Experimental Investigation on the Performance of SBS-Modified Asphalt Waterproofing Membrane by Thermo-Oxidative Aging and Freeze–Thaw Cycle

Abstract

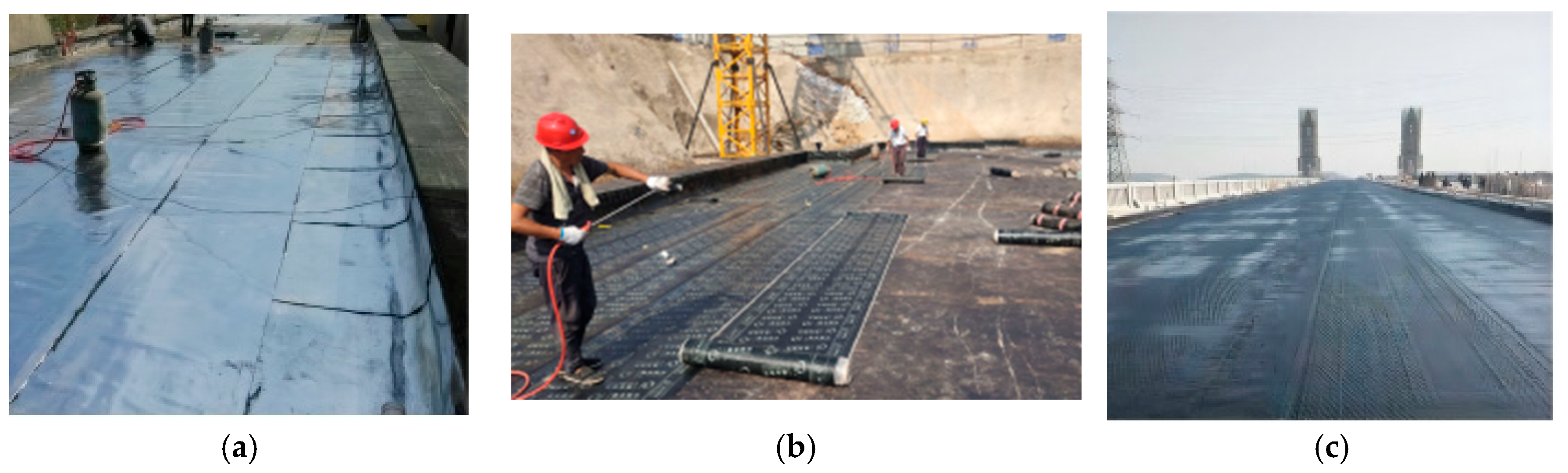

:1. Introduction

2. Experimental

2.1. Materials

2.2. Test Program

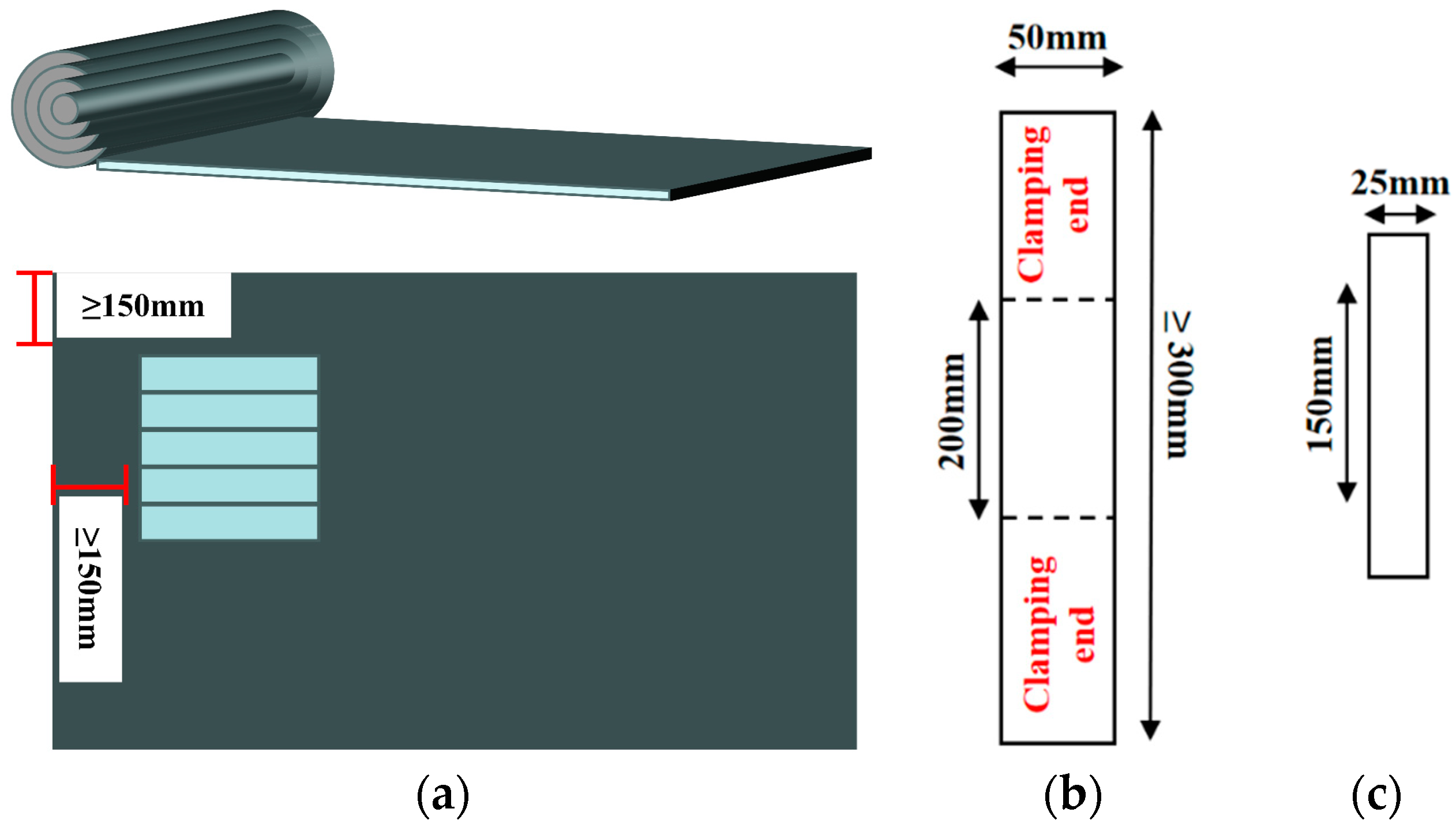

