The Effect of Feeding Sequence on the Structure and Properties of the Ethylene/1-Octene Copolymer in the Semi-Continuous Polymerization Reaction System

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization and Performance Testing

2.2.1. High-Temperature Gel Permeation Chromatography (HT-GPC)

2.2.2. 13C-Nuclear Magnetic Resonance (13C-NMR)

2.2.3. Differential Scanning Calorimetry (DSC)

2.2.4. Wide Angle X-ray Diffraction (WAXD)

2.2.5. Melting Index (MI)

2.2.6. Dynamic Mechanical Analysis (DMA)

2.2.7. Uniaxial Tension Test

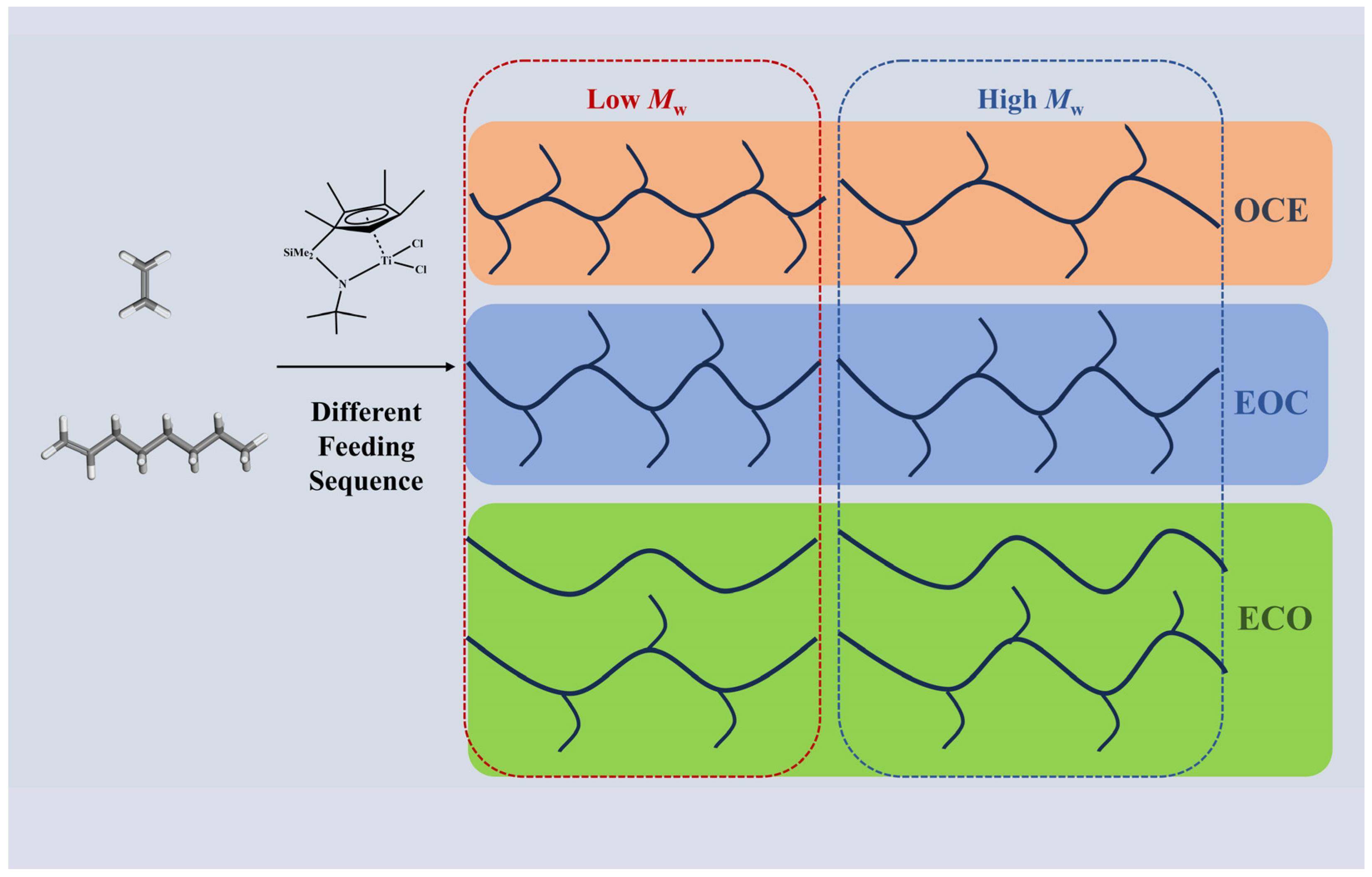

2.3. Polymerization Experiment

2.3.1. Preparation before Reaction

2.3.2. Catalyst Preparation

2.3.3. Preparation of EOC Copolymer

2.3.4. Preparation of OCE Copolymer

2.3.5. Preparation of ECO Copolymer

3. Results and Discussion

