Flat-Silk-Cocoon-Based Wearable Flexible Piezoresistive Sensor and Its Performance

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

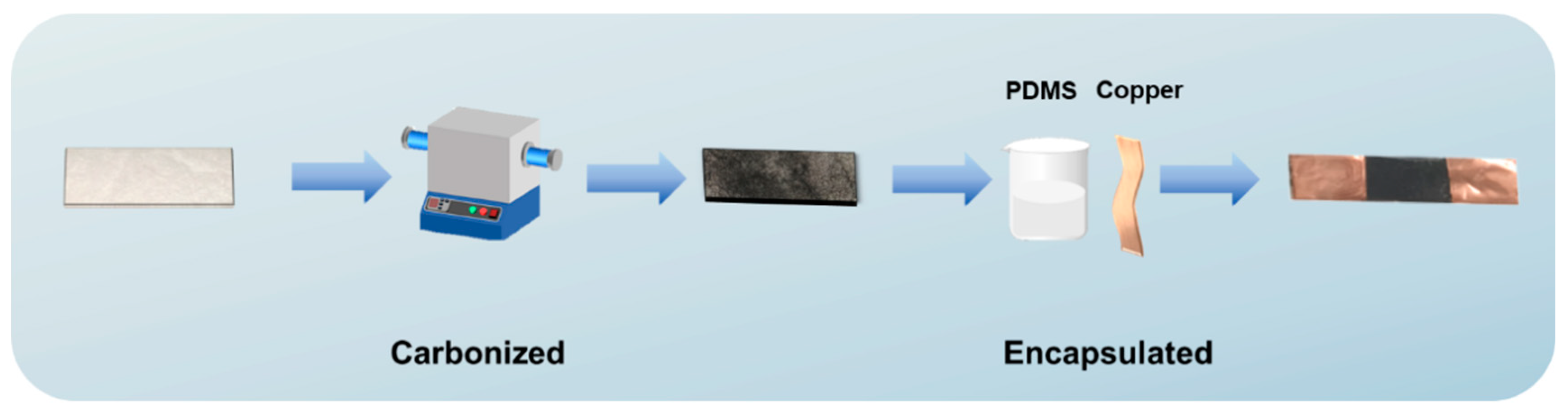

2.2. Fabrication of CFSCs and the Flexible Piezoresistive Sensor

2.3. Characterization of CFSCs

2.4. Measurement of Sensing Performance

3. Results and Discussion

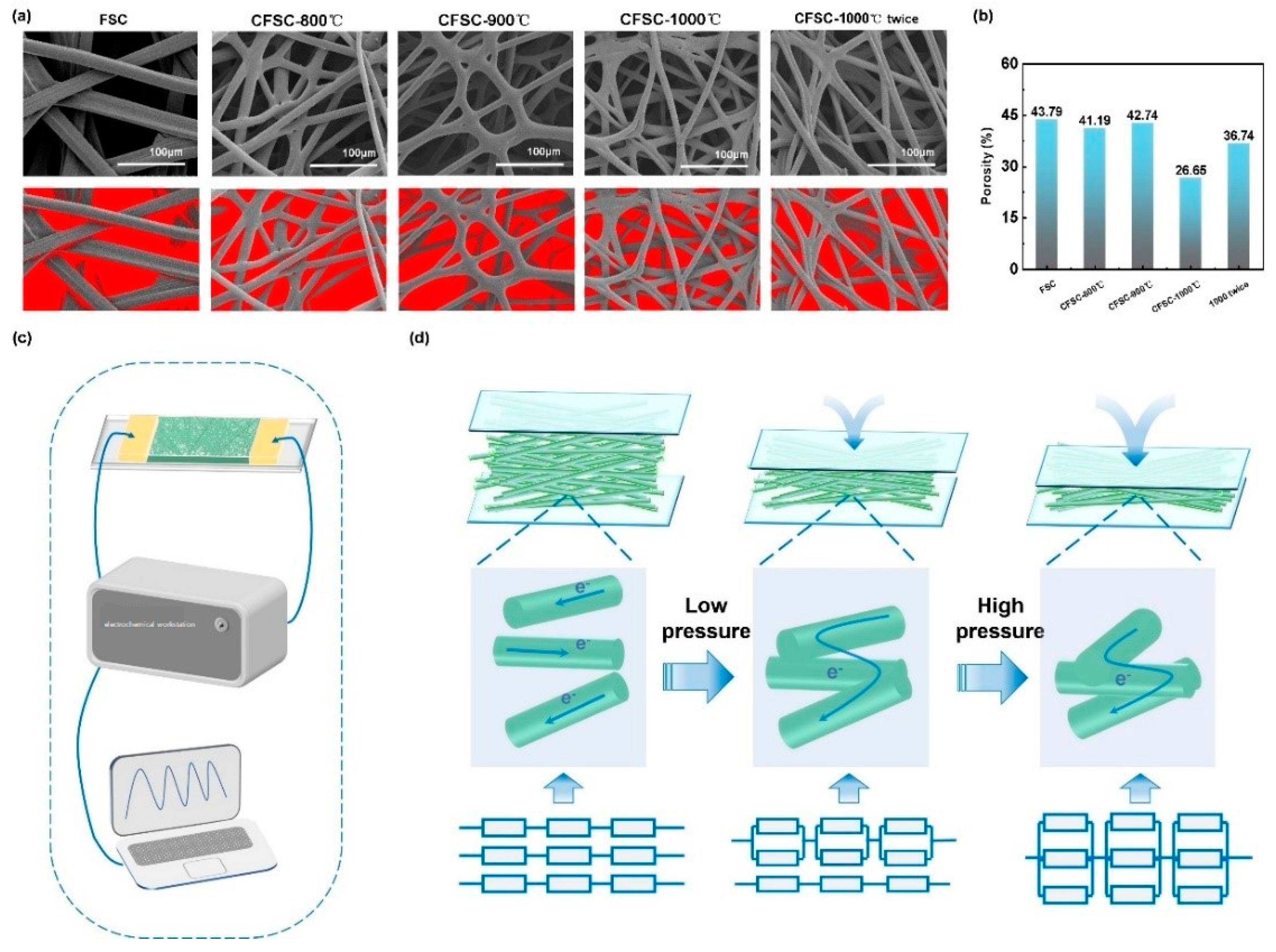

3.1. FSC form Exploration and SEM Characterization

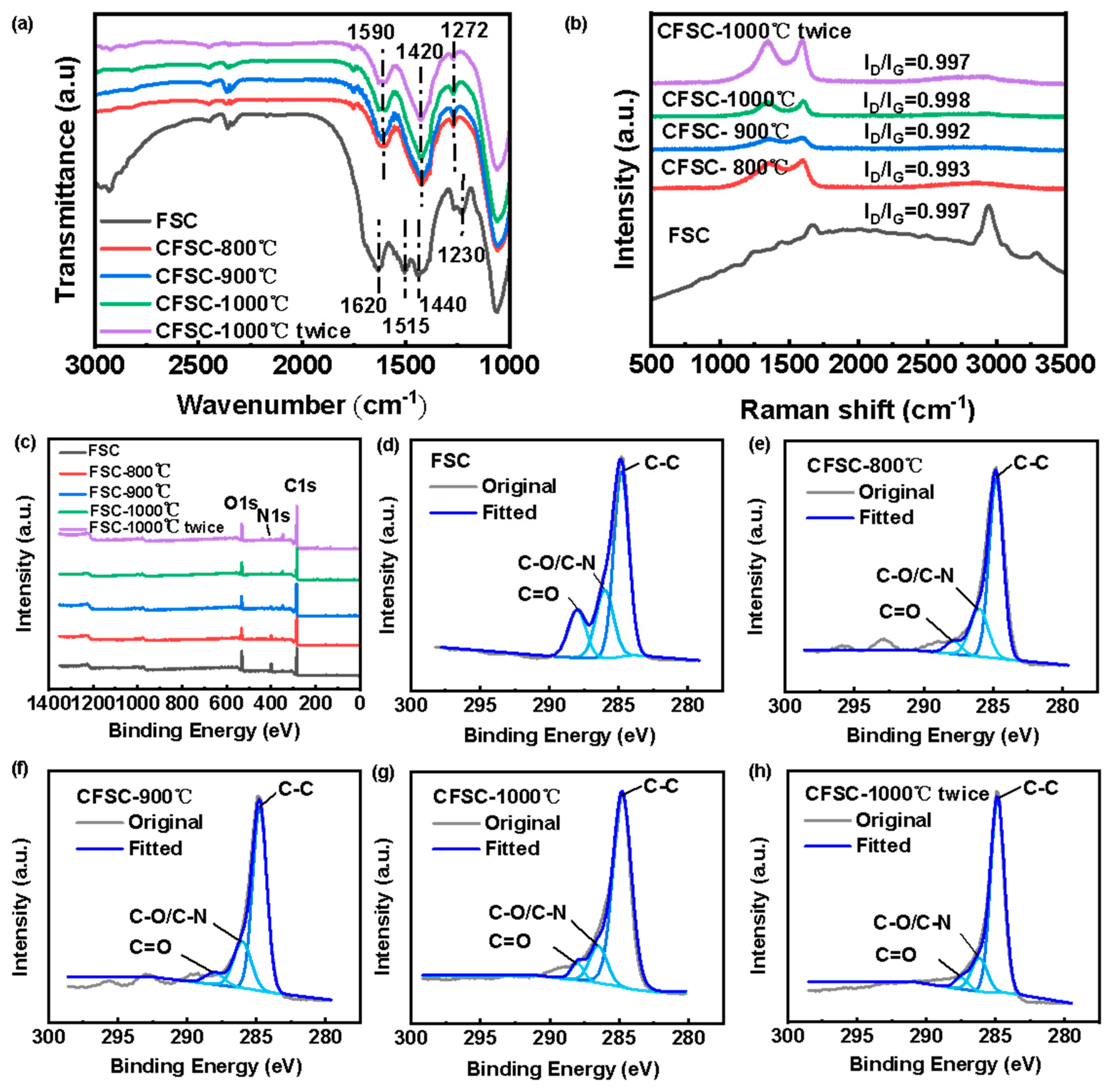

3.2. Chemical Structure Characterization

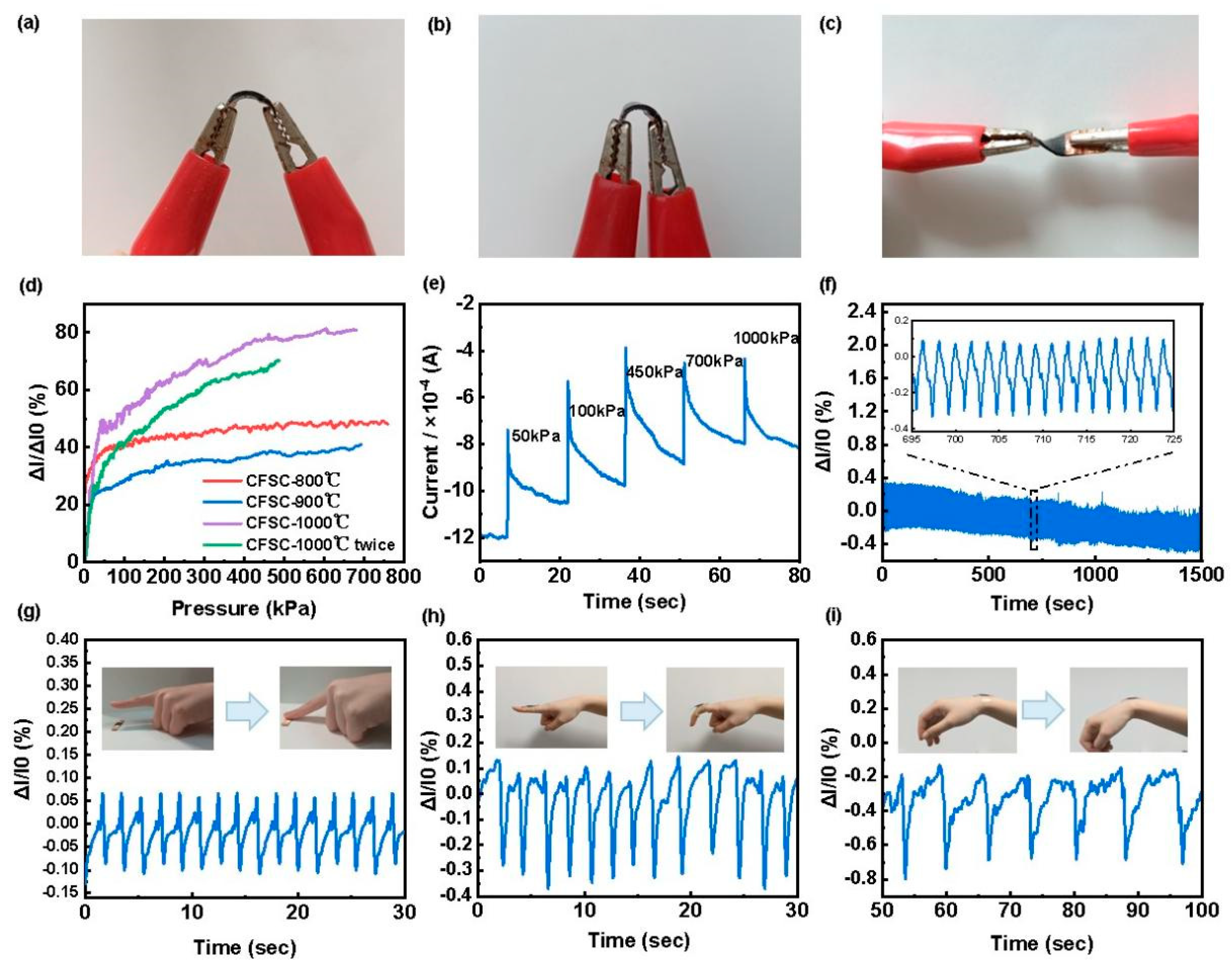

