Fabrication of High-Performance Densified Wood via High-Pressure Steam Treatment and Hot-Pressing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

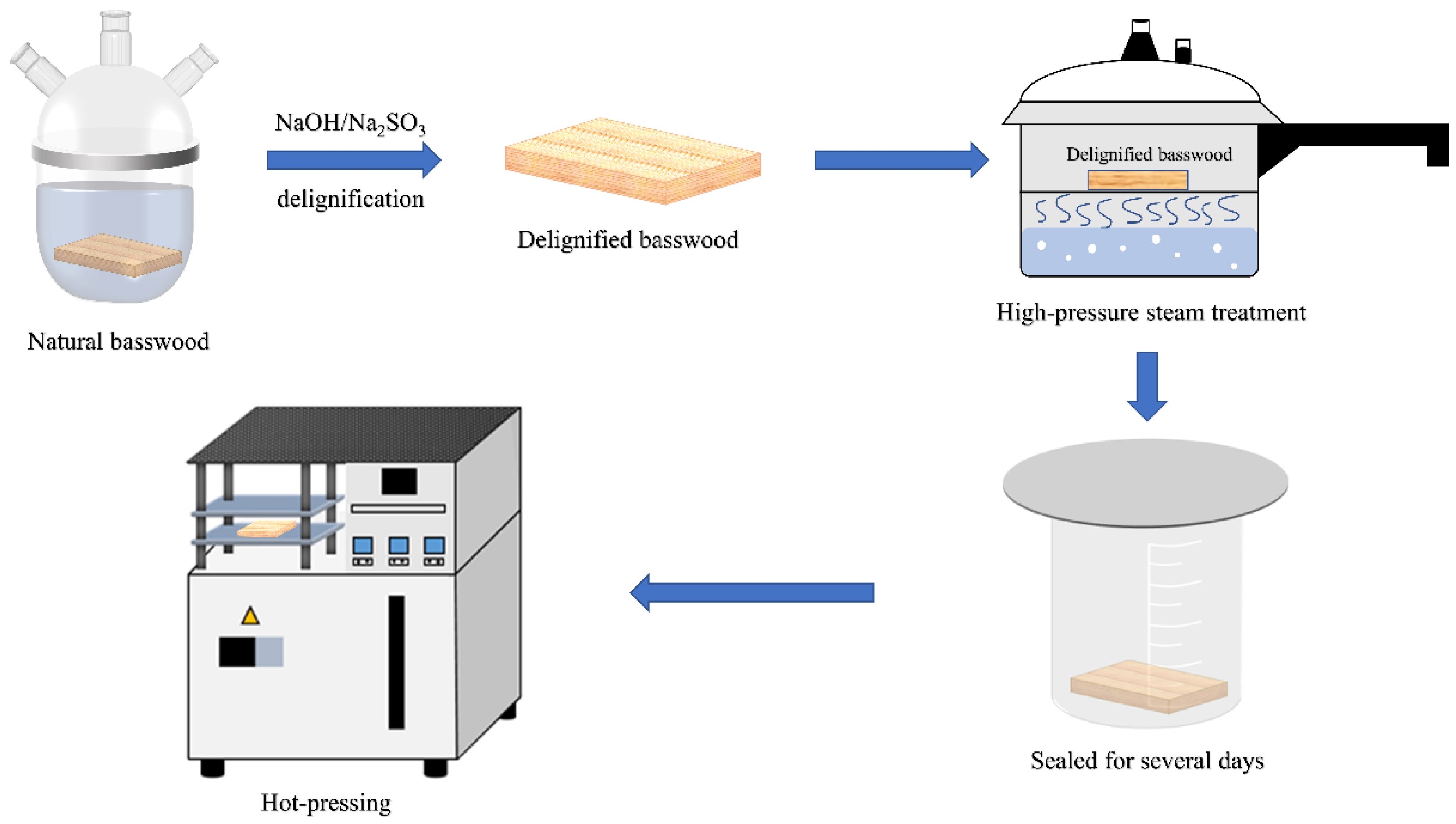

2.2. Methods

2.2.1. Chemical Delignification Procedure

2.2.2. High-Pressure Steam Treatment (HPST)

2.2.3. Densification Procedure

2.3. Measurements

2.3.1. Tensile Strength

2.3.2. Scanning Electron Microscopy Analysis (SEM)

2.3.3. X-ray Diffraction (XRD)

2.3.4. Determination of Lignin, Cellulose, and Hemicellulose Contents

- Lignin

- 2.

