Effect of Temperature Control and Rotational and Traverse Speeds on the Mechanical Properties of Friction Stir-Welded Polypropylene Plates

Abstract

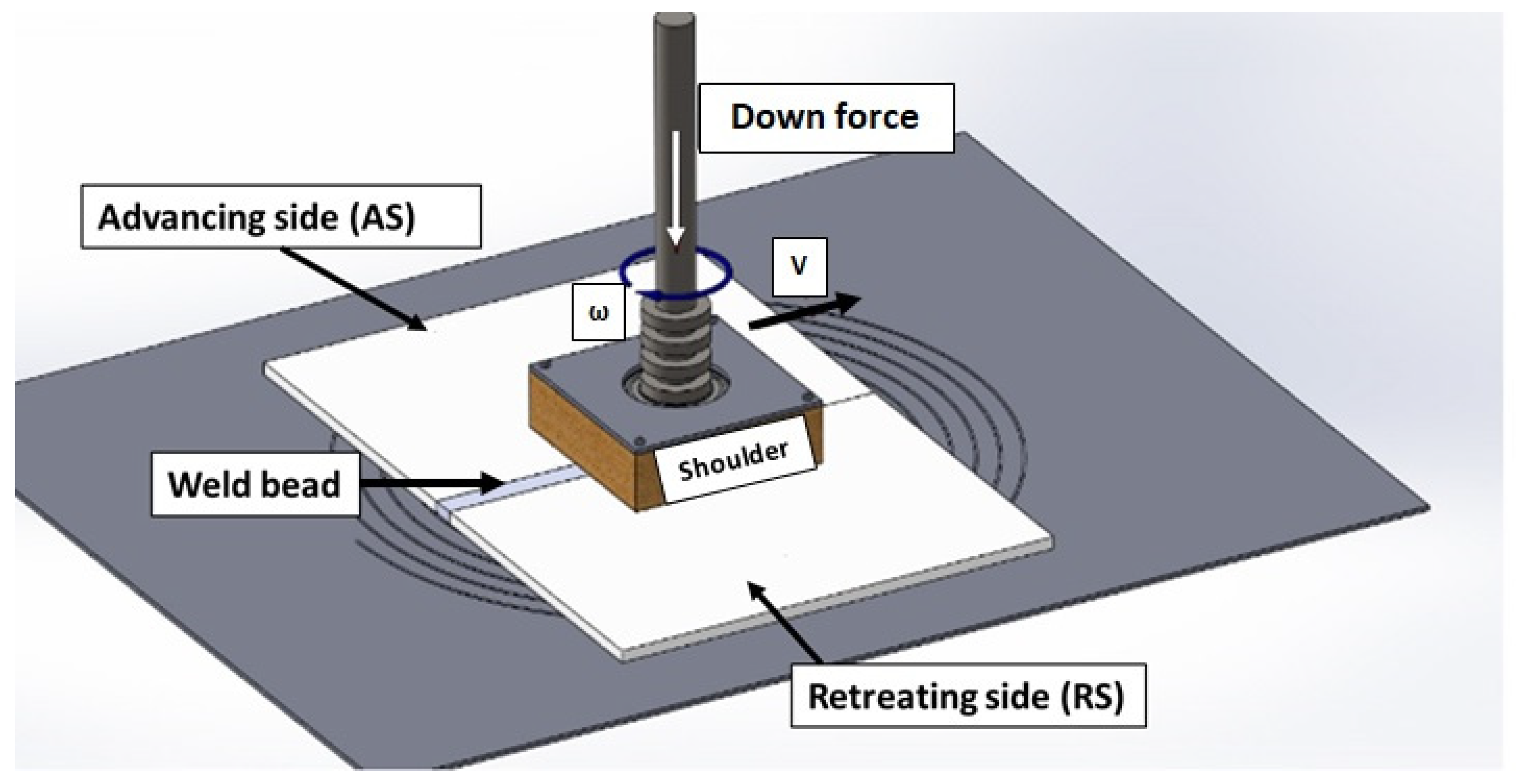

:1. Introduction

2. Materials and Methods

2.1. Polypropylene Samples

2.2. Welding Tool Configuration

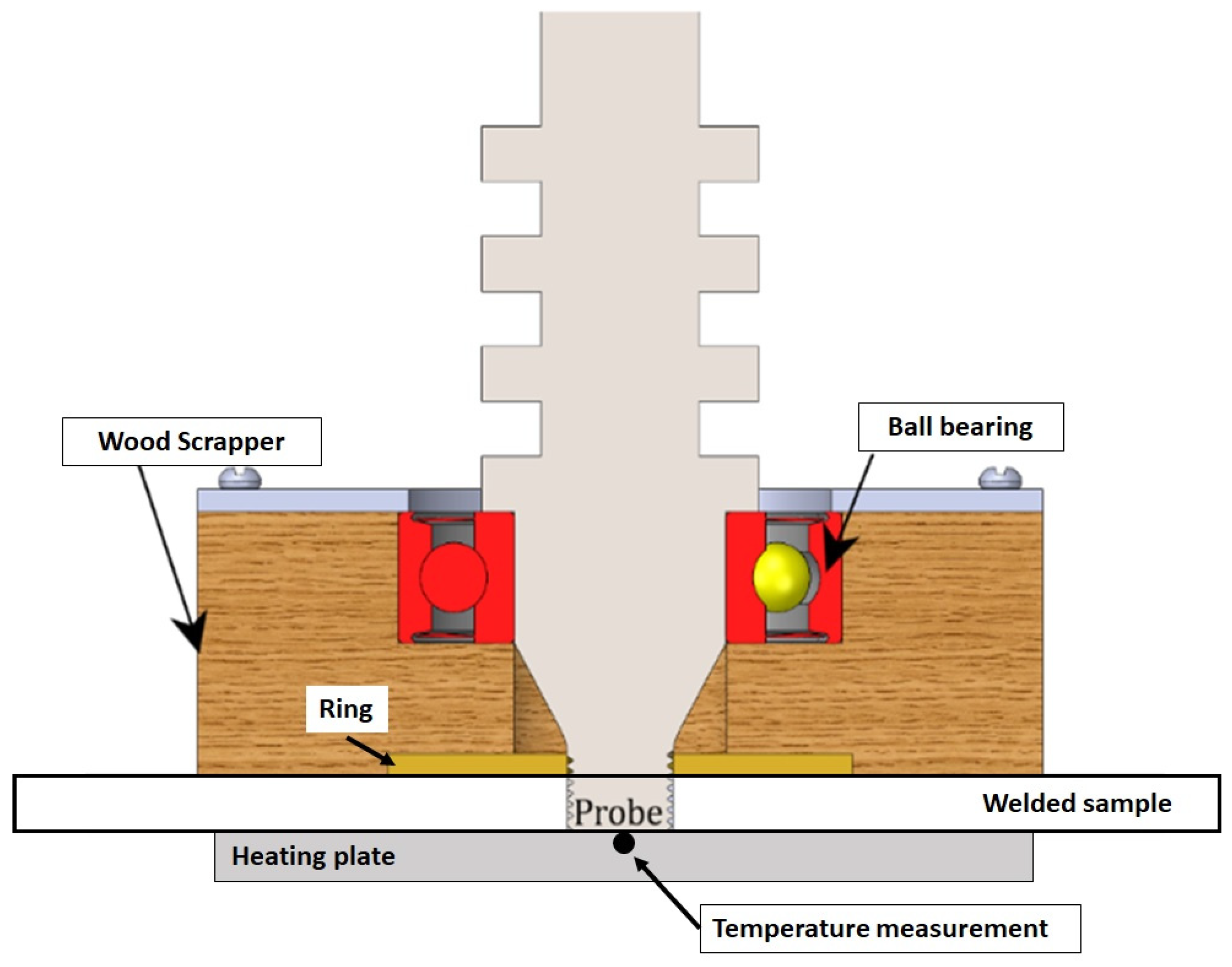

2.3. Preheating Control System and Temperature Monitoring

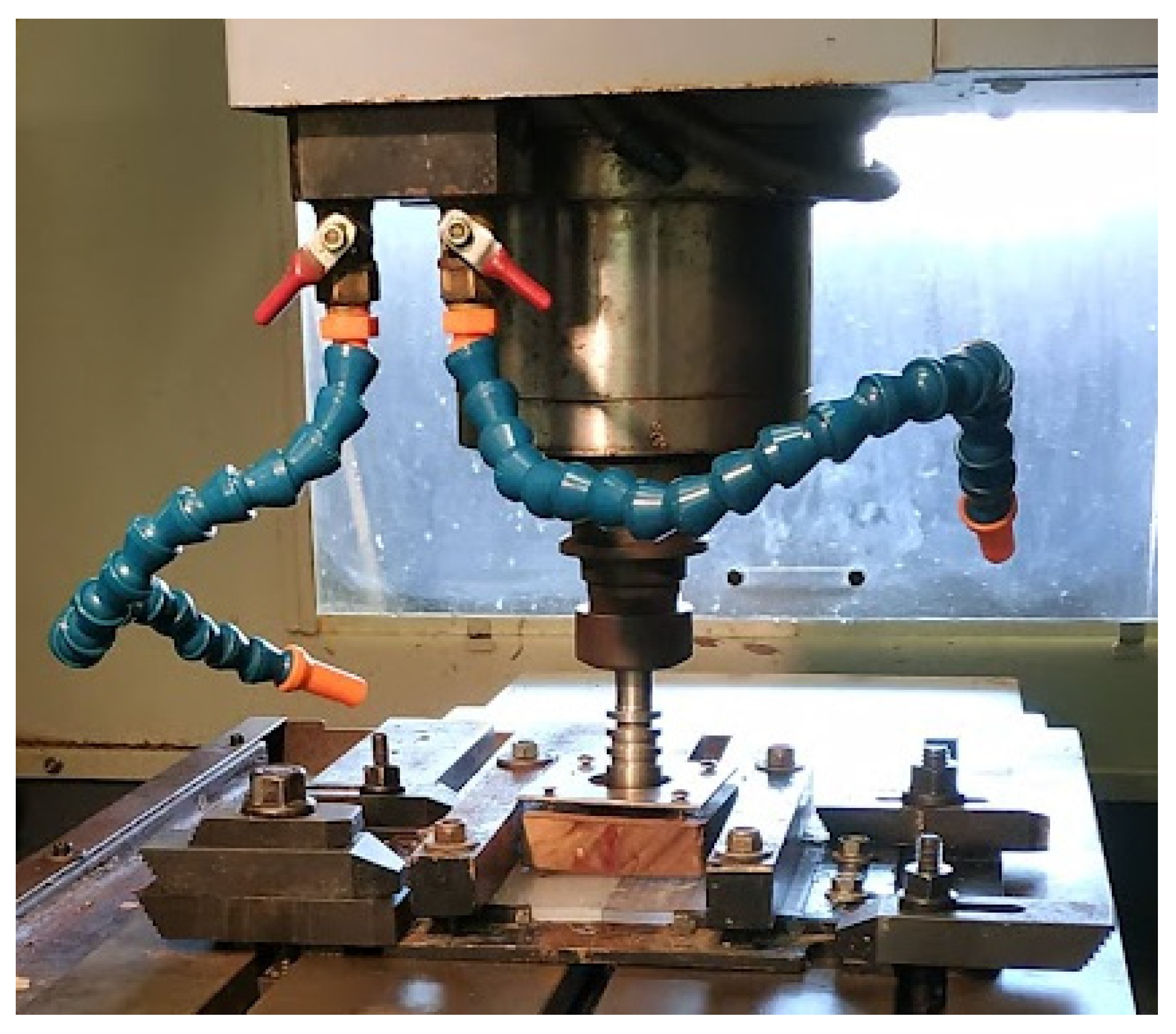

2.4. Experiment Setup and CNC Equipment

