Enhancement of Thermal Management Performance of Copper Foil Using Additive–Free Graphene Coating

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of GO

2.3. Preparation of rGO/G-Cu Composite Films

2.4. Characterization

3. Results and Discussion

3.1. Morphology and Structure of GO and G

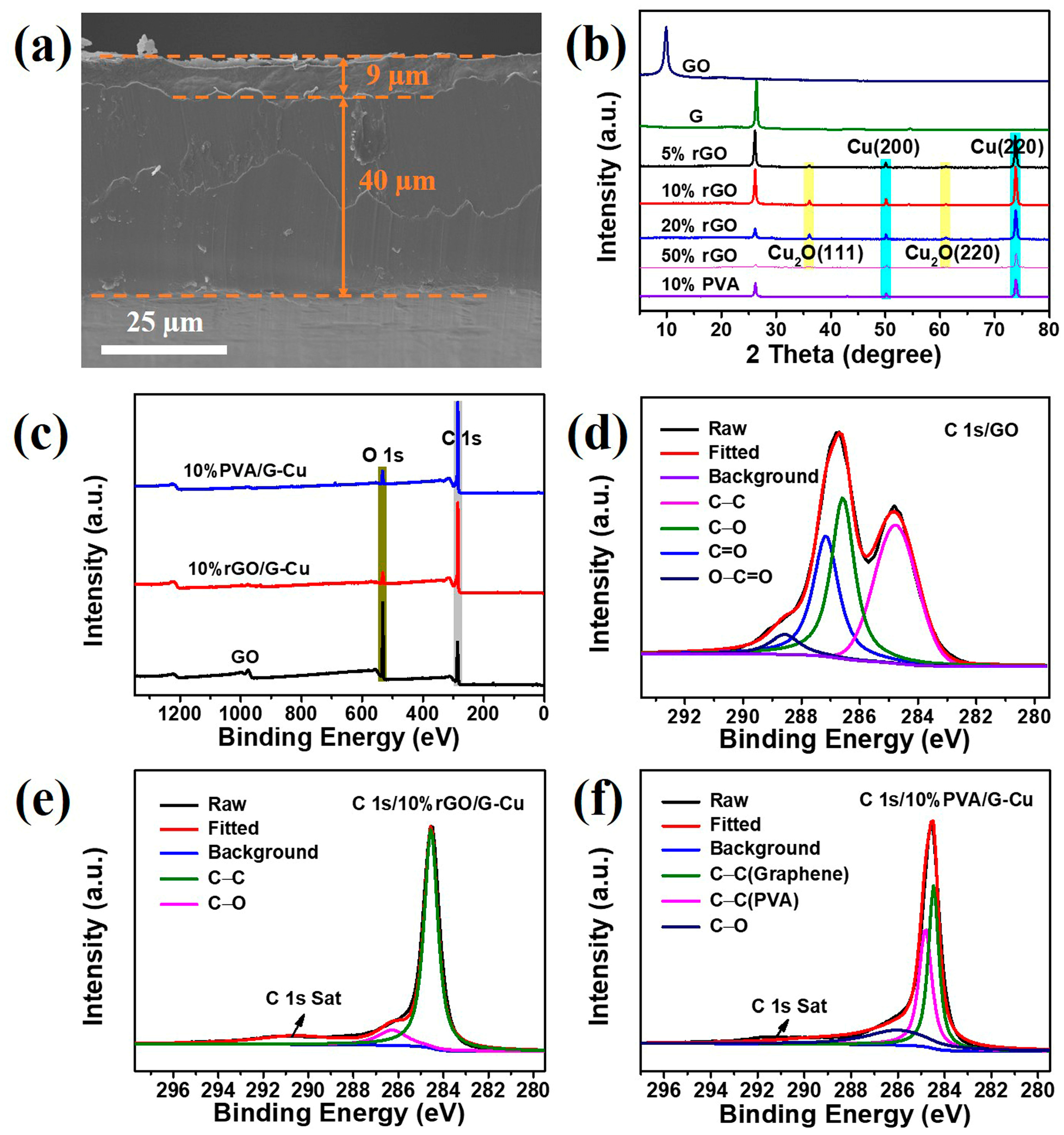

3.2. Morphology and Structure of rGO/G-Cu and 10% PVA/G-Cu

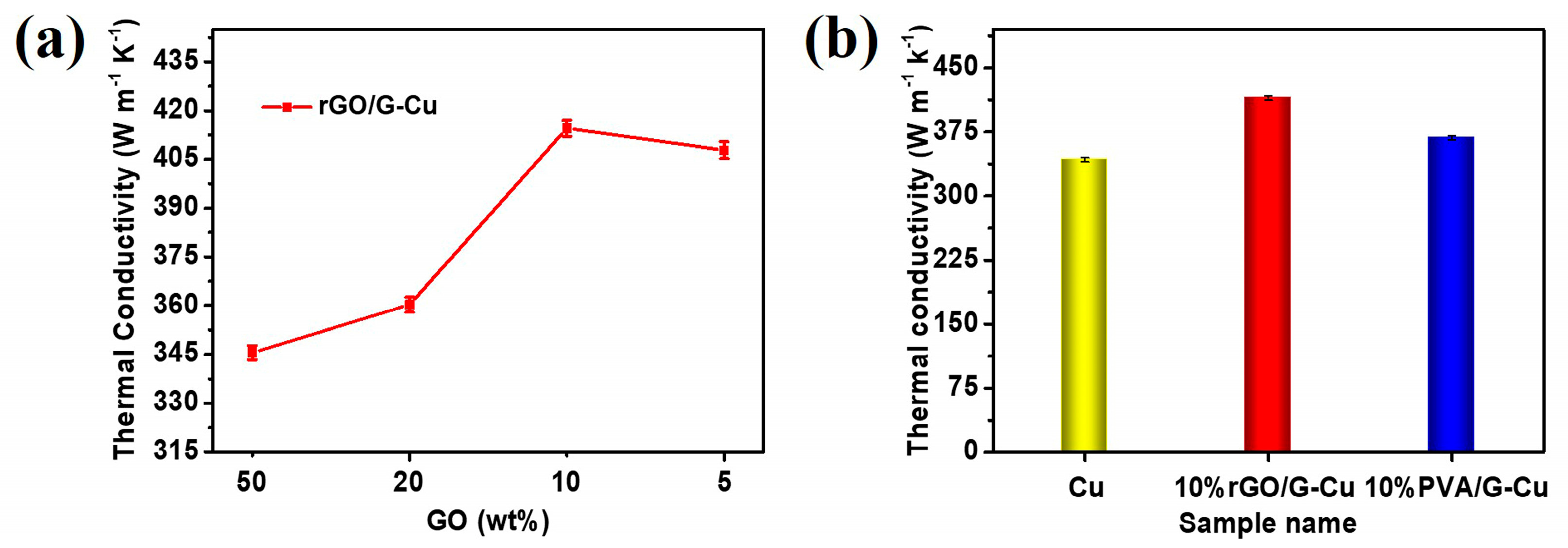

3.3. Thermal Conductivity of rGO/G-Cu and PVA/G-Cu

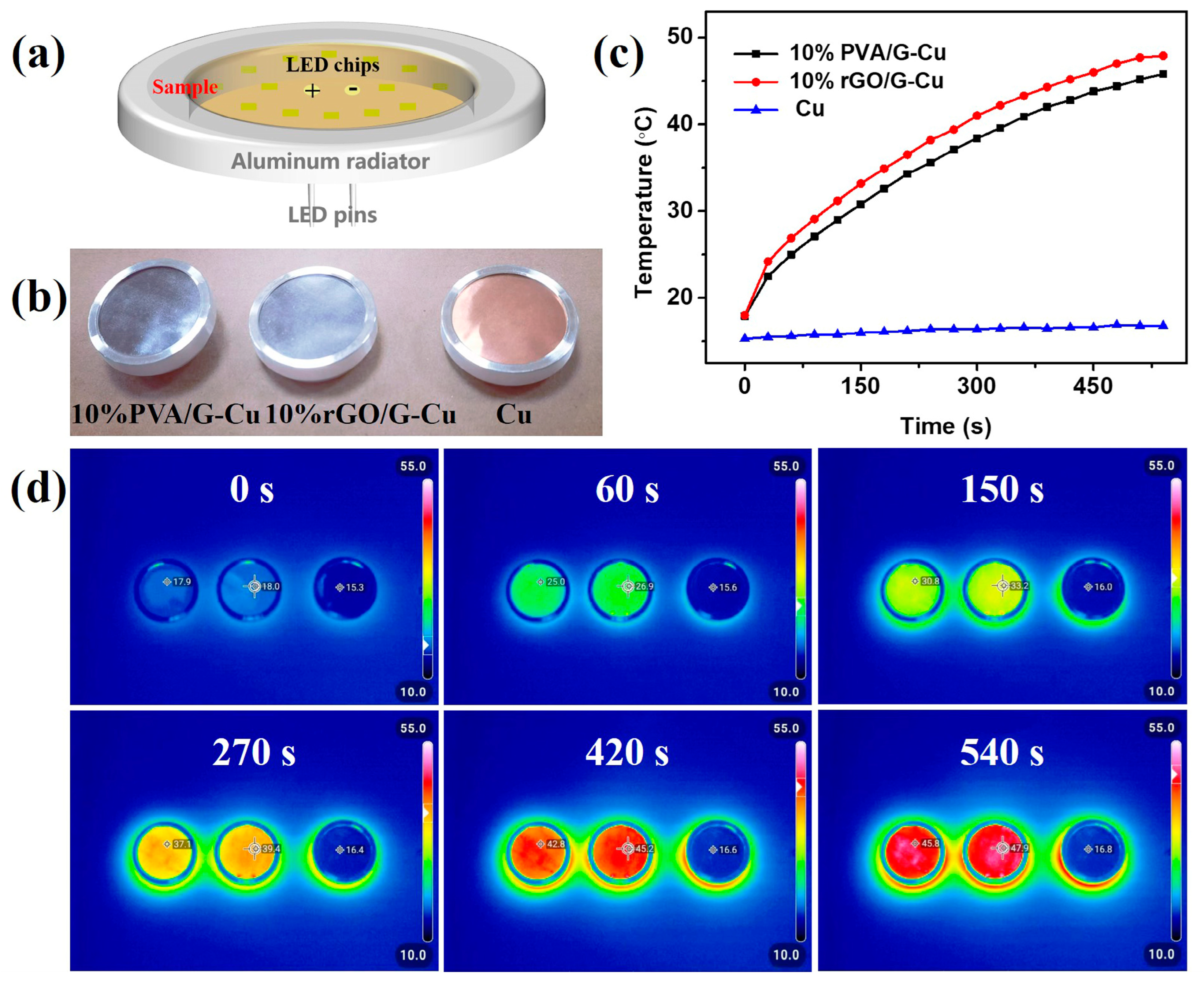

