Material Compatibility in 4D Printing: Identifying the Optimal Combination for Programmable Multi-Material Structures

Abstract

1. Introduction

- ABS (acrylonitrile butadiene styrene) and PLA (polylactic acid)—ABS and PLA are two of the most widely used thermoplastic materials in 3D printing. ABS has good strength, toughness, and thermal stability, making it suitable for printing functional parts. PLA, on the other hand, is easy to print and has good dimensional accuracy. A combination of ABS and PLA can be used to print complex structures with varying mechanical properties;

- PET (polyethylene terephthalate) and TPU (thermoplastic polyurethane)—PET is a strong, stiff, and durable material, while TPU is a flexible and rubber-like material. A combination of these two materials can be used to print complex structures with varying mechanical properties, such as objects that require both rigidity and flexibility;

- PA (polyamide or nylon) and PVA (polyvinyl alcohol)—PA is a strong and durable material, while PVA is a water-soluble material that can be used as a support material during printing. A combination of these two materials can be used to print complex structures with overhangs or intricate geometries;

- PP (polypropylene) and PC (polycarbonate)—PP is a lightweight and flexible material, while PC is a strong and rigid material. A combination of these two materials can be used to print complex structures with varying mechanical properties, such as objects that require both flexibility and strength.

- Stimulus-responsive properties—The materials should have responsive properties that can be triggered by specific external stimuli, such as temperature, humidity, or light. For example, shape memory polymers can exhibit a reversible change in shape or properties in response to temperature;

- Compatibility with 3D printing techniques—The materials should be compatible with the 3D printing techniques used for fabricating the structures. For example, materials with a low melting point can be printed using Fused Deposition Modelling (FDM) printers, whereas materials with a high viscosity require more advanced printing techniques like Stereolithography (SLA);

- Mechanical properties—The materials should have adequate mechanical properties to support the printed structures and withstand the desired stimuli. This includes factors such as stiffness, strength, and elasticity;

