Sandwich-Structured Carbon Nanotube Composite Films for Multifunctional Sensing and Electrothermal Application

Abstract

:1. Introduction

2. Experimental Materials and Methods

2.1. Materials

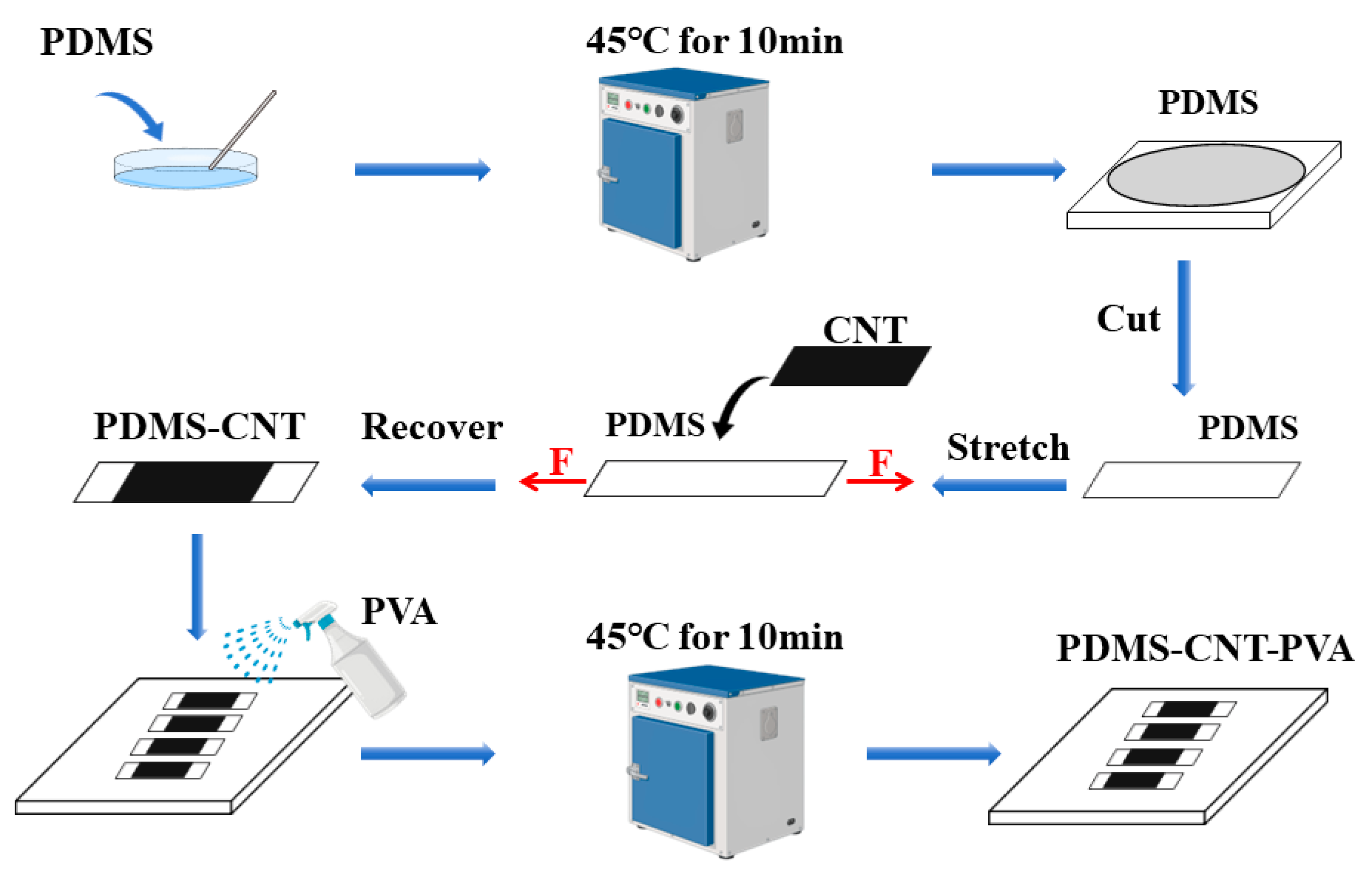

2.2. Preparation of PDMS-CNTs-PVA Films

2.3. Characterization

3. Results and Discussions

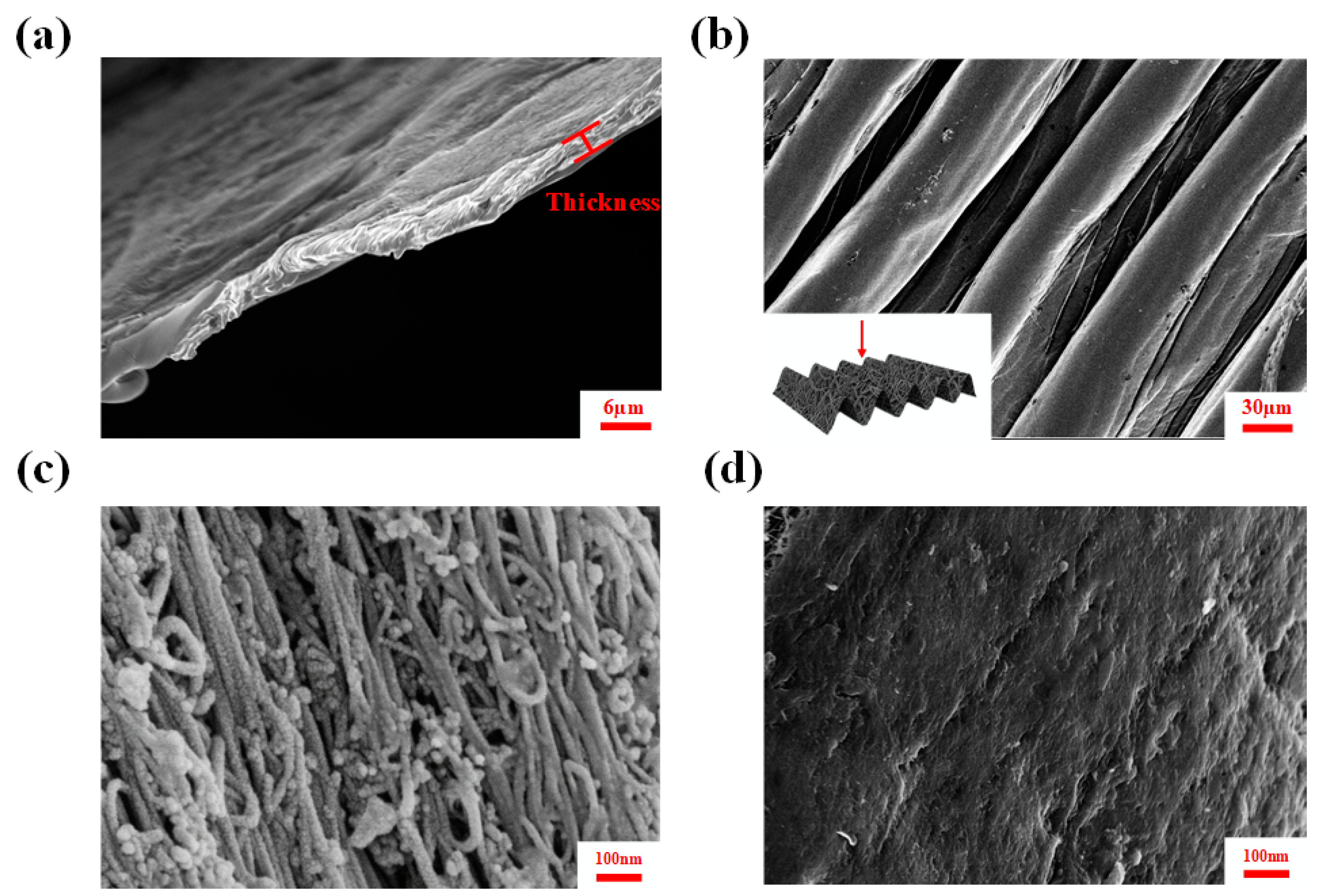

3.1. Morphologies

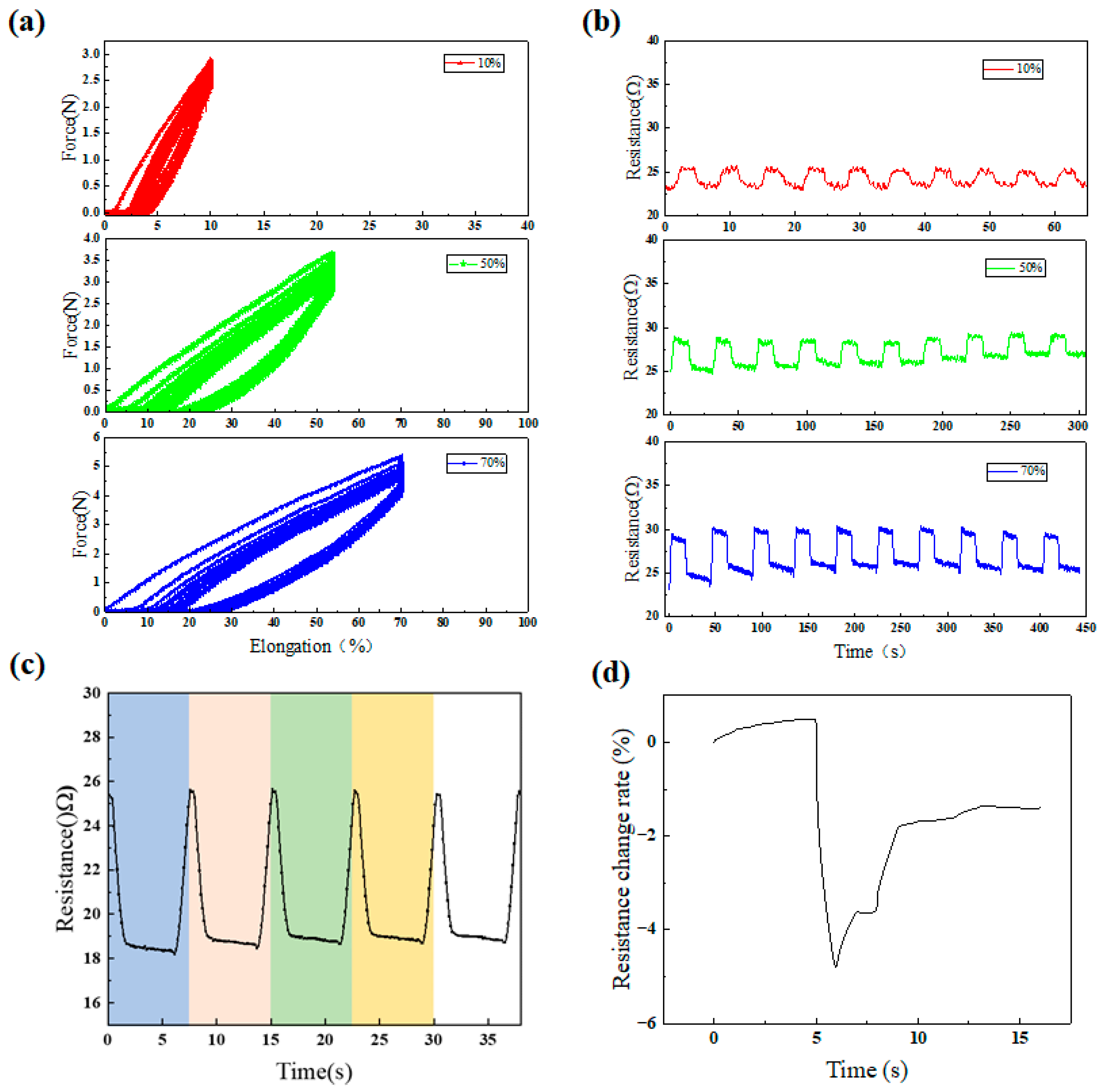

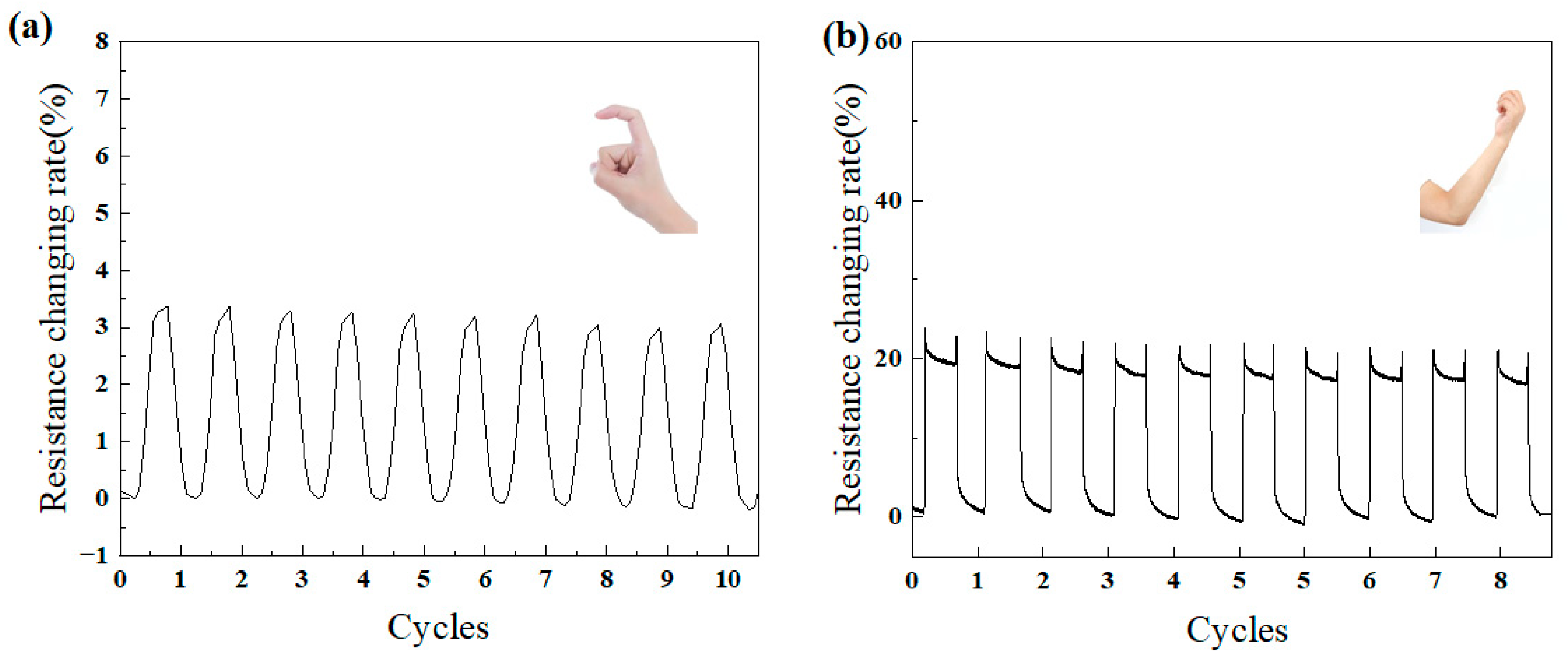

