The Influence of a Microstructural Conformation of Oriented Floating Films of Semiconducting Polymers on Organic Device Performance

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Thin Film Characterization

2.3. OFET Fabrication

2.4. OSD Fabrication

2.5. Organic Bistable Memristor Fabrication

3. Results and Discussion

3.1. Thin-Film Microstructure

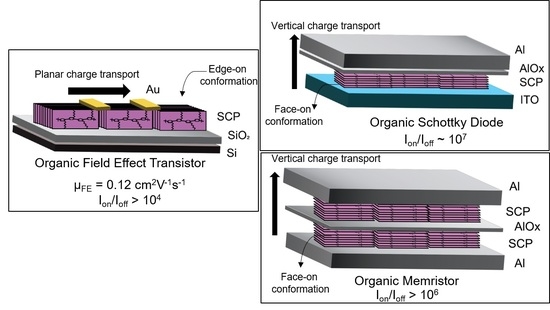

3.2. Device Characteristics

3.2.1. OFET Performance

3.2.2. OSD Performance

3.2.3. Organic Bistable Memristor

| (a) OFETs: | |||

| Technique | µ (cm2V−1s−1) | On/Off Ratio | Reference |

| UFTM | 0.12 | 104 | This work |

| Drop casting | 8.4 × 10−2 | 104 | [44] |

| Solvent-drop casting | 0.16 | 104 | [45] |

| Spin coating | 3.8 × 10−2 | 2.4 × 105 | [46] |

| Spin coating | 1.4 × 10−2 | 1 × 104 | [47] |

| Dip coating | 8.5 × 10−2 | 1.5 × 104 | [48] |

| (b) OSDs: | |||

| Technique | On/Off Ratio | Reference | |

| Spin coating | 8.6 × 106 | This work | |

| Nanofiber solution casting | 1.2 × 103 | [49] | |

| Wet deposition | 106 | [50] | |

| Spin coating | 1.11 × 106 | [30] | |

| Spin coating | 103 | [30] | |

| Spin coating | 8.8 × 102 | [38] | |

| (c) Organic memristors: | |||

| Polymer | Technique | On/Off Ratio | Reference |

| PTB-7 | UFTM | 2.1 × 106 | This work |

| P3HT:LiClO4 | Spin coating | 103 | [51] |

| PVA | Spin coating | 104 | [52] |

| Cu-TCNQ | Vapor deposition | 4 × 102 | [53] |

| PVA-PEDOT: PSS | Spin coating | 102 | [54] |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sirringhaus, H. Device Physics of Solution-Processed Organic Field-Effect Transistors. Adv. Mater. 2005, 17, 2411–2425. [Google Scholar] [CrossRef]

- Sirringhaus, H. 25th Anniversary Article: Organic Field-Effect Transistors: The Path Beyond Amorphous Silicon. Adv. Mater. 2014, 26, 1319–1335. [Google Scholar] [CrossRef]

- Oh, J.Y.; Rondeau-Gagné, S.; Chiu, Y.-C.; Chortos, A.; Lissel, F.; Wang, G.-J.N.; Schroeder, B.C.; Kurosawa, T.; Lopez, J.; Katsumata, T.; et al. Intrinsically Stretchable and Healable Semiconducting Polymer for Organic Transistors. Nature 2016, 539, 411–415. [Google Scholar] [CrossRef]

- Xu, J.; Wu, H.-C.; Zhu, C.; Ehrlich, A.; Shaw, L.; Nikolka, M.; Wang, S.; Molina-Lopez, F.; Gu, X.; Luo, S.; et al. Multi-Scale Ordering in Highly Stretchable Polymer Semiconducting Films. Nat. Mater. 2019, 18, 594–601. [Google Scholar] [CrossRef]

- Abdullah, M.; Al-Nashy, B.O.; Korotcenkov, G.; Al-Khursan, A.H. QDs of Wide Band Gap II–VI Semiconductors Luminescent Properties and Photodetector Applications. In Handbook of II-VI Semiconductor-Based Sensors and Radiation Detectors; Springer International Publishing: Cham, Switzerland, 2023; pp. 399–425. [Google Scholar]

- Sirringhaus, H.; Brown, P.J.; Friend, R.H.; Nielsen, M.M.; Bechgaard, K.; Langeveld-Voss, B.M.W.; Spiering, A.J.H.; Janssen, R.A.J.; Meijer, E.W.; Herwig, P.; et al. Two-Dimensional Charge Transport in Self-Organized, High-Mobility Conjugated Polymers. Nature 1999, 401, 685–688. [Google Scholar] [CrossRef]