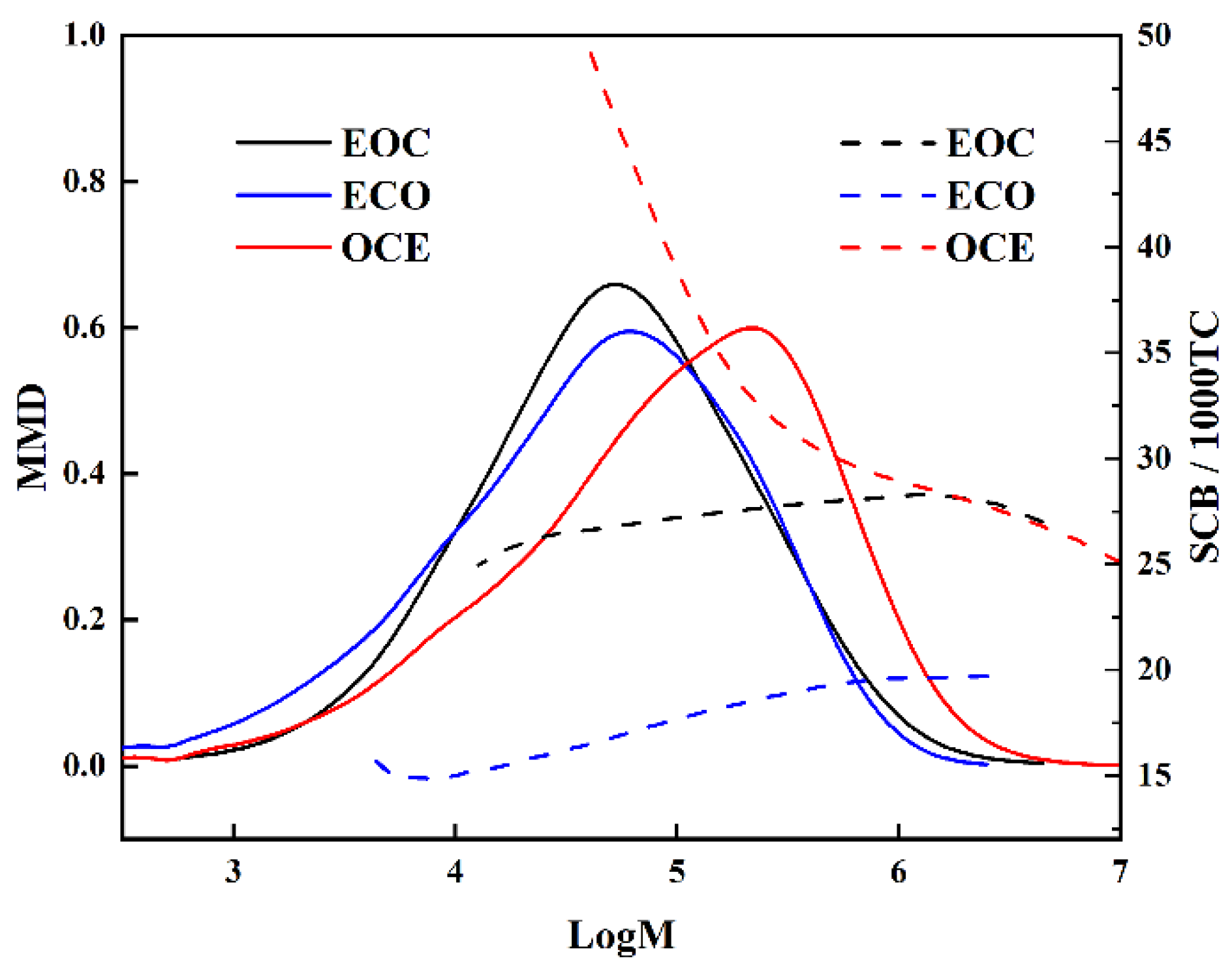

3.1. Mw and Molecular Weight Distribution (MWD)

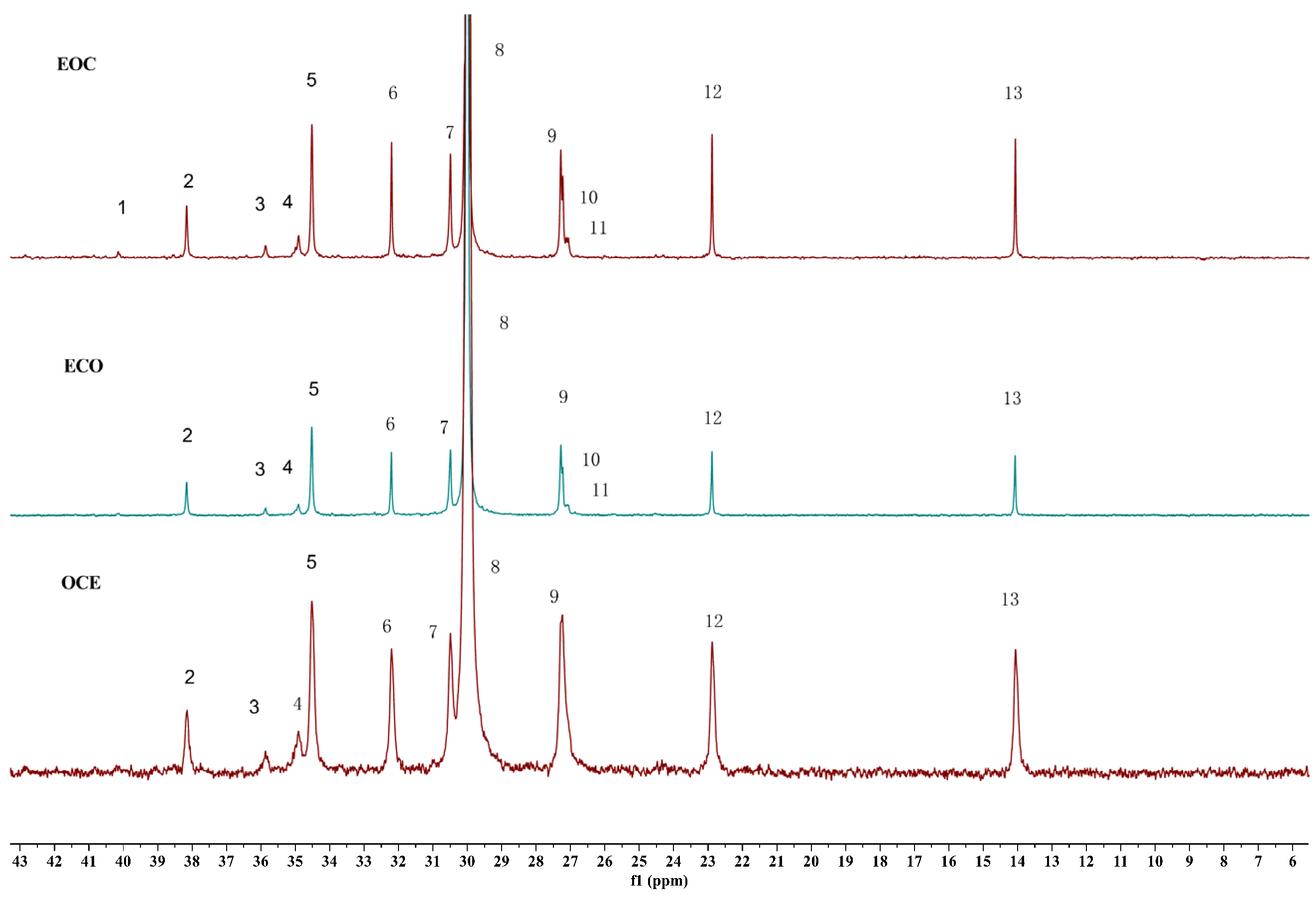

3.2. Chemical Composition

3.3. Thermal Performance

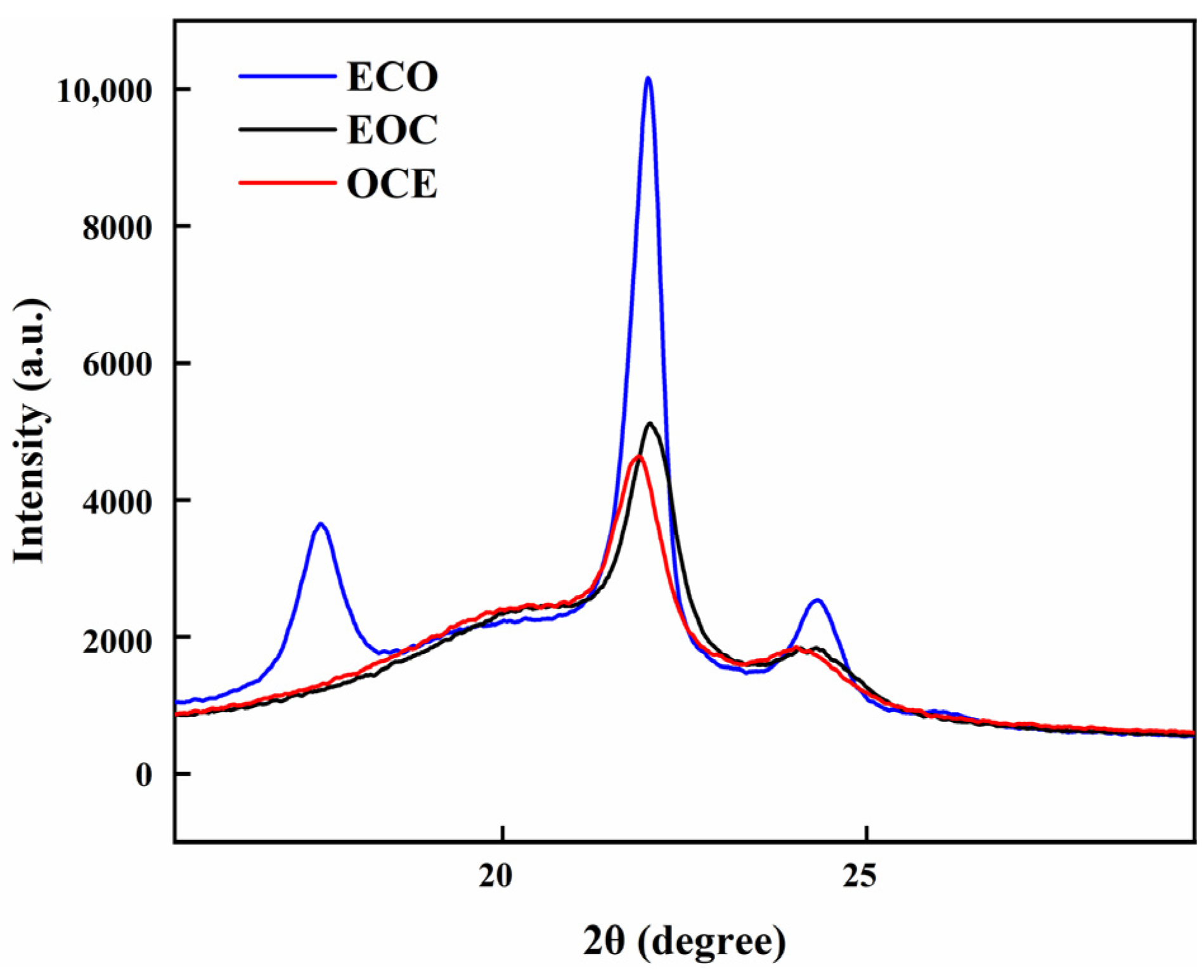

3.4. WAXD Analysis

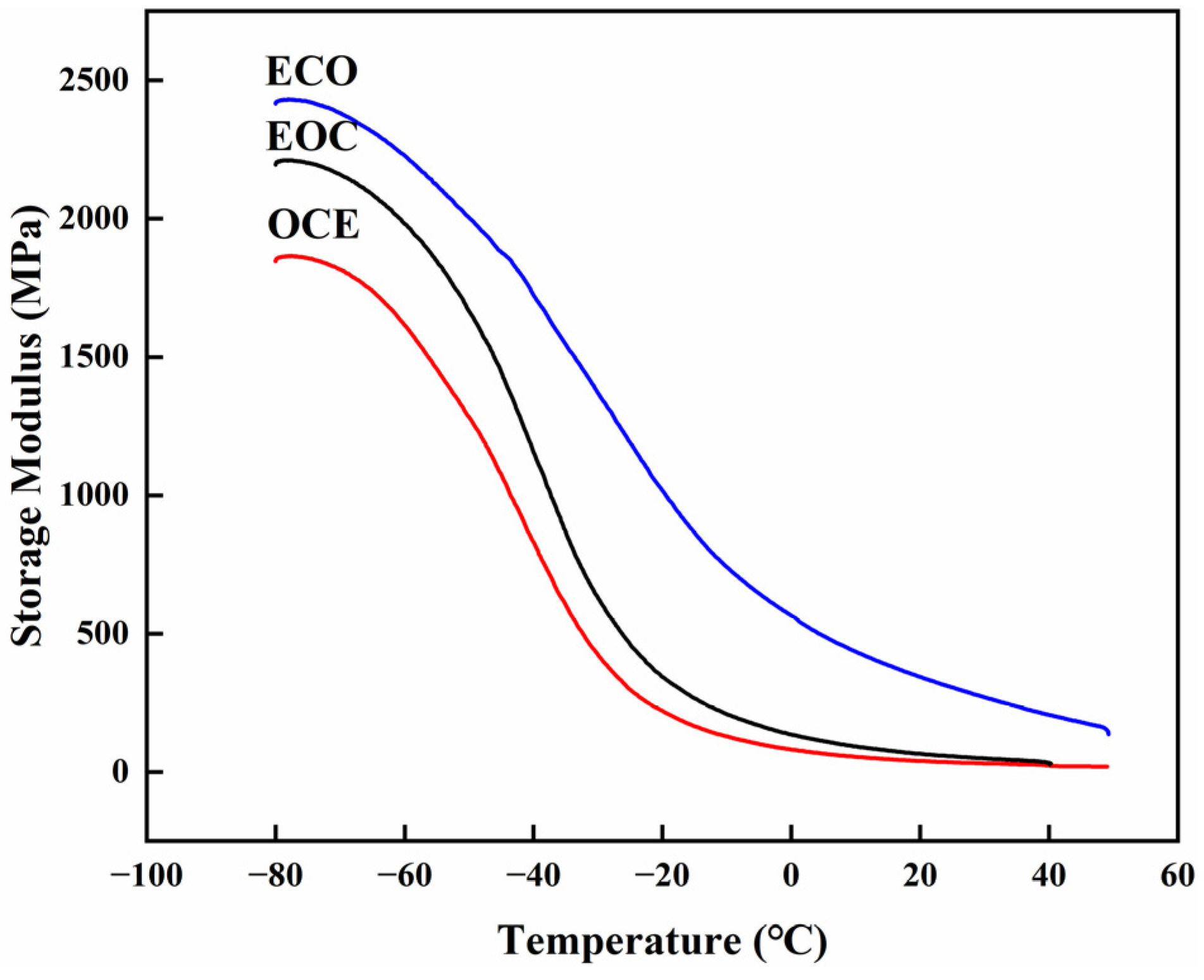

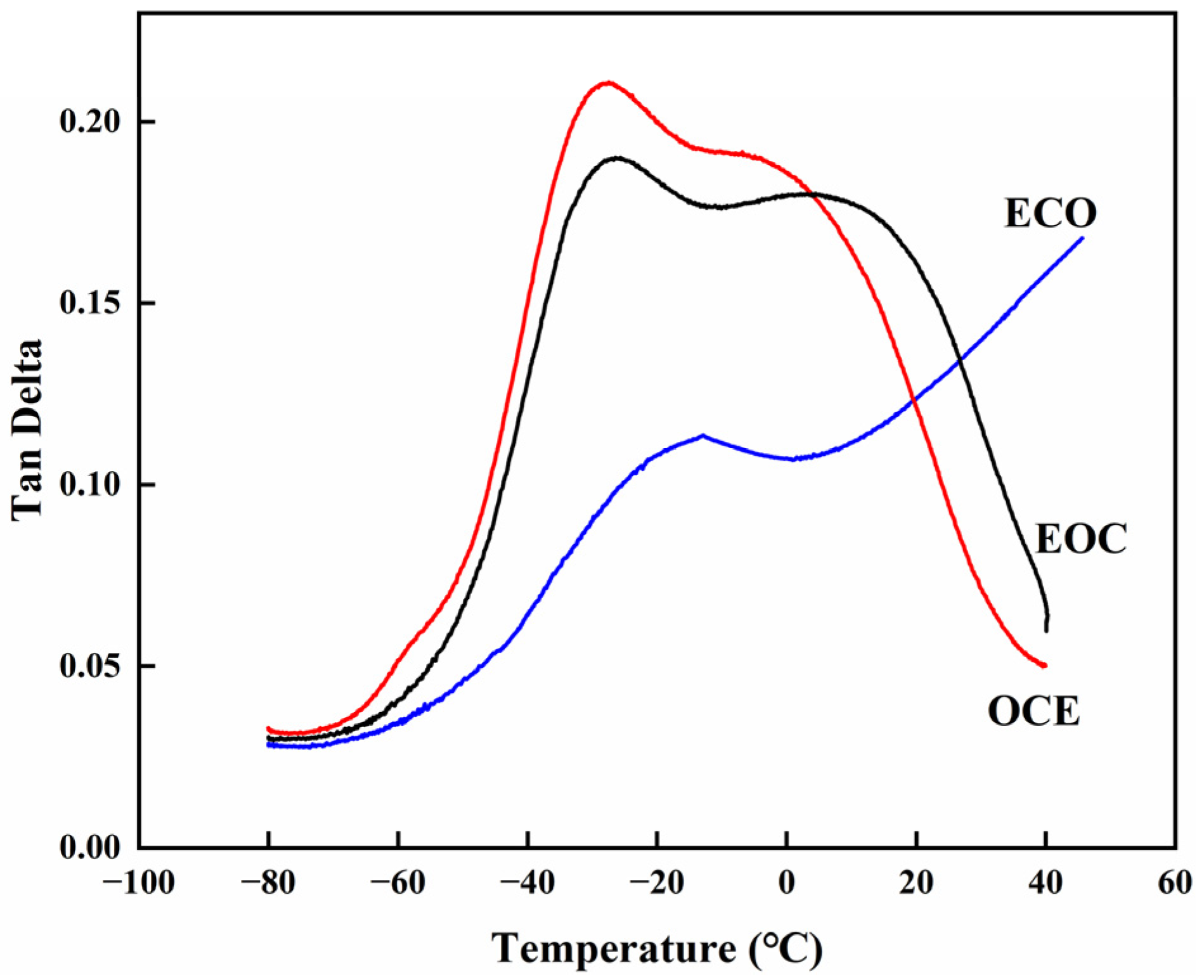

3.5. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ostoja Starzewski, A.; Steinhauser, N.; Xin, B.S. Decisive progress in metallocene-catalyzed elastomer synthesis. Macromolecules 2008, 41, 4095–4101. [Google Scholar] [CrossRef]

- Xu, G.; Xiao, Y.; Wang, W.; Li, B.; Liu, P. Rheological and Mechanical Study of Comb-Branched Polyolefin Elastomers Containing Macromer Residues. Macromolecules 2023, 56, 3064–3072. [Google Scholar] [CrossRef]