3.3. The Sensing Performance

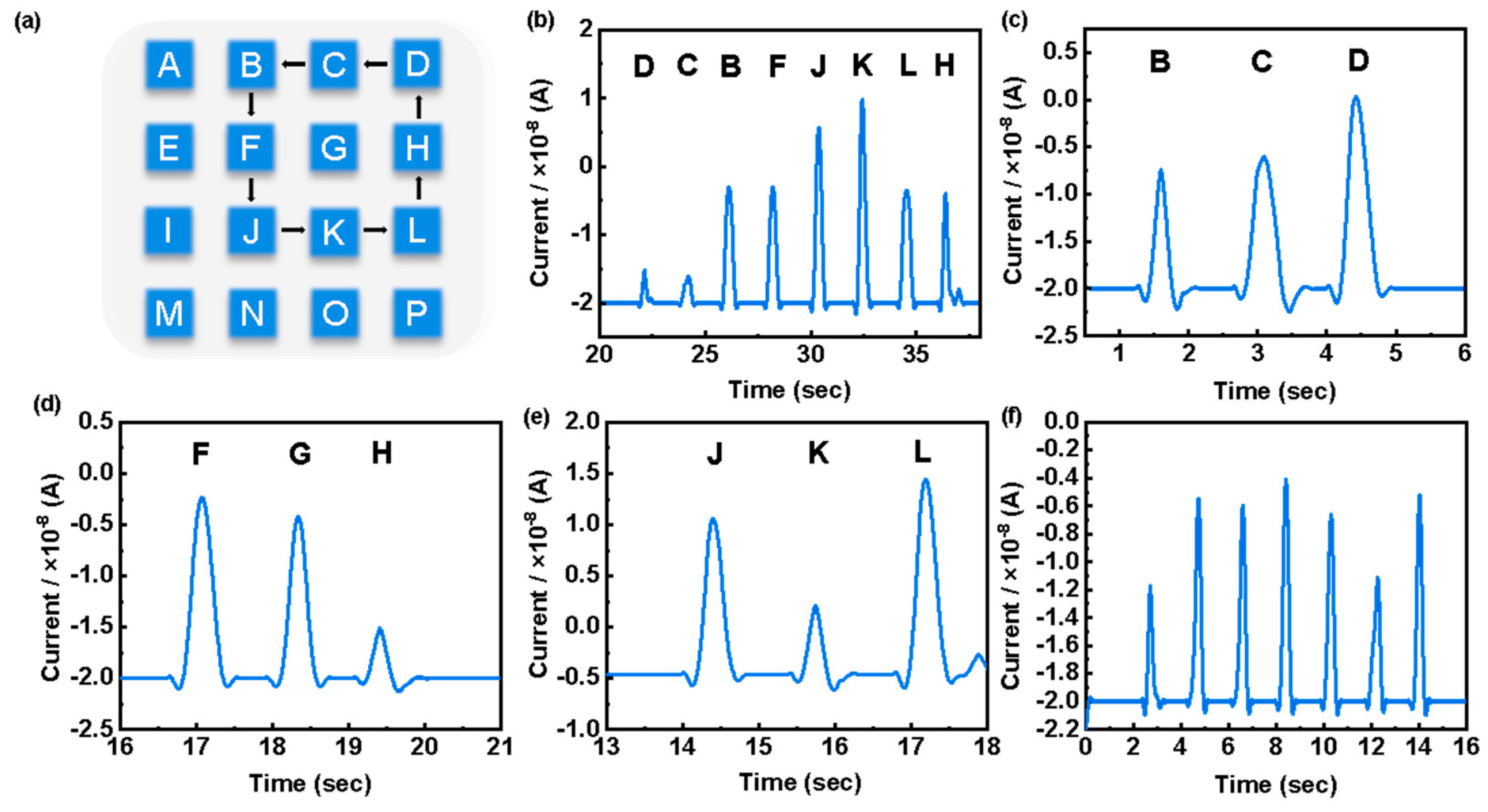

3.4. Human–Computer Interaction

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kenry; Yeo, J.C.; Lim, C.T. Emerging flexible and wearable physical sensing platforms for healthcare and biomedical applications. Microsyst. Nanoeng. 2016, 2, 16043. [Google Scholar] [CrossRef]

- Liu, Q.X.; Liu, Z.G.; Li, C.G.; Xie, K.W.; Zhu, P.; Shao, B.Q.; Zhang, J.M.; Yang, J.L.; Zhang, J.; Wang, Q.; et al. Highly Transparent and Flexible Iontronic Pressure Sensors Based