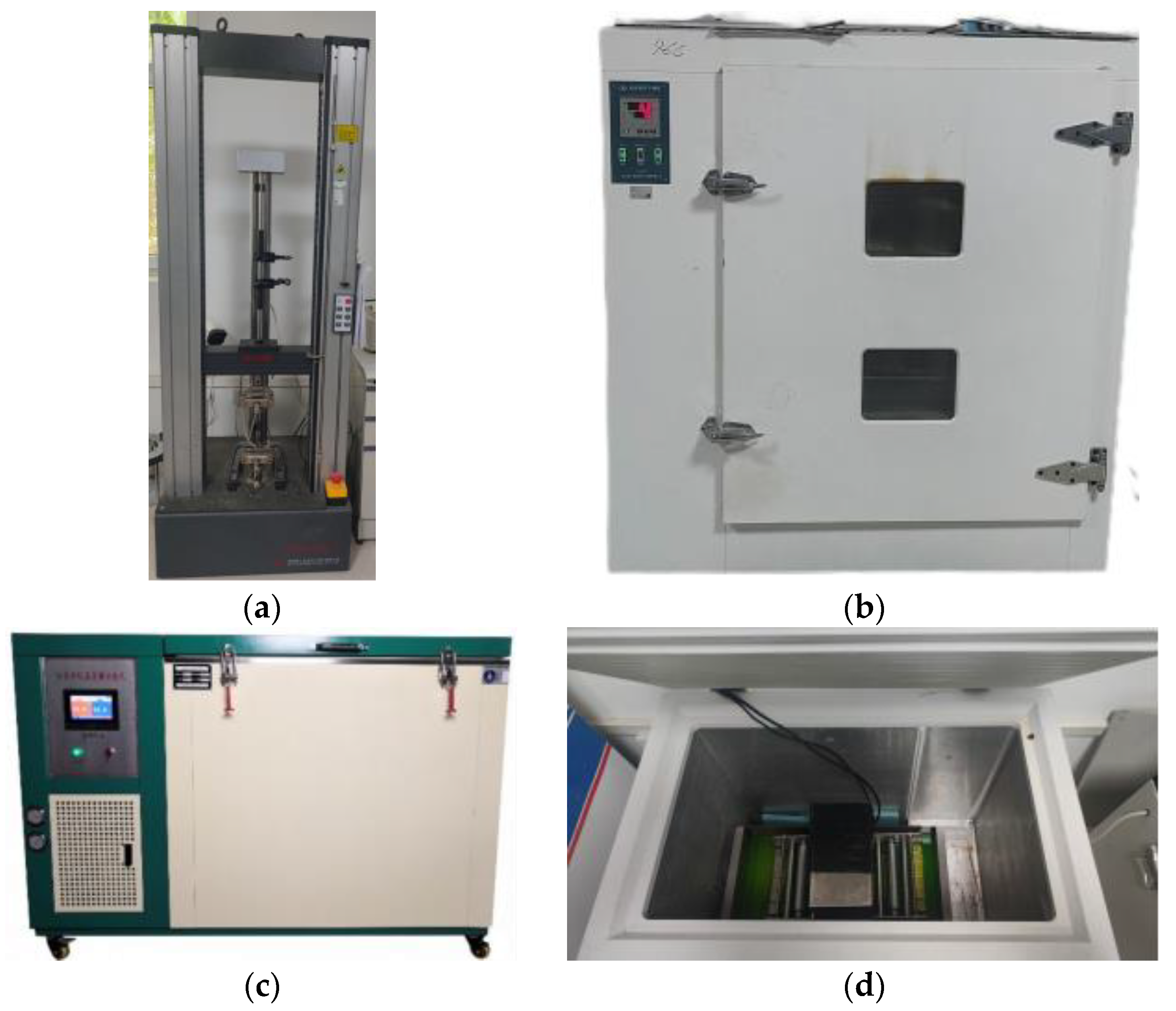

2.3. Specimen Preparation and Test Equipment

3. Results and Discussion

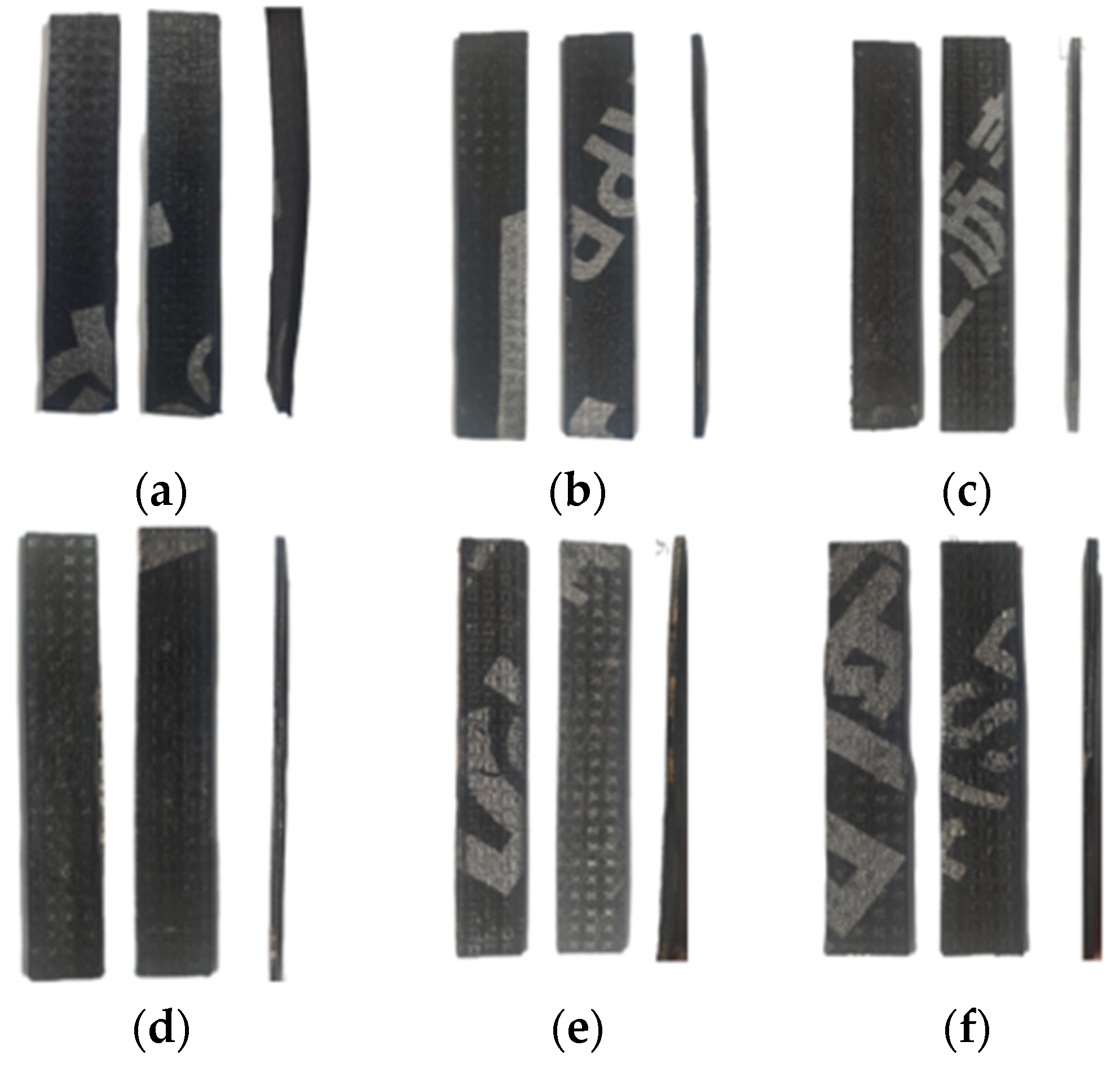

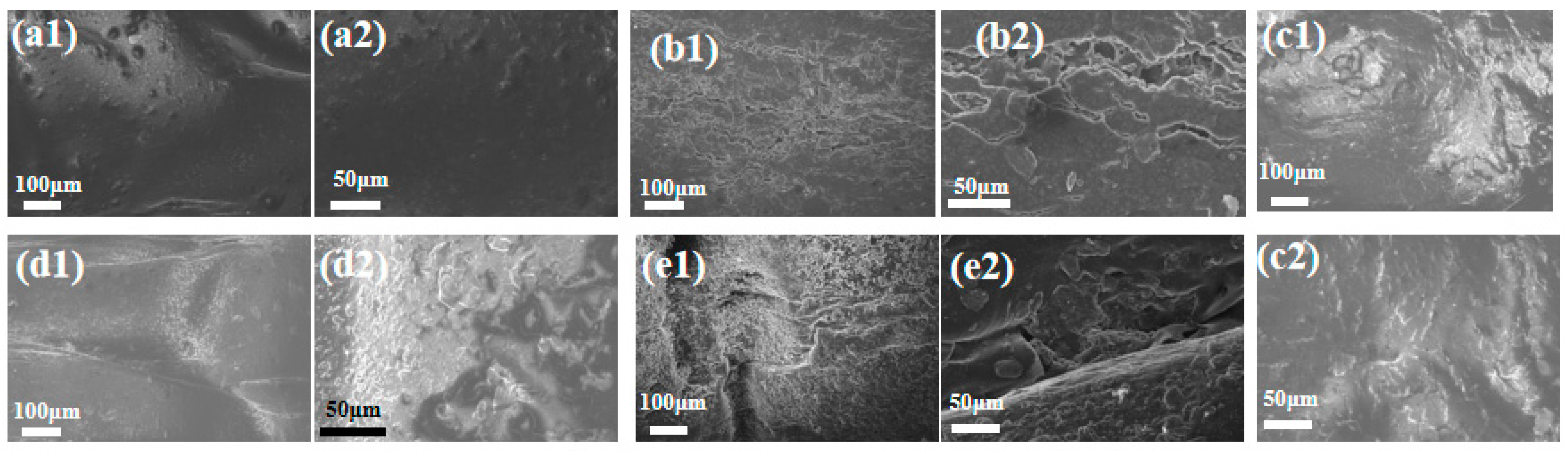

3.1. Apparent Appearance and SEM Analysis

3.2. Quality Loss Rate

3.3. Low-Temperature Flexibility

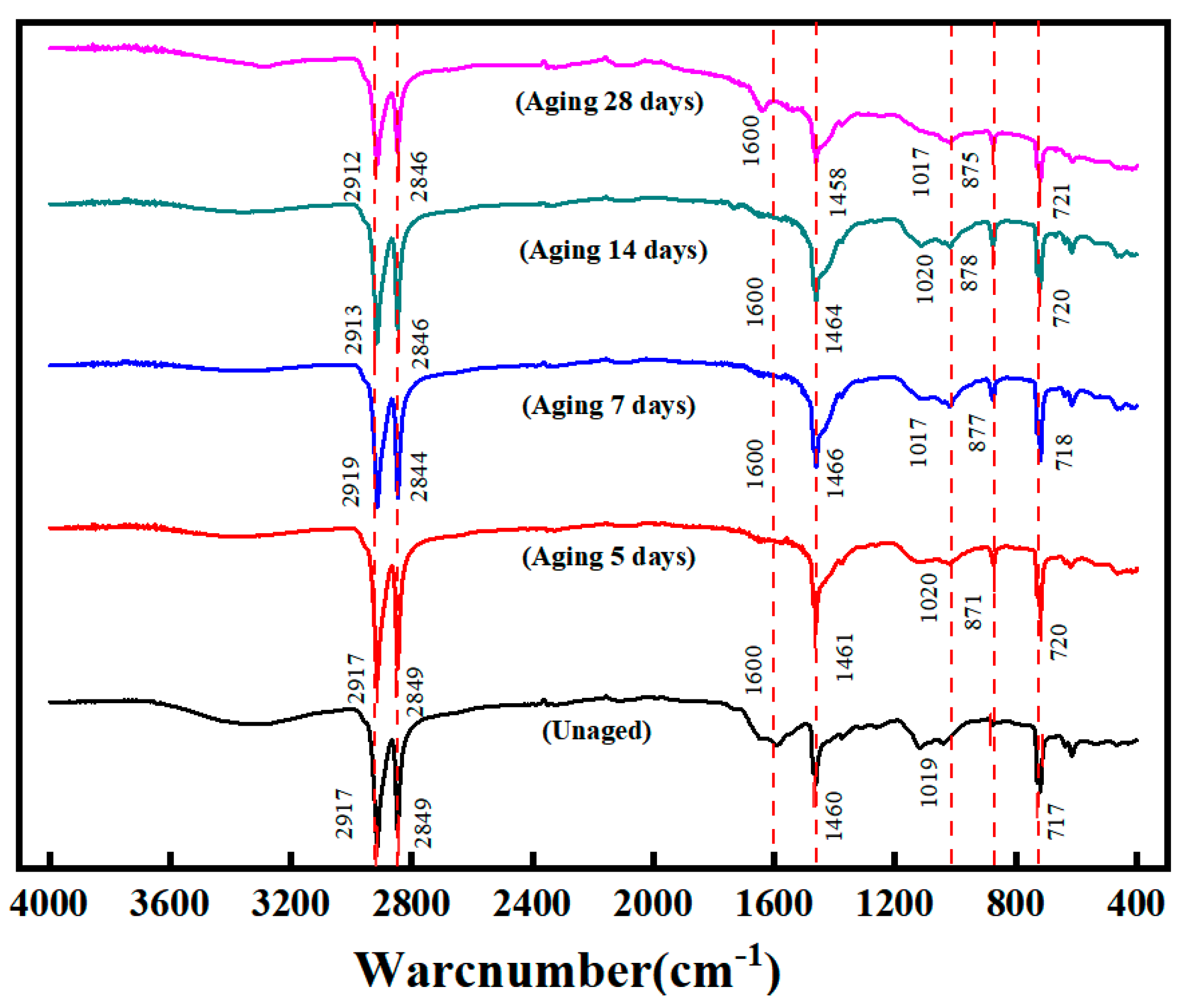