3.2. Electrical Behavior and Sensing Properties of PDMS-CNTs-PVA Composite Films

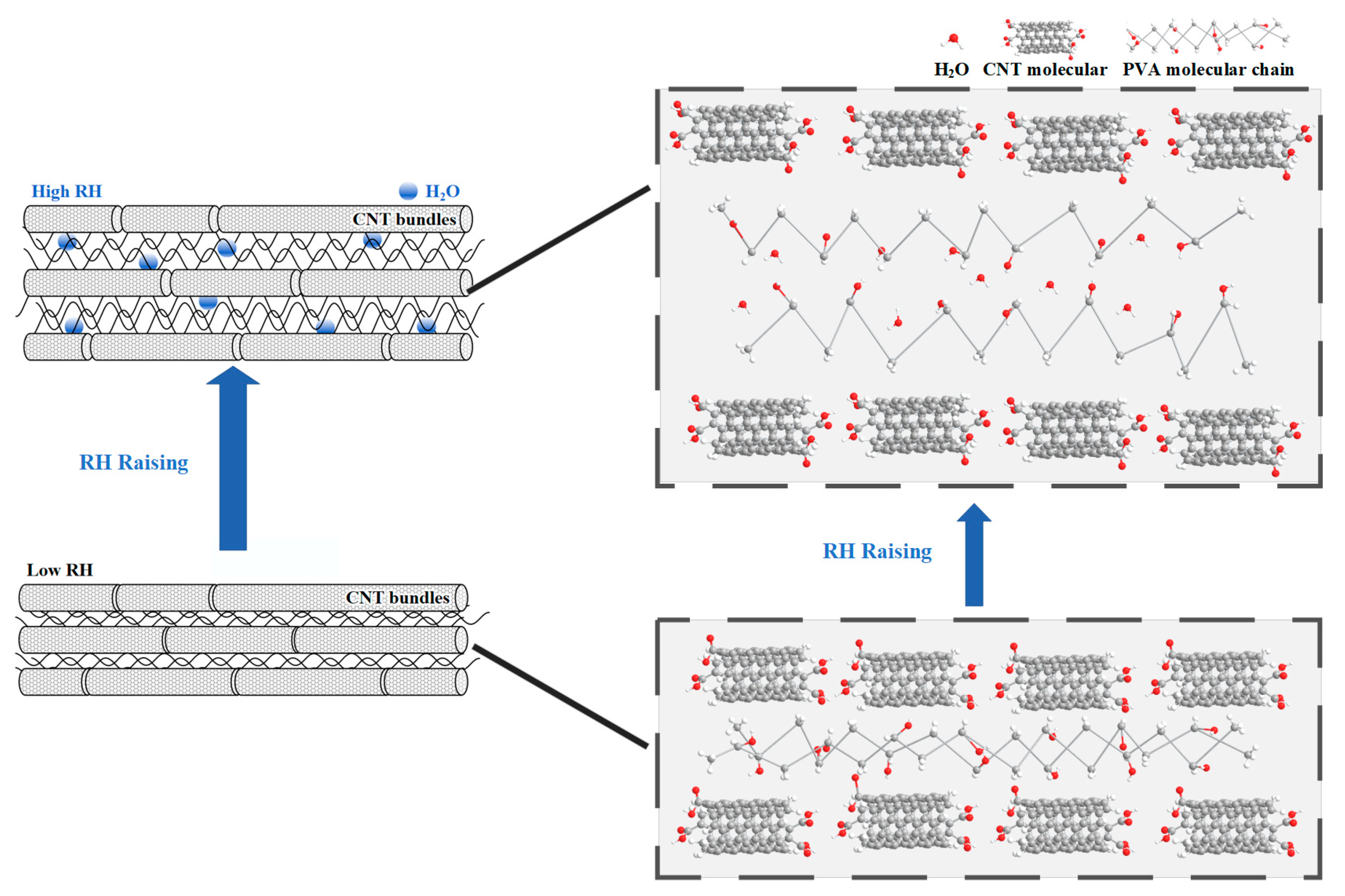

3.3. Water-Sensing Properties

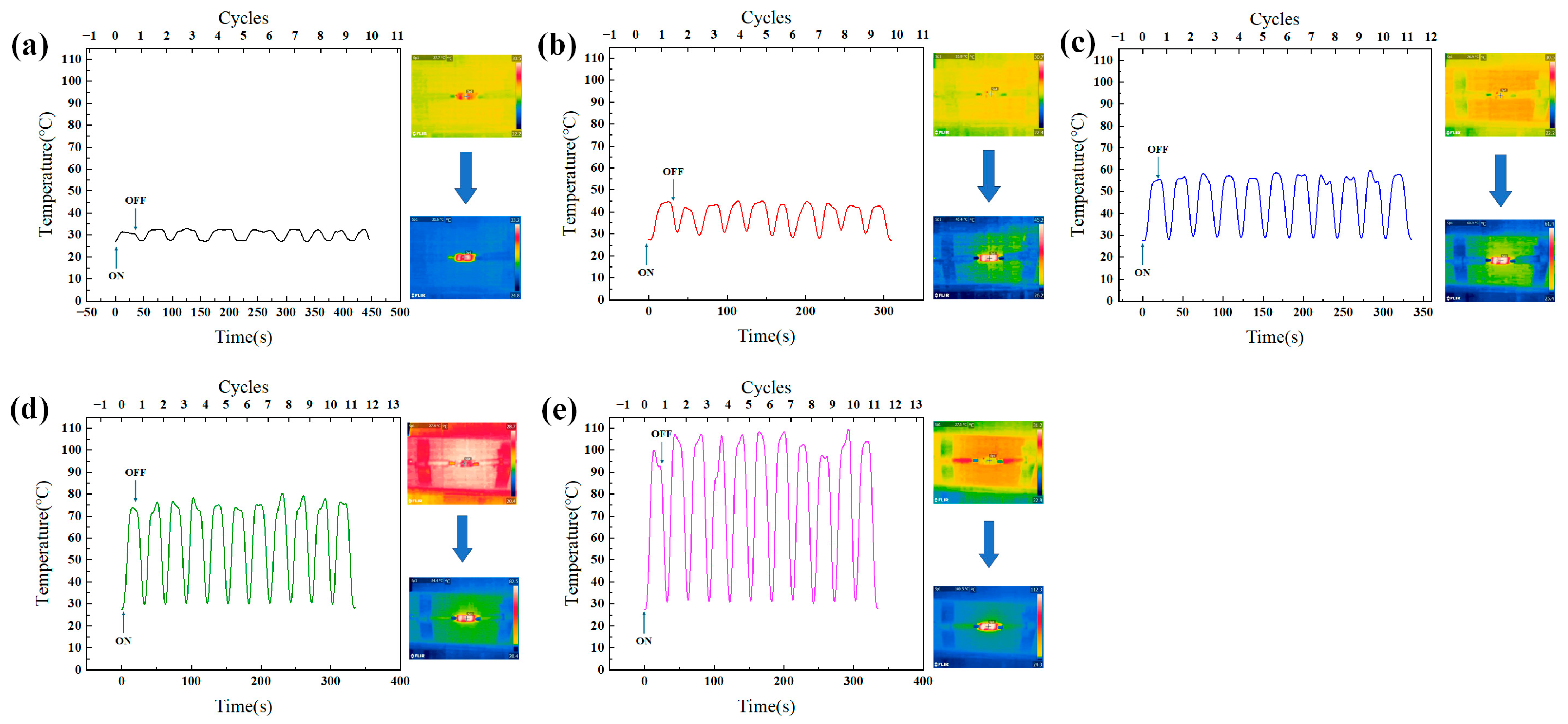

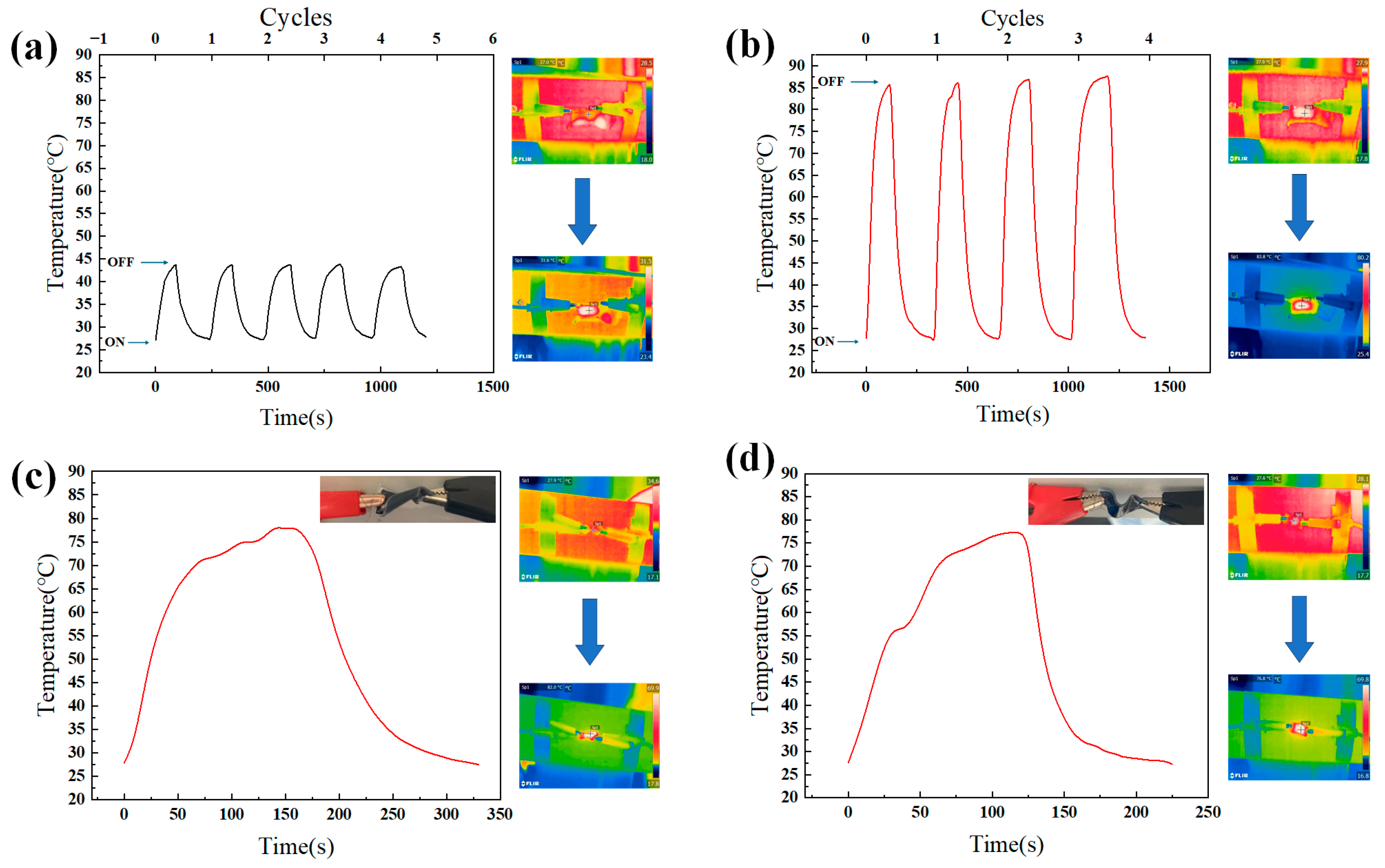

3.4. Electrothermal Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gillan, L.; Hiltunen, J.; Behfar, M.H.; Rönkä, K. Advances in Design and Manufacture of Stretchable Electronics. Jpn. J. Appl. Phys. 2022, 61, SE0804. [Google Scholar] [CrossRef]

