Assessment of Degree of Conversion and Volumetric Shrinkage of Novel Self-Adhesive Cement

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Design

2.2. Materials

2.3. Degree of Conversion (DC)

2.4. Volumetric Shrinkage

2.5. Flexural Strength, Flexural Modulus, Water Sorption, and Solubility

2.6. Statistical Analysis

3. Results

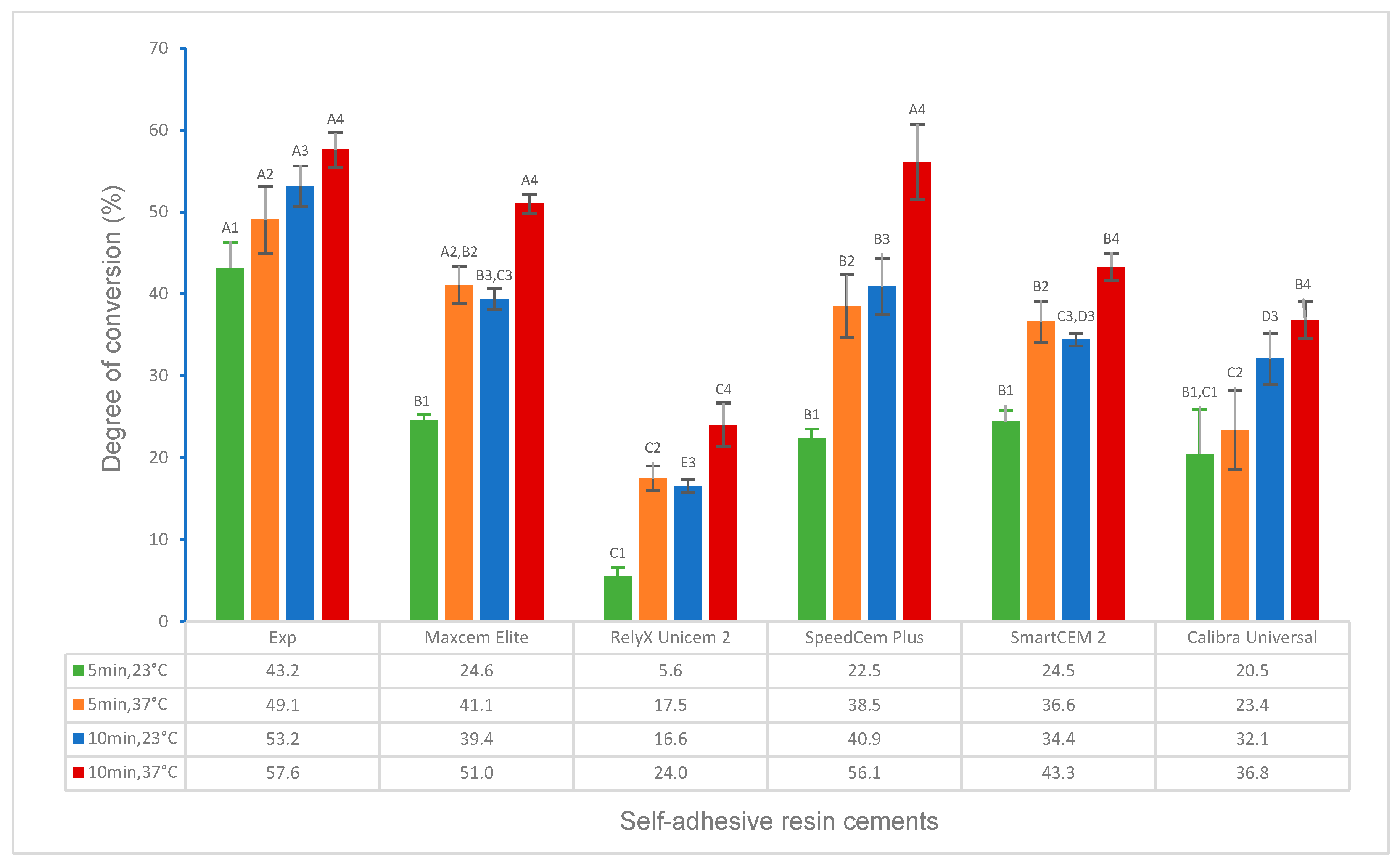

3.1. Effect of Cement Materials on DC under Different Activation Modes

3.2. Effect of Temperature on DC under Different Activation Modes

3.3. Effect of Time on DC under Different Curing Scenarios

3.4. Correlations between the Degree of Conversion and Flexural Strength, Flexural Modulus, and Water Solubility

3.5. Volumetric Shrinkage under Different Curing Modes

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Radovic, I.; Monticelli, F.; Goracci, C.; Vulicevic, Z.R.; Ferrari, M. Self-adhesive resin cements: A literature review. J. Adhes. Dent. 2008, 10, 251–258. [Google Scholar]

- Aguiar, T.R.; Andre, C.B.; Correr-Sobrinho, L.; Arrais, C.A.; Ambrosano, G.M.; Giannini, M. Effect of storage times and mechanical load cycling on dentin bond strength of conventional and self-adhesive resin luting cements. J. Prosthet. Dent. 2014, 111, 404–410. [Google Scholar] [CrossRef] [PubMed]

- Christensen, C.J. The best cement types for indirect restorations. Clin. Rep. 2011, 4, 1–3. [Google Scholar]

- Souza, G.D.; Braga, R.R.; Cesar, P.F.; Lopes, G.C. Correlation between clinical performance and degree of conversion of resin cements: A literature review. J. Appl. Oral. Sci. 2015, 23, 358–368. [Google Scholar] [CrossRef]

