MXene Based Flame Retardant and Electrically Conductive Polymer Coatings

Abstract

:1. Introduction

2. Methodologies for Characteristic Performance

2.1. Material Characterisation

2.2. Flame Retardancy Characterisations

2.3. Electrical Conductivity Characterisation

3. MXene-Based Polymer Coatings

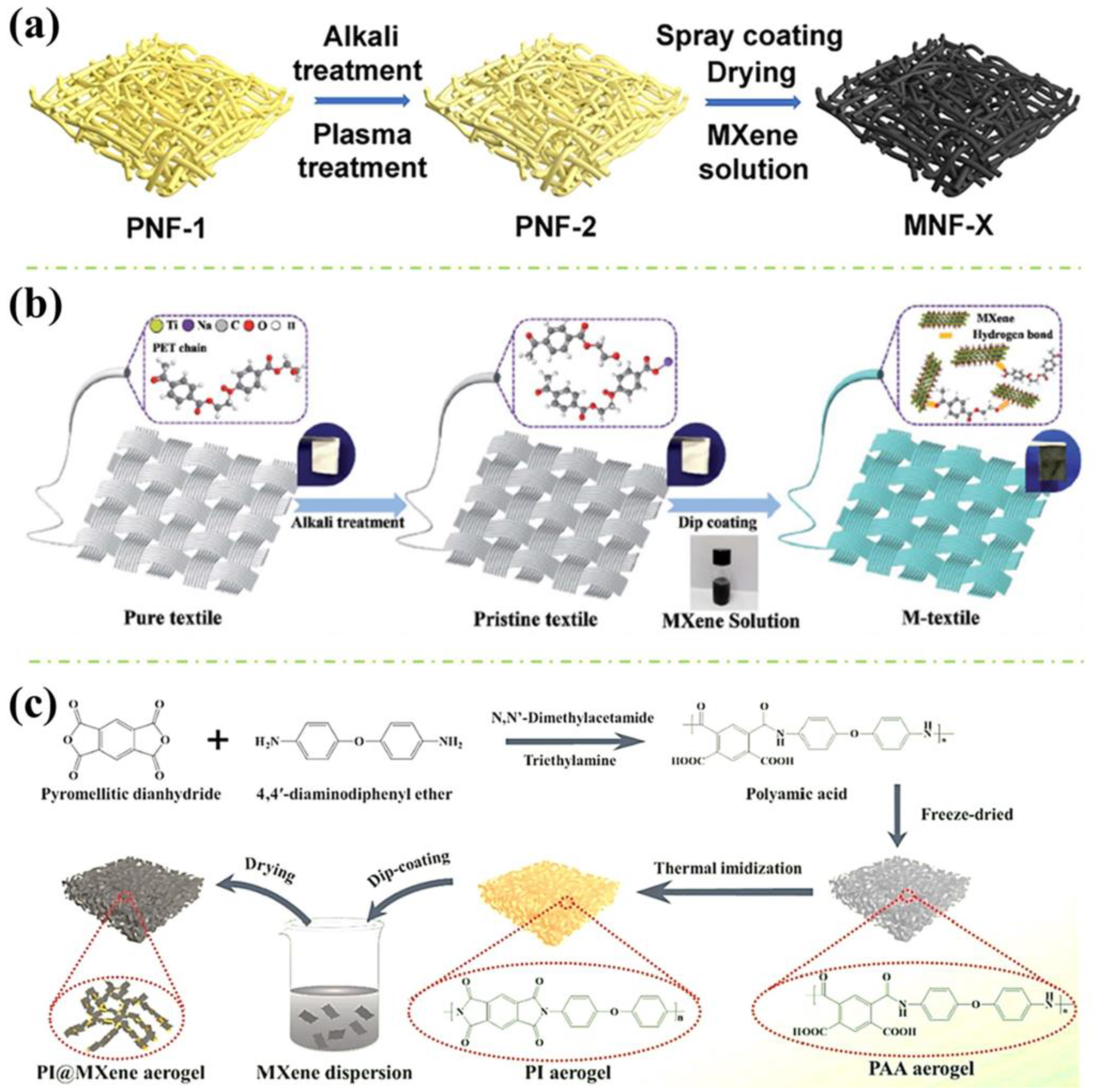

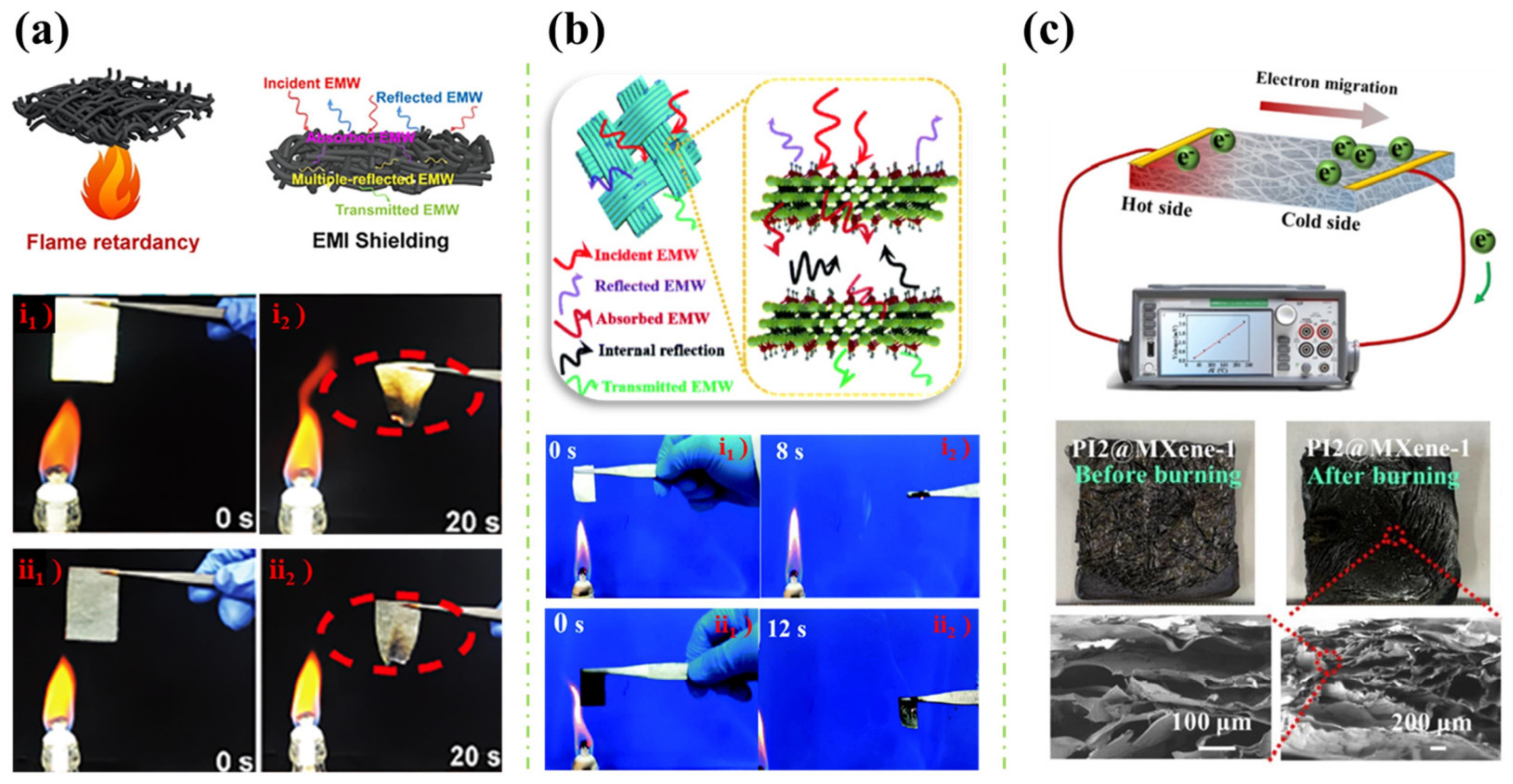

3.1. Single Coating of Unmodified MXene

3.2. Single Type Coating of Modified MXene

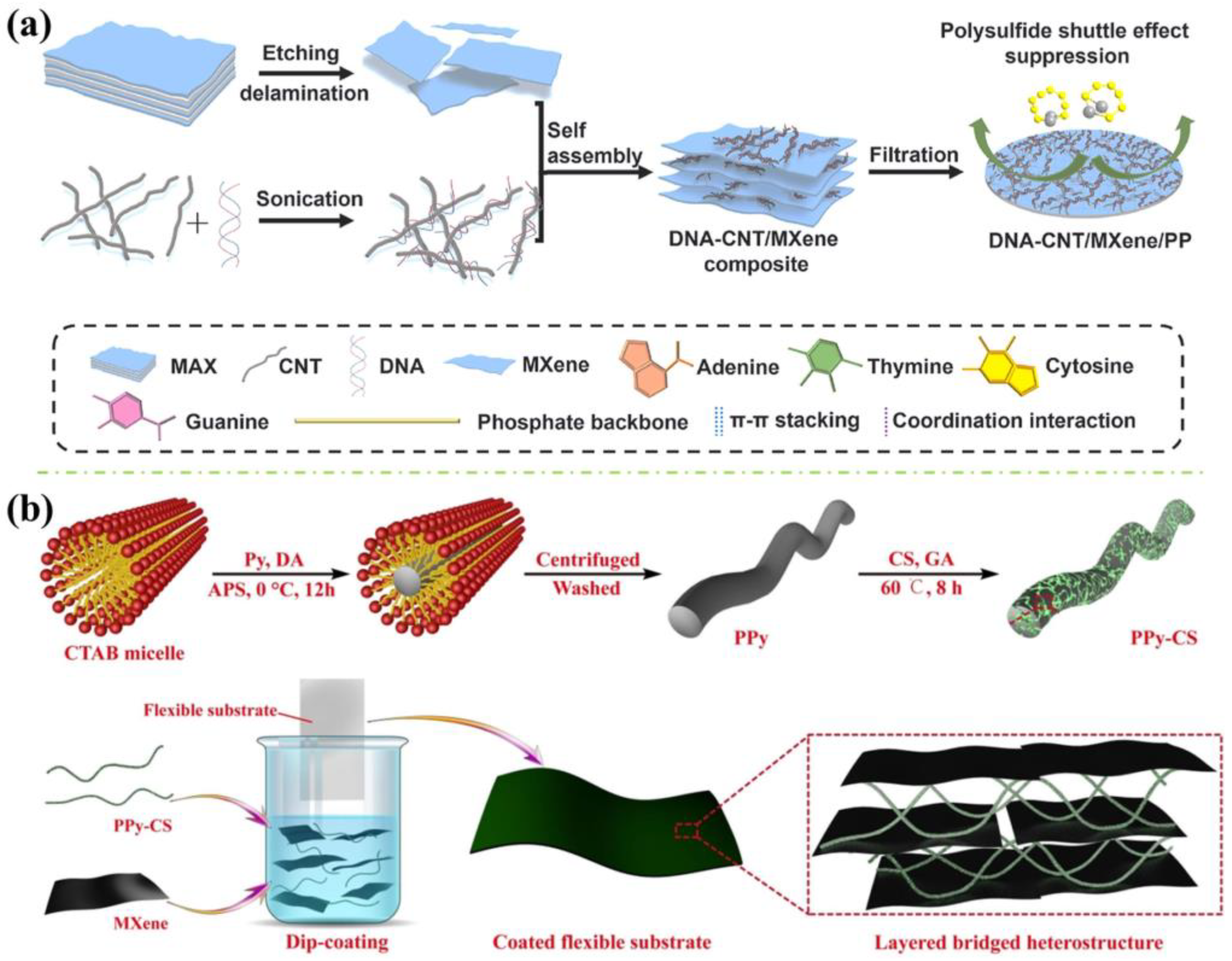

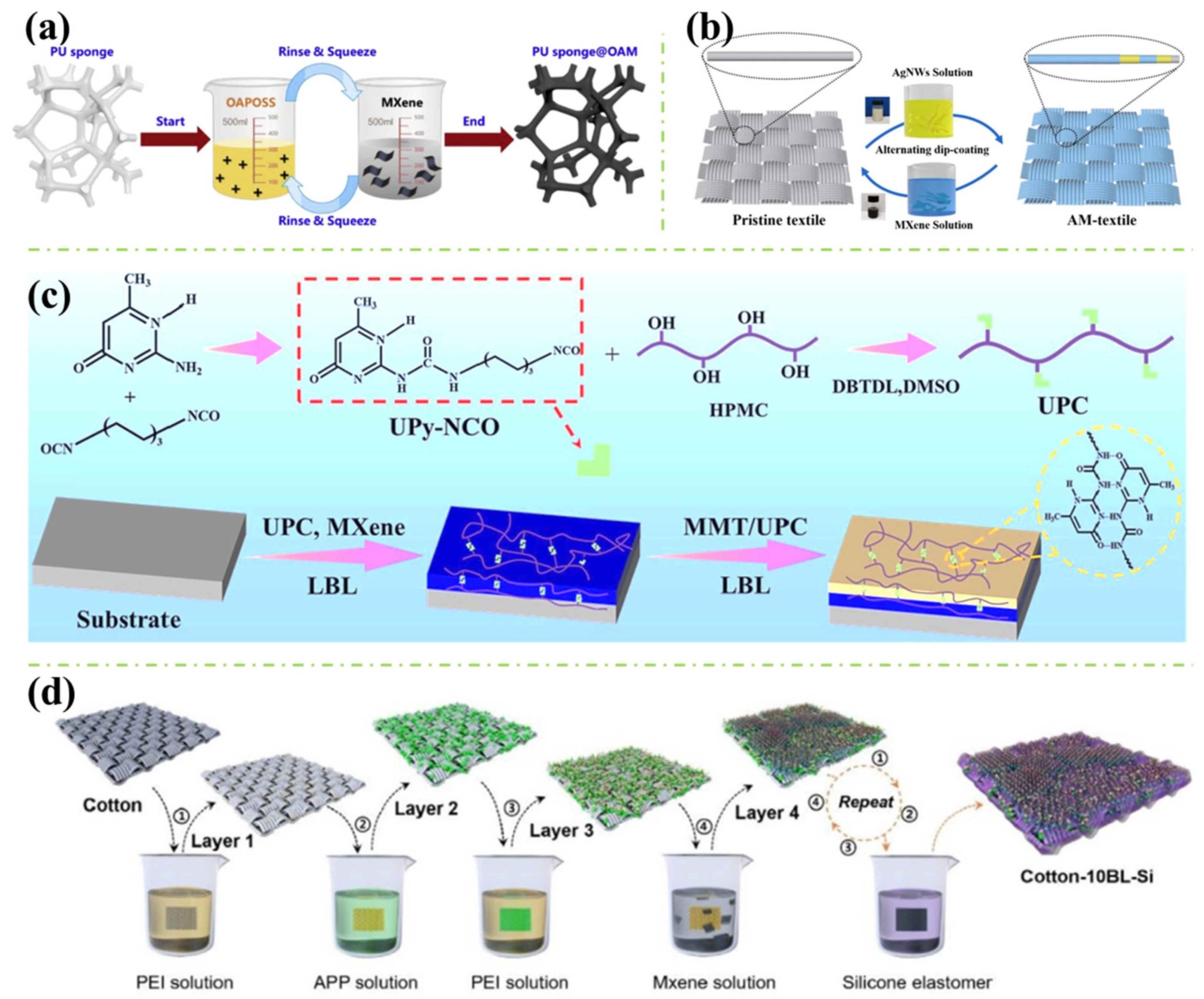

3.3. Multilayer Coatings of Unmodified MXene Overlapping with Other Materials

3.4. Multilayer Coatings of Modified MXene Overlapping with Other Materials

4. Conclusions and Perspectives

Author Contributions

Funding

Conflicts of Interest

References

- Liang, S.; Neisius, N.M.; Gaan, S. Recent developments in flame retardant polymeric coatings. Prog. Org. Coat. 2013, 76, 1642–1665. [Google Scholar] [CrossRef]

- Yang, Y.; Yu, G.; Cha, J.J.; Wu, H.; Vosgueritchian, M.; Yao, Y.; Bao, Z.; Cui, Y. Improving the performance of lithium-sulfur batteries by conductive polymer coating. ACS Nano 2011, 5, 9187–9193. [Google Scholar] [CrossRef] [PubMed]

- Xue, P.; Tao, X.M.; Kwok, K.W.Y.; Leung, M.Y.; Yu, T.X. Electromechanical behavior of fibers coated with an electrically conductive polymer. Text. Res. J. 2016, 74, 929–936. [Google Scholar] [CrossRef]

- Idumah, C.I.; Obele, C.M.; Emmanuel, E.O.; Hassan, A. Recently emerging nanotechnological advancements in polymer nanocomposite coatings for anti-corrosion, anti-fouling and self-healing. Surf. Interfaces 2020, 21, 100734. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Zhang, M.; Cui, Y.; Bao, D.; Peng, J.; Gao, Y.; Lin, D.; Geng, H.; Zhu, Y.; Wang, H. A novel polymer composite coating with high thermal conductivity and unique anti-corrosion performance. Chem. Eng. J. 2022, 439, 135660. [Google Scholar] [CrossRef]

