Biodegradation Study of Food Packaging Materials: Assessment of the Impact of the Use of Different Biopolymers and Soil Characteristics

Abstract

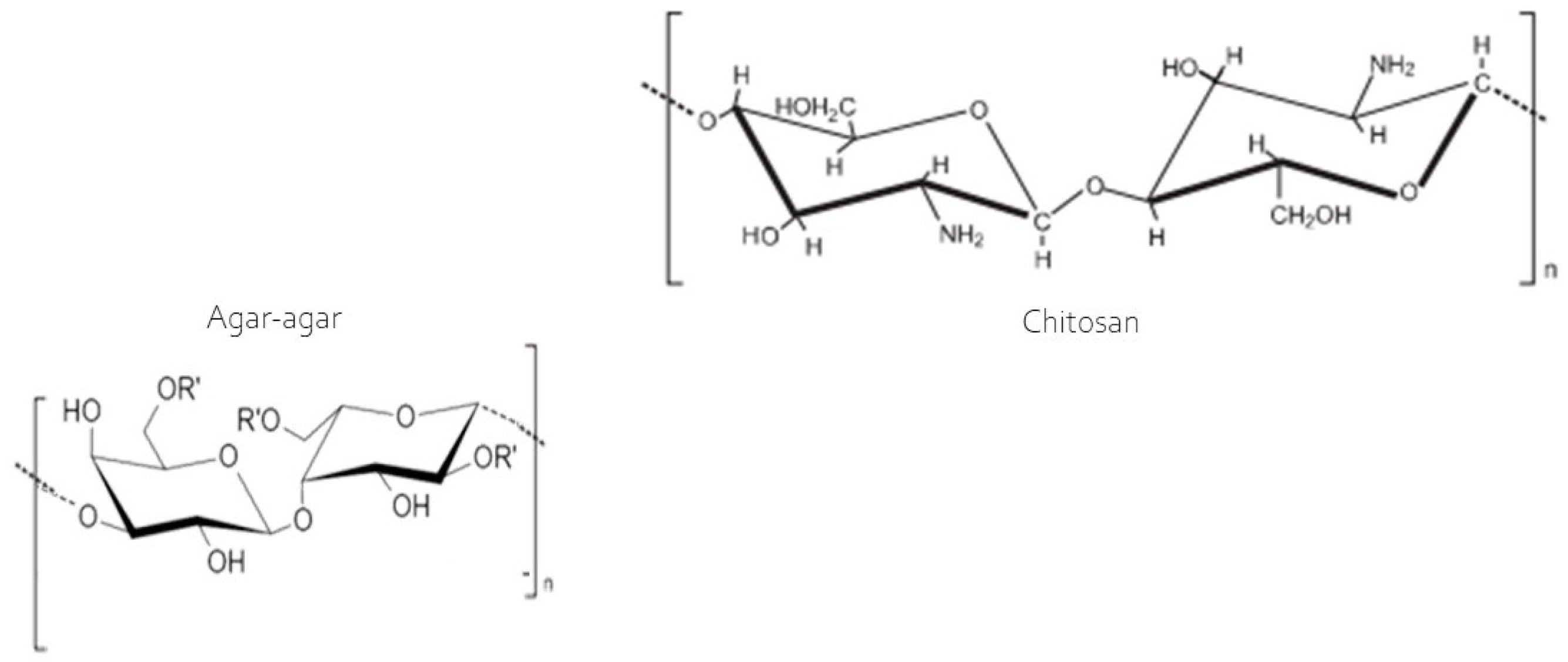

1. Introduction

2. Materials and Methods

2.1. Reagents

2.2. Preparation of Biopolymeric Membranes

2.3. Characterization of Membranes

2.4. Biodegradation in Soil

2.5. Soil Characterization

2.6. Statistical Analysis

3. Results

3.1. Physical, Chemical, Structural, and Barrier Characteristics of Membranes Subjected to Biodegradation

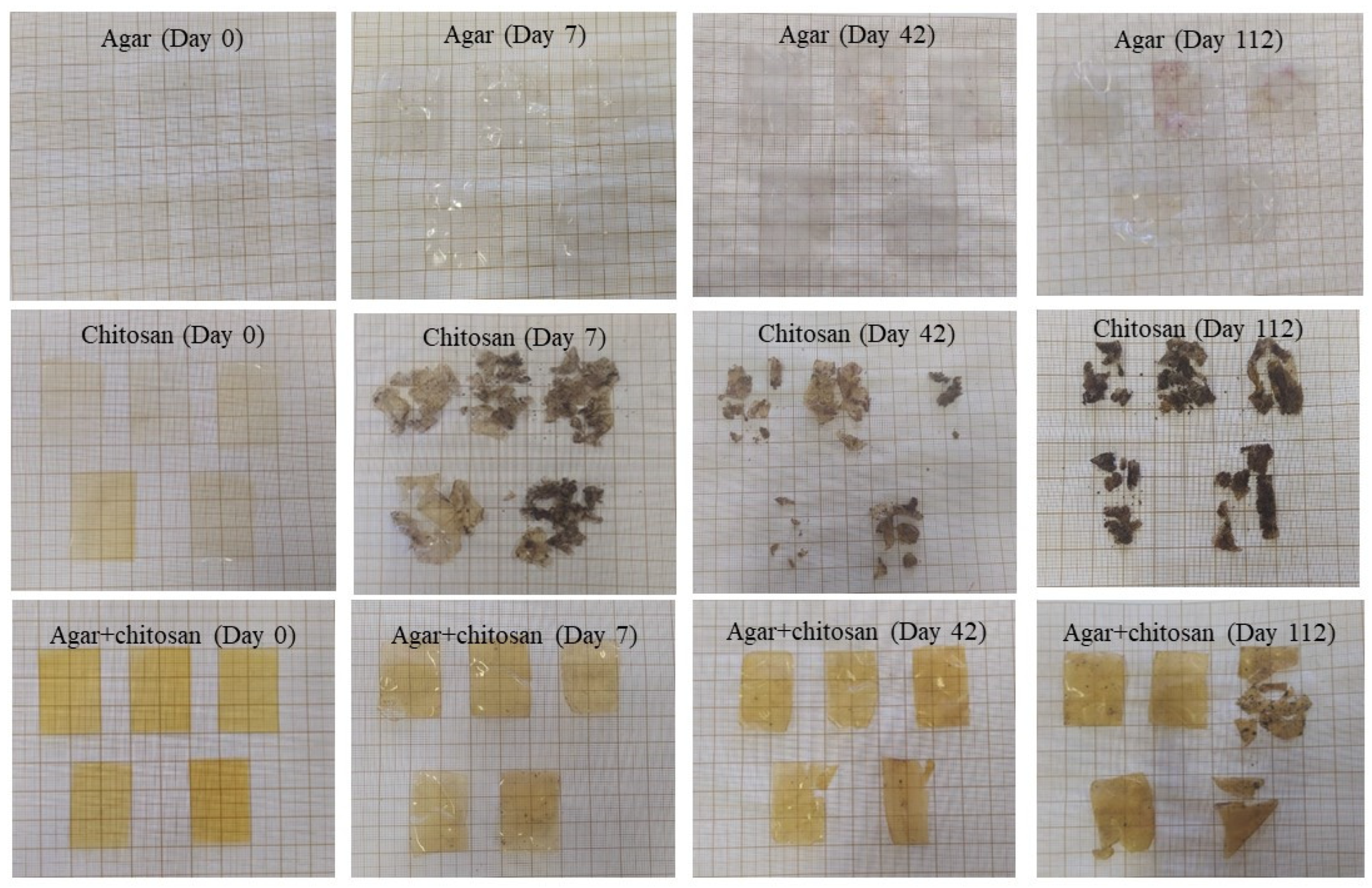

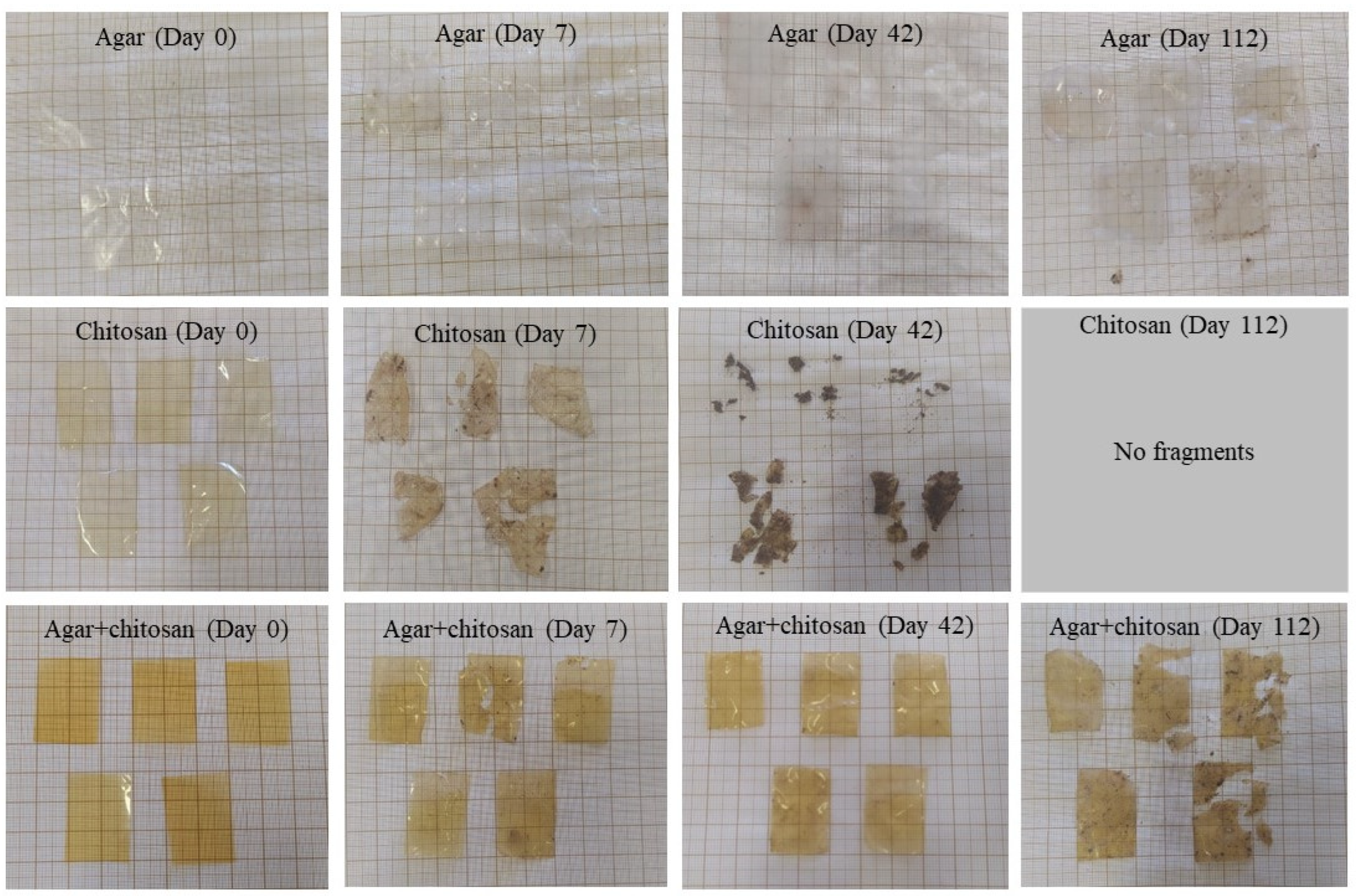

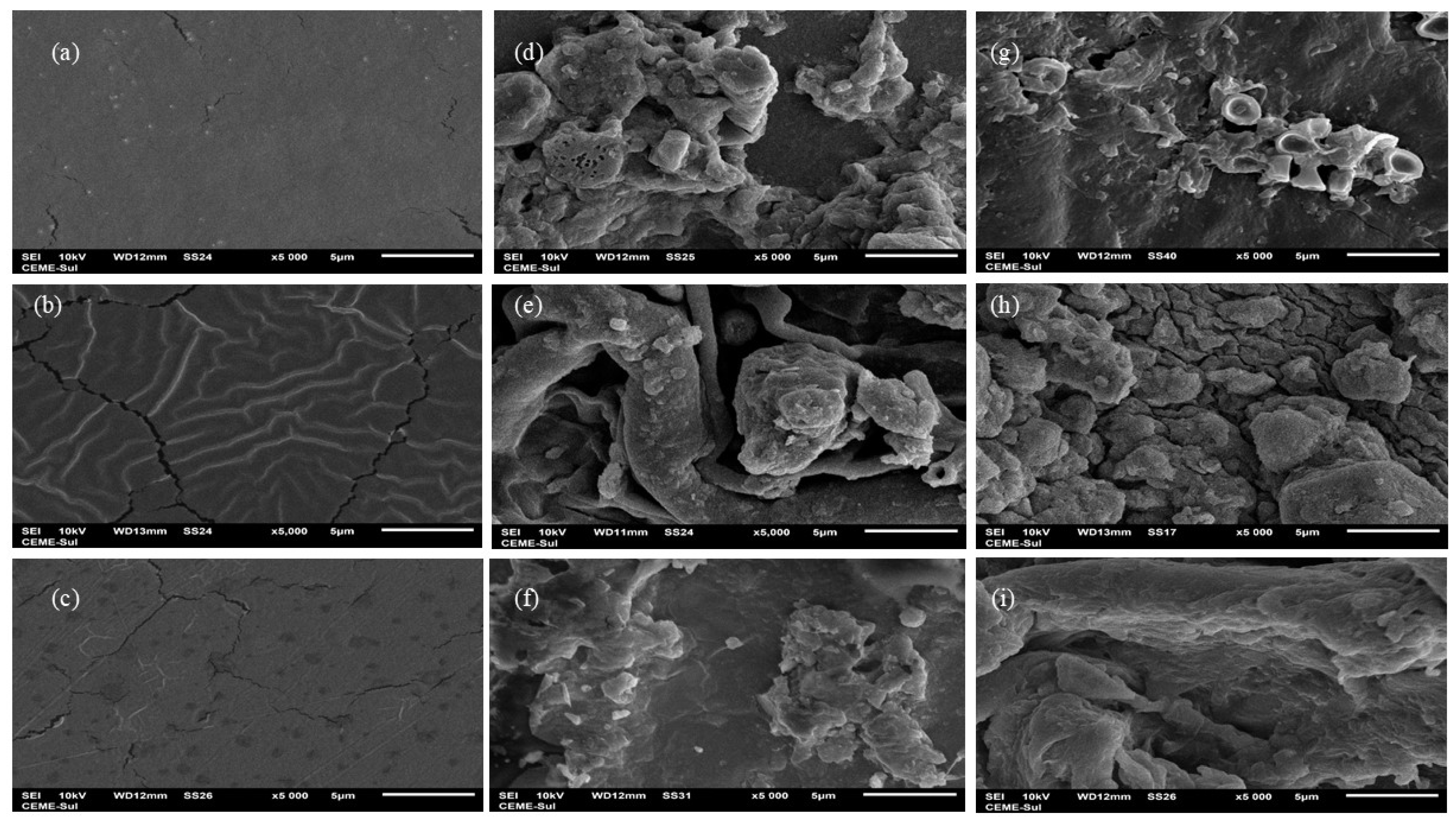

3.2. Structural Property of Membranes after Biodegradation in Soil

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brooks, A.L.; Wang, S.; Jambeck, J.R. The Chinese Import Ban and Its Impact on Global Plastic Waste Trade; American Association for the Advancement of Science: Washington, DC, USA, 2018. [Google