2. Materials and Methods

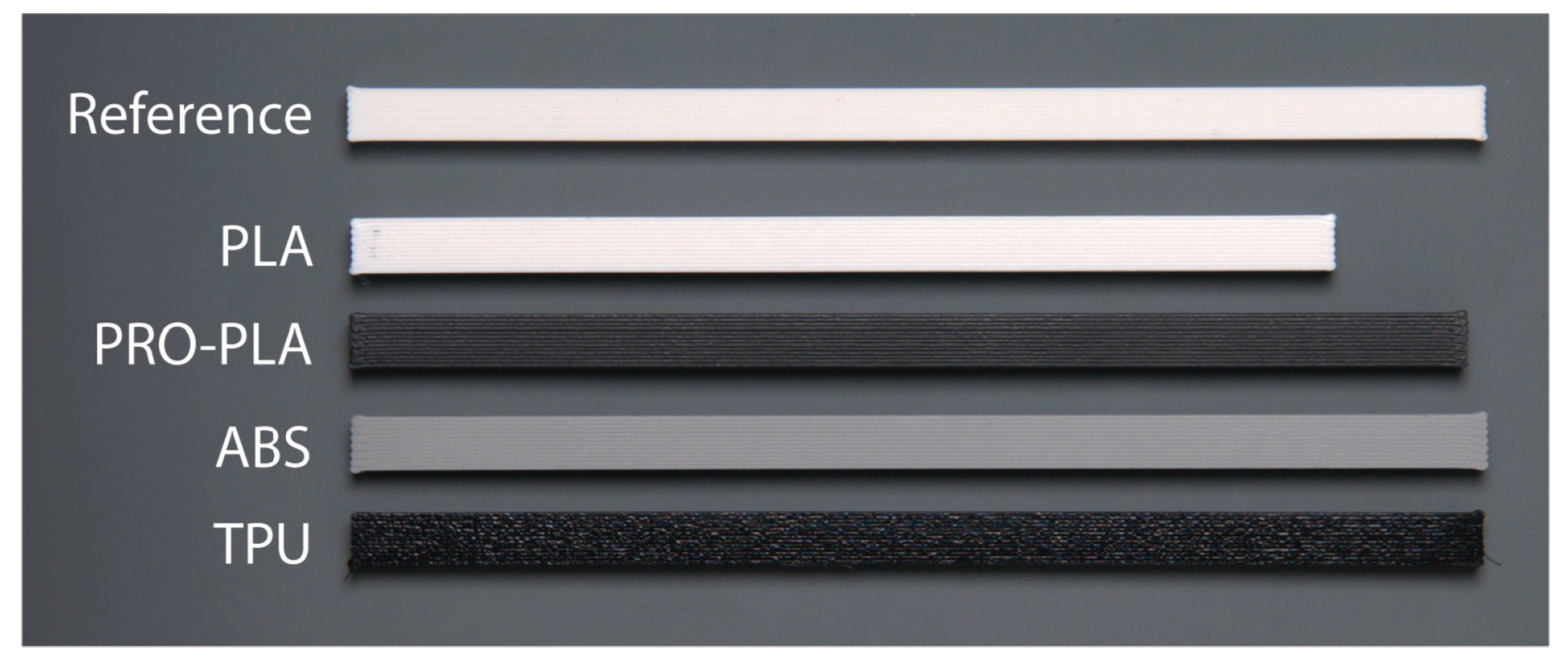

2.1. Materials and Printing Procedures

2.2. Material Characterization

2.2.1. Thermal and Thermomechanical Properties

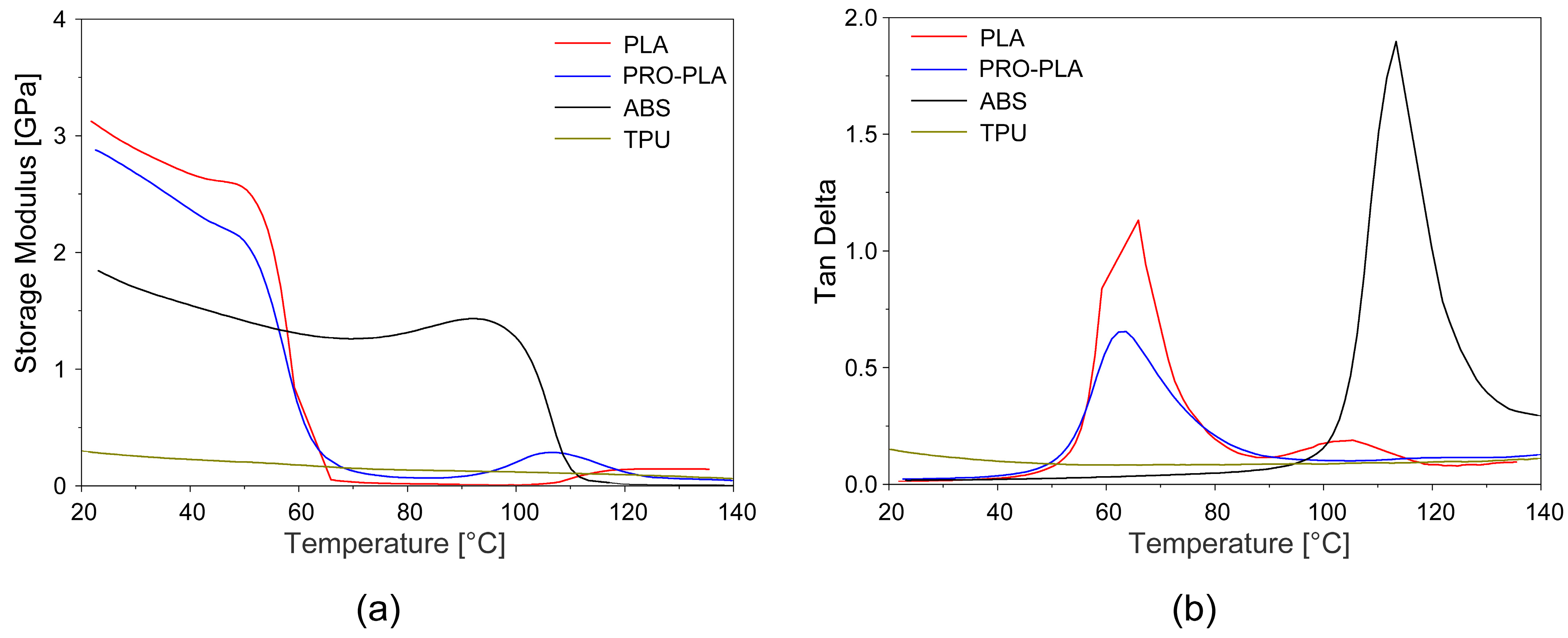

Dynamic Mechanical Properties

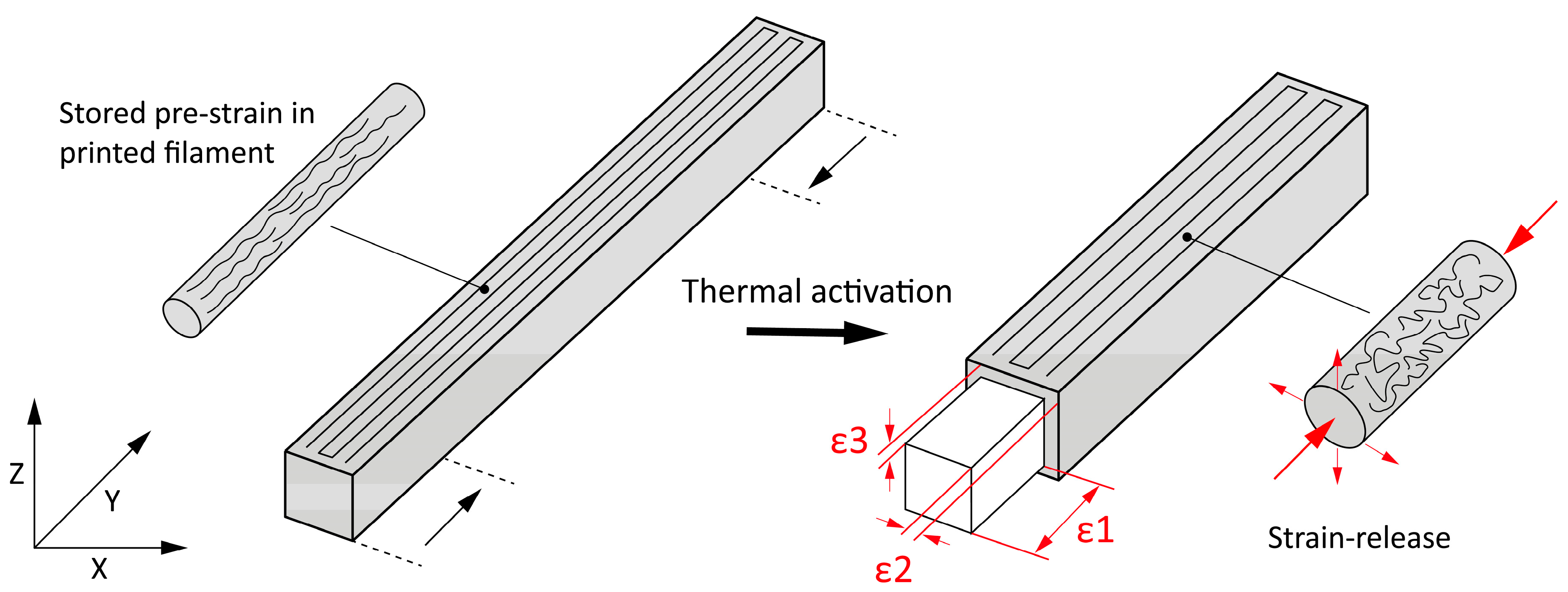

Dimensional Strain

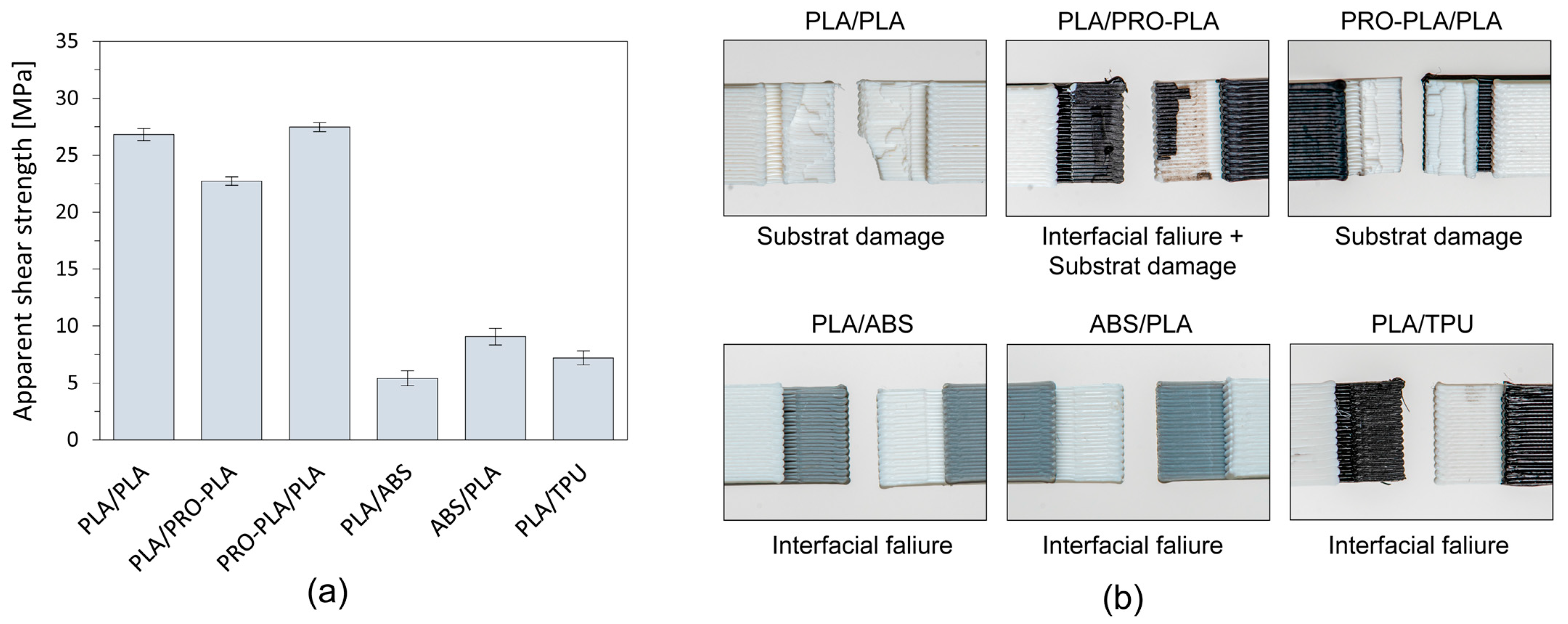

2.2.2. Apparent Shear Strength