- Mohite, A.S.; Rajpurkar, Y.D.; More, A.P. Bridging the gap between rubbers and plastics: A review on thermoplastic polyolefin elastomers. Polym. Bull. 2022, 79, 1309–1343. [Google Scholar] [CrossRef]

- Kong, Y.; Yi, J.; Dou, X.; Liu, W.; Huang, Q.; Gao, K.; Yang, W. With different structure ligands heterogeneous Ziegler–Natta catalysts for the preparation of copolymer of ethylene and 1-octene with high comonomer incorporation. Polymer 2010, 51, 3859–3866. [Google Scholar] [CrossRef]

- Czaja, K.; Białek, M. Microstructure of ethylene-1-hexene and ethylene-1-octene copolymers obtained over Ziegler–Natta catalysts supported on MgCl2 (THF)2. Polymer 2001, 42, 2289–2297. [Google Scholar] [CrossRef]

- Soga, K.; Shiono, T. Ziegler-Natta catalysts for olefin polymerizations. Prog. Polym. Sci. 1997, 22, 1503–1546. [Google Scholar] [CrossRef]

- Alt, H.G.; Köppl, A. Effect of the nature of metallocene complexes of group IV metals on their performance in catalytic ethylene and propylene polymerization. Chem. Rev. 2000, 100, 1205–1222. [Google Scholar] [CrossRef] [PubMed]

- Braunschweig, H.; Breitling, F. Constrained geometry complexes—Synthesis and applications. Coord. Chem. Rev. 2006, 250, 2691–2720. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, Q.; Jiang, H.; Chen, A.; Zou, C. Bidentate Pyridyl-Amido Hafnium Catalysts for Copolymerization of Ethylene with 1-Octene and Norbornene. Eur. J. Inorg. Chem. 2023, 26, e202200725. [Google Scholar] [CrossRef]

- Kaminsky, W. Highly active metallocene catalysts for olefin polymerization. J. Chem. Soc. Dalton Trans. 1998, 9, 1413–1418. [Google Scholar] [CrossRef]

- Lian, K.; Zhu, Y.; Li, W.; Dai, S.; Chen, C. Direct synthesis of thermoplastic polyolefin elastomers from nickel-catalyzed ethylene polymerization. Macromolecules 2017, 50, 6074–6080. [Google Scholar] [CrossRef]

- Wannaborworn, M.; Praserthdam, P.; Jongsomjit, B. Observation of different catalytic activity of various 1-olefins during ethylene/1-olefin copolymerization with homogeneous metallocene catalysts. Molecules 2011, 16, 373–383. [Google Scholar] [CrossRef] [PubMed]

- Zou, B.; Zhan, Y.; Xie, X.; Zhang, T.; Qiu, R.; Zhu, F. Synthesis of ultrahigh-molecular-weight ethylene/1-octene copolymers with salalen titanium (IV) complexes activated by methyaluminoxane. RSC Adv. 2022, 12, 11715–11721. [Google Scholar] [CrossRef]

- Ronellenfitsch, M.; Gehrmann, T.; Wadepohl, H.; Enders, M. Improving 1-Hexene Incorporation of Highly Active Cp–Chromium-Based Ethylene Polymerization Catalysts. Macromolecules 2017, 50, 35–43. [Google Scholar] [CrossRef]

