kong, H.; Song, Z.; Li, W.; Bao, Y.; Qu, D.; Ma, Y.; Liu, Z.; Wang, W.; Wang, Z.; Niu, L.; et al. Skin-inspired hair–epidermis–dermis hierarchical structures for electronic skin sensors with high sensitivity over a wide linear range. ACS Nano 2021, 15, 16218–16227. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.; Tang, J.; Yan, T.; Pan, Z. Performance of flexible strain sensors with different transition mechanisms: A review. IEEE Sens. J. 2022, 22, 7475–7498. [Google Scholar] [CrossRef]

- Wu, Y.; Tang, J.; Ma, S.; Zhang, K.; Yan, T.; Pan, Z. A review of flexible strain sensors based on natural fiber materials. Adv. Mater. Technol. 2023, 8, 2201503. [Google Scholar] [CrossRef]

- Yadav, A.; Yadav, N.; Wu, Y.; RamaKrishna, S.; Hongyu, Z. Wearable strain sensors: State-of-the-art and future applications. Mater. Adv. 2023, 4, 1444–1459. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, Y.; Zhang, K.; Deng, H.; Fu, Q. Recent progress in flexible capacitive sensors: Structures and properties. Nano Mater. Sci. 2023, 5, 265–277. [Google Scholar] [CrossRef]

- Liu, Y.; Jiang, X.; Yang, H.; Qin, H.; Wang, W. Structural Engineering in Piezoresistive Micropressure Sensors: A Focused Review. Micromachines 2023, 14, 1507. [Google Scholar] [CrossRef] [PubMed]

- Afsarimanesh, N.; Nag, A.; Sarkar, S.; Sabet, G.S.; Han, T.; Mukhopadhyay, S.C. A review on fabrication, characterization and implementation of wearable strain sensors. Sens. Actuators A Phys. 2020, 315, 112355. [Google Scholar] [CrossRef]

- Hong, S.; Rachim, V.P.; Baek, J.H.; Park, S.M. Real-time multiaxial strain mapping using computer vision integrated optical sensors. NPJ Flex. Electron. 2023, 7, 30. [Google Scholar] [CrossRef]

- Xue, F.; Peng, Q.; Ding, R.; Li, P.; Zhao, X.; Zheng, H.; Xu, L.; Tang, Z.; Zhang, X.; He, X. Ultra-sensitive, highly linear, and hysteresis-free strain sensors enabled by gradient stiffness sliding strategy. npj Flex. Electron. 2024, 8, 14. [Google Scholar] [CrossRef]

- Yuan, L.; Zhao, T.; Li, T.; Zhang, H.; Chen, L.; Zhang, J. Flexible, anisotropic strain sensor based on interdigital capacitance for multi-direction discrimination. Sens. Actuators A Phys. 2023, 359, 114459. [Google Scholar] [CrossRef]

- Arena, M.; Viscardi, M. Strain state detection in composite structures: Review and new challenges. J. Compos. Sci. 2020, 4, 60. [Google Scholar] [CrossRef]

- Caffrey, E.; Garcia, J.R.; O’Suilleabhain, D.; Gabbett, C.; Carey, T.; Coleman, J.N. Quantifying the piezoresistive mechanism in high-performance printed graphene strain sensors. ACS Appl. Mater. Interfaces 2022, 14, 7141–7151. [Google Scholar] [CrossRef] [PubMed]

- Grassi, A.; Cecchi, F.; Maselli, M.; Röling, M.; Laschi, C.; Cianchetti, M. Warp-knitted textile as a strain sensor: Char-acterization procedure and application in a comfortable wearable goniometer. IEEE Sens. J. 2017, 17, 5927–5936. [Google Scholar] [CrossRef]

- Pancham, P.P.; Chiu, W.H.; Mukherjee, A.; Lo, C.Y. Strain Visualization in Flexible Sensors with Functional Materials: A Review. Adv. Mater. Interfaces 2023, 10, 2300029. [Google Scholar] [CrossRef]

