Effects of C-S-H Seed Prepared by Wet Grinding on the Properties of Cement Containing Large Amounts of Silica Fume

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.2.1. Preparation of C-S-H Seed

2.2.2. Concrete Sample Preparation

2.3. Experiment Method

2.3.1. Particle Size Distribution Test

2.3.2. Viscosity Test

2.3.3. Fourier Transform Infrared Spectroscopy (FTIR) Test

2.3.4. Zeta Potential Test

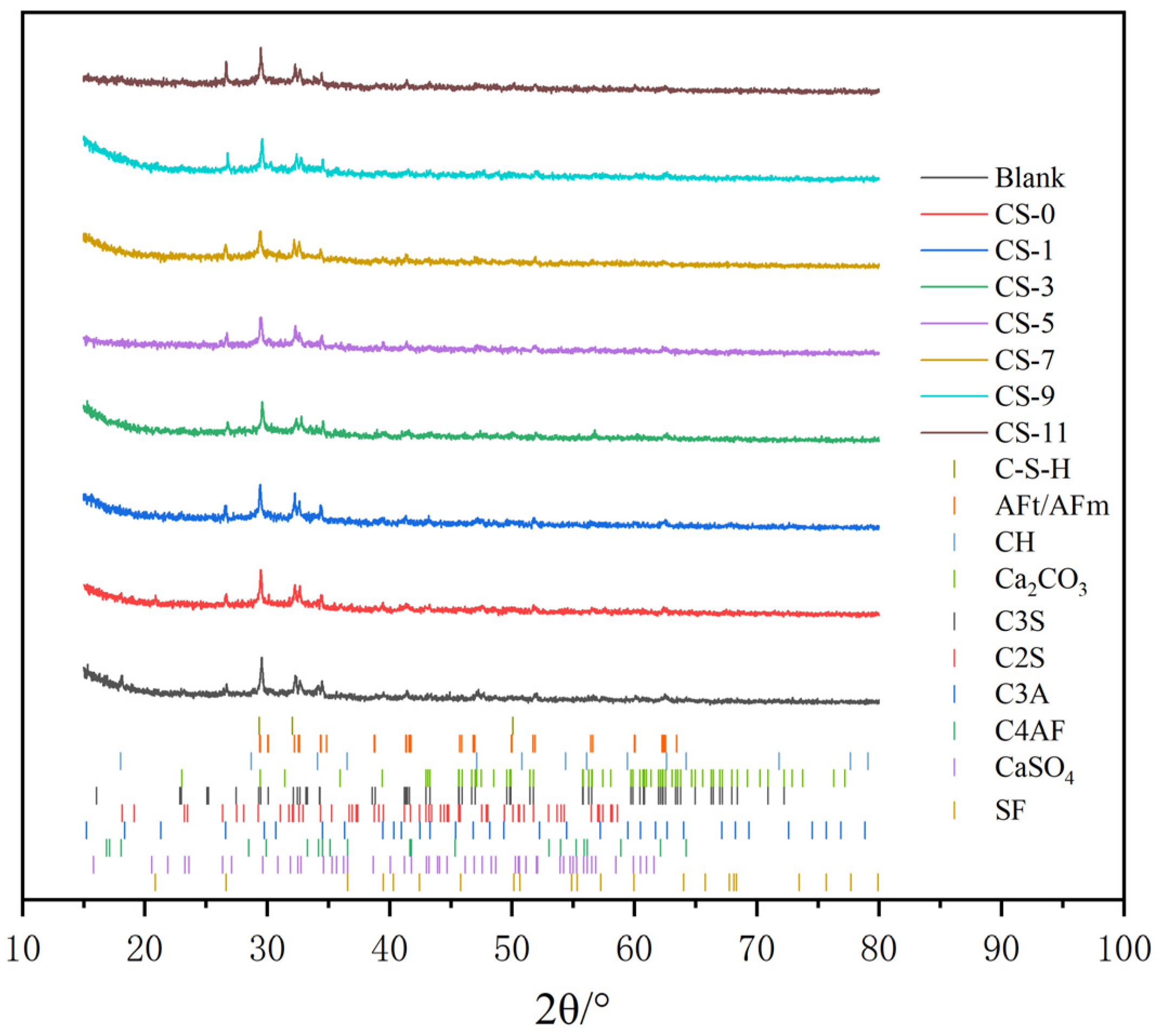

2.3.5. X-ray Diffraction (XRD) Test

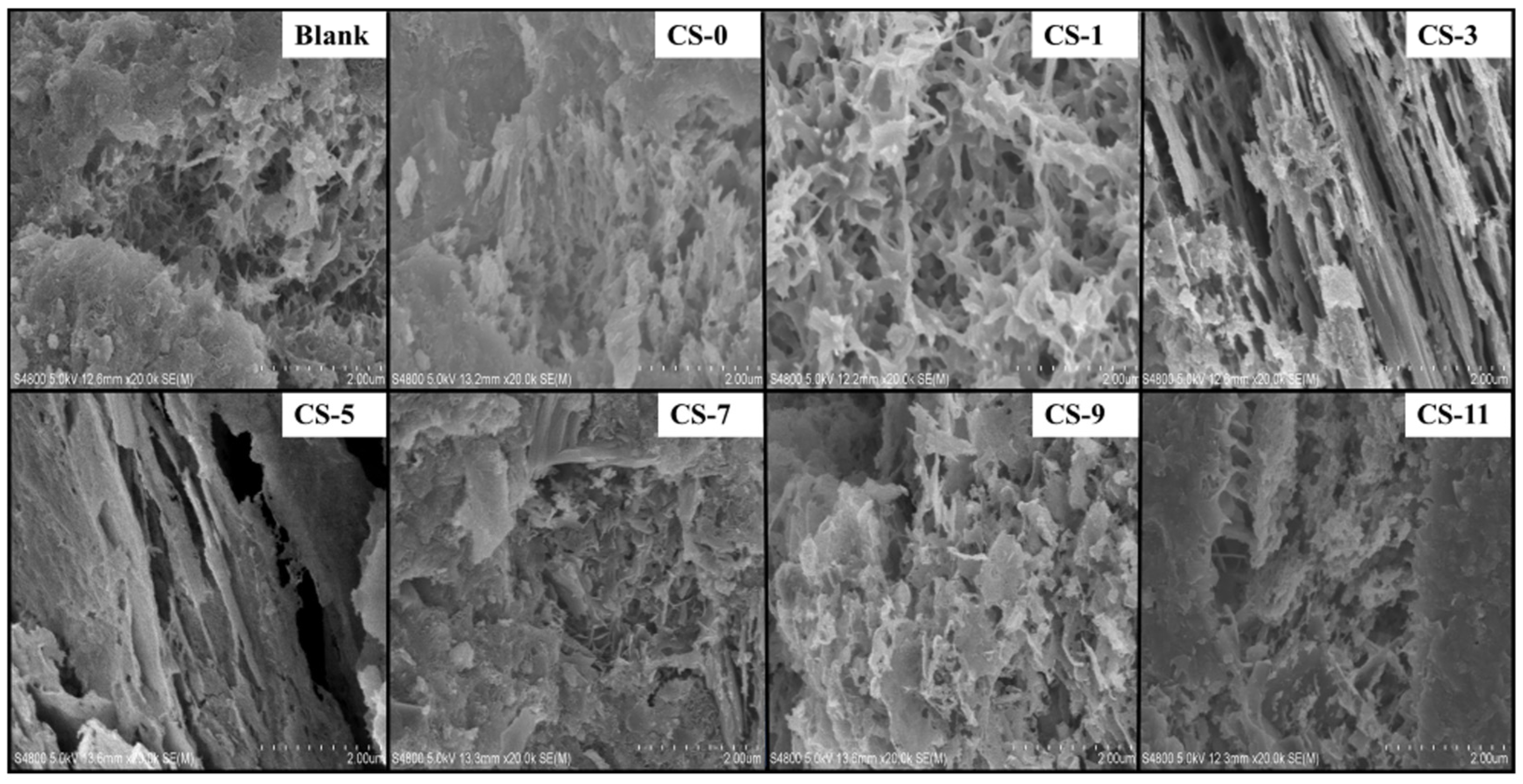

2.3.6. Scanning Electron Microscope (SEM) Test

