Study of Plugging Compositions Based on Synthetic Resins for Repair and Insulation Work in Wells

Abstract

:1. Introduction

- Hardening compositions;

- Gel-forming compositions;

- Foam and emulsion compositions;

- Sediment-forming materials;

- Combined materials.

1.1. Grouting Compositions Based on Synthetic Resins

1.2. Advantages of Using Synthetic Resins over Cement Compositions

- Isolation of water inflow;

- Eliminating leaks in the production casing;

- Fastening the bottomhole zone of sand-producing wells;

- Elimination of inter-casing pressure;

- Additional strengthening of cement.

2. Materials and Methods

2.1. Materials

- -

- Resol phenol-formaldehyde resin—50.0–80.0% vol.;

- -

- Polyatomic alcohols—50.0–20.0% vol.;

- -

- Lignin sulfo derivative—5.0–25.0 wt% (over).

- -

- Mixture of mineral acids (concentration 10.0–30.0 wt%)—95.0 wt%;

- -

- Corrosion inhibitor—5.0 wt%.

2.2. Experimental Methods

2.2.1. Preparation of Grouting Solution

2.2.2. Determination of the Loss of Fluidity Time of Plugging Composition

2.2.3. Determination of the Degree of Hardening of the Plugging Composition

2.2.4. Determination of the Elastic-Strength Characteristics of the Plugging Composition

2.2.5. Determination of the Freezing Point of the Components of the Composition

3. Results and Discussion

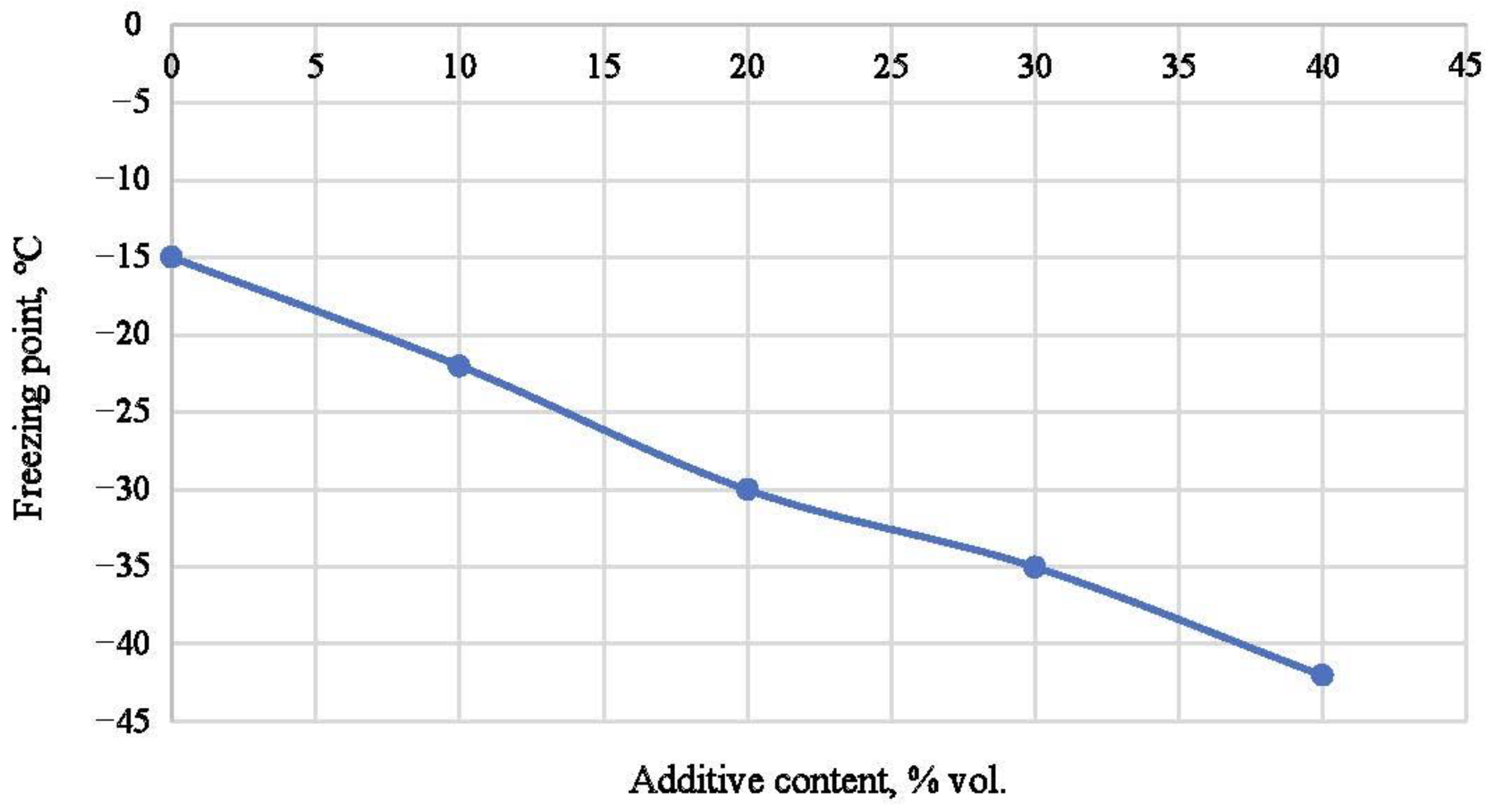

3.1. Selection of an Additive to Reduce the Freezing Point of the Phenol-Formaldehyde Resin