- Meng, Z.; Zhang, M.; Guo, C.; Fan, Q.; Zhang, H.; Gao, N.; Zhang, Z. Recent progress in sensing and computing techniques for human activity recognition and motion analysis. Electronics 2020, 9, 1357. [Google Scholar] [CrossRef]

- Tang, J.; Wu, Y.; Ma, S.; Yan, T.; Pan, Z. Flexible strain sensor based on CNT/TPU composite nanofiber yarn for smart sports bandage. Compos. Part B Eng. 2022, 232, 109605. [Google Scholar] [CrossRef]

- Kumar, A.; Rakesh Kumar, R.K.; Shaikh, M.O.; Lu, C.H.; Yang, J.Y.; Chang, H.L.; Chuang, C.H. Ultrasensitive strain sensor utilizing a AgF–AgNW hybrid nanocomposite for breath monitoring and pulmonary function analysis. ACS Appl. Mater. Interfaces 2022, 14, 55402–55413. [Google Scholar] [CrossRef] [PubMed]

- Vitazkova, D.; Foltan, E.; Kosnacova, H.; Micjan, M.; Donoval, M.; Kuzma, A.; Kopani, M.; Vavrinsky, E. Advances in Respiratory Monitoring: A Comprehensive Review of Wearable and Remote Technologies. Biosensors 2024, 14, 90. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Liu, C.; Zou, H.; Che, L.; Sun, P.; Yan, J.; Wang, Z.L. Integrated wearable smart sensor system for real-time multi-parameter respiration health monitoring. Cell Rep. Phys. Sci. 2023, 4, 101191. [Google Scholar] [CrossRef]

- Hussain, T.; Ullah, S.; Fernández-García, R.; Gil, I. Wearable sensors for respiration monitoring: A review. Sensors 2023, 23, 7518. [Google Scholar] [CrossRef] [PubMed]

- Milone, A.; Monteduro, A.G.; Rizzato, S.; Leo, A.; Di Natale, C.; Kim, S.S.; Maruccio, G. Advances in materials and technologies for gas sensing from environmental and food monitoring to breath analysis. Adv. Sustain. Syst. 2023, 7, 2200083. [Google Scholar] [CrossRef]

- Li, S.; Zhang, Y.; Liang, X.; Wang, H.; Lu, H.; Zhu, M.; Zhang, Y. Humidity-sensitive chemoelectric flexible sensors based on metal-air redox reaction for health management. Nat. Commun. 2022, 13, 5416. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Qu, D.; Guo, L.; Zhou, G.; Zhang, G.; Du, T.; Wu, W. MXene/TPU Composite Film for Humidity Sensing and Human Respiration Monitoring. Adv. Sens. Res. 2024, 3, 2300014. [Google Scholar] [CrossRef]

- Sun, J.; Xiu, K.; Wang, Z.; Hu, N.; Zhao, L.; Zhu, H.; Kong, F.; Xiao, J.; Cheng, L.; Bi, X. Multifunctional wearable humidity and pressure sensors based on biocompatible graphene/bacterial cellulose bioaerogel for wireless monitoring and early warning of sleep apnea syndrome. Nano Energy 2023, 108, 108215. [Google Scholar] [CrossRef]

- Vanegas, E.; Igual, R.; Plaza, I. Sensing systems for respiration monitoring: A technical systematic review. Sensors 2020, 20, 5446. [Google Scholar] [CrossRef] [PubMed]

- Nicolò, A.; Massaroni, C.; Schena, E.; Sacchetti, M. The importance of respiratory rate monitoring: From healthcare to sport and exercise. Sensors 2020, 20, 6396. [Google Scholar] [CrossRef] [PubMed]

- Jubran, A. Advances in respiratory monitoring during mechanical ventilation. Chest 1999, 116, 1416–1425. [Google Scholar] [CrossRef] [PubMed]

- Shaik, T.; Tao, X.; Higgins, N.; Li, L.; Gururajan, R.; Zhou, X.; Acharya, U.R. Remote patient monitoring using artificial intelligence: Current state, applications, and challenges. Wiley Interdiscip. Rev. Data Min. Knowl. Discov. 2023, 13, e1485. [Google Scholar] [CrossRef]

