Rheological and Mechanical Characterization of 3D-Printable Solid Propellant Slurry

Abstract

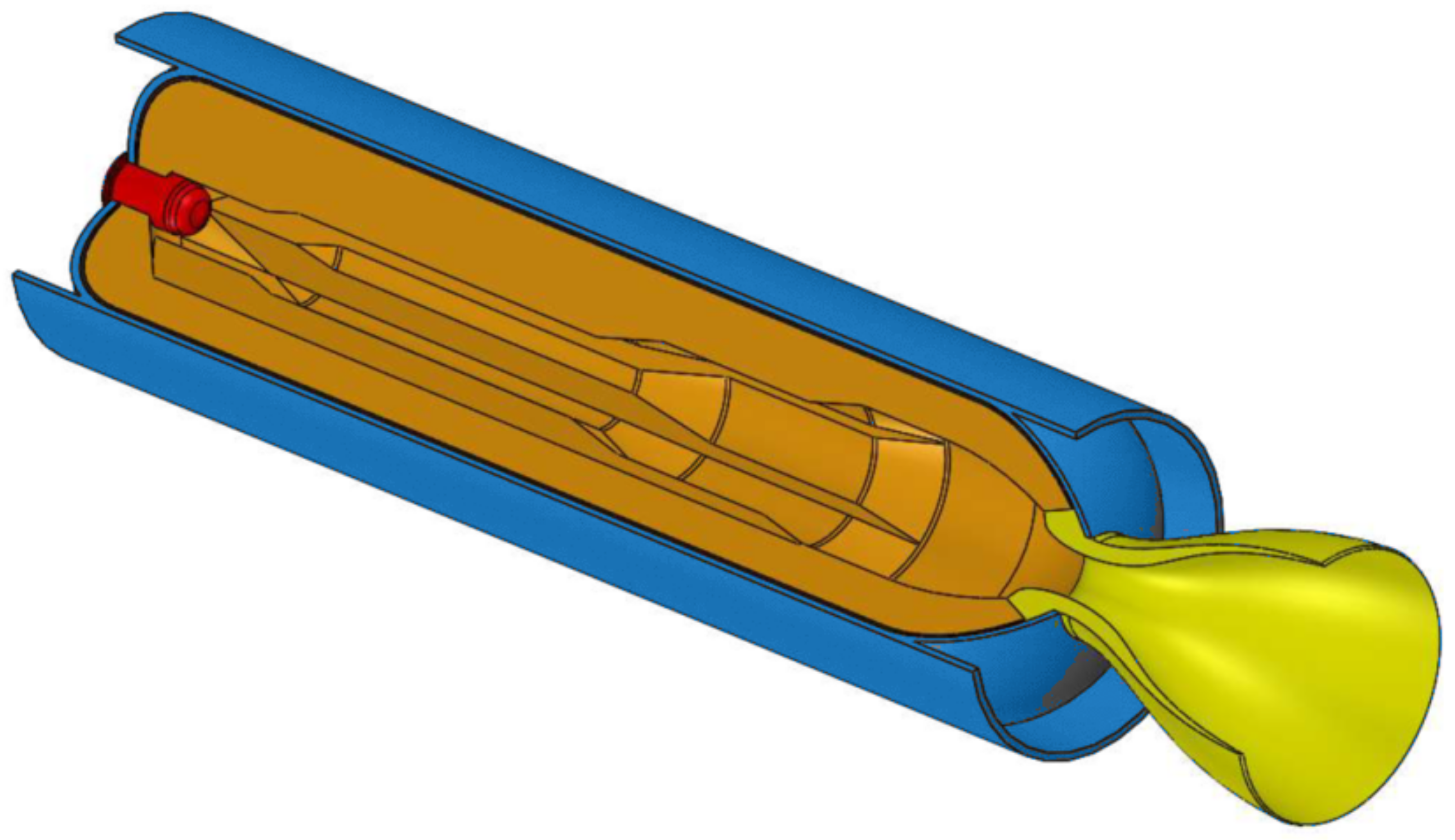

1. Introduction

2. Experimental Part

2.1. Materials

2.2. Methods

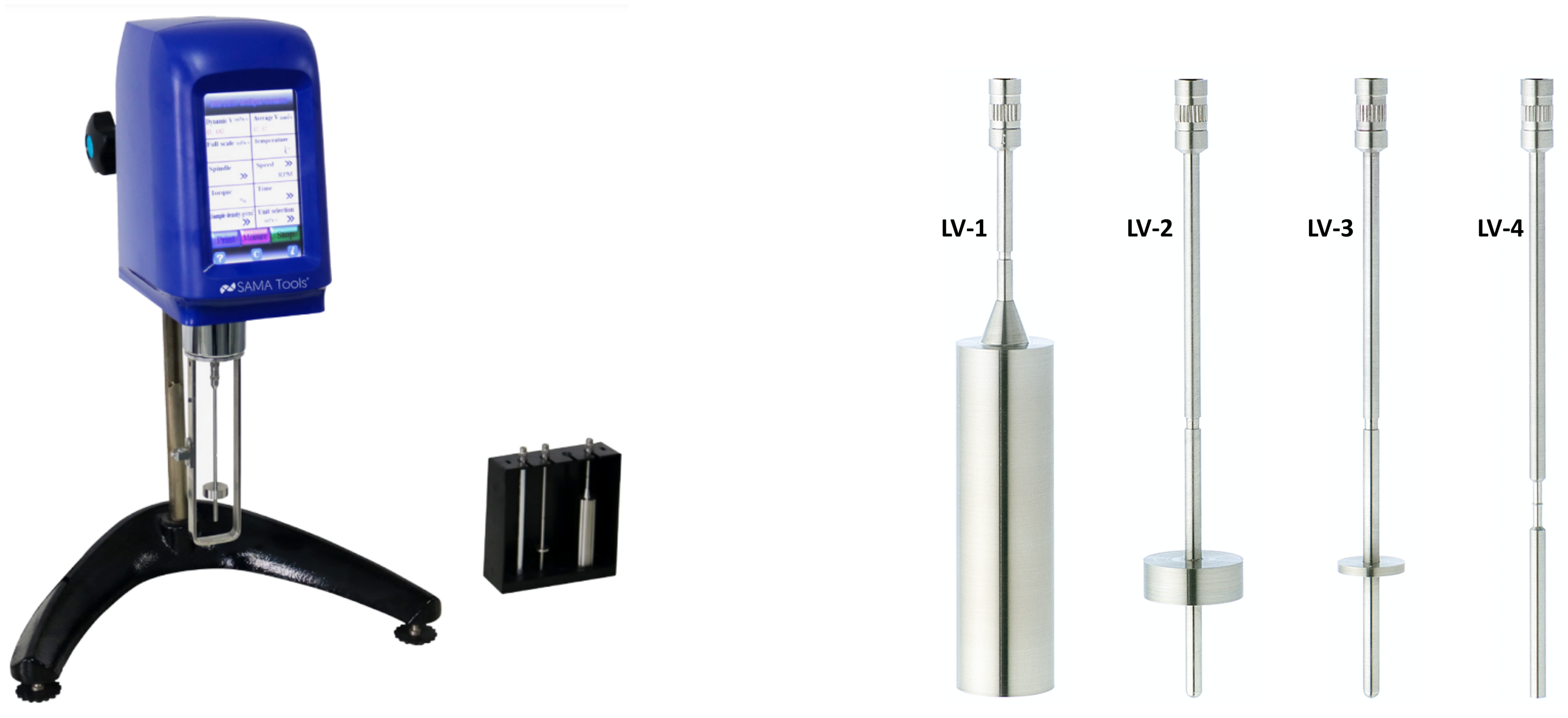

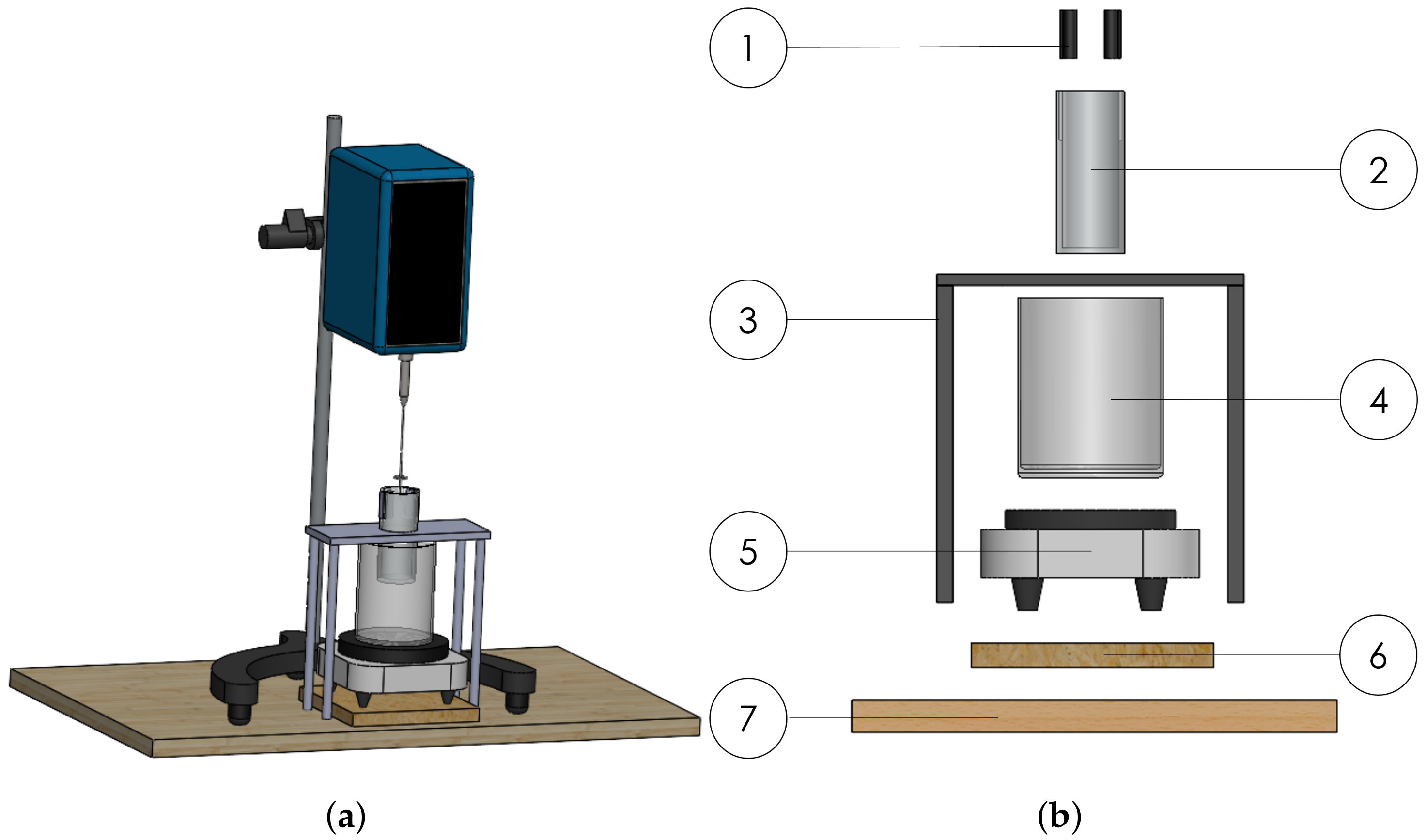

2.2.1. Viscosity Measurements

2.2.2. UV-Curing

- A first letter indicating the type of test (T = tensile, C = compression);

- A second letter indicating the temperature condition (A = ambient temperature, P = printing temperature);

- A progressive numerical code indicating the individual series each with specific characteristics.