3.4. Practical Applications of Composite Films in LED Chips Heat Dissipation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, P.; Yuan, P.; Jiang, X.; Zhai, S.; Zeng, J.; Xian, Y.; Qin, H.; Yang, D. A theoretical review on interfacial thermal transport at the nanoscale. Small 2018, 14, 1702769. [Google Scholar] [CrossRef]

- Li, Z.; Lv, L.; Li, J. Combination of heat storage and thermal spreading for high power portable electronics cooling. Int. J. Heat Mass Transfer 2016, 98, 550–557. [Google Scholar] [CrossRef]

- Hao, Y.; Ming, X.; Lu, J.; Cao, M.; Zhang, P.; Shi, H.; Li, K.; Gao, Y.; Wang, L.; Fang, W.; et al. Bidirectionally High-Thermally Conductive and Environmentally Adaptive Graphene Thick Films Enabled by Seamless Bonding Assembly for Extreme ThermalManagement. Adv. Funct. Mater. 2024, 2400110. [Google Scholar] [CrossRef]

- Hwang, F.S.; Confrey, T.; Reidy, C.; Picovici, D.; Callaghan, D.; Culliton, D.; Nolan, C. Review of battery thermal management systems in electric vehicles. Renew. Sustain. Energy Rev. 2024, 192, 114171. [Google Scholar] [CrossRef]