3.4. FTIR Analysis

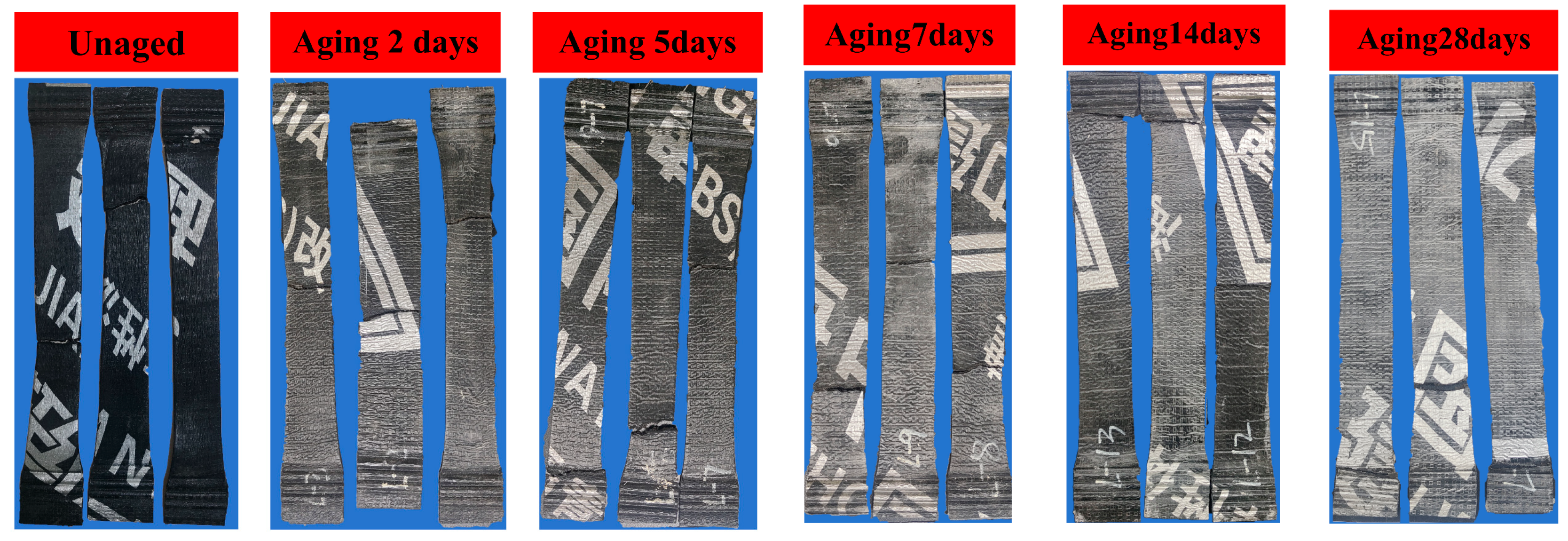

3.5. Tensile Properties of Waterproofing Membranes

tension/clamping distance × 100%.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Lopes, J.G.; Correia, J.R.; MacHado, M.X.B. Dimensional stability of waterproofing bituminous sheets used in low slope roofs. Constr. Build. Mater. 2011, 25, 3229–3235. [Google Scholar] [CrossRef]

- Singh, B.; Kumar, P. Effect of polymer modification on the aging properties of asphalt binders: Chemical and morphological investigation. Constr. Build. Mater. 2019, 205, 633–641. [Google Scholar] [CrossRef]

- Mazumder, M.; Ahmed, R.; Wajahat Ali, A.; Lee, S.J. SEM and ESEM techniques used for analysis of asphalt binder and mixture: A state of the art review. Constr. Build. Mater. 2018, 186, 313–329. [Google Scholar] [CrossRef]

- He, Y.; Cao, Z.; Liu, Z.; Li, J.; Yu, J.; Ge, Y. Influence of heat and ultraviolet aging on the structure and properties of high dosage SBS modified bitumen for waterproof. Constr. Build. Mater. 2021, 287, 122986. [Google Scholar] [CrossRef]

- Garrido, M.; António, D.; Lopes, J.G.; Correia, J.R. Performance of different joining techniques used in the repair of bituminous waterproofing membranes. Constr. Build. Mater. 2018, 158, 346–358. [Google Scholar] [CrossRef]