- Wu, C.J.; Nayab, S.; Woo, H.Y.; Hahn, J.S.; Lee, H.S.; Kang, S.O.; Lee, H. Synthesis and X-ray crystal structure of [Me2Si (C5Me2H2)(tBuN)] MCl2 (M = Ti, Zr) bearing a 3, 4-dimethylcyclopentadienyl ring: Investigation of the substitution effect on the cyclopentadienyl (Cp) ring for catalytic performance in ethylene/1-octene (co) polymerization. Polyhedron 2014, 67, 199–204. [Google Scholar] [CrossRef]

- Joung, U.G.; Wu, C.J.; Lee, S.H.; Lee, C.H.; Lee, E.J.; Han, W.-S.; Kang, S.O.; Lee, B.Y. Phenylene-bridged Cp/carboxamide ligands for titanium complexes of various binding modes and their ethylene/1-octene copolymerization. Organometallics 2006, 25, 5122–5130. [Google Scholar] [CrossRef]

- Wu, Q.; Su, Q.; Ye, L.; Li, G.; Mu, Y. Propylene polymerization to high molecular weight atactic polypropylene and copolymerization with 1-hexene using monocyclopentadienyl titanium catalysts. Dalton Trans. 2010, 39, 2525–2535. [Google Scholar] [CrossRef]

- Yuan, W.; Li, W.; Dai, S. Preparation of polyethylene thermoplastic elastomers using CS-symmetric nickel catalysts in ethylene polymerization. Polymer 2023, 285, 126322. [Google Scholar] [CrossRef]

- Lebedev, A.Y.; Izmer, V.V.; Asachenko, A.F.; Tzarev, A.A.; Uborsky, D.V.; Homutova, Y.A.; Shperber, E.R.; Canich, J.A.M.; Voskoboynikov, A.Z. Group 4 Metallocenes Bearing η5-2-(N-Azolyl) indenyl Ligands: Synthesis, Structure Characterization, and Olefin Polymerization Catalysis. Organometallics 2009, 28, 1800–1816. [Google Scholar] [CrossRef]

- Dankova, M.; Waymouth, R.M. High comonomer selectivity in ethylene/hexene copolymerization by unbridged indenyl metallocenes. Macromolecules 2003, 36, 3815–3820. [Google Scholar] [CrossRef]

- Huo, L.; Lv, M.; Li, M.; Ni, X.; Guan, J.; Liu, J.; Mei, S.; Yang, Y.; Zhu, M.; Feng, Q.; et al. Amorphous MnO2 Lamellae Encapsulated Covalent Triazine Polymer-Derived Multi-Heteroatoms-Doped Carbon for ORR/OER Bifunctional Electrocatalysis. Adv. Mater. 2024, 36, 2312868. [Google Scholar] [CrossRef]

- Sun, M.; Xiao, Y.; Liu, K.; Yang, X.; Liu, P.; Jie, S.; Hu, J.; Shi, S.; Wang, Q.; Lim, K.H.; et al. Synthesis and characterization of polyolefin thermoplastic elastomers: A review. Can. J. Chem. Eng. 2023, 101, 4886–4906. [Google Scholar] [CrossRef]

- Mehdiabadi, S.; Soares, J.B. Quantifying the copolymerization kinetics of ethylene and 1-octene catalyzed with rac-Et (Ind)2ZrCl2 in a solution reactor. Macromolecules 2016, 49, 2448–2457. [Google Scholar] [CrossRef]

- Zhang, M.; Lynch, D.; Wanke, S. Effect of molecular structure distribution on melting and crystallization behavior of 1-butene/ethylene copolymers. Polymer 2001, 42, 3067–3075. [Google Scholar] [CrossRef]

- Simanke, A.G.; Galland, G.B.; Freitas, L.; da Jornada, J.A.H.; Quijada, R.; Mauler, R.S. Influence of the comonomer content on the thermal and dynamic mechanical properties of metallocene ethylene/1-octene copolymers. Polymer 1999, 40, 5489–5495. [Google Scholar] [CrossRef]

- Ohtaki, H.; Deplace, F.; Vo, G.D.; LaPointe, A.M.; Shimizu, F.; Sugano, T.; Kramer, E.J.; Fredrickson, G.H.; Coates, G.W. Allyl-terminated polypropylene macromonomers: A route to polyolefin elastomers with excellent elastic behavior. Macromolecules 2015, 48, 7489–7494. [Google Scholar] [CrossRef]

- Zhang, K.; Liu, P.; Wang, W.-J.; Li, B.-G.; Liu, W.; Zhu, S. Preparation of comb-shaped polyolefin elastomers having ethylene/1-octene copolymer backbone and long chain polyethylene branches via a tandem metallocene catalyst system. Macromolecules 2018, 51, 8790–8799. [Google Scholar] [CrossRef]

- Leone, G.; Canetti, M.; Pierro, I.; Zanchin, G.; De Rosa, C.; Ricci, G.; Bertini, F. (Micro) structure, thermal behavior and mechanical properties of ethylene–propylene–1-octadecene terpolymers from chain-walking polymerization of 1-octadecene. Polymer 2019, 166, 27–37. [Google Scholar] [CrossRef]

- He, Y.; Qiu, X.; Klosin, J.; Cong, R.; Roof, G.R.; Redwine, D. Terminal and internal unsaturations in poly (ethylene-co-1-octene). Macromolecules 2014, 47, 3782–3790. [Google Scholar] [CrossRef]