- Gurau, M.C.; Delongchamp, D.M.; Vogel, B.M.; Lin, E.K.; Fischer, D.A.; Sambasivan, S.; Richter, L.J. Measuring Molecular Order in Poly(3-Alkylthiophene) Thin Films with Polarizing Spectroscopies. Langmuir 2007, 23, 834–842. [Google Scholar] [CrossRef]

- O’Connor, B.T.; Reid, O.G.; Zhang, X.; Kline, R.J.; Richter, L.J.; Gundlach, D.J.; DeLongchamp, D.M.; Toney, M.F.; Kopidakis, N.; Rumbles, G. Morphological Origin of Charge Transport Anisotropy in Aligned Polythiophene Thin Films. Adv. Funct. Mater. 2014, 24, 3422–3431. [Google Scholar] [CrossRef]

- Ning, G.-H.; Chen, Z.; Gao, Q.; Tang, W.; Chen, Z.; Liu, C.; Tian, B.; Li, X.; Loh, K.P. Salicylideneanilines-Based Covalent Organic Frameworks as Chemoselective Molecular Sieves. J. Am. Chem. Soc. 2017, 139, 8897–8904. [Google Scholar] [CrossRef] [PubMed]

- Bhimanapati, G.R.; Lin, Z.; Meunier, V.; Jung, Y.; Cha, J.; Das, S.; Xiao, D.; Son, Y.; Strano, M.S.; Cooper, V.R.; et al. Recent Advances in Two-Dimensional Materials beyond Graphene. ACS Nano 2015, 9, 11509–11539. [Google Scholar] [CrossRef] [PubMed]

- Chang, J.-F.; Sun, B.; Breiby, D.W.; Nielsen, M.M.; Sölling, T.I.; Giles, M.; McCulloch, I.; Sirringhaus, H. Enhanced Mobility of Poly(3-Hexylthiophene) Transistors by Spin-Coating from High-Boiling-Point Solvents. Chem. Mater. 2004, 16, 4772–4776. [Google Scholar] [CrossRef]

- Yang, H.; LeFevre, S.W.; Ryu, C.Y.; Bao, Z. Solubility-Driven Thin Film Structures of Regioregular Poly(3-Hexyl Thiophene) Using Volatile Solvents. Appl. Phys. Lett. 2007, 90, 172116. [Google Scholar] [CrossRef]

- Soeda, J.; Matsui, H.; Okamoto, T.; Osaka, I.; Takimiya, K.; Takeya, J. Highly Oriented Polymer Semiconductor Films Compressed at the Surface of Ionic Liquids for High-Performance Polymeric Organic Field-Effect Transistors. Adv. Mater. 2014, 26, 6430–6435. [Google Scholar] [CrossRef]

- Kajiya, D.; Ozawa, S.; Koganezawa, T.; Saitow, K. Enhancement of Out-of-Plane Mobility in P3HT Film by Rubbing: Aggregation and Planarity Enhanced with Low Regioregularity. J. Phys. Chem. C 2015, 119, 7987–7995. [Google Scholar] [CrossRef]

- Osaka, I.; Takimiya, K. Backbone Orientation in Semiconducting Polymers. Polymer 2015, 59, A1–A15. [Google Scholar] [CrossRef]

- Zhao, F.; Wang, C.; Zhan, X. Morphology Control in Organic Solar Cells. Adv. Energy Mater. 2018, 8, 1703147. [Google Scholar] [CrossRef]

- Pandey, M.; Kumari, N.; Nagamatsu, S.; Pandey, S.S. Recent Advances in the Orientation of Conjugated Polymers for Organic Field-Effect Transistors. J. Mater. Chem. C 2019, 7, 13323–13351. [Google Scholar] [CrossRef]

- Ma, J.; Hashimoto, K.; Koganezawa, T.; Tajima, K. Enhanced Vertical Carrier Mobility in Poly(3-Alkylthiophene) Thin Films Sandwiched between Self-Assembled Monolayers and Surface-Segregated Layers. Chem. Commun. 2014, 50, 3627–3630. [Google Scholar] [CrossRef]