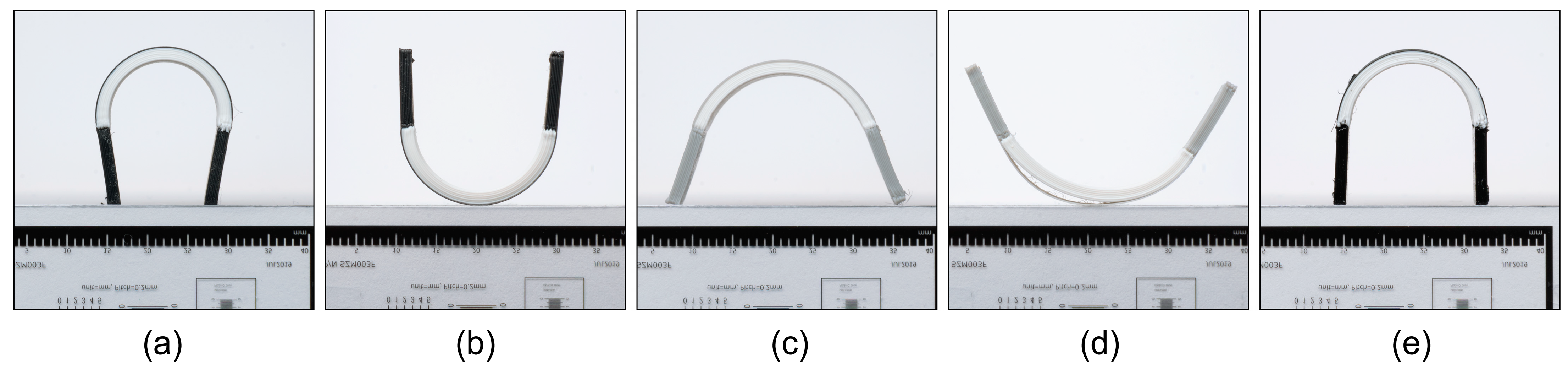

2.2.3. Experimental Determination of the Shape Transformation

3. Results

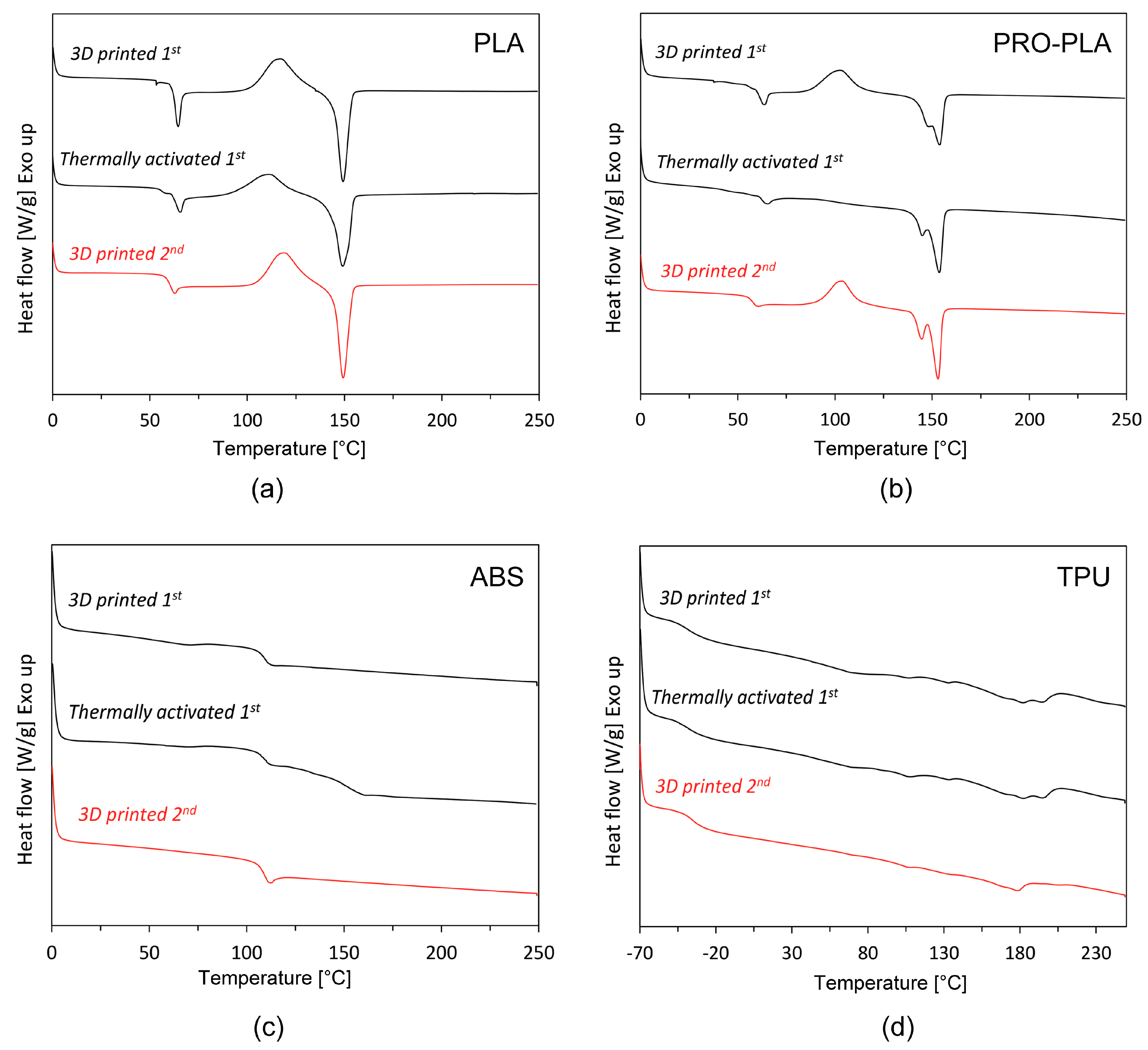

3.1. Thermal Analysis

3.1.1. The Crystallization Behavior and Melting Characteristics

3.1.2. Dynamic Mechanical Properties

3.1.3. Dimensional Strain

3.2. Apparent Shear Strength

3.3. Experimental Determination of the Shape Transformation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tan, D.; Nokhodchi, A.; Maniruzzaman, M. 3D and 4D Printing Technologies: Innovative Process Engineering and Smart Additive Manufacturing. In 3D and 4D Printing in Biomedical Applications: Process Engineering and Additive Manufacturing; Maniruzzaman, M., Ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2019; pp. 25–52. [Google Scholar]