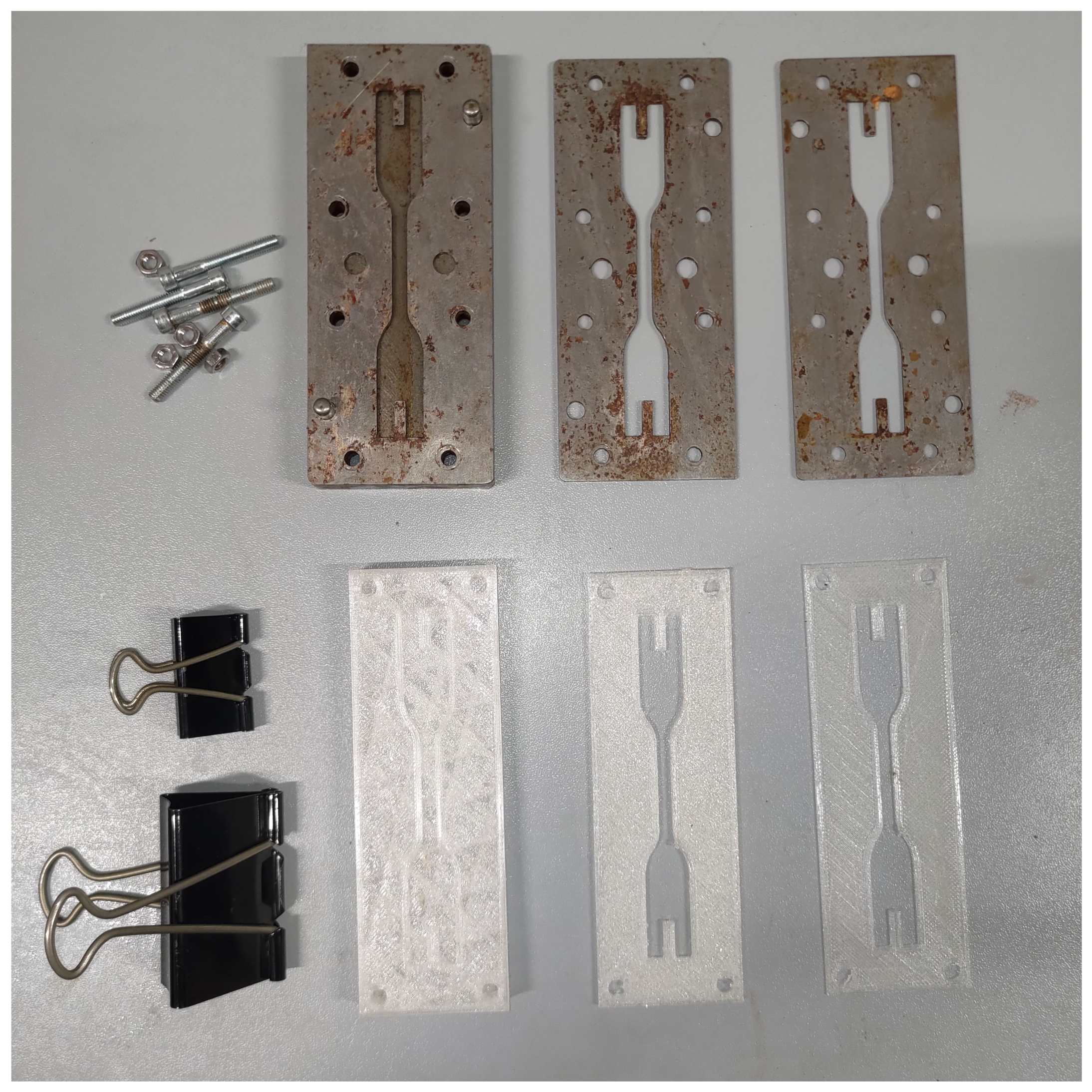

2.2.3. Uniaxial Tensile Tests

- A test speed of 0.3 mm/s was set;

- The geometry of the multilayer specimen followed the DIN_53504_1994 standard [27];

- In order to have a better clamping to the testing machine and to avoid the specimen breakage in the terminal gripping part, an alternative clamping system based on a metal joint made of an eyelet–carabiner series was set up.

