The Effect of Fibrillation, Semi-Dry Pressing, and Surface Treatment on the Barrier Properties of Water Molecules and Oxygen on Food Packaging Paper

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

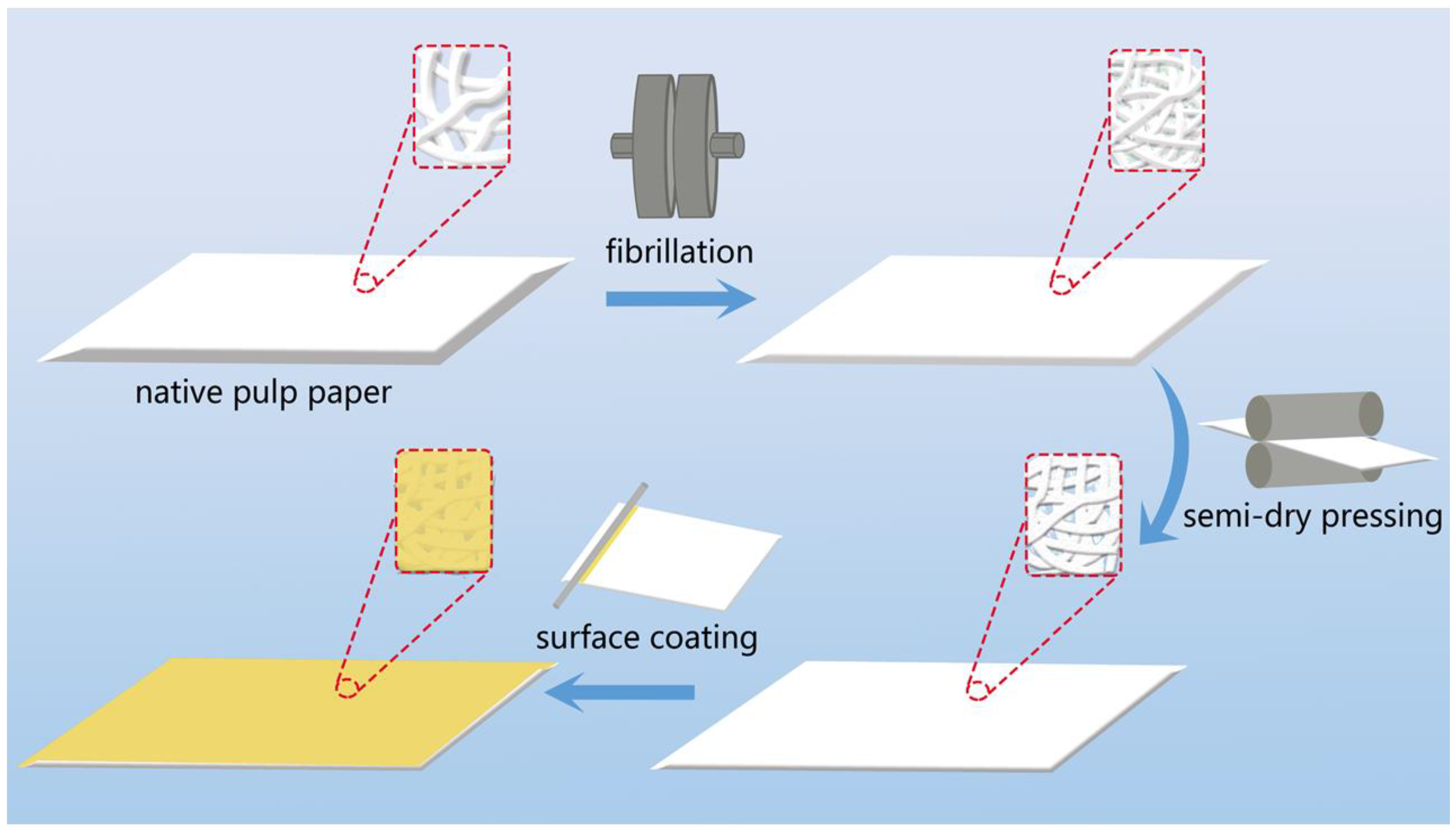

2.2. Methods

2.2.1. Fiber Fibrillation and Based Paper Preparation

2.2.2. Paper Semi-Dry Pressing

2.2.3. Film-Forming Agent Paper Surface Coating

2.2.4. Mechanical Properties Testing of Paper