3.2. Selection of an Additive to Reduce Water Separation

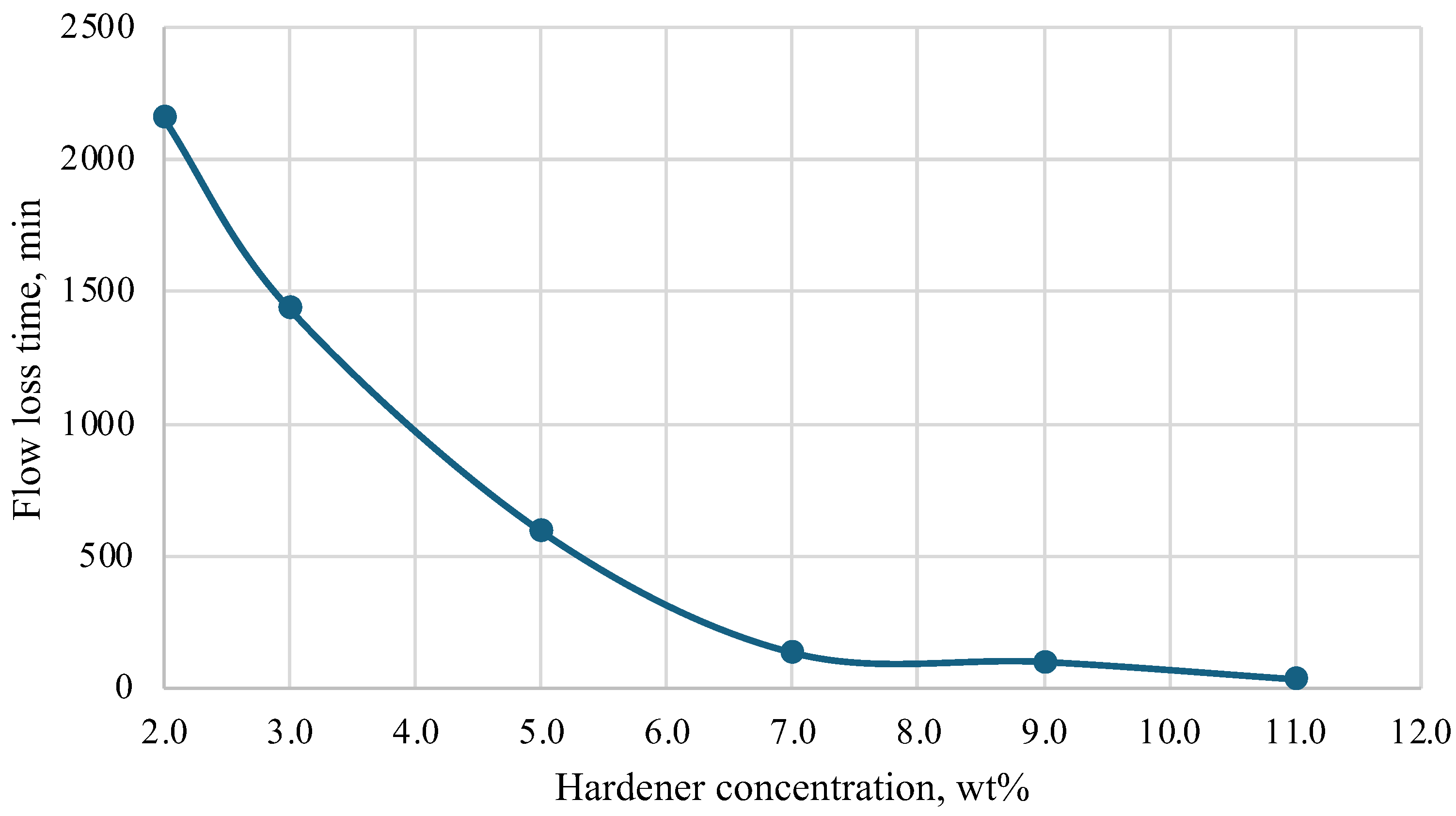

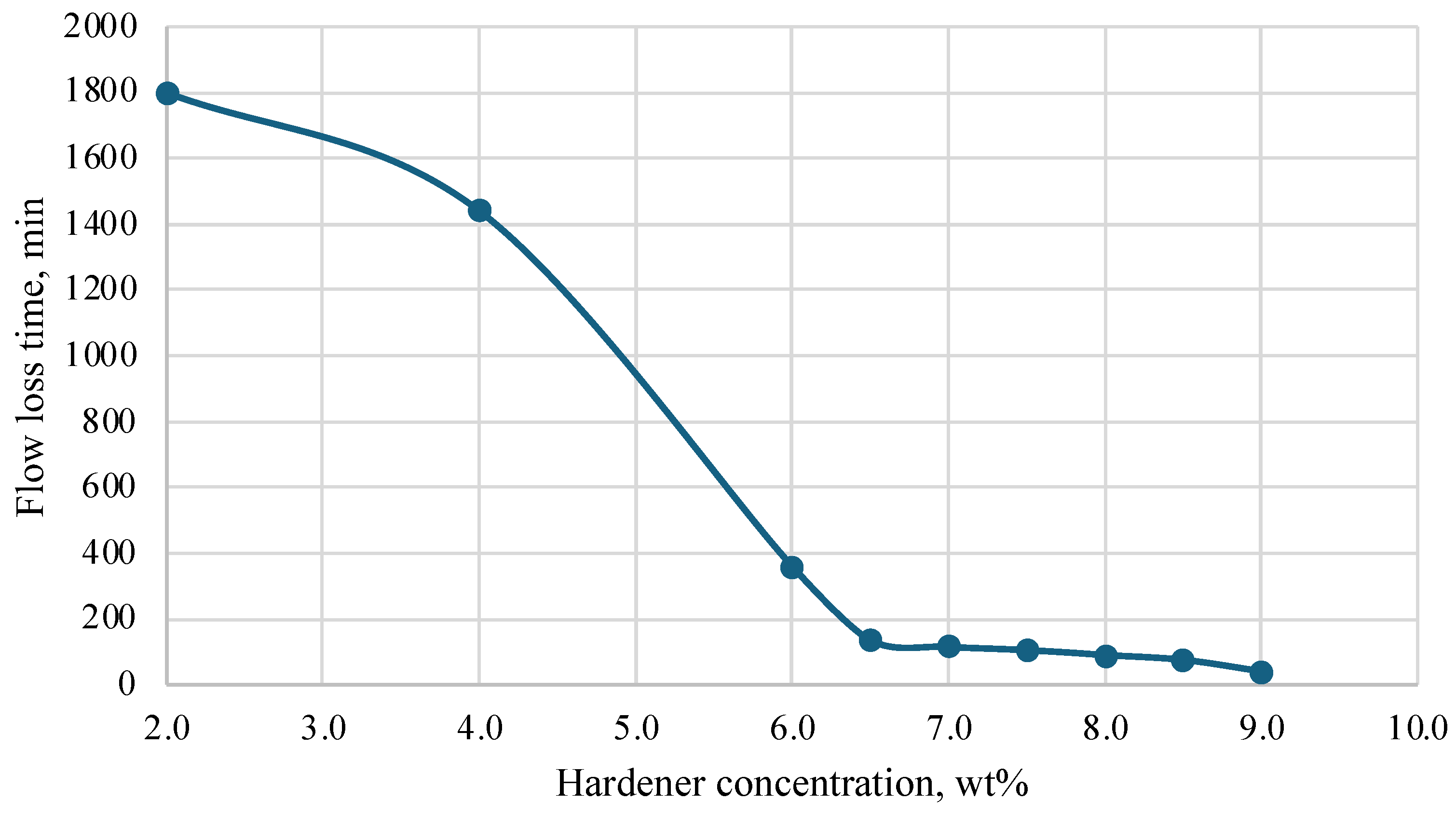

3.3. Selection of Hardener Concentration

3.4. Evaluation of the Elastic-Strength Properties of the Developed Composition

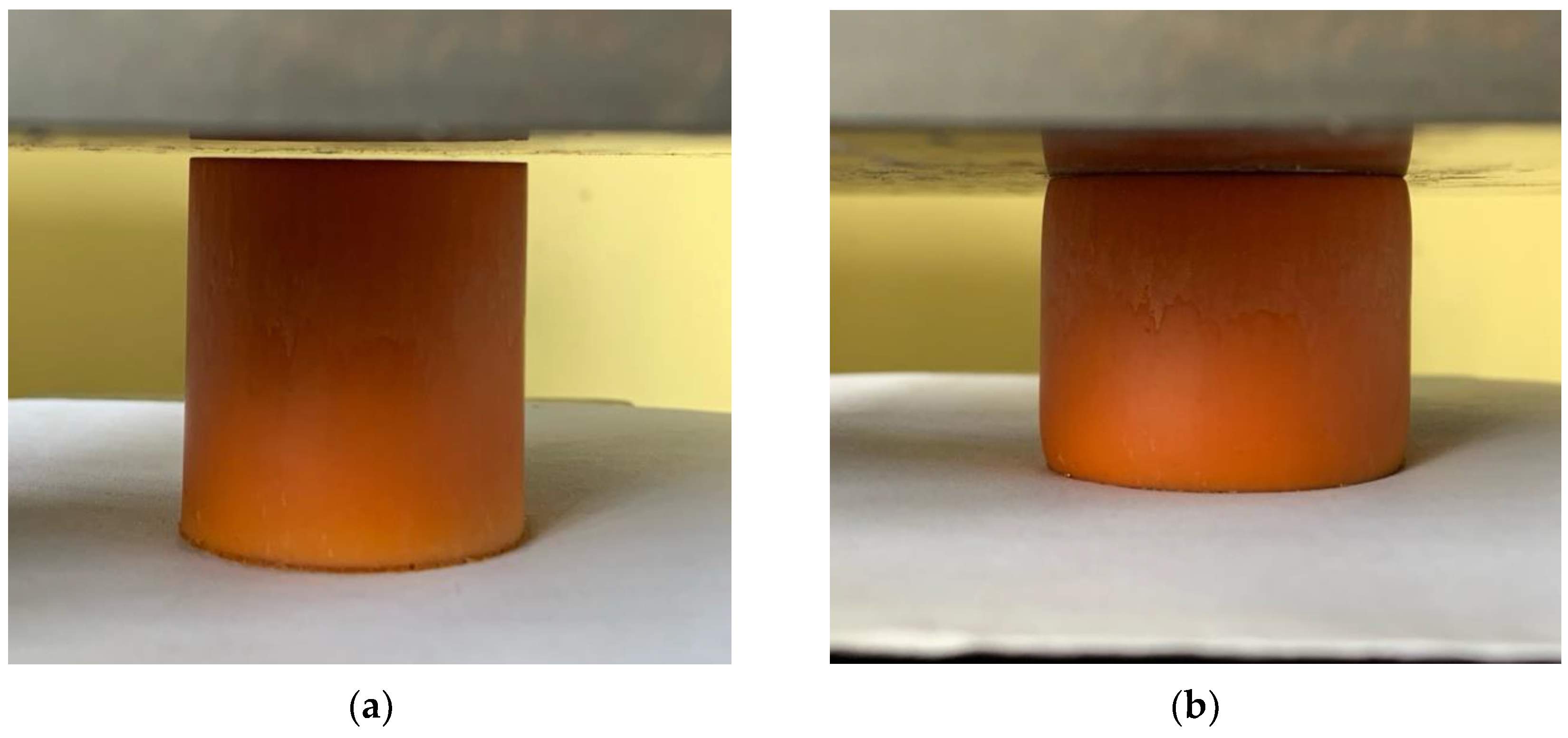

3.4.1. Determination of Poisson’s Ratio

3.4.2. Determination of Young’s Modulus (Modulus of Elasticity)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations and Symbols