Scholar]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, Use, and Fate of All Plastics Ever Made; American Association for the Advancement of Science: Washington, DC, USA, 2017. [Google Scholar]

- Masmoudi, F.; Bessadok, A.; Dammak, M.; Jaziri, M.; Ammar, E. Biodegradable Packaging Materials Conception Based on Starch and Polylactic Acid (PLA) Reinforced with Cellulose. Environ. Sci. Pollut. Res. 2016, 23, 20904. [Google Scholar] [CrossRef] [PubMed]

- Walker, T.R.; Fequet, L. Current Trends of Unsustainable Plastic Production and Micro(Nano)Plastic Pollution. TrAC Trends Anal. Chem. 2023, 160, 116984. [Google Scholar] [CrossRef]

- Avila, L.B.; Pinto, D.; Silva, L.F.O.; de Farias, B.S.; Moraes, C.C.; Da Rosa, G.S.; Dotto, G.L. Antimicrobial Bilayer Film Based on Chitosan/Electrospun Zein Fiber Loaded with Jaboticaba Peel Extract for Food Packaging Applications. Polymers 2022, 14, 5457. [Google Scholar] [CrossRef] [PubMed]

- Avila, L.B.; Barreto, E.R.C.; Moraes, C.C.; Morais, M.M.; da Rosa, G.S. Promising New Material for Food Packaging: An Active and Intelligent Carrageenan Film with Natural Jaboticaba Additive. Foods 2022, 11, 792. [Google Scholar] [CrossRef] [PubMed]

- Contessa, C.R.; da Rosa, G.S.; Moraes, C.C. New Active Packaging Based on Biopolymeric Mixture Added with Bacteriocin as Active Compound. Int. J. Mol. Sci. 2021, 22, 628. [Google Scholar] [CrossRef]

- Madni, A.; Kousar, R.; Naeem, N.; Wahid, F. Recent Advancements in Applications of Chitosan-Based Biomaterials for Skin Tissue Engineering. J. Bioresour. Bioprod. 2021, 6, 11–25. [Google Scholar] [CrossRef]

- Naveed, M.; Phil, L.; Sohail, M.; Hasnat, M.; Baig, M.M.F.A.; Ihsan, A.U.; Shumzaid, M.; Kakar, M.U.; Mehmood Khan, T.; Akabar, M.D.; et al. Chitosan Oligosaccharide (COS): An Overview. Int. J. Biol. Macromol. 2019, 129, 827–843. [Google Scholar] [CrossRef]

