Fabrication of PVA–Silica Sol Wood Composites via Delignification and Freezing Pretreatment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

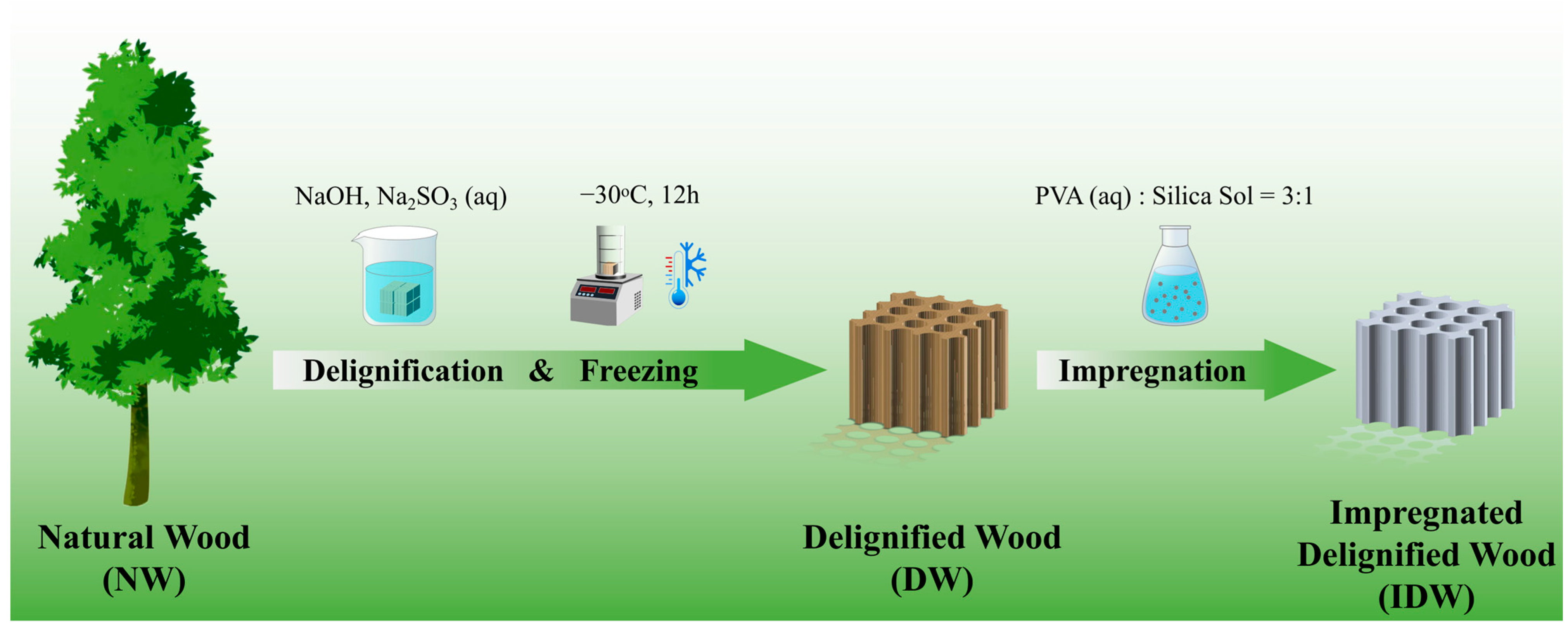

2.2. Delignification–Freezing Pretreatment of the Poplar Wood Blocks

2.3. Preparation of PVA–Silica Sol-Modified Impregnating Solution

2.4. Preparation of PVA–Silica Sol-Modified Wood Based on Delignified Lignin Wood Framework

2.5. Characterization

3. Results and Discussion

3.1. Impregnation Rate and Weight Increase Rate