- Ma, S.; Ma, M.; Huang, Z.; Hu, Y.; Shao, Y. Research on the improvement of rainfall infiltration behavior of expansive soil slope by the protection of polymer waterproof coating. Soils Found. 2023, 63, 101299. [Google Scholar] [CrossRef]

- Jinno, H.; Fukuda, K.; Xu, X.; Park, S.; Suzuki, Y.; Koizumi, M.; Yokota, T.; Osaka, I.; Takimiya, K.; Someya, T. Stretchable and waterproof elastomer-coated organic photovoltaics for washable electronic textile applications. Nat. Energy 2017, 2, 780–785. [Google Scholar] [CrossRef]

- He, X.; Wu, J.; Huang, X.; Chen, Y.; Zhang, L.; Sheng, X. Three-in-one polymer nanocomposite coating via constructing tannic acid functionalized MXene/BP hybrids with superior corrosion resistance, friction resistance, and flame-retardancy. Chem. Eng. Sci. 2024, 283, 119429. [Google Scholar] [CrossRef]

- Bedel, V.; Lonjon, A.; Dantras, É.; Bouquet, M. Innovative conductive polymer composite coating for aircrafts lightning strike protection. J. Appl. Polym. Sci. 2020, 137, 48700. [Google Scholar] [CrossRef]

- Zhang, N.; Yang, F.; Li, L.; Shen, C.; Castro, J.; Lee, L.J. Thickness effect on particle erosion resistance of thermoplastic polyurethane coating on steel substrate. Wear 2013, 303, 49–55. [Google Scholar] [CrossRef]

- Duan, S.; Wang, Z.; Zhang, L.; Liu, J.; Li, C. Three-dimensional highly stretchable conductors from elastic fiber mat with conductive polymer coating. ACS Appl. Mater. Interfaces 2017, 9, 30772–30778. [Google Scholar] [CrossRef]

- Ates, M. A review on conducting polymer coatings for corrosion protection. J. Adhes. Sci. Technol. 2016, 30, 1510–1536. [Google Scholar] [CrossRef]

- Zhang, S.; Jiang, Y.; Sun, Y.; Sun, J.; Xu, B.; Li, H.; Gu, X. Preparation of flame retardant and conductive epoxy resin composites by incorporating functionalized multi-walled carbon nanotubes and graphite sheets. Polym. Adv. Technol. 2021, 32, 2093–2101. [Google Scholar] [CrossRef]