on an Opaque to Transparent Transition. Adv. Sci. 2020, 7, 2000348. [Google Scholar] [CrossRef]

- Ma, Y.; Zheng, Q.; Liu, Y.; Shi, B.J.; Xue, X.; Ji, W.P.; Liu, Z.; Jin, Y.M.; Zou, Y.; An, Z.; et al. Self-Powered, One-Stop, and Multifunctional Implantable Triboelectric Active Sensor for Real-Time Biomedical Monitoring. Nano Lett. 2016, 16, 6042–6051. [Google Scholar] [CrossRef] [PubMed]

- Li, T.F.; Li, G.R.; Liang, Y.M.; Cheng, T.Y.; Dai, J.; Yang, X.X.; Liu, B.Y.; Zeng, Z.D.; Huang, Z.L.; Luo, Y.W.; et al. Fast-moving soft electronic fish. Sci. Adv. 2017, 3, e1602045. [Google Scholar] [CrossRef] [PubMed]

- Takei, K.; Honda, W.; Harada, S.; Arie, T.; Akita, S. Toward flexible and wearable human-interactive health-monitoring devices. Adv. Healthc. Mater. 2015, 4, 487–500. [Google Scholar] [CrossRef] [PubMed]

- Ding, Y.; Xu, T.; Onyilagha, O.; Fong, H.; Zhu, Z.T. Recent Advances in Flexible and Wearable Pressure Sensors Based on Piezoresistive 3D Monolithic Conductive Sponges. ACS Appl. Mater. Interfaces 2019, 11, 6685–6704. [Google Scholar] [CrossRef] [PubMed]

- Fiorillo, A.S.; Critello, C.D.; Pullano, S.A. Theory; technology and applications of piezoresistive sensors: A review. Sens. Actuators A Phys. 2018, 281, 156–175. [Google Scholar] [CrossRef]

- Duan, L.; D’Hooge, D.R.; Cardon, L. Recent progress on flexible and stretchable piezoresistive strain sensors: From design to application. Prog. Mater. Sci. 2020, 114, 100617. [Google Scholar] [CrossRef]

- Zheng, Q.; Lee, J.; Shen, X.; Chen, X.D.; Kim, J.K. Graphene-based wearable piezoresistive physical sensors. Mater. Today 2020, 36, 158–179. [Google Scholar] [CrossRef]