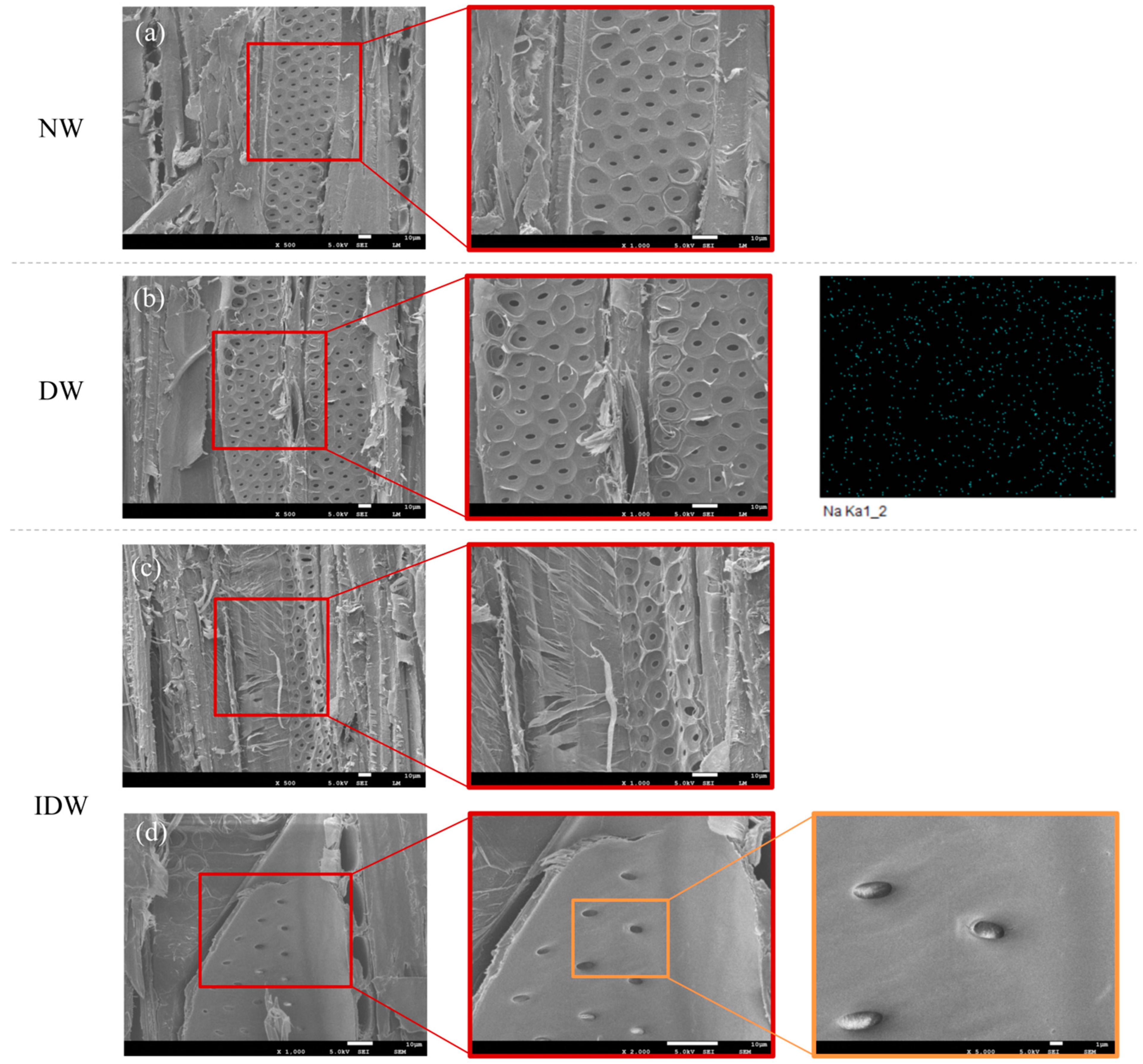

3.2. Micromorphology and Microstructure

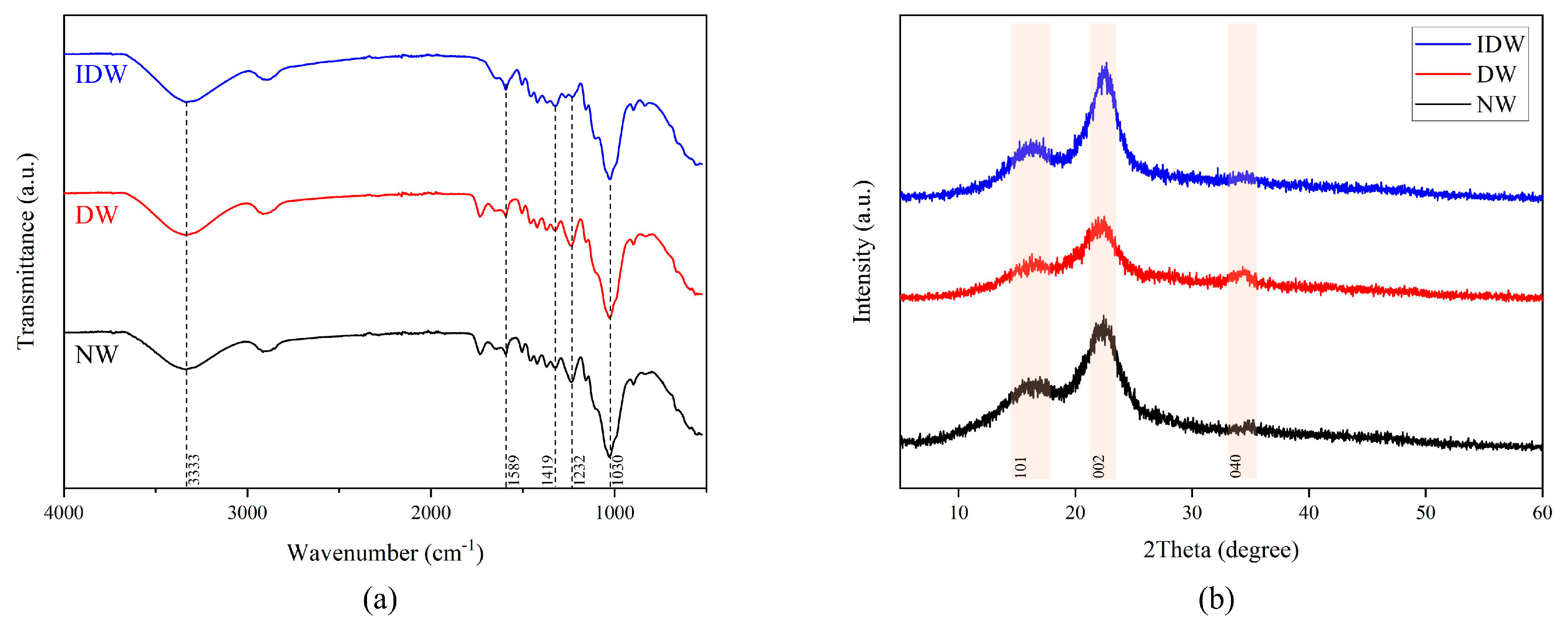

3.3. Chemical Composition

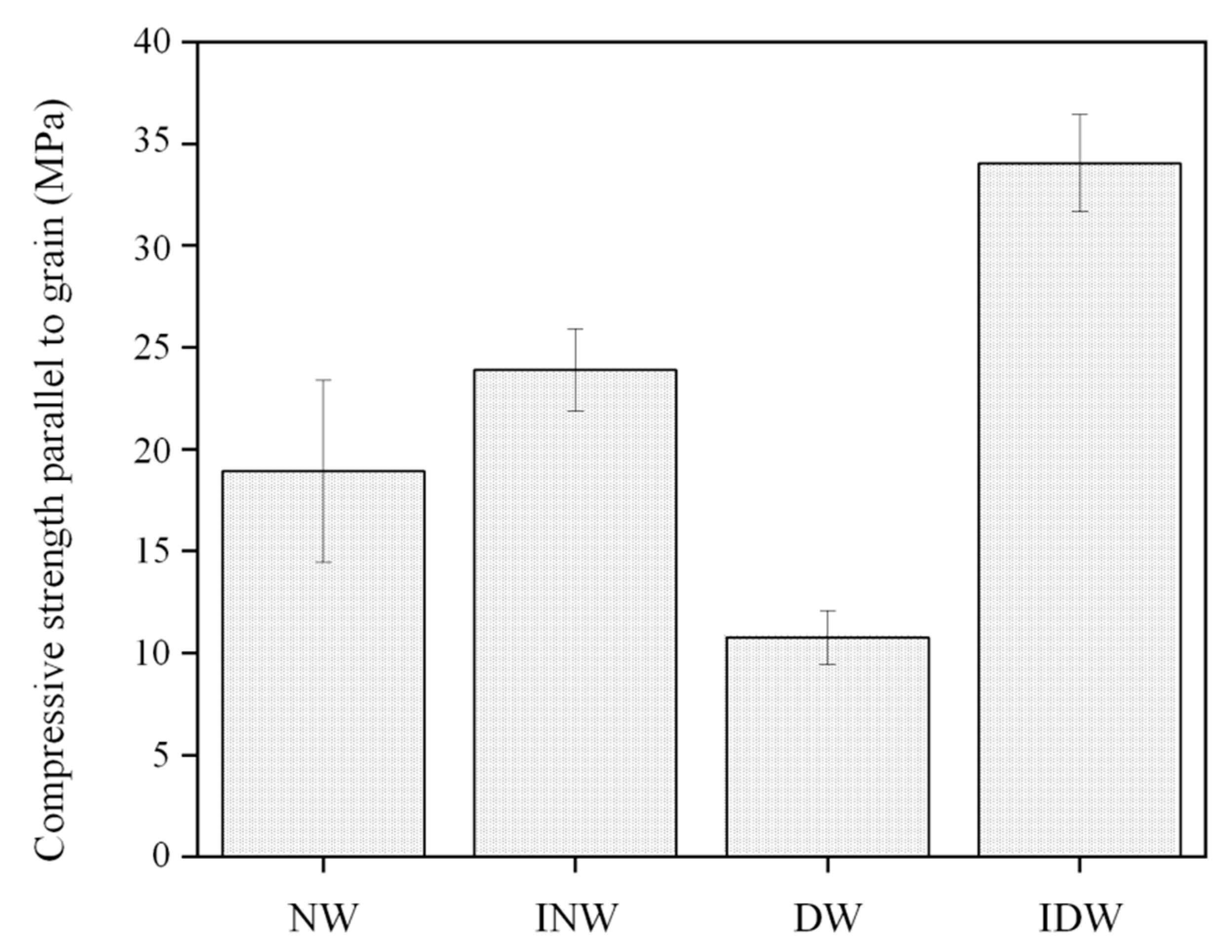

3.4. Physical and Mechanical Properties

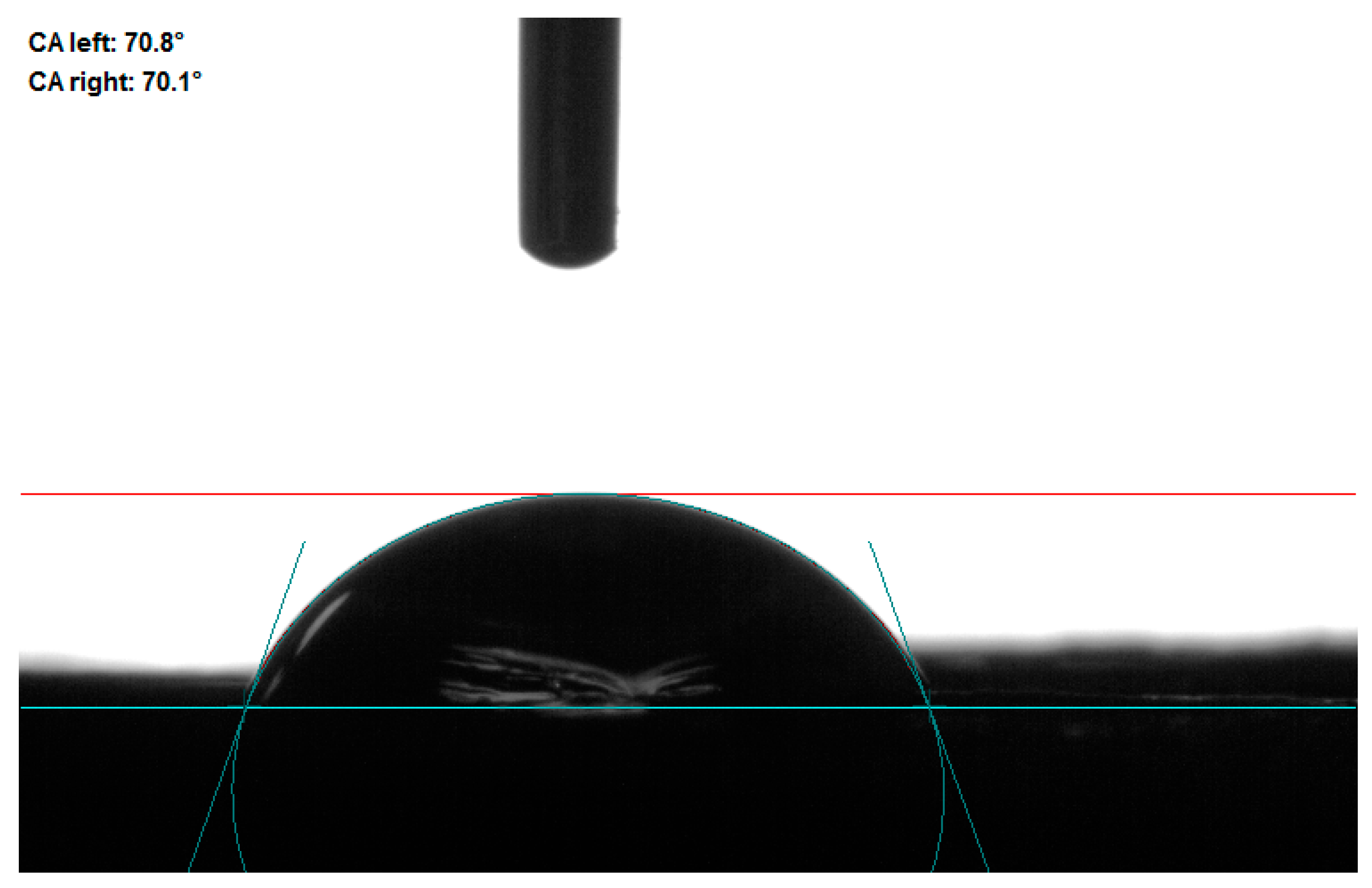

3.5. Water Contact Angle, Hygroscopicity and Dry Shrinkage

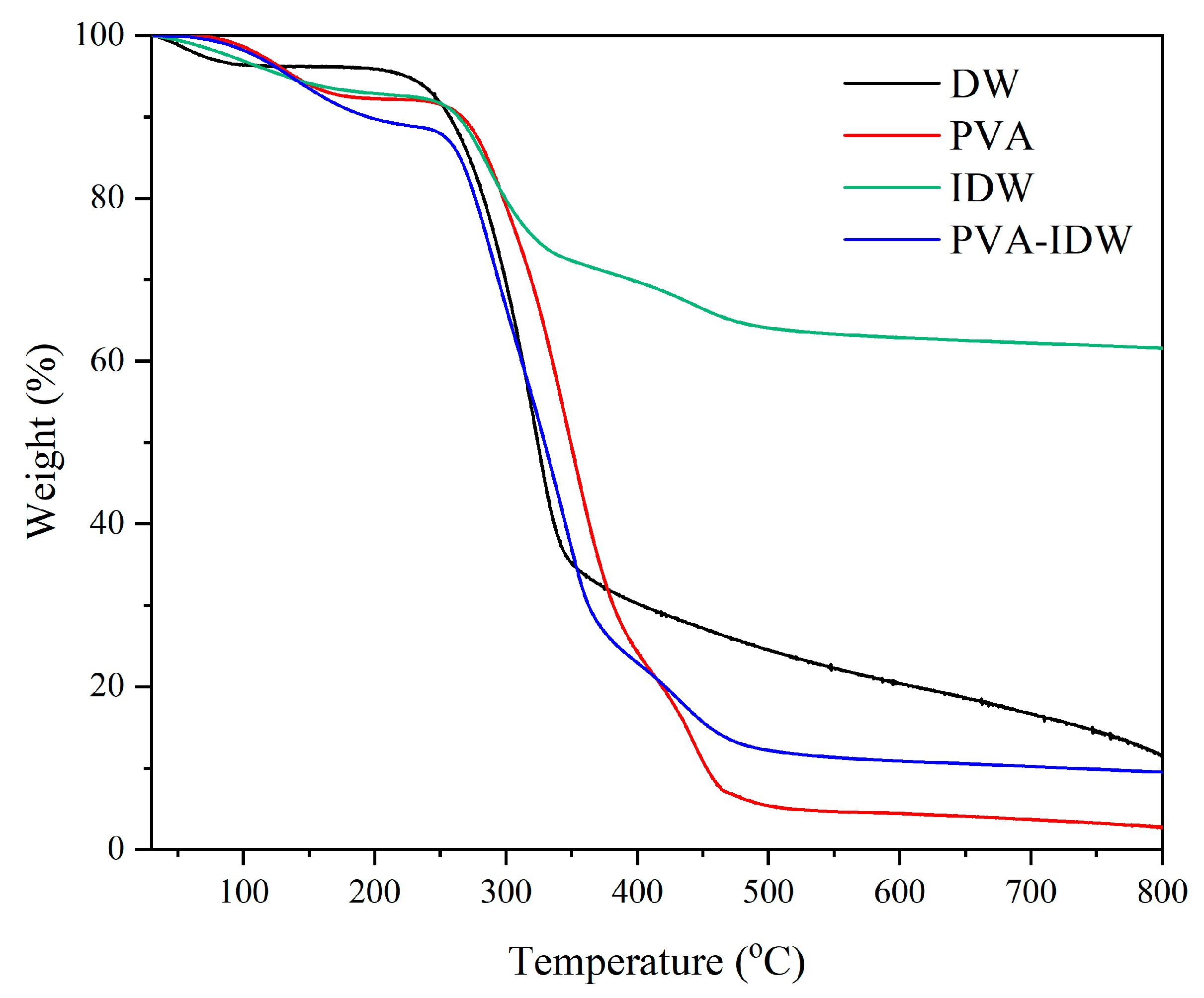

3.6. Thermogravimetric Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rudd, L.; Kulshreshtha, S.; Belcher, K.; Amichev, B. Carbon