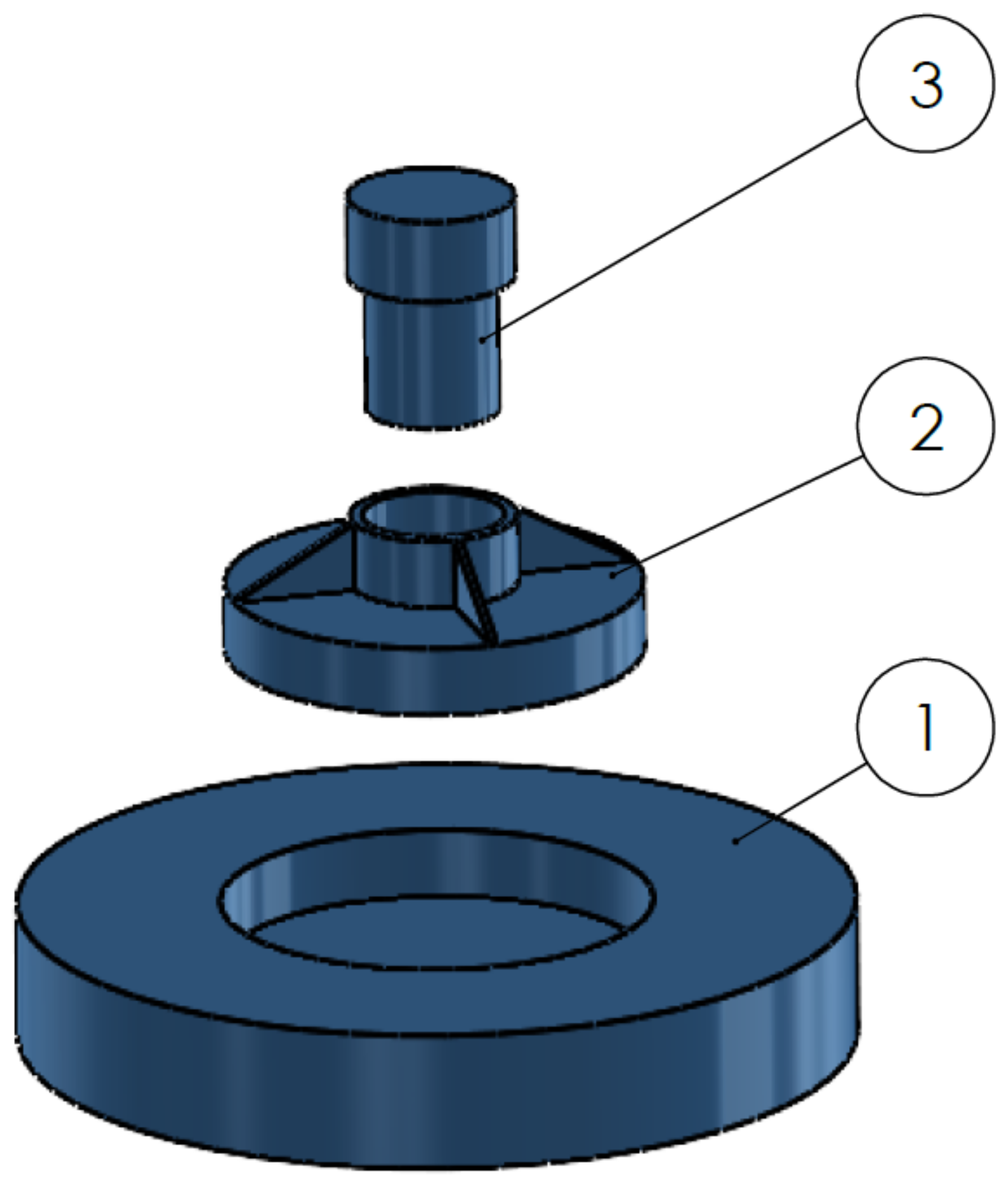

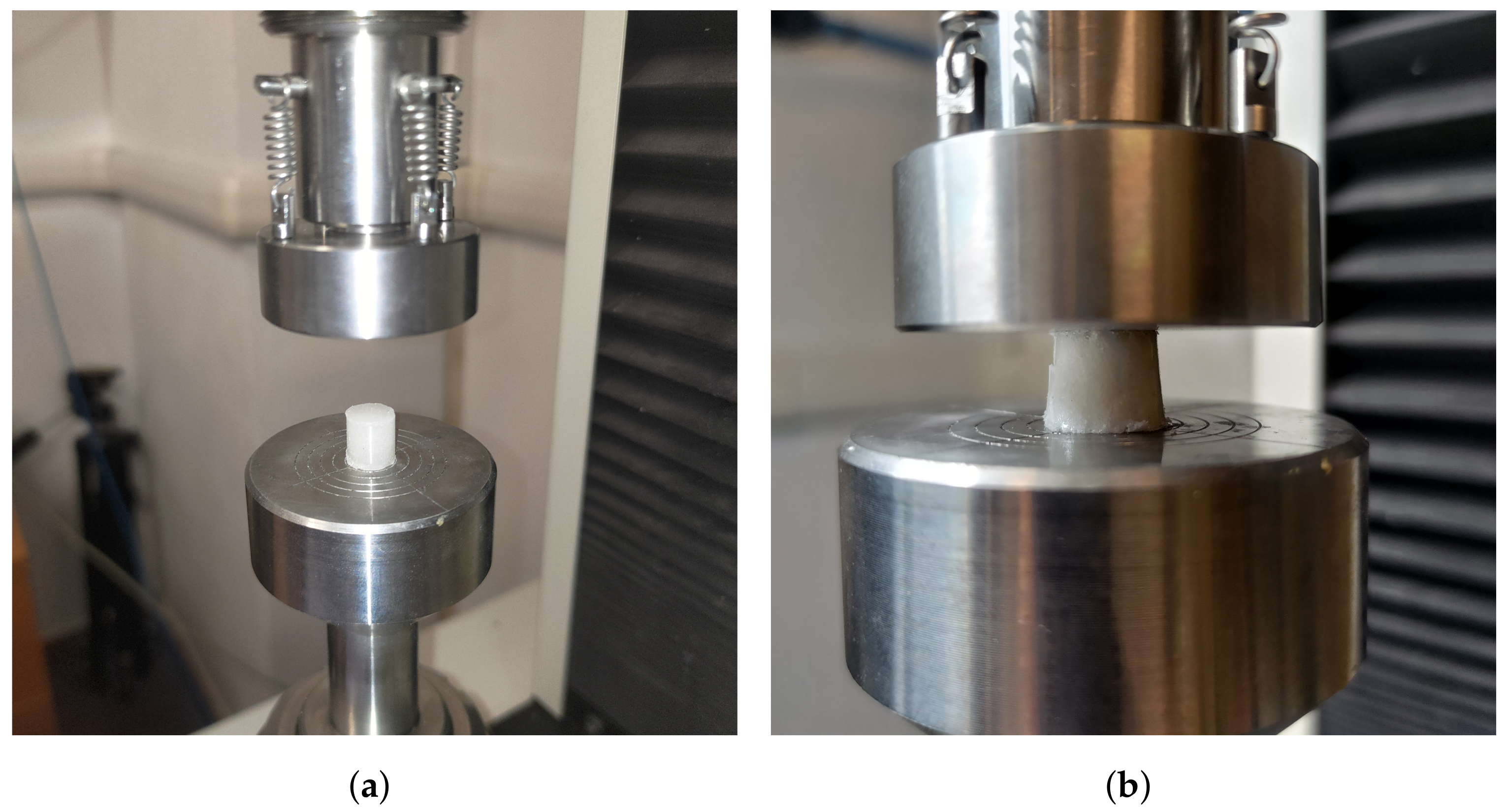

2.2.4. Compression Tests

- A circular bottom plate, with a circular recess in the center, to provide stability during the manufacturing.

- A second component, to be inserted into the circular recess, which contains the actual mold of the specimen (cylinder of diameter and height 10 mm) where the slurry is inserted; it has a through hole, so the lower surface is in direct contact with the surface of the recess in the first component.

- A cylinder that can be inserted into the through hole, allowing the extraction of the produced sample.

- At the same operating temperature, an increase in test speed determines higher apparent stiffness;

- At the same test speed, an increase in test temperature determines a lower stiffness.

