A Novel and Green Method for Preparing Highly Conductive PEDOT:PSS Films for Thermoelectric Energy Harvesting

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

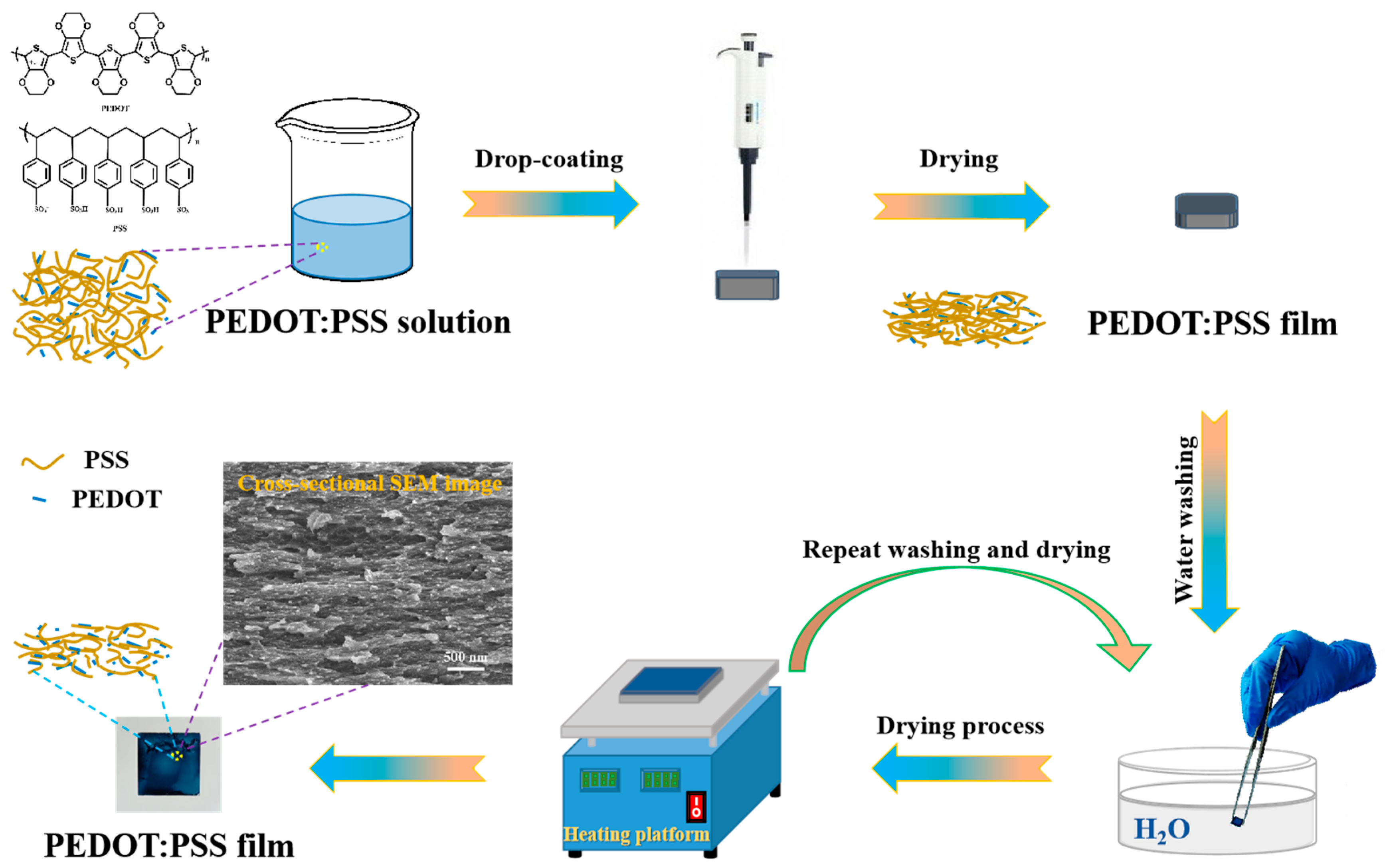

2.2. Pre-Treatment and Film Preparation

2.3. Characterizations and Measurements

3. Results and Discussion

3.1. Fabrication of PEDOT:PSS Film and the Water Treatment

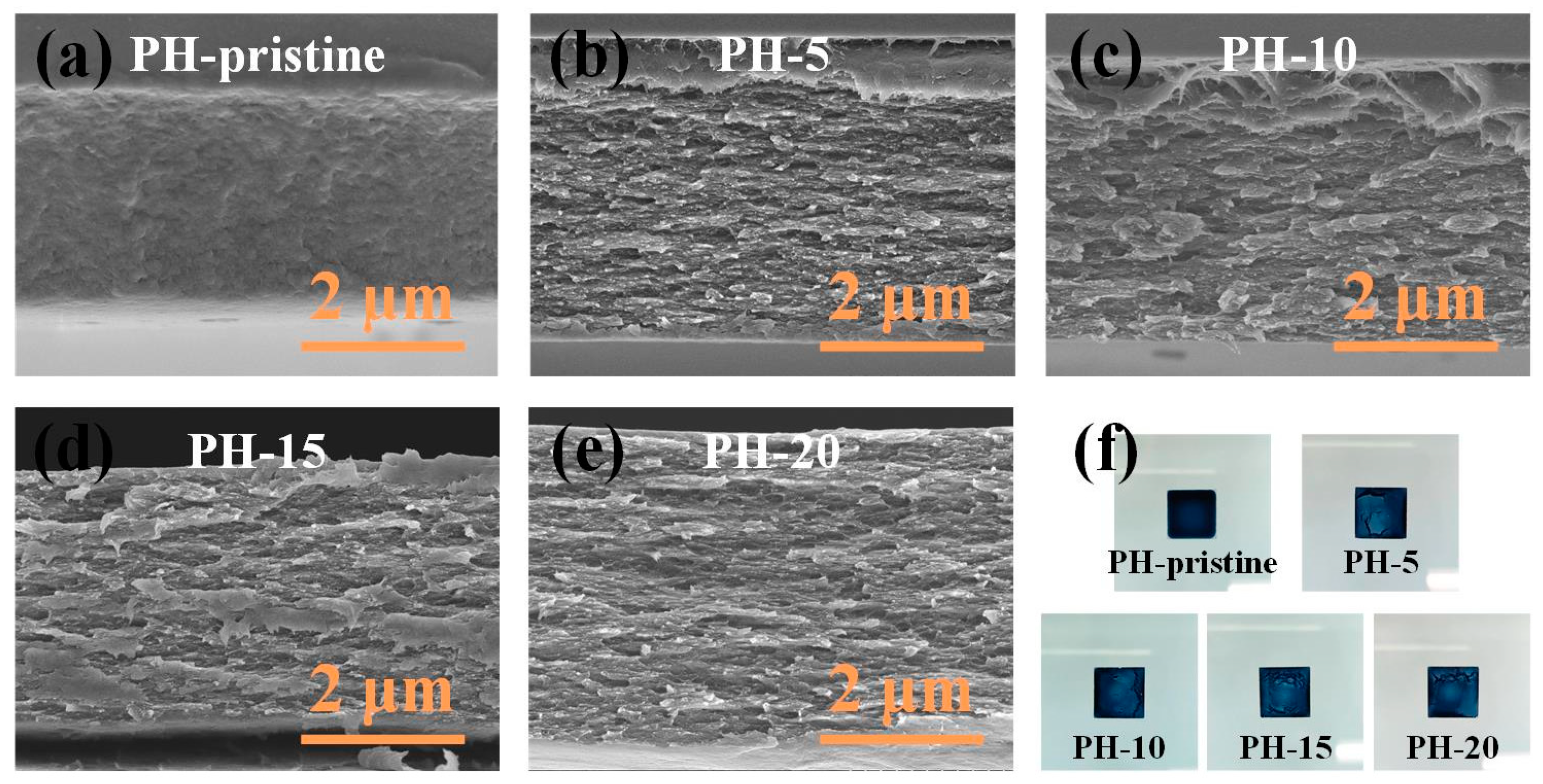

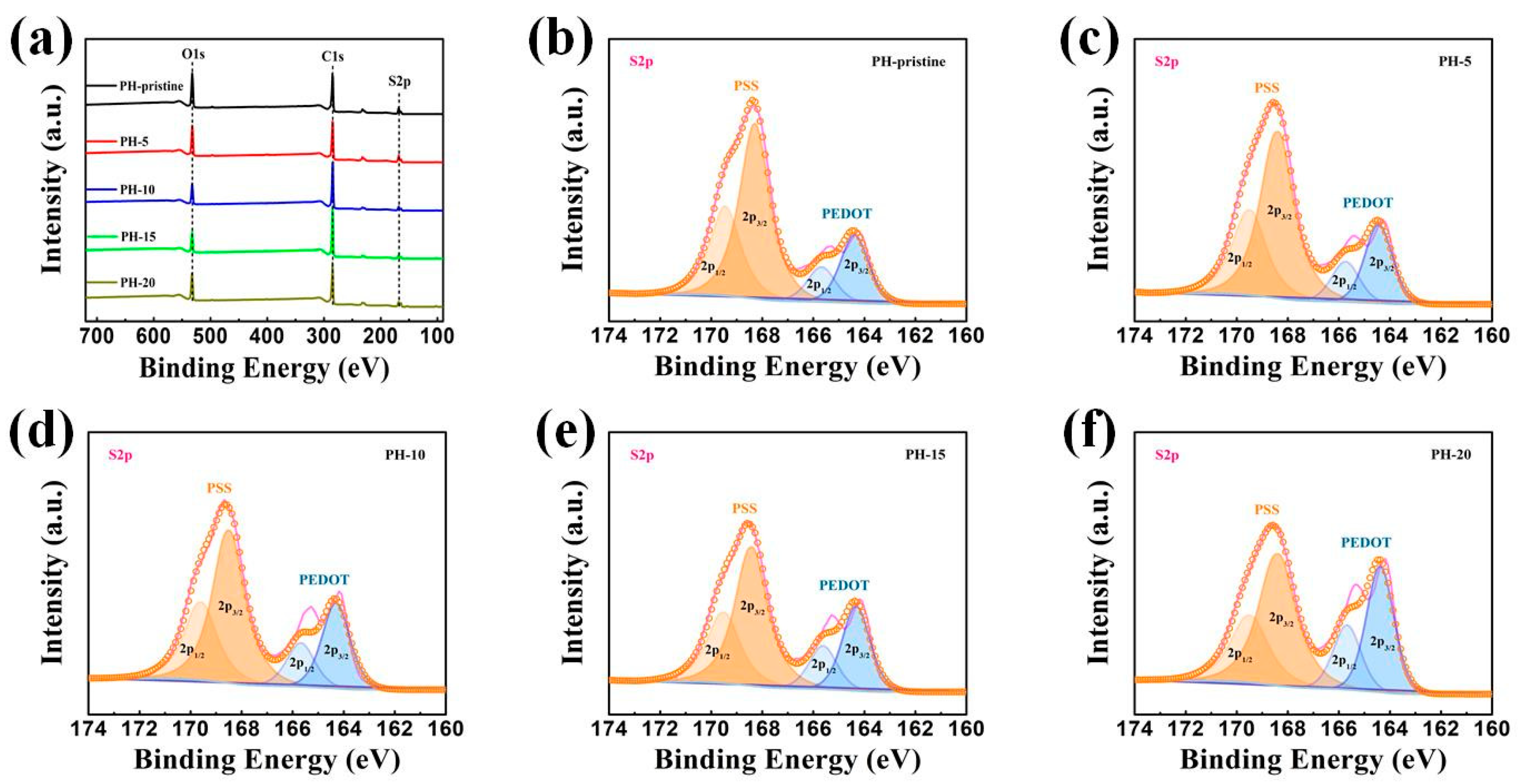

3.2. Structure Characterization and Analysis

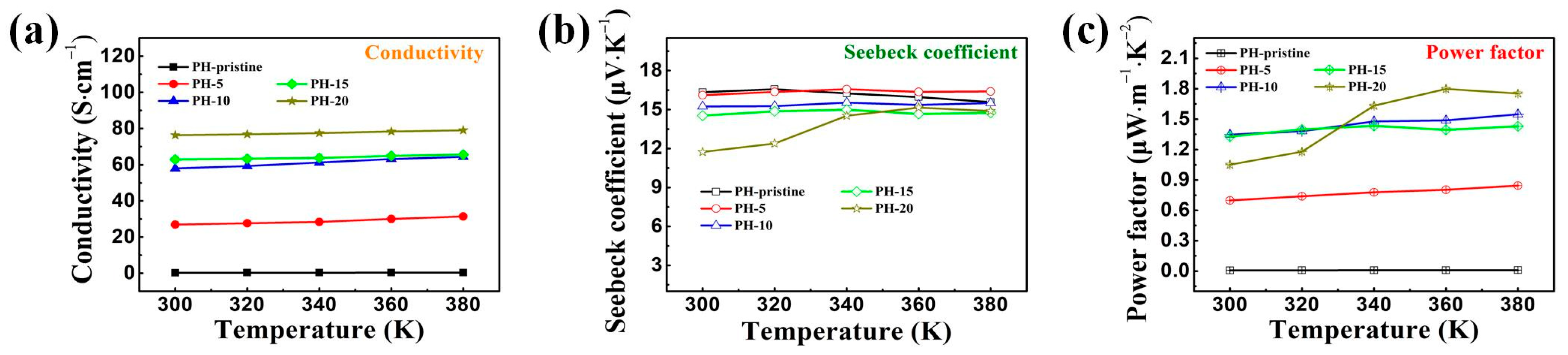

3.3. Thermoelectric Performance of PEDOT:PSS Film Prepared via Water Treatment

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Østergaard, P.A.; Duic, N.; Noorollahi, Y.; Mikulcic, H.; Kalogirou, S. Sustainable