Highly Soft, Abrasion-Resistant, and Moisture-Absorbent Wool/PA56 Blended Yarns for Seating Fabrics

Abstract

:1. Introduction

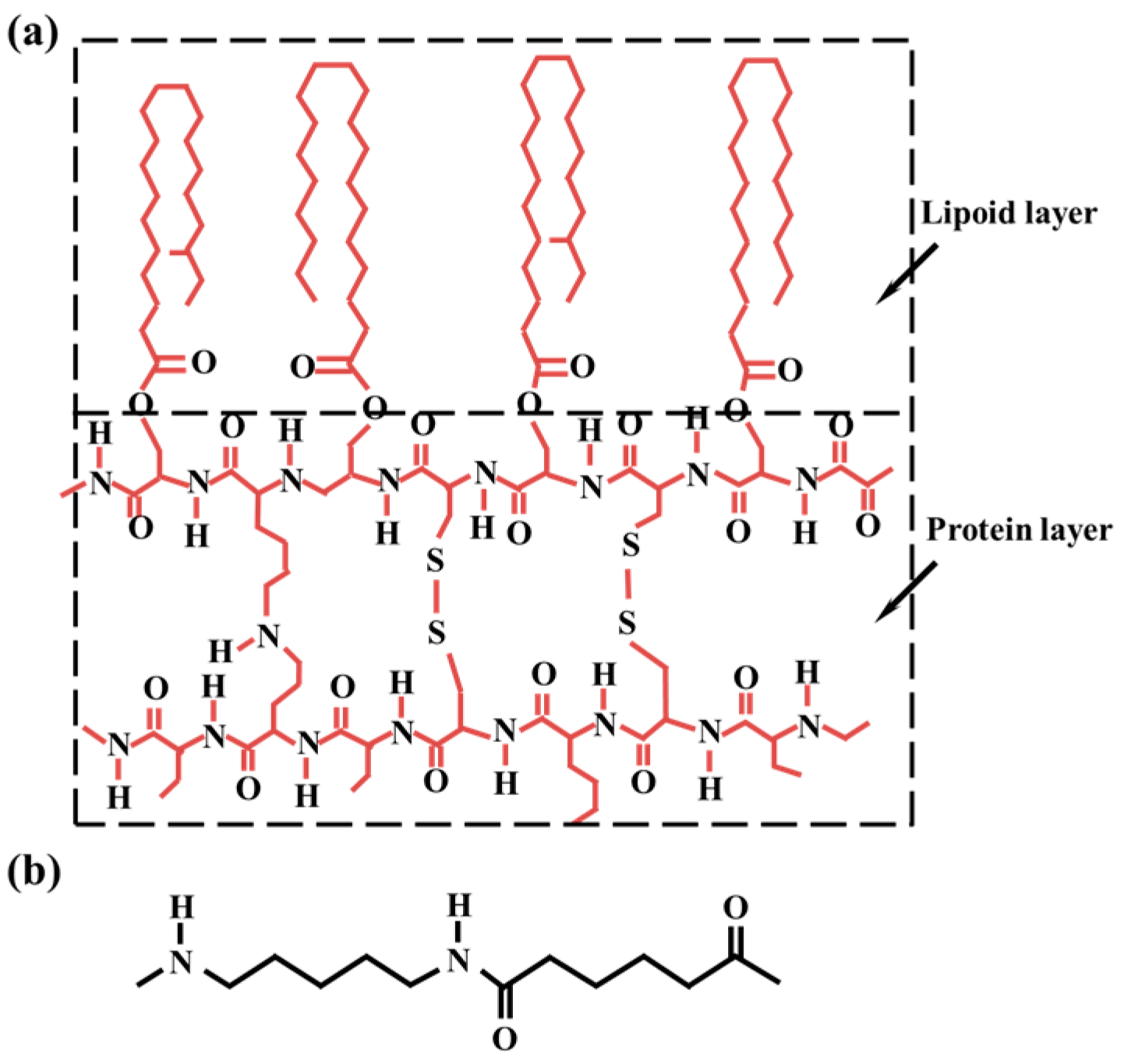

2. Materials and Methods

2.1. Materials

2.2. Preparation of Blended Yarns

2.3. Measure Methods and Equipment

3. Results and Discussion

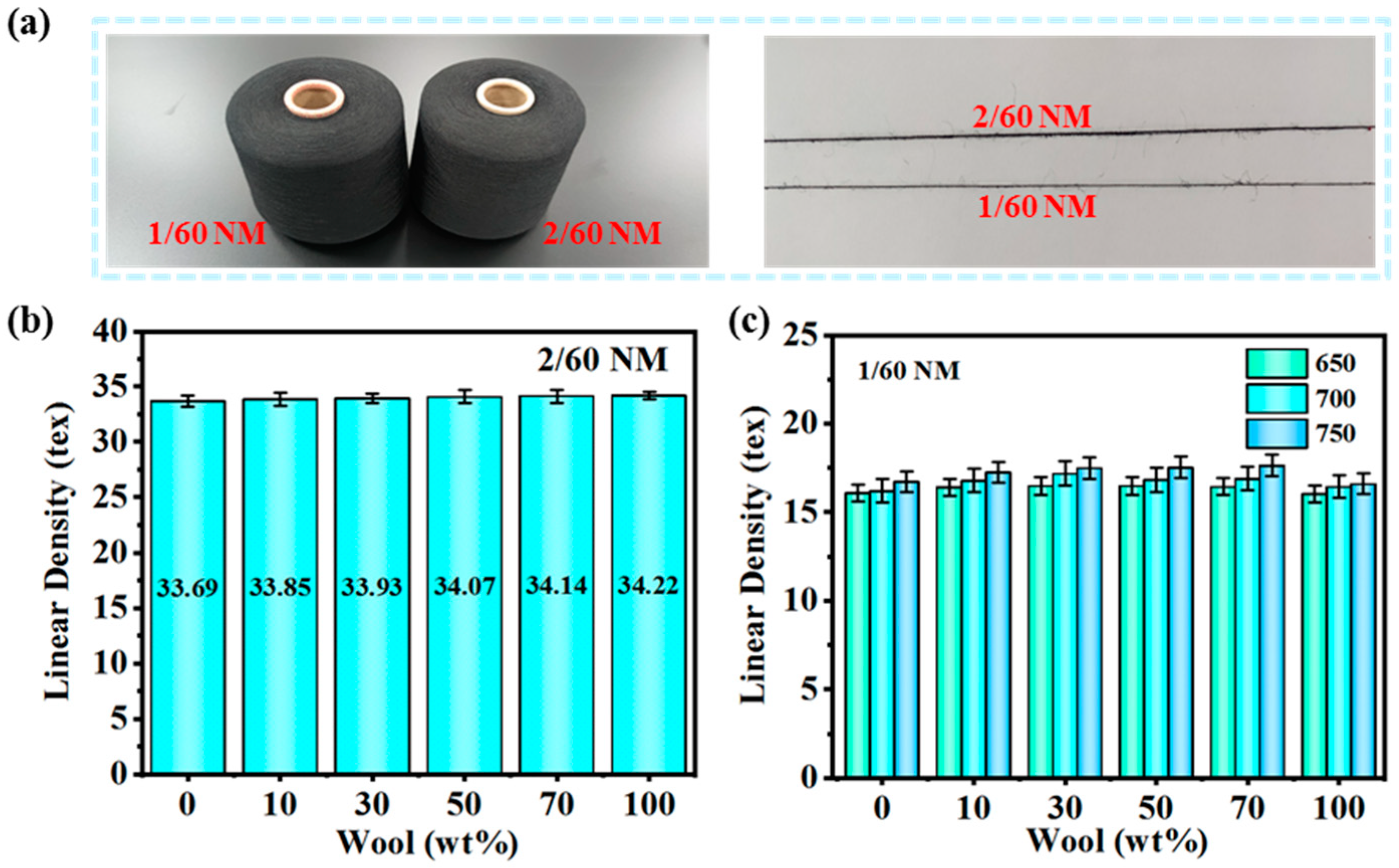

3.1. Linear Density Analysis of Yarns

3.2. Wicking Height Analysis of Yarns

3.3. Boiling Water Shrinkage Analysis of Yarns