3. Results and Discussion

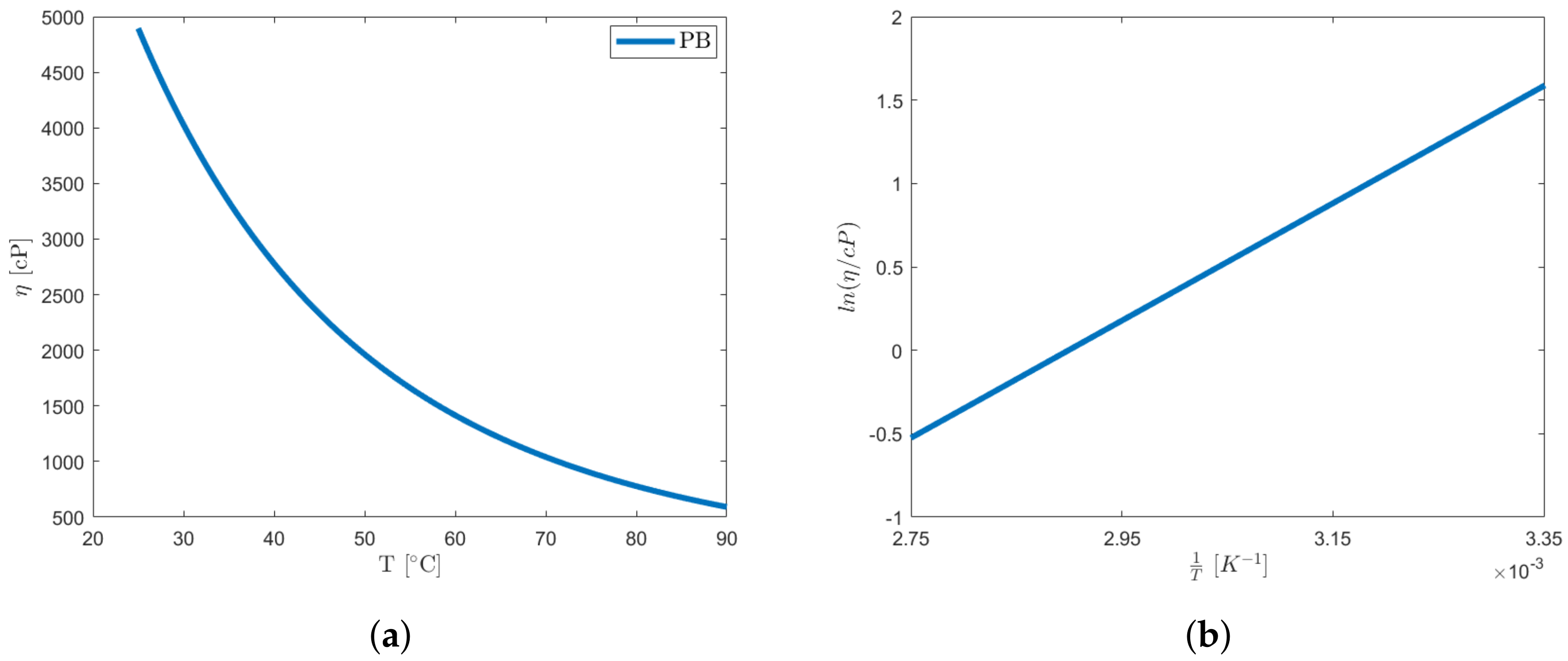

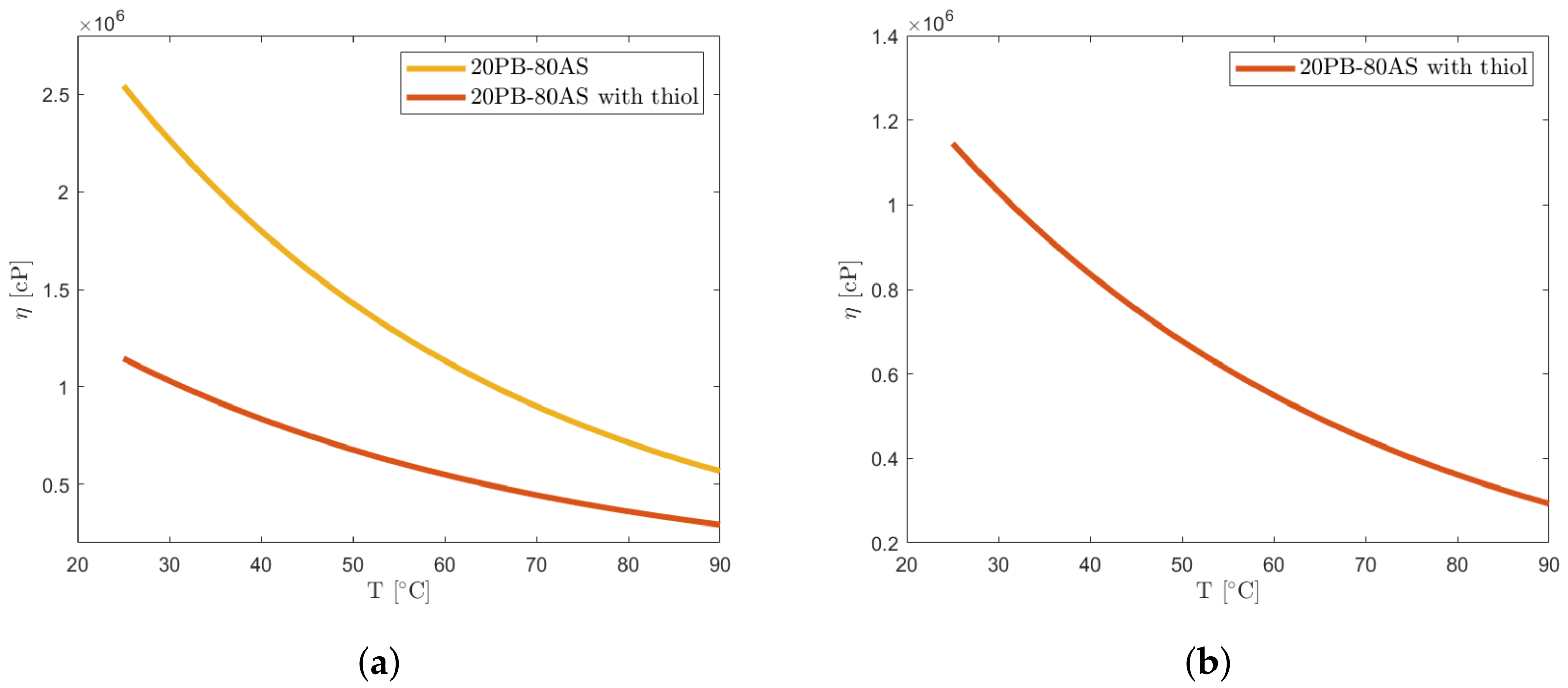

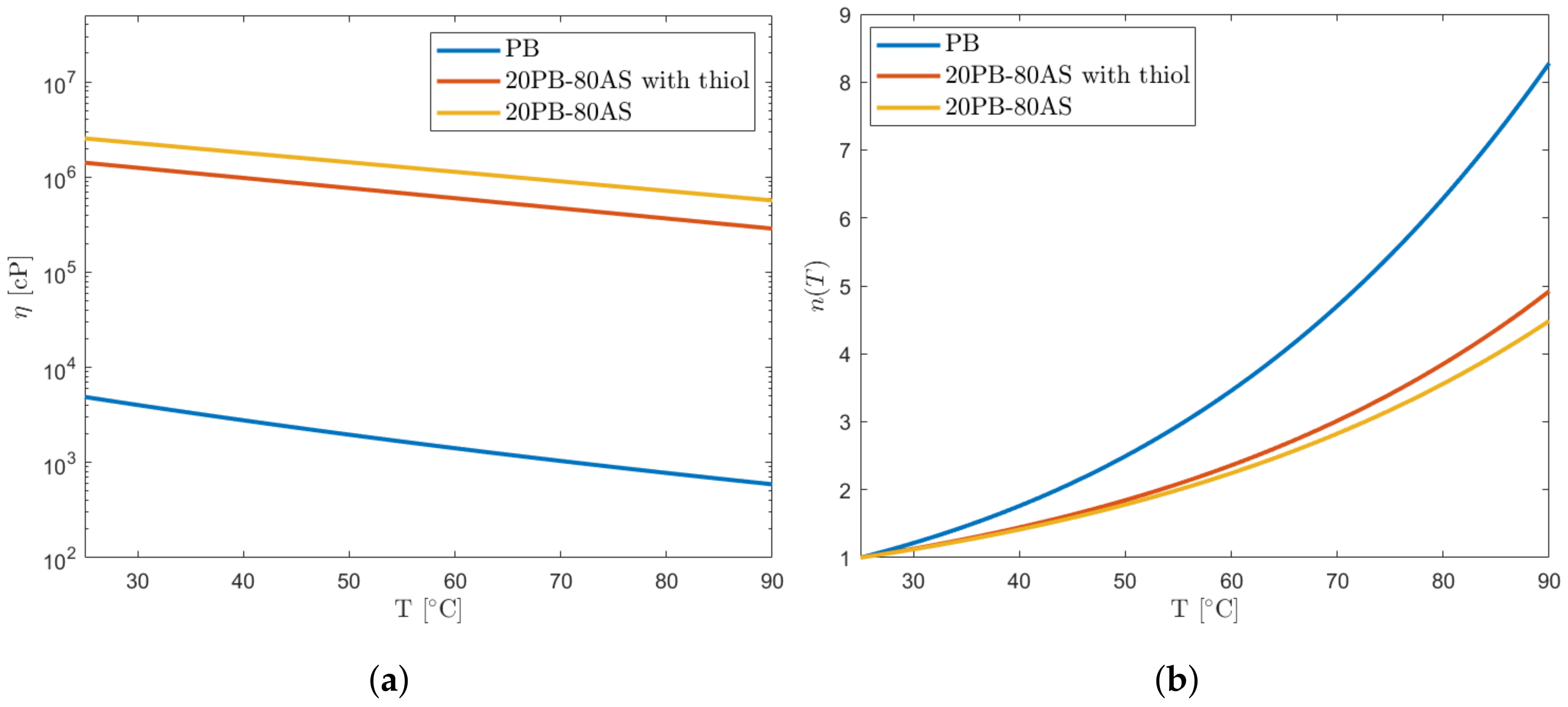

3.1. Viscosity Tests

3.2. Mechanical Testing

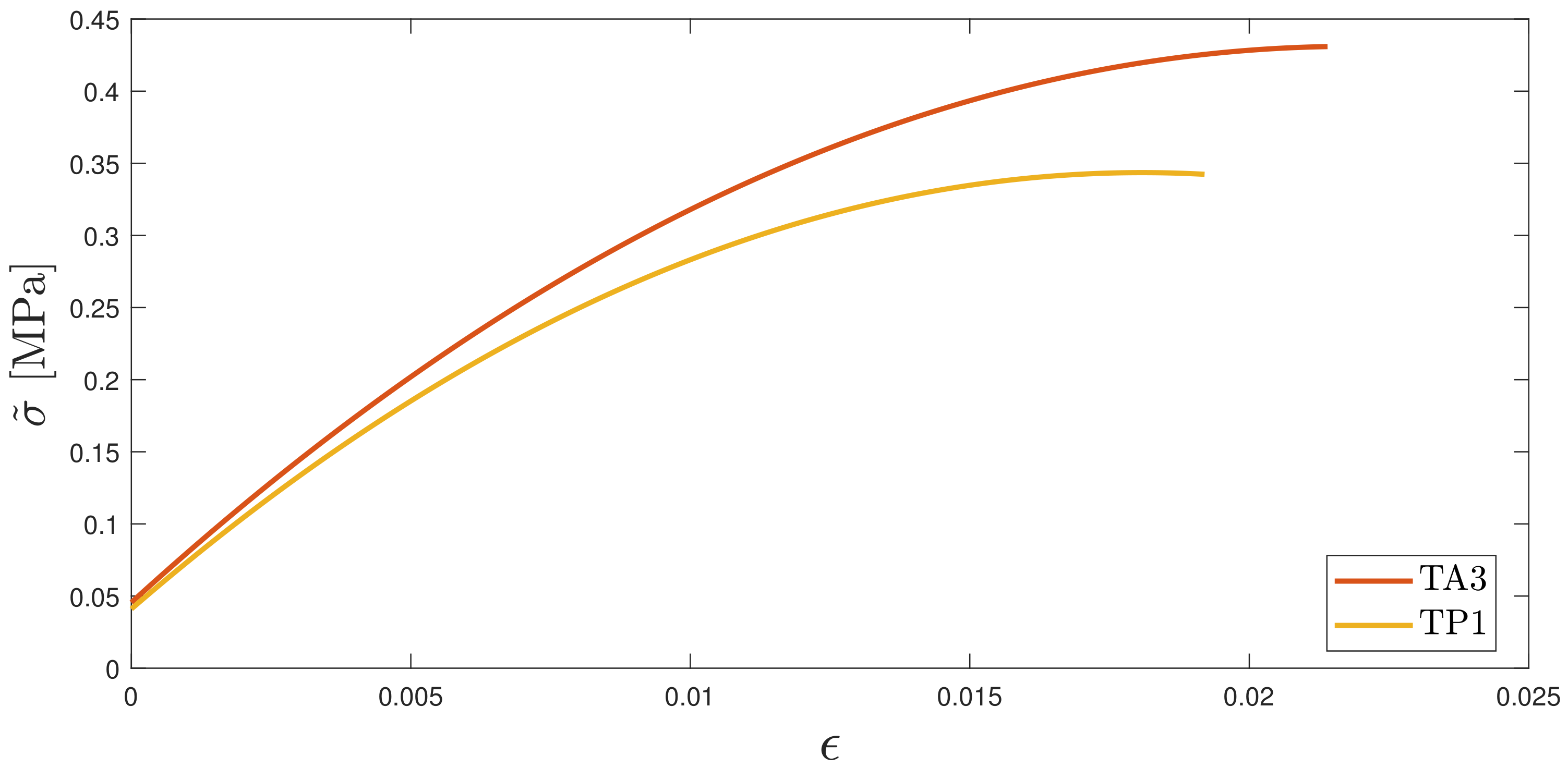

3.2.1. Tensile Tests Results

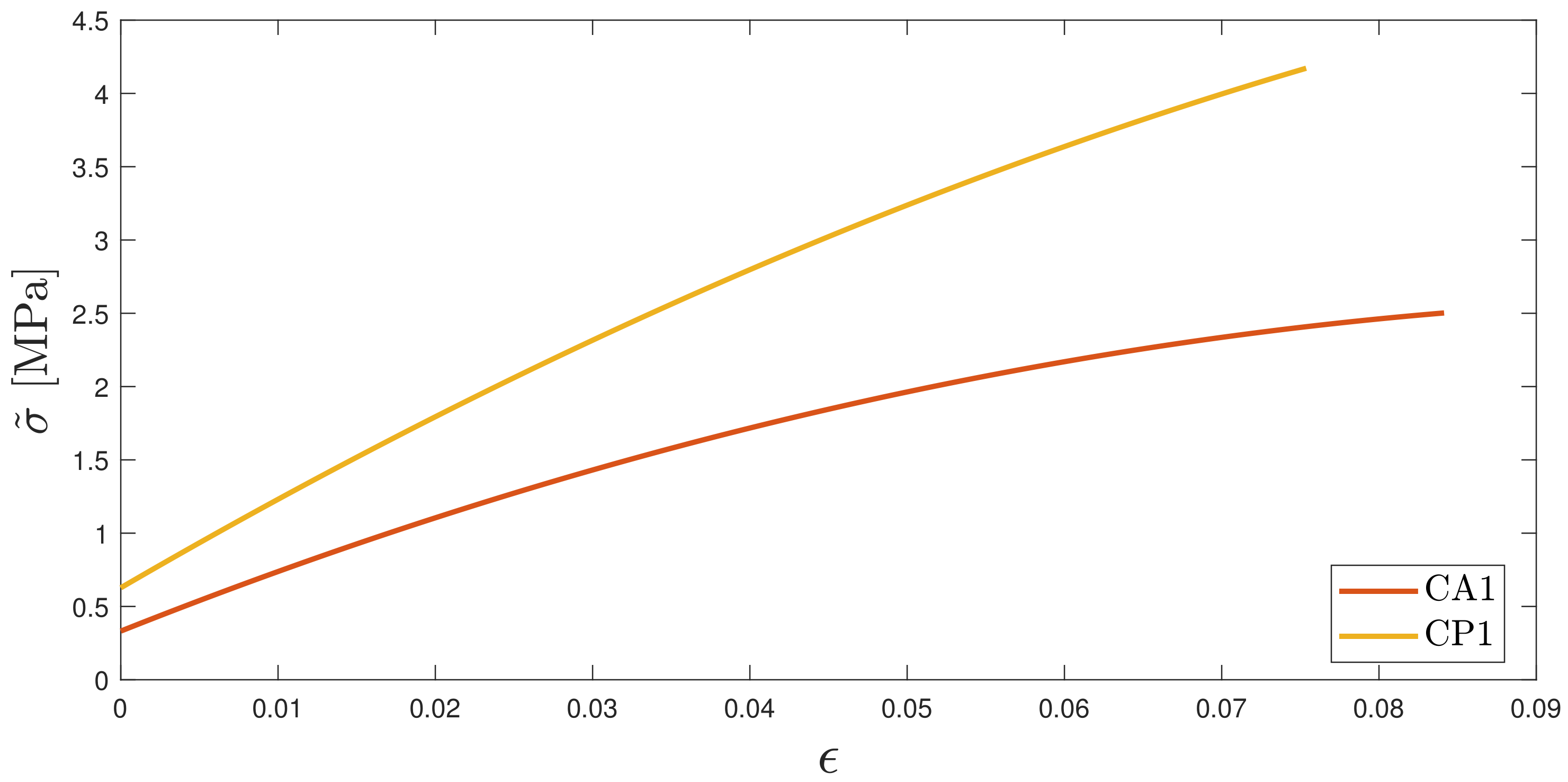

3.2.2. Compression Tests Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AP | Ammonium Perchlorate |

| AS | Ammonium Sulfate |

| BAPO | Bis-(2,4,6-trimethylbenzoyl) phenylphosphine oxide |

| HTPB | Hydroxyl-Terminated Polybutadiene |