- Ahmed, A.; Arya, S.; Gupta, V.; Furukawa, H.; Khosla, A. 4D printing: Fundamentals, materials, applications, and challenges. Polymer 2021, 228, 123926. [Google Scholar] [CrossRef]

- Melly, S.K.; Liu, L.; Liu, Y.; Leng, J. On 4D printing as a revolutionary fabrication technique for smart structures. Smart Mater. Struct. 2020, 29, 083001. [Google Scholar] [CrossRef]

- Chu, H.; Yang, W.; Sun, L.; Cai, S.; Yang, R.; Liang, W.; Yu, H.; Liu, L. 4D printing: A review on recent progresses. Micromachines 2020, 11, 796. [Google Scholar] [CrossRef] [PubMed]

- Subeshan, B.; Baddam, Y.; Asmatulu, E. Current progress of 4D-printing technology. Prog. Addit. Manuf. 2021, 6, 495–516. [Google Scholar] [CrossRef]

- Zhou, X.; Ren, L.; Song, Z.; Li, G.; Zhang, J.; Li, B.; Wu, Q.; Li, W.; Ren, L.; Liu, Q. Advances in 3D/4D printing of mechanical metamaterials: From manufacturing to applications. Compos. B Eng. 2023, 254, 110585. [Google Scholar] [CrossRef]

- Rafiee, M.; Farahani, R.D.; Therriault, D. Multi-material 3D and 4D printing: A survey. Adv. Sci. 2020, 7, 1902307. [Google Scholar] [CrossRef]

- Mohol, S.S.; Sharma, V. Functional applications of 4D printing: A review. Rapid Prototyp. J. 2021, 27, 1501–1522. [Google Scholar] [CrossRef]

- Nugroho, W.T.; Dong, Y.; Pramanik, A.; Leng, J.; Ramakrishna, S. Smart polyurethane composites for 3D or 4D printing: General-purpose use, sustainability and shape memory effect. Compos. B Eng. 2021, 223, 109104. [Google Scholar] [CrossRef]

- Vatanparast, S.; Boschetto, A.; Bottini, L.; Gaudenzi, P. New trends in 4D printing: A critical review. Appl. Sci. 2023, 13, 7744. [Google Scholar] [CrossRef]

- Riley, K.S.; Ang, K.J.; Martin, K.A.; Chan, W.K.; Faber, J.A.; Arrieta, A.F. Encoding multiple permanent shapes in 3D printed structures. Mater. Des. 2020, 194, 108888. [Google Scholar] [CrossRef]

- Valino, A.D.; Dizon, J.R.C.; Espera, A.H., Jr.; Chen, Q.; Messman, J.; Advincula, R.C. Advances in 3D printing of thermoplastic polymer composites and nanocomposites. Prog. Polym. Sci. 2019, 98, 101162. [Google Scholar] [CrossRef]

- Goo, B.; Hong, C.H.; Park, K. 4D printing using anisotropic thermal deformation of 3D-printed thermoplastic parts. Mater. Des. 2020, 188, 108485. [Google Scholar] [CrossRef]

- Jiang, Z.; Diggle, B.; Tan, M.L.; Viktorova, J.; Bennett, C.W.; Connal, L.A. Extrusion 3D printing of polymeric materials with advanced properties. Adv. Sci. 2020, 7, 2001379. [Google Scholar] [CrossRef] [PubMed]

- Ryan, K.R.; Down, M.P.; Banks, C.E. Future of additive manufacturing: Overview of 4D and 3D printed smart and advanced materials and their applications. Chem. Eng. J. 2021, 403, 126162. [Google Scholar] [CrossRef]

- Ali, M.H.; Abilgaziyev, A.; Adair, D. 4D printing: A critical review of current developments, and future prospects. Int. J. Adv. Manuf. Technol. 2019, 105, 701–717. [Google Scholar] [CrossRef]

- Choi, J.; Kwon, O.C.; Jo, W.; Lee, H.J.; Moon, M.W. 4D printing technology: A review. 3D Print. Addit. Manuf. 2015, 2, 159–167. [Google Scholar] [CrossRef]

- Mitchell, A.; Lafont, U.; Hołyńska, M.; Semprimoschnig, C.J.A.M. Additive manufacturing—A review of 4D printing and future applications. Addit. Manuf. 2018, 24, 606–626. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Aberoumand, M.; Soltanmohammadi, K.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Zolfagharian, A.; Baghani, M. A New Strategy for Achieving Shape Memory Effects in 4D Printed Two-Layer Composite Structures. Polymer 2022, 14, 5446. [Google Scholar] [CrossRef] [PubMed]