2.5. Process Parameters Selection

2.6. Experimental Design

2.7. Experiments and Samples Preparation

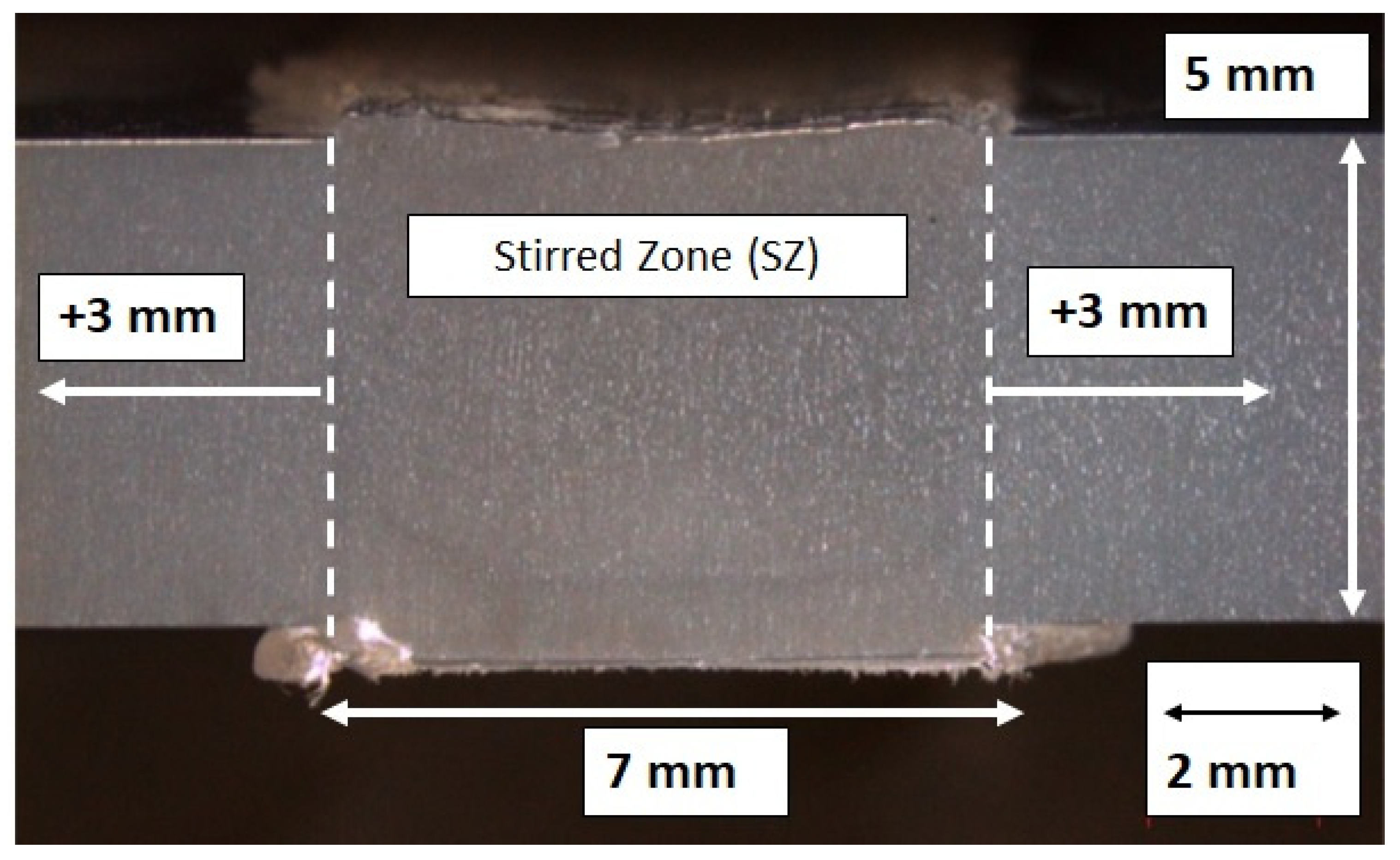

2.8. Microhardness Measurements

2.9. Differential Scanning Calorimetry Analysis and Fractography

3. Results

3.1. Tensile Test Results

3.2. Analysis of Variance

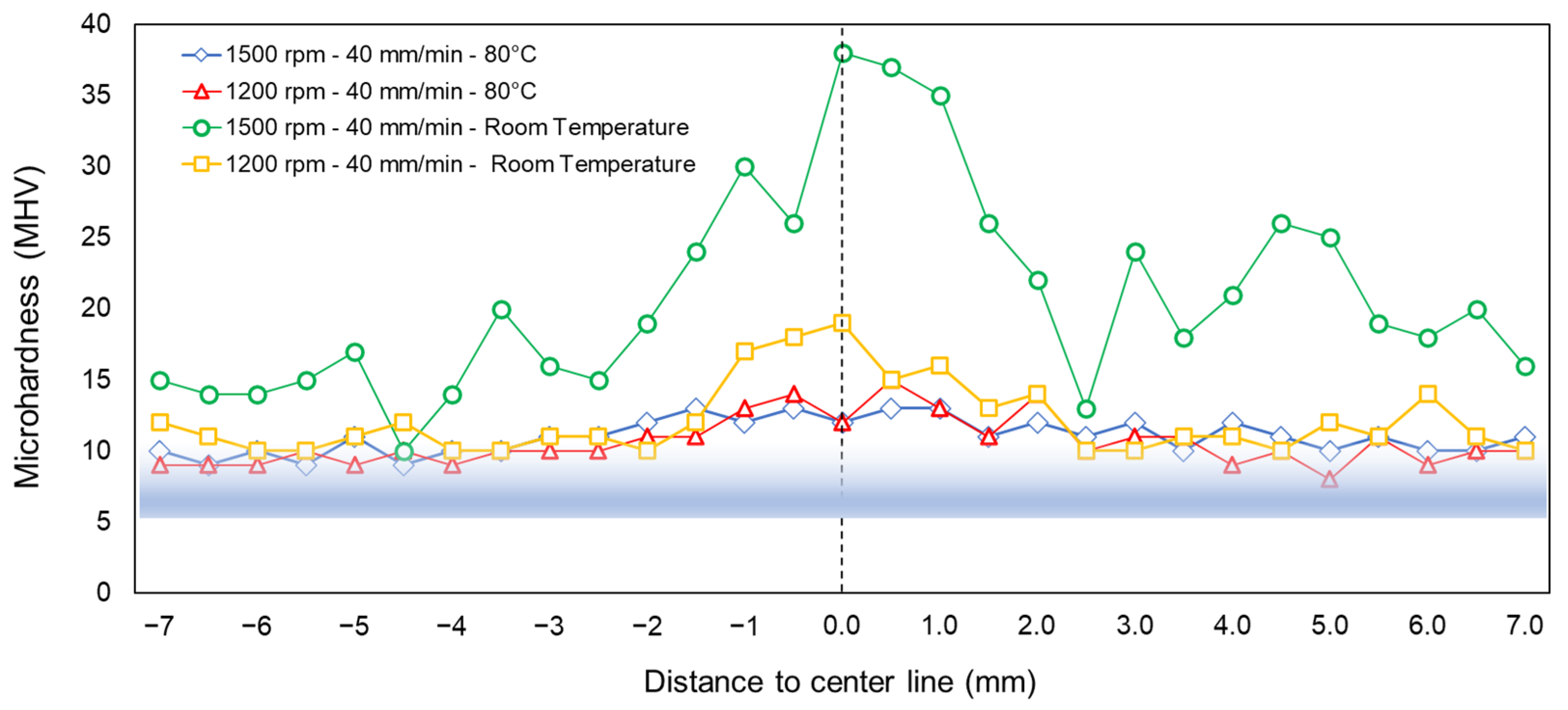

3.3. Microhardness Profiles

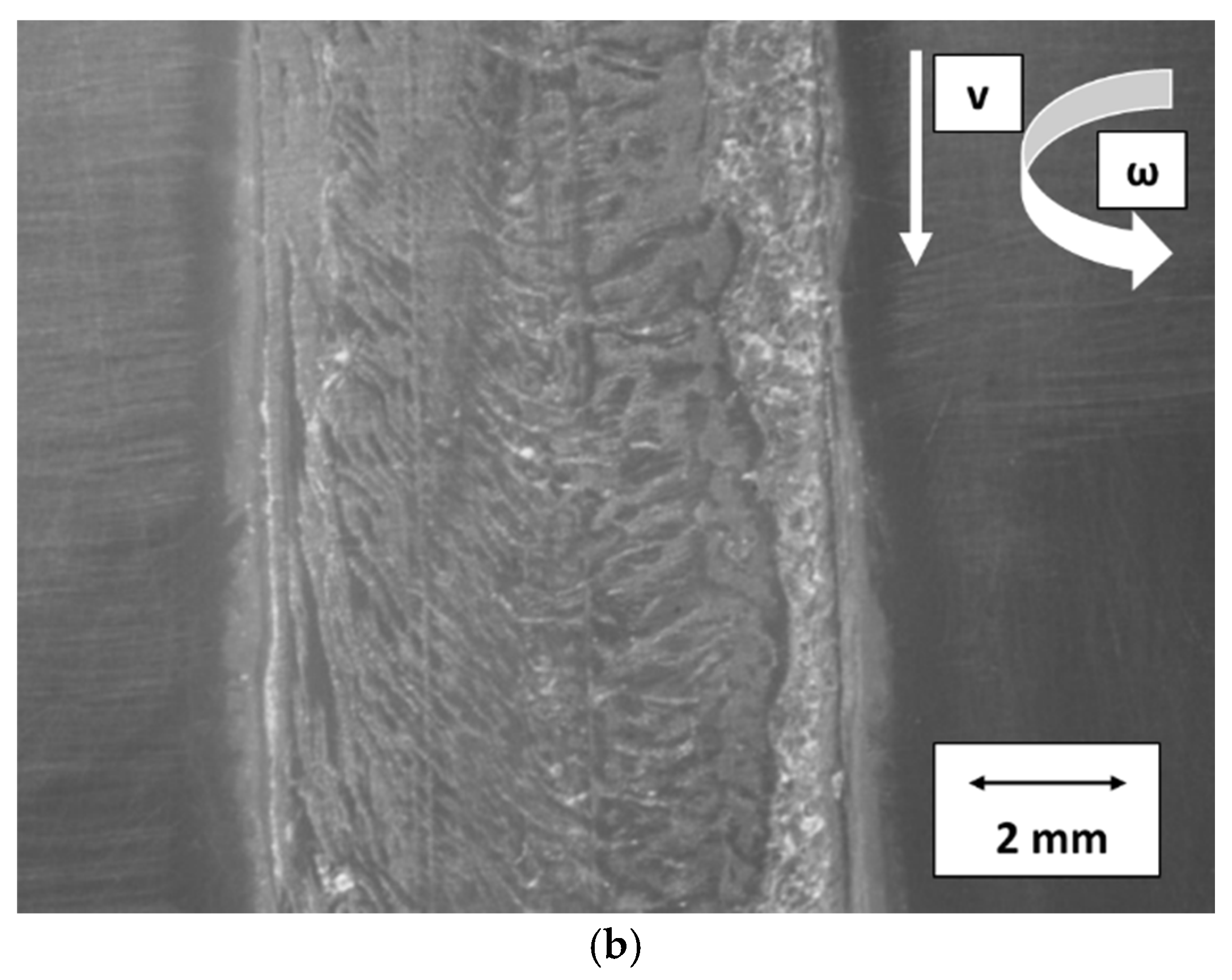

3.4. Optical Microscopy Analysis for FSW Joints