3.4. Microscopic Morphology Analysis of Yarns

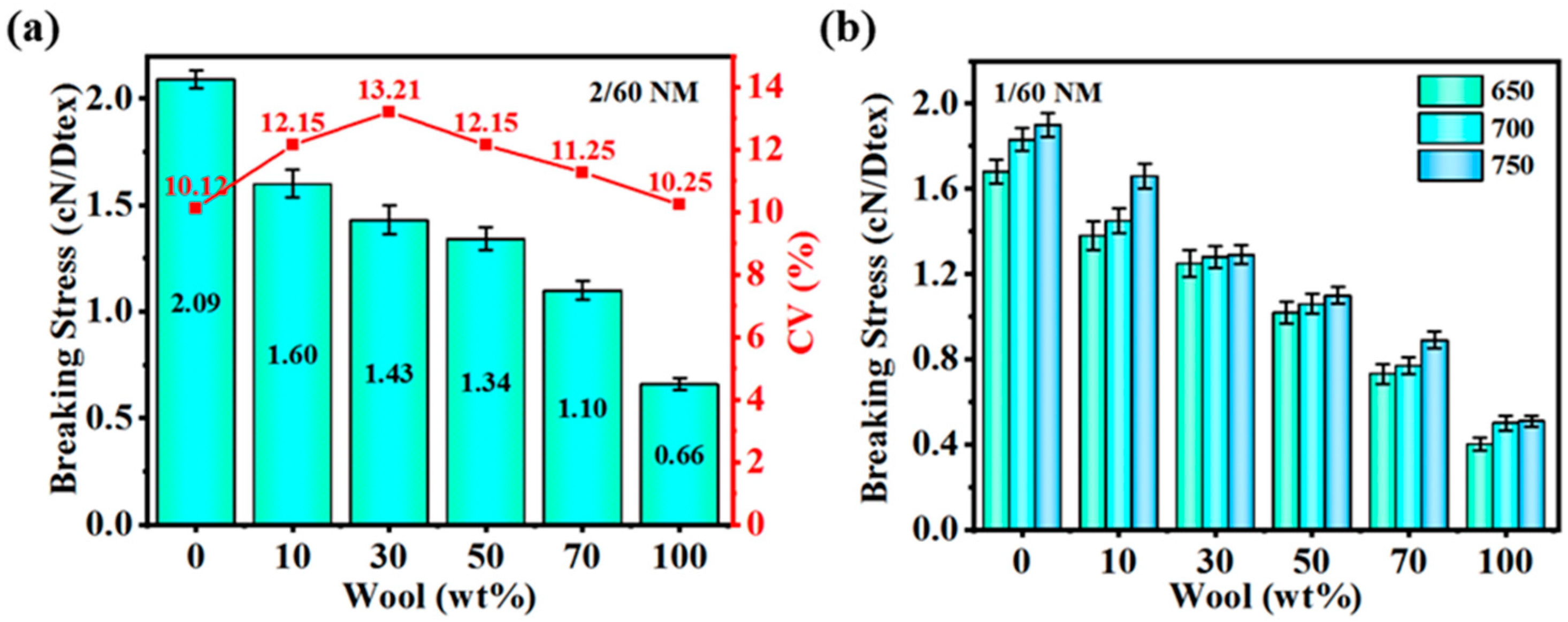

3.5. Strength Analysis of Yarns

3.6. Analysis of Yarn Elongation at Break

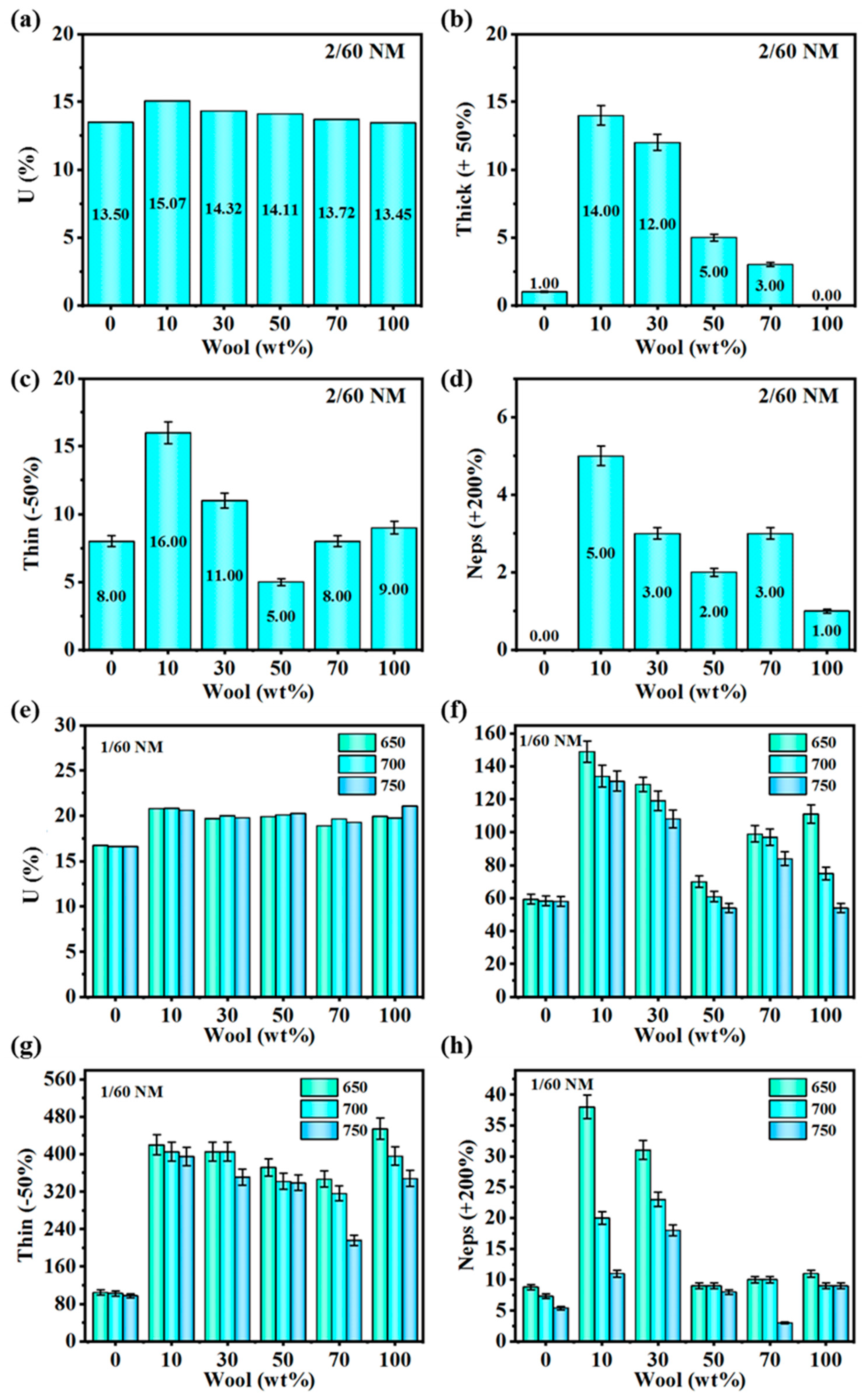

3.7. Stem Analysis of Yarns

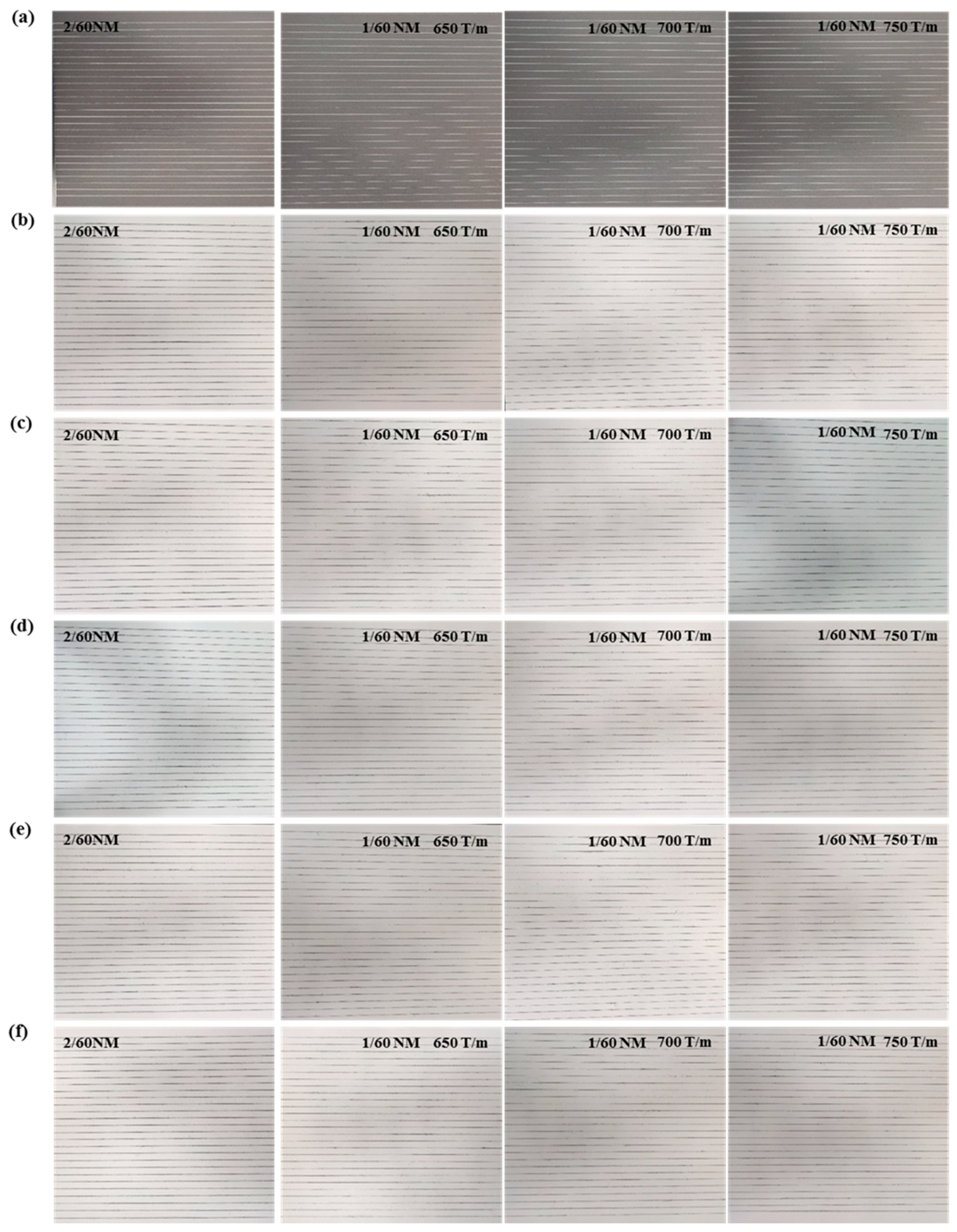

3.8. Hairiness Analysis of Yarns

3.9. Friction Performance Analysis of Yarn

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Gao, Y.B.; Yang, T.T.; Xia, Y.M.; He, Y. Synthesis and characterization of alternating