- Cellulose and Hemicellulose

3. Results and Discussion

3.1. Effect of Delignification

3.2. Effect of Pressure in Hot-Pressing

3.3. Effect of HPST and Moisture Content

3.4. Morphological Analysis

3.5. Statistical Analysis

3.6. Summary of Enhancement Mechanisms

4. Conclusions

- FTIR analysis and determination of lignin, cellulose, and hemicellulose showed that lignin and hemicellulose were partly removed from basswood after the delignification treatment.

- XRD analysis revealed an increase in the crystallinity of cellulose and a decrease in crystal size after delignification treatment, which indicated that the regular alignment of cellulose was not affected by delignification.

- Removal of lignin made the wood cell wall porous, which had an effect on the tensile strength of HDDW. Moderate removal of lignin resulted in a significant increase in the tensile strength of HDDW, while excessive removal of lignin resulted in a decrease in the tensile strength of HDDW.

- Higher pressure in hot-pressing enhanced the tensile strength of HDDW by shortening the interfacial distance between cellulose fibers, which also changed the number of hydrogen bonds between cellulose fibers. However, excessive pressure led to higher counter pressure from water, which resulted in the fracture of cellulose fibers and a decrease in the tensile strength of HDDW.

- Moisture absorbed by HDDW through HPST could form hydrogen bonds with hydroxyl groups on multiple cellulose molecules during the hot-pressing process, which led to a shorter interfacial distance between cellulose fibers and more hydrogen bonds. Excessive moisture also resulted in higher counter pressure and a decrease in the tensile strength of HDDW.

- The microscopic morphology observed by SEM was consistent with the above conclusions. The cellulose fibers of HDDW were more tightly bonded compared to hot-pressed basswood, which was the source of the high tensile strength of HDDW.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, G.; Chen, C.; Pei, Y.; He, S.; Liu, Y.; Jiang, B.; Jiao, M.; Gan, W.; Liu, D.; Yang, B.; et al. A strong, flame-retardant, and thermally insulating wood laminate. Chem. Eng. J. 2020, 383, 123109. [Google Scholar] [CrossRef]

- Guan, Q.-F.; Yang, H.-B.; Han, Z.-M.; Ling, Z.-C.; Yu, S.-H. An all-natural bioinspired structural material for plastic replacement. Nat. Commun. 2020, 11, 5401. [Google Scholar] [CrossRef] [PubMed]

- Guo, W.; Kalali, E.N.; Wang, X.; Xing, W.; Zhang, P.; Song, L.; Hu, Y. Processing bulk natural bamboo into a strong and flame-retardant composite material. Ind. Crop Prod. 2019, 138, 111478. [Google Scholar] [CrossRef]

- He, S.; Chen, C.; Li, T.; Song, J.; Zhao, X.; Kuang, Y.; Liu, Y.; Pei, Y.; Hitz, E.; Kong, W.; et al. An Energy-Efficient, Wood-Derived Structural Material Enabled by Pore Structure Engineering towards Building Efficiency. Small Methods 2019, 4, 1900747. [Google Scholar] [CrossRef]

- Kumar, A.; Jyske, T.; Petrič, M. Delignified Wood from Understanding the Hierarchically Aligned Cellulosic Structures to Creating Novel Functional Materials: A Review. Adv. Sustain. Syst. 2021, 5, 2000251. [Google Scholar] [CrossRef]

- Guan, Q.F.; Yang, H.B.; Yin, C.H.; Han, Z.M.; Yang, K.P.; Ling, Z.C.; Yu, S.H. Nacre-Inspired Sustainable Coatings with Remarkable Fire-Retardant and Energy-Saving Cooling Performance. ACS Mater. Lett. 2021, 3, 243–248. [Google Scholar] [CrossRef]

- Chen, C.; Li, Z.; Mi, R.; Dai, J.; Xie, H.; Pei, Y.; Li, J.; Qiao, H.; Tang, H.; Yang, B.; et al. Rapid Processing of Whole Bamboo with Exposed, Aligned Nanofibrils toward a High-Performance Structural Material. ACS Nano 2020, 14, 5194–5202. [Google Scholar] [CrossRef] [PubMed]

- Rol, F.; Belgacem, M.N.; Gandini, A.; Bras, J. Recent advances in surface-modified cellulose nanofibrils. Prog. Polym. Sci. 2019, 88, 241–264. [Google Scholar] [CrossRef]