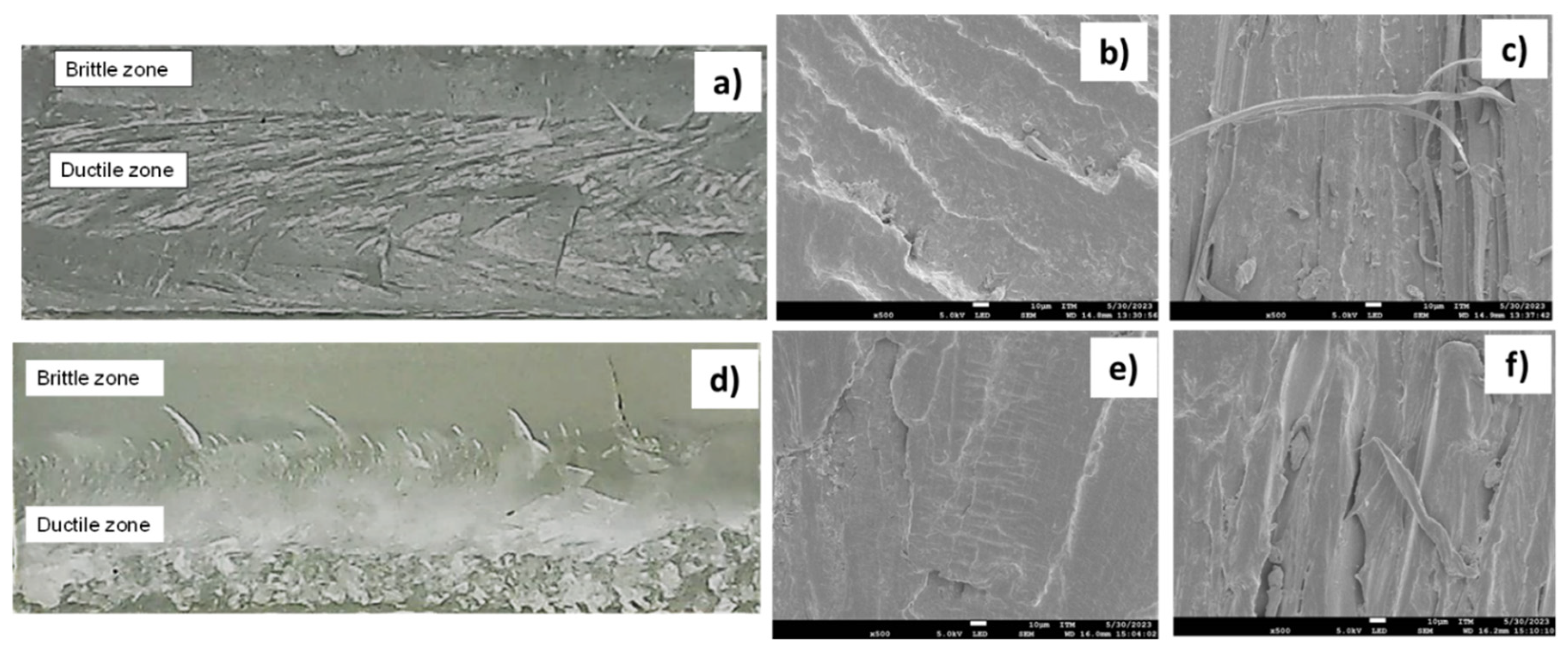

3.5. Fractography of the FSW Joints Using DSC and SEM

4. Discussion

4.1. Mechanical and Physical Properties

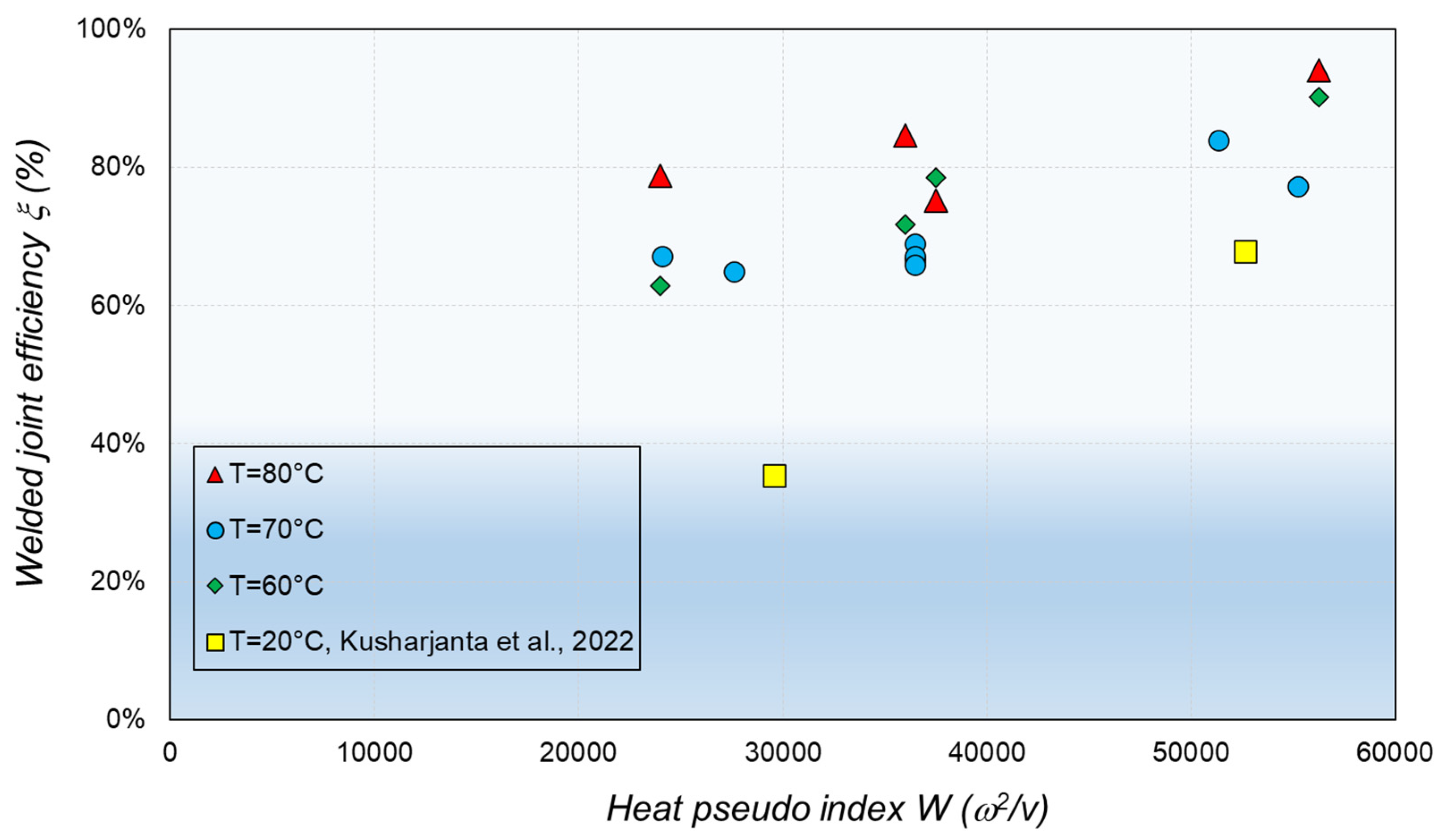

4.2. Thermal History and FSW Joint Efficiency

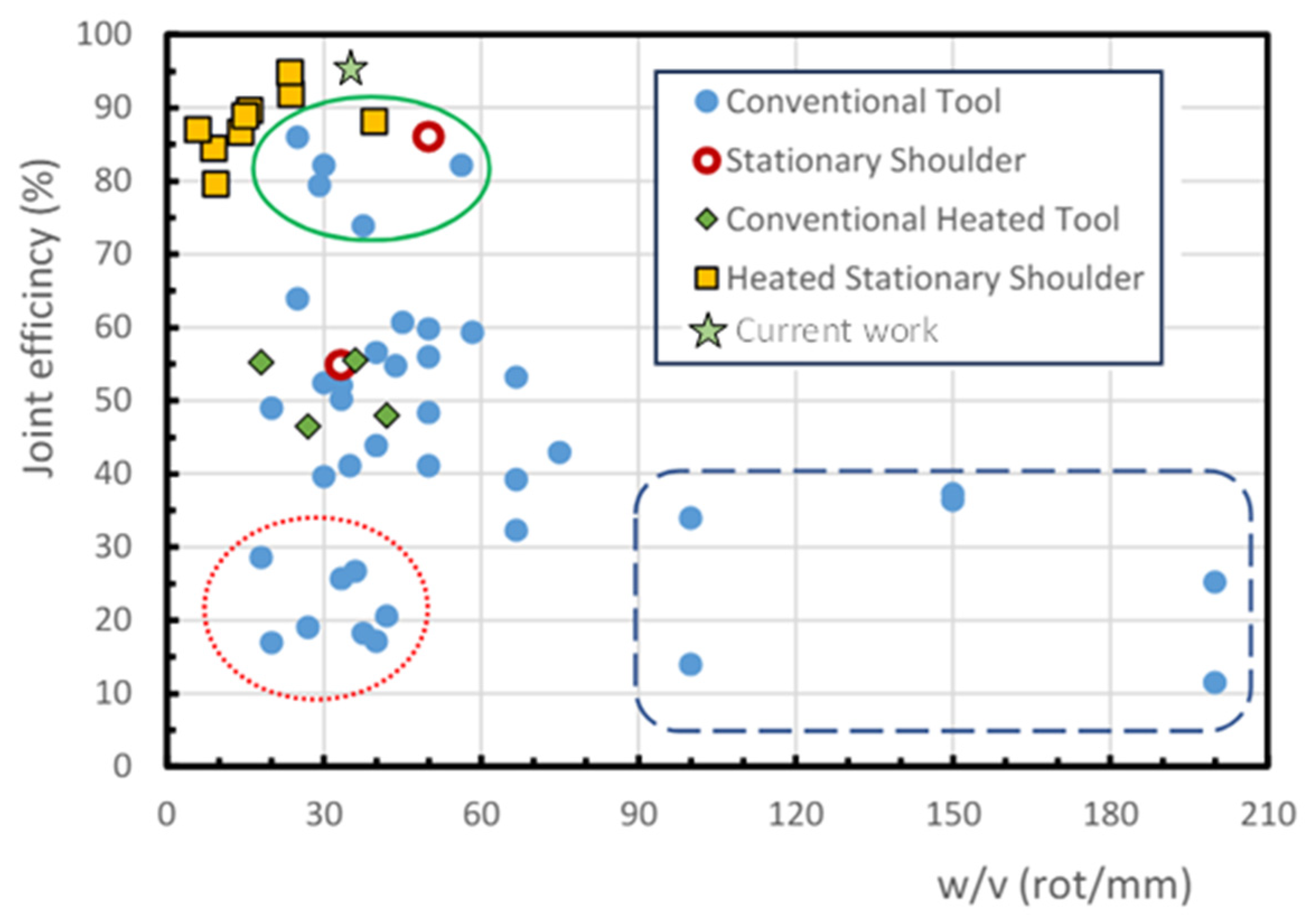

4.3. Effects of Welding Parameters on Joint Efficiency

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, Y.; Meng, X.; Xie, Y.; Wan, L.; Lv, Z.; Cao, J.; Feng, J. Friction stir welding/processing