| RIW | Repair and insulation work |

| PFR | Phenol-formaldehyde resin |

| LMC | Low-molecular compound |

| HMC | High-molecular compound |

| h0 | Initial longitudinal size |

| d0 | Initial transverse size |

| h1 | Final longitudinal size |

| d1 | Final transverse size |

| Δh | Absolute longitudinal strains |

| Δd | Absolute transverse strains |

| εl | Relative longitudinal deformations |

| εt | Relative transverse deformations |

| Poisson’s ratio | |

| E | Young’s modulus, MPa |

| R | Ultimate compressive strength, MPa |

References

- Demakhin, S.A. Himicheskie Metody Ogranicheniya Vodopritoka v Neftyanye Skvazhiny; Nedra: Moscow, Russia, 2011; ISBN 978-5-8365-0376-5. [Google Scholar]

- Magadova, L.A.; Efimov, N.N.; Kozlov, A.N.; Shidginov, Z.A.; Efimov, M.N. K Voprosu Povysheniya Kachestva Remontno-Izolyacionnyh Rabot v Nizkopronicaemyh Kollektorah Neftyanyh i Gazovyh Skvazhin. Territoriya Neftegaz: Moscow, Russia, 2012; pp. 80–87. [Google Scholar]

- GOST 34532-2019; Cementy Tamponazhnye. Metody Ispytanij. Standartinform: Moscow, Russia, 2019.

- Nguyen, H.; Zatar, W.; Mutsuyoshi, H. Mechanical Properties of Hybrid Polymer Composite. In Hybrid Polymer Composite Materials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 83–113. [Google Scholar]

- Goraev, I.M.; Ibragimov, A.A. Phenol-Formaldehyde Resins; Vestnik Magistratury: Yoshkar-Ola, Russia, 2019; pp. 11–17. [Google Scholar]

- Vitkalova, I.A.; Torlova, A.S.; Pikalov, E.S. Technology of preparation and properties of phenol-formaldehyde resins and compositions based on them. Sci. Rev. Tech. Sci. 2017, 2, 15–28. [Google Scholar]

- Vorob’ev, S.V.; Gorbunov, P.A.; Maksimenko, O.V.; Khabibullin, D.Y. Thermal Conditions of Oil and Gas Deposits in the Northern Part of the West Siberian Plate. Oil Gas Geol. Geol. Neft. Gaza 2018, 5, 29–35. [Google Scholar] [CrossRef]

- Akutin, M.S.; Brodskij, G.S.; Raevskaya, V.I.; Sokolov, A.D.; Stal’nova, M.A.; Timofeev, A.V.; Fajdel’, I.Y.A.; Sharshkova, E.S.; Yakobson, B.V. Sposob Otverzhdeniya Novolachnyh Fenolformal’degidnyh Smol. USSR Patent SU 336334 A1, 21 April 1972. [Google Scholar]

- Mejer, N.; Fulon, R. Otverditel’ Dlya Rezol’nyh Fenolformal’degidnyh Smol. USSR Patent SU 1011054 A3, 7 April 1983. [Google Scholar]

- Eroshenko, V. Study of the kinetics of the process of the curing of reshonic phenolomomedehide resin modified by metal salts. Univ. News North-Cauc. Reg. Tech. Sci. Ser. 2019, 2, 48–54. [Google Scholar] [CrossRef]

- Alsaihati, Z.A.; Al-Yami, A.S.; Wagle, V.; BinAli, A.; Mukherjee, T.S.; Al-Kubaisi, A.; Halim, A.H.; Khalil, M.; Alsafran, A. An Overview of Polymer Resin Systems Deployed for Remedial Operations in Saudi Arabia. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, 24–27 April 2017; pp. 1–15. [Google Scholar]

- Jones, P.J.; London, B.A.; Tennison, L.B.; Karcher, J.D. Unconventional Remediation in the Utica Shale Using Advanced Resin Technologies. In Proceedings of the SPE Eastern Regional Meeting, Pittsburgh, PA, USA, 20–22 August 2013; pp. 1–6. [Google Scholar]

- Elyas, O.; Alyami, A.; Wagle, V.; Alhareth, N. Use of Polymer Resins for Surface Annulus Isolation Enhancement. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, 23–26 April 2018; pp. 1–8. [Google Scholar]

- Urdaneta, J.A.; Arroyave, J.M.; Jones, P.; Amaya, J.L.; Coral, A.; Hernandez, H. Novel Gas Shutoff Resin System for Well Abandonment Applications in Colombia: A Case History. In Proceedings of the SPE Latin America and Caribbean Petroleum Engineering Conference, Maracaibo, Venezuela, 21–23 May 2014; pp. 1–7. [Google Scholar]

