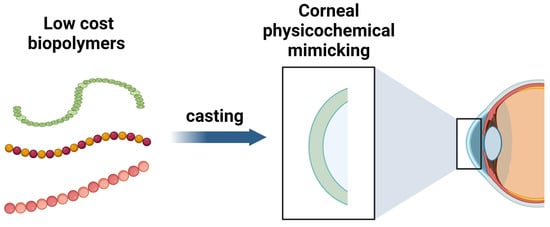

Mimicking the Physicochemical Properties of the Cornea: A Low-Cost Approximation Using Highly Available Biopolymers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Hydrogel Preparation

2.3. Hydrogel-Swelling Determination

2.4. Characterization

2.4.1. Fourier Transform Infrared (FTIR) Spectroscopy

2.4.2. Simultaneous Thermal Analysis (STA)

2.4.3. Optical Properties

2.4.4. pH and Enzymatic Degradation

2.5. Cytocompatibility Evaluation

3. Results and Discussion

3.1. Reagent Selection and Hydrogel Preparation

3.2. Hydrogel Swelling

3.3. Hydrogel FTIR Molecular Analysis

3.4. Hydrogel Optical Properties

3.5. Hydrogel Thermal Stability Analysis

3.6. Hydrogel Degradation

3.7. Hydrogel Cytocompatibility

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Levin, L.A.; Nilsson, S.F.; Ver Hoeve, J.; Wu, S.; Kaufman, P.L.; Alm, A. Adler’s Physiology of the Eye E-Book: Expert Consult-Online and Print; Elsevier Health Sciences: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Mathews, P.M.; Lindsley, K.; Aldave, A.J.; Akpek, E.K. Etiology of Global Corneal Blindness and Current Practices of Corneal Transplantation: A Focused Review. Cornea 2018, 37, 1198–1203. [Google Scholar] [CrossRef] [PubMed]

- Porth, J.M.; Deiotte, E.; Dunn, M.; Bashshur, R. A Review of the Literature on the Global Epidemiology of Corneal Blindness. Cornea 2019, 38, 1602–1609. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization. World Report on Vision; World Health Organization: Geneva, Switzerland, 2019.

- Eckert, K.A.; Carter, M.J.; Lansingh, V.C.; Wilson, D.A.; Furtado, J.M.; Frick, K.D.; Resnikoff, S. A Simple Method for Estimating the Economic Cost of Productivity Loss Due to Blindness and Moderate to Severe Visual Impairment. Ophthalmic Epidemiol. 2015, 22, 349–355. [Google Scholar] [CrossRef] [PubMed]

- Tran, B.; Global Burden of Disease Cancer Collaboration. Global, regional, and national incidence, prevalence, and years lived with disability for 354 diseases and injuries for 195 countries and territories, 1990–2017: A systematic analysis for the Global Burden of Disease Study 2017. Lancet 2018, 392, 1789–1858. [Google Scholar]

- Chuck, R.S.; Jacobs, D.S.; Lee, J.K.; Afshari, N.A.; Vitale, S.; Shen, T.T.; Keenan, J.D. Refractive Errors & Refractive Surgery Preferred Practice Pattern®. Ophthalmology 2018, 125, 1–104. [Google Scholar]

- Vincent, S.J.; Fadel, D. Optical considerations for scleral contact lenses: A review. Contact Lens Anterior Eye 2019, 42, 598–613. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Ng, S.M.; Akpek, E.K.; Ahmad, S. Artificial corneas versus donor corneas for repeat corneal transplants. Cochrane Database Syst. Rev. 2020, 5, Cd009561. [Google Scholar]

- Avadhanam, V.S.; Smith, H.E.; Liu, C. Keratoprostheses for corneal blindness: A review of contemporary devices. Clin. Ophthalmol. 2015, 9, 697–720. [Google Scholar] [CrossRef] [PubMed]

- Ortiz-Morales, G.; Loya-Garcia, D.; Colorado-Zavala, M.F.; Gomez-Elizondo, D.E.; Soifer, M.; Srinivasan, B.; Agarwal, S.; Rodríguez-Garcia, A.; Perez, V.L.; Amescua, G.; et al. The evolution of the modified osteo-odonto-keratoprosthesis, its reliability, and long-term visual rehabilitation prognosis: An analytical review. Ocul. Surf. 2022, 24, 129–144. [Google Scholar] [CrossRef]

- Kaur, J. Osteo-odonto keratoprosthesis: Innovative dental and ophthalmic blending. J. Indian Prosthodont. Soc. 2018, 18, 89–95. [Google Scholar] [CrossRef]

- Iannetti, L.; Liberali, M.; Armentano, M.; Alisi, L.; Visioli, G.; Mastromarino, D.; Brauner, E.; Iannetti, G. Osteo-odonto-keratoprosthesis According to Strampelli Original Technique: A Retrospective Study with Up to 30 Years of Follow-up. Am. J. Ophthalmol. 2022, 242, 56–68. [Google Scholar] [CrossRef] [PubMed]