- Pervez, S.; Nawaz, M.A.; Jamal, M.; Jan, T.; Maqbool, F.; Shah, I.; Aman, A.; Ul Qader, S.A. Improvement of Catalytic Properties of Starch Hydrolyzing Fungal Amyloglucosidase: Utilization of Agar-Agar as an Organic Matrix for Immobilization. Carbohydr. Res. 2019, 486, 107860. [Google Scholar] [CrossRef]

- Shankar, S.; Reddy, J.P.; Rhim, J.W. Effect of Lignin on Water Vapor Barrier, Mechanical, and Structural Properties of Agar/Lignin Composite Films. Int. J. Biol. Macromol. 2015, 81, 267–273. [Google Scholar] [CrossRef]

- Nair, N.R.; Sekhar, V.C.; Nampoothiri, K.M.; Pandey, A. Biodegradation of Biopolymers. In Current Developments in Biotechnology and Bioengineering: Production, Isolation and Purification of Industrial Products; Elsevier Inc.: Amsterdam, The Netherlands, 2016; pp. 739–755. ISBN 9780444636621. [Google Scholar]

- Swetha, T.A.; Bora, A.; Mohanrasu, K.; Balaji, P.; Raja, R.; Ponnuchamy, K.; Muthusamy, G.; Arun, A. A Comprehensive Review on Polylactic Acid (PLA) Synthesis, Processing and Application in Food Packaging. Int. J. Biol. Macromol. 2023, 234, 123715. [Google Scholar] [CrossRef]