- Takagaki, T.; Ko, A.K.; Halabi, S.; Sato, T.; Ikeda, M.; Nikaido, T.; Burrow, M.F.; Tagami, J. Adhesion durability of dual-cure resin cements and acid–base resistant zone formation on human dentin. Dent. Mater. 2019, 35, 945–952. [Google Scholar]

- Novais, V.R.; Raposo, L.H.A.; Miranda, R.R.D.; Lopes, C.D.C.A.; Simamoto, P.C.J.; Soares, C.J. Degree of conversion and bond strength of resin-cements to feldspathic ceramic using different curing modes. J. Appl. Oral. Sci. 2017, 25, 61–68. [Google Scholar] [CrossRef] [PubMed]

- Pulido, C.A.; de Oliveira Franco, A.P.G.; Gomes, G.M.; Bittencourt, B.F.; Kalinowski, H.J.; Gomes, J.C.; Gomes, O.M.M. An in situ evaluation of the polymerization shrinkage, degree of conversion, and bond strength of resin cements used for luting fiber posts. J. Prosthet. Dent. 2016, 116, 570–576. [Google Scholar] [CrossRef]

- Nima, G.; Makishi, P.; Fronza, B.M.; Ferreira, P.V.C.; Braga, R.R.; Reis, A.F.; Giannini, M. Polymerization kinetics, shrinkage stress, and bond strength to dentin of conventional and self-adhesive resin cements. J. Adhes. Dent. 2022, 24, 355–366. [Google Scholar] [PubMed]

- Gordilho, A.C.; Swerts DM, O.; Miranda, M.E.; Boaro, L.C.; Brandt, W.C. Degree of conversion and cohesive strength of conventional dual resin and self-adhesive cements by using of different forms of activation. Res. Soc. Dev. 2021, 10, e20910917850. [Google Scholar] [CrossRef]

- Sunico-Segarra, M.; Segarra, A.; Sunico-Segarra, M.; Segarra, A. Resin Cements: Factors Affecting Clinical Performance. In A Practical Clinical Guide to Resin Cements; Springer: Berlin/Heidelberg, Germany, 2015; pp. 9–22. [Google Scholar]