of polymers and polymer matrix composites. Compos. Part A Appl. Sci. Manuf. 2018, 105, 235–257. [Google Scholar] [CrossRef]

- Sahu, S.K.; Mishra, D.; Mahto, R.P.; Sharma, V.M.; Pal, S.K.; Pal, K.; Banerjee, S.; Dash, P. Friction stir welding of polypropylene sheet. Eng. Sci. Technol. Int. J. 2018, 21, 245–254. [Google Scholar] [CrossRef]

- Nandan, R.; DebRoy, T.; Bhadeshia, H. Recent advances in friction-stir welding process, weldment structure and properties. Prog. Mater. Sci. 2008, 6, 980–1023. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Lohwasser, D.; Zhan, C. Friction Stir Welding: From Basics to Applications; Elsevier: Amsterdam, The Netherlands, 2009; ISBN 978-1845694500. [Google Scholar]

- Ribeiro, L.; Pinto, G.F.; Baptista, A.; Monteiro, J. Hydrogen Electrical Vehicles; Study on a New Hydrogen Storage System–Performance, Permeation, and Filling/Refilling; Scrivener Publishing LLC: Beverly, MA, USA, 2023; pp. 11–46. [Google Scholar] [CrossRef]

- Maddah, H.A. Polypropylene as a Promising Plastic: A Review. Prog. Mater. Sci. 2016, 6, 1–11. [Google Scholar]

- Campbell, F. Manufacturing Processes for Advanced Composites; Elsevier: Amsterdam, The Netherlands, 2004; ISBN 1-85617-415-8. [Google Scholar]

- McCarville, D.A.; Schaefer, H.A. Composites; Processing and Joining of Thermoplastic Composites; ASM International: Novelty, OH, USA, 2001; Volume 21, pp. 633–645. [Google Scholar] [CrossRef]