2.2.5. Paper Water Vapor and Oxygen Barrier Test

2.2.6. Paper Porosity Testing

2.2.7. Characterization of Fiber and Paper Surface Morphology

3. Results and Discussion

3.1. Degree of Fibrillation and Paper Properties

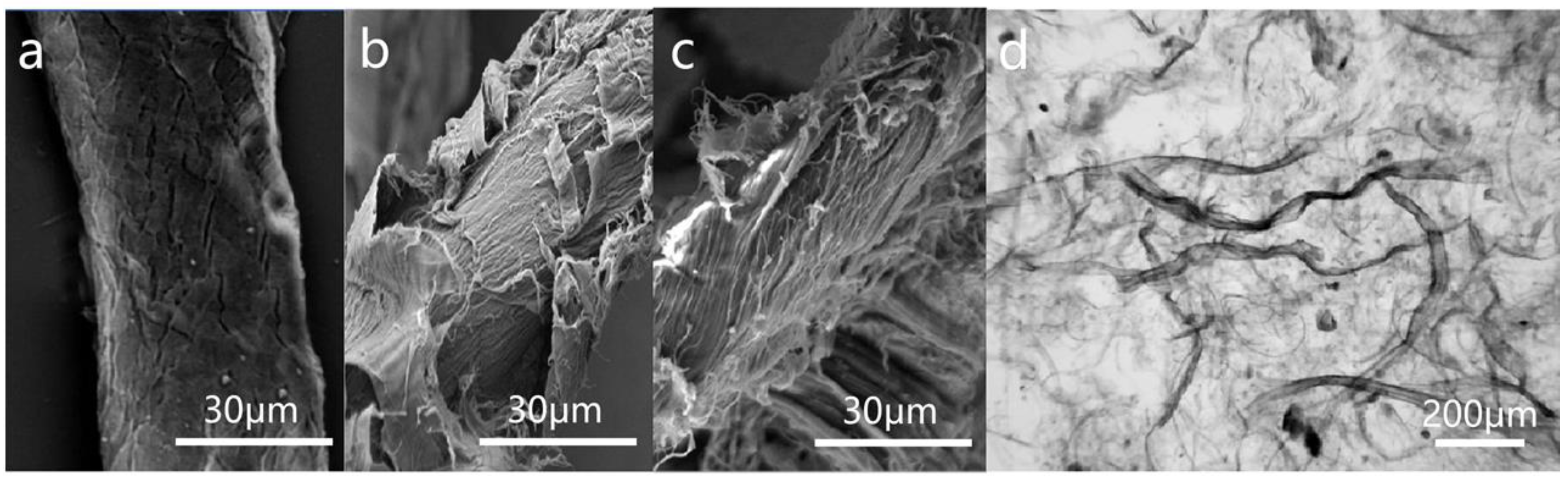

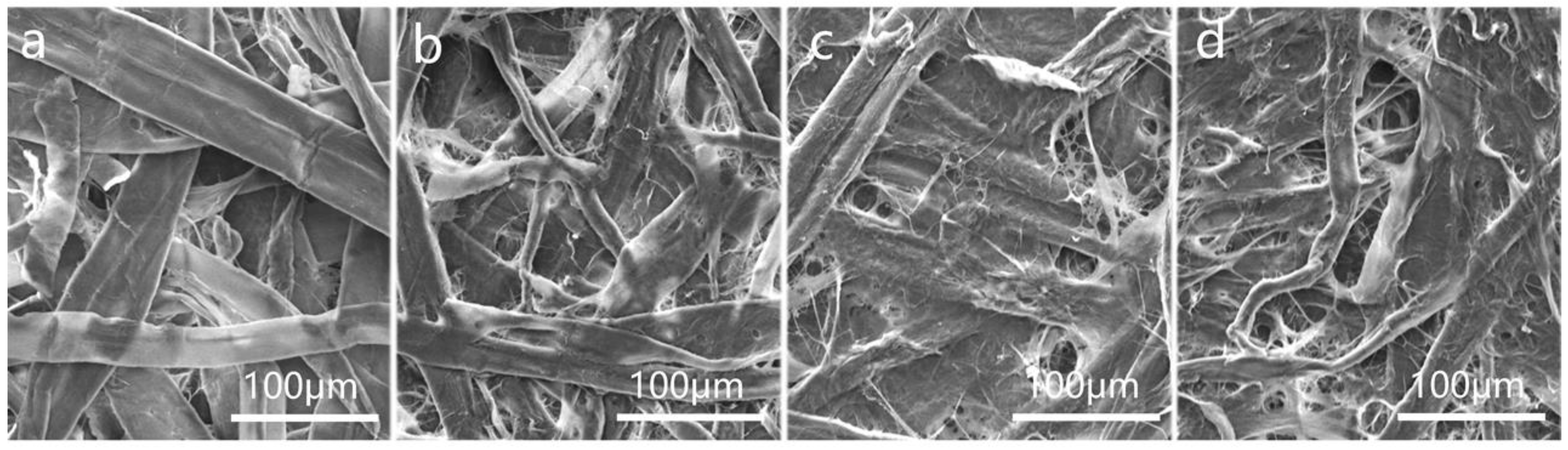

3.1.1. Degree of Fibrillation and Paper Surface Morphological Structure

3.1.2. Degree of Fibrillation and Mechanical and Barrier Properties of Paper

