Extrusion Parameters Optimization and Mechanical Properties of Bio-Polyamide 11-Based Biocomposites Reinforced with Short Basalt Fibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

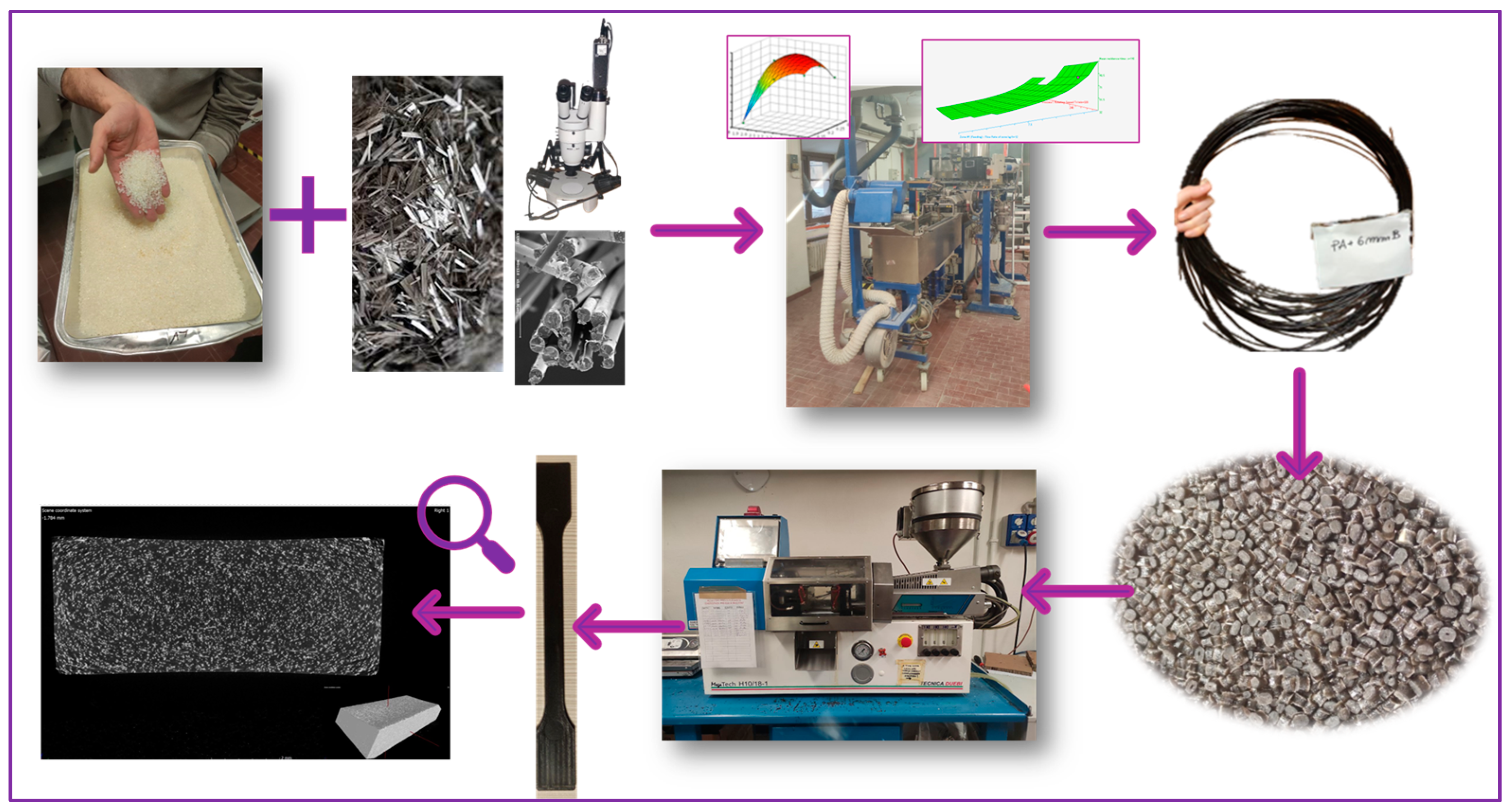

2.2. Primary and Secondary Processing

2.3. Optical and SEM Analysis

2.4. Imaging—Microtomography (μ-CT)

2.5. Mechanical Characterization

2.6. IFSS Evaluation: Theoretical Background

3. Results

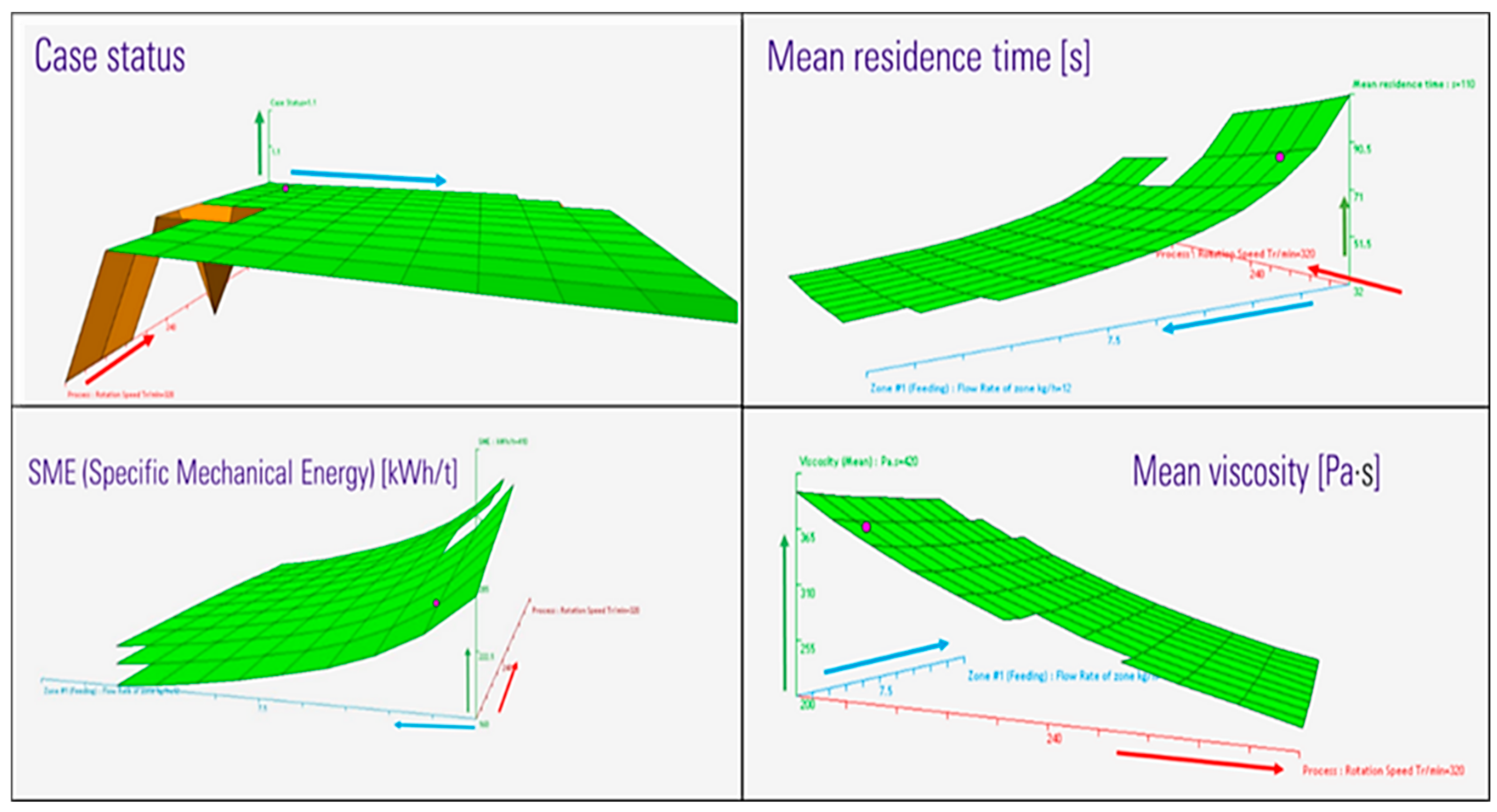

3.1. Twin-Screw Extrusion Optimization and DOE Results

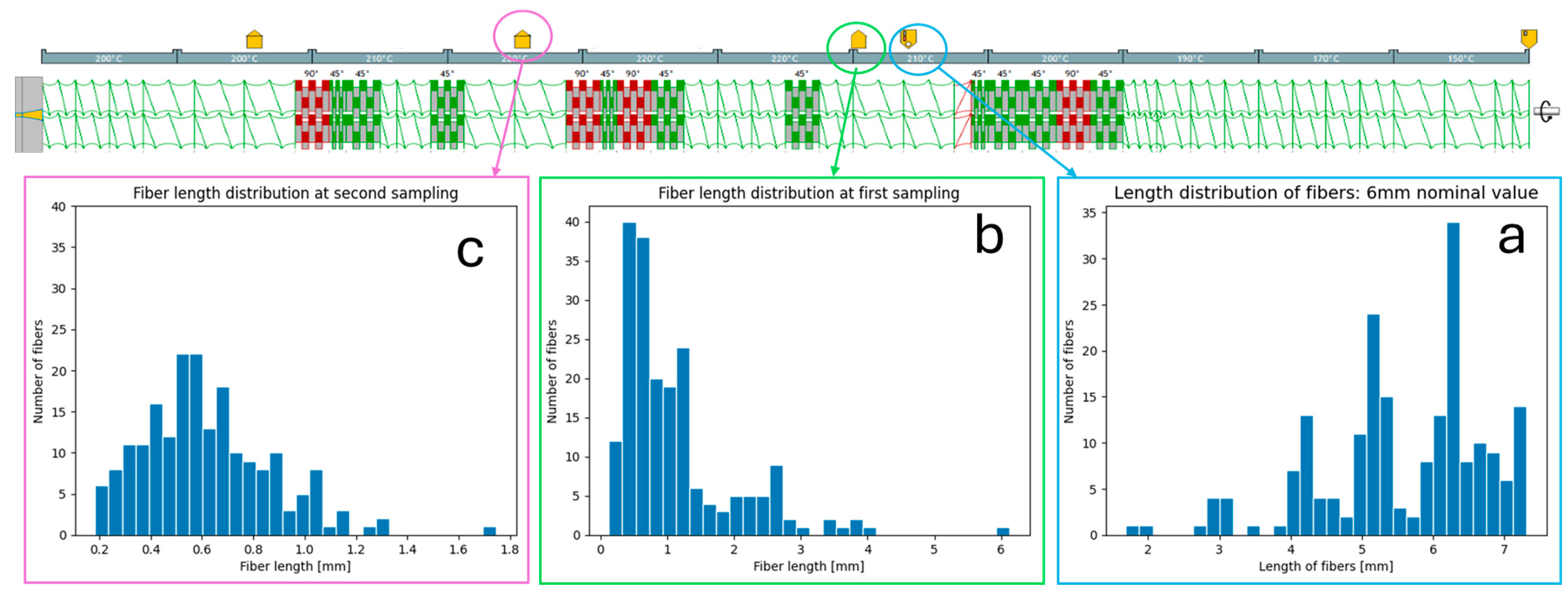

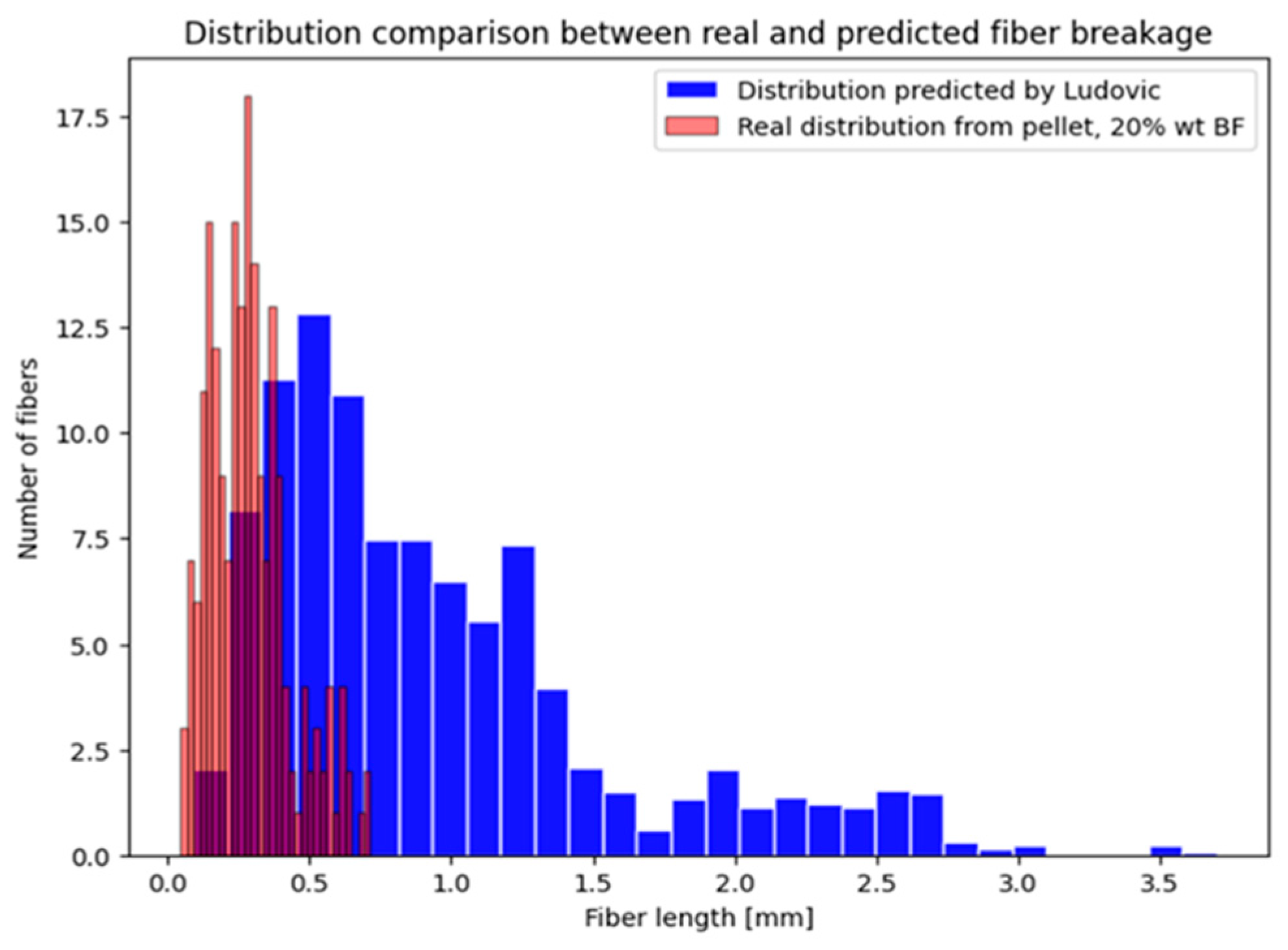

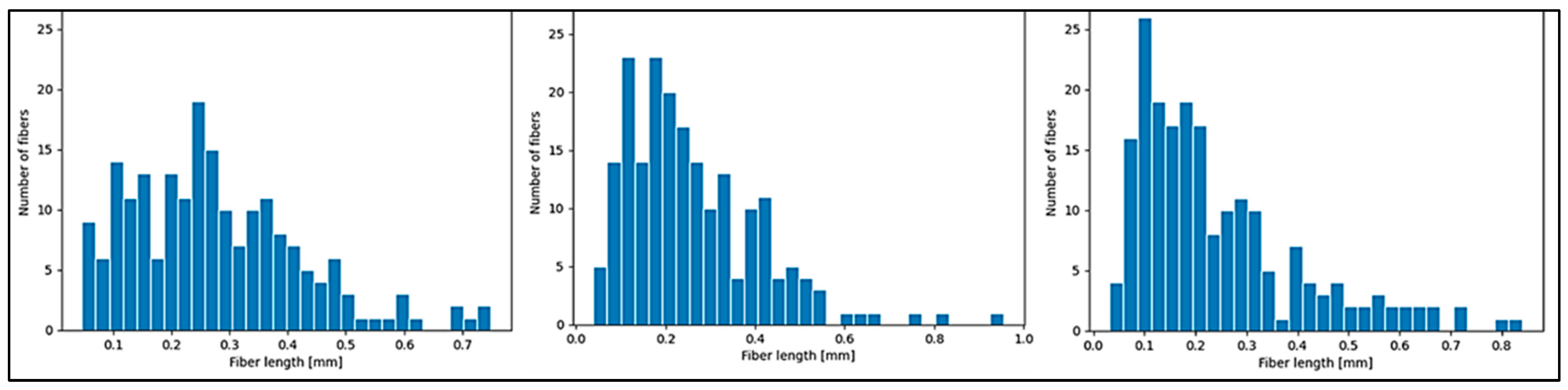

3.2. Fiber Breakage Evolution Along the Extrusion Process and Comparison Predicted/Real Fiber Breakage

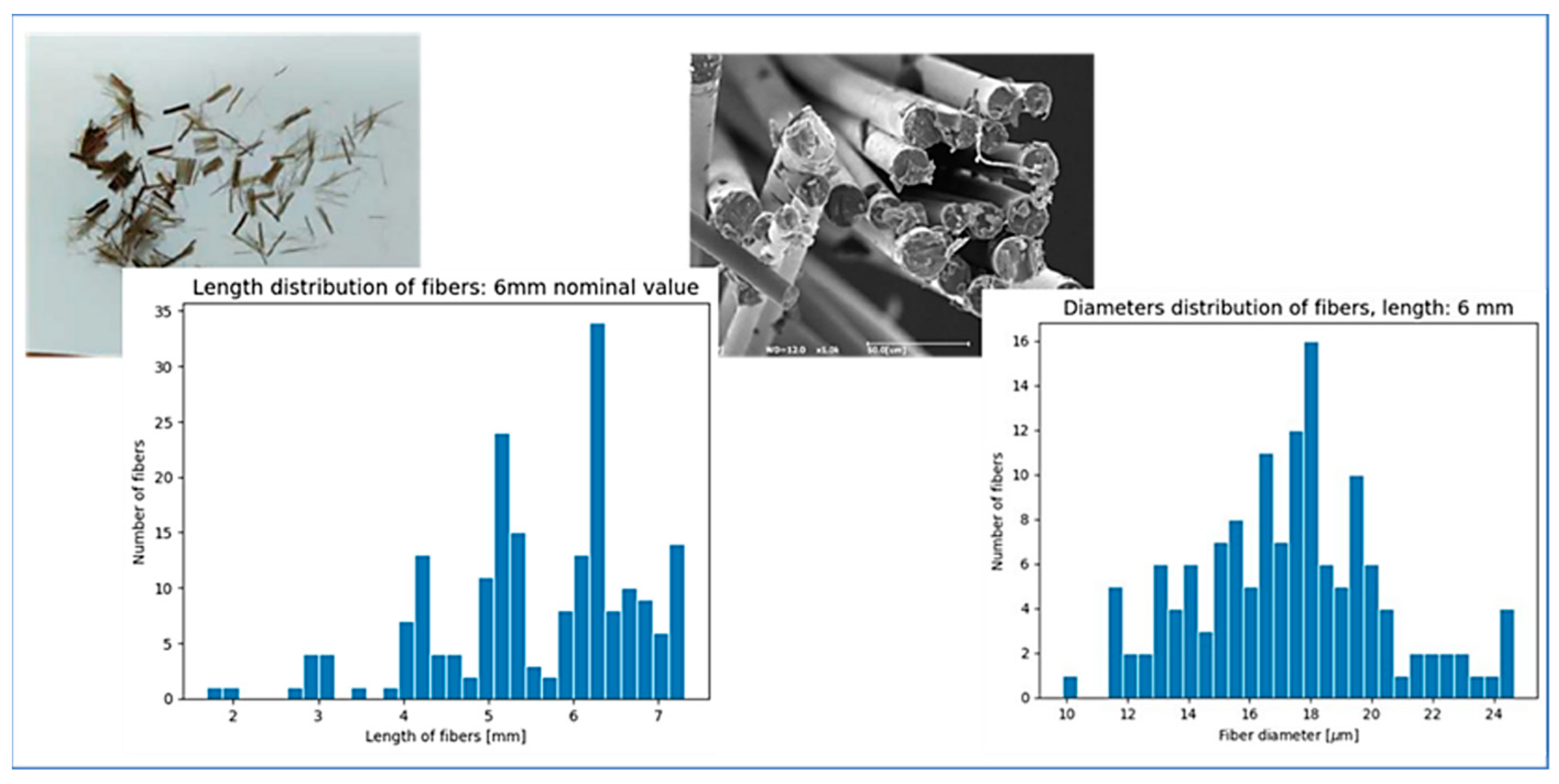

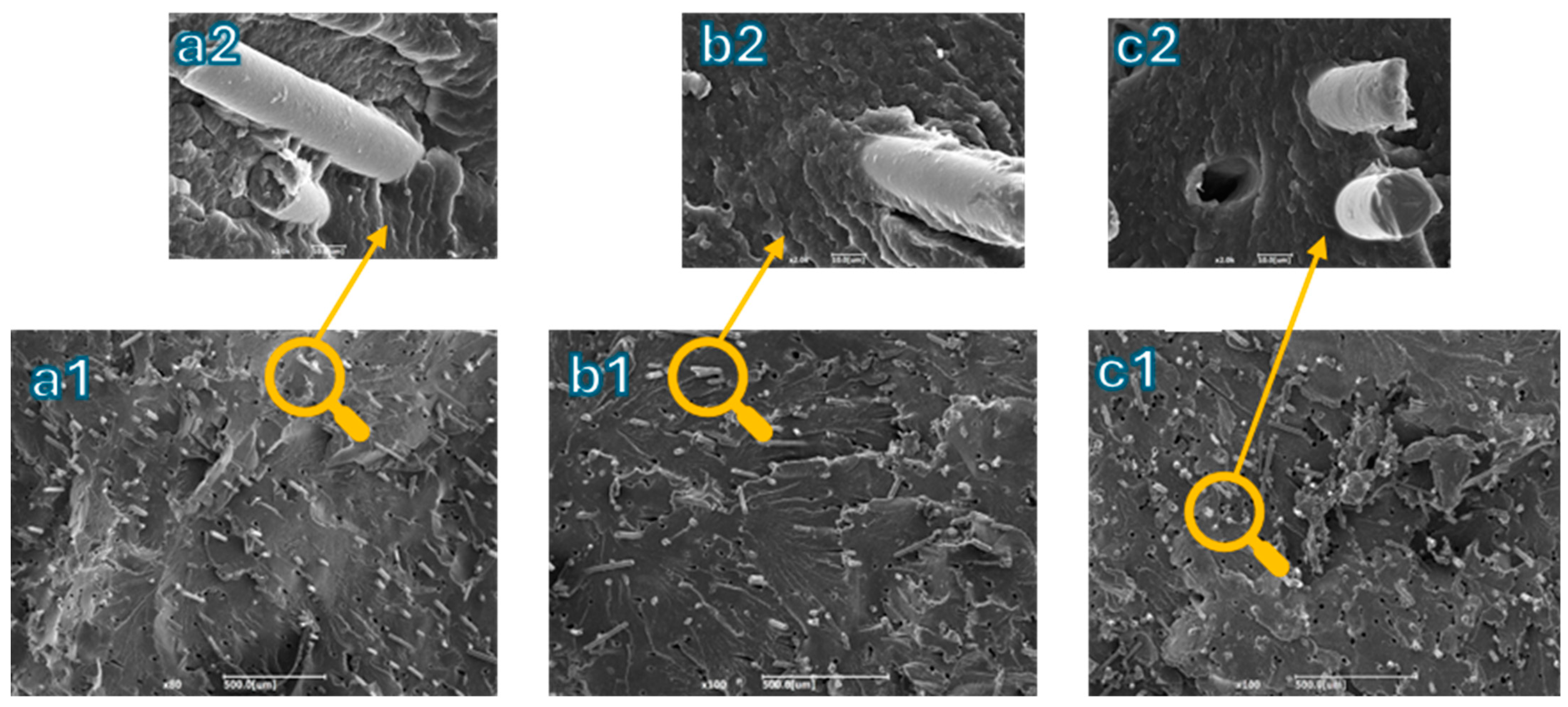

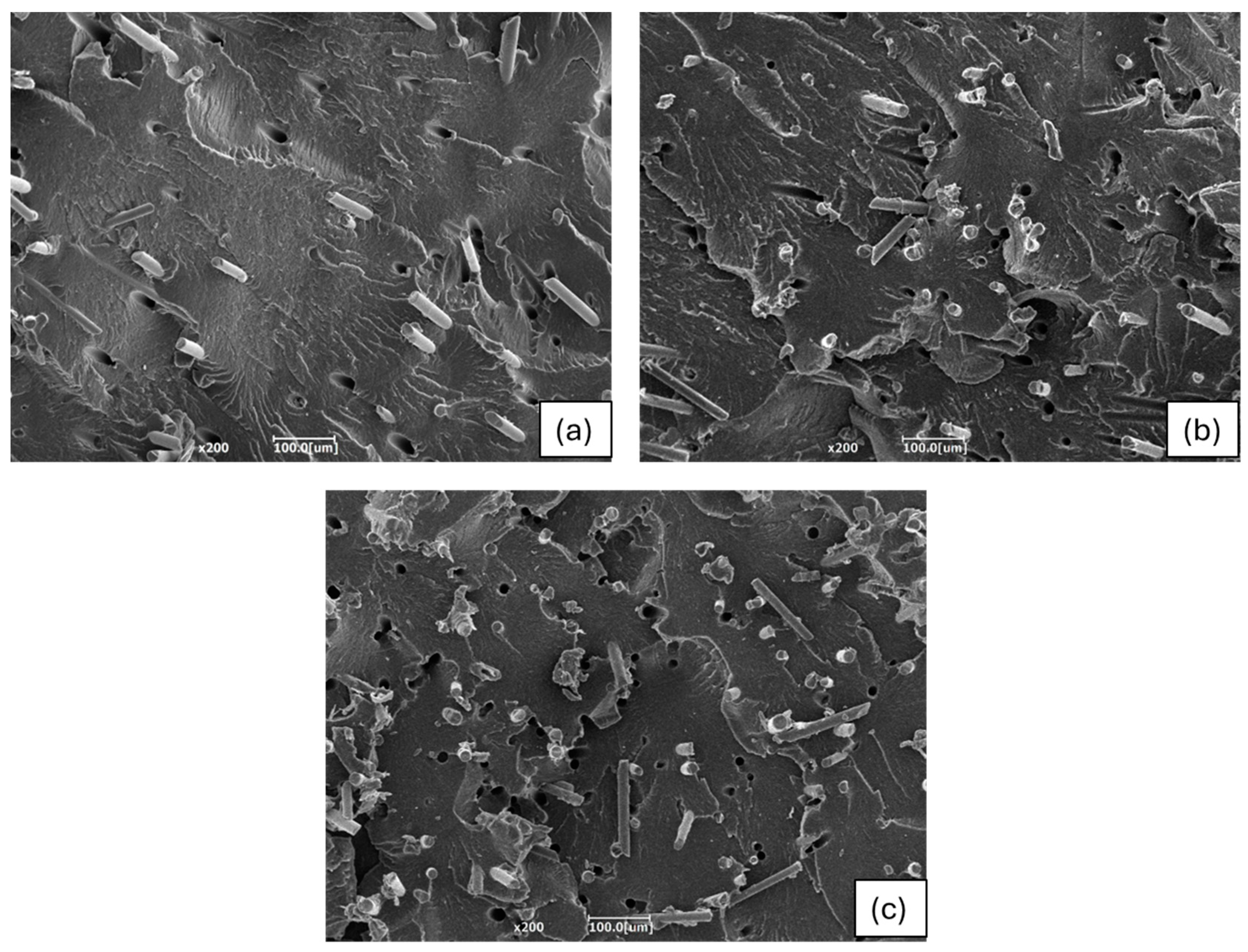

3.3. Morphological Results

3.4. IFSS Estimation