- Leskovics, K.; Kollár, M.; Bárczy, P. A study of structure and mechanical properties of welded joints in polyethylene pipes, Composites. Mater. Sci. Eng. A 2006, 419, 138–143. [Google Scholar] [CrossRef]

- Payganeh, G.H.; Arab, N.M.; Asl, Y.D.; Ghasemi, F.A.; Boroujeni, M.S. Effects of friction stir welding process parameters on appearance and strength of polypropylene composite welds. Int. J. Phys. Sci. 2011, 6, 4595–4601. [Google Scholar]

- Kusharjanta, B.; Raharjo, W.P.; Triyono, T. Temperature Comparison of Initial, Middle and Final Point of Polypropylene Friction Stir Welded; AIP Conference Proceedings; AIP Publishing: College Park, MD, USA, 2016; Volume 1717, p. 040011. [Google Scholar] [CrossRef]

- Mirabzadeh, R.; Parvaneh, V.; Ehsani, A. Experimental and numerical investigation of the generated heat in polypropylene sheet joints using friction stir welding (FSW). Int. J. Mater. Form. 2021, 14, 1067–1083. [Google Scholar] [CrossRef]

- Stadler, G.R.; Szebényi, G.; Horváth, R. Investigation of Weld Forces and Strength of Friction Stir Welded Polypropylene Period. Polytech. Mech. Eng. 2023, 67, 183–189. [Google Scholar] [CrossRef]

- Reddy, V.J.; Rajasekhar, A.; Krishnaiah, A. Impact of Process Parameters on the Mechanical Properties of Friction Stir Welded Joints on Polypropylene Sheets. Int. J. Mech. Eng. 2024, 11, 50–57. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.; Ahuja, I.; Penna, R.; Feo, L. Weldability of thermoplastic materials for friction stir welding–A state of art review and future applications. Compos. Part B Eng. 2018, 137, 1–15. [Google Scholar] [CrossRef]

- Pereira, M.; Amaro, A.; Reis, P.; Loureiro, A. Effect of Friction Stir Welding Techniques and Parameters on Polymers Joint Efficiency–A Critical Review. Polymers 2021, 13, 2056. [Google Scholar] [CrossRef] [PubMed]

- Moreno-Moreno, M.; Romero, Y.; Zambrano, H.R.; Restrepo, C.; Afonso, C.; Unfried, J. Mechanical and thermal properties of friction stir welded joints of high density polyethylene using a non-rotational shoulder tool. Int. J. Adv. Manuf. Technol. 2018, 97, 2489–2499. [Google Scholar] [CrossRef]

- Kiss, Z.; Czigány, T. Applicability of friction stir welding in polymeric materials. Period. Polytech. Mech. Eng. 2007, 51, 15–18. [Google Scholar] [CrossRef]

- Azarsa, E.; Mostafapour, A. Experimental investigation on flexural behavior of friction stir welded high density polyethylene sheets. J. Manuf. Process. 2014, 16, 149–155. [Google Scholar] [CrossRef]

- Banjare, P.N.; Sahlot, P.; Arora, A. An assisted heating tool design for FSW of thermoplastics. J. Mater. Process. Technol. 2017, 239, 83–91. [Google Scholar] [CrossRef]

- Panneerselvam, K.; Lenin, K. Effects and defects of the polypropylene plate for different parameters in friction stir welding process. Int. J. Res. Eng. Technol. 2013, 2, 143–152. [Google Scholar]

- Jaiganesh, V.; Balaiya, M.; Elamparithy, G. Optimization of Process Parameters on Friction Stir Welding of High Density Polypropylene Plate. Procedia Eng. 2014, 97, 1957–1965. [Google Scholar] [CrossRef]

- Montgomery Douglas, C. Design and Analysis of Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- ASTM D638-02a 08; Standard Test Method for Tensile Properties of Plastics. ASTM International, American Society for Testing and Materials: West Conshohocken, PA, USA, 2003; pp. 46–58.

- ASTM E384-17; Standard Test Method for Microindentation Hardness of Materials. ASTM International, American Society for Testing and Materials: West Conshohocken, PA, USA, 2017; pp. 281–293.

- Kong, Y.; Hay, J.N. The measurement of the crystallinity of polymers by DSC. Polymer 2002, 43, 3873–3878. [Google Scholar] [CrossRef]

- Noor Hasanah, T.I.T.; Wijeyesekera, D.C.; bin Bakar, I.; Saidin, W. New lightweight construction material: Cellular mat using recycled plastic. Key Eng. Mater. 2013, 594, 503–510. [Google Scholar] [CrossRef]

- Jones, H.; McClements, J.; Ray, D.; Hindle, C.S.; Kalloudis, M.; Koutsos, V. Thermomechanical Properties of Virgin and Recycled Polypropylene—High-Density Polyethylene Blends. Polymer 2023, 15, 4200. [Google Scholar] [CrossRef] [PubMed]

- Dodge, Y. Least Significant Difference Test. In The Concise Encyclopedia of Statistics; Springer: New York, NY, USA, 2008. [Google Scholar] [CrossRef]

- Razavi, M.; Cheng, S.; Huang, D.; Zhang, S.; Wang, S.Q. Crazing and yielding in glassy polymers of high molecular weight. Polymer 2020, 197, 122445. [Google Scholar] [CrossRef]

- Bowden, P.B. The Yield Behaviour of Glassy Polymers. In The Physics of Glassy Polymers; Materials Science Series; Haward, R.N., Ed.; Springer: Dordrecht, UK, 1973. [Google Scholar] [CrossRef]

- Sichina, W. Measurement of Percent Crystallinity of Thermoplastics; DSC as Problem Solving Tool; PerkinElmer Instruments, The Physics of Glassy Polymers: Norwalk, CT, USA, 2000. [Google Scholar]

- Butylina, S.; Martikka, O.; Kärki, T. Physical and mechanical properties of wood-polypropylene composites made with virgin and/or recycled polypropylene. Polym. Plast. Technol. Eng. 2020, 50, 1040–1046. [Google Scholar] [CrossRef]

- Nath, R.K.; Jha, V.; Maji, P.; Barma, J.D. A novel double-side welding approach for friction stir welding of polypropylene plate. Int. J. Adv. Manuf. Technol. 2021, 113, 691–703. [Google Scholar] [CrossRef]