- Tekcin, M.; Hamzaoglu, D.R.T.; Kursun, S. Flexible humidity sensor for smart agricultural applications. Flex. Print. Electron. 2023, 8, 035003. [Google Scholar] [CrossRef]

- Thalman, R. Development and Testing of a Rocket-Based Sensor for Atmospheric Sensing Using an Unmanned Aerial System. Sensors 2024, 24, 1768. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.Y.; Lee, G.B. Humidity sensors: A review. Sens. Lett. 2005, 3, 1–15. [Google Scholar] [CrossRef]

- González Rivero, R.A.; Morera Hernández, L.E.; Schalm, O.; Hernández Rodríguez, E.; Alejo Sánchez, D.; Morales Pérez, M.C.; Martinez Laguardia, A. A low-cost calibration method for temperature, relative humidity, and carbon dioxide sensors used in air quality monitoring systems. Atmosphere 2023, 14, 191. [Google Scholar] [CrossRef]

- Aix, M.L.; Schmitz, S.; Bicout, D.J. Calibration methodology of low-cost sensors for high-quality monitoring of fine particulate matter. Sci. Total Environ. 2023, 889, 164063. [Google Scholar] [CrossRef]

- Chen, X.; Mei, S.; Zhao, W.; Zhang, Y.; Zhang, X.; Cui, Z.; Fu, P.; Pang, X.; Liu, M.; Ye, Y. Thermoplastic polyamide elastomer based flexible humidity sensor for breath monitoring. Mater. Des. 2023, 235, 112438. [Google Scholar] [CrossRef]

- Li, X.; Zhuang, Z.; Qi, D.; Zhao, C. High sensitive and fast response humidity sensor based on polymer composite nanofibers for breath monitoring and non-contact sensing. Sens. Actuators B Chem. 2021, 330, 129239. [Google Scholar] [CrossRef]

- Dai, J.; Zhao, H.; Lin, X.; Liu, S.; Fei, T.; Zhang, T. Design strategy for ultrafast-response humidity sensors based on gel polymer electrolytes and application for detecting respiration. Sens. Actuators B Chem. 2020, 304, 127270. [Google Scholar] [CrossRef]

- Wolkoff, P.; Azuma, K.; Carrer, P. Health, work performance, and risk of infection in office-like environments: The role of indoor temperature, air humidity, and ventilation. Int. J. Hyg. Environ. Health 2021, 233, 113709. [Google Scholar] [CrossRef] [PubMed]

- Amit, M.; Chukoskie, L.; Skalsky, A.J.; Garudadri, H.; Ng, T.N. Flexible pressure sensors for objective assessment of motor disorders. Adv. Funct. Mater. 2020, 30, 1905241. [Google Scholar] [CrossRef]

- Sun, Y.; Gao, X.; Fang, H.; Lu, M.; Yao, D.; Lu, C. Hydrophobic multifunctional flexible sensors with a rapid humidity response for long-term respiratory monitoring. ACS Sustain. Chem. Eng. 2023, 11, 2375–2386. [Google Scholar] [CrossRef]

- Meena, J.S.; Choi, S.B.; Jung, S.B.; Kim, J.W. Electronic textiles: New age of wearable technology for healthcare and fitness solutions. Mater. Today Bio 2023, 19, 100565. [Google Scholar] [CrossRef]

- Saxena, P.; Shukla, P. A review on recent developments and advances in environmental gas sensors to monitor toxic gas pollutants. Environ. Prog. Sustain. Energy 2023, 42, e14126. [Google Scholar] [CrossRef]

- Lawaniya, S.D.; Kumar, S.; Yu, Y.; Rubahn, H.G.; Mishra, Y.K.; Awasthi, K. Functional nanomaterials in flexible gas sensors: Recent progress and future prospects. Mater. Today Chem. 2023, 29, 101428. [Google Scholar] [CrossRef]

- Sudheep, C.V.; Verma, A.; Jasrotia, P.; Hmar, J.J.L.; Gupta, R.; Verma, A.S.; Jyoti; Kumar, A.; Kumar, T. Revolutionizing gas sensors: The role of composite materials with conducting polymers and transition metal oxides. Results Chem. 2023, 7, 101255. [Google Scholar] [CrossRef]