- Fagerholm, P.; Lagali, N.S.; Carlsson, D.J.; Merrett, K.; Griffith, M. Corneal regeneration following implantation of a biomimetic tissue-engineered substitute. Clin. Transl. Sci. 2009, 2, 162–164. [Google Scholar] [CrossRef] [PubMed]

- Jirásková, N.; Rozsival, P.; Burova, M.; Kalfertova, M. AlphaCor artificial cornea: Clinical outcome. Eye 2011, 25, 1138–1146. [Google Scholar] [CrossRef] [PubMed]

- Khosravimelal, S.; Mobaraki, M.; Eftekhari, S.; Ahearne, M.; Seifalian, A.M.; Gholipourmalekabadi, M. Hydrogels as Emerging Materials for Cornea Wound Healing. Small 2021, 17, e2006335. [Google Scholar] [CrossRef]

- Borene, M.L.; Barocas, V.H.; Hubel, A. Mechanical and Cellular Changes During Compaction of a Collagen-Sponge-Based Corneal Stromal Equivalent. Ann. Biomed. Eng. 2004, 32, 274–283. [Google Scholar] [CrossRef] [PubMed]

- Crabb, R.A.; Hubel, A. Influence of matrix processing on the optical and biomechanical properties of a corneal stroma equivalent. Tissue Eng. Part A 2008, 14, 173–182. [Google Scholar] [CrossRef] [PubMed]

- Kong, B.; Mi, S. Electrospun Scaffolds for Corneal Tissue Engineering: A Review. Materials 2016, 9, 614. [Google Scholar] [CrossRef] [PubMed]

- Sklenářová, R.; Akla, N.; Latorre, M.J.; Ulrichová, J.; Franková, J. Collagen as a Biomaterial for Skin and Corneal Wound Healing. J. Funct. Biomater. 2022, 13, 249. [Google Scholar] [CrossRef] [PubMed]

- Lai, J.-Y. Corneal Stromal Cell Growth on Gelatin/Chondroitin Sulfate Scaffolds Modified at Different NHS/EDC Molar Ratios. Int. J. Mol. Sci. 2013, 14, 2036–2055. [Google Scholar] [CrossRef]

- Rose, J.B.; Pacelli, S.; Haj, A.J.E.; Dua, H.S.; Hopkinson, A.; White, L.J.; Rose, F.R.A.J. Gelatin-Based Materials in Ocular Tissue Engineering. Materials 2014, 7, 3106–3135. [Google Scholar] [CrossRef]

- Bray, L.J.; George, K.A.; Hutmacher, D.W.; Chirila, T.V.; Harkin, D.G. A dual-layer silk fibroin scaffold for reconstructing the human corneal limbus. Biomaterials 2012, 33, 3529–3538. [Google Scholar] [CrossRef] [PubMed]

- Jangamreddy, J.R.; Haagdorens, M.K.C.; Mirazul Islam, M.; Lewis, P.; Samanta, A.; Fagerholm, P.; Liszka, A.; Ljunggren, M.K.; Buznyk, O.; Alarcon, E.I.; et al. Short peptide analogs as alternatives to collagen in pro-regenerative corneal implants. Acta Biomater. 2018, 69, 120–130. [Google Scholar] [CrossRef] [PubMed]

- Shafiq, M.A.; Gemeinhart, R.A.; Yue, B.Y.; Djalilian, A.R. Decellularized human cornea for reconstructing the corneal epithelium and anterior stroma. Tissue Eng. Part C Methods 2012, 18, 340–348. [Google Scholar] [CrossRef] [PubMed]

- Hashimoto, Y.; Hattori, S.; Sasaki, S.; Honda, T.; Kimura, T.; Funamoto, S.; Kobayashi, H.; Kishida, A. Ultrastructural analysis of the decellularized cornea after interlamellar keratoplasty and microkeratome-assisted anterior lamellar keratoplasty in a rabbit model. Sci. Rep. 2016, 6, 27734. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.M.; Ravichandran, R.; Olsen, D.; Ljunggren, M.K.; Fagerholm, P.; Lee, C.J.; Griffith, M.; Phopase, J. Self-assembled collagen-like-peptide implants as alternatives to human donor corneal transplantation. RSC Adv. 2016, 6, 55745–55749. [Google Scholar] [CrossRef]

- Fertala, A. Three Decades of Research on Recombinant Collagens: Reinventing the Wheel or Developing New Biomedical Products? Bioengineering 2020, 7, 155. [Google Scholar] [CrossRef] [PubMed]

- Paredes-Puerto, A.; Camacho-Villegas, T.; Vallejo-Cardona, A.; Esquivel-Solís, H. Colágenas recombinantes para andamios de ingeniería de tejidos. Rev. Mex. Ing. Biomédica 2017, 38, 103–114. [Google Scholar] [CrossRef]

- Bonato, P.; Bagno, A. Replace or Regenerate? Diverse Approaches to Biomaterials for Treating Corneal Lesions. Biomimetics 2024, 9, 202. [Google Scholar] [CrossRef]