- Aljabo, A.; Xia, W.; Liaqat, S.; Khan, M.A.; Knowles, J.C.; Ashley, P.; Young, A.M. Conversion, shrinkage, water sorption, flexural strength and modulus of remineralizing dental composites. Dent. Mater. 2015, 31, 1279–1289. [Google Scholar] [CrossRef]

- Ferracane, J.L. Correlation between hardness and degree of conversion during the setting reaction of unfilled dental restorative resins. Dent. Mater. 1985, 1, 11–14. [Google Scholar] [CrossRef]

- Ferracane, J.L.; Berge, H.X. Fracture toughness of experimental dental composites aged in ethanol. J. Dent. Res. 1995, 74, 1418–1423. [Google Scholar] [CrossRef]

- Ferracane, J.L.; Mitchem, J.C.; Condon, J.R.; Todd, R. Wear and marginal breakdown of composites with various degrees of cure. J. Dent. Res. 1997, 76, 1508–1516. [Google Scholar] [CrossRef] [PubMed]

- Spahl, W.; Budzikiewicz, H.; Geurtsen, W. Extractable residual monomers from various resin materials-a qualitative study. J. Dent. Res. 1994, 73, 295–299. [Google Scholar]

- Hansel, C.; Leyhausen, G.; Mai, U.E.H.; Geurtsen, W. Effects of various resin composite (co)monomers and extracts on two caries-associated micro-organisms in vitro. J. Dent. Res. 1998, 77, 60–67. [Google Scholar] [CrossRef] [PubMed]

- Kleverlaan, C.J.; Feilzer, A.J. Polymerization shrinkage and contraction stress of dental resin composites. Dent. Mater. 2005, 21, 1150–1157. [Google Scholar] [CrossRef] [PubMed]

- Davidson, C.L.; Feilzer, A.J. Polymerization shrinkage and polymerization shrinkage stress in polymer-based restoratives. J. Dent. 1997, 25, 435–440. [Google Scholar] [CrossRef] [PubMed]

- Eick, J.D.; Welch, F.H. Polymerization shrinkage of posterior composite resins and its possible influence on postoperative sensitivity. Quintessence Int. 1986, 17, 103–111. [Google Scholar] [PubMed]

- He, X.; Yu, S.; Wang, H.; Tian, Z.; Zhang, J.; Zhao, Y.; Gong, H.; Shi, Z.; Cui, Z.; Zhu, S. A novel resin cement to improve bonding interface durability. RSC Adv. 2022, 12, 24288–24300. [Google Scholar] [CrossRef] [PubMed]

- Ling, L.; Ma, Y.M.; Chen, Y.L.; Malyala, R. Physical, Mechanical and adhesive properties of novel self-adhesive resin cement. Int. J. Dent. 2022, 2022, 4475394. [Google Scholar] [CrossRef]

- ISO 4049:2009; Polymer-Based Restorative Materials, 4th ed. International Standard: Geneva, Switzerland, 2009.

- Christensen, C.J. Self-adhesive resin cements-a replacement or an alternative? Clin. Rep. 2009, 2, 3–4. [Google Scholar]

- Maxcem Elite, Instructions for Use. Kerr Corporation, DMC4148, 02/2021. Available online: https://www.kerrdental.com/kerr-restoratives/maxcem-elite-self-etch-self-adhesive-resin-dental-cement#docs (accessed on 20 February 2024).

- Vrochari, A.D.; Eliades, G.; Hellwig, E.; Wrbas, K.T. Curing efficiency of four self-etching, self-adhesive resin cements. Dent. Mater. 2009, 25, 1104–1108. [Google Scholar] [CrossRef] [PubMed]

- Pegoraro, T.A.; Fulgêncio, R.; Butignon, L.E.; Manso, A.P.; Carvalho, R.M. Effects of temperature and aging on working/setting time of dual-cured resin cements. Oper. Dent. 2015, 40, E222–E229. [Google Scholar] [CrossRef] [PubMed]

- RelyX™ Unicem 2, Instructions for Use. 3M ESPE, 3/2019. Available online: https://www.3m.com/3M/en_US/p/d/b00007450/ (accessed on 20 February 2024).