3.5. Results of Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Dace, E.; Cascavilla, A.; Bianchi, M.; Chioatto, E.; Zecca, E.; Ladu, L.; Yilan, G. Barriers to Transitioning to a Circular Bio-Based Economy: Findings from an Industrial Perspective. Sustain. Prod. Consum. 2024, 48, 407–418. [Google Scholar] [CrossRef]

- von Vacano, B.; Mangold, H.; Vandermeulen, G.W.M.; Battagliarin, G.; Hofmann, M.; Bean, J.; Künkel, A. Sustainable Design of Structural and Functional Polymers for a Circular Economy. Angew. Chem. Int. Ed. 2023, 62, e202210823. [Google Scholar] [CrossRef] [PubMed]

- Sergi, C.; Tirillò, J.; Seghini, M.C.; Sarasini, F.; Fiore, V.; Scalici, T. Durability of Basalt/Hemp Hybrid Thermoplastic Composites. Polymers 2019, 11, 603. [Google Scholar] [CrossRef]

- Jamshaid, H.; Mishra, R. A Green Material from Rock: Basalt Fiber—A Review. J. Text. Inst. 2016, 107, 923–937. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A Review on Basalt Fibre and Its Composites. Compos. B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Asadi, A.; Baaij, F.; Mainka, H.; Rademacher, M.; Thompson, J.; Kalaitzidou, K. Basalt