- Seager, R.D.; Chauraya, A.; Zhang, S.; Whittow, W.; Vardaxoglou, Y. Flexible Radio Frequency Connectors for Textile Electronics. Electron. Lett. 2013, 49, 1371–1373. [Google Scholar] [CrossRef]

- Mo, R. Functional Nanomaterial-Based Flexible Electronics. Coatings 2022, 12, 809. [Google Scholar] [CrossRef]

- Hussain, T.; Ullah, S.; Fernández-García, R.; Gil, I. Wearable Sensors for Respiration Monitoring: A Review. Sensors 2023, 23, 7518. [Google Scholar] [CrossRef] [PubMed]

- Akagi, T.; Dohta, S.; Morimoto, T.; Matsui, Y.; Shimooka, S. Development of Compact Flexible Displacement Sensors Using Ultrasonic Sensor for Wearable Actuators. MATEC Web Conf. 2016, 51, 02002. [Google Scholar] [CrossRef]

- Chae, H.S.; Cho, W.J.; Kim, S.H.; Han, K.H. Usability Studies on Sensor Smart Clothing. In Human-Computer Interaction. Ambient, Ubiquitous and Intelligent Interaction; Jacko, J.A., Ed.; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2009; Volume 5612, pp. 725–730. ISBN 978-3-642-02579-2. [Google Scholar]

- Oh, J.Y.; Bao, Z. Second Skin Enabled by Advanced Electronics. Adv. Sci. 2019, 6, 1900186. [Google Scholar] [CrossRef]

- Froyen, A.A.F.; Schenning, A.P.H.J. A Multifunctional Structural Coloured Electronic Skin Monitoring Body Motion and Temperature. Soft Matter 2023, 19, 361–365. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Chai, Y. Design and Applications of Graphene-Based Flexible and Wearable Physical Sensing Devices. 2D Mater. 2021, 8, 022001. [Google Scholar] [CrossRef]

- An, N.; Qin, J.; Zhou, X.; Wang, Q.; Fang, C.; Guo, J.; Nan, B. Recent Progress in Cellulose-Based Flexible Sensors. J. Renew. Mater. 2022, 10, 2319–2334. [Google Scholar] [CrossRef]

- El Gharbi, M.; Fernández-García, R.; Ahyoud, S.; Gil, I. A Review of Flexible Wearable Antenna Sensors: Design, Fabrication Methods, and Applications. Materials 2020, 13, 3781. [Google Scholar] [CrossRef]