- Skrypnychuk, V.; Wetzelaer, G.-J.A.H.; Gordiichuk, P.I.; Mannsfeld, S.C.B.; Herrmann, A.; Toney, M.F.; Barbero, D.R. Ultrahigh Mobility in an Organic Semiconductor by Vertical Chain Alignment. Adv. Mater. 2016, 28, 2359–2366. [Google Scholar] [CrossRef]

- Skrypnychuk, V.; Boulanger, N.; Yu, V.; Hilke, M.; Mannsfeld, S.C.B.; Toney, M.F.; Barbero, D.R. Enhanced Vertical Charge Transport in a Semiconducting P3HT Thin Film on Single Layer Graphene. Adv. Funct. Mater. 2015, 25, 664–670. [Google Scholar] [CrossRef]

- Wang, F.; Hashimoto, K.; Segawa, H.; Tajima, K. Effects of Chain Orientation in Self-Organized Buffer Layers Based on Poly(3-Alkylthiophene)s for Organic Photovoltaics. ACS Appl. Mater. Interfaces 2018, 10, 8901–8908. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.; Hashimoto, K.; Koganezawa, T.; Tajima, K. End-On Orientation of Semiconducting Polymers in Thin Films Induced by Surface Segregation of Fluoroalkyl Chains. J. Am. Chem. Soc. 2013, 135, 9644–9647. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.-C.; Chen, S.-Y.; Yang, Y.-W.; Hsu, C.-S.; Tajima, K. Face-on Reorientation of π-Conjugated Polymers in Thin Films by Surface-Segregated Monolayers. J. Mater. Chem. A 2020, 8, 6268–6275. [Google Scholar] [CrossRef]

- Don Park, Y.; Lim, J.A.; Lee, H.S.; Cho, K. Interface Engineering in Organic Transistors. Mater. Today 2007, 10, 46–54. [Google Scholar] [CrossRef]

- Sharma, S.; Vats, A.K.; Tang, L.; Kaishan, F.; Toyoda, J.; Nagamatsu, S.; Ando, Y.; Tamagawa, M.; Tanaka, H.; Pandey, M.; et al. High Field-Effect Mobility in Oriented Thin Films of D-A Type Semiconducting Polymers by Engineering Stable Interfacial System. Chem. Eng. J. 2023, 469, 143932. [Google Scholar] [CrossRef]

- Syafutra, H.; Toyoda, J.; Pandey, M.; Kumari, N.; Benten, H.; Nakamura, M. Perfectness of the Main-Chain Alignment in the Conjugated Polymer Films Prepared by the Floating Film Transfer Method. Appl. Phys. Lett. 2022, 120, 203301. [Google Scholar] [CrossRef]

- DeLongchamp, D.M.; Vogel, B.M.; Jung, Y.; Gurau, M.C.; Richter, C.A.; Kirillov, O.A.; Obrzut, J.; Fischer, D.A.; Sambasivan, S.; Richter, L.J.; et al. Variations in Semiconducting Polymer Microstructure and Hole Mobility with Spin-Coating Speed. Chem. Mater. 2005, 17, 5610–5612. [Google Scholar] [CrossRef]

- Rivnay, J.; Steyrleuthner, R.; Jimison, L.H.; Casadei, A.; Chen, Z.; Toney, M.F.; Facchetti, A.; Neher, D.; Salleo, A. Drastic Control of Texture in a High Performance N-Type Polymeric Semiconductor and Implications for Charge Transport. Macromolecules 2011, 44, 5246–5255. [Google Scholar] [CrossRef]

- Biniek, L.; Leclerc, N.; Heiser, T.; Bechara, R.; Brinkmann, M. Large Scale Alignment and Charge Transport Anisotropy of PBTTT Films Oriented by High Temperature Rubbing. Macromolecules 2013, 46, 4014–4023. [Google Scholar] [CrossRef]

- Kumari, N.; Pandey, M.; Hamada, K.; Hirotani, D.; Nagamatsu, S.; Hayase, S.; Pandey, S.S. Role of Device Architecture and AlOX Interlayer in Organic Schottky Diodes and Their Interpretation by Analytical Modeling. J. Appl. Phys. 2019, 126, 125501. [Google Scholar] [CrossRef]

- Sharma, S.; Nagamatsu, S.; Singh, V.; Pandey, S.S. Facile Fabrication and Characterization of Oriented and Multilayer Thin Films of Solution Processable Conjugated Polymer. Phys. Status Solidi 2023, 220, 2300194. [Google Scholar] [CrossRef]