copolyoxamide with high heat resistance and excellent crystallization property. Polymer 2021, 237, 124385. [Google Scholar] [CrossRef]

- Mi, J.; Zhou, Y.; Ma, S.; Zhou, X.; Xu, S.; Yang, Y.; Sun, Y.; Xia, Q.; Zhu, H.; Wang, S.; et al. High-strength and ultra-tough whole spider silk fibers spun from transgenic silkworms. Matter 2023, 6, 3661–3683. [Google Scholar] [CrossRef]

- Li, Y.L.; Hao, X.M.; Guo, Y.F.; Chen, X.; Yang, Y.; Wang, J.M. Study on the Acid Resistant Properties of Bio-Based Nylon 56 Fiber Compared with the Fiber of Nylon 6 and Nylon 66. Adv. Mater. Res. 2014, 1048, 57–61. [Google Scholar] [CrossRef]

- Zhao, Z.-Y.; Chang, R.-D.; Zillante, G. Challenges for China’s energy conservation and emission reduction. Energy Policy 2014, 74, 709–713. [Google Scholar] [CrossRef]

- Wang, Y.; Kang, H.-L.; Wang, R.; Liu, R.-G.; Hao, X.-M. Crystallization of polyamide 56/polyamide 66 blends: Non-isothermal crystallization kinetics. J. Appl. Polym. Sci. 2018, 135, 46409. [Google Scholar] [CrossRef]

- Siddiqui, M.N.; Redhwi, H.H.; Achilias, D.S. Simulation of the thermal degradation kinetics of biobased/biodegradable and non-biodegradable polymers using the random chain-scission model. Capabilities and limitations. J. Anal. Appl. Pyrolysis 2022, 168, 105767. [Google Scholar] [CrossRef]

- Yang, H.; Liu, W. Bio-based Polyamide 56: Recent advances in basic and applied research. Polym. Eng. Sci. 2023, 63, 2484–2497. [Google Scholar] [CrossRef]