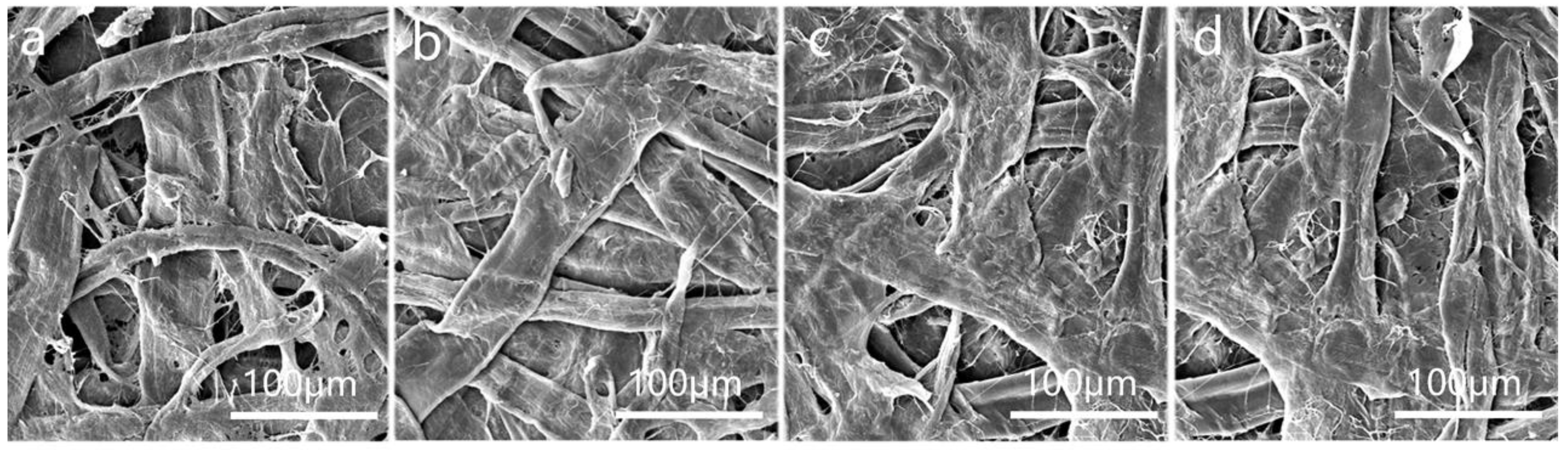

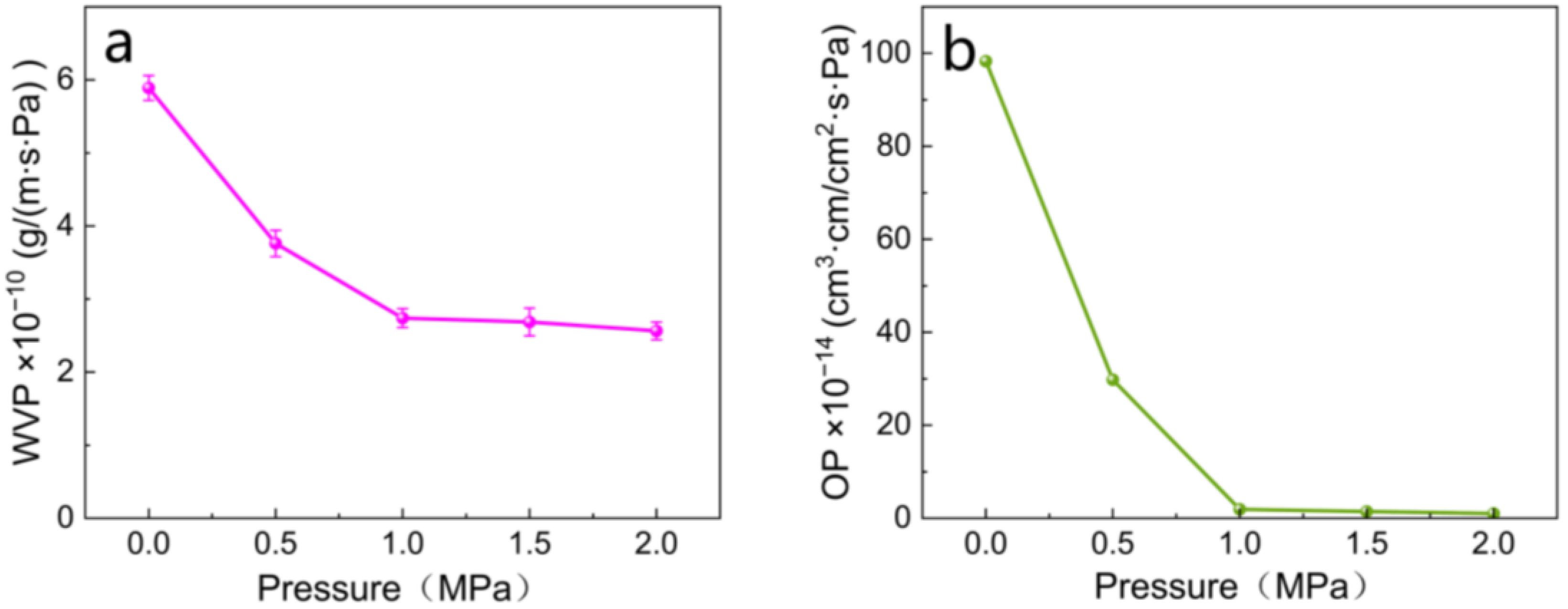

3.2. Paper Semi-Dry Pressing and Paper Barrier Properties

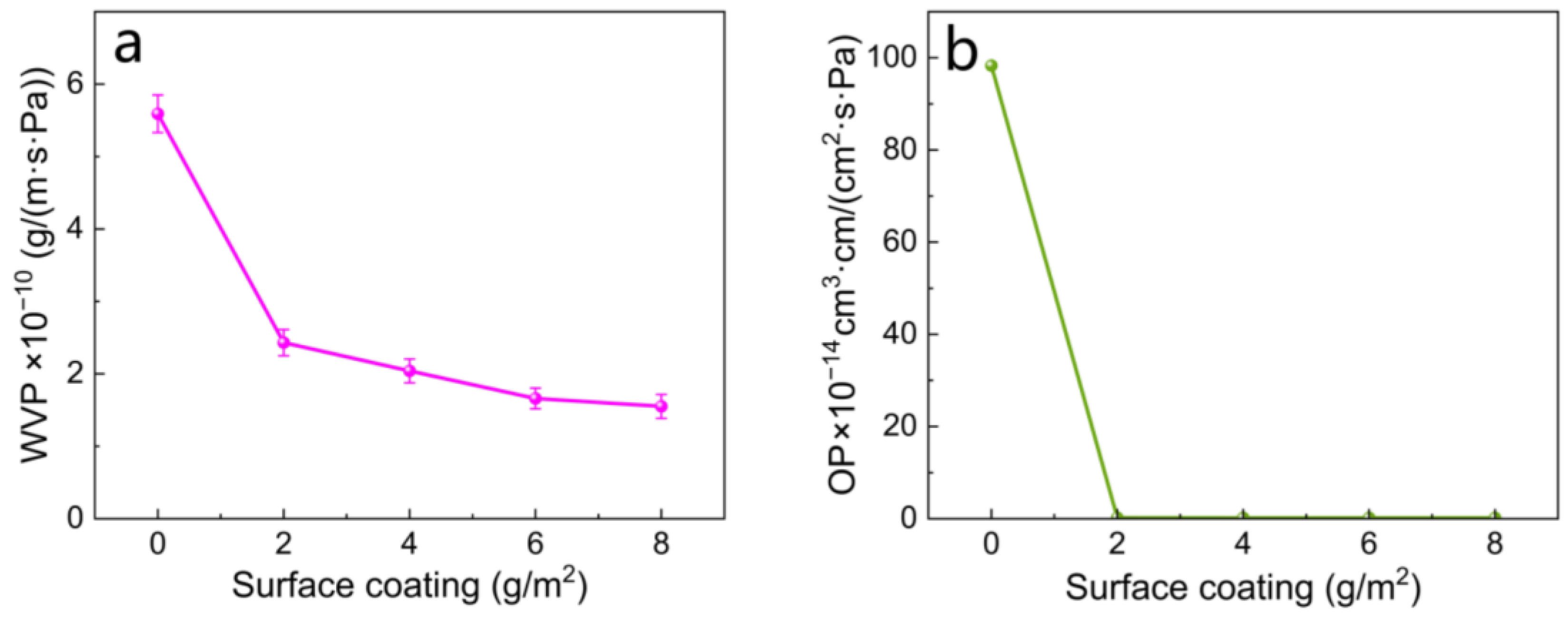

3.3. Surface Sizing and Paper Barrier Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, H.Y.; Liu, T.X.; Hsu, C.H.; Cho, Y.S.; Xu, Z.J.; Liao, S.C.; Zeng, B.H.; Jiang, Y.L.; Lien, S.Y. Thin-Film Coated Plastic Wrap for Food Packaging. Materials 2017, 10, 821. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Huang, Y.; Wang, X.-Y.; Wu, Z.-Y.; Weng, Y.-X. Kinetic analysis of PGA/PBAT plastic films for strawberry fruit preservation quality and enzyme activity. J. Food Compos. Anal. 2022, 108, 104439–104449. [Google Scholar] [CrossRef]

- Silva, E.G.S.; Cardoso, S.; Bettencourt, A.F.; Ribeiro, I.A.C. Latest Trends in Sustainable Polymeric Food Packaging Films. Foods 2023, 12, 168. [Google Scholar] [CrossRef] [PubMed]

- Rillig, M.C. Microplastic in Terrestrial Ecosystems and the Soil? Environ. Sci. Technol. 2012, 46, 6453–6454. [Google Scholar] [CrossRef] [PubMed]

- Kato, L.S.; Conte-Junior, C.A. Safety of Plastic Food Packaging: The Challenges about Non-Intentionally Added Substances (NIAS) Discovery, Identification and Risk Assessment. Polymers 2021, 13, 2077. [Google Scholar] [CrossRef] [PubMed]