life cycle assessment of shelterbelts in Saskatchewan, Canada. J. Environ. Manag. 2021, 297, 113400. [Google Scholar] [CrossRef] [PubMed]

- Mora Rollo, A.; Rollo, A.; Mora, C. The tree-lined path to carbon neutrality. Nat. Rev. Earth Environ. 2020, 1, 332. [Google Scholar] [CrossRef]

- Nian, V. The carbon neutrality of electricity generation from woody biomass and coal, a critical comparative evaluation. Appl. Energy 2016, 179, 1069–1080. [Google Scholar] [CrossRef]

- Zhang, C.; Ge-Zhang, S.; Wang, Y.; Mu, H. A Wooden Carbon-Based Photocatalyst for Water Treatment. Int. J. Mol. Sci. 2024, 25, 4743. [Google Scholar] [CrossRef] [PubMed]

- Dong, L.; Bettinger, P.; Liu, Z. Estimating the optimal internal carbon prices for balancing forest wood production and carbon sequestration: The case of northeast China. J. Clean. Prod. 2021, 281, 125342. [Google Scholar] [CrossRef]

- Shakeel, U.; Li, X.; Wang, B.; Geng, F.; Zhang, Q.; Zhang, K.; Xu, X.; Xu, J. Structure and integrity of sequentially extracted lignin during poplar (alkaline) pretreatment. Process Biochem. 2022, 117, 198–208. [Google Scholar] [CrossRef]

- Yang, H.; Wang, H.; Cai, T.; Ge-Zhang, S.; Mu, H. Light and wood: A review of optically transparent wood for architectural applications. Ind. Crops Prod. 2023, 204, 117287. [Google Scholar] [CrossRef]

- Yang, L.; Liu, H. A review of Eucalyptus wood collapse and its control during drying. BioResources 2018, 13, 2171–2181. [Google Scholar] [CrossRef]