| PB | Polybutadiene |

| PPCF | Polypropylene-Reinforced Carbon Fiber |

| PTTM | Pentaerythritol tetrakis(3-mercaptopropionate) |

| UV | Ultraviolet |

| TPU | Thermoplastic Polyurethane |

| Nomenclature | |

| A | Area, |

| Arrhenius pre-exponential factor, cP | |

| Arrhenius activation energy, kJ· | |

| E | Young’s modulus, MPa |

| Compression mean Young’s modulus, MPa | |

| Tensile mean Young’s modulus, MPa | |

| F | Applied force, N |

| Gauge length, m | |

| Natural logarithm | |

| R | Gas constant, J· |

| Coefficient of determination | |

| Root mean square error | |

| T | Temperature, °C or K |

| Ambient temperature, °C or K | |

| Displacement, m | |

| Strain | |

| Viscosity, cP | |

| Stress, MPa | |

| Fitted stress, MPa | |

| Ultimate mean compression stress, MPa | |

| Ultimate mean tensile stress, MPa | |

| Diameter, cm |

References

- Sutton, G.P.; Biblarz, O. Rocket Propulsion Elements; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Mason, B.P.; Roland, C.M. Solid Propellants. Rubber Chem. Technol. 2019, 92, 1–24. [Google Scholar] [CrossRef]