- Kadac-Czapska, K.; Knez, E.; Gierszewska, M.; Olewnik-Kruszkowska, E.; Grembecka, M. Microplastics Derived from Food Packaging Waste-Their Origin and Health Risks. Materials 2023, 16, 674. [Google Scholar] [CrossRef]

- Fernandez-Santos, J.; Valls, C.; Cusola, O.; Blanca Roncero, M. Improving Filmogenic and Barrier Properties of Nanocellulose Films by Addition of Biodegradable Plasticizers. ACS Sustain. Chem. Eng. 2021, 9, 9647–9660. [Google Scholar]

- Wang, Y.; Zhang, X.; Kan, L.; Shen, F.; Ling, H.; Wang, X. All-biomass-based eco-friendly waterproof coating for paper-based green packaging. Green Chem. 2022, 24, 7039–7048. [Google Scholar] [CrossRef]

- Jiang, X.; Li, Q.; Li, X.; Meng, Y.; Ling, Z.; Ji, Z.; Chen, F. Preparation and Characterization of Degradable Cellulose-Based Paper with Superhydrophobic, Antibacterial, and Barrier Properties for Food Packaging. Int. J. Mol. Sci. 2022, 23, 11158. [Google Scholar] [CrossRef]

- Khakalo, A.; Kouko, J.; Filpponen, I.; Retulainen, E.; Rojas, O.J. In-Plane Compression and Biopolymer Permeation Enable Super-stretchable Fiber Webs for Thermoforming toward 3-D Structures. ACS Sustain. Chem. Eng. 2017, 5, 9114–9125. [Google Scholar] [CrossRef]

- Despond, S.; Espuche, E.; Cartier, N.; Domard, A. Barrier properties of paper-chitosan and paper-Chitosan-Carnauba wax films. J. Appl. Polym. Sci. 2005, 98, 704–710. [Google Scholar] [CrossRef]

- Dury-Brun, C.; Jury, V.; Guillard, V.; Desobry, S.; Voilley, A.; Chalier, P. Water barrier properties of treated-papers and application to sponge cake storage. Food Res. Int. 2006, 39, 1002–1011. [Google Scholar] [CrossRef]

- Zhu, Q.; Tan, J.; Li, D.; Zhang, T.; Liu, Z.; Cao, Y. Cross-linked chitosan/tannin extract as a biodegradable and repulpable coating for paper with excellent oil-resistance, gas barrier and UV-shielding. Prog. Org. Coat. 2023, 176, 107399–107409. [Google Scholar] [CrossRef]

- Chen, X.; Xiao, B.; Yang, Y.; Jiang, Y.; Song, X.; Chen, F.; Wang, W.; Wu, J.; Meng, Y. A novel paper-based composite film with enhanced oxygen and water vapor barrier properties. Prog. Org. Coat. 2024, 186, 108042–108050. [Google Scholar] [CrossRef]

- Cheng, Z.; Li, J.; Su, M.; Xiao, N.; Zhong, L.; Zhang, X.; Chen, S.; Chen, Q.; Liang, W.; Liu, M. High-Barrier Oxidized Cellulose Nanofibril/Chitosan Coating for Functional Food Packaging Materials. ACS Appl. Polym. Mater. 2024, 6, 2877–2888. [Google Scholar] [CrossRef]

- Wang, J.; Gardner, D.J.; Stark, N.M.; Bousfield, D.W.; Tajvidi, M.; Cai, Z. Moisture and Oxygen Barrier Properties of Cellulose Nanomaterial-Based Films. ACS Sustain. Chem. Eng. 2018, 6, 49–70. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, H.; Jia, R.; Dai, Y.; Dong, H.; Hou, H.; Guo, Q. High performance extrusion blown starch/polyvinyl alcohol/clay nanocomposite films. Food Hydrocoll. 2018, 79, 534–543. [Google Scholar] [CrossRef]

- Mohamed, S.A.A.; El-Sakhawy, M.; El-Sakhawy, M.A.M. Polysaccharides, Protein and Lipid -Based Natural Edible Films in Food Packaging: A Review. Carbohydr. Polym. 2020, 238, 116178–116192. [Google Scholar] [CrossRef]