- Li, R.; Yang, G.-X.; Qin, Y.-N.; Liu, L.; Jiang, Z.-Y. Molecular Mobility in the Amorphous Phase Determines the Critical Strain of Fibrillation in the Tensile Stretching of Polyethylene. Chin. J. Polym. Sci. 2020, 38, 740–747. [Google Scholar] [CrossRef]

- Wang, Y.; Kang, H.-L.; Guo, Y.-F.; Liu, R.-G.; Hao, X.-M.; Qiao, R.-R.; Yan, J.-L. The structures and properties of bio-based polyamide 56 fibers prepared by high-speed spinning. J. Appl. Polym. Sci. 2020, 137, 49344. [Google Scholar] [CrossRef]

- Eltahir, Y.A.; Saeed, H.A.M.; Xia, Y.; Yong, H.; Wang, Y. Mechanical properties, moisture absorption, and dyeability of polyamide 5,6 fibers. J. Text. Inst. 2016, 107, 208–214. [Google Scholar] [CrossRef]

- Eltahir, Y.A.; Saeed, H.A.M.; Chen, Y.; Xia, Y.; Wang, Y. Parameters characterizing the kinetics of the non-isothermal crystallization of polyamide 5,6 determined by differential scanning calorimetry. J. Polym. Eng. 2014, 34, 353–358. [Google Scholar] [CrossRef]

- Liu, B.; Hu, G.; Zhang, J.; Yan, W. Non-isothermal crystallization, yellowing resistance and mechanical properties of heat-resistant nylon 10T/66/titania dioxide/glass fibre composites. Rsc Adv. 2019, 9, 7057–7064. [Google Scholar] [CrossRef]

- Zhang, G.; Yan, G.-M.; Yu, T.; Lu, J.-H.; Huang, X.; Wang, X.-J.; Yang, J. Semiaromatic Polyamides Containing Carboxyl Unit: Synthesis and Properties. Ind. Eng. Chem. Res. 2017, 56, 9275–9284. [Google Scholar] [CrossRef]

- Wang, L.; Jiang, H.; Du, Y.; Zhao, Y.; Guan, Y.; Liu, X. Washable Antibacterial Modified Bio-based PA56 with High Toughness. ACS Appl. Polym. Mater. 2023, 5, 4986–4992. [Google Scholar] [CrossRef]

- Chong, Y.; Wang, L.; Xu, X.; Zhuang, X.; Zheng, R.; Cao, D.; Chen, Y. Preparation and Property Study of PA56/POE-g-MAH-GMA/PPO Ternary Alloy. Adv. Polym. Technol. 2023, 2023, 1–8. [Google Scholar] [CrossRef]

- Jin, W.-J.; Dong, S.; Guan, J.-P.; Cheng, X.-W.; Qin, C.-X.; Chen, G.-Q. Multifunctional and sustainable DOPO-derivative coating for flame-retardant, antibacterial and UV-protective of polyamide 56 protective biomaterials. Surf. Interfaces 2023, 42, 103513. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhang, N.; Wang, Q.; Wang, P.; Yu, Y.; Yuan, J. A controlled, highly effective and sustainable approach to the surface performance improvement of wool fibers. J. Mol. Liq. 2021, 322, 114952. [Google Scholar] [CrossRef]

- Singh, M.K.; Shakyawar, D.B.; Bajpai, P.; Gangwar, A.K.S. Pashmina Fiber Blended Woven Fabrics for High Functional Performances. J. Nat. Fibers 2023, 20, 2139324. [Google Scholar] [CrossRef]

- Ahumada, O.; Cocca, M.; Gentile, G.; Martuscelli, E.; D’Orazio, L. Uniaxial tensile properties of yarns: Effects of moisture level on the shape of stress-strain curves. Text. Res. J. 2004, 74, 1001–1006. [Google Scholar] [CrossRef]

- Cao, Q.; Zhou, Y.; Yu, C. Application of image processing technology on testing blending ratio and blending irregularity of blended yarns. Text. Res. J. 2023, 93, 3945–3955. [Google Scholar] [CrossRef]