development using renewable energy technology. Renew. Energy 2020, 146, 2430–2437. [Google Scholar] [CrossRef]

- You, S.; Bi, S.; Huang, J.; Jia, Q.; Yuan, Y.; Xia, Y.; Xiao, Z.; Sun, Z.; Liu, J.; Sun, S.; et al. Additive-Enhanced Crystallization of Solution Process for Planar Perovskite Solar Cells with Efficiency Exceeding 19 %. Chem. A Eur. J. 2017, 23, 18140–18145. [Google Scholar] [CrossRef]

- Cheng, N.; Liu, Z.; Li, W.; Yu, Z.; Lei, B.; Zi, W.; Xiao, Z.; Sun, S.; Zhao, Z.; Zong, P.-A. Cu2ZnGeS4 as a novel hole transport material for carbon-based perovskite solar cells with power conversion efficiency above 18%. Chem. Eng. J. 2023, 454, 140146. [Google Scholar] [CrossRef]

- Gielen, D.; Boshell, F.; Saygin, D.; Bazilian, M.D.; Wagner, N.; Gorini, R. The role of renewable energy in the global energy transformation. Energy Strategy Rev. 2019, 24, 38–50. [Google Scholar] [CrossRef]

- Zhang, Q.; Sun, Y.; Xu, W.; Zhu, D. Organic Thermoelectric Materials: Emerging Green Energy Materials Converting Heat to Electricity Directly and Efficiently. Adv. Mater. 2014, 26, 6829–6851. [Google Scholar] [CrossRef]

- Zeng, Y.J.; Wu, D.; Cao, X.H.; Zhou, W.X.; Tang, L.M.; Chen, K.Q. Nanoscale Organic Thermoelectric Materials: Measurement, Theoretical Models, and Optimization Strategies. Adv. Funct. Mater. 2019, 30, 1903873. [Google Scholar] [CrossRef]

- Kong, F.; Liu, C.; Song, H.; Xu, J.; Huang, Y.; Zhu, H.; Wang, J. Effect of solution pH value on thermoelectric performance of free-standing PEDOT:PSS films. Synth. Met. 2013, 185–186, 31–37. [Google Scholar] [CrossRef]

- Kumar, S.R.S.; Kurra, N.; Alshareef, H.N. Enhanced high temperature thermoelectric response of sulphuric acid treated conducting polymer thin films. J. Mater. Chem. C 2016, 4, 215–221. [Google Scholar] [CrossRef]

- Kim, J.; Jang, J.G.; Hong, J.-I.; Kim, S.H.; Kwak, J. Sulfuric acid vapor treatment for enhancing the thermoelectric properties of PEDOT:PSS thin-films. J. Mater. Sci. Mater. Electron. 2016, 27, 6122–6127. [Google Scholar] [CrossRef]

- Song, H.; Kong, F.; Liu, C.; Xu, J.; Jiang, Q.; Shi, H. Improved thermoelectric performance of PEDOT:PSS film treated with camphorsulfonic acid. J. Polym. Res. 2013, 20, 316. [Google Scholar] [CrossRef]