- Amariei, S.; Ursachi, F.; Petraru, A. Development of New Biodegradable Agar-Alginate Membranes for Food Packaging. Membranes 2022, 12, 576. [Google Scholar] [CrossRef] [PubMed]

- Fonseca-García, A.; Jiménez-Regalado, E.J.; Aguirre-Loredo, R.Y. Preparation of a Novel Biodegradable Packaging Film Based on Corn Starch-Chitosan and Poloxamers. Carbohydr. Polym. 2021, 251, 117009. [Google Scholar] [CrossRef] [PubMed]

- Soares, J.M.A.; Silva Júnior, E.D.; de Veras, B.O.; Yara, R.; de Albuquerque, P.B.S.; de Souza, M.P. Active Biodegradable Film Based on Chitosan and Cenostigma Nordestinum ’ Extracts for Use in the Food Industry. J. Polym. Environ. 2021, 30, 217–231. [Google Scholar] [CrossRef]

- ASTM Standard D882-09; Standard Test Method for Tensile Properties of Thin Plastic Sheeting. ASTM International: Amsterdam, The Netherlands, 2012.

- Gontard, N.; Guilbert, S.; Cuq, J.-L. Edible Wheat Gluten Films: Influence of the Main Process Variables on Film Properties Using Response Surface Methodology. J. Food Sci. 1992, 57, 190–195. [Google Scholar] [CrossRef]

- Bunhak, É.J.; Mendes, E.S.; Pereira, N.C.; Cavalcanti, O.A. Influência Do Sulfato de Condroitina Na Formação de Filmes Isolados de Polimetacrilato: Avaliação Do Índice de Intumescimento e Permeabilidade Ao Vapor d’água. Quim. Nova 2007, 30, 312–317. [Google Scholar] [CrossRef]

- ASTM Standard E96/E96M–16; Standard Test Methods for Water Vapor Transmission of Materials 1. ASTM International: Amsterdam, The Netherlands, 2016.

- Martucci, J.F.; Ruseckaite, R.A. Biodegradable Three-Layer Film Derived from Bovine Gelatin. J. Food Eng. 2010, 99, 377–383. [Google Scholar] [CrossRef]

- da Silva, N.; Junqueira, V.C.A.; de Arruda Silveira, N.F.; Taniwaki, M.H.; Gomes, R.A.R.; Okazaki, M.M. Manual de Métodos de Análise Microbiológica de Alimentos e Água; Blucher: São Paulo, Brazil, 2018; ISBN 9788521212256. [Google Scholar]

- Kaya, M.; Ravikumar, P.; Ilk, S.; Mujtaba, M.; Akyuz, L.; Labidi, J.; Salaberria, A.M.; Cakmak, Y.S.; Erkul, S.K. Production and Characterization of Chitosan Based Edible Films from Berberis Crataegina’s Fruit Extract and Seed Oil. Innov. Food Sci. Emerg. Technol. 2018, 45, 287–297. [Google Scholar] [CrossRef]

- Roy, S.; Rhim, J.W. Preparation of Gelatin/Carrageenan-Based Color-Indicator Film Integrated with Shikonin and Propolis for Smart Food Packaging Applications. ACS Appl. Biol. Mater. 2021, 4, 770–779. [Google Scholar] [CrossRef]

- Wang, X.; Yong, H.; Gao, L.; Li, L.; Jin, M.; Liu, J. Preparation and Characterization of Antioxidant and PH-Sensitive Films Based on Chitosan and Black Soybean Seed Coat Extract. Food Hydrocoll. 2019, 89, 56–66. [Google Scholar] [CrossRef]

- Contessa, C.R.; Rosa, G.S.d.; Moraes, C.C.; Burkert, J.F. de M. Agar-Agar and Chitosan as Precursors in the Synthesis of Functional Film for Foods: A Review. Macromol 2023, 3, 275–289. [Google Scholar] [CrossRef]

- Oliveira, D.; Rosa, D.; Zavareze, G.S. Terms and Conditions Privacy Policy Search: (TITLE-ABS-KEY(Agroindustria)) AND (Agroindustria) 1) Deamici Development of Cookies from Agroindustrial by-Products [Article@Desenvolvimento de Biscoitos a Partir de Subprodutos Da Agroindústria]. Rev. Bras. Frutic. 2018, 40. [Google Scholar] [CrossRef]

- Martiny, T.R.; Raghavan, V.; de Moraes, C.C.; da Rosa, G.S.; Dotto, G.L. Bio-Based Active Packaging: Carrageenan Film with Olive Leaf Extract for Lamb Meat Preservation. Foods 2020, 9, 1759. [Google Scholar] [CrossRef] [PubMed]

- Rani, R.; Gosh, T.; Badwaik, L.S. Optimization of Mustard, Soybean and Flaxseed Meal Blend Formulation for Development of Biopolymeric Film and Its Characterization. Sustain. Chem. Pharm. 2023, 33, 101147. [Google Scholar] [CrossRef]

- Long, J.; Zhang, W.; Zhao, M.; Ruan, C.Q. The Reduce of Water Vapor Permeability of Polysaccharide-Based Films in Food Packaging: A Comprehensive Review. Carbohydr. Polym. 2023, 321, 121267. [Google Scholar] [CrossRef]