- Yang, Z.; Guo, W.; Yang, P.; Hu, J.; Duan, G.; Liu, X.; Gu, Z.; Li, Y. Metal-phenolic network green flame retardants. Polymer 2021, 221, 123627. [Google Scholar] [CrossRef]

- Kundu, C.K.; Li, Z.; Khan, M.A.R.; Försth, M.; Das, O. Polypyrrole-modified multi-functional coatings for improved electro-conductive, hydrophilic and flame-retardant properties of polyamide 66 textiles. J. Coat. Technol. Res. 2023, 20, 1223–1234. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, B.-W.; Wang, Y.-Z.; Fu, T.; Zhao, H.-B. P-doped PANI/AgMWs nano/micro coating towards high-efficiency flame retardancy and electromagnetic interference shielding. Compos. Part B Eng. 2022, 238, 109944. [Google Scholar] [CrossRef]

- Liu, B.W.; Zhao, H.B.; Wang, Y.Z. Advanced flame-retardant methods for polymeric materials. Adv. Mater. 2022, 34, e2107905. [Google Scholar] [CrossRef]

- Naguib, M.; Mashtalir, O.; Carle, J.; Presser, V.; Lu, J.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-dimensional transition metal carbides. ACS Nano 2012, 6, 1322–1331. [Google Scholar] [CrossRef]

- Naguib, M.; Halim, J.; Lu, J.; Cook, K.M.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. New two-dimensional niobium and vanadium carbides as promising materials for Li-ion batteries. J. Am. Chem. Soc. 2013, 135, 15966–15969. [Google Scholar] [CrossRef]

- Jia, L.; Zhou, S.; Ahmed, A.; Yang, Z.; Liu, S.; Wang, H.; Li, F.; Zhang, M.; Zhang, Y.; Sun, L. Tuning MXene electrical conductivity towards multifunctionality. Chem. Eng. J. 2023, 475, 146361. [Google Scholar] [CrossRef]

- Lin, B.; Yuen, A.C.Y.; Chen, T.B.Y.; Yu, B.; Yang, W.; Zhang, J.; Yao, Y.; Wu, S.; Wang, C.H.; Yeoh, G.H. Experimental and numerical perspective on the fire performance of MXene/Chitosan/Phytic acid coated flexible polyurethane foam. Sci. Rep. 2021, 11, 4684. [Google Scholar] [CrossRef]