- Nesic, A.; Cabrera-Barjas, G.; Dimitrijevic-Brankovic, S.; Davidovic, S.; Radovanovic, N.; Delattre, C. Prospect of Polysaccharide-Based Materials as Advanced Food Packaging. Molecules 2020, 25, 135. [Google Scholar] [CrossRef]

- Quilez-Molina, A.I.; Paul, U.C.; Merino, D.; Athanassiou, A. Composites of Thermoplastic Starch and Lignin-Rich Agricultural Waste for the Packaging of Fatty Foods. ACS Sustain. Chem. Eng. 2022, 10, 15402–15413. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, X.; Wang, D.; Fang, C.; Zhang, W.; Wang, C.; Huang, Z. Lysozyme-based composite membranes and their potential application for active packaging. Food Biosci. 2021, 43, 101078–101088. [Google Scholar] [CrossRef]

- Hanani, Z.A.N.; Husna, A.B.A.; Syahida, S.N.; Khaizura, M.A.B.N.; Jamilah, B. Effect of different fruit peels on the functional properties of gelatin/polyethylene bilayer films for active packaging. Food Packag. Shelf Life 2018, 18, 201–211. [Google Scholar] [CrossRef]

- Zabaleta, I.; Blanco-Zubiaguirre, L.; Nilsu Baharli, E.; Olivares, M.; Prieto, A.; Zuloaga, O.; Elizalde, M.P. Occurrence of per- and polyfluorinated compounds in paper and board packaging materials and migration to food simulants and foodstuffs. Food Chem. 2020, 321, 126746–126756. [Google Scholar] [CrossRef]

- Wang, W.; Lockwood, K.; Boyd, L.M.; Davidson, M.D.; Movafaghi, S.; Vahabi, H.; Khetani, S.R.; Kota, A.K. Superhydrophobic Coatings with Edible Materials. ACS Appl. Mater. Interfaces 2016, 8, 18664–18668. [Google Scholar] [CrossRef]

- Shi, H.; Wu, L.; Luo, Y.; Yu, F.; Li, H. A facile method to prepare cellulose fiber-based food packaging papers with improved mechanical strength, enhanced barrier, and antibacterial properties. Food Biosci. 2022, 48, 101729–101740. [Google Scholar] [CrossRef]

- Vaezi, K.; Asadpour, G.; Sharifi, S.H. Effect of coating with novel bio nanocomposites of cationic starch/cellulose nanocrystals on the fundamental properties of the packaging paper. Polym. Test. 2019, 80, 106080–106091. [Google Scholar] [CrossRef]

- He, S.; Wu, X.; Zhang, X.; Sun, J.; Tian, F.; Guo, S.; Du, H.; Li, P.; Huang, Y. Preparation and properties of thermal insulation coating based on silica aerogel. Energy Build. 2023, 298, 113556–113568. [Google Scholar] [CrossRef]

- Guz, L.; Gonzalez-Seligra, P.; Ochoa-Yepes, O.; Estevez-Areco, S.; Fama, L.; Goyanes, S. Influence of Different Commercial Modified Cassava Starches on the Physicochemical Properties of Thermoplastic Edible Films Obtained by Flat-Die Extrusion. Starch-Starke 2021, 73, 167–177. [Google Scholar] [CrossRef]

- Ren, H.; Mo, W.; Li, B. Effect of surfactants on the cellulosic fiber characteristics during paper recycling. Cellulose 2023, 30, 7939–7953. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, Q.; Zhang, J.; Ding, G.; Xu, G.; Liu, Z.; Cui, G. A superior thermostable and nonflammable composite membrane towards high power battery separator. Nano Energy 2014, 10, 277–287. [Google Scholar] [CrossRef]