Fibers as a Sustainable and Cost-Effective Alternative to Glass Fibers in Sheet Molding Compound (SMC). Compos. B Eng. 2017, 123, 210–218. [Google Scholar] [CrossRef]

- Fořt, J.; Kočí, J.; Černý, R. Environmental Efficiency Aspects of Basalt Fibers Reinforcement in Concrete Mixtures. Energies 2021, 14, 7736. [Google Scholar] [CrossRef]

- Tavadi, A.R.; Naik, Y.; Kumaresan, K.; Jamadar, N.I.; Rajaravi, C. Basalt Fiber and Its Composite Manufacturing and Applications: An Overview. Int. J. Eng. Sci. Technol. 2022, 13, 50–56. [Google Scholar] [CrossRef]

- Dhand, V.; Mittal, G.; Rhee, K.Y.; Park, S.J.; Hui, D. A Short Review on Basalt Fiber Reinforced Polymer Composites. Compos. B Eng. 2015, 73, 166–180. [Google Scholar] [CrossRef]

- Gao, Y.Q.; Jia, C.; Meng, L.; Li, X.H. Heat Resistance Study of Basalt Fiber Material via Mechanical Tests. IOP Conf. Ser. Mater. Sci. Eng. 2017, 283, 012016. [Google Scholar] [CrossRef]

