Comprehensive Investigation of Epoxy Adhesives for Structural Applications in Saudi Arabia: Mechanical Performance, Environmental Impacts, and Analysis on Health

Abstract

1. Introduction

2. Applicable Scenarios and Occupational Safety Information

2.1. Product Purposes and Features

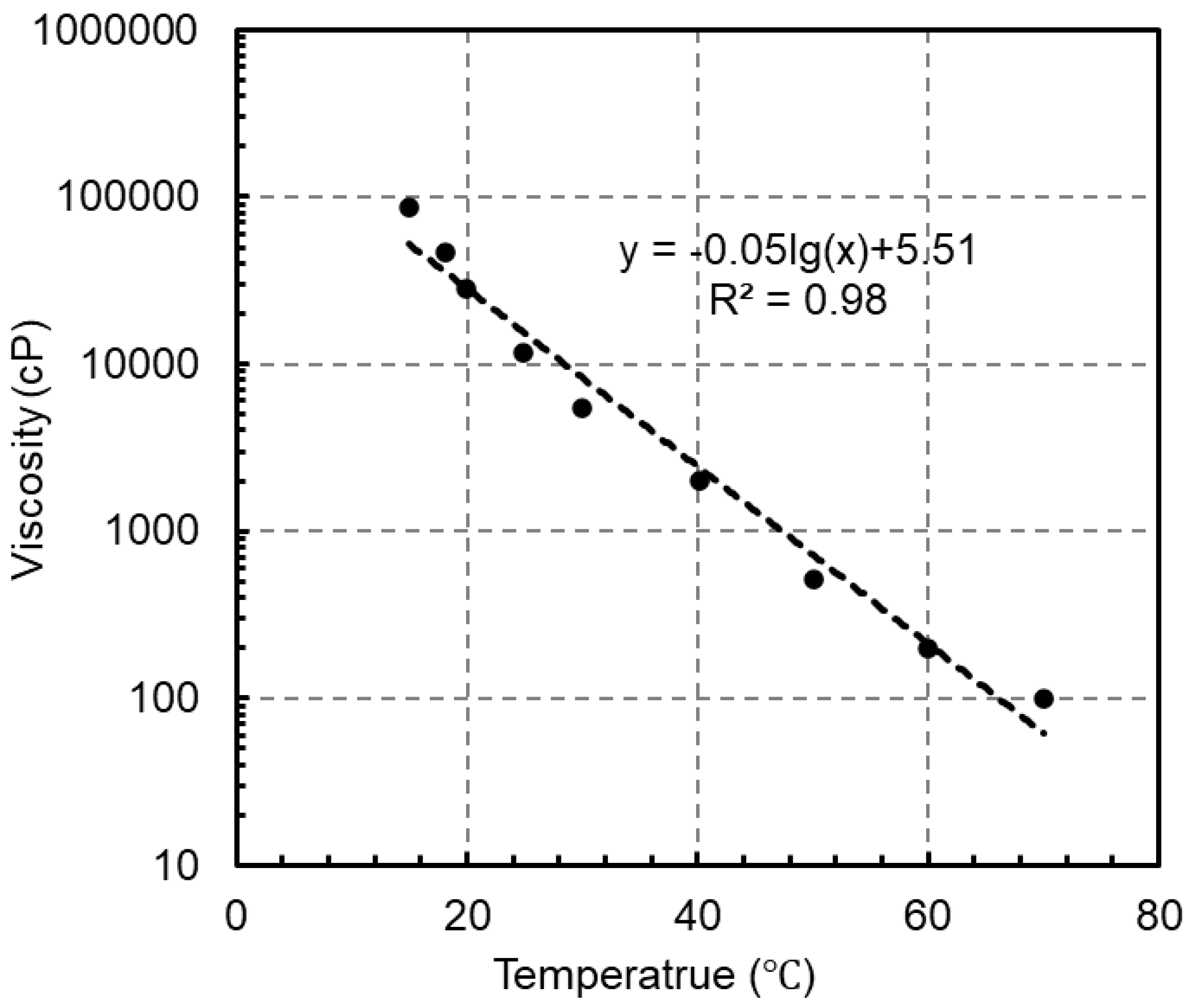

2.2. Applicable Temperature

2.3. Hazards Identification and Prevention

3. Mechanical Property Tests

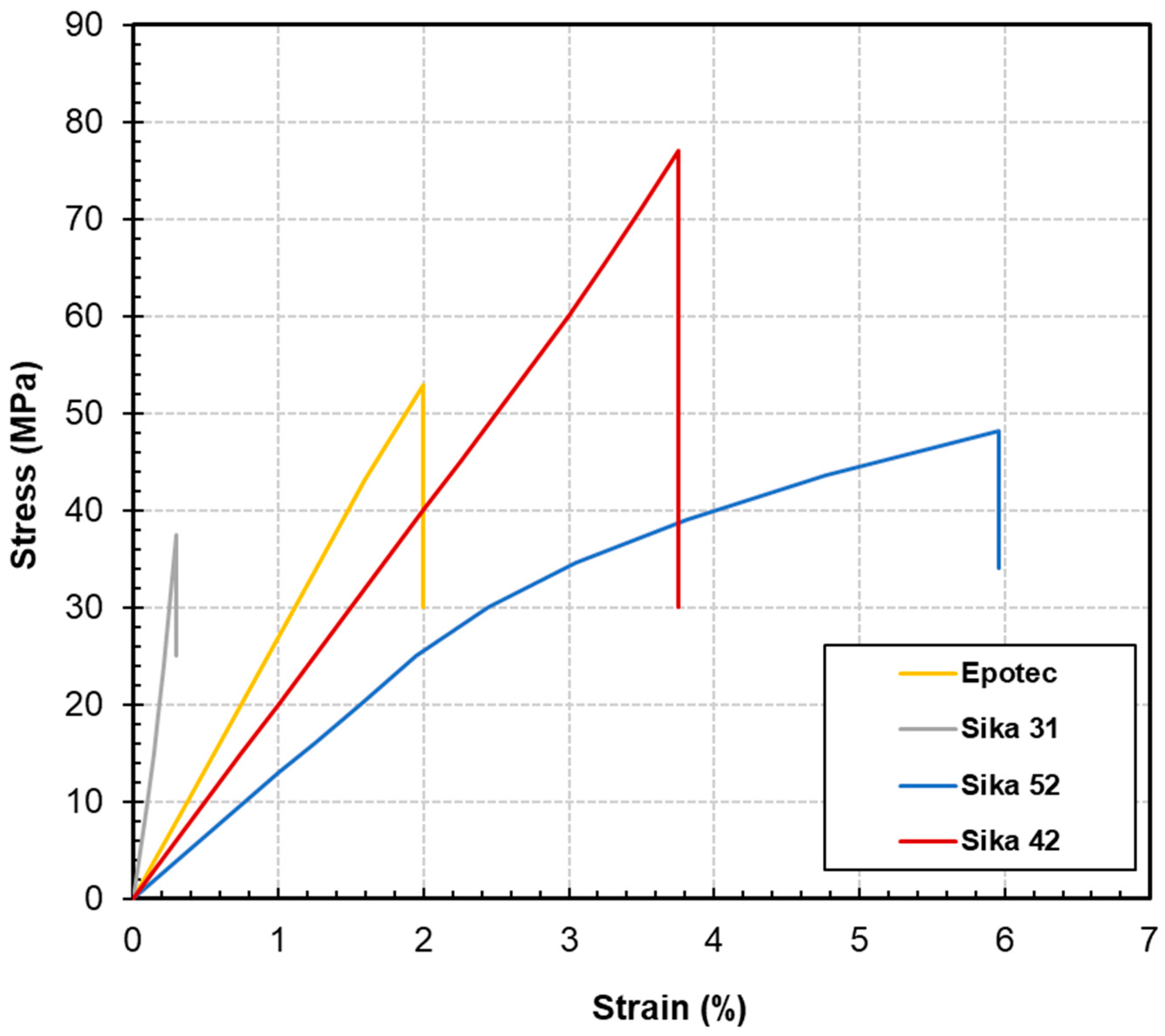

3.1. Tensile Tests

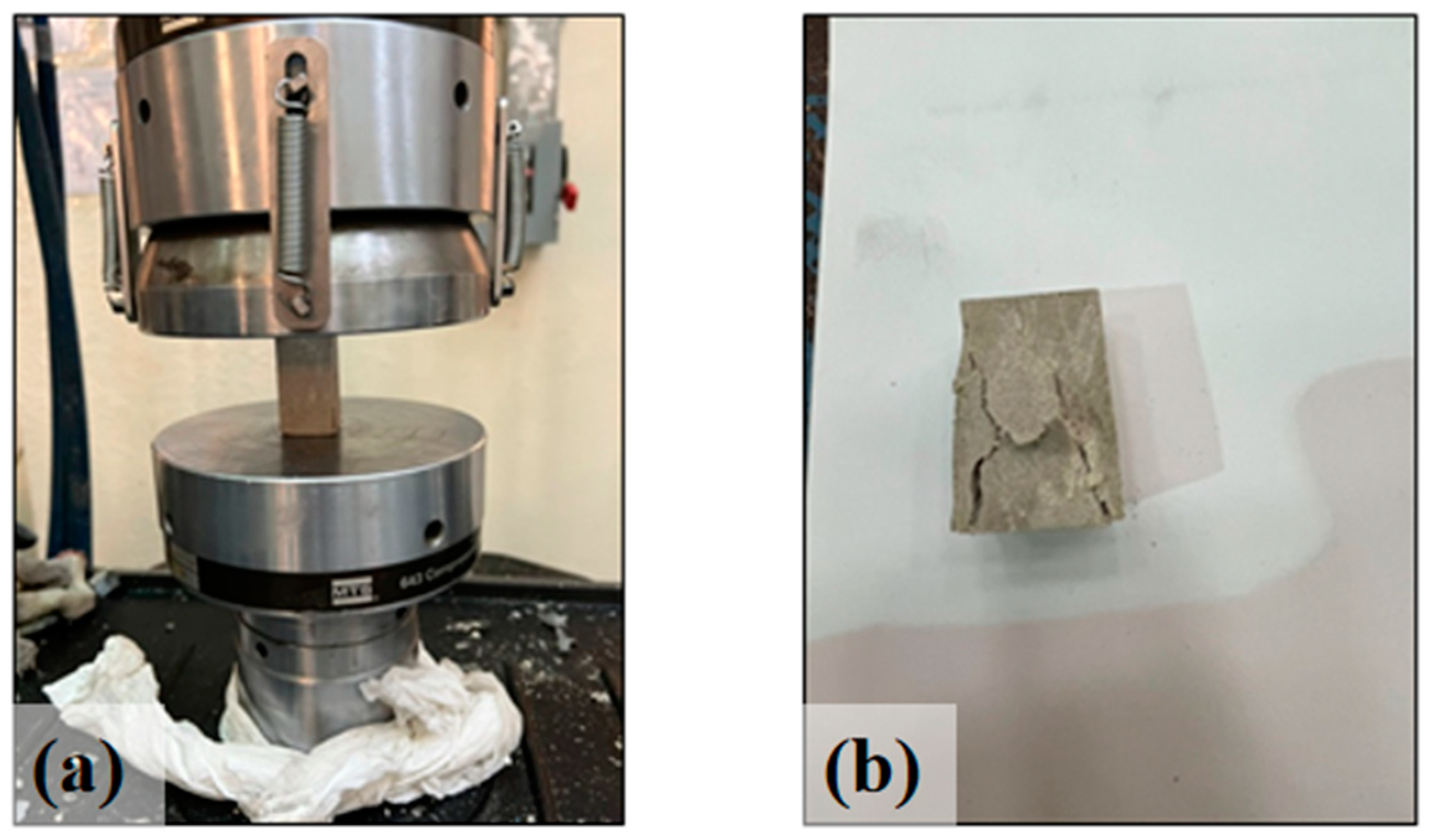

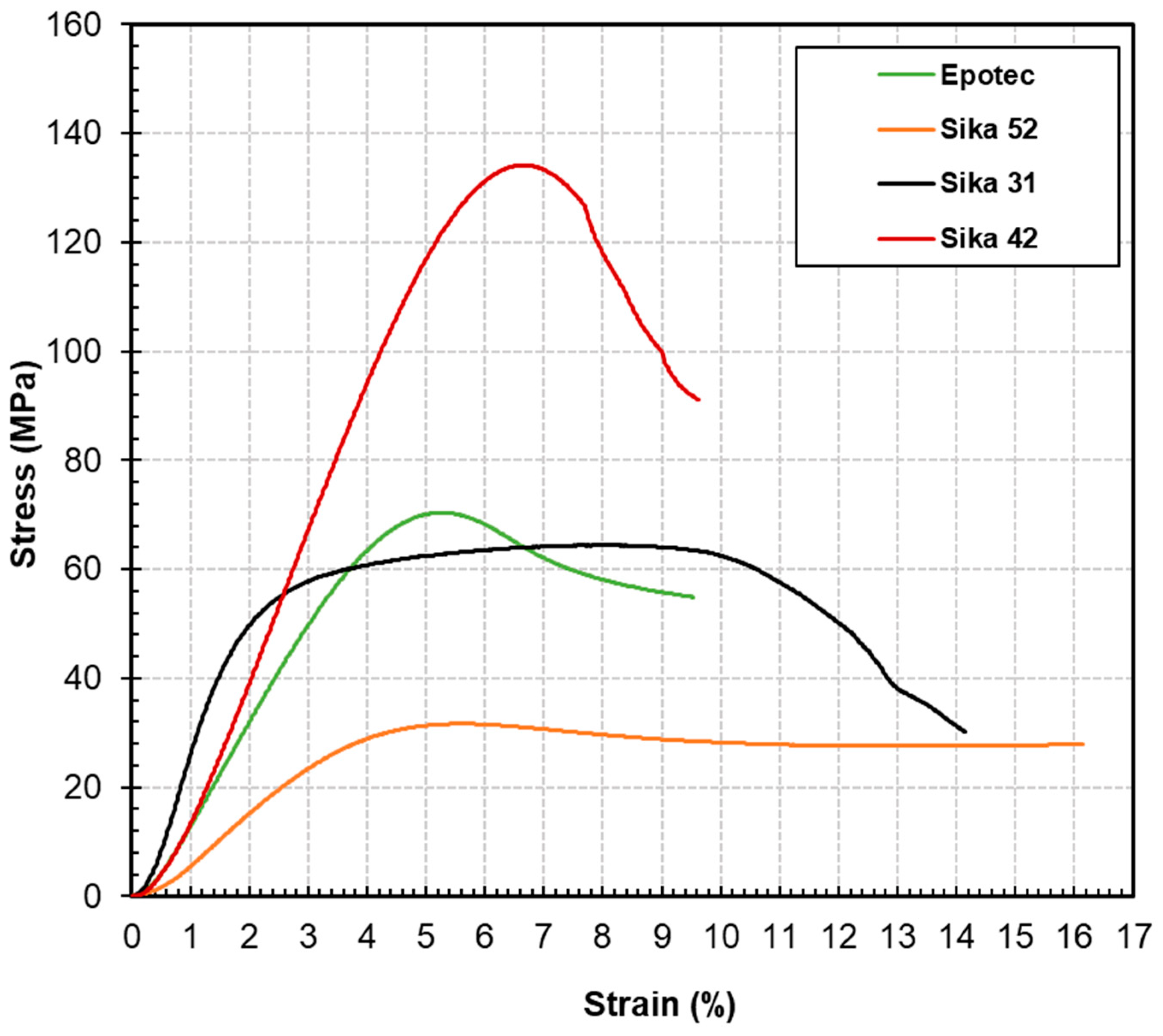