- Huang, Y.; Fan, X.; Chen, S.C.; Zhao, N. Emerging Technologies of Flexible Pressure Sensors: Materials, Modeling, Devices, and Manufacturing. Adv. Funct. Mater. 2019, 29, 1808501–1808509. [Google Scholar] [CrossRef]

- Wang, L.; Jackman, J.A.; Tan, E.; Park, J.H.; Potroz, M.G.; Hwang, E.T.; Cho, N.J. High-performance, flexible electronic skin sensor incorporating natural microcapsule actuators. Nano Energy 2017, 36, 38–45. [Google Scholar] [CrossRef]

- Li, Y.; Samad, Y.A.; Liao, K. From cotton to wearable pressure sensor. J. Mater. Chem. A 2015, 3, 2181–2187. [Google Scholar] [CrossRef]

- Chen, S.; Li, S.; Peng, S.; Huang, Y.; Zhao, J.; Tang, W.; Guo, X. Silver nanowire/polymer composite soft conductive film fabricated by large-area compatible coating for flexible pressure sensor array. J. Semicond. 2018, 39, 196–201. [Google Scholar] [CrossRef]

- Andreia, D.S.; Nuno, P.; Pedro, A.; Santos, R.; Fortunato, E.; Martins, R.; Aguas, H.; Igreja, R. Piezoresistive E-Skin Sensors Produced with Laser Engraved Molds. Adv. Electron. Mater. 2018, 4, 1800182. [Google Scholar]

- dos Santos, A.; Fortunato, E.; Martins, R.; Águas, H.; Igreja, R. Transduction Mechanisms, Micro-Structuring Techniques, and Applications of Electronic Skin Pressure Sensors: A Review of Recent Advances. Sensors 2020, 20, 4407. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Huang, W.; Yao, G.; Gao, M.; Wei, X.B.; Liu, Z.W.; Zhang, H.; Gong, T.X.; Yu, B. Highly sensitive flexible tactile sensors based on microstructured multiwall carbon nanotube arrays. Scr. Mater. 2017, 129, 61–64. [Google Scholar] [CrossRef]

- Huang, Z.; Gao, M.; Yan, Z.; Pan, T.S.; Khan, S.A.; Zhang, Y.; Zhang, H.L.; Lin, Y. Pyramid microstructure with single walled carbon nanotubes for flexible and transparent micro-pressure sensor with ultra-high sensitivity. Sens. Actuators A Phys. 2017, 266, 345–351. [Google Scholar] [CrossRef]

- Choong, C.L.; Shim, M.B.; Lee, B.S.; Jeon, S.; Ko, D.S.; Kang, T.H.; Bae, J.; Lee, S.H.; Byun, K.E.; Im, J.; et al. Highly Stretchable Resistive Pressure Sensors Using a Conductive Elastomeric Composite on a Micropyramid Array. Adv. Mater. 2014, 26, 3451–3458. [Google Scholar] [CrossRef]

- Wang, C.; Xia, K.; Zhang, Y.; Kaplan, D.L. Silk-Based Advanced Materials for Soft Electronics. Acc. Chem. Res. 2019, 52, 2916–2927. [Google Scholar] [CrossRef]

- Wang, Q.; Jian, M.; Wang, C.Y.; Zhang, Y.Y. Carbonized Silk Nanofiber Membrane for Transparent and Sensitive Electronic Skin. Adv. Funct. Mater. 2017, 27, 1605657. [Google Scholar] [CrossRef]

- Wang, C.; Li, X.; Gao, E.; Jian, M.Q.; Xia, K.L.; Wang, Q.; Xu, Z.P.; Ren, T.L.; Zhang, Y.Y. Carbonized Silk Fabric for Ultrastretchable, Highly Sensitive, and Wearable Strain Sensors. Adv. Mater. 2016, 28, 6640–6648. [Google Scholar] [CrossRef] [PubMed]

- Lu, Z.; Zhang, H.; Mao, C.; Li, C.M. Silk fabric-based wearable thermoelectric generator for energy harvesting from the human body. Appl. Energy 2016, 164, 57–63. [Google Scholar] [CrossRef]