- Davenas, A. Development of Modern Solid Propellants. J. Propuls. Power 2003, 19, 1108–1128. [Google Scholar] [CrossRef]

- Galavotti, A.; Noè, C.; Polizzi, G.; Antonaci, P.; Maggi, F.; Masseni, F.; Pastrone, D. Solid Rocket Propellant Photo-Polymerization with an In-House LED-UV Prototype. Polymers 2023, 15, 1633. [Google Scholar] [CrossRef] [PubMed]

- Mezger, M.J.; Tindle, K.J.; Pantoya, M.; Groven, L.J.; Kalyon, D. (Eds.) Energetic Materials: Advanced Processing Technologies for Next-Generation Materials, 1st ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar] [CrossRef]

- Zhang, J.; He, K.; Zhang, D.; Dong, J.; Li, B.; Liu, Y.; Gao, G.; Jiang, Z. Three-dimensional printing of energetic materials: A review. Energetic Mater. Front. 2022, 3, 97–108. [Google Scholar] [CrossRef]

- Muravyev, N.V.; Monogarov, K.A.; Schaller, U.; Fomenkov, I.V.; Pivkina, A.N. Progress in Additive Manufacturing of Energetic Materials: Creating the Reactive Microstructures with High Potential of Applications. Propellants Explos. Pyrotech. 2019, 44, 941–969. [Google Scholar] [CrossRef]

- Lajoie, J.; Blocker, J.; Sippel, T. Rheological, Ballistic, and Mechanical Properties of 3D Printed, Photocured Composite Propellants. J. Propuls. Power 2023, 39, 936–944. [Google Scholar] [CrossRef]

- McClain, M.; Afriat, A.; Montano, B.J.; Ray, S.; Rhoads, J.; Gunduz, I.E.; Son, S.F. Investigation of Additively Manufactured Layered Composite Solid Propellant. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, Florida, USA, 6–10 January 2020. AIAA Paper 2020-1427. [Google Scholar] [CrossRef]

- McClain, M.S.; Afriat, A.; Montano, B.J.; Rhoads, J.F.; Gunduz, I.E.; Son, S.F. Dynamic Combustion of Functionally Graded Additively Manufactured Composite Solid Propellant. J. Propuls. Power 2021, 37, 725–732. [Google Scholar] [CrossRef]

- Gunduz, I.; McClain, M.; Cattani, P.; Chiu, G.C.; Rhoads, J.; Son, S. 3D printing of extremely viscous materials using ultrasonic vibrations. Addit. Manuf. 2018, 22, 98–103. [Google Scholar] [CrossRef]

- Noè, C.; Iannucci, L.; Malburet, S.; Graillot, A.; Sangermano, M.; Grassini, S. New UV-Curable Anticorrosion Coatings from Vegetable Oils. Macromol. Mater. Eng. 2021, 306, 2100029. [Google Scholar] [CrossRef]

- Liu, F.; Liu, A.; Tao, W.; Yang, Y. Preparation of UV curable organic/inorganic hybrid coatings-a review. Prog. Org. Coat. 2020, 145, 105685. [Google Scholar] [CrossRef]

- Lucey, M. UV curable coatings for electronic components. IEEE Trans. Compon. Packag. Manuf. Technol. Part A 1994, 17, 326–333. [Google Scholar] [CrossRef]

- Zanon, M.; Montalvillo-Jiménez, L.; Bosch, P.; Cue-López, R.; Martínez-Campos, E.; Sangermano, M.; Chiappone, A. Photocurable Thiol–yne Alginate Hydrogels for Regenerative Medicine Purposes. Polymers 2022, 14, 4709. [Google Scholar] [CrossRef]

- Mendes-Felipe, C.; Oliveira, J.; Etxebarria, I.; Vilas-Vilela, J.L.; Lanceros-Mendez, S. State-of-the-Art and Future Challenges of UV Curable Polymer-Based Smart Materials for Printing Technologies. Adv. Mater. Technol. 2019, 4, 1800618. [Google Scholar] [CrossRef]

- Zhang, L.; Shi, X.; Zhang, Z.; Kuchel, R.P.; Namivandi-Zangeneh, R.; Corrigan, N.; Jung, K.; Liang, K.; Boyer, C. Porphyrinic Zirconium Metal–Organic Frameworks (MOFs) as Heterogeneous Photocatalysts for PET-RAFT Polymerization and Stereolithography. Angew. Chem. Int. Ed. 2021, 60, 5489–5496. [Google Scholar] [CrossRef] [PubMed]

- Kirby, L.; Lawrence, A.; Udaykumar, H.; Sippel, T.; Song, X. Pressure-assisted binder jet additive manufacturing of solid propellants. Addit. Manuf. 2023, 77, 103808. [Google Scholar] [CrossRef]

- Chen, N.; He, C.; Pang, S. Additive manufacturing of energetic materials: Tailoring energetic performance via printing. J. Mater. Sci. Technol. 2022, 127, 29–47. [Google Scholar] [CrossRef]

- Pastrone, D.; Sangermano, M.; Garino, S.; Maggi, F. Composite Propellant Manufacturing Process Based on Deposition and Light-Activated Polymerization for Solid Rocket Motors. WO2020212785A1, 20 October 2020. [Google Scholar]

- Garino, S.; Antonaci, P.; Pastrone, D.; Sangermano, M.; Maggi, F. Photo-polymerization for additive manufacturing of composite solid propellants. Acta Astronaut. 2021, 182, 58–65. [Google Scholar] [CrossRef]

- Li, W.; Ghazanfari, A.; Leu, M.C.; Landers, R.G. Extrusion-on-demand methods for high solids loading ceramic paste in freeform extrusion fabrication. Addit. Manuf. 2017, 14, 193–205. [Google Scholar] [CrossRef]

- Bisbee, W.; Flanagan, J.; Grant, L.; Hamermesh, C.; Hilzinger, J.; Fujikawa, C.; Lawton, E. Study to Find Simulants for Fuels for Use in Structures Fatigue Testing. Technical Report, Publisher or Source, 1963. Available online: https://archive.org/details/DTIC_AD0427123 (accessed on 20 December 2023).

- ASTM D2196-20; Standard Test Methods for Rheological Properties of Non-Newtonian Materials by Rotational Viscometer. American Society for Testing and Materials: West Conshohocken, PA, USA, 2020. [CrossRef]

- Mischenko, S.; Mordasov, M.; Savenkov, A.; Sychev, V. Analysis of the influence of sizes of a vessel with a liquid on the readings of Brookfield viscometer. Meas. Tech. 2020, 63, 288–294. [Google Scholar] [CrossRef]

- AMETEK Brookfield. More Solutions to Sticky Problems: A Guide to Getting More from Your Brookfield Viscometer and Rheometer; AMETEK Brookfield: Middleboro, MA, USA, 2012. [Google Scholar]

- DIN 53504:1994-05; Prüfung von Kautschuk und Elastomeren; Bestimmung von Reißfestigkeit, Zugfestigkeit, Reißdehnung und Spannungswerten im Zugversuch. Deutsches Institut für Normung e.V.: Berlin, Germany, 1994.