- Knudsen, K.; Leon, G.A.; Sanabria, A.E.; Ansari, A.; Pino, R.M. First Application of Thermal Activated Resin as Unconventional LCM in the Middle East. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 9–12 November 2015. [Google Scholar]

- Beharie, C.; Francis, S.; Øvestad, K.H. Resin: An Alternative Barrier Solution Material. In Proceedings of the SPE Bergen One Day Seminar, Bergen, Norway, 22 April 2015. [Google Scholar]

- Ishbaev, G.; Dil’miev, M.; Ishbaev, R.; Latypov, T. Development of Grouting Materials with High Impact Strength. Burenie i Neft’ 2015, 9, 38–41. [Google Scholar]

- Gnibidin, V.N. The results of the research in the field of loss prevention the tightness of the annulus of the wells in the result static and dynamic loads. Bulatovskie Chteniya 2017, 3, 54–59. [Google Scholar]

- Korobov, I.Y.; Popov, S.N. Evaluation of the Degree of the Effect of Hardening Time and the Influence of the Clay Acid Reagent on the Elastic-Strength Properties of Cement Stone. Actual Probl. Oil Gas 2019, 4, 2019. [Google Scholar] [CrossRef]

- Blinov, P.A.; Shansherov1, A.V.; Cheremshantsev, D.M.; Kuznetsova, N.Y.; Nikishin, V.V. Analysis and selection of a grouting mixture, resistant to dynamic loads, in order to improve the support tightness quality in the annulus. Bull. Tomsk. Polytech. Univ. Geo Assets Eng. 2022, 333, 115–123. [Google Scholar] [CrossRef]

- Wasnik, A.; Mete, S.; Ghosh, B. Application of Resin System for Sand Consolidation, Mud-Loss Control, and Channel Repairing. In Proceedings of the SPE International Thermal Operations and Heavy Oil Symposium, Calgary, AB, Canada, 1–3 November 2005. [Google Scholar]

- Lettner, M.; Hesser, F.; Hedeler, B.; Schwarzbauer, P.; Stern, T. Barriers and Incentives for the Use of Lignin-Based Resins: Results of a Comparative Importance Performance Analysis. J. Clean. Prod. 2020, 256, 120520. [Google Scholar] [CrossRef]

- Abanum, A.M.; Appah, D. Laboratory Studies of Chemicals for Sand Consolidation (Scon) in the Niger Delta Fields. In Proceedings of the SPE Nigeria Annual International Conference and Exhibition, Lagos, Nigeria, 5–7 August 2013. [Google Scholar]

- Hashmi, A.A.; Al-Yami, A.S.; Dahmoush, A.A.; Wagle, V.; Alanqari, A.; Alshaikh, Y.; Gumsani, A.M.; Aramco, S.; Ali, W.; Al-Turki, A.; et al. Epoxy Resins-Cement Slurries for Primary Cementing Application. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 9–12 November 2020. [Google Scholar]

- Zalivin, V.G. Developing Hardenable Foam Compositions for Well Tamping. Earth Sci. Subsoil Use 2019, 42, 336–348. [Google Scholar] [CrossRef]

- Kabir, A.H. Chemical Water & Gas Shutoff Technology—An Overview. In Proceedings of the SPE Asia Pacific Improved Oil Recovery Conference, Kuala Lumpur, Malaysia, 8–9 October 2001. [Google Scholar]

- Yami, A.; Buwaidi, H.; Al-Herz, A.; Mukherjee, T.S.; Bedford, D.; Viso, R.; Hugentobler, K. Application of Heavy Weight Cement-Resin Blend System to Prevent CCA Pressure in Saudi Arabia Deep Gas Fields. In Proceedings of the SPE Oil and Gas India Conference and Exhibition, Mumbai, India, 4–6 April 2017; pp. 4–6. [Google Scholar]

- Hakiki, F.; Salam, D.D.; Akbari, A.; Nuraeni, N.; Aditya, W.; Siregar, S. Is Epoxy-Based Polymer Suitable for Water Shut-Off Application? In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Bali, Indonesia, 20–22 October 2015. [Google Scholar]

- GOST 20287-2023 (ISO 3016:2019); Petroleum and Related Products from Natural or Synthetic Sources—Determination of Pour Point. MOD: London, UK, 2024.