- Lin, B.; Yuen, A.C.Y.; Oliver, S.; Liu, J.; Yu, B.; Yang, W.; Wu, S.; Yeoh, G.H.; Wang, C.H. Dual functionalisation of polyurethane foam for unprecedented flame retardancy and antibacterial properties using layer-by-layer assembly of MXene chitosan with antibacterial metal particles. Compos. Part B Eng. 2022, 244, 110147. [Google Scholar] [CrossRef]

- Lin, B.; Yuen, A.C.Y.; Li, A.; Zhang, Y.; Chen, T.B.Y.; Yu, B.; Lee, E.W.M.; Peng, S.; Yang, W.; Lu, H.D.; et al. MXene/chitosan nanocoating for flexible polyurethane foam towards remarkable fire hazards reductions. J. Hazard. Mater. 2020, 381, 120952. [Google Scholar] [CrossRef]

- Gong, K.; Yin, L.; Pan, H.; Mao, S.; Liu, L.; Zhou, K. Novel exploration of the flame retardant potential of bimetallic MXene in epoxy composites. Compos. Part B Eng. 2022, 237, 109862. [Google Scholar] [CrossRef]

- Ling, Z.; Ren, C.E.; Zhao, M.Q.; Yang, J.; Giammarco, J.M.; Qiu, J.; Barsoum, M.W.; Gogotsi, Y. Flexible and conductive MXene films and nanocomposites with high capacitance. Proc. Natl. Acad. Sci. USA 2014, 111, 16676–16681. [Google Scholar] [CrossRef]

- Raagulan, K.; Braveenth, R.; Jang, H.J.; Seon Lee, Y.; Yang, C.M.; Mi Kim, B.; Moon, J.J.; Chai, K.Y. Electromagnetic Shielding by MXene-Graphene-PVDF Composite with Hydrophobic, Lightweight and Flexible Graphene Coated Fabric. Materials 2018, 11, 1803. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Zhang, H.B.; Xie, X.; Yang, R.; Liu, Z.; Liu, Y.; Yu, Z.Z. Multifunctional, Superelastic, and Lightweight MXene/Polyimide Aerogels. Small 2018, 14, e1802479. [Google Scholar] [CrossRef] [PubMed]

- Jin, X.; Wang, J.; Dai, L.; Liu, X.; Li, L.; Yang, Y.; Cao, Y.; Wang, W.; Wu, H.; Guo, S. Flame-retardant poly(vinyl alcohol)/MXene multilayered films with outstanding electromagnetic interference shielding and thermal conductive performances. Chem. Eng. J. 2020, 380, 122475. [Google Scholar] [CrossRef]

- Mao, M.; Yu, K.-X.; Cao, C.-F.; Gong, L.-X.G.; Zhang, G.-D.; Zhao, L.Z.; Song, P.; Gao, J.-F.; Tang, L.-C. Facile and green fabrication of flame-retardant Ti3C2Tx MXene networks for ultrafast, reusable and weather-resistant fire warning. Chem. Eng. J. 2022, 427, 131615. [Google Scholar] [CrossRef]

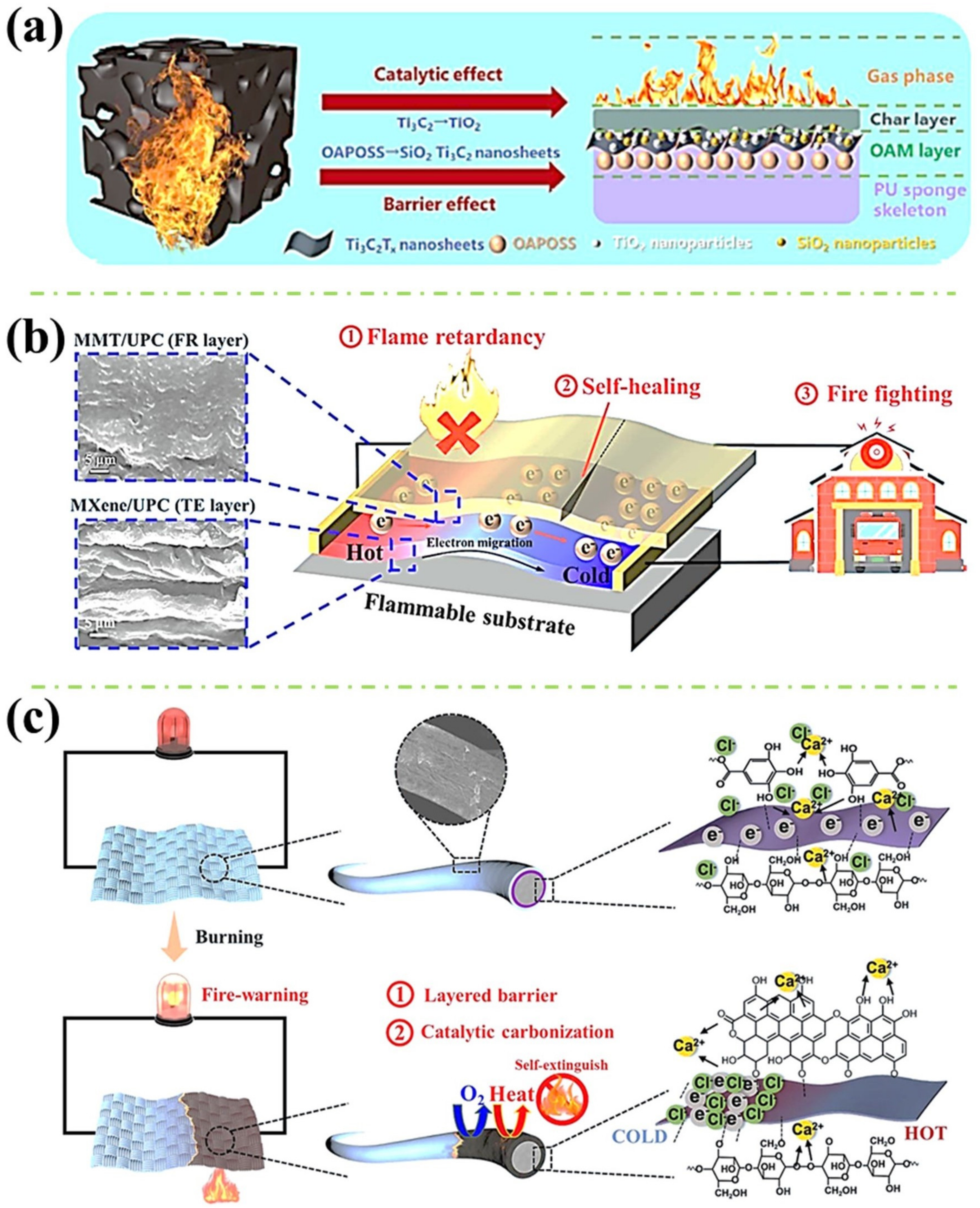

- Wang, X.; Lei, Z.; Ma, X.; He, G.; Xu, T.; Tan, J.; Wang, L.; Zhang, X.; Qu, L.; Zhang, X. A lightweight MXene-coated nonwoven fabric with excellent flame retardancy, EMI Shielding, and electrothermal/photothermal conversion for wearable heater. Chem. Eng. J. 2022, 430, 132605. [Google Scholar] [CrossRef]

- He, G.F.; Wang, L.L.; Bao, X.J.; Lei, Z.W.; Ning, F.G.; Li, M.; Zhang, X.S.; Qu, L.J. Synergistic flame retardant weft-knitted alginate/viscose fabrics with MXene coating for multifunctional wearable heaters. Compos. Part B Eng. 2022, 232, 109618. [Google Scholar] [CrossRef]