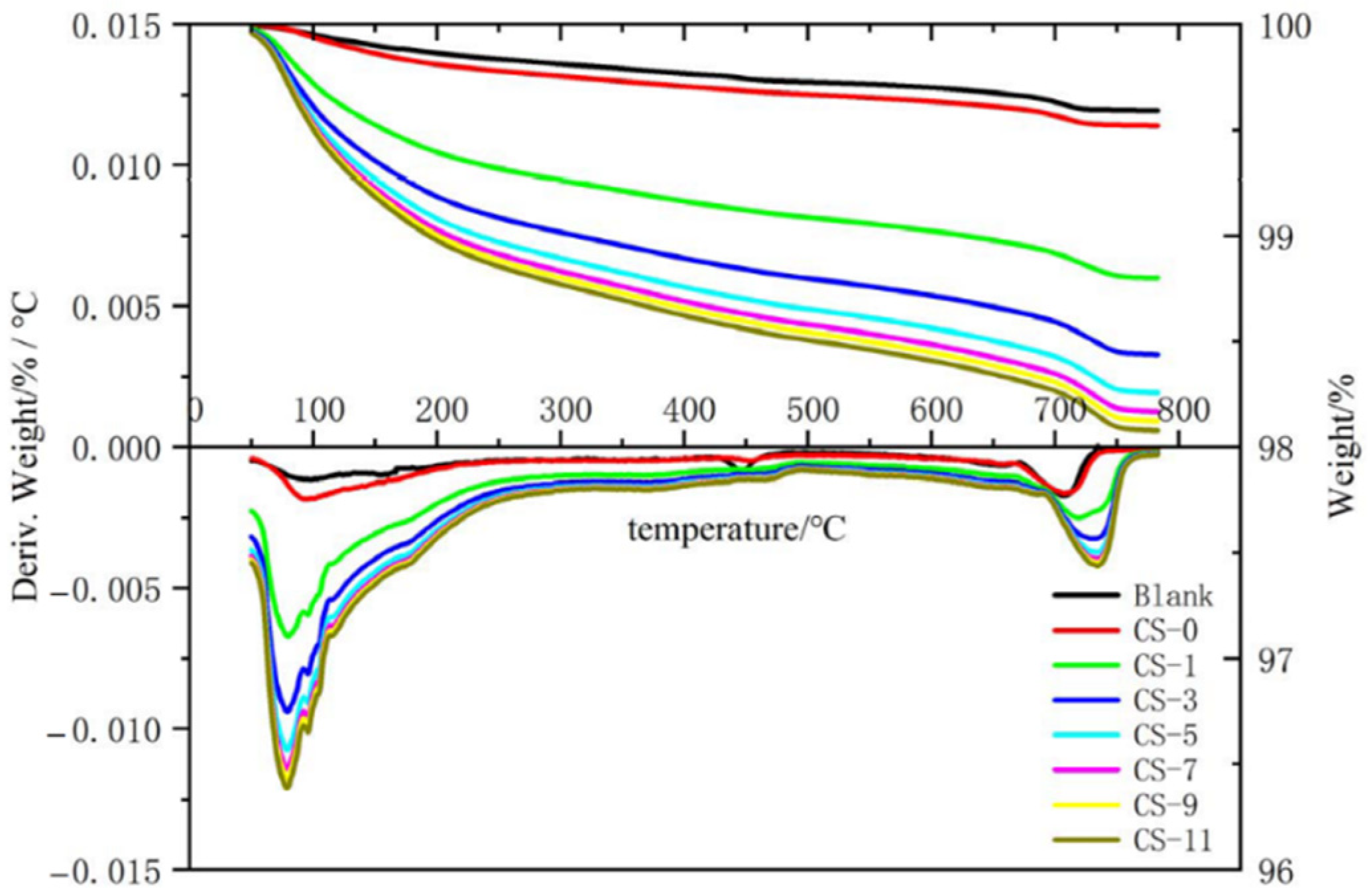

2.3.7. Thermogravimetry–Differential Scanning Calorimetry (TD) Analysis

2.3.8. Concrete Compressive Strength

3. Results

3.1. C-S-H Seed Properties

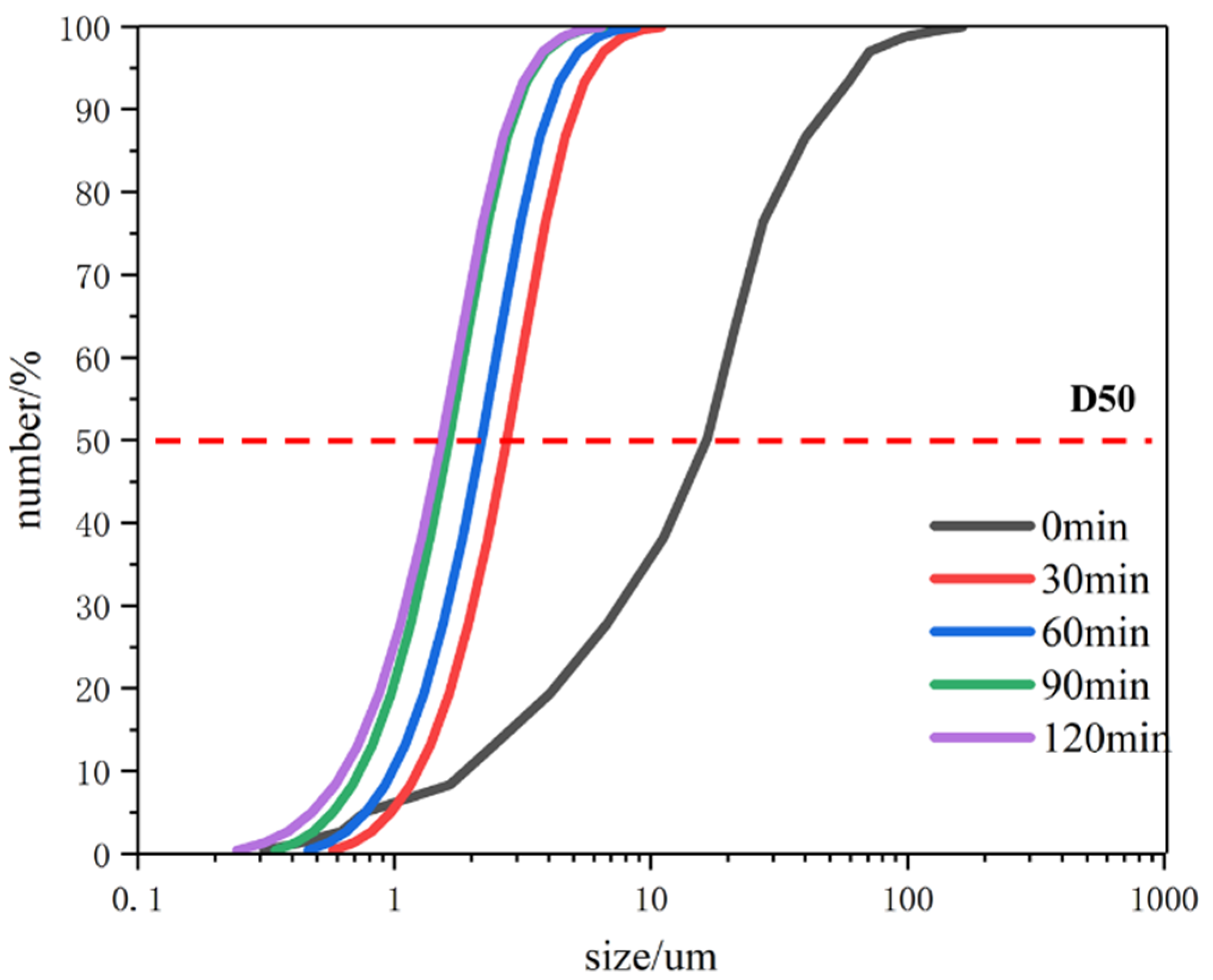

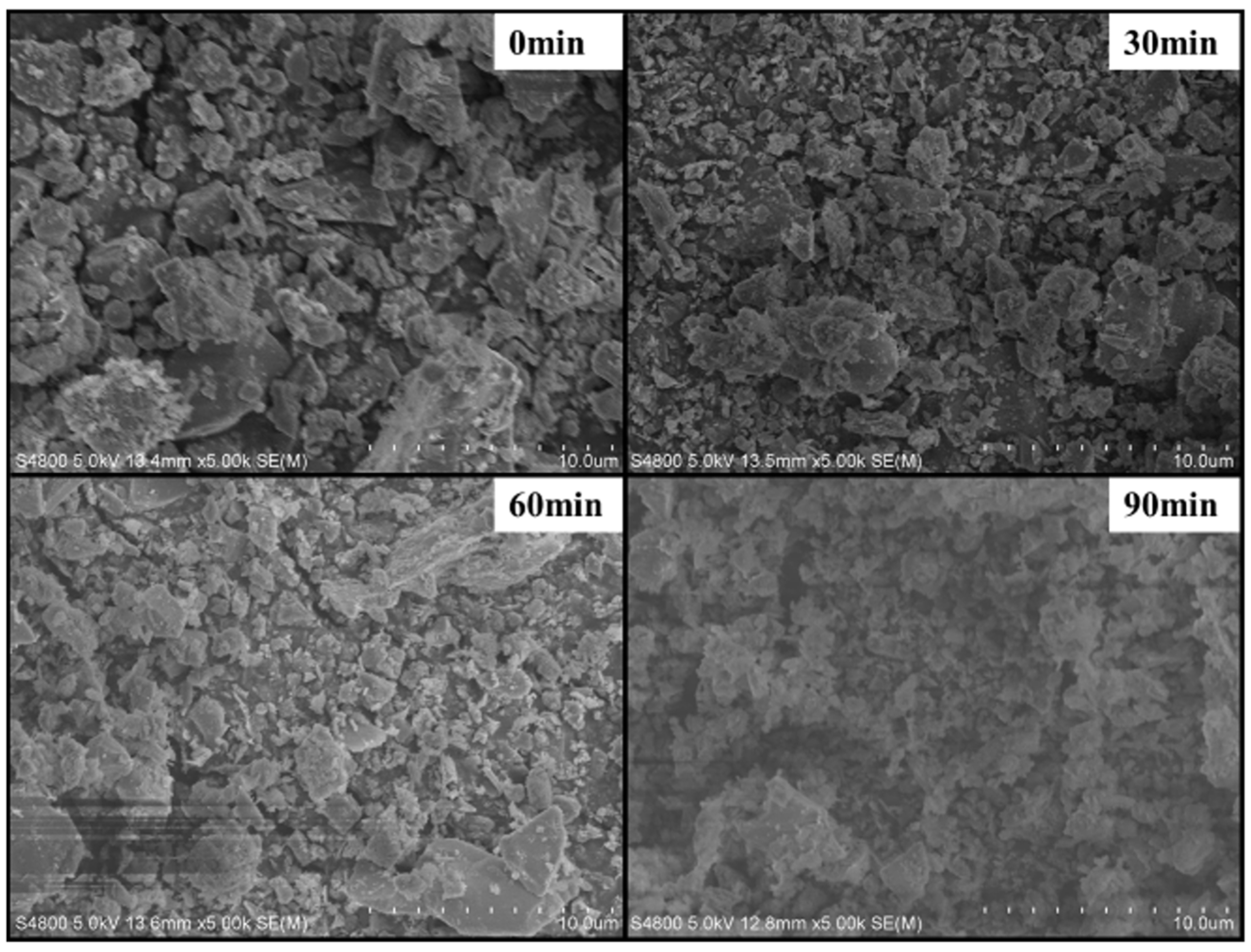

3.1.1. Particle Size (PS) Distribution

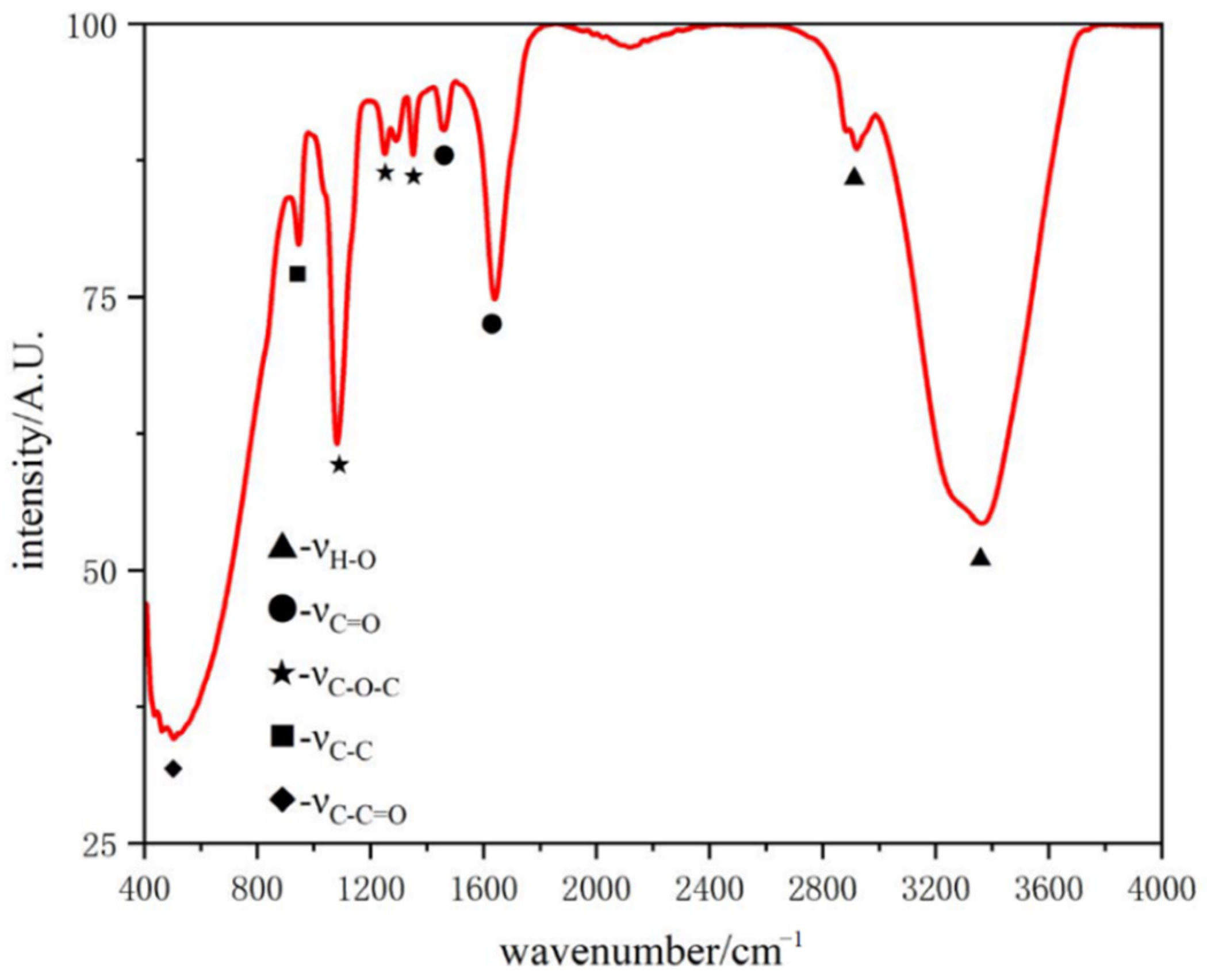

3.1.2. FTIR

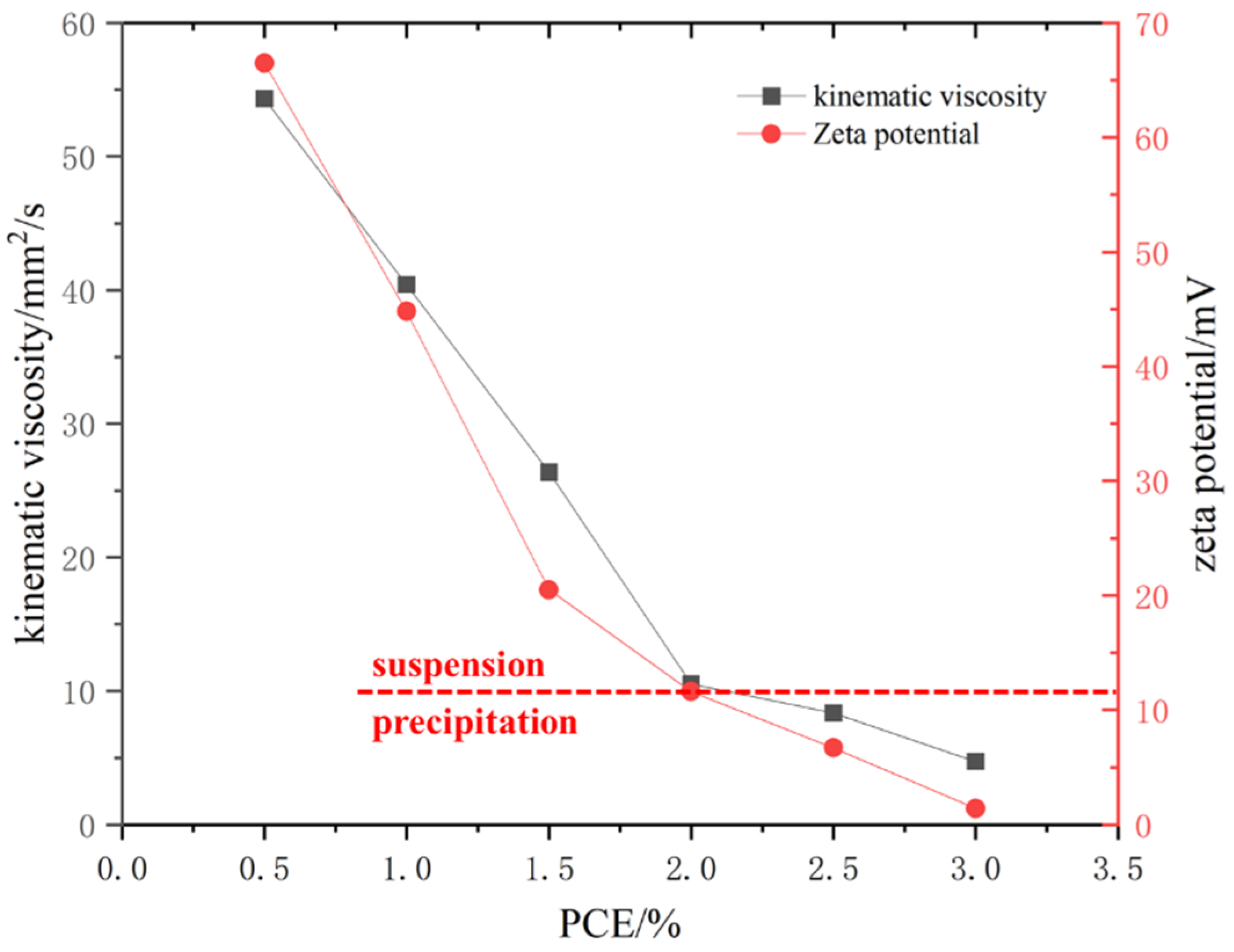

3.1.3. Viscosity and Zeta Potential

3.1.4. XRD

3.1.5. TD

3.2. Concrete Properties

3.2.1. Compressive Strength

3.2.2. XRD