- Ouyang, J. Solution-Processed PEDOT:PSS Films with Conductivities as Indium Tin Oxide through a Treatment with Mild and Weak Organic Acids. ACS Appl. Mater. Interfaces 2013, 5, 13082–13088. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.Y.; Jung, J.H.; Lee, D.E.; Joo, J. Enhancement of electrical conductivity of poly(3,4-ethylenedioxythiophene)/poly(4-styrenesulfonate) by a change of solvents. Synth. Met. 2002, 126, 311–316. [Google Scholar] [CrossRef]

- Kim, G.H.; Shao, L.; Zhang, K.; Pipe, K.P. Engineered doping of organic semiconductors for enhanced thermoelectric efficiency. Nat. Mater. 2013, 12, 719–723. [Google Scholar] [CrossRef] [PubMed]

- Takano, T.; Masunaga, H.; Fujiwara, A.; Okuzaki, H.; Sasaki, T. PEDOT Nanocrystal in Highly Conductive PEDOT:PSS Polymer Films. Macromolecules 2012, 45, 3859–3865. [Google Scholar] [CrossRef]

- Lee, S.H.; Park, H.; Kim, S.; Son, W.; Cheong, I.W.; Kim, J.H. Transparent and flexible organic semiconductor nanofilms with enhanced thermoelectric efficiency. J. Mater. Chem. A 2014, 2, 7288–7294. [Google Scholar] [CrossRef]

- Kishi, N.; Kondo, Y.; Kunieda, H.; Hibi, S.; Sawada, Y. Enhancement of thermoelectric properties of PEDOT:PSS thin films by addition of anionic surfactants. J. Mater. Sci. Mater. Electron. 2017, 29, 4030–4034. [Google Scholar] [CrossRef]

- Zhu, Z.; Liu, C.; Jiang, F.; Xu, J.; Liu, E. Effective treatment methods on PEDOT:PSS to enhance its thermoelectric performance. Synth. Met. 2017, 225, 31–40. [Google Scholar] [CrossRef]

- Xia, Y.; Ouyang, J. Salt-Induced Charge Screening and Significant Conductivity Enhancement of Conducting Poly(3,4-ethylenedioxythiophene):Poly(styrenesulfonate). Macromolecules 2009, 42, 4141–4147. [Google Scholar] [CrossRef]

- Badre, C.; Marquant, L.; Alsayed, A.M.; Hough, L.A. Highly Conductive Poly(3,4-ethylenedioxythiophene):Poly (styrenesulfonate) Films Using 1-Ethyl-3-methylimidazolium Tetracyanoborate Ionic Liquid. Adv. Funct. Mater. 2012, 22, 2723–2727. [Google Scholar] [CrossRef]

- Liu, C.; Xu, J.; Lu, B.; Yue, R.; Kong, F. Simultaneous Increases in Electrical Conductivity and Seebeck Coefficient of PEDOT:PSS Films by Adding Ionic Liquids into a Polymer Solution. J. Electron. Mater. 2012, 41, 639–645. [Google Scholar] [CrossRef]

- Du, Y.; Shi, Y.; Meng, Q.; Shen, S.Z. Preparation and thermoelectric properties of flexible SWCNT/PEDOT:PSS composite film. Synth. Met. 2020, 261, 116318. [Google Scholar] [CrossRef]

- Wei, S.; Huang, X.; Deng, L.; Yan, Z.-C.; Chen, G. Facile preparations of layer-like and honeycomb-like films of poly(3,4-ethylenedioxythiophene)/carbon nanotube composites for thermoelectric application. Compos. Sci. Technol. 2021, 208, 108759. [Google Scholar] [CrossRef]

- See, K.C.; Feser, J.P.; Chen, C.E.; Majumdar, A.; Urban, J.J.; Segalman, R.A. Water-Processable Polymer−Nanocrystal Hybrids for Thermoelectrics. Nano Lett. 2010, 10, 4664–4667. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Xie, L.; Wang, L.; Chen, W.; Wei, W.; Chen, X.; Luo, S.; Dong, L.; Dai, Q.; Huang, Y.; et al. Hierarchical Porous RGO/PEDOT/PANI Hybrid for Planar/Linear Supercapacitor with Outstanding Flexibility and Stability. Nanomicro. Lett. 2020, 12, 17. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; He, Y.; Cao, K. Flexible Surface-Enhanced Raman Scattering Substrates: A Review on Constructions, Applications, and Challenges. Adv. Mater. Interfaces 2021, 8, 2100982. [Google Scholar] [CrossRef]