- Liu, X.Y.; Jin, X.X.; Li, L.; Wang, J.F.; Yang, Y.Y.; Cao, Y.X.; Wang, W.J. Air-permeable, multifunctional, dual-energy-driven MXene-decorated polymeric textile-based wearable heaters with exceptional electrothermal and photothermal conversion performance. J. Mater. Chem. A 2020, 8, 12526–12537. [Google Scholar] [CrossRef]

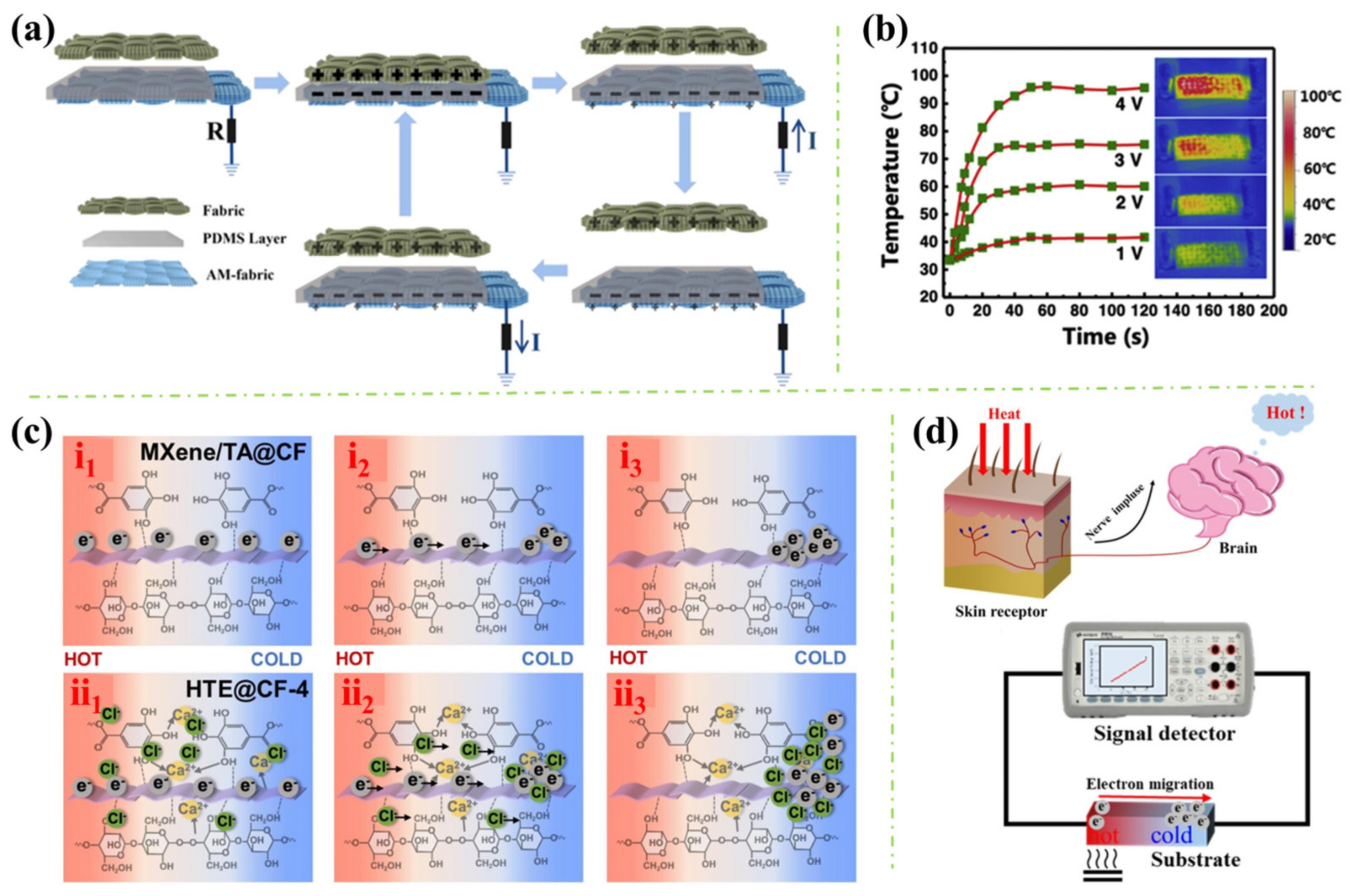

- Jiang, C.C.; Chen, J.Y.; Lai, X.J.; Li, H.Q.; Zeng, X.R.; Zhao, Y.N.; Zeng, Q.T.; Gao, J.F.; Wu, Z.Z.; Qiu, Y.K. Mechanically robust and multifunctional polyimide/MXene composite aerogel for smart fire protection. Chem. Eng. J. 2022, 434, 134630. [Google Scholar] [CrossRef]

- Hou, Y.; Huang, Z.D.; Chen, Z.; Li, X.L.; Chen, A.; Li, P.; Wang, Y.B.; Zhi, C.Y. Bifunctional separators design for safe lithium-ion batteries: Suppressed lithium dendrites and fire retardance. Nano Energy 2022, 97, 107204. [Google Scholar] [CrossRef]

- Yu, B.; Tawiah, B.; Wang, L.Q.; Yin Yuen, A.C.; Zhang, Z.C.; Shen, L.L.; Lin, B.; Fei, B.; Yang, W.; Li, A.; et al. Interface decoration of exfoliated MXene ultra-thin nanosheets for fire and smoke suppressions of thermoplastic polyurethane elastomer. J. Hazard. Mater. 2019, 374, 110–119. [Google Scholar] [CrossRef]

- Shi, Y.Q.; Liu, C.; Duan, Z.P.; Yu, B.; Liu, M.H.; Song, P.A. Interface engineering of MXene towards super-tough and strong polymer nanocomposites with high ductility and excellent fire safety. Chem. Eng. J. 2020, 399, 125829. [Google Scholar] [CrossRef]

- Li, Y.; Li, M.; Zhu, Y.-C.; Song, S.; Li, S.-N.; Aarons, J.; Tang, L.-C.; Bae, J. Polysulfide-inhibiting, thermotolerant and nonflammable separators enabled by DNA co-assembled CNT/MXene networks for stable high-safety Li–S batteries. Compos. Part B Eng. 2023, 251, 110465. [Google Scholar] [CrossRef]

- Xie, H.; Li, K.; Nian, J.; Zheng, J.; Lai, X.; Wu, W.; Su, X.; Wu, Y.; Zhang, X. A flexible thermoelectric nanocoating with layered bridged heterostructure for sensitive thermosensation and high fire safety. Compos. Part A Appl. Sci. Manuf. 2023, 166, 107385. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, Q.; Zhang, S.; Fan, X.; Qin, J.; Shi, X.; Zhang, G. rGO/MXene sandwich-structured film at spunlace non-woven fabric substrate: Application to EMI shielding and electrical heating. J. Colloid Interface Sci. 2022, 614, 194–204. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.Y.; Dai, Z.H.; Zhang, Y.F.; Zhang, W.W.; Gu, J.; Hu, C.S.; Lin, X.Y. Multifunctional waterproof MXene-coated wood with high electromagnetic shielding performance. Cellulose 2022, 29, 5883–5893. [Google Scholar] [CrossRef]