- Khandelwal, S.; Rhee, K.Y. Recent Advances in Basalt-Fiber-Reinforced Composites: Tailoring the Fiber-Matrix Interface. Compos. B Eng. 2020, 192, 108011. [Google Scholar] [CrossRef]

- Bednarowski, D.; Bazan, P.; Kuciel, S. Enhancing Strength and Sustainability: Evaluating Glass and Basalt Fiber-Reinforced Biopolyamide as Alternatives for Petroleum-Based Polyamide Composite. Polymers 2023, 15, 3400. [Google Scholar] [CrossRef] [PubMed]

- Aslam Shaikh, A.; Anil Pradhan, A.; Mahesh Kotasthane, A.; Patil, S.; Karuppanan, S. Comparative Analysis of Basalt/E-Glass/S2-Fibreglass-Carbon Fiber Reinforced Epoxy Laminates Using Finite Element Method. Mater. Today Proc. 2022, 63, 630–638. [Google Scholar] [CrossRef]

- Sergi, C.; Botta, L.; Tirillò, J.; Sarasini, F. Basalt/Polypropylene Composites: The Effects of Mechanical Reprocessing on Their Morphological, Thermal, Rheological and Mechanical Behavior. Mater. Today Sustain. 2024, 27, 100843. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A Review of the Recent Developments in Biocomposites Based on Natural Fibres and Their Application Perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Khan, F.; Hossain, N.; Hasan, F.; Rahman, S.M.; Khan, S.; Safiullah, A.Z.A.; Chowdhury, M.A. Advances of natural fiber composites in diverse engineering applications—A review. Appl. Eng. Sci. 2024, 18, 100184. [Google Scholar] [CrossRef]

- Sergi, C.; Vitiello, L.; Russo, P.; Tirillò, J.; Sarasini, F. Toughened Bio-Polyamide 11 for Impact-Resistant Intraply Basalt/Flax Hybrid Composites. Macromol 2022, 2, 154–167. [Google Scholar] [CrossRef]

- Jariyavidyanont, K.; Focke, W.; Androsch, R. Thermal Properties of Biobased Polyamide 11. In Thermal Properties of Bio-Based Polymers; Di Lorenzo, M.L., Androsch, R., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 143–187. [Google Scholar]

- Khedr, M.S.F. Bio-Based Polyamide. Phys. Sci. Rev. 2023, 8, 827–847. [Google Scholar] [CrossRef]

- Di Lorenzo, M.L.; Longo, A.; Androsch, R. Polyamide 11/Poly(Butylene Succinate) Bio-Based Polymer Blends. Materials 2019, 12, 2833. [Google Scholar] [CrossRef]