- Guan, Q.-F.; Han, Z.-M.; Yang, H.-B.; Ling, Z.-C.; Yu, S.-H. Regenerated isotropic wood. Natl. Sci. Rev. 2021, 8, nwaa230. [Google Scholar] [CrossRef]

- Guan, Q.-F.; Yang, H.-B.; Han, Z.-M.; Ling, Z.-C.; Yang, K.-P.; Yin, C.-H.; Yu, S.-H. Plant Cellulose Nanofiber-Derived Structural Material with High-Density Reversible Interaction Networks for Plastic Substitute. Nano Lett. 2021, 21, 8999–9004. [Google Scholar] [CrossRef]

- Li, Z.; Chen, C.; Xie, H.; Yao, Y.; Zhang, X.; Brozena, A.; Li, J.; Ding, Y.; Zhao, X.; Hong, M.; et al. Sustainable high-strength macrofibres extracted from natural bamboo. Nat. Sustain. 2021, 5, 235–244. [Google Scholar] [CrossRef]

- Li, Z.; Chen, C.; Mi, R.; Gan, W.; Dai, J.; Jiao, M.; Xie, H.; Yao, Y.; Xiao, S.; Hu, L. A Strong, Tough, and Scalable Structural Material from Fast-Growing Bamboo. Adv. Mater. 2020, 32, e1906308. [Google Scholar] [CrossRef] [PubMed]

- Golzar, M.; Ghaderi, A. Effect of temperature on the spring back of cellulose-based sheet in hot pressing. Int. J. Adv. Manuf. Technol. 2008, 42, 633–642. [Google Scholar] [CrossRef]

- Kariz, M.; Kuzman, M.K.; Sernek, M.; Hughes, M.; Rautkari, L.; Kamke, F.A.; Kutnar, A. Influence of temperature of thermal treatment on surface densification of spruce. Eur. J. Wood Wood Prod. 2016, 75, 113–123. [Google Scholar] [CrossRef]

- Kiaei, M.; Rad, M.B.; Amani, N. Influence of Densification Temperature on Some Physical and Mechanical Properties of Pterocarya Fraxinifolia Wood. Drv. Ind. 2018, 69, 283–287. [Google Scholar] [CrossRef]

- Xiao, L.; Ding, Y.; Yan, G. Effect of hot-pressing temperature on characteristics of alkali pretreated reed straw bio-board. J. Wood Chem. Technol. 2021, 41, 160–168. [Google Scholar] [CrossRef]

- Wehsener, J.; Brischke, C.; Meyer-Veltrup, L.; Hartig, J.; Haller, P. Physical, mechanical and biological properties of thermo-mechanically densified and thermally modified timber using the Vacu3-process. Eur. J. Wood Wood Prod. 2017, 76, 809–821. [Google Scholar] [CrossRef]

- Navi, P.; Heger, F. Combined Densification and Thermo-Hydro-Mechanical Processing of Wood. MRS Bull. 2004, 29, 332–336. [Google Scholar] [CrossRef]

- Navi, P.; Pizzi, A. Property changes in thermo-hydro-mechanical processing. Holzforschung 2015, 69, 863–873. [Google Scholar] [CrossRef]

- Sandberg, D.; Haller, P.; Navi, P. Thermo-hydro and thermo-hydro-mechanical wood processing: An opportunity for future environmentally friendly wood products. Wood Mater. Sci. Eng. 2013, 8, 64–88. [Google Scholar] [CrossRef]

- Frey, M.; Widner, D.; Segmehl, J.S.; Casdorff, K.; Keplinger, T.; Burgert, I. Delignified and Densified Cellulose Bulk Materials with Excellent Tensile Properties for Sustainable Engineering. ACS Appl. Mater. Interfaces 2018, 10, 5030–5037. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Leiste, U.H.; Fourney, W.L.; Liu, Y.; Chen, Q.; Li, T. Hardened wood as a renewable alternative to steel and plastic. Matter 2021, 4, 3941–3952. [Google Scholar] [CrossRef]

- Li, Y.; Fu, Q.; Yu, S.; Yan, M.; Berglund, L. Optically Transparent Wood from a Nanoporous Cellulosic Template: Combining Functional and Structural Performance. Biomacromolecules 2016, 17, 1358–1364. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Pang, Z.; Chen, C.; Xia, Q.; Zhou, Y.; Jing, S.; Wang, R.; Ray, U.; Gan, W.; Li, C.; et al. All-Natural, Degradable, Rolled-Up Straws Based on Cellulose Micro- and Nano-Hybrid Fibers. Adv. Funct. Mater. 2020, 30, 1910417. [Google Scholar] [CrossRef]

- Keplinger, T.; Wittel, F.K.; Rüggeberg, M.; Burgert, I. Wood Derived Cellulose Scaffolds-Processing and Mechanics. Adv. Mater. 2021, 33, e2001375. [Google Scholar] [CrossRef] [PubMed]

- ISO 527-1:2012; Plastics—Determination of Tensile Properties—Part 1: General Principles. CEN: Oak Brook, IL, USA, 2012; 34p, A4.