- Evans, J.D. Straightforward Statistics for the Behavioral Sciences; Thomson Brooks/Cole Publishing, Co.: Belmont, CA, USA, 1996. [Google Scholar]

- Moore, D.S.; Notz, W.I.; Flinger, M.A. The Basic Practice of Statistics, 6th ed.; W. H. Freeman and Company: New York, NY, USA, 2013. [Google Scholar]

- Aldhafyan, M.; Silikas, N.; Watts, D.C. Influence of curing modes on conversion and shrinkage of dual cure resin-cements. Dent. Mater. 2022, 38, 194–203. [Google Scholar] [CrossRef]

- Ling, L.; Xu, X.; Choi, G.Y.; Billodeaux, D.; Guo, G.; Diwan, R.M. Novel F-releasing composite with improved mechanical properties. J. Dent. Res. 2009, 88, 83–88. [Google Scholar] [CrossRef] [PubMed]

- Moraes, L.G.P.; Rocha, R.S.F.; Menegazzo, L.M.; AraÚjo, E.B.D.; Yukimitu, K.; Moraes, J.C.S. Infrared spectroscopy: A tool for determination of the degree of conversion in dental composites. J. Appl. Oral. Sci. 2008, 16, 145–149. [Google Scholar] [CrossRef] [PubMed]

- Aguiar, T.R.; Francescantonio, M.D.; Ambrosano, G.M.B.; Giannini, M. Effect of curing mode on bond strength of self-adhesive resin luting cements to dentin. J. Biomed. Mater. Res. B Appl. Biomater. 2010, 93, 122–127. [Google Scholar] [CrossRef]

- Pereira, S.G.; Fulgêncio, R.; Nunes, T.G.; Toledano, M.; Osorio, R.; Carvalho, R.M. Effect of curing protocol on the polymerization of dual-cured resin cements. Dent. Mater. 2010, 26, 710–718. [Google Scholar] [CrossRef]

- Emami, N.; Söderholm, K.J. Young’s modulus and degree of conversion of different combination of light-cure dental resins. Open Dent. J. 2009, 3, 202–207. [Google Scholar] [CrossRef][Green Version]

- Maletin, A.; Ristic, I.; Veljovic, T.; Ramic, B.; Puskar, T.; Jeremic-Knezevic, M.; Koprivica, D.D.; Milekic, B.; Vukoje, K. Influence of dimethacrylate monomer on the polymerization efficacy of resin-based dental cements-FTIR analysis. Polymers 2022, 14, 247. [Google Scholar] [CrossRef]

- Ilie, N.; Simon, A. Effect of curing mode on the micro-mechanical properties of dual cured self-adhesive resin cements. Clin. Oral. Investig. 2012, 16, 505–512. [Google Scholar] [CrossRef]

- Aguiar, T.R.; Francescantonio, M.D.; Arrais, C.A.G.; Ambrosano, G.M.B.; Davanzo, C.; Giannini, M. Influence of curing mode and time on degree of conversion of one conventional and two self-adhesive resin cements. Oper. Dent. 2010, 35, 295–299. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, M.; Cesar, P.F.; Giannini, M.; Rueggeberg, F.A.; Rodrigues, J.; Arrais, C.A. Effect of temperature on the degree of conversion and working time of dual-cured resin cements exposed to different curing conditions. Oper. Dent. 2012, 37, 370–379. [Google Scholar] [CrossRef]

- Emami, N.; Söderholm, K.J. Influence of light-curing procedures and photo-initiator/co-initiator composition on the degree of conversion of light-curing resins. J. Mater. Sci. Mater. Med. 2005, 16, 47–52. [Google Scholar] [CrossRef] [PubMed]