- Ma, L.; Pyo, S.; Ouyang, J.; Xu, Q.; Yang, Y. Nonvolatile Electrical Bistability of Organic/Metal-Nanocluster/Organic System. Appl. Phys. Lett. 2003, 82, 1419–1421. [Google Scholar] [CrossRef]

- Nagamatsu, S.; Misaki, M.; Chikamatsu, M.; Kimura, T.; Yoshida, Y.; Azumi, R.; Tanigaki, N.; Yase, K. Crystal Structure of Friction-Transferred Poly(2,5-Dioctyloxy-1,4-Phenylenevinylene). J. Phys. Chem. B 2007, 111, 4349–4354. [Google Scholar] [CrossRef]

- Sharma, S.; Vats, A.K.; Pandey, M.; Nagamatsu, S.; Chen, J.-C.; Pandey, S.S. Unraveling the Implications of Macromolecular Orientation on the Planar and Vertical Charge Transport in Organic Electronic Devices. ACS Appl. Polym. Mater. 2022, 4, 8315–8323. [Google Scholar] [CrossRef]

- Sharma, S.; Kumari, N.; Nagamatsu, S.; Nakamura, M.; Pandey, S.S. Bistable Resistive Memory Switches Fabricated by Floating Thin Films of Conjugated Polymers. Mater. Today Electron. 2023, 4, 100043. [Google Scholar] [CrossRef]

- Liu, C.; Li, G.; Di Pietro, R.; Huang, J.; Noh, Y.-Y.; Liu, X.; Minari, T. Device Physics of Contact Issues for the Overestimation and Underestimation of Carrier Mobility in Field-Effect Transistors. Phys. Rev. Appl. 2017, 8, 034020. [Google Scholar] [CrossRef]

- Choi, H.H.; Cho, K.; Frisbie, C.D.; Sirringhaus, H.; Podzorov, V. Critical Assessment of Charge Mobility Extraction in FETs. Nat. Mater. 2018, 17, 2–7. [Google Scholar] [CrossRef]

- Gunduz, B.; Yahia, I.S.; Yakuphanoglu, F. Electrical and Photoconductivity Properties of P-Si/P3HT/Al and p-Si/P3HT:MEH-PPV/Al Organic Devices: Comparison Study. Microelectron. Eng. 2012, 98, 41–57. [Google Scholar] [CrossRef]

- Güllü, Ö.; Aydoğan, Ş.; Türüt, A. High Barrier Schottky Diode with Organic Interlayer. Solid State Commun. 2012, 152, 381–385. [Google Scholar] [CrossRef]

- Kaneto, K.; Takashima, W. Fabrication and Characteristics of Schottky Diodes Based on Regioregular Poly(3-Hexylthiophene)/Al Junction. Curr. Appl. Phys. 2001, 1, 355–361. [Google Scholar] [CrossRef]

- Sze, S.M.; Ng, K.K. Physics of Semiconductor Devices; Wiley: Hoboken, NJ, USA, 2006; ISBN 9780471143239. [Google Scholar]

- Ma, L.P.; Liu, J.; Yang, Y. Organic Electrical Bistable Devices and Rewritable Memory Cells. Appl. Phys. Lett. 2002, 80, 2997–2999. [Google Scholar] [CrossRef]

- Bozano, L.D.; Kean, B.W.; Beinhoff, M.; Carter, K.R.; Rice, P.M.; Scott, J.C. Organic Materials and Thin-Film Structures for Cross-Point Memory Cells Based on Trapping in Metallic Nanoparticles. Adv. Funct. Mater. 2005, 15, 1933–1939. [Google Scholar] [CrossRef]

- Sethuraman, K.; Ochiai, S.; Kojima, K.; Mizutani, T. Performance of Poly(3-Hexylthiophene) Organic Field-Effect Transistors on Cross-Linked Poly(4-Vinyl Phenol) Dielectric Layer and Solvent Effects. Appl. Phys. Lett. 2008, 92, 183302. [Google Scholar] [CrossRef]

- Singh, K.A.; Sauvé, G.; Zhang, R.; Kowalewski, T.; McCullough, R.D.; Porter, L.M. Dependence of Field-Effect Mobility and Contact Resistance on Nanostructure in Regioregular Poly(3-Hexylthiophene) Thin Film Transistors. Appl. Phys. Lett. 2008, 92, 263303. [Google Scholar] [CrossRef]