- Zhou, X.; Pan, C.; Liang, A.; Wang, L.; Wong, W.-Y. Thermoelectric properties of composite films prepared with benzodithiophene derivatives and carbon nanotubes. Compos. Sci. Technol. 2017, 145, 40–45. [Google Scholar] [CrossRef]

- Jang, D.; Yoon, H.N.; Seo, J.; Cho, H.J.; Kim, G.M.; Kim, Y.-K.; Yang, B. Improved electromagnetic interference shielding performances of carbon nanotube and carbonyl iron powder (CNT@CIP)-embedded polymeric composites. J. Mater. Res. Technol. 2022, 18, 1256–1266. [Google Scholar] [CrossRef]

- Gao, L.; Liu, F.; Wei, Q.; Cai, Z.; Duan, J.; Li, F.; Li, H.; Lv, R.; Wang, M.; Li, J.; et al. Fabrication of Highly Conductive Porous Fe3O4@RGO/PEDOT:PSS Composite Films via Acid Post-Treatment and Their Applications as Electrochemical Supercapacitor and Thermoelectric Material. Polymers 2023, 15, 3453. [Google Scholar] [CrossRef]

- Liu, F.-W.; Zhong, F.; Wang, S.-C.; Xie, W.-H.; Chen, X.; Hu, Y.-G.; Ge, Y.-Y.; Gao, Y.; Wang, L.; Liang, Z.-Q. Facile fabrication of highly flexible, porous PEDOT:PSS/SWCNTs films for thermoelectric applications. Chin. Phys. B 2022, 31, 027303. [Google Scholar] [CrossRef]

- Kim, N.; Kee, S.; Lee, S.H.; Lee, B.H.; Kahng, Y.H.; Jo, Y.R.; Kim, B.J.; Lee, K. Highly Conductive PEDOT:PSS Nanofibrils Induced by Solution-Processed Crystallization. Adv. Mater. 2013, 26, 2268–2272. [Google Scholar] [CrossRef]

- Kim, N.; Lee, B.H.; Choi, D.; Kim, G.; Kim, H.; Kim, J.-R.; Lee, J.; Kahng, Y.H.; Lee, K. Role of Interchain Coupling in the Metallic State of Conducting Polymers. Phys. Rev. Lett. 2012, 109, 106405. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Cai, K.; Shen, S. Enhanced thermoelectric properties of poly(3,4-ethylenedioxythiophene) thin films treated with H2SO4. Org. Electron. 2014, 15, 3087–3095. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, Q.; Zhang, W.; Yang, S. Conductivity enhancement of PEDOT:PSS film via sulfonic acid modification: Application as transparent electrode for ITO-free polymer solar cells. Sci. China Chem. 2018, 61, 1179–1186. [Google Scholar] [CrossRef]

- Zhou, X.; Pan, C.; Gao, C.; Shinohara, A.; Yin, X.; Wang, L.; Li, Y.; Jiang, Q.; Yang, C.; Wang, L. Thermoelectrics of two-dimensional conjugated benzodithiophene-based polymers: Density-of-states enhancement and semi-metallic behavior. J. Mater. Chem. A 2019, 7, 10422–10430. [Google Scholar] [CrossRef]

- Ashizawa, S.; Horikawa, R.; Okuzaki, H. Effects of solvent on carrier transport in poly(3,4-ethylenedioxythiophene)/poly(4-styrenesulfonate). Synth. Met. 2005, 153, 5–8. [Google Scholar] [CrossRef]

- Jiang, Q.; Lan, X.; Liu, C.; Shi, H.; Zhu, Z.; Zhao, F.; Xu, J.; Jiang, F. High-performance hybrid organic thermoelectric SWNTs/PEDOT:PSS thin-films for energy harvesting. Mater. Chem. Front. 2018, 2, 679–685. [Google Scholar] [CrossRef]