- Marques, J.A.; Lopes, J.G.; Correia, J.R. Durability of the adhesion between bituminous coatings and self-protection mineral granules of waterproofing membranes. Constr. Build. Mater. 2011, 25, 138–144. [Google Scholar] [CrossRef]

- Liu, K.; Xu, G.; Voyer, R. Durability and cold temperature performance of SBS-modified bituminous roofing membranes. In Roofing Research and Standards Development: 5th Volume; ASTM International: West Conshohocken, PA, USA, 2004; pp. 97–118. [Google Scholar] [CrossRef]

- Di Luca, G.; Filomia, M.; Fuoco, A.; Chiappetta, G.; Figoli, A. Effect of Graphene Oxide on Liquid Water-Based Waterproofing Bituminous Membranes. Polymers 2022, 14, 2221. [Google Scholar] [CrossRef]

- Feng, Z.G.; Wang, S.J.; Bian, H.J.; Guo, Q.L.; Li, X.J. FTIR and rheology analysis of aging on different ultraviolet absorber modified bitumens. Constr. Build. Mater. 2016, 115, 48–53. [Google Scholar] [CrossRef]

- Mazzotta, F.; Lantieri, C.; Vignali, V.; Simone, A.; Dondi, G.; Sangiorgi, C. Performance evaluation of recycled rubber waterproofing bituminous membranes for concrete bridge decks and other surfaces. Constr. Build. Mater. 2017, 136, 524–532. [Google Scholar] [CrossRef]

- Rupal, A.; Sharma, S.K.; Tyagi, G.D. Experimental investigation on mechanical properties of polyurethane modified bituminous waterproofing membrane. Mater. Today Proc. 2020, 27, 467–474. [Google Scholar] [CrossRef]

- He, Y.; Zhang, T.; Mao, S.; Zeng, S.; Wu, L.; Yu, J. Investigation of Antiaging Performance and Service Life of OMMT/SBS Modified Bitumen Waterproof Membranes. J. Mater. Civ. Eng. 2024, 36, 04024025. [Google Scholar] [CrossRef]

- Chen, Q.T.; Wang, Z.X. Analysis of Aging Mechanism of SBS Modified Asphalt. J. Wuhan Univ. Technol. 2021, 45, 145–1150. (In Chinese) [Google Scholar]

- Xu, Z.M.; Li, W.Z.; Duan, W.F. Research on aging analysis of SBS modified asphalt. New Build. Mater. 2014, 41, 71–72+86. (In Chinese) [Google Scholar]

- Ge, B.; Wang, J.X.; Wang, S.L. Experimental Research on Durability of SBS Modiifed Bituminous Sheet Materials(2)--Soaking Aging and Freezing-Thawing Cycles Aging. Constr. Qual. 2015, 33, 28–32. (In Chinese) [Google Scholar]

- Ge, B.; Wang, J.X.; Wang, S.L. Experimental Research on Durability of SBS Modiifed Bituminous Sheet Materials(1)--Natural Aging. Constr. Qual. 2015, 33, 74–77. (In Chinese) [Google Scholar]

- Huang, X.; Wang, L. Evolution of Low-Temperature Properties of Warm-Mix Rubber-Modified Asphalt under Freeze–Thaw Cycles. J. Mater. Civ. Eng. 2023, 35, 1–13. [Google Scholar] [CrossRef]

- Wu, H.; Liang, N.X. Analysis of the Ultraviolet Aging of SBR Modified Asphalt Mixture. J. Chongqing Jiaotong Univ. 2007, 2, 72–74. (In Chinese) [Google Scholar]

- Ge, Y.Y.; Wang, Y.C.; Bai, S.L. Analysis of durability of SBS modified bituminous waterproof sheet based on actual engineering cases. New Build. Mater. 2020, 47, 159–163. (In Chinese) [Google Scholar]

- Ge, Y.Y.; Lin, H.W.; Lin, T. Experimental research on durability of SBS modified bituminous waterproof sheet. New Build. Mater. 2020, 47, 126–129. [Google Scholar]

- Peng, Y.; Longlong, W. Interface Temperature of EPS Exterior Insulation System in High. Temperature 2019. Available online: https://d.wanfangdata.com.cn/periodical/ChlQZXJpb2RpY2FsQ0hJTmV3UzIwMjQwNzA0Eg1jc2p6MjAxOTMxMDIyGghrNjFtcTJndA%3D%3D (accessed on 8 August 2024). (In Chinese).