- Alavi, T.; Rezvanian, M.; Ahmad, N.; Mohamad, N.; Ng, S.F. Pluronic-F127 Composite Film Loaded with Erythromycin for Wound Application: Formulation, Physicomechanical and in Vitro Evaluations. Drug Deliv. Transl. Res. 2019, 9, 508–519. [Google Scholar] [CrossRef]

- Tavassoli, M.; Khezerlou, A.; Punia Bangar, S.; Bakhshizadeh, M.; Haghi, P.B.; Moghaddam, T.N.; Ehsani, A. Functionality Developments of Pickering Emulsion in Food Packaging: Principles, Applications, and Future Perspectives. Trends Food Sci. Technol. 2023, 132, 171–187. [Google Scholar] [CrossRef]

- Li, Y.; Tang, C.; He, Q. Effect of Orange (Citrus sinensis L.) Peel Essential Oil on Characteristics of Blend Films Based on Chitosan and Fish Skin Gelatin. Food Biosci. 2021, 41, 100927. [Google Scholar] [CrossRef]

- Huang, X.; Luo, X.; Liu, L.; Dong, K.; Yang, R.; Lin, C.; Song, H.; Li, S.; Huang, Q. Formation Mechanism of Egg White Protein/κ-Carrageenan Composite Film and Its Application to Oil Packaging. Food Hydrocoll 2020, 105, 105780. [Google Scholar] [CrossRef]

- Carissimi, M.; Flôres, S.H.; Rech, R. Effect of Microalgae Addition on Active Biodegradable Starch Film. Algal Res. 2018, 32, 201–209. [Google Scholar] [CrossRef]

- Wang, L.F.; Rhim, J.W. Preparation and Application of Agar/Alginate/Collagen Ternary Blend Functional Food Packaging Films. Int. J. Biol. Macromol. 2015, 80, 460–468. [Google Scholar] [CrossRef]

- Li, D.; Ye, Y.; Li, D.; Li, X.; Mu, C. Biological Properties of Dialdehyde Carboxymethyl Cellulose Crosslinked Gelatin-PEG Composite Hydrogel Fibers for Wound Dressings. Carbohydr. Polym. 2016, 137, 508–514. [Google Scholar] [CrossRef] [PubMed]

- Diop, C.I.K.; Beltran, S.; Sanz, M.T.; Garcia-Tojal, J.; Trigo-lopez, M. Designing Bilayered Composite Films by Direct Agar/Chitosan and Citric Acid-Crosslinked PVA/Agar Layer-by-Layer Casting for Packaging Applications. Food Hydrocoll 2023, 144, 108987. [Google Scholar] [CrossRef]

- Kanmani, P.; Rhim, J.W. Antimicrobial and Physical-Mechanical Properties of Agar-Based Films Incorporated with Grapefruit Seed Extract. Carbohydr. Polym. 2014, 102, 708–716. [Google Scholar] [CrossRef]

- Yuan, Y.; Lee, T.R. Contact Angle and Wetting Properties. Springer Ser. Surf. Sci. 2013, 51, 3–34. [Google Scholar] [CrossRef]

- Contessa, C.R.; de Souza, N.B.; Gonçalo, G.B.; de Moura, C.M.; da Rosa, G.S.; Moraes, C.C. Development of Active Packaging Based on Agar-Agar Incorporated with Bacteriocin of Lactobacillus sakei. Biomolecules 2021, 11, 1869. [Google Scholar] [CrossRef]

- Jang, Y.; Nam Kim, K.; Woo, J.R. Post-Consumer Plastic Packaging Waste from Online Food Delivery Services in South Korea. Waste Manag. 2023, 156, 177–186. [Google Scholar] [CrossRef]

- Quan, C.; Chen, C.; Gao, N.; Liu, D. Enhancing the Volatile Fatty Acids Production from Food Waste as Well as Polylactate Plastic Degradation by Coupled with Hydrothermal Pretreatment. Fuel 2024, 359, 130480. [Google Scholar] [CrossRef]

- Hassoun, A.; Boukid, F.; Ozogul, F.; Aït-Kaddour, A.; Soriano, J.M.; Lorenzo, J.M.; Perestrelo, R.; Galanakis, C.M.; Bono, G.; Bouyahya, A.; et al. Creating New Opportunities for Sustainable Food Packaging through Dimensions of Industry 4.0: New Insights into the Food Waste Perspective. Trends Food Sci. Technol. 2023, 142, 104238. [Google Scholar] [CrossRef]

- Oberlintner, A.; Bajić, M.; Kalčíková, G.; Likozar, B.; Novak, U. Biodegradability Study of Active Chitosan Biopolymer Films Enriched with Quercus Polyphenol Extract in Different Soil Types. Environ. Technol. Innov. 2021, 21, 101318. [Google Scholar] [CrossRef]