- Liu, C.; Jiang, F.; Huang, M.; Lu, B.; Yue, R.; Xu, J. Free-Standing PEDOT-PSS/Ca3Co4O9 Composite Films as Novel Thermoelectric Materials. J. Electron. Mater. 2010, 40, 948–952. [Google Scholar] [CrossRef]

- Andrei, V.; Bethke, K.; Madzharova, F.; Bronneberg, A.C.; Kneipp, J.; Rademann, K. In Situ Complementary Doping, Thermoelectric Improvements, and Strain-Induced Structure within Alternating PEDOT:PSS/PANI Layers. ACS Appl. Mater. Interfaces 2017, 9, 33308–33316. [Google Scholar] [CrossRef]

- Shi, H.; Liu, C.; Xu, J.; Song, H.; Lu, B.; Jiang, F.; Zhou, W.; Zhang, G.; Jiang, Q. Facile Fabrication of PEDOT:PSS/Polythiophenes Bilayered Nanofilms on Pure Organic Electrodes and Their Thermoelectric Performance. ACS Appl. Mater. Interfaces 2013, 5, 12811–12819. [Google Scholar] [CrossRef]

- Song, H.; Liu, C.; Xu, J.; Jiang, Q.; Shi, H. Fabrication of a layered nanostructure PEDOT:PSS/SWCNTs composite and its thermoelectric performance. RSC Adv. 2013, 3, 22065–22071. [Google Scholar] [CrossRef]

- Jiang, F.-X.; Xu, J.-K.; Lu, B.-Y.; Xie, Y.; Huang, R.-J.; Li, L.F. Thermoelectric Performance of Poly(3,4-ethylenedioxythiophene):Poly(styrenesulfonate). Chin. Phys. Lett. 2008, 25, 2202–2205. [Google Scholar]

- Ely, F.; Matsumoto, A.; Zoetebier, B.; Peressinotto, V.S.; Hirata, M.K.; de Sousa, D.A.; Maciel, R. Handheld and automated ultrasonic spray deposition of conductive PEDOT:PSS films and their application in AC EL devices. Org. Electron. 2014, 15, 1062–1070. [Google Scholar] [CrossRef]

| Raman Bands (cm−1) | Assignments |

|---|---|

| 1566, 1493 | asymmetrical Cα=Cβ vibrations |

| 1428 | symmetric Cα=Cβ(–O) stretching vibrations of the five-membered thiophene ring |

| 1367 | Cβ–Cβ stretching |

| 1254 | Cα–Cα inter ring stretching |

| 1117 | bending vibration of C–C ring |

| 1094 | C–O–C stretching |

| 988 | deformation of the oxyethylene ring |

| 701 | deformation of the symmetric C–S–C |

| 576 | deformation of the oxyethylene ring |

| 437 | SO2 bending |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, F.; Gao, L.; Duan, J.; Li, F.; Li, J.; Ge, H.; Cai, Z.; Li, H.; Wang, M.; Lv, R.; et al. A Novel and Green Method for Preparing Highly Conductive PEDOT:PSS Films for Thermoelectric Energy Harvesting. Polymers 2024, 16, 266. https://doi.org/10.3390/polym16020266

Liu F, Gao L, Duan J, Li F, Li J, Ge H, Cai Z, Li H, Wang M, Lv R, et al. A Novel and Green Method for Preparing Highly Conductive PEDOT:PSS Films for Thermoelectric Energy Harvesting. Polymers. 2024; 16(2):266. https://doi.org/10.3390/polym16020266

Chicago/Turabian StyleLiu, Fuwei, Luyao Gao, Jiajia Duan, Fuqun Li, Jingxian Li, Hongbing Ge, Zhiwei Cai, Huiying Li, Mengke Wang, Ruotong Lv, and et al. 2024. "A Novel and Green Method for Preparing Highly Conductive PEDOT:PSS Films for Thermoelectric Energy Harvesting" Polymers 16, no. 2: 266. https://doi.org/10.3390/polym16020266

APA StyleLiu, F., Gao, L., Duan, J., Li, F., Li, J., Ge, H., Cai, Z., Li, H., Wang, M., Lv, R., & Li, M. (2024). A Novel and Green Method for Preparing Highly Conductive PEDOT:PSS Films for Thermoelectric Energy Harvesting. Polymers, 16(2), 266. https://doi.org/10.3390/polym16020266