- Nath, R.K.; Maji, P.; Barma, J.D. Development of a Self-Heated Friction Stir Welding tool for welding of polypropylene sheets. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 1–13. [Google Scholar] [CrossRef]

- Tan, C.J.; Andriyana, A.; Ang, B.C.; Wong, D. Mechanical deformation and fracture mechanisms of polymeric fibres from the perspective of fractography–A review. Eur. Polym. J. 2020, 134, 109924. [Google Scholar] [CrossRef]

- Kusharjanta, B.; Soenoko, R.; Purnowidodo, A.; Irawan, Y.S. Analysis of tensile strength, crystallinity, crystallite size, and thermal stability of polypropylene joined by friction stir welding. J. Appl. Eng. Sci. 2022, 20, 85–90. [Google Scholar] [CrossRef]

- Li, J.; Zhu, Z.; Li, T.; Peng, X.; Jiang, S.; Turng, L.S. Quantification of the Young’s modulus for poly-propylene: Influence of initial crystallinity and service temperature. J. Appl. Polym. Sci. 2020, 137, 48581. [Google Scholar] [CrossRef]

| E GPa | Sy (MPa) | Sut (MPa) | Tm (°C) | Density (g/cm3) | Tg (°C) |

|---|---|---|---|---|---|

| 0.714 | 12.0–43.0 | 35.5 MPa | 130–171 | 0.9705 | −20 |

| Factor | Units | Low | High |

|---|---|---|---|

| w | rpm | 1200 | 1500 |

| v | mm/min | 40 | 60 |

| T | °C | 60 | 80 |

| Specimen | ω (rpm) | v (mm/min) | T (°C) | Sut (MPa) | ξ (%) | W |

|---|---|---|---|---|---|---|

| 1 | 1350 | 50 | 53 | 21.86 | 62% | 36,450 |

| 2 | 1500 | 60 | 60 | 27.89 | 79% | 37,500 |

| 3 | 1500 | 40 | 60 | 32.01 | 90% | 56,250 |

| 4 | 1350 | 50 | 70 | 23.85 | 67% | 36,450 |

| 5 | 1200 | 60 | 80 | 28.00 | 79% | 24,000 |

| 6 | 1350 | 66 | 70 | 23.08 | 65% | 27,614 |

| 7 | 1200 | 60 | 60 | 22.34 | 63% | 24,000 |

| 8 | 1500 | 60 | 80 | 26.71 | 75% | 37,500 |

| 9 | 1350 | 50 | 70 | 23.42 | 66% | 36,450 |

| 10 | 1602 | 50 | 70 | 29.81 | 84% | 51,328 |

| 11 | 1097 | 50 | 70 | 23.86 | 67% | 24,068 |

| 12 | 1350 | 50 | 86 | 28.43 | 80% | 36,450 |

| 13 | 1200 | 40 | 80 | 30.07 | 85% | 36,000 |

| 14 | 1500 | 40 | 80 | 33.41 | 94% | 56,250 |

| 15 | 1350 | 33 | 70 | 27.43 | 77% | 55,227 |

| 16 | 1350 | 50 | 70 | 23.63 | 67% | 36,450 |

| 17 | 1200 | 40 | 60 | 25.48 | 72% | 36,000 |

| 18 | 1350 | 50 | 70 | 24.51 | 69% | 36,450 |

| Source | Square Sum | Freedom Degree | Mean Square | F-Ratio | p-Value |

|---|---|---|---|---|---|

| A:w | 42.6583 | 1 | 42.6583 | 14.56 | 0.0051 |

| B: v | 39.9086 | 1 | 39.9086 | 13.62 | 0.0061 |

| C: T | 33.9085 | 1 | 33.9085 | 11.57 | 0.0093 |

| AA | 31.1614 | 1 | 31.1614 | 10.64 | 0.0115 |

| AB | 3.93401 | 1 | 3.93401 | 1.34 | 0.28 |

| AC | 12.5751 | 1 | 12.5751 | 4.29 | 0.072 |

| BB | 12.9278 | 1 | 12.9278 | 4.41 | 0.0689 |

| BC | 0.285013 | 1 | 0.285013 | 0.1 | 0.7631 |

| CC | 11.9522 | 1 | 11.9522 | 4.08 | 0.0781 |

| Total Error | 23.4405 | 8 | 2.93007 | - | - |

| Total | 197.791 | 17 | - | - | - |

| Specimen | DZ/FA | Crystallinity | Reference |

|---|---|---|---|

| 1 | 65.7 | 76.2 | Present work |

| 14 | 37.9 | 65.2 | Present work |

| PP | - | 36.4 | [30] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Balaguera, M.; Zambrano, H.R.; Chamorro Coneo, R.J.; Santa Marín, J.F.; Unfried-Silgado, J. Effect of Temperature Control and Rotational and Traverse Speeds on the Mechanical Properties of Friction Stir-Welded Polypropylene Plates. Polymers 2024, 16, 3110. https://doi.org/10.3390/polym16223110

Balaguera M, Zambrano HR, Chamorro Coneo RJ, Santa Marín JF, Unfried-Silgado J. Effect of Temperature Control and Rotational and Traverse Speeds on the Mechanical Properties of Friction Stir-Welded Polypropylene Plates. Polymers. 2024; 16(22):3110. https://doi.org/10.3390/polym16223110

Chicago/Turabian StyleBalaguera, Miguelangel, Habib R. Zambrano, Ramiro J. Chamorro Coneo, Juan Felipe Santa Marín, and Jimy Unfried-Silgado. 2024. "Effect of Temperature Control and Rotational and Traverse Speeds on the Mechanical Properties of Friction Stir-Welded Polypropylene Plates" Polymers 16, no. 22: 3110. https://doi.org/10.3390/polym16223110

APA StyleBalaguera, M., Zambrano, H. R., Chamorro Coneo, R. J., Santa Marín, J. F., & Unfried-Silgado, J. (2024). Effect of Temperature Control and Rotational and Traverse Speeds on the Mechanical Properties of Friction Stir-Welded Polypropylene Plates. Polymers, 16(22), 3110. https://doi.org/10.3390/polym16223110