- Missio, A.L.; Mattos, B.D.; De Cademartori, P.H.; Gatto, D.A. Effects of two-step freezing-heat treatments on Japanese raisintree (Hovenia dulcis thunb.) wood properties. J. Wood Chem. Technol. 2016, 36, 16–26. [Google Scholar] [CrossRef]

- Liu, H.; Gao, J.; Chen, Y. Effects of pre-freezing prior to drying upon some physical and mechanical properties of Eucalyptus urophylla× Eucalyptus grandis wood. BioResources 2015, 10, 6417–6427. [Google Scholar] [CrossRef]

- Farid, T.; Rafiq, M.I.; Ali, A.; Tang, W. Transforming wood as next-generation structural and functional materials for a sustainable future. EcoMat 2022, 4, e12154. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, Y.; Yang, F.; Yang, L.; Wang, J.; Zhou, J.; Wang, J. A highly transparent compressed wood prepared by cell wall densification. Wood Sci. Technol. 2022, 56, 669–686. [Google Scholar] [CrossRef]

- Luo, H.; Si, R.; Liu, J.; Li, P.; Tao, Y.; Zhao, X.; Chen, H. Preparing the reinforced wood via embedding cellulose nanocrystals (CNC) into delignified fast-growing wood followed by densification. Cellulose 2022, 29, 7377–7396. [Google Scholar] [CrossRef]

- Wang, J.; Liu, J.; Li, J.; Zhu, J.Y. Characterization of microstructure, chemical, and physical properties of delignified and densified poplar wood. Materials 2021, 14, 5709. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Ge-Zhang, S.; Han, Y.; Yang, H.; Ou-Yang, W.; Zhu, H.; Hao, J.; Wang, J. Ultraviolet-assisted modified delignified wood with high transparency. Appl. Sci. 2022, 12, 7406. [Google Scholar] [CrossRef]

- Jakob, M.; Czabany, I.; Veigel, S.; Müller, U.; Gindl-Altmutter, W. Comparing the suitability of domestic spruce, beech, and poplar wood for high-strength densified wood. Eur. J. Wood Wood Prod. 2022, 80, 859–876. [Google Scholar] [CrossRef]

- Spear, M.J.; Curling, S.F.; Dimitriou, A.; Ormondroyd, G.A. Review of functional treatments for modified wood. Coatings 2021, 11, 327. [Google Scholar] [CrossRef]

- Wan, C.; Liu, X.; Huang, Q.; Cheng, W.; Su, J.; Wu, Y. A Brief Review of Transparent Wood: Synthetic Strategy, Functionalization and Applications. Curr. Org. Synth. 2021, 18, 615–623. [Google Scholar] [CrossRef] [PubMed]

- Kango, S.; Kalia, S.; Celli, A.; Njuguna, J.; Habibi, Y.; Kumar, R. Surface modification of inorganic nanoparticles for development of organic–inorganic nanocomposites—A review. Prog. Polym. Sci. 2013, 38, 1232–1261. [Google Scholar] [CrossRef]

- Yu, J.; Wang, A.C.; Zhang, M.; Lin, Z. Water treatment via non-membrane inorganic nanoparticles/cellulose composites. Mater. Today 2021, 50, 329–357. [Google Scholar] [CrossRef]

- Mulla, M.Z.; Rahman, M.R.T.; Marcos, B.; Tiwari, B.; Pathania, S. Poly lactic acid (Pla) nanocomposites: Effect of inorganic nanoparticles reinforcement on its performance and food packaging applications. Molecules 2021, 26, 1967. [Google Scholar] [CrossRef] [PubMed]

- Dong, X.; Zhuo, X.; Wei, J.; Zhang, G.; Li, Y. Wood-based nanocomposite derived by in situ formation of organic–inorganic hybrid polymer within wood via a sol–gel method. ACS Appl. Mater. Interfaces 2017, 9, 9070–9078. [Google Scholar] [CrossRef] [PubMed]

- Chang, H.; Tu, K.; Wang, X.; Liu, J. Facile preparation of stable superhydrophobic coatings on wood surfaces using silica-polymer nanocomposites. BioResources 2015, 10, 2585–2596. [Google Scholar] [CrossRef]

- De Hoyos-Martínez, P.L.; Issaoui, H.; Herrera, R.; Labidi, J.; Charrier-El Bouhtoury, F. Wood Fireproofing Coatings Based on Biobased Phenolic Resins. ACS Sustain. Chem. Eng. 2021, 9, 1729–1740. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, Q.; Zhou, X.; Hao, J.; Gault, B.; Zhang, Q.; Dong, C.; Nieh, T.G. A Novel Soft-Magnetic B2-Based Multiprincipal-Element Alloy with a Uniform Distribution of Coherent Body-Centered-Cubic Nanoprecipitates. Adv. Mater. 2021, 33, 2006723. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Dong, L.; Wu, J.; Shi, J.; Gao, Q.; Zhu, C.; Morikawa, H. Leaf-meridian bio-inspired nanofibrous electronics with uniform distributed microgrid and 3D multi-level structure for wearable applications. NPJ Flex. Electron. 2022, 6, 34. [Google Scholar] [CrossRef]

- Shi, Y.C.; Ma, B.G.; Guan, J.P.; Ye, B.; Yu, L.C.; Wu, Z.M.; Shen, X.J.; Habaue, S. Rational design of a functionalized silicone polymer for modifying epoxy-based composites. J. Mater. Res. Technol. 2022, 19, 3867–3876. [Google Scholar] [CrossRef]

- GB/T 1935-2009; Method of Testing in Compressivestrength Parallel to Grain of Wood. National Standards of People’s Republic of China: Beijing, China, 2009.