- GB 18242-2008; Styrene Butadiene Styrene (SBS) Modified Bituminous Sheet Materials. Standardization Administration of China (SAC): Beijing, China. (In Chinese)

- Zhang, Z.; Liang, X.; Li, P. Evaluation method of asphalt aging properties. J. Traffic Transp. Eng. 2005, 1, 1–5. [Google Scholar]

- Zhou, Y.; Du, L.; Liu, X.; Zhang, K.; Xu, P.; Zhang, Y. Microscopic performance of modified asphalt based on aging. Constr. Build. Mater. 2021, 279, 122429. [Google Scholar] [CrossRef]

- Zhou, S.; Tan, Y.; Meng, L.; Wang, H. Study on Anti-freezing Properties of Cold Mix Asphalt. Highw. Eng. 2017, 42, 21–24+30. [Google Scholar]

- Zhai, R.; Hao, P.; Li, G. Anti-reflection Cracking Performance of Asphalt Mixture under Freeze Thaw Cycles. J. Build. Mater. 2018, 21, 1000–1004. [Google Scholar]

- Wang, Y. Study on Indicators Evaluating Asphalt Aging and the Aging Degree. Subgrade Eng. 2014, 6, 63–68. [Google Scholar]

- Chen, H.; Zhou, Y.; Wang, B. Dynamic mechanics performance of aged SBS modified-asphalt. J. Chang. Univ. 2009, 29, 1–5. [Google Scholar]

- Li, L.; Guo, Z.; Ran, L.; Zhang, J. Study on low-temperature cracking performance of asphalt under heat and light together conditions. Materials 2020, 13, 1541. [Google Scholar] [CrossRef]

- Yao, S.; Ge, Q. Analysis of Factors Influencing Tensile Test of Self-adhesive Polymer Modified Bitumen Waterproofing Membrane. China Build. Waterproofing 2018, 24, 27–30. [Google Scholar]

| Property | Measured Values |

|---|---|

| Thicknesses (mm) | 3.2 |

| Tensile strength (N/50 mm) | 1330/1065 |

| Mass per unit area (kg/m2) | 3.8 |

| Soluble matter content (g/m2) | 2310 |

| Maximum applicable temperature | 90 °C |

| Materials | Aging Temperature (°C) | Freeze–Thaw Cycle Temperature (°C) |

|---|---|---|

| SBS-modified asphalt waterproofing membrane | 80 | −20 to 23 |

| Testing time (day) | 2, 5, 7, 14, 28 | 2, 5, 7, 14, 28 |

| Wavenumber (cm−1) | Corresponding Peak |

|---|---|

| 2920 | Asymmetric stretching vibration of CH2 |

| 2850 | Symmetric stretching vibration of CH2 |

| 1700 | Carbonyl (C=O) absorption peak of aldehydes, ketones and acids |

| 1600 | Aromatic (C=C) absorption Peak |

| 1030 | Sulfoxide group (S=O) stretch vibration absorption |

| 965 | Butadiene Double Bond (C=C) |

| 700 | Polystyrene bonds |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Li, X.; Sun, G.; Ma, X.; Du, H. Experimental Investigation on the Performance of SBS-Modified Asphalt Waterproofing Membrane by Thermo-Oxidative Aging and Freeze–Thaw Cycle. Polymers 2024, 16, 2593. https://doi.org/10.3390/polym16182593

Wang J, Li X, Sun G, Ma X, Du H. Experimental Investigation on the Performance of SBS-Modified Asphalt Waterproofing Membrane by Thermo-Oxidative Aging and Freeze–Thaw Cycle. Polymers. 2024; 16(18):2593. https://doi.org/10.3390/polym16182593

Chicago/Turabian StyleWang, Juanjuan, Xian Li, Guojun Sun, Xingpeng Ma, and Hongwei Du. 2024. "Experimental Investigation on the Performance of SBS-Modified Asphalt Waterproofing Membrane by Thermo-Oxidative Aging and Freeze–Thaw Cycle" Polymers 16, no. 18: 2593. https://doi.org/10.3390/polym16182593