3.2. Compressive Tests

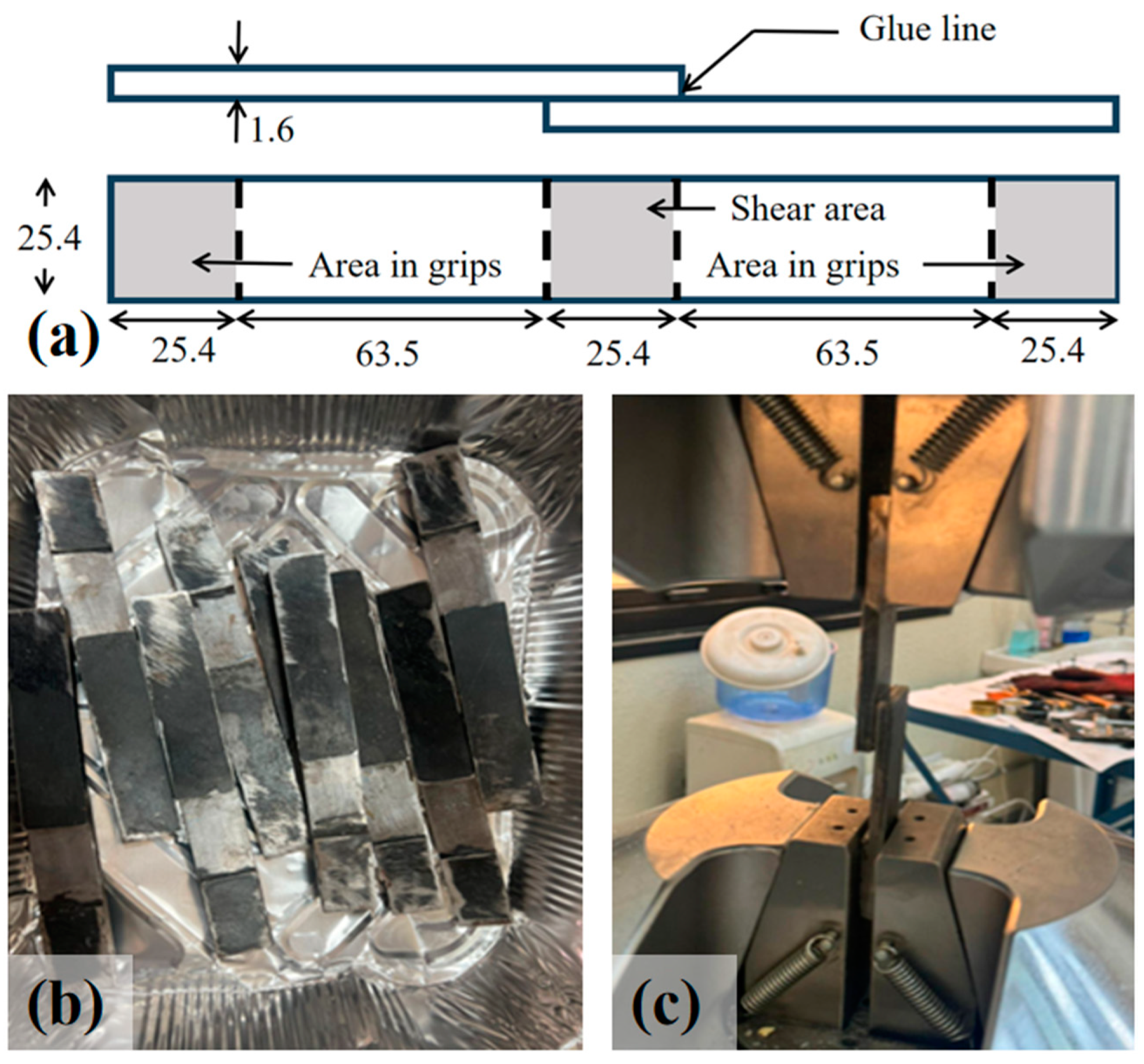

3.3. Shear Tests

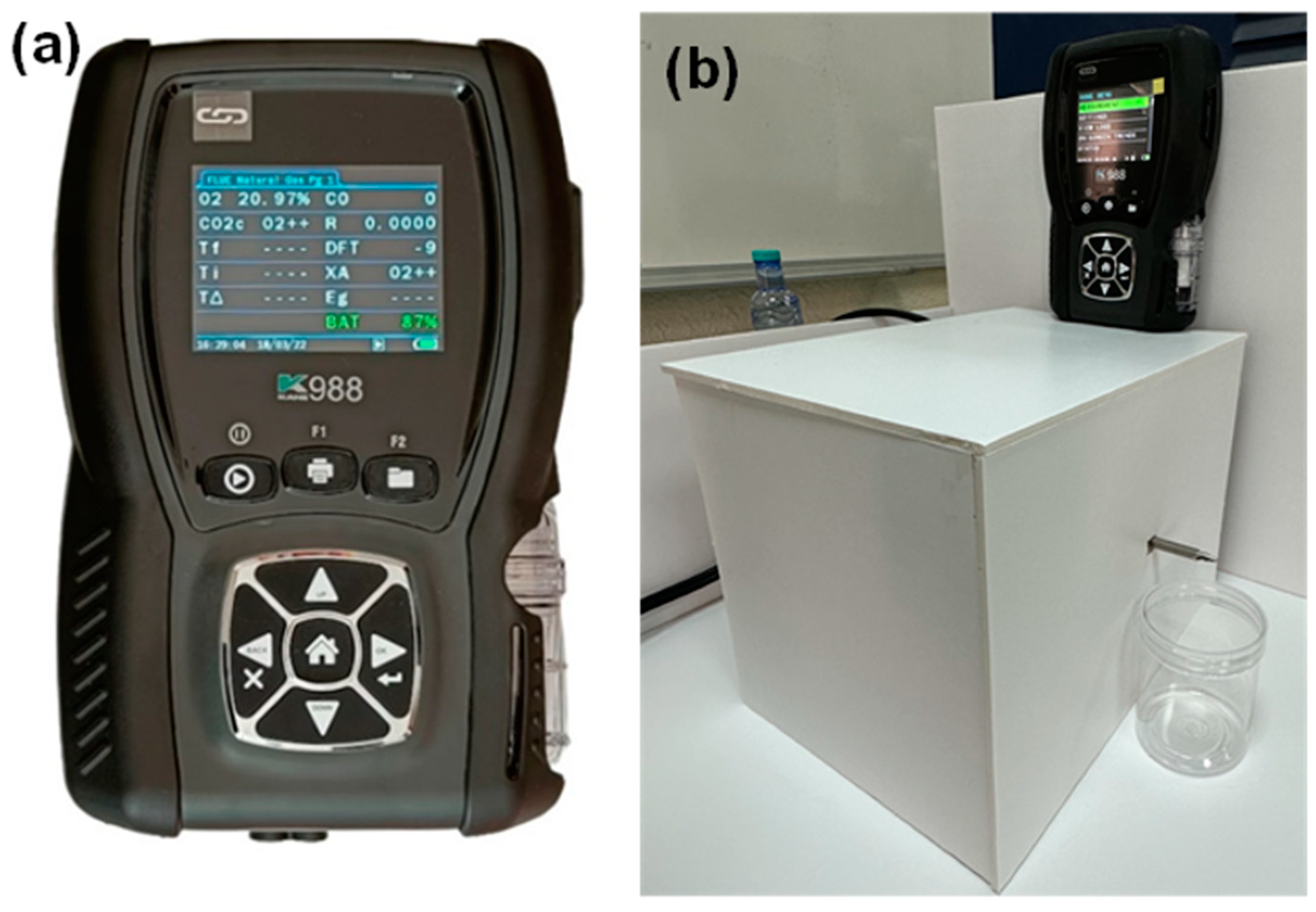

4. Pollutant Emission Tests

5. Discussion

6. Conclusions

- (1)

- Sika 42 is ideal for the temperature and humidity conditions in Saudi Arabia, with a pot life of 48 min at 40 °C. Sika 31 only operates effectively between 10 and 30 °C, while Sika 52’s pot life decreases to just 10 min under heat, underscoring Sika 42’s advantage for construction applications. Data on Epotec’s pot life vary with curing agents but are currently unavailable.