3.2.3. TD

4. Conclusions

- The wet grinding process can reduce the PS of C-S-H seed and promote its hydration degree. With the increase in wet grinding time, the PS of the C-S-H seed agent continued to decrease, and the hydration degree continued to increase. When the wet grinding time exceeded 90 min, the PS and hydration degree of the C-S-H seed agent no longer increased. There are few reports on the study of wet grinding of C-S-H seed, and its key parameters are not yet clear. Further research on this is necessary.

- The addition of PCE can reduce the dynamic viscosity of the C-S-H seed suspension and make it have good fluidity. When the amount of PCE increased to 1.5%, the dynamic viscosity of the C-S-H seed suspension was significantly reduced. When the amount exceeds 2%, the dynamic viscosity decreased slowly, that is, the amount of PCE in the C-S-H seed suspension should not be less than 1.5%.

- PCE can cause the C-S-H seed suspension to agglomerate and precipitate; With the increase in the amount of PCE, the zeta potential of the C-S-H seed gradually decreased. When the amount of PCE in the crystal seed was greater than 2%, the zeta potential was less than 20 mV, precipitate formed in the C-S-H seed suspension, and the amount of PCE in the C-S-H seed suspension should not be greater than 2.0%. PCE affects the viscosity and zeta potential of C-S-H seed suspension by adsorbing C-S-H seeds and the influence of –COOH group on the surface charge of C-S-H seeds. Further research is needed to investigate how the molecular structure of PCE and the –COO– group affect C-S-H seed suspension, which will help design PCE for C-S-H seed suspension.