- Joshi, S.; Rawat, K.; Karunakaran, C.; Rajamohan, V.; Mathew, A.T.; Koziol, K.; Thakur, V.K.; Balan, A.S.S. 4D printing of materials for the future: Opportunities and challenges. Appl. Mater. Today 2020, 18, 100490. [Google Scholar] [CrossRef]

- Blok, L.G.; Longana, M.L.; Yu, H.; Woods, B.K. An investigation into 3D printing of fibre reinforced thermoplastic composites. Addit. Manuf. 2018, 22, 176–186. [Google Scholar] [CrossRef]

- Prabhakar, M.M.; Saravanan, A.K.; Lenin, A.H.; Mayandi, K.; Ramalingam, P.S. A short review on 3D printing methods, process parameters and materials. Mater. Today Proc. 2021, 45, 6108–6114. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; Núñez, P.J.; García-Plaza, E.; García-Moreno, I.; Reverte, J.M. Additive manufacturing of continuous fibre reinforced thermoplastic composites using fused deposition modelling: Effect of process parameters on mechanical properties. Compos. Sci. Technol. 2019, 181, 107688. [Google Scholar] [CrossRef]

- León-Calero, M.; Reyburn Valés, S.C.; Marcos-Fernández, Á.; Rodríguez-Hernandez, J. 3D printing of thermoplastic elastomers: Role of the chemical composition and printing parameters in the production of parts with controlled energy absorption and damping capacity. Polymer 2021, 13, 3551. [Google Scholar] [CrossRef]

- Dana, H.R.; Barbe, F.; Delbreilh, L.; Azzouna, M.B.; Guillet, A.; Breteau, T. Polymer additive manufacturing of ABS structure: Influence of printing direction on mechanical properties. J. Manuf. Process. 2019, 44, 288–298. [Google Scholar] [CrossRef]

- Shymborska, Y.; Budkowski, A.; Raczkowska, J.; Donchak, V.; Melnyk, Y.; Vasiichuk, V.; Stetsyshyn, Y. Switching it Up: The Promise of Stimuli-Responsive Polymer Systems in Biomedical Science. Chem. Rec. 2024, 24, e202300217. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Urban, M.W. Redefining polymer science via multi-stimulus responsiveness. Chem 2023, 9, 1362–1377. [Google Scholar] [CrossRef]

- Png, Z.M.; Wang, C.G.; Yeo JC, C.; Lee JJ, C.; Surat’man, N.E.; Tan, Y.L.; Zhu, Q. Stimuli-responsive structure–property switchable polymer materials. Mol. Syst. Des. Eng. 2023, 8, 1097–1129. [Google Scholar] [CrossRef]

- Paoletti, I.; Ceccon, L. The evolution of 3D printing in AEC: From experimental to consolidated techniques. In 3D Printing; Cvetković, D., Ed.; IntechOpen: London, UK, 2018; pp. 39–69. [Google Scholar] [CrossRef]

- Fischbach, M.; Weinberg, K. Effect of physical aging on the flexural creep in 3D printed thermoplastic. In IUTAM 2023: Creep in Structures VI; Altenbach, H., Naumenko, K., Eds.; Springer: Cham, Switzerland, 2023; pp. 115–130. [Google Scholar]

- Shafranek, R.T.; Millik, S.C.; Smith, P.T.; Lee, C.U.; Boydston, A.J.; Nelson, A. Stimuli-responsive materials in additive manufacturing. Prog. Polym. Sci. 2019, 93, 36–67. [Google Scholar] [CrossRef]

- Boydston, A.J.; Cao, B.; Nelson, A.; Ono, R.J.; Saha, A.; Schwartz, J.J.; Thrasher, C.J. Additive manufacturing with stimuli-responsive materials. J. Mater. Chem. A 2018, 6, 20621–20645. [Google Scholar] [CrossRef]

- Bi, H.; Ye, G.; Sun, H.; Ren, Z.; Gu, T.; Xu, M. Mechanically robust, shape memory, self-healing and 3D printable thermoreversible cross-linked polymer composites toward conductive and biomimetic skin devices applications. Addit. Manuf. 2022, 49, 102487. [Google Scholar] [CrossRef]

- Regis, J.E.; Renteria, A.; Hall, S.E.; Hassan, M.S.; Marquez, C.; Lin, Y. Recent trends and innovation in additive manufacturing of soft functional materials. Materials 2021, 14, 4521. [Google Scholar] [CrossRef] [PubMed]

- González-Henríquez, C.M.; Sarabia-Vallejos, M.A.; Rodriguez-Hernandez, J. Polymers for additive manufacturing and 4D-printing: Materials, methodologies, and biomedical applications. Prog. Polym. Sci. 2019, 94, 57–116. [Google Scholar] [CrossRef]

- Rajkumar, A.R.; Shanmugam, K. Additive manufacturing-enabled shape transformations via FFF 4D printing. J. Mater. Res. 2018, 33, 4362–4376. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X. An accurate finite element approach for programming 4D-printed self-morphing structures produced by fused deposition modelling. Mech. Mater. 2020, 151, 103628. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X. 4D-printed bi-material composite laminate for manufacturing reversible shape-change structures. Compos. B Eng. 2021, 219, 108918. [Google Scholar] [CrossRef]

- Wang, F.; Luo, F.; Huang, Y.; Cao, X.; Yuan, C. 4D Printing Via Multispeed Fused Deposition Modeling. Adv. Mater. Technol. 2023, 8, 2201383. [Google Scholar] [CrossRef]