- (2)

- Sika 42 presents greater potential hazards according to OSHA, necessitating stricter safety measures. As a three-component adhesive, it requires higher technical qualifications and a higher level of training for personnel, making Sika 31 and Epotec more accessible options.

- (3)

- Mechanical tests show that Sika 31 has a tensile modulus of 10.4 GPa and a compressive modulus of 2.7 GPa, far exceeding other adhesives. Sika 42 boasts the highest tensile (75.7 MPa) and compressive strengths (133.8 MPa). In contrast, Sika 52 exhibits the lowest moduli, indicating significant deformation under load but effective impact absorption.

- (4)

- Epotec ranks second for tensile (52.9 MPa) and compressive strengths (70.7 MPa), making it a viable alternative. Sika 31 excels in tensile strain control, while Sika 52 suits applications requiring flexibility against any potential impacts.

- (5)

- Among all the epoxy adhesive samples after mixing, neither CO nor NO were detected. Only SO2 was detected in Sikadur®-31 CF, with a maximum concentration of only 2 ppm, while the other three types of adhesive samples exhibited detections of both SO2 and NO2. After 120 min of mixing, no target harmful gases were detected in any of the samples.

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xie, H.; Li, C.; Wang, Q. A critical review on performance and phase separation of thermosetting epoxy asphalt binders and bond coats. Constr. Build. Mater. 2022, 326, 126792. [Google Scholar] [CrossRef]

- Sousa, J.M.; Correia, J.R.; Cabral-Fonseca, S. Durability of an epoxy adhesive used in civil structural applications. Constr. Build. Mater. 2018, 161, 618–633. [Google Scholar] [CrossRef]

- Almutairi, A.D.; Bai, Y.; Ferdous, W. Flexural Behaviour of GFRP-Softwood Sandwich Panels for Prefabricated Building Construction. Polymers 2023, 15, 2102. [Google Scholar] [CrossRef] [PubMed]

- Fang, H.; Bai, Y.; Liu, W.; Qi, Y.; Wang, J. Connections and structural applications of fibre reinforced polymer composites for civil infrastructure in aggressive environments. Compos. Part B Eng. 2019, 164, 129–143. [Google Scholar] [CrossRef]

- Feng, P.; Wu, Y.; Liu, T. Non-uniform fiber-resin distributions of pultruded GFRP profiles. Compos. Part B Eng. 2022, 231, 109543. [Google Scholar] [CrossRef]

- Shrestha, K.; Shrestha, P.P.; Batista, J. Evaluating Life-Cycle Unit Costs of Traditional Cement Concrete and New Polymer Concrete Manholes in Wastewater Systems. Buildings 2024, 14, 2835. [Google Scholar] [CrossRef]

- Dunaj, P. Mesoscale Modeling of Polymer Concrete Dynamic Properties. Polymers 2023, 15, 4311. [Google Scholar] [CrossRef]

- Dai, Y.; Bai, Y.; Cai, Z. Thermal and mechanical evaluation on integration of GFRP and thin-film flexible PV cells for building applications. J. Clean. Prod. 2021, 289, 125809. [Google Scholar] [CrossRef]

- Cai, Z.; Bai, Y.; Almutairi, A.D.; Ding, C. Low-high-low cyclic performance of screw connections for fibre-polymer composites. Constr. Build. Mater. 2024, 419, 135454. [Google Scholar] [CrossRef]

- Yang, X.; Bai, Y.; Ding, F. Structural performance of a large-scale space frame assembled using pultruded GFRP composites. Compos. Struct. 2015, 133, 986–996. [Google Scholar] [CrossRef]

- Dai, Y.; Dai, X.; Bai, Y.; He, X. Aerodynamic Performance of an Adaptive GFRP Wind Barrier Structure for Railway Bridges. Materials 2020, 13, 4214. [Google Scholar] [CrossRef] [PubMed]

- Gu, X.; Dai, Y.; Jiang, J. Test and Evaluation for Bonding Property Between GFRP and Concrete. J. Test. Eval. 2016, 44, 878–884. [Google Scholar] [CrossRef]

- Gu, X.; Dai, Y.; Jiang, J. Flexural behavior investigation of steel-GFRP hybrid-reinforced concrete beams based on experimental and numerical methods. Eng. Struct. 2020, 206, 110117. [Google Scholar]

- Dai, Y.; Bai, Y.; Keller, T. Stress mitigation for adhesively bonded photovoltaics with fibre reinforced polymer composites in load carrying applications. Compos. Part B Eng. 2019, 177, 107420. [Google Scholar] [CrossRef]

- Almutairi, A.D.; Bai, Y.; Wang, Y.; Jeske, J. Mechanical performance of fibre reinforced polymer confined softwood timber for pole applications. Compos. Struct. 2020, 235, 111807. [Google Scholar] [CrossRef]

- Zhang, L.; Dai, Y.; Bai, Y.; Chen, W.; Ye, J. Fire performance of loaded fibre reinforced polymer multicellular composite structures with fire-resistant panels. Constr. Build. Mater. 2021, 296, 123733. [Google Scholar] [CrossRef]

- Guo, H.; Li, R.; Sun, L.; Chen, S.; Miao, H. Inspecting epoxy layer defects in steel-epoxy-steel sandwich structures using guided waves. Measurement. J. Int. Meas. Confed. 2024, 231, 114551. [Google Scholar] [CrossRef]

- Ke, L.; Qiu, M.; Chen, Z.; Zhou, J.; Feng, Z.; Long, J. An interpretable machine learning model for predicting bond strength of CFRP-steel epoxy-bonded interface. Compos. Struct. 2023, 326, 117639. [Google Scholar] [CrossRef]