- Segal, L.G.J.M.A.; Creely, J.J.; Martin, A.E., Jr.; Conrad, C.M. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-ray Diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Chen, C.; Kuang, Y.; Zhu, S.; Burgert, I.; Keplinger, T.; Gong, A.; Li, T.; Berglund, L.; Eichhorn, S.J.; Hu, L. Structure–property–function relationships of natural and engineered wood. Nat. Rev. Mater. 2020, 5, 642–666. [Google Scholar] [CrossRef]

- Chen, C.; Wang, L.; Bu, X.; Feng, Q.; Li, S.; Xu, Z.; Li, D. Construction of high-strength aligned bamboo fibre/high density polyethylene composites. Mater. Today Commun. 2023, 34, 105037. [Google Scholar] [CrossRef]

- da Silveira, P.H.; Santos, M.C.; Chaves, Y.S.; Ribeiro, M.P.; Marchi, B.Z.; Monteiro, S.N.; Gomes, A.V.; Tapanes, N.D.; Pereira, P.S.; Bastos, D.C. Characterization of Thermo-Mechanical and Chemical Properties of Polypropylene/Hemp Fiber Biocomposites: Impact of Maleic Anhydride Compatibilizer and Fiber Content. Polymers 2023, 15, 3271. [Google Scholar] [CrossRef]

- Shi, J.; Peng, J.; Huang, Q.; Cai, L.; Shi, S.Q. Fabrication of densified wood via synergy of chemical pretreatment, hot-pressing and post mechanical fixation. J. Wood Sci. 2020, 66, 5. [Google Scholar] [CrossRef]

- Oliaei, E.; Berthold, F.; Berglund, L.A.; Lindström, T. Eco-Friendly High-Strength Composites Based on Hot-Pressed Lignocellulose Microfibrils or Fibers. ACS Sustain. Chem. Eng. 2021, 9, 1899–1910. [Google Scholar] [CrossRef]

- Luo, H.; Si, R.; Liu, J.; Li, P.; Tao, Y.; Zhao, X.; Chen, H. Preparing the reinforced wood via embedding cellulose nanocrystals (CNC) into delignified fast-growing wood followed by densification. Cellulose 2022, 29, 7377–7396. [Google Scholar] [CrossRef]

- Reiniati, I.; Osman, N.B.; Mc Donald, A.G.; Laborie, M.P. Linear viscoelasticity of hot-pressed hybrid poplar relates to densification and to the in situ molecular parameters of cellulose. Ann. For. Sci. 2014, 72, 693–703. [Google Scholar] [CrossRef]

- Laine, K.; Segerholm, K.; Wålinder, M.; Rautkari, L.; Hughes, M. Wood densification and thermal modification: Hardness, set-recovery and micromorphology. Wood Sci. Technol. 2016, 50, 883–894. [Google Scholar] [CrossRef]

- Liu, H.; Shang, J.; Chen, X.; Kamke, F.A.; Guo, K. The influence of thermal-hydro-mechanical processing on chemical characterization of Tsuga heterophylla. Wood Sci. Technol. 2013, 48, 373–392. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, M.; Lu, Z.; Jia, W. Hot pressing technology investigation of light-weight wooden brick. Constr. Build. Mater. 2020, 265, 120426. [Google Scholar] [CrossRef]

- Fang, C.-H.; Mariotti, N.; Cloutier, A.; Koubaa, A.; Blanchet, P. Densification of wood veneers by compression combined with heat and steam. Eur. J. Wood Wood Prod. 2011, 70, 155–163. [Google Scholar] [CrossRef]

- Yin, J.; Yuan, T.; Lu, Y.; Song, K.; Li, H.; Zhao, G.; Yin, Y. Effect of compression combined with steam treatment on the porosity, chemical compositon and cellulose crystalline structure of wood cell walls. Carbohydr. Polym. 2017, 155, 163–172. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Ye, Y.; Lam, F.; Pu, J.; Jiang, F. Hydrogen-bonding-induced assembly of aligned cellulose nanofibers into ultrastrong and tough bulk materials. J. Mater. Chem. A 2019, 7, 27023–27031. [Google Scholar] [CrossRef]