- GB/T 1934.1-2009; Method for Determination of the Water Absorption of Wood. National Standards of People’s Republic of China: Beijing, China, 2009.

- Al Arni, S. Extraction and isolation methods for lignin separation from sugarcane bagasse: A review. Ind. Crops Prod. 2018, 115, 330–339. [Google Scholar] [CrossRef]

- Pejic, B.; Vukcevic, M.; Kostic, M.; Skundric, P. Biosorption of heavy metal ions from aqueous solutions by short hemp fibers: Effect of chemical composition. J. Hazard. Mater. 2009, 164, 146–153. [Google Scholar] [CrossRef]

- Alqrinawi, H.; Ahmed, B.; Wu, Q.; Hai, L. Effect of partial delignification and densification on chemical, morphological, and mechanical properties of wood: Structural property evolution. Ind. Crops Prod. 2024, 213, 118430. [Google Scholar] [CrossRef]

- Yang, H.; Wang, D.; Han, Y.; Tian, P.; Gao, C.; Yang, X.; Mu, H.; Zhang, M. Preparation and properties of modified poplar impregnated with PVA-nano silica sol composite dispersion system. J. Wood Chem. Technol. 2022, 42, 211–221. [Google Scholar] [CrossRef]

- Ge-Zhang, S.; Yang, H.; Mu, H. Interfacial solar steam generator by MWCNTs/carbon black nanoparticles coated wood. Alex. Eng. J. 2023, 63, 1–10. [Google Scholar] [CrossRef]

- Wu, S.S.; Tao, X.; Xu, W. Thermal conductivity of Poplar wood veneer impregnated with graphene/polyvinyl alcohol. Forests 2021, 12, 777. [Google Scholar] [CrossRef]

- Vitas, S.; Segmehl, J.S.; Burgert, I.; Etienne, C. Porosity and pore size distribution of native and delignified beech wood determined by mercury intrusion porosimetry. Materials 2019, 12, 416. [Google Scholar] [CrossRef]

- Liang, R.; Zhu, Y.H.; Wen, L.; Zhao, W.W.; Kuai, B.B.; Zhang, Y.L.; Cai, L.P. Exploration of effect of delignification on the mesopore structure in poplar cell wall by nitrogen absorption method. Cellulose 2020, 27, 1921–1932. [Google Scholar] [CrossRef]

- Ilic, J. Advantages of prefreezing for reducing shrinkage-related degrade in eucalypts: General considerations and review of the literature. Wood Sci. Technol. 1995, 29, 277–285. [Google Scholar] [CrossRef]

- Rooni, V.; Raud, M.; Kikas, T. The freezing pre-treatment of lignocellulosic material: A cheap alternative for Nordic countries. Energy 2017, 139, 1–7. [Google Scholar] [CrossRef]

- Ji, Y.; Zhang, H.; Zhang, C.; Quan, Z.; Huang, M.; Wang, L. Fluorescent and mechanical properties of silicon quantum dots modified sodium alginate-carboxymethylcellulose sodium nanocomposite bio-polymer films. Polymers 2019, 11, 1476. [Google Scholar] [CrossRef] [PubMed]

- Lv, Q.; Wang, W.; Liu, Y. Study on thermal insulation performance of cross-laminated bamboo wall. J. Renew. Mater. 2019, 7, 1231–1250. [Google Scholar] [CrossRef]

- Yuan, T.; Zhang, T.; Huang, Y.; Wu, Y.; Wang, X.; Li, Y. Study on bamboo longitudinal flattening technology. Polymers 2022, 14, 816. [Google Scholar] [CrossRef]

- Ding, L.; Han, X.; Jiang, S. Impregnation of poplar wood with multi-functional composite modifier and induction of in-situ polymerization by heating. J. Wood Chem. Technol. 2021, 41, 220–228. [Google Scholar] [CrossRef]

- Xu, E.; Wang, D.; Lin, L. Chemical structure and mechanical properties of wood cell walls treated with acid and alkali solution. Forests 2020, 11, 87. [Google Scholar] [CrossRef]

- Jiang, F.; Li, T.; Li, Y.; Zhang, Y.; Gong, A.; Dai, J.; Hitz, E.; Luo, W.; Hu, L. Wood-based nanotechnologies toward sustainability. Adv. Mater. 2018, 30, 1703453. [Google Scholar] [CrossRef]