- Watschke, H.; Waalkes, L.; Schumacher, C.; Vietor, T. Development of novel test specimens for characterization of multi-material parts manufactured by material extrusion. Appl. Sci. 2018, 8, 1220. [Google Scholar] [CrossRef]

- Ren, L.; He, Y.; Ren, Z.; Wang, Z.; Zhou, X.; Wu, Q.; Wang, K.; Li, B.; Liu, Q. Multi-parameter-encoded 4D printing of liquid crystal elastomers for programmable shape morphing behaviors. Addit. Manuf. 2023, 61, 103376. [Google Scholar] [CrossRef]

- Akhoundi, B.; Nabipour, M.; Hajami, F.; Shakoori, D. An Experimental Study of Nozzle Temperature and Heat Treatment (Annealing) Effects on Mechanical Properties of High-Temperature Polylactic Acid in Fused Deposition Modeling. Polym Eng Sci. 2020, 8, 873–1092. [Google Scholar] [CrossRef]

- Yu, F.; Liu, T.; Zhao, X.; Yu, X.; Lu, A.; Wang, J. Effects of talc on the mechanical and thermal properties of polylactide. J. Appl. Polym. Sci. 2012, 25, E99–E109. [Google Scholar] [CrossRef]

- Rafie, M.A.F.; Marsilla, K.I.K.; Hamid, Z.A.A.; Rusli, A.; Abdullah, M.K. Enhanced mechanical properties of plasticized polylactic acid filament for fused deposition modelling: Effect of in situ heat treatment. Prog. Rubber Plast. Recycl. Technol. 2020, 36, 131–142. [Google Scholar] [CrossRef]

- Jalali, A.; Huneault, M.A.; Elkoun, S. Effect of thermal history on nucleation and crystallization of poly (lactic acid). J. Mater. Sci. 2016, 51, 7768–7779. [Google Scholar] [CrossRef]

- Benwood, C.; Anstey, A.; Andrzejewski, J.; Misra, M.; Mohanty, A.K. Improving the Impact Strength and Heat Resistance of 3D Printed Models: Structure, Property, and Processing Correlations during Fused Deposition Modeling (FDM) of Poly(Lactic Acid). ACS Omega 2018, 3, 4400–4411. [Google Scholar] [CrossRef] [PubMed]

- Frick, A.; Rochman, A. Characterization of TPU-elastomers by thermal analysis (DSC). Polym. Test. 2004, 23, 413–417. [Google Scholar] [CrossRef]

- Gallu, R.; Méchin, F.; Dalmas, F.; Gérard, J.-F.; Perrin, R.; Loup, F. On the use of solubility parameters to investigate phase separation-morphology-mechanical behavior relationships of TPU. Polymer 2020, 207, 122882. [Google Scholar] [CrossRef]

- Billah, K.M.M.; Lorenzana, F.A.R.; Martinez, N.L.; Chacon, S.; Wicker, R.B.; Espalin, D. Thermal analysis of thermoplastic materials filled with chopped fiber for large area 3D printing. In Proceedings of the 30th Annual International Solid Freeform Fabrication Symposium 2019: An Additive Manufacturing Conference, Austin, TX, USA, 12–14 August 2019; The University of Texas at Austin: Austin, TX, USA, 2019; pp. 892–898. [Google Scholar]

- An, B.; Tao, Y.; Gu, J.; Cheng, T.; Chen, X.A.; Zhang, X.; Zhao, W.; Do, Y.; Takahashi, S.; Wu, H.-Y.; et al. Thermorph: Democratizing 4D Printing of Self-Folding Materials and Interfaces. In Proceedings of the 2018 CHI Conference on Human Factors in Computing Systems, Montreal, QC, Canada, 21–26 April 2018; Mandryk, R.L., Hancock, M., Perry, M., Cox, A.L., Eds.; Association for Computing Machinery: New York, NY, USA, 2018. Paper No. 260. [Google Scholar]

- Zhang, W.; Ge, Z.; Li, D. Design and Research of Form Controlled Planar Folding Mechanism based on 4D Printing Technology. Chin. J. Mech. Eng. 2023, 36, 99. [Google Scholar] [CrossRef]

- Kuang, X.; Zhao, Z.; Chen, K.; Fang, D.; Kang, G.; Qi, H.J. High-speed 3D printing of high-performance thermosetting polymers via two-stage curing. Macromol. Rapid Commun. 2018, 39, 1700809. [Google Scholar] [CrossRef]

- Zhang, Q.; Weng, S.; Hamel, C.M.; Montgomery, S.M.; Wu, J.; Kuang, X.; Zhou, K.; Qi, H.J. Design for the reduction of volume shrinkage-induced distortion in digital light processing 3D printing. Extrem. Mech. Lett. 2021, 48, 101403. [Google Scholar] [CrossRef]