- Ghosh, S.; Nitin, B.; Remanan, S.; Bhattacharjee, Y.; Ghorai, A.; Dey, T.; Das, T.K.; Das, N.C. A Multifunctional Smart Textile Derived from Merino Wool/Nylon Polymer Nanocomposites as Next Generation Microwave Absorber and Soft Touch Sensor. ACS Appl. Mater. Interfaces 2020, 12, 17988–18001. [Google Scholar] [CrossRef] [PubMed]

- Önder, E.; Kalaoglu, F.; Özipek, B. Influence of varying structural parameters on the properties of 50/50 wool/polyester blended fabrics. Text. Res. J. 2003, 73, 854–860. [Google Scholar] [CrossRef]

- Celik, A.; Yilmaz, K.; Canpolat, O.; Al-mashhadani, M.M.; Aygörmez, Y.; Uysal, M. High-temperature behavior and mechanical characteristics of boron waste additive metakaolin based geopolymer composites reinforced with synthetic fibers. Constr. Build. Mater. 2018, 187, 1190–1203. [Google Scholar] [CrossRef]

- Mihalyi, S.; Tagliavento, M.; Boschmeier, E.; Archodoulaki, V.-M.; Bartl, A.; Quartinello, F.; Guebitz, G.M. Simultaneous saccharification and fermentation with Weizmannia coagulans for recovery of synthetic fibers and production of lactic acid from blended textile waste. Resour. Conserv. Recycl. 2023, 196, 107060. [Google Scholar] [CrossRef]

- Liu, D. Value evaluation system of ecological environment damage compensation caused by air pollution. Environ. Technol. Innov. 2021, 22, 101473. [Google Scholar] [CrossRef]

- GB/T 4743-2009; Textiles-Yarn from Packages-Determination of Lineardensity (Mass per unit Length) by the Skein Method. Standards Press of China: Beijing, China, 2009.

- AATCC TM197-2011; Test MVethod for Vertical Wicking of Textiles. American Association of Textile Chemists and Colorists: Piedmont, NC, USA, 2019.

- GB/T 6505-2001; Test Method for Thermal Shrinkage of Synthetic Filament Yarns. Standards Press of China: Beijing, China, 2001.

- GB/T3916-2013; Textiles-Yarns from Packages-Determination of Single-End Breaking Force and Elongation at Break Using Constant Rate of Extension (CRE) Tester. Standards Press of China: Beijing, China, 2013.

- GB/T 3292.2-2009; Textiles-Unevenness of Textile strands Part 2: Photoelectricity Method. Standards Press of China: Beijing, China, 2009.

- FZ/T10186-2000; Textiles-Test Method for Yarn Hairness-Projection Counting Method. State Textile Industry Bureau of China: Beijing, China, 2000.

- Gavcar, B.; Sumer, E.H.; Sagbas, B.; Katiyar, J.K. Effect of build orientation on the green tribological properties of multi-jet fusion manufactured PA12 parts. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2023, 237, 2213–2223. [Google Scholar] [CrossRef]

| Public Branch (NM) | Twist (T/m) | Wool | |||||

|---|---|---|---|---|---|---|---|

| 0 wt% (%) | 10 wt% (%) | 30 wt% (%) | 50 wt% (%) | 70 wt% (%) | 100 wt% (%) | ||

| 2/60 | 700 | 4.8 | 0 | 0 | 0 | 0 | 0 |

| 650 | 4.0 | 0 | 0 | 0 | 0 | 0 | |

| 1/60 | 700 | 5.2 | 0 | 0 | 0 | 0 | 0 |

| 750 | 2.0 | 0 | 0 | 0 | 0 | 0 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, S.; Wang, Z.; Wang, X.; Jiang, J. Highly Soft, Abrasion-Resistant, and Moisture-Absorbent Wool/PA56 Blended Yarns for Seating Fabrics. Polymers 2024, 16, 2052. https://doi.org/10.3390/polym16142052

Wu S, Wang Z, Wang X, Jiang J. Highly Soft, Abrasion-Resistant, and Moisture-Absorbent Wool/PA56 Blended Yarns for Seating Fabrics. Polymers. 2024; 16(14):2052. https://doi.org/10.3390/polym16142052

Chicago/Turabian StyleWu, Shuangquan, Zebo Wang, Xinhou Wang, and Jinhua Jiang. 2024. "Highly Soft, Abrasion-Resistant, and Moisture-Absorbent Wool/PA56 Blended Yarns for Seating Fabrics" Polymers 16, no. 14: 2052. https://doi.org/10.3390/polym16142052