- Lee, H.; Lee, D.; Kim, Y. Heating performance of a coolant-source heat pump using waste heat from stack and electric devices in fuel cell electric vehicles under cold conditions. Energy Convers. Manag. 2022, 252, 115092. [Google Scholar] [CrossRef]

- Moore, A.L.; Shi, L. Emerging challenges and materials for thermal management of electronics. Mater. Today 2014, 17, 163–174. [Google Scholar] [CrossRef]

- Lin, Y.; Li, P.; Liu, W.; Chen, J.; Liu, X.; Jiang, P.; Huang, X. Application-Driven High-Thermal-Conductivity Polymer Nanocomposites. ACS Nano 2024, 18, 3851–3870. [Google Scholar] [CrossRef] [PubMed]

- Blet, N.; Lips, S.; Sartre, V. Heats pipes for temperature homogenization: A literature review. Appl. Therm. Eng. 2017, 118, 490–509. [Google Scholar] [CrossRef]

- Waldrop, M.M. The chips are down for Moore’s law. Nature 2016, 530, 144–147. [Google Scholar] [CrossRef]

- Nika, D.L.; Balandin, A.A. Phonons and thermal transport in graphene and graphene-based materials. Rep. Prog. Phys. 2017, 80, 036502. [Google Scholar] [CrossRef]

- Ghosh, S.; Calizo, I.; Teweldebrhan, D.; Pokatilov, E.P.; Nika, D.L.; Balandin, A.A.; Bao, W.; Miao, F.; Lau, C.N. Extremely high thermal conductivity of graphene: Prospects for thermal management applications in nanoelectronic circuits. Appl. Phys. Lett. 2008, 92, 151911. [Google Scholar] [CrossRef]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior thermal conductivity of single-layer graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef] [PubMed]

- Shahil, K.M.F.; Balandin, A.A. Graphene-multilayer graphene nanocomposites as highly efficient thermal interface materials. Nano Lett. 2012, 12, 861–867. [Google Scholar] [CrossRef] [PubMed]

- Peng, L.; Xu, Z.; Liu, Z.; Guo, Y.; Li, P.; Gao, C. Ultrahigh thermal conductive yet superflexible graphene films. Adv. Mater. 2017, 29, 1700589. [Google Scholar]

- Hsieh, C.-C.; Liu, W.-R. Synthesis and characterization of nitrogen-doped graphene nanosheets/copper composite film for thermal dissipation. Carbon 2017, 118, 1–7. [Google Scholar] [CrossRef]

- Sun, C.; Zhang, X.; Zhao, N.; He, C. Influence of spark plasma sintering temperature on the microstructure and strengthening mechanisms of discontinuous threedimensional graphene-like network reinforced Cu matrix composites. Mater. Sci. Eng. A 2019, 756, 82–91. [Google Scholar] [CrossRef]

- Chen, F.; Ying, J.; Wang, Y.; Du, S.; Liu, Z.; Huang, Q. Effects of graphene content on the microstructure and properties of copper matrix composites. Carbon 2016, 96, 836–842. [Google Scholar] [CrossRef]

- Ali, S.; Ahmad, F.; Yusoff, P.S.M.M.; Muhamad, N.; Oñate, E.; Raza, M.R.; Malik, E. A review of graphene reinforced Cu matrix composites for thermal management of smart electronics. Compos. Part A 2021, 144, 106357. [Google Scholar]

- Li, X.; Cai, W.; An, J.; Kim, S.; Nah, J.; Yang, D.; Piner, R.; Velamakanni, A.; Jung, I.; Tutuc, E.; et al. Large-area synthesis of high-quality and uniform graphene films on copper foils. Science 2009, 324, 1312–1314. [Google Scholar] [CrossRef]

- Li, J.; Zhang, P.; He, H.; Shi, B. Enhanced the thermal conductivity of flexible copper foil by introducing graphene. Mater. Des. 2020, 187, 108373. [Google Scholar] [CrossRef]