- Nuhoglu, D.; Tasaltin, C.; Gurol, I. QCM and SAW gas and VOC sensors based on metal oxide composites (principles, fabrication, sensing materials, and performances). In Complex and Composite Metal Oxides for Gas VOC and Humidity Sensors Volume 1; Elsevier: Amsterdam, The Netherlands, 2024; pp. 223–252. [Google Scholar]

- Huang, X.; Pang, R.; Yang, M.; Zhang, S.; Guo, F.; Xu, J.; Shang, Y. Flexible Gas Sensors Based on Carbon Nanotube Hybrid Films: A Review. Adv. Mater. Technol. 2023, 8, 2300616. [Google Scholar] [CrossRef]

- Png, Z.M.; Wang, C.G.; Yeo, J.C.C.; Lee, J.J.C.; Surat’man, N.E.; Tan, Y.L.; Xu, J.W.; Loh, J.X.; Zhu, Q. Stimuli-responsive structure–property switchable polymer materials. Mol. Syst. Des. Eng. 2023, 8, 1097–1129. [Google Scholar] [CrossRef]

- Sun, F.; Jiang, H.; Wang, H.; Zhong, Y.; Xu, Y.; Xing, Y.; Zhu, M. Soft fiber electronics based on semiconducting polymer. Chem. Rev. 2023, 123, 4693–4763. [Google Scholar] [CrossRef]

- Zheng, F.; Jiang, H.Y.; Yang, X.T.; Guo, J.H.; Sun, L.; Guo, Y.Y.; Hu, H.; Yao, M.S. Reviews of wearable healthcare systems based on flexible gas sensors. Chem. Eng. J. 2024, 490, 151874. [Google Scholar] [CrossRef]

- Banga, I.; Paul, A.; Poudyal, D.C.; Muthukumar, S.; Prasad, S. Recent Advances in Gas Detection Methodologies with a Special Focus on Environmental Sensing and Health Monitoring Applications—A Critical Review. ACS Sens. 2023, 8, 3307–3319. [Google Scholar] [CrossRef] [PubMed]

- Jia, Y.; Yue, X.; Wang, Y.; Yan, C.; Zheng, G.; Dai, K.; Liu, C.; Shen, C. Multifunctional stretchable strain sensor based on polydopamine/reduced graphene oxide/electrospun thermoplastic polyurethane fibrous mats for human motion detection and environment monitoring. Compos. Part B Eng. 2020, 183, 107696. [Google Scholar] [CrossRef]

- Mokhtari, F.; Cheng, Z.; Raad, R.; Xi, J.; Foroughi, J. Piezofibers to smart textiles: A review on recent advances and future outlook for wearable technology. J. Mater. Chem. A 2020, 8, 9496–9522. [Google Scholar] [CrossRef]

- Hou, Z.; Liu, X.; Tian, M.; Zhang, X.; Qu, L.; Fan, T.; Miao, J. Smart fibers and textiles for emerging clothe-based wearable electronics: Materials, fabrications and applications. J. Mater. Chem. A 2023, 11, 17336–17372. [Google Scholar] [CrossRef]

- Idumah, C.I. Design, fabrication, characterization and properties of metallic and conductive smart polymeric textiles for multifunctional applications. Nano-Struct. Nano-Objects 2023, 35, 100982. [Google Scholar] [CrossRef]

- Zhao, P.; Song, Y.; Xie, P.; Zhang, F.; Xie, T.; Liu, G.; Zhao, J.; Han, S.T.; Zhou, Y. All-Organic Smart Textile Sensor for Deep-Learning-Assisted Multimodal Sensing. Adv. Funct. Mater. 2023, 33, 2301816. [Google Scholar] [CrossRef]

- Yang, K.; McErlain-Naylor, S.A.; Isaia, B.; Callaway, A.; Beeby, S. E-textiles for sports and fitness sensing: Current state, challenges, and future opportunities. Sensors 2024, 24, 1058. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Y.; Liang, X.; Zhang, Y. Smart fibers and textiles for personal health management. ACS Nano 2021, 15, 12497–12508. [Google Scholar] [CrossRef] [PubMed]