- Ramesh, P.; Muthukkumarasamy, S.; Dhanabalan, K.; Sadhasivam, T.; Gurunathan, K. Synthesis and characterization of Ag and TiO2 nanoparticles and their anti-microbial activities. Dig. J. Nanomater. Biostruct. 2012, 7, 1501–1508. [Google Scholar]

- Iwamoto, S.; Nakagaito, A.N.; Yano, H. Nano-fibrillation of pulp fibers for the processing of transparent nanocomposites. Appl. Phys. A Mater. 2007, 89, 461–466. [Google Scholar] [CrossRef]

- Upadhyay, A.; Lucia, L.; Pal, L. Harnessing total chemical-free paper and packaging materials barrier properties by mechanical modification of cellulosic fibers for food security and environmental sustainability. Appl. Mater. Today 2023, 35, 101973–101987. [Google Scholar] [CrossRef]

- Chen, Y.; Wan, J.; Zhang, X.; Ma, Y.; Wang, Y. Effect of beating on recycled properties of unbleached eucalyptus cellulose fiber. Carbohydr. Polym. 2012, 87, 730–736. [Google Scholar] [CrossRef]

- Kjellgren, H.; Engström, G. The relationship between energy requirement and barrier properties in the production of greaseproof paper. Tappi J. 2005, 4, 7–11. [Google Scholar]

- Wan, J.; Yang, J.; Ma, Y.; Wang, Y. Effects of pulp preparation and papermaking processes on the properties of occ fibers. Bioresources 2011, 6, 1615–1630. [Google Scholar] [CrossRef]

- Lowe, R.M.; Page, D.H.; Waterhouse, J.F.; Hsieh, J.; Cheluka, N.; Ragauskas, A.J. Deformation behavior of wet lignocellulosic fibers. Holzforschung 2007, 61, 261–266. [Google Scholar] [CrossRef]

- Thuy, V.T.T.; Hao, L.T.; Jeon, H.; Koo, J.M.; Park, J.; Lee, E.S.; Hwang, S.Y.; Choi, S.; Park, J.; Oh, D.X. Sustainable, self-cleaning, transparent, and moisture/oxygen-barrier coating films for food packaging. Green Chem. 2021, 23, 2658–2667. [Google Scholar] [CrossRef]

- Lavoine, N.; Desloges, I.; Khelifi, B.; Bras, J. Impact of different coating processes of microfibrillated cellulose on the mechanical and barrier properties of paper. J. Mater. Sci. 2014, 49, 2879–2893. [Google Scholar] [CrossRef]

- Wilpiszewska, K.; Czech, Z. Water-Soluble Pressure-Sensitive Adhesives Containing Carboxymethyl Starch with Improved Adhesion to Paper. J. Polym. Environ. 2018, 26, 1453–1458. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, Y.; Wang, S.; Xu, T.; Bian, H.; Dai, H. The Effect of Fibrillation, Semi-Dry Pressing, and Surface Treatment on the Barrier Properties of Water Molecules and Oxygen on Food Packaging Paper. Polymers 2024, 16, 1892. https://doi.org/10.3390/polym16131892

Duan Y, Wang S, Xu T, Bian H, Dai H. The Effect of Fibrillation, Semi-Dry Pressing, and Surface Treatment on the Barrier Properties of Water Molecules and Oxygen on Food Packaging Paper. Polymers. 2024; 16(13):1892. https://doi.org/10.3390/polym16131892

Chicago/Turabian StyleDuan, Yuqing, Shumei Wang, Tingting Xu, Huiyang Bian, and Hongqi Dai. 2024. "The Effect of Fibrillation, Semi-Dry Pressing, and Surface Treatment on the Barrier Properties of Water Molecules and Oxygen on Food Packaging Paper" Polymers 16, no. 13: 1892. https://doi.org/10.3390/polym16131892

APA StyleDuan, Y., Wang, S., Xu, T., Bian, H., & Dai, H. (2024). The Effect of Fibrillation, Semi-Dry Pressing, and Surface Treatment on the Barrier Properties of Water Molecules and Oxygen on Food Packaging Paper. Polymers, 16(13), 1892. https://doi.org/10.3390/polym16131892