- Jiang, B.; Wang, H.; Wen, G.; Wang, E.; Fang, X.; Liu, G.; Zhou, W. Copper-graphite-copper sandwich: Superior heat spreader with excellent heat-dissipation ability and good weldability. RSC Adv. 2016, 6, 25128–25136. [Google Scholar] [CrossRef]

- Wang, S.; Han, S.; Xin, G.; Lin, J.; Wei, R.; Lian, J.; Sun, K.; Zu, X.; Yu, Q. High-quality graphene directly grown on Cu nanoparticles for Cu-graphene nanocomposites. Mater. Des. 2018, 139, 181–187. [Google Scholar] [CrossRef]

- Ding, J.; Zhao, H.; Yu, H. Bio-Inspired Multifunctional Graphene-Epoxy Anticorrosion Coatings by Low-Defect Engineered Graphene. ACS Nano 2022, 16, 710–720. [Google Scholar] [CrossRef] [PubMed]

- Peng, L.; Yu, H.; Chen, C.; He, Q.; Zhang, H.; Zhao, F.; Qin, M.; Feng, Y.; Feng, W. Tailoring Dense, Orientation-Tunable, and Interleavedly Structured Carbon-Based Heat Dissipation Plates. Adv. Sci. 2023, 10, 2205962. [Google Scholar] [CrossRef] [PubMed]

- Cheng, C.; Shi, W.-H.; Teng, T.-P.; Yang, C.-R. Evaluation of Surfactants on Graphene Dispersion and Thermal Performance for Heat Dissipation Coating. Polymers 2022, 14, 952. [Google Scholar] [CrossRef] [PubMed]

- Poorsargol, M.; Alimohammadian, M.; Sohrabi, B.; Dehestani, M. Dispersion of graphene using surfactant mixtures: Exper-imental and molecular dynamics simulation studies. Appl. Surf. Sci. 2019, 464, 440–450. [Google Scholar] [CrossRef]

- Yeon, C.; Yun, S.J.; Lee, K.-S.; Lim, J.W. High-yield graphene exfoliation using sodium dodecyl sulfate accompanied by alcohols as surface-tension-reducing agents in aqueous solution. Carbon 2015, 83, 136–143. [Google Scholar] [CrossRef]

- Pan, X.; Debije, M.G.; Schenning, A.P.H.J.; Bastiaansen, C.W.M. Enhanced Thermal Conductivity in Oriented Polyvinyl Alcohol/Graphene Oxide Composites. ACS Appl. Mater. Interfaces 2021, 13, 28864–28869. [Google Scholar] [CrossRef]

- Chen, Q.; Ma, Z.; Wang, Z.; Liu, L.; Zhu, M.; Lei, W.; Song, P. Scalable, Robust, Low-Cost, and Highly Thermally Conductive Anisotropic Nanocomposite Films for Safe and Efficient Thermal Management. Adv. Funct. Mater. 2022, 32, 2110782. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Z.; Li, T.; Ma, P.; Zhang, X.; Xia, B.; Chen, M.; Du, M.; Liu, T.; Dong, W. Artificial nacre epoxy nanomaterials based on Janus graphene oxide for thermal management applications. ACS Appl. Mater. Interfaces 2020, 12, 44273–44280. [Google Scholar] [CrossRef]

- Chen, Y.; Xiao, H.; Kang, R.; Ling, Y.; Guo, L.; Dai, W.; Nishimura, K.; Lin, C.T.; Jiang, N.; Yu, J. Highly flexible biodegradable cellulose nanofiber/graphene heat spreader films with improved mechanical property and enhanced thermal conductivity. J. Mater. Chem. C 2018, 6, 12739–12745. [Google Scholar] [CrossRef]

- Trivedi, S.; Pamidi, V.; Bautista, S.P.; Shamsudin, F.N.A.; Weil, M.; Barpanda, P.; Bresser, D.; Fichtner, M. Water-Soluble Inorganic Binders for Lithium-Ion and Sodium-Ion Batteries. Adv. Energy Mater. 2024, 14, 2303338. [Google Scholar] [CrossRef]