- Yoshida, T.; Touji, M.; Takagi, H.; Shimizu, N.; Igarashi, N.; Sakurai, S.; Uchida, M.; Kaneko, Y. Structure and Mechanical Properties of Biobased Polyamide 11 Specimens Subjected to Different Heat Treatments. Polym. J. 2024, 56, 833–845. [Google Scholar] [CrossRef]

- Jariyavidyanont, K.; Williams, J.L.; Rhoades, A.M.; Kühnert, I.; Focke, W.; Androsch, R. Crystallization of Polyamide 11 during Injection Molding. Polym. Eng. Sci. 2018, 58, 1053–1061. [Google Scholar] [CrossRef]

- Prasad, V.; Alliyankal Vijayakumar, A.; Jose, T.; George, S.C. A Comprehensive Review of Sustainability in Natural-Fiber-Reinforced Polymers. Sustainability 2024, 16, 1223. [Google Scholar] [CrossRef]

- Greco, A.; Maffezzoli, A.; Casciaro, G.; Caretto, F. Mechanical Properties of Basalt Fibers and Their Adhesion to Polypropylene Matrices. Compos. B Eng. 2014, 67, 233–238. [Google Scholar] [CrossRef]

- Raajeshkrishna, C.R.; Pradeep, A.S.; Rishi Kumar, R.D. Influence of Fiber Content on Mechanical, Tribological Properties of Short Basalt Fiber-Reinforced Nylon 6 and Polypropylene Composites. J. Thermoplast. Compos. Mater. 2019, 34, 765–779. [Google Scholar] [CrossRef]

- Blackman, Z.; Olonisakin, K.; MacFarlane, H.; Rodriguez-Uribe, A.; Tripathi, N.; Mohanty, A.K.; Misra, M. Sustainable Basalt Fiber Reinforced Polyamide 6,6 Composites: Effects of Fiber Length and Fiber Content on Mechanical Performance. Compos. Part. C Open Access 2024, 14, 100495. [Google Scholar] [CrossRef]

- Vitiello, L.; Russo, P.; Papa, I.; Lopresto, V.; Mocerino, D.; Filippone, G. Flexural Properties and Low-Velocity Impact Behavior of Polyamide 11/Basalt Fiber Fabric Laminates. Polymers 2021, 13, 1055. [Google Scholar] [CrossRef]

- Papa, I.; Bruno, M.; Napolitano, F.; Esposito, L.; Lopresto, V.; Russo, P. Numerical and Mechanical Analysis of Laminated PA11/Twill Basalt Composites with Enhanced Flame Behavior. Compos. Struct. 2024, 338, 118123. [Google Scholar] [CrossRef]

- Barczewski, M.; Hejna, A.; Andrzejewski, J.; Aniśko, J.; Piasecki, A.; Mróz, A.; Ortega, Z.; Rutkowska, D.; Sałasińska, K. The Recyclability of Fire-Retarded Biobased Polyamide 11 (PA11) Composites Reinforced with Basalt Fibers (BFs): The Influence of Reprocessing on Structure, Properties, and Fire Behavior. Molecules 2024, 29, 3233. [Google Scholar] [CrossRef]

- Coughlin, N.; Drake, B.; Fjerstad, M.; Schuster, E.; Waege, T.; Weerakkody, A.; Letcher, T. Development and Mechanical Properties of Basalt Fiber-Reinforced Acrylonitrile Butadiene Styrene for In-Space Manufacturing Applications. J. Compos. Sci. 2019, 3, 89. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Ghabezi, P.; Steinbach, J.; Flanagan, T.; Finnegan, W.; Mitchell, S.; Harrison, N. Experimental Study on Mechanical Properties of Material Extrusion Additive Manufactured Parts from Recycled Glass Fibre-Reinforced Polypropylene Composite. Compos. Sci. Technol. 2023, 241, 110125. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive Manufacturing of Carbon Fiber Reinforced Thermoplastic Composites Using Fused Deposition Modeling. Compos. B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Zhuang, H.; Pu, R.; Zong, Y.; Dai, G.C. Relationship between Fiber Degradation and Residence Time Distribution in the Processing of Long Fiber Reinforced Thermoplastics. Express Polym. Lett. 2008, 2, 560–568. [Google Scholar] [CrossRef]

- Deák, T.; Czigány, T.; Maršálková, M.; Militký, J. Manufacturing and Testing of Long Basalt Fiber Reinforced Thermoplastic Matrix Composites. Polym. Eng. Sci. 2010, 50, 2448–2456. [Google Scholar] [CrossRef]

- Adole, O.; Anguilano, L.; Minton, T.; Campbell, J.; Sean, L.; Valisios, S.; Tarverdi, K. Basalt Fibre-Reinforced High Density Polyethylene Composite Development Using the Twin Screw Extrusion Process. Polym. Test. 2020, 91, 106467. [Google Scholar] [CrossRef]

- Aliotta, L.; Gasenge, M.; Gigante, V.; Lazzeri, A. Micromechanical Deformation Processes and Failure of PBS Based Composites Containing Ultra-Short Cellulosic Fibers for Injection Molding Applications. Polymers 2022, 14, 4499. [Google Scholar] [CrossRef]

- Durin, A.; De Micheli, P.; Nguyen, H.-C.; David, C.; Valette, R.; Vergnes, B. Comparison between 1D and 3D Approaches for Twin-Screw Extrusion Simulation. Int. Polym. Process. 2014, 29, 641–648. [Google Scholar] [CrossRef]

- Gigante, V.; Aliotta, L.; Dal Pont, B.; Titone, V.; Botta, L.; La Mantia, F.P.; Lazzeri, A. Tailoring Morphology and Mechanical Properties of PLA/PBSA Blends Optimizing the Twin-Screw Extrusion Processing Parameters Aided by a 1D Simulation Software. Polym. Test. 2023, 129, 108294. [Google Scholar] [CrossRef]

- Gigante, V.; Gallone, G.; Aliotta, L.; Lazzeri, A. Twin-Screw Extrusion Optimization and Study of Morphological, Thermal, Mechanical and Fracture Properties of Sustainable Poly(Lactic Acid) (PLA) and Poly(Butylene Sebacate) (PBSe) Blends. Mater. Today Sustain. 2024, 28, 100953. [Google Scholar] [CrossRef]

- Aliotta, L.; Lazzeri, A. A Proposal to Modify the Kelly-Tyson Equation to Calculate the Interfacial Shear Strength (IFSS) of Composites with Low Aspect Ratio Fibers. Compos. Sci. Technol. 2020, 186, 107920. [Google Scholar] [CrossRef]

- Pearson, A.; Liao, W.; Kazemi, Y.; Duncan, M.; Slingerland, E.; Kakroodi, A.; Heydrich, M.; Hammami, A.; Naguib, H.E. Fiber-Matrix Adhesion between High-Density Polyethylene and Carbon Fiber. Polym. Test. 2022, 105, 107423. [Google Scholar] [CrossRef]

- ASTM D6866; Standard Test Methods for Determining the Biobased Content of Solid, Liquid, and Gaseous Samples Using Radiocarbon Analysis. ASTM International: West Conshohocken, PA, USA, 2022.