- Vosooghi, A.; Saiidi, M.S. Design Guidelines for Rapid Repair of Earthquake-Damaged Circular RC Bridge Columns Using CFRP. J. Bridge Eng. 2013, 18, 827–836. [Google Scholar] [CrossRef]

- Ke, L.; Li, Y.-L.; Li, C.; Cheng, Z.; Ma, K.; Zeng, J. Bond behavior of CFRP-strengthened steel structures and its environmental influence factors: A critical review. Sustain. Struct. 2024, 4, 805–817. [Google Scholar] [CrossRef]

- Satasivam, S.; Bai, Y.; Yang, Y.; Zhu, L.; Zhao, X.-L. Mechanical performance of two-way modular FRP sandwich slabs. Compos. Struct. 2018, 184, 904–916. [Google Scholar] [CrossRef]

- Satasivam, S.; Bai, Y.; Zhao, X.-L. Adhesively bonded modular GFRP web–flange sandwich for building floor construction. Compos. Struct. 2014, 111, 381–392. [Google Scholar] [CrossRef]

- Correia, J.R.; Keller, T.; Garrido, M.; Sá, M.; Firmo, J.P.; Abu Shahid, M.; Machado, M. Mechanical properties of FRP materials at elevated temperature—Definition of a temperature conversion factor for design in service conditions. Constr. Build. Mater. 2023, 367, 130298. [Google Scholar] [CrossRef]

- Dai, Y.; Bai, Y.; Keller, T. Thermal and mechanical performances of GFRP sandwich structures with integrated amorphous silicon photovoltaic cells. Compos. Struct. 2022, 290, 115524. [Google Scholar] [CrossRef]

- Rahman, M.M.; Islam, A.M. Application of epoxy resins in building materials: Progress and prospects. Polym. Bull. 2022, 79, 1949–1975. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Wong, H.S.; Abousnina, R.; AlAjarmeh, O.S.; Zhuge, Y.; Schubel, P. Optimal design for epoxy polymer concrete based on mechanical properties and durability aspects. Constr. Build. Mater. 2020, 232, 117229. [Google Scholar] [CrossRef]

- Gui, D.; Gao, X.; Hao, J.; Liu, J. Preparation and characterization of liquid crystalline polyurethane-imide modified epoxy resin composites. Polym. Eng. Sci. 2014, 54, 1704–1711. [Google Scholar] [CrossRef]

- Wang, J.; Dai, Q.; Guo, S.; Si, R. Mechanical and durability performance evaluation of crumb rubber-modified epoxy polymer concrete overlays. Constr. Build. Mater. 2019, 203, 469–480. [Google Scholar] [CrossRef]

- Li, G.; Zhang, A.; Song, Z.; Shi, C.; Wang, Y.; Zhang, J. Study on the resistance to seawater corrosion of the cementitious systems containing ordinary Portland cement or/and calcium aluminate cement. Constr. Build. Mater. 2017, 157, 852–859. [Google Scholar] [CrossRef]

- Luo, S.; Qian, Z.; Wang, H. Condition survey and analysis of epoxy asphalt concrete pavement on Second Nanjing Yangtze River Bridge: A ten-year review. J. Southeast Univ. 2011, 27, 417–422. [Google Scholar]

- Zhou, D.; Liang, R.; Kang, Y. A review of chemo-rheological and thermo-rheological investigations on epoxy asphalt cementitious materials. Constr. Build. Mater. 2023, 395, 132309. [Google Scholar] [CrossRef]

- Luo, Z.; Liu, T.; Wu, Y.; Yuan, H.; Qian, G.; Meng, X.; Cai, J. Study on Epoxy Resin-Modified Asphalt Binders with Improved Low-Temperature Performance. Adv. Civ. Eng. 2021, 2021, 5513338. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, Y.; Gong, J.; Li, C.; Xi, Z.; Cai, J.; Xie, H. Microstructures, thermal and mechanical properties of epoxy asphalt binder modified by SBS containing various styrene-butadiene structures. Mater. Struct. 2018, 51, 86. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J.; Chen, R.; Cai, J.; Xi, Z.; Xie, H. Ethylene vinyl acetate copolymer modified epoxy asphalt binders: Phase separation evolution and mechanical properties. Constr. Build. Mater. 2017, 137, 55–65. [Google Scholar] [CrossRef]

- Apostolidis, P.; Liu, X.; Erkens, S.; Scarpas, A. Characterization of epoxy-asphalt binders by differential scanning calorimetry. Constr. Build. Mater. 2020, 249, 118800. [Google Scholar] [CrossRef]

- Wang, C.; Fan, Z.; Li, C.; Zhang, H.; Xiao, X. Preparation and engineering properties of low-viscosity epoxy grouting materials modified with silicone for microcrack repair. Constr. Build. Mater. 2021, 290, 123270. [Google Scholar] [CrossRef]

- Que, Y.; Dai, Y.; Hong, Q.; Fang, L.; Zhang, C. Pull-Out Tests for GFRP/BFRP/Steel Bars Used as Nailing for Coal-Bearing Soil Slopes in Humid Regions. J. Test. Eval. 2023, 52, 491–510. [Google Scholar] [CrossRef]

- Ramasamy, E.; Karthikeyan, V.; Rameshkumar, K.; Veerappan, G. Glass-to-glass encapsulation with ultraviolet light curable epoxy edge sealing for stable perovskite solar cells. Mater. Lett. 2019, 250, 51–54. [Google Scholar] [CrossRef]

- Dong, S.; Zhou, P.; Ning, Z.; Wu, X.; Li, C.; Xian, G. Durability of carbon- and glass-fiber reinforced thermoplastic polymer composites: A literature review. J. Build. Eng. 2024, 98, 111055. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, X.-L.; Xian, G.; Wu, G.; Singh Raman, R.K.; Al-Saadi, S.; Haque, A. Long-term durability of basalt- and glass-fibre reinforced polymer (BFRP/GFRP) bars in seawater and sea sand concrete environment. Constr. Build. Mater. 2017, 139, 467–489. [Google Scholar] [CrossRef]