- C-S-H seed can improve the early performance of concrete while adding silica fume to replace cement, making the concrete denser and improving the strength of concrete. When the amount of C-S-H seed agent was less than 5%, the concrete strength increased less. When the amount of C-S-H seed agent was higher than 7%, due to the small particle size of C-S-H seed, this will increase the unit water consumption of concrete, making the concrete workability worse and causing the concrete strength to decrease. Therefore, the amount of C-S-H seed agent should be controlled at 5%~7%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Blotevogel, S.; Doussang, L.; Poirier, M.; André, L.; Canizarès, A.; Simon, P.; Montouillout, V.; Kaknics, J.; Patapy, C.; Cyr, M. The influence of Al2O3, CaO, MgO and TiO2 content on the early-age reactivity of GGBS in blended cements, alkali-activated materials and supersulfated cements. Cem. Concr. Res. 2024, 178, 107439. [Google Scholar] [CrossRef]

- Jiang, J.; Miao, Y.; Wang, H.; Dong, X.; Li, Y.; Lin, J.; Lu, Z. In-situ dispersion of nano-TiO2 to highly reinforce cement paste. Constr. Build. Mater. 2023, 409, 133962. [Google Scholar] [CrossRef]

- Abo-El-Enein, S.; El-Hosiny, F.; El-Gamal, S.; Amin, M.S.; Ramadan, M. Gamma radiation shielding, fire resistance and physicochemical characteristics of Portland cement pastes modified with synthesized Fe2O3 and ZnO nanoparticles. Constr. Build. Mater. 2018, 706, 173687. [Google Scholar] [CrossRef]

- Han, B.; Wang, Z.; Zeng, S.; Zhou, D.; Yu, X.; Cui, X.; Ou, J. Properties and modification mechanisms of nano-zirconia filled reactive powder concrete. Constr. Build. Mater. 2017, 434, 141426. [Google Scholar] [CrossRef]

- Marrero, R.; Corr, J.; Espinosa, H.; Shah, S. Characterization of adhesion strength between carbon nanotubes and cementitious materials. Cem. Concr. Compos. 2023, 138, 104953. [Google Scholar] [CrossRef]

- Reches, Y. Nanoparticles as concrete additives: Review and perspectives. Constr. Build. Mater. 2018, 495, 175483. [Google Scholar] [CrossRef]

- Uthaman, S.; Vishwakarma, V.; George, R.; Ramachandran, D.; Kumari, K.; Preetha, R.; Premila, M.; Rajaraman, R.; Mudali, U.K.; Amarendra, G. Enhancement of strength and durability of fly ash concrete in seawater environments: Synergistic effect of nanoparticles. Constr. Build. Mater. 2018, 459, 187448. [Google Scholar] [CrossRef]

- Tao, M.; Qiang, Y.; Hu, A.; Xu, C.; Lin, L. Effect of compound nano-CaCO3 addition on strength development and microstructure of cement-stabilized soil in the marine environment. Constr. Build. Mater. 2017, 81, 151775. [Google Scholar]

- Li, W.; Wang, R.; Wang, Y.; Zuo, W.; Hong, J.; Luo, S.; Wang, P. The acceleration effect of nano C-S-H-PCE on the microstructure formation and evolution at early age of cement paste. Mater. Struct. 2023, 56, 4. [Google Scholar] [CrossRef]

- Shen, X.; Feng, P.; Zhang, Y.; de Souza, F.B.; Duan, W. Multi-step nucleation of C-S-H: DFT simulation on silicate oligomerization and Si(Qn) evolution dynamics. Constr. Build. Mater. 2024, 439, 137372. [Google Scholar] [CrossRef]

- Yu, J.; Wang, K.; Yang, P.; Li, M.; Dong, B.; Jin, Z.; Hong, S.; Ma, H. Simulation of calcium carbonate nucleation processes in confined C-S-H nanopores with different calcium-silicon ratios. Constr. Build. Mater. 2024, 438, 137157. [Google Scholar] [CrossRef]

- Li, Y.; Tang, E. Research on C-S-H and C-S-H Dehydration Relative to Cement Stone Structure Modification. J. Ceram. 1991, 4, 373–380. [Google Scholar]

- Li, J.; Tang, E. Effect of synthetic C-S-H gel on the interface zone between cement stone and aggregate. J. Wuhan Univ. Technol. 1997, 2, 9–12. [Google Scholar]

- Thomas, J.; Hamlin, M.; Jennings, J. Influence of Nucleation Seeding on the Hydration Mechanisms of Tricalcium Silicate and Cement. J. Phys. Chem. 2009, 113, 4327–4334. [Google Scholar] [CrossRef]

- Wiroonpochit, P.; Boonmee, P.; Kerdlap, W.; Chisti, Y.; Hansupalak, N. Synthesis of low crystalline thermally insulating calcium silicate hydrate via a simple template-assisted sol–gel method. Constr. Build. Mater. 2022, 353, 129081. [Google Scholar] [CrossRef]

- Tian, H.; Stephan, D.; Lothenbach, B.; Lehmann, C. Influence of foreign ions on calcium silicate hydrate under hydrothermal conditions: A review. Constr. Build. Mater. 2021, 301, 124071. [Google Scholar] [CrossRef]

- Chen, G.; Lin, M.; Chen, Y.; Kong, G.; Geng, Z. Alkali-reinforced hydrothermal solidification of waste soil. Mater. Chem. Phys. 2022, 289, 126505. [Google Scholar] [CrossRef]

- Li, M.; Tan, H.; He, X.; Jian, S.; Zheng, Z.; Su, Y.; Yang, J.; Wang, Y.; Luo, Z. Preparation of nano cement particles by wet-grinding and its effect on hydration of cementitious system. Constr. Build. Mater. 2021, 307, 125051. [Google Scholar] [CrossRef]

- Ji, G.; Peng, X.; Wang, S.; Li, J.; Sun, K.; Chi, H. Influence of ground quartz sand finesses on the formation of poorly ordered calcium silicate hydrate prepared by dynamically hydrothermal synthesis. Case Stud. Constr. Mater. 2024, 20, e02746. [Google Scholar] [CrossRef]

- Gu, X.; Tan, H.; He, X.; Zhang, J.; Li, M.; Su, Y.; Yang, J. Nano C-S-H seeds prepared from ground granulated blast-furnace slag-carbide slag and its application in Portland cement. Constr. Build. Mater. 2022, 329, 127204. [Google Scholar] [CrossRef]