- Wang, Z.-H.; Liu, B.-W.; Zeng, F.-R.; Lin, X.-C.; Zhang, J.-Y.; Wang, X.-L.; Wang, Y.-Z.; Zhao, H.-B. Fully recyclable multifunctional adhesive with high durability, transparency, flame retardancy, and harshenvironment resistance. Sci. Adv. 2022, 8, eadd8527. [Google Scholar] [CrossRef]

- Chu, K.; Wang, X.; Li, Y.; Huang, D.; Geng, Z.; Zhao, X.; Liu, H.; Zhang, H. Thermal properties of graphene/metal composites with aligned graphene. Mater. Des. 2018, 140, 85–94. [Google Scholar] [CrossRef]

- Luo, B.; Chi, M.; Zhang, Q.; Li, M.; Chen, C.; Wang, X.; Wang, S.; Min, D. Fabrication of Lignin-Based Nano Carbon Film-Copper Foil Composite with Enhanced Thermal Conductivity. Nanomaterials 2019, 9, 1681. [Google Scholar] [CrossRef]

- Goli, P.; Ning, H.; Li, X.; Lu, C.Y.; Novoselov, K.S.; Balandin, A.A. Thermal properties of graphene-copper-graphene heterogeneous films. Nano Lett. 2014, 14, 1497–1503. [Google Scholar] [CrossRef]

- Chen, H.; Müller, M.B.; Gilmore, K.J.; Wallace, G.G.; Li, D. Mechanically strong, electrically conductive, and biocompatible graphene paper. Adv. Mater. 2008, 20, 3557–3561. [Google Scholar] [CrossRef]

- Yeh, C.-N.; Huang, H.; Lim, A.T.O.; Jhang, R.-H.; Chen, C.-H.; Huang, J. Binder-free graphene oxide doughs. Nat. Commun. 2019, 10, 422. [Google Scholar] [CrossRef]

- Dikin, D.A.; Stankovich, S.; Zimney, E.J.; Piner, R.D.; Dommett, G.H.B.; Evmenenko, G.; Nguyen, S.T.; Ruoff, R.S. Preparation and characterization of graphene oxide paper. Nature 2007, 448, 457–460. [Google Scholar] [CrossRef]

- Luo, J.; Cote, L.J.; Tung, V.C.; Tan, A.T.L.; Goins, P.E.; Wu, J.; Huang, J. Graphene Oxide Nanocolloids. J. Am. Chem. Soc. 2010, 132, 17667–17669. [Google Scholar] [CrossRef]

- Voylov, D.N.; Agapov, A.L.; Sokolov, A.P.; Shulga, Y.M.; Arbuzov, A.A. Room temperature reduction of multilayer graphene oxide film on a copper substrate: Penetration and participation of copper phase in redox reactions. Carbon 2014, 69, 563–570. [Google Scholar] [CrossRef]

- Hummers, W.S., Jr.; Offeman, R.E. Preparation of graphitic oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Chen, W.H.; Liu, P.J.; Min, L.Z.; Zhou, Y.M.; Liu, Y.; Wang, Q.; Duan, W.F. Non-covalently Functionalized Graphene Oxide-Based Coating to Enhance Thermal Stability and Flame Retardancy of PVA Film. Nano-Micro Lett. 2018, 10, 39. [Google Scholar] [CrossRef] [PubMed]

- Suk, J.W.; Piner, R.D.; An, J.; Ruoff, R.S. Mechanical Properties of Monolayer Graphene Oxide. ACS Nano 2010, 4, 6557–6564. [Google Scholar] [CrossRef] [PubMed]

- He, P.; Zhou, J.; Tang, H.; Yang, S.; Liu, Z.; Xie, X.; Ding, G. Electrochemically modified graphite for fast preparation of large-sized graphene oxide. J. Colloid Interface Sci. 2019, 542, 387–391. [Google Scholar] [CrossRef] [PubMed]

- Hernandez, Y.; Nicolosi, V.; Lotya, M.; Blighe, F.M.; Sun, Z.; De, S.; McGovern, I.T.; Holland, B.; Byrne, M.; Gun’Ko, Y.K.; et al. High-yield production of graphene by liquid-phase exfoliation of graphite. Nat. Nanotech. 2008, 3, 563–568. [Google Scholar] [CrossRef] [PubMed]