- Jang, S.; Choi, J.Y.; Yoo, E.S.; Lim, D.Y.; Lee, J.Y.; Kim, J.K.; Pang, C. Printable wet-resistive textile strain sensors using bead-blended composite ink for robustly integrative wearable electronics. Compos. Part B Eng. 2021, 210, 108674. [Google Scholar] [CrossRef]

- Liu, X.; Miao, J.; Fan, Q.; Zhang, W.; Zuo, X.; Tian, M.; Zhu, S.; Zhang, X.; Qu, L. Smart textile based on 3D stretchable silver nanowires/MXene conductive networks for personal healthcare and thermal management. ACS Appl. Mater. Interfaces 2021, 13, 56607–56619. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Li, Y.; Bick, M.; Chen, J. Smart textiles for electricity generation. Chem. Rev. 2020, 120, 3668–3720. [Google Scholar] [CrossRef] [PubMed]

- Alam, T.; Saidane, F.; Al Faisal, A.; Khan, A.; Hossain, G. Smart-textile strain sensor for human joint monitoring. Sens. Actuators A Phys. 2022, 341, 113587. [Google Scholar] [CrossRef]

- Li, X.; Koh, K.H.; Farhan, M.; Lai, K.W.C. An ultraflexible polyurethane yarn-based wearable strain sensor with a polydimethylsiloxane infiltrated multilayer sheath for smart textiles. Nanoscale 2020, 12, 4110–4118. [Google Scholar] [CrossRef]

- Bidsorkhi, H.C.; Faramarzi, N.; Ali, B.; Ballam, L.R.; D’Aloia, A.G.; Tamburrano, A.; Sarto, M.S. Wearable Graphene-based smart face mask for Real-Time human respiration monitoring. Mater. Des. 2023, 230, 111970. [Google Scholar] [CrossRef] [PubMed]

- Vidhya, C.M.; Maithani, Y.; Singh, J.P. Recent advances and challenges in textile electrodes for wearable biopotential signal monitoring: A comprehensive review. Biosensors 2023, 13, 679. [Google Scholar] [CrossRef]

- Yin, J.; Wang, S.; Di Carlo, A.; Chang, A.; Wan, X.; Xu, J.; Xiao, X.; Chen, J. Smart textiles for self-powered biomonitoring. Med-X 2023, 1, 3. [Google Scholar] [CrossRef]

- Sarraj, S.; Szymiczek, M.; Jurczyk, S. Influence of herbal fillers addition on selected properties of silicone subjected to accelerated aging. Polymers 2022, 15, 42. [Google Scholar] [CrossRef]

- Sarraj, S.; Szymiczek, M.; Jędrejek, D.; Soluch, A.; Kurpanik, R. Sage-modified polydimethylsiloxane applied as antibacterial wound dressing material. Polimery 2024, 69, 33–43. [Google Scholar] [CrossRef]

- Mazur, K.; Singh, R.; Friedrich, R.P.; Genç, H.; Unterweger, H.; Sałasińska, K.; Bogucki, R.; Kuciel, S.; Cicha, I. The effect of antibacterial particle incorporation on the mechanical properties, biodegradability, and biocompatibility of PLA and PHBV composites. Macromol. Mater. Eng. 2020, 305, 2000244. [Google Scholar] [CrossRef]

- Mazur, M.; Masłowiec, D. Antimicrobial activity of lactones. Antibiotics 2022, 11, 1327. [Google Scholar] [CrossRef] [PubMed]

- Felice, B.; Sánchez, M.A.; Socci, M.C.; Sappia, L.D.; Gómez, M.I.; Cruz, M.K.; Felice, C.J.; Marti, M.; Pividori, M.I.; Simonelli, G.; et al. Controlled degradability of PCL-ZnO nanofibrous scaffolds for bone tissue engineering and their antibacterial activity. Mater. Sci. Eng. C 2018, 93, 724–738. [Google Scholar] [CrossRef] [PubMed]