- Yang, J.; Zeng, J.; He, X.; Zhang, Y.; Su, Y.; Tan, H. Sustainable clinker-free solid waste binder produced from wet-ground granulated blast-furnace slag, phosphogypsum and carbide slag. Constr. Build. Mater. 2022, 330, 127218. [Google Scholar] [CrossRef]

- Li, Y.; Fang, J.; Cheng, L.; He, X.; Su, Y.; Tan, H. Mechanical performance, hydration characteristics and microstructures of high volume blast furnace ferronickel slag cement mortar by wet grinding activation. Constr. Build. Mater. 2022, 320, 126148. [Google Scholar] [CrossRef]

- Wang, Y.; Tan, H.; Gu, X.; He, X.; Zhang, J. Preparation of nano-kaolin by wet-grinding process and its application as accelerator in Portland cement. J. Build. Eng. 2021, 44, 103401. [Google Scholar] [CrossRef]

- Liu, X.; Ma, B.; Tan, H.; He, X.; Zhao, R.; Chen, P.; Su, Y.; Yang, J. Preparation of ultrafine fly ash by wet grinding and its utilization for immobilizing chloride ions in cement paste. Waste Manag. 2020, 113, 456–468. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Yang, M.; He, X.; Ma, M.; Fan, M.; Su, Y.; Tan, H. Green reaction-type nucleation seed accelerator prepared from coal fly ash ground in water environment. Constr. Build. Mater. 2021, 306, 124840. [Google Scholar] [CrossRef]

- Tan, H.; Du, C.; He, X.; Li, M.; Zhang, J.; Zheng, Z.; Su, Y.; Yang, J.; Deng, X.; Wang, Y. Enhancement of compressive strength of high-volume fly ash cement paste by wet grinded cement: Towards low carbon cementitious materials. Constr. Build. Mater. 2022, 323, 126458. [Google Scholar] [CrossRef]

- Feng, X.; Zhuo, C.; Yin, S. Synthesizing high-quality C-S-H seeds using the impinging stream precipitation method. J. Sustain. Cem.-Based Mater. 2024, 13, 841–853. [Google Scholar] [CrossRef]

- Deng, X.; Tan, H.; Yang, Z.; He, X.; Wang, J.; Jian, S.; Huang, J.; Yang, J. C-S-H based nucleation seed prepared from waste glass powder and carbide slag and its application in Portland cement. Constr. Build. Mater. 2024, 416, 135258. [Google Scholar] [CrossRef]

- Cohen, S. Colloid Science; Science Press: Alexandria, Australia, 2012. [Google Scholar]

- Xu, R.; Li, X.; Zuo, D. Flow Field Simulation of Ball-milling Impact towards Dispersion of Nano-suspension and Experimental Verification. J. Mater. Sci. Eng. 2013, 31, 737–742. [Google Scholar]

- Chwadaka, P.; Damodhara, R. Modeling the particle size of nanomaterials synthesized in a planetary ball mill. OpenNano 2023, 14, 100191. [Google Scholar]

- GB/T 50081-2019; Standard Test Methods for Physical and Mechanical Properties of Concrete. Standardization Administration of China: Beijing, China, 2019.

- GB/T 13476-2023; Pretensioned Spun Concrete Piles. Standardization Administration of China: Beijing, China, 2023.

- GB/T 17671-2021; Test Method of Cement Mortar Strength. Standardization Administration of China: Beijing, China, 2021.

- GB/T 30514-2014; Glass Capillary Kinematic Viscometer-Specifications and Operating Instructions. Standardization Administration of China: Beijing, China, 2014.

- Guan, J.; Liu, S.; Liu, X.; Zhang, G.; Lai, G.; Gao, R.; Zhu, H.; Huang, M.; Wang, Z.; Cui, S. Effect of side chain ionizability of polycarboxylate superplasticizer on cement hydration. Constr. Build. Mater. 2024, 436, 136940. [Google Scholar] [CrossRef]

- Plank, J.; Hirsch, C. Impact of zeta potential of early cement hydration phases on superplasticizer adsorption. Cem. Concr. Res. 2007, 37, 537–542. [Google Scholar] [CrossRef]

- Luc, N.; Alexander, E.; Matthias, K. A kinetic analysis of the role of polymers in mineral nucleation. The exampleof gypsum. Cem. Concr. Res. 2019, 124, 105837. [Google Scholar]

- Made, J.; Muthukannan, V.; Camellia, P.; Ferry, F. Dispersion of amorphous silica nanoparticles via beads milling processand their particle size analysis, hydrophobicity and anti-bacterial activity. Adv. Powder Technol. 2020, 31, 370–380. [Google Scholar] [CrossRef]

- Fenda, F.; Ferry, F.; Sparisoma, V. Experimental and simulation study of solid flows in beads mill. Adv. Powder Technol. 2021, 32, 2703–2711. [Google Scholar]

- Tao, Y.; Jae, W.; Xiong, S. Physicochemical properties of nano fish bone prepared by wet media milling. LWT—Food Sci. Technol. 2015, 64, 367–373. [Google Scholar]

- Liu, H.; Sun, X.; Du, H.; Lu, H.; Ma, Y.; Shen, W.; Tian, Z. Effects and threshold of water film thickness on multi-mineral cement paste. Cem. Concr. Compos. 2020, 112, 103677. [Google Scholar] [CrossRef]

- Zhang, Z.; Feng, Q.; Zhu, W.; Lin, X.; Chen, K.; Yin, W.; Lu, C. Influence of Sand-Cement Ratio and Polycarboxylate Superplasticizer on the Basic Properties of Mortar Based on Water Film Thickness. Materials 2021, 14, 4850. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Ma, Y.; Wang, J.; Gao, N.; Hu, Z.; Liu, J.; Wang, K. A novel shrinkage-reducing polycarboxylate superplasticizer for cement-based materials: Synthesis, performance and mechanisms. Constr. Build. Mater. 2022, 321, 126342. [Google Scholar] [CrossRef]