- Yona, A.M.C.; Žigon, J.; Matjaž, P.; Petrič, M. Potentials of silicate-based formulations for wood protection and improvement of mechanical properties: A review. Wood Sci. Technol. 2021, 55, 887–918. [Google Scholar] [CrossRef]

- Cai, Y.; Wu, Y.; Yang, F.; Gan, J.; Wang, Y.; Zhang, J. Wood sponge reinforced with polyvinyl alcohol for sustainable oil–water separation. ACS Omega 2021, 6, 12866–12876. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Guan, P.; Ma, X.; Ping, L.; Zhenyu, S.; Xianjun, L.; Yingfeng, Z. Study on the Effect of Acrylic Acid Emulsion on the Properties of Poplar Wood Modified by Sodium Silicate Impregnation. Forests 2023, 14, 1221. [Google Scholar] [CrossRef]

- Lu, Y.; Feng, M.; Zhan, H. Preparation of SiO2–wood composites by an ultrasonic-assisted sol–gel technique. Cellulose 2014, 21, 4393–4403. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, W.; Liu, W.; Xueqing, Q. High performance PVA/lignin nanocomposite films with excellent water vapor barrier and UV-shielding properties. Int. J. Biol. Macromol. 2020, 142, 551–558. [Google Scholar] [CrossRef]

- Jiang, J.; Zhou, Y.; Mei, C.; Cao, J. Polyethylene glycol and silica sol penetration improves hydrophobicity and dimensional stability of wood after a short-time treatment. Eur. J. Wood Wood Prod. 2021, 79, 1395–1404. [Google Scholar] [CrossRef]

- Wang, Y.; Ge-Zhang, S.; Mu, P.; Wang, X.; Li, S.; Qiao, L.; Mu, H. Advances in Sol-Gel-Based Superhydrophobic Coatings for Wood: A Review. Int. J. Mol. Sci. 2023, 24, 9675. [Google Scholar] [CrossRef]

- Ge-Zhang, S.; Cai, T.; Yang, H.; Ding, Y.; Song, M. Biology and nature: Bionic superhydrophobic surface and principle. Front. Bioeng. Biotechnol. 2022, 10, 1033514. [Google Scholar] [CrossRef] [PubMed]

- Ge-Zhang, S.; Yang, H.; Ni, H.; Mu, H.; Zhang, M. Biomimetic superhydrophobic metal/nonmetal surface manufactured by etching methods: A mini review. Front. Bioeng. Biotechnol. 2022, 10, 958095. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Koubaa, A.; Tao, Y.; Peng, L. The emerging development of transparent wood: Materials, characteristics, and applications. Curr. For. Rep. 2022, 8, 333–345. [Google Scholar] [CrossRef]

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Bana, R.; Banthia, A.K. Mechanical and thermal analysis of poly (Vinyl-Alcohol) and modified wood dust composites. J. Wood Chem. Technol. 2011, 31, 218–232. [Google Scholar] [CrossRef]

- Gankhuyag, S.; Bae, D.S.; Lee, K. One-pot synthesis of SiO2@ Ag mesoporous nanoparticle coating for inhibition of Escherichia coli bacteria on various surfaces. Nanomaterials 2021, 11, 549. [Google Scholar] [CrossRef]

- Cai, T.; Ge-Zhang, S.; Song, M. Anthocyanins in metabolites of purple corn. Front. Plant Sci. 2023, 14, 1154535. [Google Scholar] [CrossRef]

| NW | IDW | ||

|---|---|---|---|

| Water absorption (%) | 1 day | 96 | 68 |

| 3 day | 121 | 83 | |

| 7 day | 142 | 94 | |

| 10 day | 148 | 99 | |

| 12 day | 152 | 101 | |

| 14 day | 155 | 103 | |

| Full Dry Shrinkage (%) | Radial | 5.7 | 6.2 |

| Tangential | 7.1 | 6.9 | |

| Volume | 12.8 | 12.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cong, R.; Cai, T.; Ge-Zhang, S.; Yang, H.; Zhang, C. Fabrication of PVA–Silica Sol Wood Composites via Delignification and Freezing Pretreatment. Polymers 2024, 16, 1949. https://doi.org/10.3390/polym16131949

Cong R, Cai T, Ge-Zhang S, Yang H, Zhang C. Fabrication of PVA–Silica Sol Wood Composites via Delignification and Freezing Pretreatment. Polymers. 2024; 16(13):1949. https://doi.org/10.3390/polym16131949

Chicago/Turabian StyleCong, Rizheng, Taoyang Cai, Shangjie Ge-Zhang, Hong Yang, and Chang Zhang. 2024. "Fabrication of PVA–Silica Sol Wood Composites via Delignification and Freezing Pretreatment" Polymers 16, no. 13: 1949. https://doi.org/10.3390/polym16131949