- Sergeev, V.A.; Shitikov, V.K.; Nechaev, A.I.; Chizhova, N.V.; Kudryavceva, N.N. Oksimetil’nye Proizvodnye Fenolov v Kachestve Otverditelej Novolachnyh Smol. VMS. Seriya B, 1995; 37, 1043–1046. [Google Scholar]

- Rusakov, D.S. Modification of Phenol-Formaldehyde Resin by the Products of Sulfite and Pulp Production. Syst. Methods Technol. 2016, 1, 113–119. [Google Scholar]

- Shishlov, O.F.; Baulina, N.S.; Gluhih, V.V. Vliyanie Otverditelej Na Kinetiku Otverzhdeniya Rezol’nyh Fenolkardanolformal’degidnyh Smol. Vestn. Kazan. Tekhnologicheskogo Univ. 2012, 15, 38–41. [Google Scholar]

- Wei, Q.; Wang, W.-H. Properties of Phenol Formaldehyde Resin Modified with Silane Coupling Agent (KH550). Int. J. Adhes. Adhes. 2018, 84, 166–172. [Google Scholar] [CrossRef]

- Shutilov, V.A. Fundamentals of Ultrasound Physics: Tutorial; CRC Press: London, UK, 1980. [Google Scholar]

| Injectivity | The Injectivity Index | Type of Plugging Material |

|---|---|---|

| High | <2000 | Normal API cement |

| 2000–4000 | API Cement is a fine blend of 50–80% Class C, G, or H cement with 20–50% microcement | |

| 4000–6000 | Solid-free materials (resins/monomer) and microcement | |

| Low | >6000 | Solid-free materials (resins/monomer) Water-based monomer mixture |

| Property | Thermal-Activated Resin | Traditional Cement |

|---|---|---|

| Water permeability, mD | <0.5 | 1600 |

| Compressive strength, MPa | 77 | 58 |

| Flexural strength, MPa | 43 | 10 |

| Failure flexural strain, % | 1.9 | 0.32 |

| E-modulus, MPa | 2240 | 3700 |

| Tensile strength, MPa | 60 | 1 |

| Density, S.G. | 0.75–2.5 | 1.5+ |

| No. | Hardener Concentration, wt% | Flow Loss Time, min | h0, mm | d0, mm | h1, mm | d1, mm | Δh, mm | Δd, mm | ℇt | ℇl | S, mm2 | R, MPa | E, MPa | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 9.0 | 355 | 28.55 | 49.05 | 25.32 | 49.54 | −7.73 | 0.49 | 0.010 | −0.27 | 0.037 | 1888.63 | 8.88 | 32.81 |

| 2 | 12.0 | 164 | 28.46 | 49.6 | 26.33 | 49.93 | −7.43 | 0.33 | 0.007 | −0.26 | 0.025 | 1931.22 | 7.79 | 29.81 |

| 3 | 14.0 | 65 | 31.12 | 49.76 | destruction of the sample | destruction of the sample | – | – | – | – | – | 1943.70 | 7.88 | – |

| 4 | 15.0 | 80 | 28.83 | 49.9 | 27.45 | 49.63 | −7.71 | −0.27 | −0.005 | −0.27 | 0.020 | 1954.65 | 6.42 | 23.99 |

| 5 | 16.0 | 60 | 31.27 | 49.52 | destruction of the sample | destruction of the sample | – | – | – | – | – | 1925.00 | 5.22 | – |

| No. | Hardener Concentration, wt% | Flow Loss Time, min | h0, mm | d0, mm | h1, mm | d1, mm | Δh, mm | Δd, mm | ℇt | ℇl | S, mm2 | R, MPa | E, MPa | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 3.0 | >1440 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 2 | 5.0 | 600 | 27.82 | 48.7 | 24.43 | 51.98 | −8.36 | 3.28 | 0.07 | −0.30 | 0.224 | 1861.77 | 13.06 | 40.13 |

| 3 | 7.0 | 140 | 28.25 | 48.84 | 24.43 | 51.98 | −8.29 | 3.14 | 0.06 | −0.29 | 0.219 | 1872.49 | 12.21 | 45.01 |

| 4 | 9.0 | 105 | 28.34 | 48.32 | 26.31 | 48.7 | −6.62 | 0.38 | 0.008 | −0.23 | 0.034 | 1832.83 | 10.93 | 46.78 |

| 5 | 11.0 | 40 | 29.63 | 48.76 | destruction of the sample | destruction of the sample | – | – | – | – | – | 1866.36 | 8.95 | – |