- Kanchanason, V.; Plank, J. Role of pH on the structure, composition and morphology of C-S-H-PCE nanocomposites and their effect on early strength development of Portland cement. Cem. Concr. Res. 2017, 102, 98. [Google Scholar] [CrossRef]

- Abbas, S.N.; Qureshi, M.I.; Alkharisi, M.K.; Alturki, M.; Ahmad, Z. Combined effect of silica fume and various fibers on fresh and hardened properties of concrete incorporating HDPE aggregates. Cem. Concr. Res. 2024, 445, 137940. [Google Scholar] [CrossRef]

- Hou, D.; Li, H.; Zhang, L.; Zhang, J. Nano-scale mechanical properties investigation of C-S-H from hydratedtri-calcium silicate by nano-indentation and molecular dynamics simulation. Cem. Concr. Res. 2018, 189, 265–275. [Google Scholar]

- Wang, Y.; Wang, X.; Yao, F.; Lin, C.; Xu, S.; Li, Y.; Du, J.; Pan, L. What are the mechanisms of functional monomers’ effect on air entrainment of polycarboxylate superplasticizers in cement paste and mortar. Constr. Build. Mater. 2024, 442, 137038. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, Y.; Xie, Y.; Liu, Y.; Tao, J.; Liu, R.; Li, Z.; Liu, F.; Li, M. The effect of alkyl acrylate ester side chain length of polycarboxylate superplasticizer on the flow behaviour of concrete. Constr. Build. Mater. 2024, 443, 137691. [Google Scholar] [CrossRef]

- Mehmet, S.; Egemen, T.; Jale, Y.; Malayoglu, U. The effect of nano-biochar produced from various raw materials on flow and mechanical properties of mortar. Constr. Build. Mater. 2024, 416, 135404. [Google Scholar]

- Kim, G.; Cho, S.; Moon, J.; Suh, H.; Her, S.; Sim, S.; Bae, S. Investigation of the hydrate formation and mechanical performance of limestone calcined clay cement paste incorporating nano-CaCO3 and nano-SiO2 as partial limestone substitutes. Constr. Build. Mater. 2024, 418, 135335. [Google Scholar] [CrossRef]

- Yun, J.; Zhao, C.; Li, X.; Zhang, W.; Liu, H.; Liu, B. Rheological properties and early mechanical strength of oil-well cement modified by hybrid nano-silica and nano-hexagonal boron nitride. Constr. Build. Mater. 2022, 356, 129291. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, L.; Shi, J.; Luo, Q.; Jiang, J.; Hou, D. Full process of calciumsilicate hydrate decalcification: Molecular structure, dynamics. and mechanical properties. Cem. Concr. Res. 2022, 161, 106964. [Google Scholar] [CrossRef]

- Tennis, P.; Jennings, H. A model for two types of calcium silicate hydrate in the microstructure of Portland cement pastes. Cem. Concr. Res. 2000, 30, 855–863. [Google Scholar] [CrossRef]

| Sample | SiO2 | Al2O3 | CaO | Fe2O3 | SO3 | MgO | LOI |

|---|---|---|---|---|---|---|---|

| Cement | 22.84 | 4.53 | 61.98 | 3.41 | 2.83 | 2.61 | 1.80 |

| GGBS | 34.13 | 13.52 | 40.88 | 0.51 | 2.36 | 6.79 | 1.81 |

| SF | 98.31 | 0.14 | 0.56 | 0.21 | 0.12 | 0.31 | 0.35 |

| Sample | Cement | GGBS | SF | Sand | Aggregate | Water | C-S-H Seed |

|---|---|---|---|---|---|---|---|

| Blank | 320 | 85 | 40 | 620 | 1380 | 110 | 0 |

| CS-0 | 250 | 85 | 110 | 620 | 1380 | 110 | 0 |

| CS-1 | 246 | 85 | 110 | 620 | 1380 | 110 | 18 |

| CS-3 | 237 | 85 | 110 | 620 | 1380 | 110 | 54 |

| CS-5 | 228 | 85 | 110 | 620 | 1380 | 110 | 89 |

| CS-7 | 219 | 85 | 110 | 620 | 1380 | 110 | 125 |

| CS-9 | 210 | 85 | 110 | 620 | 1380 | 110 | 160 |

| CS-11 | 201 | 85 | 110 | 620 | 1380 | 110 | 196 |

| Sample | Cement | GGBS | SF | Water | C-S-H Seed |

|---|---|---|---|---|---|

| Blank | 320 | 85 | 40 | 110 | 0 |

| CS-0 | 250 | 85 | 110 | 110 | 0 |

| CS-1 | 246 | 85 | 110 | 110 | 18 |

| CS-3 | 237 | 85 | 110 | 110 | 54 |

| CS-5 | 228 | 85 | 110 | 110 | 89 |

| CS-7 | 219 | 85 | 110 | 110 | 125 |

| CS-9 | 210 | 85 | 110 | 110 | 160 |

| CS-11 | 201 | 85 | 110 | 110 | 196 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Zhao, P.; Tian, Y.; Liu, J. Effects of C-S-H Seed Prepared by Wet Grinding on the Properties of Cement Containing Large Amounts of Silica Fume. Polymers 2024, 16, 2769. https://doi.org/10.3390/polym16192769

Wang S, Zhao P, Tian Y, Liu J. Effects of C-S-H Seed Prepared by Wet Grinding on the Properties of Cement Containing Large Amounts of Silica Fume. Polymers. 2024; 16(19):2769. https://doi.org/10.3390/polym16192769

Chicago/Turabian StyleWang, Shiheng, Peng Zhao, Yaogang Tian, and Jianan Liu. 2024. "Effects of C-S-H Seed Prepared by Wet Grinding on the Properties of Cement Containing Large Amounts of Silica Fume" Polymers 16, no. 19: 2769. https://doi.org/10.3390/polym16192769

APA StyleWang, S., Zhao, P., Tian, Y., & Liu, J. (2024). Effects of C-S-H Seed Prepared by Wet Grinding on the Properties of Cement Containing Large Amounts of Silica Fume. Polymers, 16(19), 2769. https://doi.org/10.3390/polym16192769