- Guk, K.; Han, G.; Lim, J.; Jeong, K.; Kang, T.; Lim, E.-K.; Jung, J. Evolution of Wearable Devices with Real-Time Disease Monitoring for Personalized Healthcare. Nanomaterials 2019, 9, 813. [Google Scholar] [CrossRef] [PubMed]

- Dai, B.; Gao, C.; Xie, Y. Flexible Wearable Devices for Intelligent Health Monitoring. View 2022, 3, 20220027. [Google Scholar] [CrossRef]

- Su, Y.; Ma, C.; Chen, J.; Wu, H.; Luo, W.; Peng, Y.; Luo, Z.; Li, L.; Tan, Y.; Omisore, O.M.; et al. Printable, Highly Sensitive Flexible Temperature Sensors for Human Body Temperature Monitoring: A Review. Nanoscale Res. Lett. 2020, 15, 200. [Google Scholar] [CrossRef] [PubMed]

- Nan, X.; Wang, X.; Kang, T.; Zhang, J.; Dong, L.; Dong, J.; Xia, P.; Wei, D. Review of Flexible Wearable Sensor Devices for Biomedical Application. Micromachines 2022, 13, 1395. [Google Scholar] [CrossRef]

- Fang, S.; Wang, R.; Ni, H.; Liu, H.; Liu, L. A Review of Flexible Electric Heating Element and Electric Heating Garments. J. Ind. Text. 2022, 51, 101S–136S. [Google Scholar] [CrossRef]

- Repon, M.R.; Mikučionienė, D. Progress in Flexible Electronic Textile for Heating Application: A Critical Review. Materials 2021, 14, 6540. [Google Scholar] [CrossRef]

- Lin, X.; Ling, Z.; Fang, X.; Zhang, Z. Flexibility and Shape Memory of Phase Change Material Capable of Rapid Electric Heating Function for Wearable Thermotherapy. Appl. Energy 2022, 327, 120141. [Google Scholar] [CrossRef]

- Lim, H.; Kim, H.S.; Qazi, R.; Kwon, Y.; Jeong, J.; Yeo, W. Advanced Soft Materials, Sensor Integrations, and Applications of Wearable Flexible Hybrid Electronics in Healthcare, Energy, and Environment. Adv. Mater. 2020, 32, 1901924. [Google Scholar] [CrossRef]

- Wang, B.; Zhou, W.; Wu, J.; Sun, L.; Wang, M.; Zhang, W. A Phase Change Thermal Storage Material and Its Performance for Floor Electric Heating System. J. Energy Storage 2023, 59, 106518. [Google Scholar] [CrossRef]

- Saito, M.; Kanai, E.; Fujita, H.; Aso, T.; Matsutani, N.; Fujie, T. Flexible Induction Heater Based on the Polymeric Thin Film for Local Thermotherapy. Adv. Funct. Mater. 2021, 31, 2102444. [Google Scholar] [CrossRef]

- Rothmaier, M.; Luong, M.P.; Clemens, F. Textile Pressure Sensor Made of Flexible Plastic Optical Fibers. Sensors 2008, 8, 4318–4329. [Google Scholar] [CrossRef]

- Du, B.; Yin, M.; Yang, K.; Wang, S.; Pei, Y.; Luo, R.; Zhou, S.; Li, H. Ultrafast Polymerization of a Self-Adhesive and Strain Sensitive Hydrogel-Based Flexible Sensor for Human Motion Monitoring and Handwriting Recognition. Polymers 2024, 16, 1595. [Google Scholar] [CrossRef]

- Bu, Y.; Wu, J.; Zhang, Z.; Wei, Q.; Su, B.; Wang, Y. Design and Analysis of Porous Elastomeric Polymer Based on Electro-Mechanical Coupling Characteristics for Flexible Pressure Sensor. Polymers 2024, 16, 701. [Google Scholar] [CrossRef]

- Li, J.-W.; Chen, H.-F.; Huang, P.-H.; Kuo, C.-F.J.; Cheng, C.-C.; Chiu, C.-W. Photocurable Carbon Nanotube/Polymer Nanocomposite for the 3D Printing of Flexible Capacitive Pressure Sensors. Polymers 2023, 15, 4706. [Google Scholar] [CrossRef] [PubMed]

- Bae, J.; Hwang, Y.; Park, S.J.; Ha, J.-H.; Kim, H.J.; Jang, A.; An, J.; Lee, C.-S.; Park, S.-H. Study on the Sensing Signal Profiles for Determination of Process Window of Flexible Sensors Based on Surface Treated PDMS/CNT Composite Patches. Polymers 2018, 10, 951. [Google Scholar] [CrossRef] [PubMed]

- Jung, Y.; Jung, K.K.; Kim, D.H.; Kwak, D.H.; Ko, J.S. Linearly Sensitive and Flexible Pressure Sensor Based on Porous Carbon Nanotube/Polydimethylsiloxane Composite Structure. Polymers 2020, 12, 1499. [Google Scholar] [CrossRef] [PubMed]