- Xian, G.; Guo, R.; Li, C. Combined effects of sustained bending loading, water immersion and fiber hybrid mode on the mechanical properties of carbon/glass fiber reinforced polymer composite. Compos. Struct. 2022, 281, 115060. [Google Scholar] [CrossRef]

- Algonaiman, R.; Almutairi, A.S.; Al Zhrani, M.M.; Barakat, H. Effects of Prenatal Exposure to Bisphenol A Substitutes, Bisphenol S and Bisphenol F on Offspring’s Health: Evidence from Epidemiological and Experimental Studies. Biomolecules 2023, 13, 1616. [Google Scholar] [CrossRef] [PubMed]

- Laborde-Castérot, H.; Rosenberg, N.; Dupont, P.; Garnier, R. Is the incidence of aliphatic amine-induced occupational rhinitis and asthma underestimated? Am. J. Ind. Med. 2014, 57, 1303–1310. [Google Scholar] [CrossRef]

- Alfantookh, N.; Osman, Y.; Ellaythey, I. Implications of transition towards manufacturing on the environment: Saudi Arabia’s Vision 2030 Context. J. Risk Financ. Manag. 2023, 16, 44. [Google Scholar] [CrossRef]

- Hines, C.J.; Jackson, M.V.; Deddens, J.A.; Clark, J.C.; Ye, X.; Christianson, A.L.; Meadows, J.W.; Calafat, A.M. Urinary Bisphenol A (BPA) Concentrations among Workers in Industries that Manufacture and Use BPA in the USA. Ann. Work. Expo. Health 2017, 61, 164–182. [Google Scholar] [CrossRef]

- Lei, D.; Hong, T.; Li, L.; Chen, L.; Luo, X.; Wu, Q.; Liu, Z. Isobaric tags for relative and absolute quantitation-based proteomics analysis of the effect of ginger oil on bisphenol A-induced breast cancer cell proliferation. Oncol. Lett. 2021, 21, 101. [Google Scholar] [CrossRef]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2014.

- Bai, Y.; Qiu, C. Load-Dependent Composite Action for Beam Nonlinear and Ductile Behavior. J. Struct. Eng. 2020, 146, 04020028. [Google Scholar] [CrossRef]

- ASTM D695-15; Standard Test Method for Compressive Properties of Rigid Plastics. ASTM: West Conshohocken, PA, USA, 2015.

- ASTM D1002-10; Standard Test Method for Apparent Shear Strength of Adhesives Bonded Metal Joints. ASTM: West Conshohocken, PA, USA, 2019.

- Liu, L.; Wang, X.; Wu, Z.; Keller, T. Tension-tension fatigue behavior of ductile adhesively-bonded FRP joints. Compos. Struct. 2021, 268, 113925. [Google Scholar] [CrossRef]

- Liu, L.; Wang, X.; Wu, Z.; Keller, T. Tension-tension fatigue behavior of basalt composite hybrid joints. Int. J. Fatigue 2024, 184, 108318. [Google Scholar] [CrossRef]

- Jion, M.M.M.F.; Jannat, J.N.; Mia, M.Y.; Ali, M.A.; Islam, M.S.; Ibrahim, S.M.; Pal, S.C.; Islam, A.; Sarker, A.; Malafaia, G.; et al. A critical review and prospect of NO2 and SO2 pollution over Asia: Hotspots, trends, and sources. Sci. Total Environ. 2023, 876, 162851. [Google Scholar] [CrossRef]

- Chen, J.; Zeng, Y.; Lau, A.K.H.; Guo, C.; Wei, X.; Lin, C.; Huang, B.; Lao, X.Q. Chronic exposure to ambient PM2.5/NO2 and respiratory health in school children: A prospective cohort study in Hong Kong. Ecotoxicol. Environ. Saf. 2023, 252, 114558. [Google Scholar] [CrossRef] [PubMed]

- Galvao, E.S.; Junior, N.C.R.; Goulart, E.V.; Kumar, P.; Santos, J.M. Refining Children’s exposure assessment to NO2, SO2, and O3: Incorporating indoor-to-outdoor concentration ratios and individual daily routine. Chemosphere 2024, 364, 143155. [Google Scholar] [CrossRef] [PubMed]

- Hwang, J.; Kim, J. Study on Decline of Trees by Acid Rainfall. Korean J. Ecol. 2023, 27, 347–353. [Google Scholar]

| Product | Epotec | Sika 31 | Sika 42 | Sika 52 | |||

|---|---|---|---|---|---|---|---|

| Product use | Adhesive | Adhesive | Grouting | Sealing | |||

| Storage temperature | N/A * | 5 to 30 °C | 5 to 30 °C | 5 to 30 °C | |||

| Application temperature | <80 °C | 10 to 30 °C | 20 to 35 °C | 25 to 40 °C | |||

| Pot life | N/A | 10 °C | 145 min | 23 °C | 105 min | 23 °C | 70 min |

| 23 °C | 55 min | 40 °C | 48 min | 30 °C | 30 min | ||

| 30 °C | 35 min | 40 °C | 10 min | ||||

| Service temperature | N/A | N/A | −40 to 60 °C | N/A | |||

| Epotec | Sika 31 | Sika 42 | Sika 52 | |||||

|---|---|---|---|---|---|---|---|---|

| Part A | Part B | Part A | Part B | Part C | Part A | Part B | ||

| Physical state | Liquid | Liquid | Paste | Liquid | Liquid | Powder | Liquid | Liquid |

| Color | Light yellow | Grey | Black | Clear, straw-like | Yellow | Light gray | Transparent | Yellow |

| Odour | Light | Epoxy-like | Characteristic | Aromatic | Amine-like | Odorless | Epoxy-like | Amine-like |