- Jia, X.C.; Shen, B.; Zhang, L.H.; Zheng, W.G. Waterproof MXene-decorated wood-pulp fabrics for high-efficiency electromagnetic interference shielding and Joule heating. Compos. Part B Eng. 2020, 198, 108250. [Google Scholar] [CrossRef]

- Wang, B.; Jia, P.; He, R.; Song, L.; Hu, Y. Multilayer joule heating and electromagnetic interference shielding composite fabric with high interfacial durability. J. Colloid Interface Sci. 2023, 633, 1069–1082. [Google Scholar] [CrossRef]

- Zhao, W.L.; Zheng, Y.Q.; Qian, J.N.; Zhaofa, Z.; Jin, Z.M.; Qiu, H.B.; Zhu, C.Y.; Hong, X.H. AgNWs/MXene derived multifunctional knitted fabric capable of high electrothermal conversion efficiency, large strain and temperature sensing, and EMI shielding. J. Alloys Compd. 2022, 923, 166471. [Google Scholar] [CrossRef]

- Cheng, W.; Zhang, Y.; Tao, Y.; Lu, J.; Liu, J.; Wang, B.; Song, L.; Jie, G.; Hu, Y. Durable electromagnetic interference (EMI) shielding ramie fabric with excellent flame retardancy and Self-healing performance. J. Colloid Interface Sci. 2021, 602, 810–821. [Google Scholar] [CrossRef]

- Cheng, W.H.; Zhang, Y.; Tian, W.X.; Liu, J.J.; Lu, J.Y.; Wang, B.B.; Xing, W.Y.; Hu, Y. Highly efficient MXene-coated flame retardant cotton fabric for electromagnetic interference shielding. Ind. Eng. Chem. Res. 2020, 59, 14025–14036. [Google Scholar] [CrossRef]

- Lu, J.Y.; Liao, C.; Cheng, L.; Jia, P.F.; Yin, Z.T.; Song, L.; Wang, B.B.; Hu, Y. Cleaner production to a multifunctional polyurethane sponge with high fire safety and low toxicity release. J. Clean. Prod. 2022, 333, 130172. [Google Scholar] [CrossRef]

- Liu, X.Y.; Du, X.Y.; Li, L.; Cao, Y.X.; Yang, Y.Y.; Wang, W.J.; Wang, J.F. Multifunctional AgNW@MXene decorated polymeric textile for highly-efficient electro-/photothermal conversion and triboelectric nanogenerator. Compos. Part A Appl. Sci. Manuf. 2022, 156, 106883. [Google Scholar] [CrossRef]

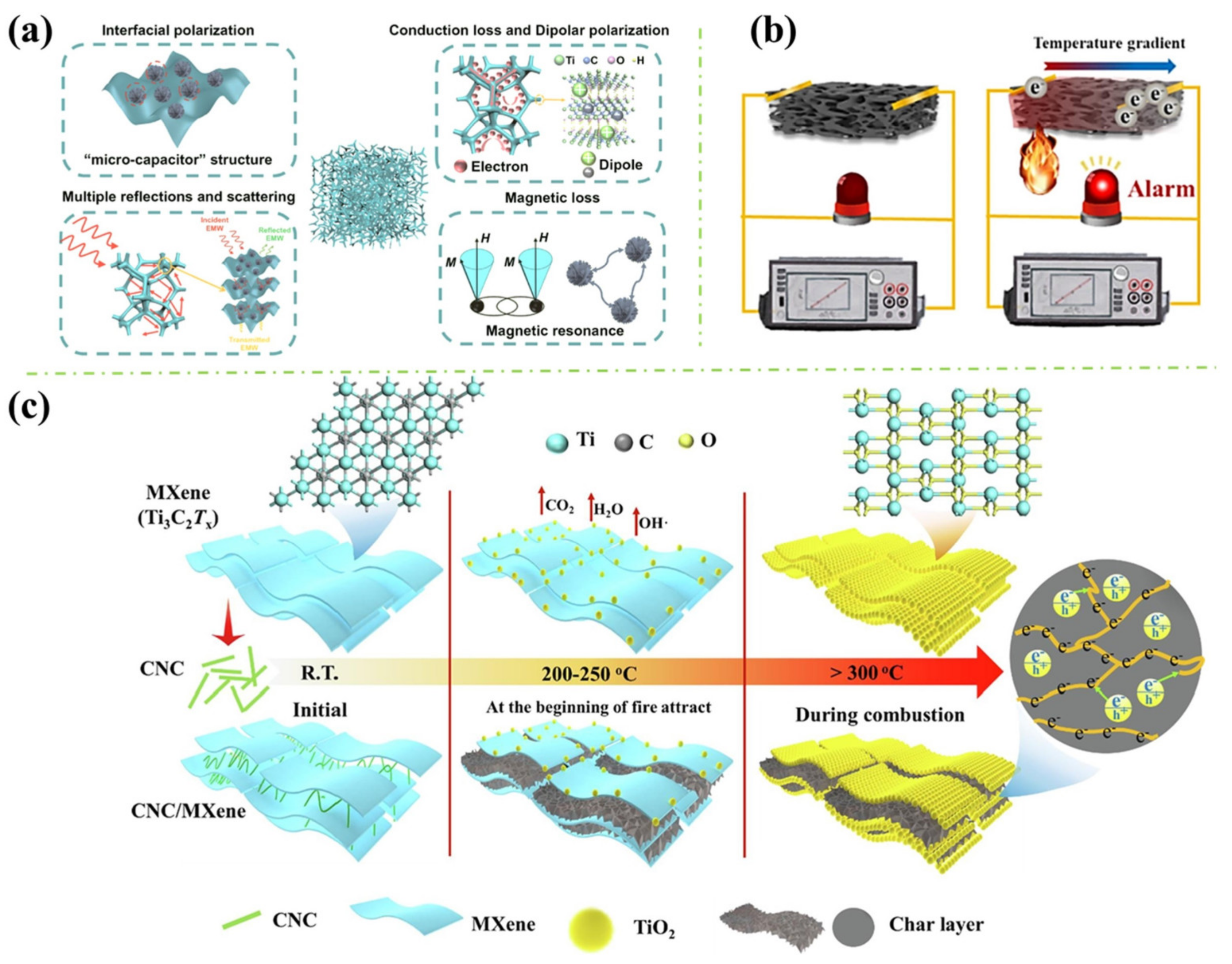

- Zeng, Q.T.; Zhao, Y.; Lai, X.J.; Jiang, C.C.; Wang, B.L.; Li, H.Q.; Zeng, X.R.; Chen, Z.H. Skin-inspired multifunctional MXene/cellulose nanocoating for smart and efficient fire protection. Chem. Eng. J. 2022, 446, 136899. [Google Scholar] [CrossRef]

- Liu, L.; Ma, Z.; Zhu, M.; Liu, L.; Dai, J.; Shi, Y.; Gao, J.; Dinh, T.; Nguyen, T.; Tang, L.-C.; et al. Superhydrophobic self-extinguishing cotton fabrics for electromagnetic interference shielding and human motion detection. J. Mater. Sci. Technol. 2023, 132, 59–68. [Google Scholar] [CrossRef]

- Wang, B.; Lai, X.; Li, H.; Jiang, C.; Gao, J.; Zeng, X. Multifunctional MXene/chitosan-coated cotton fabric for intelligent fire protection. ACS Appl. Mater. Interfaces 2021, 13, 23020–23029. [Google Scholar] [CrossRef]