- Felice, B.; Seitz, V.; Bach, M.; Rapp, C.; Wintermantel, E. Antimicrobial polymers: Antibacterial efficacy of silicone rubber–titanium dioxide composites. J. Compos. Mater. 2017, 51, 2253–2262. [Google Scholar] [CrossRef]

- Yamashita, M.; Sawano, J.; Umeda, R.; Tatsumi, A.; Kumeda, Y.; Iida, A. Structure–activity relationship studies of antimicrobial naphthoquinones derived from constituents of tabebuia avellanedae. Chem. Pharm. Bull. 2021, 69, 661–673. [Google Scholar] [CrossRef]

| S. No. | Type of Filler and Rubber | Fabrication Technique | Properties | Applications | Reference |

|---|---|---|---|---|---|

| 1. | Multi-wall carbon nanotube, titanium carbide, and silicone rubber | Solution mixing | For the best sample, the tensile strength was 1.34 MPa, while the compressive modulus stands at 3.87 MPa | Thumb pressing exhibits a voltage of ~100 mV, while the gauge factor was 23.9. | [45] |

| 2. | Multi-wall carbon nanotubes, and silicone rubber | Solution mixing | Hysteresis loss was 37.24 kJ, while the compressive modulus was ~180% higher than the unfilled sample | The thumb press results in a relative resistance change of 350. The gauge factor was 14.4 | [49] |

| 3. | Multiwalled carbon nanotubes, graphene, and silicone rubber | Solution mixing | Thermal conductivity was 1.3 W/m/K, which was 465% higher than the unfilled sample | Electromagnetic interference shielding effectiveness was 42 dB in K-band | [92] |

| 4. | Graphene and silicone rubber | Solution mixing | Mechanical stretchability was 650% | The gauge factor was 1078.1, and the response time was ~140 ms | [103] |

| 5. | Polyvinyl chloride, polydimethylsiloxane rubber, and silicone rubber | Solution mixing | The relative capacitance was up to 0.75 µF for different human motions | The gauge factor was 9.1 × 106, the linearity was 0.9997, and the response time was 17 ms | [116] |

| 6. | Graphene oxide, silk fibroin, and lithium bromide | Solution mixing | The change in current was ~10 µA/s for slow breathing and ~3.5 µA/s for fast breathing | Sensitivity of 0.09 µA/s/1%, response time of 1.05 s, and recovery time of 0.08 s | [129] |

| 7. | Thermoplasticpolyamide elastomer, | Heat-melt method | The resistance was in the MΩ range and decreased with increasing relative humidity for all composite samples | Sensor linearity was 0.99, and response time was 4 s | [141] |

| 8. | Polydopamine, thermoplastic polyurethane mats, and reduced graphene oxide | Solution mixing | Tensile strength of ~7 MPa, elongation at break of ~600% | The gauge factor was 185, and the response time of 100 ms | [157] |

| 9. | Silicone rubber, polyvinyl alcohol | Solution mixing | Tensile strength of ~9 MPa, and elongation at break of ~500% | Gauge factor was 57, wide sensing range was ~130%, excellent repeatability of >10,000, and waterproof with a contact angle of ~112°. | [164] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, V.; Alam, M.N.; Park, S.S. Review of Recent Progress on Silicone Rubber Composites for Multifunctional Sensor Systems. Polymers 2024, 16, 1841. https://doi.org/10.3390/polym16131841

Kumar V, Alam MN, Park SS. Review of Recent Progress on Silicone Rubber Composites for Multifunctional Sensor Systems. Polymers. 2024; 16(13):1841. https://doi.org/10.3390/polym16131841

Chicago/Turabian StyleKumar, Vineet, Md. Najib Alam, and Sang Shin Park. 2024. "Review of Recent Progress on Silicone Rubber Composites for Multifunctional Sensor Systems" Polymers 16, no. 13: 1841. https://doi.org/10.3390/polym16131841

APA StyleKumar, V., Alam, M. N., & Park, S. S. (2024). Review of Recent Progress on Silicone Rubber Composites for Multifunctional Sensor Systems. Polymers, 16(13), 1841. https://doi.org/10.3390/polym16131841