- Song, J.; Chen, C.; Zhu, S.; Zhu, M.; Dai, J.; Ray, U.; Li, Y.; Kuang, Y.; Li, Y.; Quispe, N.; et al. Processing bulk natural wood into a high-performance structural material. Nature 2018, 554, 224–228. [Google Scholar] [CrossRef]

- Han, X.; Wang, Z.; Ding, L.; Chen, L.; Wang, F.; Pu, J.; Jiang, S. Water molecule-induced hydrogen bonding between cellulose nanofibers toward highly strong and tough materials from wood aerogel. Chin. Chem. Lett. 2021, 32, 3105–3108. [Google Scholar] [CrossRef]

- Hou, J.; Yi, S.; Zhou, Y.; Pan, B. Moisture state variety in poplar lumber with moisture content above fibre saturation point during hot-press drying. J. Wood Sci. 2018, 64, 730–737. [Google Scholar] [CrossRef]

| Wavenumber (cm−1) | Functional Group | Corresponding Compound |

| 3430 | Stretching vibration of OH | Cellulose |

| 2920 | Stretching vibration of CH | Cellulose |

| 2850 | Stretching vibration of CH2 | Hemicellulose |

| 1740 | Stretching vibration of C=O | Hemicellulose |

| 1508 | Aromatic symmetrical stretching vibration of C=C | Lignin |

| 1463 1374 | Bending vibration of CH2 Bending vibration of CH | Lignin Cellulose, hemicellulose |

| 1238 | Stretching vibration of C-O in C-C=O | Hemicellulose |

| 1028 | Stretching vibration of C-O in C-O-C | Lignin |

| Untreated Basswood (Mean ± SD) | Delignified Basswood (Mean ± SD) | |

|---|---|---|

| CrI | 86.02 ± 0.64% | 88.36 ± 0.56% |

| Dhkl (200) | 30.37 ± 0.32 Å | 26.22 ± 0.54 Å |

| Source of Variation | Degree of Freedom | Sum of Squares | Mean Squares | F | F Critical | p-Value |

|---|---|---|---|---|---|---|

| Vin | 6 | 153,102 | 25,517 | 49.89 | 2.35 | 0.00000 |

| Vbetween | 38 | 19,436 | 511 | |||

| Total | 44 | 172,538 |

| Source of Variation | Degree of Freedom | Sum of Squares | Mean Squares | F | F Critical | p-Value |

|---|---|---|---|---|---|---|

| Vin | 3 | 19,717 | 6572 | 13.84 | 3.07 | 0.00003 |

| Vbetween | 21 | 9974 | 475 | |||

| Total | 24 | 29,691 |

| Source of Variation | Degree of Freedom | Sum of Squares | Mean Squares | F | F Critical | p-Value |

|---|---|---|---|---|---|---|

| Vin | 5 | 393,388 | 78,678 | 300.68 | 2.51 | 0.00000 |

| Vbetween | 32 | 8373 | 262 | |||

| Total | 37 | 401,761 |

| Source of Variation | Degree of Freedom | Sum of Squares | Mean Squares | F | F Critical | p-Value |

|---|---|---|---|---|---|---|

| Vin | 1 | 15,947 | 15,947 | 27.34 | 4.74 | 0.00021 |

| Vbetween | 12 | 6998 | 583 | |||

| Total | 13 | 22,945 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, W.; Jin, Y.; Guo, Y.; Deng, J.; Yu, H.; He, B. Fabrication of High-Performance Densified Wood via High-Pressure Steam Treatment and Hot-Pressing. Polymers 2024, 16, 939. https://doi.org/10.3390/polym16070939

Huang W, Jin Y, Guo Y, Deng J, Yu H, He B. Fabrication of High-Performance Densified Wood via High-Pressure Steam Treatment and Hot-Pressing. Polymers. 2024; 16(7):939. https://doi.org/10.3390/polym16070939

Chicago/Turabian StyleHuang, Weizhi, Yangxi Jin, Yi Guo, Jiaqi Deng, Haoyang Yu, and Bobing He. 2024. "Fabrication of High-Performance Densified Wood via High-Pressure Steam Treatment and Hot-Pressing" Polymers 16, no. 7: 939. https://doi.org/10.3390/polym16070939