- Lan, C.; Jia, H.; Qiu, M.; Fu, S. Ultrathin MXene/polymer coatings with an alternating structure on fabrics for enhanced electromagnetic interference shielding and fire-resistant protective performances. ACS Appl. Mater. Interfaces 2021, 13, 38761–38772. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Yin, Z.; Cheng, W.; Zhang, Y.; Hu, Y. Flame-retardant aramid fabric with durable, self-cleaning, hydrophobic, and tunable electromagnetic interference shielding properties. Compos. Part A Appl. Sci. Manuf. 2023, 166, 107392. [Google Scholar] [CrossRef]

- Zeng, Q.; Wang, B.; Lai, X.; Li, H.; Chen, Z.; Xie, H.; Zeng, X. Multifunctional MXene-coated cotton fabric with enhanced thermopower for smart fire protection. Compos. Part A Appl. Sci. Manuf. 2023, 164, 107305. [Google Scholar] [CrossRef]

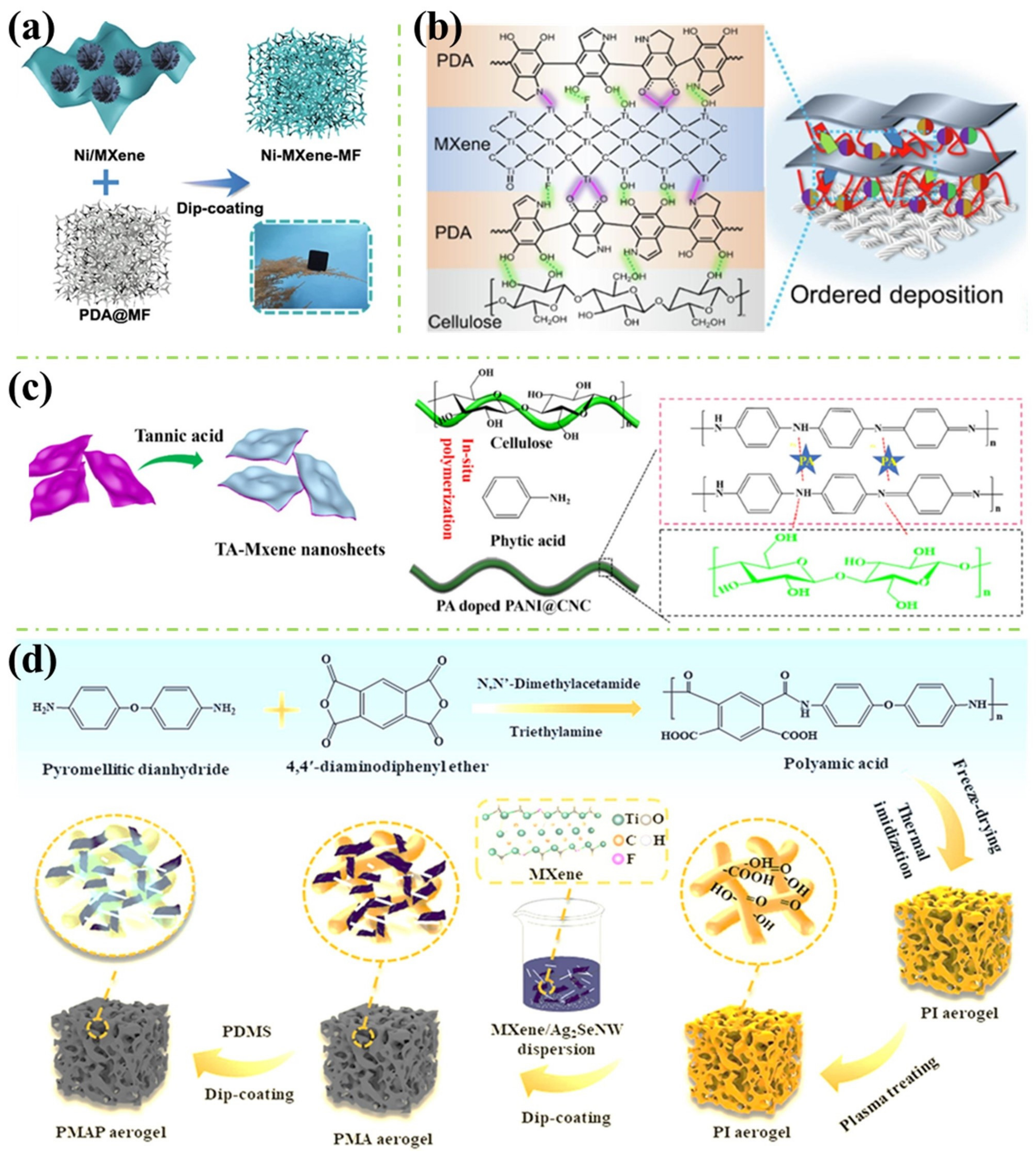

- Cheng, H.; Pan, Y.; Wang, X.; Liu, C.; Shen, C.; Schubert, D.W.; Guo, Z.; Liu, X. Ni flower/MXene-melamine foam derived 3D magnetic/conductive networks for ultra-efficient microwave absorption and infrared stealth. Nano-Micro Lett. 2022, 14, 63. [Google Scholar] [CrossRef] [PubMed]

- Yan, B.; Zhou, M.; Yu, Y.; Xu, B.; Cui, L.; Wang, Q.; Wang, P. Orderly self-stacking a high-stability coating of MXene@Polydopamine hybrid onto textiles for multifunctional personal thermal management. Compos. Part A Appl. Sci. Manuf. 2022, 160, 107038. [Google Scholar] [CrossRef]

- Mao, Y.; Wang, D.; Fu, S. Layer-by-layer self-assembled nanocoatings of Mxene and P, N-co-doped cellulose nanocrystals onto cotton fabrics for significantly reducing fire hazards and shielding electromagnetic interference. Compos. Part A Appl. Sci. Manuf. 2022, 153, 106751. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, J.; Lai, X.; Li, H.; Zeng, X.; Jiang, C.; Zeng, Q.; Li, K.; Wu, Z.; Qiu, Y. Efficient flame-retardant and multifunctional polyimide/MXene composite aerogel for intelligent fire protection. Compos. Part A Appl. Sci. Manuf. 2022, 163, 107210. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, Y.; Li, M.-C.; Zhang, S.; Zhou, W.; Mei, C.; Pan, M. Bioinspired, stable adhesive Ti3C2Tx MXene-based coatings towards fire warning, smoke suppression and VOCs removal smart wood. Chem. Eng. J. 2023, 452, 139360. [Google Scholar] [CrossRef]

- Qu, Y.; Li, X.; Wang, X.; Dai, H. Multifunctional AgNWs@MXene/AgNFs electromagnetic shielding composites for flexible and highly integrated advanced electronics. Compos. Sci. Technol. 2022, 230, 109753. [Google Scholar] [CrossRef]