- Wang, Z.; Qiang, H.; Wang, G.; Geng, B. Strength criterion of composite solid propellants under dynamic loading. Def. Technol. 2018, 14, 457–462. [Google Scholar] [CrossRef]

- Yang, L.; Xie, K.; Pei, J.; Sui, X.; Wang, N. Compressive mechanical properties of HTPB propellant at low, intermediate, and high strain rates. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Wu, W.; Li, H.; Shen, Z.; Cui, H. Research on Constant Speed Tension and Compression Mechanical Properties of Azide Polyether Propellant. Propellants Explos. Pyrotech. 2022, 47, e202200055. [Google Scholar] [CrossRef]

- Adel, W.M.; Liang, G.-Z. Analysis of Mechanical Properties for AP/HTPB Solid Propellant under Different Loading Conditions. Int. J. Aerosp. Mech. Eng. 2017, 11, 1915–1919. [Google Scholar] [CrossRef]

- Mezger, T. The Rheology Handbook, 3rd ed.; Vincentz Network Publisher: Hanover, Germany, 2011. [Google Scholar]

- Messaâdi, A.; Dhouibi, N.; Hamda, H.; Belgacem, F.B.M.; Adbelkader, Y.H.; Ouerfelli, N.; Hamzaoui, A.H. A new equation relating the viscosity Arrhenius temperature and the activation energy for some Newtonian classical solvents. J. Chem. 2015, 2015, 163262. [Google Scholar] [CrossRef]

- Akbaş, A.; Aksoy, S.; Hasırcı, N. Effects of thermal ageing on the properties and lifetime prediction of hydroxyl-terminated polybutadiene. Polymer 1994, 35, 2568–2572. [Google Scholar] [CrossRef]

- Bandgar, B.; Sharma, K.; Mukundan, T.; Krishnamurthy, V. Rheokinetic modeling of HTPB–TDI and HTPB–DOA–TDI systems. J. Appl. Polym. Sci. 2003, 89, 1331–1335. [Google Scholar] [CrossRef]

- Ma, H.; Liu, Y.; Guo, J.; Chai, T.; Yu, Y.; Yuan, J.; Jing, S.; Feng, F.; Zhong, L.; Zhou, Y.; et al. Catalyzed HTPB/HDI-trimer curing reactions and influence on pot life. Coatings 2020, 10, 1073. [Google Scholar] [CrossRef]

- Da Cunha, B.C.C.; da Costa Mattos, E.; Rocco, J.A.F.F. Influence of storage time before casting on viscosities and mechanical properties of AP/HTPB/Al solid composite propellants. FirePhysChem 2022, 2, 50–55. [Google Scholar] [CrossRef]

- Du, Y.; Zheng, J.; Yu, G. Influence of Thermally-Accelerated Aging on the Dynamic Mechanical Properties of HTPB Coating and Crosslinking Density-Modified Model for the Payne Effect. Polymers 2020, 12, 403. [Google Scholar] [CrossRef]

- Rusu, M.; Block, C.; Van Assche, G.; Mele, B. Influence of temperature and UV intensity on photo-polymerization reaction studied by photo-DSC. J. Therm. Anal. Calorim. 2012, 110, 287–294. [Google Scholar] [CrossRef]

- Tauböck, T.T.; Tarle, Z.; Marovic, D.; Attin, T. Pre-heating of high-viscosity bulk-fill resin composites: Effects on shrinkage force and monomer conversion. J. Dent. 2015, 43, 1358–1364. [Google Scholar] [CrossRef] [PubMed]

- Daronch, M.; Rueggeberg, F.; Goes, M.D. Monomer Conversion of Pre-heated Composite. J. Dent. Res. 2005, 84, 663–667. [Google Scholar] [CrossRef] [PubMed]

- Daronch, M.; Rueggeberg, F.; Goes, M.D.; Giudici, R. Polymerization Kinetics of Pre-heated Composite. J. Dent. Res. 2006, 85, 38–43. [Google Scholar] [CrossRef] [PubMed]

| Test Case | Formulation | Spindle Type | Rotational Speed (RPM) | Temperature Range (°C) | Test Duration (s) |

|---|---|---|---|---|---|

| #1 | PB only | LV-3 | 12–60 | 2512–90 | 1200 |

| #2 | 20PB-80AS | LV-4 | 0.312–0.6 | 2000 | |

| #3 | 20PB-80AS with thiol | LV-4 | 0.6 | 2100 |

| Code | Series | Curing Time for Each Layer (s) | Aging Time (h) |

|---|---|---|---|

| TA | TA1 | 40 | 24 |

| TA2 | 120 | 48 | |

| TA3 | 180 | 48 | |

| TP | TP1 | 180 | 48 |

| CA | CA1 | 180 | 48 |

| CP | CP1 | 180 | 48 |

| Test Case | Formulation | n (90 °C) |

|---|---|---|

| #1 | PB | 8.28 |

| #2 | 20PB-80AS | 4.48 |

| #3 | 20PB-80AS with thiol | 4.92 |

| Code | Series | Tensile Strength (MPa) | Young Modulus (MPa) | |

|---|---|---|---|---|

| TA | TA1 | 0.983 | ||

| TA2 | 0.982 | |||

| TA3 | 0.843 | |||

| TP | TP1 | 0.883 |

| Code | Series | Compression Strength (MPa) | Young Modulus (MPa) | |

|---|---|---|---|---|

| CA | CA1 | |||

| CP | CP1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zumbo, A.; Stumpo, L.; Antonaci, P.; Ferrero, A.; Masseni, F.; Polizzi, G.; Tetti, G.; Pastrone, D. Rheological and Mechanical Characterization of 3D-Printable Solid Propellant Slurry. Polymers 2024, 16, 576. https://doi.org/10.3390/polym16050576

Zumbo A, Stumpo L, Antonaci P, Ferrero A, Masseni F, Polizzi G, Tetti G, Pastrone D. Rheological and Mechanical Characterization of 3D-Printable Solid Propellant Slurry. Polymers. 2024; 16(5):576. https://doi.org/10.3390/polym16050576

Chicago/Turabian StyleZumbo, Alessandra, Leonardo Stumpo, Paola Antonaci, Andrea Ferrero, Filippo Masseni, Giovanni Polizzi, Giacomo Tetti, and Dario Pastrone. 2024. "Rheological and Mechanical Characterization of 3D-Printable Solid Propellant Slurry" Polymers 16, no. 5: 576. https://doi.org/10.3390/polym16050576

APA StyleZumbo, A., Stumpo, L., Antonaci, P., Ferrero, A., Masseni, F., Polizzi, G., Tetti, G., & Pastrone, D. (2024). Rheological and Mechanical Characterization of 3D-Printable Solid Propellant Slurry. Polymers, 16(5), 576. https://doi.org/10.3390/polym16050576