- Romano, D.; Tops, N.; Andablo-Reyes, E.; Ronca, S.; Rastogi, S. Influence of polymerization conditions on melting kinetics of low entangled UHMWPE and its implications on mechanical properties. Macromolecules 2014, 47, 4750–4760. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, K.; Fan, H.; Wang, W.J.; Li, B.G.; Zhu, S. Living copolymerization of ethylene/1-octene with fluorinated FI-Ti catalyst. J. Polym. Sci. Pol. Chem. 2013, 51, 405–414. [Google Scholar] [CrossRef]

- Arriola, D.J.; Carnahan, E.M.; Hustad, P.D.; Kuhlman, R.L.; Wenzel, T.T. Catalytic production of olefin block copolymers via chain shuttling polymerization. Science 2006, 312, 714–719. [Google Scholar] [CrossRef] [PubMed]

- Chi, Z.; Zhang, X.; Zhang, Y.; Xu, J. Influence of the monomer feeding sequence on the structure and properties of thermotropic liquid-crystalline poly (ester imide) s. J. Appl. Polym. Sci. 2008, 110, 3001–3008. [Google Scholar] [CrossRef]

- De Pooter, M.; Smith, P.; Dohrer, K.; Bennett, K.; Meadows, M.; Smith, C.; Schouwenaars, H.; Geerards, R. Determination of the composition of common linear low-density polyethylene copolymers by 13C-NMR spectroscopy. J. Appl. Polym. Sci. 1991, 42, 399–408. [Google Scholar] [CrossRef]

- GB/T 3682.1-2018; Plastics—Determination of the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) of Thermoplastics. Standardization Administration: Beijing, China, 2018.

- Piel, C.; Starck, P.; Seppälä, J.V.; Kaminsky, W. Thermal and mechanical analysis of metallocene-catalyzed ethene–α-olefin copolymers: The influence of the length and number of the crystallizing side chains. J. Polym. Sci. Pol. Chem. 2006, 44, 1600–1612. [Google Scholar] [CrossRef]

- Carman, C.J.; Wilkes, C.E. Monomer Sequence Distribution in Ethylene Propylene Elastomers. I. Measurement by Carbon-13 Nuclear Magnetic Resonance Spectroscopy. Rubber Chem. Technol. 1971, 44, 781–804. [Google Scholar] [CrossRef]

- Hsieh, E.T.; Randall, J.C. Monomer sequence distributions in ethylene-1-hexene copolymers. Macromolecules 1982, 15, 1402–1406. [Google Scholar] [CrossRef]

- Zhang, M.; Wanke, S.E. Quantitative determination of short-chain branching content and distribution in commercial polyethylenes by thermally fractionated differential scanning calorimetry. Polym. Eng. Sci. 2003, 43, 1878–1888. [Google Scholar] [CrossRef]

- Keating, M.; Lee, I.-H.; Wong, C.S. Thermal fractionation of ethylene polymers in packaging applications. Thermochim. Acta 1996, 284, 47–56. [Google Scholar] [CrossRef]

| Sample | Yield (g) | Act. b | The Content of 1-Octene (wt%) c | Mw d | Mw | Mw/Mn d | Tm (°C) | Density e | MFR f |

|---|---|---|---|---|---|---|---|---|---|

| OCE | 73 | 1.6 | 21.2 | 2.60 | 2.60 | 11.5 | 87 | 0.889 | 0.1 |

| EOC | 70 | 1.4 | 21.4 | 1.33 | 1.33 | 7.4 | 92 | 0.898 | 0.6 |

| ECO | 66 | 1.3 | 13.2 | 1.11 | 1.11 | 14.5 | 95; 123 | 0.914 | 0.9 |

| Peak No. | Carbon Type | Monomer Sequence | Chemical Shift (ppm) | ||

|---|---|---|---|---|---|

| ECO | EOC | OCE | |||

| 1 | αα | EOOE | 40.15 | ||

| 2 | CH | EOE | 38.16 | 38.16 | 38.15 |

| 3 | CH | OOE | 35.87 | 35.87 | 35.87 |

| 4 | αδ+CH2(6) | EEOO + EOO | 34.91 | 34.91 | 34.91 |

| 5 | αδ+CH2(6) | EOEE + EOE | 34.52 | 34.52 | 34.51 |

| 6 | CH2(3) | EOE + OOE + OOO | 32.21 | 32.21 | 32.20 |

| 7 | γδ+ | OEEE | 30.50 | 30.50 | 30.49 |

| 8 | δ+δ++CH2(4) | (EEE)n | 30.00 | 30.00 | 30.00 |

| 9 | βδ | OEE | 27.29 | 27.29 | 27.30 |

| 10 | CH2(5) | EOE + OOE + OOO | 27.23 | 27.23 | |

| 11 | βδ+ | OOEE | 27.09 | 27.13 | |

| 12 | CH2(2) | EOE + OOE + OOO | 22.90 | 22.89 | 22.88 |

| 13 | CH3 | EOE + OOE + OOO | 14.09 | 14.08 | 14.06 |

| Sample | Copolymerization Parameters | Mole Fractions | EEE | EEO | OEO | EOE | OOE | OOO | ||

|---|---|---|---|---|---|---|---|---|---|---|

| rE | rO | E | O | |||||||

| EOC | 28.62 | 0.15 | 0.96 | 0.04 | 0.90 | 0.06 | 0 | 0.03 | 0.01 | 0 |

| OCE | 34.18 | 0.18 | 0.97 | 0.03 | 0.91 | 0.06 | 0 | 0.02 | 0.01 | 0 |

| ECO | 48 | -- | 0.98 | 0.02 | 0.94 | 0.04 | 0 | 0.02 | 0 | 0 |

| Melting Point/°C | Methylene Sequence Length | Lamella Thickness, lc/nm | Share of Fraction/% | |