- Khalid, H.R.; Choudhry, I.; Jang, D.; Abbas, N.; Haider, M.S.; Lee, H.K. Facile Synthesis of Sprayed CNTs Layer-Embedded Stretchable Sensors with Controllable Sensitivity. Polymers 2021, 13, 311. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.; Pan, J.; Xu, A.; Luo, L.; Cheng, D.; Cai, G.; Wang, J.; Tang, B.; Wang, X. Conductive Cotton Fabrics for Motion Sensing and Heating Applications. Polymers 2018, 10, 568. [Google Scholar] [CrossRef]

- Han, F.; Li, J.; Zhang, Y.; Zhang, G.; Sun, R.; Wong, C. A Stretchable and Flexible Strain Sensor Based on Graphene Sponge. In Advanced Functional Materials; Han, Y., Ed.; Springer: Singapore, 2018; pp. 379–387. ISBN 9789811301094. [Google Scholar]

- Li, W.; Xu, F.; Sun, L.; Liu, W.; Qiu, Y. A Novel Flexible Humidity Switch Material Based on Multi-Walled Carbon Nanotube/Polyvinyl Alcohol Composite Yarn. Sens. Actuators B Chem. 2016, 230, 528–535. [Google Scholar] [CrossRef]

- Huang, K. Wireless Strain Sensing Using Carbon Nanotube Composite Film. Compos. Part. B 2023, 256, 110650. [Google Scholar] [CrossRef]

- Xie, J.; Pan, W.; Guo, Z. Preparation of Highly Conductive Polyurethane/Polypyrrole Composite Film for Flexible Electric Heater. J. Elastomers Plast. 2021, 53, 97–109. [Google Scholar] [CrossRef]

- Aouraghe, M.A.; Xu, F.; Liu, X.; Qiu, Y. Flexible, Quickly Responsive and Highly Efficient E-Heating Carbon Nanotube Film. Compos. Sci. Technol. 2019, 183, 107824. [Google Scholar] [CrossRef]

- Yan, J.; Jeong, Y.G. Multiwalled Carbon Nanotube/Polydimethylsiloxane Composite Films as High Performance Flexible Electric Heating Elements. Appl. Phys. Lett. 2014, 105, 051907. [Google Scholar] [CrossRef]

- Wang, X.; Li, J.; Song, H.; Huang, H.; Gou, J. Highly Stretchable and Wearable Strain Sensor Based on Printable Carbon Nanotube Layers/Polydimethylsiloxane Composites with Adjustable Sensitivity. ACS Appl. Mater. Interfaces 2018, 10, 7371–7380. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Zhu, Y.; Jiang, W. A Stretchable and Transparent Strain Sensor Based on Sandwich-like PDMS/CNTs/PDMS Composite Containing an Ultrathin Conductive CNT Layer. Compos. Sci. Technol. 2020, 186, 107938. [Google Scholar] [CrossRef]

- Peppas, N.A.; Merrill, E.W. Poly(Vinyl Alcohol) Hydrogels: Reinforcement of Radiation-Crosslinked Networks by Crystallization. J. Polym. Sci. Polym. Chem. Ed. 1976, 14, 441–457. [Google Scholar] [CrossRef]

- Jeck, S.; Scharfer, P.; Schabel, W.; Kind, M. Water Sorption in Poly(Vinyl Alcohol) Membranes: An Experimental and Numerical Study of Solvent Diffusion in a Crosslinked Polymer. Chem. Eng. Process. Process Intensif. 2011, 50, 543–550. [Google Scholar] [CrossRef]

- Saleemi, S.; Aouraghe, M.A.; Wei, X.; Liu, W.; Liu, L.; Siyal, M.I.; Bae, J.; Xu, F. Bio-Inspired Hierarchical Carbon Nanotube Yarn with Ester Bond Cross-Linkages towards High Conductivity for Multifunctional Applications. Nanomaterials 2022, 12, 208. [Google Scholar] [CrossRef]

- Aouraghe, M.A.; Zhou, M.; Qiu, Y.; Xu, F. Low-Voltage Activating, Fast Responding Electro-Thermal Actuator Based on Carbon Nanotube Film/PDMS Composites. Adv. Fiber Mater. 2021, 3, 38–46. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, C.; Liu, E.; Sun, Q.; Shao, Y. Sandwich-Structured Carbon Nanotube Composite Films for Multifunctional Sensing and Electrothermal Application. Polymers 2024, 16, 2496. https://doi.org/10.3390/polym16172496

Lu C, Liu E, Sun Q, Shao Y. Sandwich-Structured Carbon Nanotube Composite Films for Multifunctional Sensing and Electrothermal Application. Polymers. 2024; 16(17):2496. https://doi.org/10.3390/polym16172496

Chicago/Turabian StyleLu, Canyi, Encheng Liu, Qi Sun, and Yiqin Shao. 2024. "Sandwich-Structured Carbon Nanotube Composite Films for Multifunctional Sensing and Electrothermal Application" Polymers 16, no. 17: 2496. https://doi.org/10.3390/polym16172496