- Chalissery, D.; Schönfeld, D.; Walter, M.; Shklyar, I.; Andrae, H.; Schwörer, C.; Amann, T.; Weisheit, L.; Pretsch, T. Highly shrinkable objects as obtained from 4D printing. Macromol. Mater. Eng. 2022, 307, 2100619. [Google Scholar] [CrossRef]

| Material | Printing Temperature [°] | Build Plate Temperature [°] | Fan Speed [%] | Printing Speed [mm/s] |

|---|---|---|---|---|

| PLA | 195 | 30 | 100 | 50 |

| PRO-PLA | 195 | 30 | 100 | 50 |

| ABS | 260 | 60 | 0 | 50 |

| TPU | 230 | 30 | 30 | 20 |

| Material | Sample | Heating Cycle | Tg [°C] | Tcc [°C] | Tm1 [°C] | Tm2 [°C] | ΔHm [J/g] | ΔHcc [J/g] | Xc [%] |

|---|---|---|---|---|---|---|---|---|---|

| PLA | 3D printed | 1st | 63.11 | 117.09 | 149.36 | – | 24.55 | 28.31 | 30.25 |

| 2nd | 61.17 | 118.93 | 149.34 | – | 25.34 | 25.59 | 27.34 | ||

| Thermally activated | 1st | 64.09 | 111.07 | 149.08 | – | 26.48 | 17.75 | 18.96 | |

| 2nd | 61.09 | 118.70 | 149.17 | – | 23.89 | 25.24 | 26.97 | ||

| PRO-PLA | 3D printed | 1st | 61.63 | 102.66 | 147.82 | 153.83 | 20.70 | 17.27 | 18.45 |

| 2nd | 58.83 | 103.61 | 144.52 | 153.04 | 23.07 | 15.78 | 16.86 | ||

| Thermally activated | 1st | 61.86 | – | 144.91 | 153.77 | 19.93 | – | – | |

| 2nd | 57.37 | 105.89 | 143.50 | 151.71 | 22.23 | 19.47 | 20.80 | ||

| ABS | 3D printed | 1st | 109.17 | – | – | – | – | – | – |

| 2nd | 110.23 | – | – | – | – | – | – | ||

| Thermally activated | 1st | 110.21 | – | – | – | – | – | – | |

| 2nd | 109.7 | – | – | – | – | – | – | ||

| TPU | 3D printed | 1st | −38.01 | – | 177.30 | 191.53 | 13.86 | 6.487 | 3.29 |

| 2nd | −35.47 | – | 175.11 | 201.61 | 9.247 | 7.582 | 3.85 | ||

| Thermally activated | 1st | −37.90 | – | 177.90 | 192.21 | 16.41 | 6.891 | 3.50 | |

| 2nd | −36.17 | – | 175.80 | 202.20 | 9.782 | 5.130 | 2.61 |

| Material | E′ at 23 °C [GPa] | E′ at 80 °C [GPa] | Tan Delta (Damping Factor) at 80 °C |

|---|---|---|---|

| PLA | 3.123 | 0.018 | 0.251 |

| PRO-PLA | 2.877 | 0.070 | 0.257 |

| ABS | 1.822 | 1.314 | 0.067 |

| TPU | 0.279 | 0.136 | 0.110 |

| Material | ε1 [%] (Longitudinal) | ε2 [%] (Transverse) | ε3 [%] (Height) |

|---|---|---|---|

| PLA | −13.09 (±0.115) | 5.31 (±0.705) | 12.14 (±0.263) |

| PRO-PLA | −1.86 (±0.064) | −0.24 (±0.519) | 2.90 (±0.228) |

| ABS | 0.01 (±0.004) | 0.04 (±0.094) | 0.20 (±0.183) |

| TPU | −0.01 (±0.010) | 0.00 (±0.000) | −0.13 (±0.183) |

| PLA/PRO-PLA | PRO-PLA/PLA | PLA/ABS | ABS/PLA | PLA/TPU | |

|---|---|---|---|---|---|

| Mean [mm] | 8.86 | 9.62 | 12.10 | 35.03 | 9.37 |

| Std. Dev. [mm] | 0.105 | 0.141 | 0.377 | 6.877 | 0.226 |

| Max. [mm] | 8.99 | 9.83 | 12.48 | 46.80 | 9.69 |

| Min. [mm] | 8.67 | 9.41 | 11.49 | 26.86 | 9.06 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pivar, M.; Vrabič-Brodnjak, U.; Leskovšek, M.; Gregor-Svetec, D.; Muck, D. Material Compatibility in 4D Printing: Identifying the Optimal Combination for Programmable Multi-Material Structures. Polymers 2024, 16, 2138. https://doi.org/10.3390/polym16152138

Pivar M, Vrabič-Brodnjak U, Leskovšek M, Gregor-Svetec D, Muck D. Material Compatibility in 4D Printing: Identifying the Optimal Combination for Programmable Multi-Material Structures. Polymers. 2024; 16(15):2138. https://doi.org/10.3390/polym16152138

Chicago/Turabian StylePivar, Matej, Urška Vrabič-Brodnjak, Mirjam Leskovšek, Diana Gregor-Svetec, and Deja Muck. 2024. "Material Compatibility in 4D Printing: Identifying the Optimal Combination for Programmable Multi-Material Structures" Polymers 16, no. 15: 2138. https://doi.org/10.3390/polym16152138

APA StylePivar, M., Vrabič-Brodnjak, U., Leskovšek, M., Gregor-Svetec, D., & Muck, D. (2024). Material Compatibility in 4D Printing: Identifying the Optimal Combination for Programmable Multi-Material Structures. Polymers, 16(15), 2138. https://doi.org/10.3390/polym16152138