|---|---|---|---|---|

| EOC | 37.5 | 16.6 | 2.4 | 1.7 |

| 42.3 | 17.9 | 2.5 | 2.6 | |

| 47.0 | 19.2 | 2.6 | 2.9 | |

| 51.8 | 20.6 | 2.7 | 4.4 | |

| 56.6 | 22.2 | 2.9 | 4.7 | |

| 61.5 | 24.1 | 3.1 | 7.0 | |

| 66.4 | 26.2 | 3.3 | 7.0 | |

| 71.1 | 28.4 | 3.5 | 8.9 | |

| 76.0 | 31.2 | 3.7 | 10.3 | |

| 81.0 | 34.5 | 4.0 | 12.4 | |

| 85.9 | 38.3 | 4.3 | 13.2 | |

| 90.8 | 42.9 | 4.7 | 13.2 | |

| 95.5 | 48.2 | 5.2 | 8.8 | |

| 99.8 | 54.3 | 5.6 | 1.9 | |

| 105.6 | 64.9 | 6.5 | 1.0 | |

| OCE | 38.5 | 17.0 | 2.4 | 5.1 |

| 43.7 | 18.3 | 2.5 | 2.3 | |

| 47.9 | 19.5 | 2.6 | 3.4 | |

| 52.4 | 20.8 | 2.8 | 4.3 | |

| 57.2 | 22.4 | 2.9 | 5.8 | |

| 62.1 | 24.3 | 3.1 | 6.5 | |

| 67.1 | 26.5 | 3.3 | 8.5 | |

| 72.1 | 29.0 | 3.5 | 9.4 | |

| 77.0 | 31.8 | 3.8 | 10.7 | |

| 81.9 | 35.1 | 4.1 | 13.3 | |

| 86.8 | 39.0 | 4.4 | 12.9 | |

| 91.6 | 43.7 | 4.8 | 10.0 | |

| 96.2 | 49.1 | 5.2 | 4.5 | |

| 100.8 | 55.9 | 5.8 | 1.1 | |

| 104.3 | 62.2 | 6.3 | 2.2 | |

| ECO | 36.2 | 16.5 | 2.4 | 0.3 |

| 43.7 | 18.3 | 2.5 | 1.5 | |

| 47.4 | 19.3 | 2.6 | 0.4 | |

| 51.7 | 20.6 | 2.7 | 1.5 | |

| 56.4 | 22.1 | 2.9 | 1.7 | |

| 61.1 | 23.9 | 3.1 | 2.5 | |

| 66.1 | 26.0 | 3.2 | 3.2 | |

| 71.0 | 28.4 | 3.5 | 3.9 | |

| 75.8 | 31.1 | 3.7 | 4.6 | |

| 80.5 | 34.1 | 4.0 | 5.9 | |

| 85.5 | 37.9 | 4.3 | 7.4 | |

| 90.4 | 42.4 | 4.7 | 9.2 | |

| 95.4 | 48.1 | 5.1 | 10.1 | |

| 100.2 | 54.9 | 5.7 | 7.9 | |

| 105.1 | 63.9 | 6.4 | 5.6 | |

| 110.4 | 77.0 | 7.4 | 4.6 | |

| 115.8 | 96.6 | 8.7 | 5.2 | |

| 121.3 | 128.9 | 10.7 | 7.7 | |

| 126.6 | 187.3 | 13.7 | 17.0 |

| Sample | ln/nm | lw/nm | lw/ln |

|---|---|---|---|

| EOC | 3.9 | 15.8 | 4.1 |

| OCE | 3.8 | 15.1 | 4.0 |

| ECO | 6.9 | 61.0 | 8.9 |

| Sample | Xc a | Xc b |

|---|---|---|

| OCE | 11.9% | 21.4% |

| EOC | 14.2% | 23.5% |

| ECO | 37.0% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Q.; Zhang, R.; Hu, Y.; Li, J.; Yu, H.; Zheng, Y.; Qian, J. The Effect of Feeding Sequence on the Structure and Properties of the Ethylene/1-Octene Copolymer in the Semi-Continuous Polymerization Reaction System. Polymers 2024, 16, 526. https://doi.org/10.3390/polym16040526

He Q, Zhang R, Hu Y, Li J, Yu H, Zheng Y, Qian J. The Effect of Feeding Sequence on the Structure and Properties of the Ethylene/1-Octene Copolymer in the Semi-Continuous Polymerization Reaction System. Polymers. 2024; 16(4):526. https://doi.org/10.3390/polym16040526

Chicago/Turabian StyleHe, Qiqi, Ruijun Zhang, Yuexin Hu, Junhua Li, Hongbo Yu, Yong Zheng, and Jianhua Qian. 2024. "The Effect of Feeding Sequence on the Structure and Properties of the Ethylene/1-Octene Copolymer in the Semi-Continuous Polymerization Reaction System" Polymers 16, no. 4: 526. https://doi.org/10.3390/polym16040526

APA StyleHe, Q., Zhang, R., Hu, Y., Li, J., Yu, H., Zheng, Y., & Qian, J. (2024). The Effect of Feeding Sequence on the Structure and Properties of the Ethylene/1-Octene Copolymer in the Semi-Continuous Polymerization Reaction System. Polymers, 16(4), 526. https://doi.org/10.3390/polym16040526