- Brandt, W.C.; Schneider, L.F.J.; Frollini, E.; Correr-Sobrinho, L.; Sinhoreti, M.A.C. Effect of different photo-initiators and light curing units on degree of conversion of composites. Braz. Oral. Res. 2010, 24, 263–270. [Google Scholar] [CrossRef] [PubMed]

- el-Badrawy, W.A.; el-Mowafy, O.M. Chemical versus dual curing of resin inlay cements. J. Prosthet. Dent. 1995, 73, 515–524. [Google Scholar] [CrossRef] [PubMed]

- Aguiar, T.R.; Oliveira, M.D.; Arrais, C.A.G.; Ambrosano, G.M.B.; Rueggeberg, F.; Giannini, M. The effect of photopolymerization on the degree of conversion, polymerization kinetic, biaxial flexure strength, and modulus of self-adhesive resin cements. J. Prosthet. Dent. 2015, 113, 128–134. [Google Scholar] [CrossRef] [PubMed]

- de Gee, A.J.; Davidson, C.L.; Smith, A. A modified dilatometer for continuous recording of volumetric polymerization shrinkage of composite restorative materials. J. Dent. 1981, 9, 36–42. [Google Scholar] [CrossRef]

- Oberholzer, T.G.; Grobler, S.R.; Pameijer, C.H.; Rossouw, R.J. A modified dilatometer for determining volumetric polymerization shrinkage of dental materials. Meas. Sci. Technol. 2002, 13, 78–83. [Google Scholar] [CrossRef]

- Nitta, K.; Nomoto, R.; Tsubota, Y.; Tsuchikawa, M.; Hayakawa, T. Characteristics of low polymerization shrinkage flowable resin composites in newly developed cavity base materials for bulk filling technique. Dent. Mater. J. 2017, 36, 740–746. [Google Scholar] [CrossRef]

- Sharp, L.J.; Choi, I.B.; Lee, T.E.; Sy, A.; Suh, B.I. Volumetric shrinkage of composites using video imaging. J. Dent. 2003, 31, 97–103. [Google Scholar] [CrossRef] [PubMed]

- Tiba, A.; Charlton, D.G.; Vandewalle, K.S.; Ragain, J.C., Jr. Comparison of two video-imaging instruments for measuring volumetric shrinkage of dental resin components. J. Dent. 2005, 33, 757–763. [Google Scholar] [CrossRef] [PubMed]

- Braga, R.R.; Ballester, R.Y.; Ferracane, J.L. Factors involved in the development of polymerization shrinkage stress in resin composites: A systematic review. Dent. Mater. 2005, 21, 962–970. [Google Scholar] [CrossRef]

- Ferracane, J.L. Buonocore Lecture. Placing dental composites—A stressful experience. Oper. Dent. 2008, 33, 247–257. [Google Scholar] [CrossRef]

- Labella, R.; Lambrechts, P.; Van Meerbeek, B.; Vanherle, G. Polymerization shrinkage and elasticity of flowable composites and filled adhesives. Dent. Mater. 1999, 15, 128–137. [Google Scholar] [CrossRef]

- Kim, Y.S.; Choi, S.H.; Lee, B.N.; Hwang, Y.C.; Hwang, I.N.; Oh, W.M.; Ferracane, J.L.; Chang, H.S. Effect of tack cure on polymerization shrinkage of resin based luting cement. Oper. Dent. 2020, 45, E196–E206. [Google Scholar] [CrossRef] [PubMed]

- Majidinia, S.; Bagheri, H.; Ramezani, S.; Giv, M.J.; Vatanparast, N.; Namdar, F. Polymerization shrinkage, shrinkage stress, and degree of conversion in bulk-fill resin composites after different photo-activation methods. Dent. Hypotheses 2020, 11, 4–10. [Google Scholar]