| Density (g/cm3) | 1.16 (20 °C) | 1.94 (20 °C) | 1.95 (20 °C) | 1.13 (23 °C) | 0.99(23 °C) | 1.85 (23 °C) | 1.14 (20 °C) | 0.99 (20 °C) |

| Viscosity (mm2/s) | 11–14 (25 °C) | 20.5 (40 °C) | N/A | >20.5 (40 °C) | >20.5 (40 °C) | N/A | >20.5 (40 °C) | 7–20.5 (40 °C) |

| Hazard identification | H315, H319 H317, H411 | H315, H319 H317, H411 | H314, H412 H317 | H315, H319 H317, H341 | H302, H351 H314, H360 H317, H362 | H335, H372 H350 | H315, H319 H317, H411 | H304, H318 H314, H400 H317, H411 |

| Hazard Prevention | P261, P280 P264, P363 P272, P391 P273, P501 | P261, P273 P264, P280 | P261, P272 P264 | P201, P264 P202, P272 P261, P280 | P201, P264 P202, P263 P261, P272 P270, P280 | P201, P270 P202, P271 P260, P280 P264 | P261, P273 P264, P280 | P273, P280 |

| Exposure controls | Eye Hand Skin/body Respiratory | Eye Hand Skin/body | Eye Hand Skin/body Respiratory | Eye Hand Skin/body Respiratory Hygiene | Eye Hand Skin/body Respiratory Hygiene | Eye Skin/body Hygiene * | Eye Hand Skin/body | Eye Hand Skin/body |

| Mix ratio | N/A | A: B = 2: 1 by weight or volume | A: B: C = 5: 1: 36 by weight | A: B = 2: 1 by weight or volume | ||||

| Density (kg/m3) | 1.16 (at 20 °C) | 1.90 (at 20 °C) | 2.13 | 1.06 (at 20 °C) | ||||

| Code | Specification | Code | Specification |

|---|---|---|---|

| P201 | Obtain special instructions before use | P272 | Contaminated work clothing must not be allowed out of the workplace |

| P202 | Do not handle until all safety precautions have been read and understood | P273 | Avoid release to the environment |

| P260 | Do not breathe dust/fume/gas/mist/vapours/spray | P280 | Wear protective gloves/eye protection/face protection |

| P261 | Avoid breathing dust/fume/gas/mist/vapours/spray | P363 | Wash contaminated clothing before reuse |

| P263 | Avoid contact during pregnancy/while nursing | P391 | Collect spillage |

| P264 | Wash skin thoroughly after handling | P501 | Dispose of contents/container in accordance with local/regional/national/international regulations |

| P270 | Do not eat, drink or smoke when using this product |

| Epoxy Type | Tensile Strength (MPa) | Ultimate Strain | Tensile Modulus (GPa) | SD |

|---|---|---|---|---|

| Epotec | 52.9 | 2.0% | 2.7 | 1.9 |

| Sika 31 | 37.5 | 0.3% | 10.4 | 2.9 |

| Sika 42 | 75.7 | 3.8% | 2.0 | 1.1 |

| Sika 52 | 48.2 | 5.9% | 1.3 | 2.4 |

| Epoxy Type | Compressive Strength (MPa) | Ultimate Strain | Compressive Modulus (GPa) | SD |

|---|---|---|---|---|

| Epotec | 70.7 | 9.4% | 1.6 | 2.6 |

| Sika 31 | 64.3 | 14.1% | 2.7 | 1.5 |

| Sika 42 | 133.8 | 9.5% | 2.2 | 1.1 |

| Sika 52 | 31.5 | 16.1% | 0.8 | 1.8 |

| Epoxy Type | Shear Strength (MPa) | Ultimate Strain | Shear Modulus (GPa) | SD |

|---|---|---|---|---|

| Epotec | 9.6 | 1.2% | 1.4 | 1.1 |

| Sika 31 | 14.8 | 10.7% | 2.9 | 1.9 |

| Sika 42 | 14.1 | 1.4% | 3.4 | 2.4 |

| Sika 52 | 12.1 | 1.6% | 3.0 | 1.6 |

| Time | Epotec | Sika 31 | Sika 42 | Sika 52 | ||||

|---|---|---|---|---|---|---|---|---|

| NO2 | SO2 | NO2 | SO2 | NO2 | SO2 | NO2 | SO2 | |

| 5 min | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| 10 min | 0 | 1 | 0 | 0 | 0 | 0 | 2 | 2 |

| 15 min | 2 | 3 | 0 | 1 | 2 | 2 | 3 | 3 |

| 30 min | 3 | 4 | 0 | 2 | 2 | 3 | 3 | 3 |

| 60 min | 2 | 3 | 0 | 2 | 3 | 5 | 4 | 4 |

| 90 min | 0 | 1 | 0 | 0 | 0 | 0 | 5 | 5 |

| 120 min | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almutairi, A.D. Comprehensive Investigation of Epoxy Adhesives for Structural Applications in Saudi Arabia: Mechanical Performance, Environmental Impacts, and Analysis on Health. Polymers 2024, 16, 3185. https://doi.org/10.3390/polym16223185

Almutairi AD. Comprehensive Investigation of Epoxy Adhesives for Structural Applications in Saudi Arabia: Mechanical Performance, Environmental Impacts, and Analysis on Health. Polymers. 2024; 16(22):3185. https://doi.org/10.3390/polym16223185

Chicago/Turabian StyleAlmutairi, Ahmed D. 2024. "Comprehensive Investigation of Epoxy Adhesives for Structural Applications in Saudi Arabia: Mechanical Performance, Environmental Impacts, and Analysis on Health" Polymers 16, no. 22: 3185. https://doi.org/10.3390/polym16223185

APA StyleAlmutairi, A. D. (2024). Comprehensive Investigation of Epoxy Adhesives for Structural Applications in Saudi Arabia: Mechanical Performance, Environmental Impacts, and Analysis on Health. Polymers, 16(22), 3185. https://doi.org/10.3390/polym16223185