- He, W.; Wang, C.; Wang, H.; Jian, M.Q.; Lu, W.D.; Liang, X.P.; Zhang, X.; Yang, F.C.; Zhang, Y.Y. Integrated textile sensor patch for real-time and multiplex sweat analysis. Sci. Adv. 2019, 5, x649. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Ling, S.; Liang, X.; Wang, H.M.; Lu, H.J.; Zhang, Y.Y. Self-Healable Multifunctional Electronic Tattoos Based on Silk and Graphene. Adv. Funct. Mater. 2019, 29, 1808691–1808695. [Google Scholar] [CrossRef]

- Badawy, I.M.; Ali, B.A.; Abbas, W.A.; Allam, N.K. Natural silk for energy and sensing applications: A review. Environ. Chem. Lett. 2021, 19, 2141–2155. [Google Scholar] [CrossRef]

- Wu, Z.L.; Zhang, P.; Gao, M.X.; Liu, C.F.; Wang, W.; Leng, F.; Huang, C.Z. One-pot hydrothermal synthesis of highly luminescent nitrogen-doped amphoteric carbon dots for bioimaging from Bombyx mori silk–natural proteins. J. Mater. Chem. B 2013, 1, 2868. [Google Scholar] [CrossRef]

- Yang, N.; Qi, P.; Ren, J.; Yu, H.P.; Liu, S.X.; Li, J.; Chen, W.S.; Kaplan, D.L.; Ling, S.J. Polyvinyl Alcohol/Silk Fibroin/Borax Hydrogel Ionotronics: A Highly Stretchable, Self-Healable, and Biocompatible Sensing Platform. ACS Appl. Mater. Interfaces 2019, 11, 23632–23638. [Google Scholar] [CrossRef]

- Strassburg, S.; Zainuddin, S.; Scheibel, T. The Power of Silk Technology for Energy Applications. Adv. Energy Mater. 2021, 11, 2100519. [Google Scholar] [CrossRef]

- Ma, D.L.; Ma, Y.; Chen, Z.W.; Hu, A.M. A silk fabric derived carbon fibre net for transparent capacitive touch pads and all-solid supercapacitors. J. Mater. Chem. A 2017, 5, 20608–20614. [Google Scholar] [CrossRef]

- Xiang, M.; Wang, Y.; Wu, J.; Guo, Y.; Wu, H.; Zhang, Y.; Liu, H. Natural Silk Cocoon Derived Nitrogen-doped Porous Carbon Nanosheets for High Performance Lithium-Sulfur Batteries. Electrochim. Acta 2017, 227, 7–16. [Google Scholar] [CrossRef]

- Cho, S.Y.; Yun, Y.S.; Lee, S.; Jang, D.; Park, K.Y.; Kim, J.K.; Kim, B.H.; Kang, K.; Kaplan, D.L.; Jin, H.J. Carbonization of a stable β-sheet-rich silk protein into a pseudographitic pyroprotein. Nat. Commun. 2015, 6, 7145. [Google Scholar] [CrossRef] [PubMed]

- Luo, N.; Dai, W.; Li, C.; Zhou, Z.Q.; Lu, L.Y.; Poon, C.C.Y.; Chen, S.C.; Zhang, Y.T.; Zhao, N. Flexible Piezoresistive Sensor Patch Enabling Ultralow Power Cuffless Blood Pressure Measurement. Adv. Funct. Mater. 2016, 26, 1178–1187. [Google Scholar] [CrossRef]

- Liu, W.; Liu, N.; Yue, Y.; Rao, J.Y.; Luo, C.; Zhang, H.; Yang, C.X.; Su, J.; Liu, Z.T.; Gao, Y.H. A flexible and highly sensitive pressure sensor based on elastic carbon foam. J. Mater. Chem. C 2018, 6, 1451–1458. [Google Scholar] [CrossRef]