- Filipini, S.; Romani, V.P. Food Hydrocolloids Biodegradable and Active-Intelligent Films Based on Methylcellulose and ~ o (Syzygium cumini) Skins Extract for Food Packaging. Food Hydrocoll. 2020, 109, 106139. [Google Scholar] [CrossRef]

- Xu, E.; Wang, J.; Tang, J.; Ruan, S.; Ma, S.; Qin, Y.; Wang, W.; Tian, J.; Zhou, J.; Cheng, H.; et al. Heat-Induced Conversion of Multiscale Molecular Structure of Natural Food Nutrients: A Review. Food Chem. 2021, 369, 130900. [Google Scholar] [CrossRef] [PubMed]

- Byaruhanga, Y.B.; Erasmus, C.; Taylor, J.R.N. Effect of Microwave Heating of Kafirin on the Functional Properties of Kafirin Films. Cereal Chem. 2005, 82, 564–573. [Google Scholar] [CrossRef]

- Tribedi, P.; Sil, A.K. Low-Density Polyethylene Degradation by Pseudomonas Sp. AKS2 Biofilm. Environ. Sci. Pollut. Res. 2013, 20, 4146–4153. [Google Scholar] [CrossRef] [PubMed]

- Samanta, S.; Datta, D.; Halder, G. Biodegradation Efficacy of Soil Inherent Novel sp. Bacillus Tropicus (MK318648) onto Low Density Polyethylene Matrix. J. Polym. Res. 2020, 27, 1–16. [Google Scholar] [CrossRef]

- Ali, S.A.; Zakarya, S.; Khaled, S. Screening and Optimisation of the Biodegradation Potential for Low Density Polyethylene (LDPE) Films by Fusarium Equiseti and Brevibacillus Parabrevis. Biosci. Biotechnol. Res. Asia 2022, 19, 215–229. [Google Scholar] [CrossRef]

- Khruengsai, S.; Sripahco, T.; Pripdeevech, P. Low-Density Polyethylene Film Biodegradation Potential by Fungal Species from Thailand. J. Fungi 2021, 7, 594. [Google Scholar] [CrossRef]

- Coedert’, W.J.; Beatty’, M.T. Caracterjzação de Grumussolos no Sudoeste do rio Grande do sul. ii. Mineralogia e Gênese. Pesqui. Agropecuária Bras. 1971, 6, 183–193. [Google Scholar]

- Souza, M.R.d.; Hilário Garcia, A.L.; Dalberto, D.; Martins, G.; Picinini, J.; Souza, G.M.S.d.; Chytry, P.; Dias, J.F.; Bobermin, L.D.; Quincozes-Santos, A.; et al. Environmental Exposure to Mineral Coal and By-Products: Influence on Human Health and Genomic Instability. Environ. Pollut. 2021, 287, 117346. [Google Scholar] [CrossRef]

- Flores, C.G.; Schneider, H.; Marcilio, N.R.; Ferret, L.; Oliveira, J.C.P. Potassic Zeolites from Brazilian Coal Ash for Use as a Fertilizer in Agriculture. Waste Manag. 2017, 70, 263–271. [Google Scholar] [CrossRef]

- ASTM D6400; American Society for Testing and Materials. Standard Specification for Labeling of Plastics Designed to Be Aerobically Composted in Municipal or Industrial Facilities 1. Elsevier Academic Press: Cambridge, MA, USA, 2022.

- ASTM D6868; Standard Specification for Labeling of End Items That Incorporate Plastics and Polymers as Coatings or Additives with Paper and Other Substrates Designed to Be Aerobically Composted in Municipal or Industrial Facilities 1. ASTM International: Amsterdam, The Netherlands, 2011. [CrossRef]

- Albertsson, A.C. The Shape of the Biodegradation Curve for Low and High Density Polyethenes in Prolonged Series of Experiments. Eur. Polym. J. 1980, 16, 623–630. [Google Scholar] [CrossRef]

| Membrane | Chitosan (g) | Agar-Agar (g) | Glycerol (g) |

|---|---|---|---|

| Agar-agar | - | 1 | 0.3 |

| Chitosan | 1 | - | 0.3 |

| Blend | 0.5 | 0.5 | 0.3 |

| Biopolymeric Matrix | |||

|---|---|---|---|

| Agar | Chitosan | Blend (Agar + Chitosan) | |

| Thickness (mm) | 0.07 ± 0.01 a | 0.07 ± 0.01 a | 0.07 ± 0.00 a |

| Maximum Breaking Stress (MPa) | 10.84 ± 0.81 a | 4.99 ± 0.39 b | 9.61 ± 0.57 a |

| Elongation (%) | 24.44 ± 4.55 b | 45.97 ± 5.76 a | 19.63 ± 2.26 b |

| Water vapor permeability (kg·m−1·s−1·Pa−1) | 2.18 × 10−12 ± 2.26 × 10−15 a | 6.07 × 10−14 ± 4.57 × 10−15 b | 5.23 × 10−14 ± 7.89 × 10−16 c |