| No. | Hardener Concentration, wt% | Flow Loss Time, min | h0, mm | d0, mm | h1, mm | d1, mm | Δh, mm | Δd, mm | ℇt | ℇl | v | S, mm2 | R, MPa | E, MPa |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2.0 | 1800 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 2 | 4.0 | 1440 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 3 | 6.0 | 360 | 29.33 | 35.55 | 28.36 | 36.28 | −3.46 | 0.73 | 0.02 | −0.12 | 0.174 | 992.09 | 9.61 | 81.43 |

| 4 | 6.5 | 135 | 31.6 | 35.77 | 24.63 | 36.76 | −3.37 | 0.99 | 0.03 | −0.11 | 0.260 | 1004.40 | 11.63 | 109.04 |

| 5 | 7.0 | 115 | 32.64 | 34.79 | 25.7 | 35.9 | −4.75 | 1.11 | 0.03 | −0.15 | 0.219 | 950.12 | 14.62 | 100.46 |

| 6 | 7.5 | 105 | 30.72 | 35.74 | 29.23 | 36.17 | −4.34 | 0.43 | 0.01 | −0.14 | 0.085 | 1002.72 | 14.11 | 99.89 |

| 7 | 8.0 | 90 | 27.81 | 35.6 | 26.56 | 36.91 | −4.55 | 1.31 | 0.04 | −0.16 | 0.225 | 994.88 | 13.92 | 85.09 |

| 8 | 8.5 | 75 | 28.14 | 35.68 | 27.94 | 35.97 | −4.21 | 0.29 | 0.01 | −0.15 | 0.054 | 999.35 | 15.01 | 100.33 |

| No. | Hardener Concentration, wt% | Flow Loss Time, min | h0, mm | d0, mm | h1, mm | d1, mm | Δh, mm | Δd, mm | ℇt | ℇl | S, mm2 | R, MPa | E, MPa | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2.0 | 1800 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 2 | 4.0 | 1440 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 3 | 6.0 | 240 | 28.02 | 35.61 | 27.06 | 36.32 | −4.43 | 0.71 | 0.02 | −0.16 | 0.126 | 995.44 | 17.78 | 112.47 |

| 4 | 7.0 | 120 | 27.94 | 35.6 | 27.17 | 36.69 | −4.69 | 1.09 | 0.03 | −0.17 | 0.182 | 994.88 | 15.40 | 91.74 |

| 5 | 8.0 | 90 | 24.93 | 35.58 | destruction of the sample | destruction of the sample | – | – | – | – | – | 993.76 | 19.22 | – |

| Material | Ultimate Compressive Strength, MPa | Young’s Modulus, MPa | Poisson’s Ratio |

|---|---|---|---|

| Glass ** | - | 0.56·105 | 0.25 |

| Concrete ** | 10.0 | (0.146–0.196)·105 | 0.16–0.18 |

| Phenol-formaldehyde resin, 40 °C *** | 12.06 | 40.12 | 0.22 |

| Phenol-formaldehyde resin, 25 °C *** | 8.88 | 32.81 | 0.04 |

| Epoxy resin, 50 °C *** | - * | 4.02 | 0.27 |

| Rubber ** | - | 7.0 | 0.47–0.50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aksenova, S.V.; Magadova, L.A.; Kudryashov, S.I.; Silin, M.A.; Kulikov, A.N.; Gevorkian, A.V.; Polyakov, D.D. Study of Plugging Compositions Based on Synthetic Resins for Repair and Insulation Work in Wells. Polymers 2024, 16, 2077. https://doi.org/10.3390/polym16142077

Aksenova SV, Magadova LA, Kudryashov SI, Silin MA, Kulikov AN, Gevorkian AV, Polyakov DD. Study of Plugging Compositions Based on Synthetic Resins for Repair and Insulation Work in Wells. Polymers. 2024; 16(14):2077. https://doi.org/10.3390/polym16142077

Chicago/Turabian StyleAksenova, Svetlana V., Lyubov A. Magadova, Sergey I. Kudryashov, Mikhail A. Silin, Aleksandr N. Kulikov, Artem V. Gevorkian, and Denis D. Polyakov. 2024. "Study of Plugging Compositions Based on Synthetic Resins for Repair and Insulation Work in Wells" Polymers 16, no. 14: 2077. https://doi.org/10.3390/polym16142077