- Okobiah, O.; Reidy, R.F. Surface Interactions: Functionalization of Graphene Oxide and Wetting of Graphene Oxide and Graphene. Curr. Org. Chem. 2016, 20, 674–681. [Google Scholar] [CrossRef]

- Zhang, M.; Nixon, R.; Schaufelberger, F.; Pirvu, L.; Bo, G.D.; Leigh, D.A. Mechanical scission of a knotted polymer. Nat. Chem. 2024, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Cao, M.S.; Wang, X.X.; Zhang, M.; Cao, W.Q.; Fang, X.Y.; Yuan, J. Variabletemperature electron transport and dipole polarization turning flexible multifunctional microsensor beyond electrical and optical energy. Adv. Mater. 2020, 32, e1907156. [Google Scholar] [CrossRef]

- Yang, L.; Zou, M.; Wu, S.; Xu, W.; Wu, H.; Cao, A. Graphene oxide glue-electrode for fabrication of vertical, elastic, conductive columns. ACS Nano 2017, 11, 2944–2951. [Google Scholar] [CrossRef]

- Meng, S.; Ouyang, X.; Fu, J.; Niu, Y.; Ma, Y. The role of graphene/graphene oxide in cementhydration. Nanotechnol. Rev. 2021, 10, 768–778. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, D. Molecular dynamics simulation of mechanical performance of graphene/graphene oxide paper based polymer composites. Carbon 2014, 67, 784–791. [Google Scholar] [CrossRef]

- Shin, A.; Kim, Y.; Ko, S.; Han, J.H. Study on microstructure and thermal properties of a CNF/Cu nanocomposite fabricated using chemical mixing. J. Alloys Compd. 2018, 737, 21–30. [Google Scholar] [CrossRef]

| NO. | Strengthening Phase | Additive | Method | K (W·m−1·K−1) | Reference |

|---|---|---|---|---|---|

| 1 | graphene nanosheets | carboxymethyl cellulose, conducting carbon black, and Styrene Butadiene rubber | coating | 445.91 | [15] |

| 2 | nitrogen-doped graphene nanosheets | carboxymethyl cellulose, conducting carbon black, and Styrene Butadiene rubber | coating | 542.9 | [15] |

| 3 | rGO | no | electrophoretic deposition and vacuum hot pressing | 637.7 | [20] |

| 4 | synthetic graphite | no | electroplating | 526–626 | [21] |

| 5 | graphene | no | vacuum filtration and spark plasma sintering | 458 | [34] |

| 6 | lignin-based nano-carbon | no | annealing treatment at 1000 °C in an argon atmosphere | 478 | [35] |

| 7 | graphene | no | chemical vapor deposition (1030 °C) | 369.5 | [36] |

| 8 | carbon nanofiber | no | electroless plating process and vacuum hot pressing | 435 | [53] |

| 9 | pure Cu foil | — | — | 342.47 | — |

| 10 | rGO/graphene | no | coating and rolling process | 414.56 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, B.; Yuan, H.; Chen, G. Enhancement of Thermal Management Performance of Copper Foil Using Additive–Free Graphene Coating. Polymers 2024, 16, 1872. https://doi.org/10.3390/polym16131872

Hu B, Yuan H, Chen G. Enhancement of Thermal Management Performance of Copper Foil Using Additive–Free Graphene Coating. Polymers. 2024; 16(13):1872. https://doi.org/10.3390/polym16131872

Chicago/Turabian StyleHu, Bing, Huilin Yuan, and Guohua Chen. 2024. "Enhancement of Thermal Management Performance of Copper Foil Using Additive–Free Graphene Coating" Polymers 16, no. 13: 1872. https://doi.org/10.3390/polym16131872

APA StyleHu, B., Yuan, H., & Chen, G. (2024). Enhancement of Thermal Management Performance of Copper Foil Using Additive–Free Graphene Coating. Polymers, 16(13), 1872. https://doi.org/10.3390/polym16131872