- Hassan, A.; Yahya, R.; Rafiq, M.I.M.; Hussin, A.; Sheikh, M.R.K.; Hornsby, P.R. Interfacial Shear Strength and Tensile Properties of Injection-Molded, Short- and Long-Glass Fiber-Reinforced Polyamide 6,6 Composites. J. Reinf. Plast. Compos. 2011, 30, 1233–1242. [Google Scholar] [CrossRef]

- ISO 527-1A; Plastics—Determination of tensile properties. ISO: Geneva, Switzerland, 2019.

- Asoodeh, F.; Aghvami-Panah, M.; Salimian, S.; Naeimirad, M.; Khoshnevis, H.; Zadhoush, A. The Effect of Fibers’ Length Distribution and Concentration on Rheological and Mechanical Properties of Glass Fiber–Reinforced Polypropylene Composite. J. Ind. Text. 2022, 51, 8452S–8471S. [Google Scholar] [CrossRef]

- ASTM D3039; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2021.

- ISO 179-1; Plastics—Determination of Charpy Impact Properties—Part 1: Non-Instrumented Impact Test. International Organization for Standardization: Geneva, Switzerland, 2023.

- Papanicolaou, G.C.; Portan, D.V.; Kontaxis, L.C. Interrelation between Fiber–Matrix Interphasial Phenomena and Flexural Stress Relaxation Behavior of a Glass Fiber–Polymer Composite. Polymers 2021, 13, 978. [Google Scholar] [CrossRef]

- Jiang, Q.; Takayama, T.; Nishioka, A. Improving the Accuracy of the Evaluation Method for the Interfacial Shear Strength of Fiber-Reinforced Thermoplastic Polymers through the Short Beam Shear Test. Polymers 2024, 16, 883. [Google Scholar] [CrossRef] [PubMed]

- Mani, A.; Sharma, S. Interfacial Shear Strength of Carbon Nanotube Reinforced Polymer Composites: A Review. Mater. Today Proc. 2022, 50, 1774–1780. [Google Scholar] [CrossRef]

- Topçu, M.; Madabhushi, G.S.P.; Staat, M. A Generalized Shear-Lag Theory for Elastic Stress Transfer between Matrix and Fibres Having a Variable Radius. Int. J. Solids Struct. 2022, 239–240, 111464. [Google Scholar] [CrossRef]

- Kelly, A.; Tyson, W.R. Tensile Properties of Fibre-Reinforced Metals: Copper/Tungsten and Copper/Molybdenum. J. Mech. Phys. Solids 1965, 13, 339–350. [Google Scholar] [CrossRef]

- Perolo, A.; Castiglioni, A.; Ferri, D. Electrification of Polymers during Capillary Extrusion. AIP Conf. Proc. 2017, 1914, 040007. [Google Scholar]

- Yang, Y. Thermal Conductivity. In Physical Properties of Polymers Handbook; Mark, J.E., Ed.; Springer: New York, NY, USA, 2007; pp. 155–163. [Google Scholar]

- Grzesiak, S.; Pahn, M.; Klingler, A.; Akpan, E.I.; Schultz-Cornelius, M.; Wetzel, B. Mechanical and Thermal Properties of Basalt Fibre Reinforced Polymer Lamellas for Renovation of Concrete Structures. Polymers 2022, 14, 790. [Google Scholar] [CrossRef]

- D’Anna, A.; Arrigo, R.; Frache, A. Rheology, Morphology and Thermal Properties of a PLA/PHB/Clay Blend Nanocomposite: The Influence of Process Parameters. J. Polym. Environ. 2022, 30, 102–113. [Google Scholar] [CrossRef]

- Hyvärinen, M.; Jabeen, R.; Kärki, T. The Modelling of Extrusion Processes for Polymers—A Review. Polymers 2020, 12, 1306. [Google Scholar] [CrossRef]

- del Pilar Noriega, E.M.; Rauwendaal, C. Troubleshooting the Extrusion Process. In Troubleshooting the Extrusion Process; del Pilar Noriega, E.M., Rauwendaal, C., Eds.; Carl Hanser Verlag GmbH & Co. KG: München, Germany, 2019; pp. I–XVII. [Google Scholar]

- Aho, J. Rheological Characterization of Polymer Melts in Shear and Extension: Measurement Reliability and Data for Practical Processing; Tampere University of Technology: Tampere, Finland, 2011. [Google Scholar]

- Consul, P.; Beuerlein, K.-U.; Luzha, G.; Drechsler, K. Effect of Extrusion Parameters on Short Fiber Alignment in Fused Filament Fabrication. Polymers 2021, 13, 2443. [Google Scholar] [CrossRef]

- de Lima, T.; de Azevedo, A.; Marvila, M.; Candido, V.; Fediuk, R.; Monteiro, S. Potential of Using Amazon Natural Fibers to Reinforce Cementitious Composites: A Review. Polymers 2022, 14, 647. [Google Scholar] [CrossRef]

- Huang, S.; Fu, Q.; Yan, L.; Kasal, B. Characterization of Interfacial Properties between Fibre and Polymer Matrix in Composite Materials—A Critical Review. J. Mater. Res. Technol. 2021, 13, 1441–1484. [Google Scholar] [CrossRef]

- Closse, A.; Onesippe Potiron, C.; Arsene, M.-A.; Bilba, K. Assessment of Vegetable Fiber-Matrix Adhesion and Durability, in Cement-Based and Polymer-Based Composite: Principles from Literature Review. J. Compos. Mater. 2024, 58, 953–992. [Google Scholar] [CrossRef]

- Lee, C.H.; Khalina, A.; Lee, S.H. Importance of Interfacial Adhesion Condition on Characterization of Plant-Fiber-Reinforced Polymer Composites: A Review. Polymers 2021, 13, 438. [Google Scholar] [CrossRef]

- Tseng, H.-C.; Chang, R.-Y.; Hsu, C.-H. Improved Fiber Orientation Predictions for Injection Molded Fiber Composites. Compos. Part. A Appl. Sci. Manuf. 2017, 99, 65–75. [Google Scholar] [CrossRef]

- Ralph, C.; Lemoine, P.; Archer, E.; McIlhagger, A. Mechanical Properties of Short Basalt Fibre Reinforced Polypropylene and the Effect of Fibre Sizing on Adhesion. Compos. B Eng. 2019, 176, 107260. [Google Scholar] [CrossRef]

- Bowyer, W.H.; Bader, M.G. On the Re-Inforcement of Thermoplastics by Imperfectly Aligned Discontinuous Fibres. J. Mater. Sci. 1972, 7, 1315–1321. [Google Scholar] [CrossRef]