- Hu, Y.; Zhuo, H.; Chen, Z.; Wu, K.Z.; Luo, Q.S.; Liu, Q.Z.; Jing, S.S.; Liu, C.F.; Zhong, L.X.; Sun, R.C.; et al. Superelastic Carbon Aerogel with Ultrahigh and Wide-Range Linear Sensitivity. ACS Appl. Mater. Interfaces 2018, 10, 40641–40650. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Li, H.; Lai, X.; Gao, T.Y.; Liao, X.F.; Chen, W.J.; Zeng, X.R. Carbonized cotton fabric-based multilayer piezoresistive pressure sensors. Cellulose 2019, 26, 5001–5014. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, Z.; Zhou, H.; Guo, X.H.; Zhang, Y.Y.; Wang, Y.; Liu, P.; Liu, C.X.; Ma, Y.M.; Zhang, Y.G. Highly sensitive pressure sensor based on structurally modified tissue paper for human physiological activity monitoring. J. Appl. Polym. Ence 2020, 137, 48973. [Google Scholar] [CrossRef]

- Song, Z.; Li, W.; Kong, H.; Chen, M.Q.; Bao, Y.; Wang, N.; Wang, W.; Liu, Z.B.; Ma, Y.M.; He, Y.; et al. Merkel receptor-inspired integratable and biocompatible pressure sensor with linear and ultrahigh sensitive response for versatile applications. Chem. Eng. J. 2022, 444, 136481. [Google Scholar] [CrossRef]

| Samples | Chemical Composition (%) | The Relative Area of Different Chemical Bonds (%) | Atomic Ratio C/O | ||||

|---|---|---|---|---|---|---|---|

| C1s | N1s | O1s | C–C | C–O/C–N | C=O | ||

| FSC | 68.06 | 13.88 | 18.07 | 62.22 | 23.37 | 14.40 | 3.77 |

| CFSC-800 °C | 83.98 | 6.41 | 9.61 | 70.21 | 24.02 | 5.77 | 8.73 |

| CFSC-900 °C | 87.58 | 2.43 | 9.99 | 71.03 | 22.59 | 6.38 | 8.76 |

| CFSC-1000 °C | 85.85 | 1.40 | 12.75 | 79.37 | 15.06 | 5.57 | 6.73 |

| CFSC-1000 °C twice | 88.65 | 0.94 | 10.41 | 79.21 | 16.02 | 4.77 | 8.52 |

| Reference | Sensitivity (kPa−1) | Detection Range (kPa) | Response Time (ms) | Repeatability (Cycles) |

|---|---|---|---|---|

| [31] | 103.5 | 0.01 | —— | 50,000 |

| 27.5 | 18 | |||

| [12] | 6.04 | 700 | —— | 1000 |

| [32] | 100.29 | 2 | —— | 11,000 |

| 21.22 | 10 | |||

| [33] | 0.585 | 35 | 4 | 5800 |

| [14] | 13.89 | 6 | 64 | 500 |

| [34] | −2.52 | 0.16 | 20 | —— |

| −0.2 | 1.2 | |||

| −0.01 | 9 | |||

| [35] | 33.96 | 5 | —— | 6000 |

| 1.22 | 20 | |||

| [36] | 37.5 | 2 | 50 | 3000 |

| This work | 0.01 | 680.57 | —— | 800 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Cai, M.; Jia, R.; Xu, X.; Xu, M.; Cheng, G.; Cheng, L.; Dai, F. Flat-Silk-Cocoon-Based Wearable Flexible Piezoresistive Sensor and Its Performance. Polymers 2024, 16, 295. https://doi.org/10.3390/polym16020295

Liu Z, Cai M, Jia R, Xu X, Xu M, Cheng G, Cheng L, Dai F. Flat-Silk-Cocoon-Based Wearable Flexible Piezoresistive Sensor and Its Performance. Polymers. 2024; 16(2):295. https://doi.org/10.3390/polym16020295

Chicago/Turabian StyleLiu, Zulan, Mengyao Cai, Rui Jia, Xiang Xu, Mengting Xu, Guotao Cheng, Lan Cheng, and Fangyin Dai. 2024. "Flat-Silk-Cocoon-Based Wearable Flexible Piezoresistive Sensor and Its Performance" Polymers 16, no. 2: 295. https://doi.org/10.3390/polym16020295

APA StyleLiu, Z., Cai, M., Jia, R., Xu, X., Xu, M., Cheng, G., Cheng, L., & Dai, F. (2024). Flat-Silk-Cocoon-Based Wearable Flexible Piezoresistive Sensor and Its Performance. Polymers, 16(2), 295. https://doi.org/10.3390/polym16020295