- Li, X.; Sánchez del Río Saez, J.; Ao, X.; Yusuf, A.; Wang, D.-Y. Highly-sensitive fire alarm system based on cellulose paper with low-temperature response and wireless signal conversion. Chem. Eng. J. 2022, 431, 134108. [Google Scholar] [CrossRef]

| Materials | Modified Methods | Other Materials/Fillers | Reference |

|---|---|---|---|

| Ni flower + MXene | Mix + dip-coat | MF, PDA | [54] |

| CNC + MXene | Mix + LbL | Wood, PDA, APP | [58] |

| MXene | Anneal + LbL | Cellulose paper, AgNFs, AgNWs | [59] |

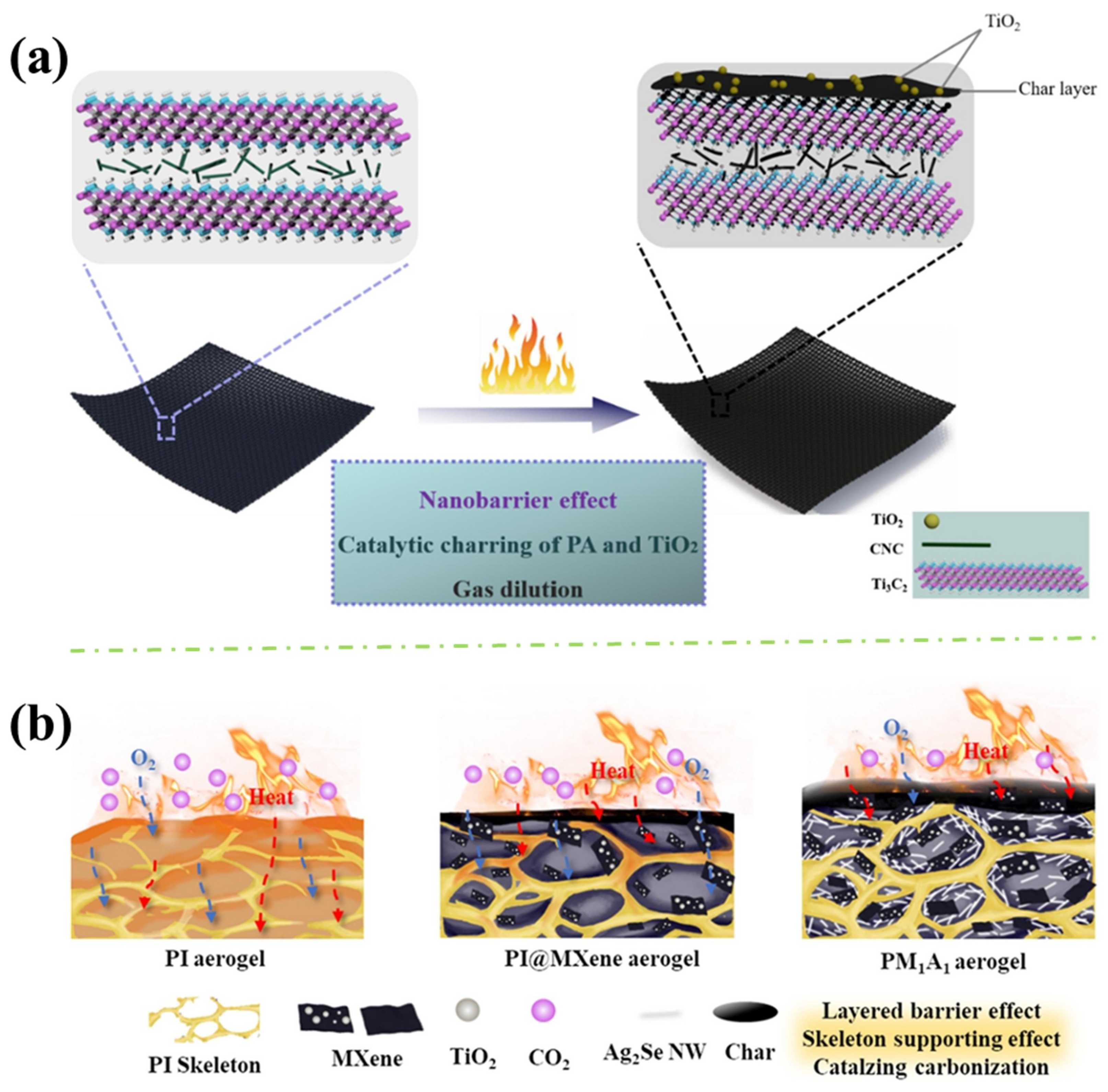

| Ag2Se NW + MXene | Mix + dip-coat | PI-aerogel, PDMS | [57] |

| GO + MXene | Mix + dip-coat | Cellulose paper, PA | [60] |

| TA + MXene | Mix + dip-coat | Cotton, PA, PANI, CNC | [56] |

| PDA + MXene | Mix + dip-coat | Cotton, PDMS | [55] |

| Coating Materials | Fire Safety Properties | Electrical Conductivity | Reference | ||||

|---|---|---|---|---|---|---|---|

| Cone | LOI | UL-94 | |||||

| pHRR Reductions (%) | THR Reductions (%) | TSR Reduction (%) | % | Rating | Coefficient (S/cm) | ||

| MXene | / | / | / | / | / | 2.30 | [30] |

| MXene | 44.97 | 19.43 | / | / | / | 2.40 # | [31] |

| MXene | 78.00 | / | / | 50 | / | 0.17 | [33] |

| PPy-CS + MXene | 43.03 | 42.40 | 42.42 | 26.80 | / | / | [38] |

| AgNWs + MXene | 31.58 * | 9.09 * | / | / | / | 186.00 | [43] |

| PEI/APP + MXene + PCL | 74.30 | 48.40 | / | 36.50 | / | 9.20 | [44] |

| PEI/APP + MXene | / | / | / | 36.50 | / | 6.70 | [45] |

| OAPOSS + MXene | 50.19 | 10.00 | 59.00 | / | / | / | [46] |

| MMT/UPC + MXene/UPC | 23.33 * | / | / | 40.00 | V-0 | / | [48] |

| PEI + APP + PEI + MXene | 42.77 | / | / | 39.50 | V-0 | 777.00 | [49] |

| CCS + MXene | 66.00 | / | / | 45.50 | / | 0.20 | [50] |

| PEI + MXene | 34.39 | 34.88 | / | / | / | 11.75 # | [51] |

| Fe3O4 nanoparticles + MXene | 11.00 | 1.61 | / | 30.00 | Pass | 1.90 | [52] |

| TA/CaCl2 + MXene | 84.65 | 74.00 | / | 35.30 | / | / | [53] |

| PA/PANI/CNC + TA/MXene | 63.00 | 31.42 | 98.29 | 32.00 | / | 1.42 | [56] |

| MXene/Ag2SeNWs + PDMS | 66.07 | / | / | 53.00 | / | / | [57] |

| PDA + APP +CNC/MXene | 41.73 | 19.02 | 33.23 | 47.40 | V-0 | / | [58] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, B.; Li, A.; De Cachinho Cordeiro, I.M.; Jia, M.; Lee, Y.X.; Yuen, A.C.Y.; Wang, C.; Wang, W.; Yeoh, G.H. MXene Based Flame Retardant and Electrically Conductive Polymer Coatings. Polymers 2024, 16, 2461. https://doi.org/10.3390/polym16172461

Lin B, Li A, De Cachinho Cordeiro IM, Jia M, Lee YX, Yuen ACY, Wang C, Wang W, Yeoh GH. MXene Based Flame Retardant and Electrically Conductive Polymer Coatings. Polymers. 2024; 16(17):2461. https://doi.org/10.3390/polym16172461

Chicago/Turabian StyleLin, Bo, Ao Li, Ivan Miguel De Cachinho Cordeiro, Ming Jia, Yuan Xien Lee, Anthony Chun Yin Yuen, Cheng Wang, Wei Wang, and Guan Heng Yeoh. 2024. "MXene Based Flame Retardant and Electrically Conductive Polymer Coatings" Polymers 16, no. 17: 2461. https://doi.org/10.3390/polym16172461