- Thomason, J.L. The Influence of Fibre Length and Concentration on the Properties of Glass Fibre Reinforced Polypropylene. 6. The Properties of Injection Moulded Long Fibre PP at High Fibre Content. Compos. Part A Appl. Sci. Manuf. 2005, 36, 995–1003. [Google Scholar] [CrossRef]

- Fu, Q.; Xu, W.; Bu, M.; Guo, B.; Niu, D. Effect and Action Mechanism of Fibers on Mechanical Behavior of Hybrid Basalt-Polypropylene Fiber-Reinforced Concrete. Structures 2021, 34, 3596–3610. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Rangappa, S.M.; Siengchin, S. Basalt Fibers: An Environmentally Acceptable and Sustainable Green Material for Polymer Composites. Constr. Build. Mater. 2024, 436, 136834. [Google Scholar] [CrossRef]

- Venkateshwaran, N.; ElayaPerumal, A.; Jagatheeshwaran, M.S. Effect of Fiber Length and Fiber Content on Mechanical Properties of Banana Fiber/Epoxy Composite. J. Reinf. Plast. Compos. 2011, 30, 1621–1627. [Google Scholar] [CrossRef]

- Aliotta, L.; Gigante, V.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A. Evaluation of Mechanical and Interfacial Properties of Bio-Composites Based on Poly(Lactic Acid) with Natural Cellulose Fibers. Int. J. Mol. Sci. 2019, 20, 960. [Google Scholar] [CrossRef]

- Song, K.; Yu, Y.; Liu, Y.; Zhao, J. Flexural Performance Study of Basalt-Fiber-Reinforced Polymer Bar Basalt-Fiber-Reinforced Concrete Beams. Buildings 2023, 13, 2583. [Google Scholar] [CrossRef]

- Li, G.; Zhang, S.; Yu, H.; Liu, G.; Wang, W.; Chen, G.; Wang, J.; Wan, W.; Lu, Q.; Chen, H.; et al. Enhancing the Mechanical Properties of Basalt Fiber/Nylon 6 Composites by Surface Roughening and Hydrogen Bonding Interaction. Polym. Compos. 2024, 45, 7801–7810. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Sain, M. Injection-molded Short Hemp Fiber/Glass Fiber-reinforced Polypropylene Hybrid Composites—Mechanical, Water Absorption and Thermal Properties. J. Appl. Polym. Sci. 2007, 103, 2432–2441. [Google Scholar] [CrossRef]

- Kawada, J.; Kitou, M.; Mouri, M.; Mitsuoka, T.; Araki, T.; Lee, C.-H.; Ario, T.; Kitou, O.; Usuki, A. Morphology Controlled PA11 Bio-Alloys with Excellent Impact Strength. ACS Sustain. Chem. Eng. 2016, 4, 2158–2164. [Google Scholar] [CrossRef]

| Bio-Polyamide 11 (wt.%) | Basalt Fibers (wt.%) | |

|---|---|---|

| Bio-PA11 | 100 | 0 |

| Bio-PA11 + 10BF | 90 | 10 |

| Bio-PA11 + 15BF | 85 | 15 |

| Bio-PA11 + 20BF | 80 | 20 |

| Bio-PA11 | Bio-PA11 + 10BF | Bio-PA11 + 15BF | Bio-PA11 + 20BF | |

|---|---|---|---|---|

| Injection pressure (bar) | 70 | 80 | 70 | 70 |

| Holding pressure (bar) | 70 | 80 | 70 | 70 |

| Holding time (s) | 3 | 3 | 3 | 3 |

| Cooling time (s) | 1 | 1 | 1 | 1 |

| Injection speed (%) | 70 | 70 | 70 | 70 |

| Temperature profile from the hopper to the mold (°C) | 200–220–230 | 200–220–230 | 200–220–230 | 200–220–230 |

| Mold temperature (°C) | 25 | 25 | 25 | 25 |

| Bio-PA11 | |

| Melting temperature (°C) | 189.3 |

| Melting enthalpy (kJ/kg) | 62.8 |

| Solid phase | |

| Heat capacity (J/kg/°C) | 1266.8 |

| Density (kg/m3) | 1030 |

| Thermal conductivity (W/m·K) | 0.23 |

| Liquid phase | |

| Heat capacity (J/kg/°C) | 2072.4 |

| Density (kg/m3) | 889.5 |

| Thermal conductivity (W/m·K) | 0.23 |

| Basalt fibers | |

| Heat capacity (J/kg/°C) | 860 |

| Density (kg/m3) | 2670 |

| Thermal conductivity (W/m/°C) | 0.031 |

| Screw Speed [RPM] | Flow Rate [kg/h] | Global Mixing Index | T Max (°C) | t in Which T > 230 °C [s] | Viscosity at the Exit [Pa·s] | SME [kWh/t] | RTD [s] |

|---|---|---|---|---|---|---|---|

| 208 | 11.10 | 0.39 | 256 | 18.00 | 696.50 | 176.10 | 39.21 |

| 224 | 10.20 | 0.37 | 241 | 20.50 | 627.37 | 187.70 | 40.24 |

| 224 | 11.10 | 0.42 | 243 | 18.30 | 636.04 | 181.90 | 38.12 |

| 240 | 10.20 | 0.41 | 251 | 23.00 | 527.61 | 194.30 | 39.28 |

| 240 | 11.10 | 0.38 | 260 | 21.30 | 581.55 | 188.10 | 37.16 |

| 256 | 11.10 | 0.40 | 257 | 22.10 | 532.46 | 194.00 | 36.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gigante, V.; Cartoni, F.; Dal Pont, B.; Aliotta, L. Extrusion Parameters Optimization and Mechanical Properties of Bio-Polyamide 11-Based Biocomposites Reinforced with Short Basalt Fibers. Polymers 2024, 16, 3092. https://doi.org/10.3390/polym16213092

Gigante V, Cartoni F, Dal Pont B, Aliotta L. Extrusion Parameters Optimization and Mechanical Properties of Bio-Polyamide 11-Based Biocomposites Reinforced with Short Basalt Fibers. Polymers. 2024; 16(21):3092. https://doi.org/10.3390/polym16213092

Chicago/Turabian StyleGigante, Vito, Francesca Cartoni, Bianca Dal Pont, and Laura Aliotta. 2024. "Extrusion Parameters Optimization and Mechanical Properties of Bio-Polyamide 11-Based Biocomposites Reinforced with Short Basalt Fibers" Polymers 16, no. 21: 3092. https://doi.org/10.3390/polym16213092

APA StyleGigante, V., Cartoni, F., Dal Pont, B., & Aliotta, L. (2024). Extrusion Parameters Optimization and Mechanical Properties of Bio-Polyamide 11-Based Biocomposites Reinforced with Short Basalt Fibers. Polymers, 16(21), 3092. https://doi.org/10.3390/polym16213092