| Water solubility (%) | 28.29 ± 0.55 c | 34.03 ± 0.90 a | 30.93 ± 0.86 b |

| Swelling (%) | |||

| 2 (min) | 57.12 ± 2.08 b | 320.84 ± 8.87 a | 47.62 ± 2.89 c |

| 5 (min) | 60.18 ± 0.95 b | 371.16 ± 7.62 a | 51.04 ± 1.94 b |

| 30 (min) | 68.84 ± 1.09 b | 381.43 ± 11.71 a | 52.25 ± 0.16 b |

| 60 (min) | 73.87 ± 1.39 c | 440.32 ± 2.76 a | 106.74 ± 18.97 b |

| Contact Angle | 43.46 ± 6.74 a | 36.07 ± 2.56 a | 38.56 ± 6.58 a |

| Soil | |

|---|---|

| Organic Matter Content (%) | 12.36 ± 0.53 |

| Moisture Content (%) | 25.03 ± 1.01 |

| Mesophilic aerobes (CFU/mL) | |

| 7 Days | 1.57 × 106 |

| 45 Days | 4.09 × 105 |

| 115 Days | 7.70 × 103 |

| Molds and yeasts (CFU/g) | |

| 7 Days | 9.60 × 104 |

| 45 Days | 1.29 × 103 |

| 115 Days | 5.20 × 103 |

| Sterilized soil | |

| Mesophilic aerobes (CFU/mL) | |

| 7 Days | 1.00 × 103 |

| 45 Days | 3.60 × 106 |

| 115 Days | 8.60 × 104 |

| Molds and yeasts (CFU/g) | |

| 7 Days | 3.00 × 104 |

| 45 Days | 2.86 × 105 |

| 115 Days | 7.00 × 103 |

| Days | Natural Soil (mm) | Sterile Soil (mm) |

|---|---|---|

| Agar membrane (control) = 0.09 ± 0.01 mm | ||

| 7 | 0.09 ± 0.01 | 0.07 ± 0.01 |

| 14 | 0.08 ± 0.02 | 0.08 ± 0.03 |

| 21 | 0.04 ± 0.01 | 0.08 ± 0.02 |

| 28 | 0.04 ± 0.01 | 0.07 ± 0.01 |

| 42 | 0.04 ± 0.02 | 0.06 ± 0.02 |

| 70 | 0.03 ± 0.01 | 0.07 ± 0.01 |

| 112 | 0.03 ± 0.00 | 0.07 ± 0.00 |

| Chitosan membrane (control) = 0.08 ± 0.01 mm | ||

| 7 | 0.07 ± 0.01 | 0.08 ± 0.01 |

| 14 | 0.14 ± 0.01 | 0.13 ± 0.02 |

| 21 | 0.13 ± 0.02 | 0.13 ± 0.02 |

| 28 | 0.12 ± 0.02 | 0.13 ± 0.01 |

| 42 | - | - |

| 70 | - | - |

| 112 | - | - |

| Agar + Chitosan membrane (control) = 0.075 ± 0.06 mm | ||

| 7 | 0.06 ± 0.01 | 0.06 ± 0.01 |

| 14 | 0.07 ± 0.01 | 0.05 ± 0.01 |

| 21 | 0.05 ± 0.01 | 0.07 ± 0.01 |

| 28 | 0.05 ± 0.01 | 0.06 ± 0.01 |

| 42 | 0.04 ± 0.01 | 0.03 ± 0.01 |

| 70 | 0.06 ± 0.01 | 0.06 ± 0.01 |

| 112 | 0.05 ± 0.01 | 0.06 ± 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Souza, A.M.N.; Avila, L.B.; Contessa, C.R.; Valério Filho, A.; de Rosa, G.S.; Moraes, C.C. Biodegradation Study of Food Packaging Materials: Assessment of the Impact of the Use of Different Biopolymers and Soil Characteristics. Polymers 2024, 16, 2940. https://doi.org/10.3390/polym16202940

de Souza AMN, Avila LB, Contessa CR, Valério Filho A, de Rosa GS, Moraes CC. Biodegradation Study of Food Packaging Materials: Assessment of the Impact of the Use of Different Biopolymers and Soil Characteristics. Polymers. 2024; 16(20):2940. https://doi.org/10.3390/polym16202940

Chicago/Turabian Stylede Souza, Amanda Martinello Neres, Luisa Bataglin Avila, Camila Ramão Contessa, Alaor Valério Filho, Gabriela Silveira de Rosa, and Caroline Costa Moraes. 2024. "Biodegradation Study of Food Packaging Materials: Assessment of the Impact of the Use of Different Biopolymers and Soil Characteristics" Polymers 16, no. 20: 2940. https://doi.org/10.3390/polym16202940

APA Stylede Souza, A. M. N., Avila, L. B., Contessa, C. R., Valério Filho, A., de Rosa, G. S., & Moraes, C. C. (2024). Biodegradation Study of Food Packaging Materials: Assessment of the Impact of the Use of Different Biopolymers and Soil Characteristics. Polymers, 16(20), 2940. https://doi.org/10.3390/polym16202940