- Han, T.; Sun, L.; Guo, Y.; Ding, S.; Jin, G.; Jiang, C.; Huang, X.; Zhang, X.; Chang, F. New Strategy for Enhancing Performance of P3HT-Based Organic Field-Effect Transistor via Regulating the Precipitated Speed of Solute in Volatile Solvents. Polym. Test. 2020, 90, 106788. [Google Scholar] [CrossRef]

- Na, J.Y.; Kang, B.; Sin, D.H.; Cho, K.; Park, Y.D. Understanding Solidification of Polythiophene Thin Films during Spin-Coating: Effects of Spin-Coating Time and Processing Additives. Sci. Rep. 2015, 5, 13288. [Google Scholar] [CrossRef]

- Podzorov, V.; Sysoev, S.E.; Loginova, E.; Pudalov, V.M.; Gershenson, M.E. Single-Crystal Organic Field Effect Transistors with the Hole Mobility ~8 cm2/Vs. Appl. Phys. Lett. 2003, 83, 3504–3506. [Google Scholar] [CrossRef]

- Chaudhary, V.; Pandey, R.K.; Prakash, R.; Singh, A.K. Self-Assembled H-Aggregation Induced High Performance Poly (3-Hexylthiophene) Schottky Diode. J. Appl. Phys. 2017, 122, 225501. [Google Scholar] [CrossRef]

- Ferchichi, K.; Pecqueur, S.; Guerin, D.; Bourguiga, R.; Lmimouni, K. High Rectification Ratio in Polymer Diode Rectifier through Interface Engineering with Self-Assembled Monolayer. Electron. Mater. 2021, 2, 445–453. [Google Scholar] [CrossRef]

- Feng, Y.; Gao, X.; Zhong, Y.-N.; Wu, J.-L.; Xu, J.-L.; Wang, S.-D. Solution-Processed Polymer Thin-Film Memristors with an Electrochromic Feature and Frequency-Dependent Synaptic Plasticity. Adv. Intell. Syst. 2019, 1, 1900022. [Google Scholar] [CrossRef]

- Oh, S.; Kim, H.; Kim, S.E.; Kim, M.-H.; Park, H.-L.; Lee, S.-H. Biodegradable and Flexible Polymer-Based Memristor Possessing Optimized Synaptic Plasticity for Eco-Friendly Wearable Neural Networks with High Energy Efficiency. Adv. Intell. Syst. 2023, 5, 2200272. [Google Scholar] [CrossRef]

- Yang, F.; Sun, L.; Duan, Q.; Dong, H.; Jing, Z.; Yang, Y.; Li, R.; Zhang, X.; Hu, W.; Chua, L. Vertical-organic-nanocrystal-arrays for Crossbar Memristors with Tuning Switching Dynamics toward Neuromorphic Computing. SmartMat 2021, 2, 99–108. [Google Scholar] [CrossRef]

- Nguyen, V.C.; Lee, P.S. Coexistence of Write Once Read Many Memory and Memristor in Blend of Poly(3,4-Ethylenedioxythiophene): Polystyrene Sulfonate and Polyvinyl Alcohol. Sci. Rep. 2016, 6, 38816. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sharma, S.; Gaurav, K.V.; Nagamatsu, S.; Pandey, S.S. The Influence of a Microstructural Conformation of Oriented Floating Films of Semiconducting Polymers on Organic Device Performance. Polymers 2024, 16, 710. https://doi.org/10.3390/polym16050710

Sharma S, Gaurav KV, Nagamatsu S, Pandey SS. The Influence of a Microstructural Conformation of Oriented Floating Films of Semiconducting Polymers on Organic Device Performance. Polymers. 2024; 16(5):710. https://doi.org/10.3390/polym16050710

Chicago/Turabian StyleSharma, Shubham, Kumar Vivek Gaurav, Shuichi Nagamatsu, and Shyam S. Pandey. 2024. "The Influence of a Microstructural Conformation of Oriented Floating Films of Semiconducting Polymers on Organic Device Performance" Polymers 16, no. 5: 710. https://doi.org/10.3390/polym16050710

APA StyleSharma, S., Gaurav, K. V., Nagamatsu, S., & Pandey, S. S. (2024). The Influence of a Microstructural Conformation of Oriented Floating Films of Semiconducting Polymers on Organic Device Performance. Polymers, 16(5), 710. https://doi.org/10.3390/polym16050710