- Dewaele, M.; Truffier-Boutry, D.; Devaux, J.; Leloup, G. Volume contraction in photocured dental resins: The shrinkage-conversion relationship revisited. Dent. Mater. 2006, 22, 359–365. [Google Scholar] [CrossRef]

- Chen, L.; Suh, B.I.; Gleave, C.; Choi, W.J.; Hyun, J.; Nam, J. Effects of light-, self-, and tack-curing on degree of conversion and physical strength of dual-cure resin cements. Am. J. Dent. 2016, 29, 67–70. [Google Scholar]

| Curing Scenarios | Self-Cure (SC) | Light Cure (LC) | Dual Cure (DC) |

|---|---|---|---|

| 1 | 5 min at 23 °C | ||

| 2 | 5 min at 37 °C | ||

| 3 | 10 min at 23 °C | ||

| 4 | 10 min at 37 °C | ||

| 5 | 20 s at 23 °C | ||

| 6 | 20 s at 37 °C | ||

| 7 | SC 10 min + LC 20 s at 23 °C | ||

| 8 | SC 10 min + LC 20 s at 37 °C | ||

| 9 | LC 20 s + SC 10 min at 23 °C | ||

| 10 | LC 20 s + SC 10 min at 37 °C | ||

| 11 | LC 20 s + SC 5 min at 23 °C | ||

| 12 | LC 20 s + SC 5 min at 37 °C |

| Material | Manufacturer | Resin | Filler | Filler Content (wt.%) |

|---|---|---|---|---|

| Exp. SARC | Glidewell | BisGMA, UDMA, TEGDMA, MDP, initiators and inhibitor | Barium boron fluoroaluminosilicate glass, fumed silica, ytterbium fluoride | 70 |

| MaxCem Elite | Kerr | Methacrylate esters, GPDM, HEMA, activators and stabilizers | Mineral fillers, ytterbium fluoride | 69 |

| RelyX Unicem 2 | 3M ESPE | Methacrylated phosphoric esters, dimethacrylates, TEGDMA, acetate, sodium persulfate, substituted pyrimidine, stabilizers | Glass fillers, silica, calcium hydroxide | 70 |

| SpeedCEM Plus | Ivoclar Vivadent | UDMA, TEGDMA, PEGDMA, DDDMA, MDP, dibenzoyl peroxide, stabilizer | Barium glass, silica ytterbium trifluoride | 75 (Base) /69.8 (Cat) |

| SmartCEM 2 | Dentsply Sirona | UDMA, EBPADMA, Di- and tri-functional function diluents, PENTA, 4-META, initiators, accelerators, stabilizer | Barium boron fluoroaluminosilicate glass, amorphous silicon dioxide | 69 |

| Calibra Universal | Dentsply Sirona | UDMA, Di- and Tri-Methacrylate, Phosphoric acid modified acrylate, initiators, accelerators, stabilizer, BHT | Barium boron fluo roaluminosilicate, amorphous silicon dioxide | 73 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ling, L.; Chen, Y.; Malyala, R. Assessment of Degree of Conversion and Volumetric Shrinkage of Novel Self-Adhesive Cement. Polymers 2024, 16, 581. https://doi.org/10.3390/polym16050581

Ling L, Chen Y, Malyala R. Assessment of Degree of Conversion and Volumetric Shrinkage of Novel Self-Adhesive Cement. Polymers. 2024; 16(5):581. https://doi.org/10.3390/polym16050581

Chicago/Turabian StyleLing, Long, Yulin Chen, and Raj Malyala. 2024. "Assessment of Degree of Conversion and Volumetric Shrinkage of Novel Self-Adhesive Cement" Polymers 16, no. 5: 581. https://doi.org/10.3390/polym16050581

APA StyleLing, L., Chen, Y., & Malyala, R. (2024). Assessment of Degree of Conversion and Volumetric Shrinkage of Novel Self-Adhesive Cement. Polymers, 16(5), 581. https://doi.org/10.3390/polym16050581