- Lukin, I.; Erezuma, I.; Maeso, L.; Zarate, J.; Desimone, M.F.; Al-Tel, T.H.; Dolatshahi-Pirouz, A.; Orive, G. Progress in Gelatin as Biomaterial for Tissue Engineering. Pharmaceutics 2022, 14, 1177. [Google Scholar] [CrossRef]

- Kim, Y.H.; Baek, N.S.; Han, Y.H.; Chung, M.A.; Jung, S.D. Enhancement of neuronal cell adhesion by covalent binding of poly-D-lysine. J. Neurosci. Methods 2011, 202, 38–44. [Google Scholar] [CrossRef]

- Ye, R.; Liu, S.; Zhu, W.; Li, Y.; Huang, L.; Zhang, G.; Zhang, Y. Synthesis, Characterization, Properties, and Biomedical Application of Chitosan-Based Hydrogels. Polymers 2023, 15, 2482. [Google Scholar] [CrossRef] [PubMed]

- El Merhie, A.; Salerno, M.; Heredia-Guerrero, J.A.; Dante, S. Graphene-enhanced differentiation of neuroblastoma mouse cells mediated by poly-D-lysine. Colloids Surf. B Biointerfaces 2020, 191, 110991. [Google Scholar] [CrossRef]

- Farris, S.; Song, J.; Huang, Q. Alternative Reaction Mechanism for the Cross-Linking of Gelatin with Glutaraldehyde. J. Agric. Food Chem. 2010, 58, 998–1003. [Google Scholar] [CrossRef]

- Echave, C.M.; Saenz del Burgo, L.; Pedraz, L.J.; Orive, G. Gelatin as Biomaterial for Tissue Engineering. Curr. Pharm. Des. 2017, 23, 3567–3584. [Google Scholar] [CrossRef]

- Jagga, S.; Hasnain, M.S.; Nayak, A.K. Chapter 14—Chitosan-based scaffolds in tissue engineering and regenerative medicine. In Chitosan in Biomedical Applications; Hasnain, M.S., Beg, S., Nayak, A.K., Eds.; Academic Press: Cambridge, MA, USA, 2022. [Google Scholar]

- Hendler, R.M.; Weiss, O.E.; Morad, T.; Sion, G.; Kirby, M.; Dubinsky, Z.; Barbora, A.; Minnes, R.; Baranes, D. A Poly-D-lysine-Coated Coralline Matrix Promotes Hippocampal Neural Precursor Cells’ Differentiation into GFAP-Positive Astrocytes. Polymers 2023, 15, 4054. [Google Scholar] [CrossRef] [PubMed]

- Zarrintaj, P.; Ghorbani, S.; Barani, M.; Singh Chauhan, N.P.; Khodadadi Yazdi, M.; Saeb, M.R.; Ramsey, J.D.; Hamblin, M.R.; Mozafari, M.; Mostafavi, E. Polylysine for skin regeneration: A review of recent advances and future perspectives. Bioeng. Transl. Med. 2022, 7, e10261. [Google Scholar] [CrossRef]

- Bonanno, J.A.; Srinivas, S.P. Regulation of Corneal Endothelial Function. In Encyclopedia of the Eye; Dartt, D.A., Ed.; Academic Press: Oxford, UK, 2010. [Google Scholar]

- Costagliola, C.; Romano, V.; Forbice, E.; Angi, M.; Pascotto, A.; Boccia, T.; Semeraro, F. Corneal oedema and its medical treatment. Clin. Exp. Optom. 2013, 96, 529–535. [Google Scholar] [CrossRef]

- Gibney, R.; Matthyssen, S.; Patterson, J.; Ferraris, E.; Zakaria, N. The Human Cornea as a Model Tissue for Additive Biomanufacturing: A Review. Procedia CIRP 2017, 65, 56–63. [Google Scholar] [CrossRef]

- Anicuta, S.-G.; Dobre, L.; Stroescu, M.; Jipa, I. Fourier transform infrared (FTIR) spectroscopy for characterization of antimicrobial films containing chitosan. Analele Univ. Ńii Din Oradea Fasc. Ecotoxicologie Zooteh. Şi Tehnol. De Ind. Aliment. 2010, 2010, 1234–1240. [Google Scholar]

- Heras-Mozos, R.; López-Carballo, G.; Hernández, R.; Gavara, R.; Hernández Muñoz, P. pH modulates antibacterial activity of hydroxybenzaldehyde derivatives immobilized in chitosan films via reversible Schiff bases and its application to preserve freshly-squeezed juice. Food Chem. 2023, 403, 134292. [Google Scholar] [CrossRef]

- Migneault, I.; Dartiguenave, C.; Bertrand, M.J.; Waldron, K.C. Glutaraldehyde: Behavior in aqueous solution, reaction with proteins, and application to enzyme crosslinking. Biotechniques 2004, 37, 790–796, 798–802. [Google Scholar] [CrossRef] [PubMed]

- Boettner, E.A.; Wolter, J.R. Transmission of the Ocular Media. Investig. Ophthalmol. Vis. Sci. 1962, 1, 776–783. [Google Scholar]

- Peris-Martínez, C.; García-Domene, M.C.; Penadés, M.; Luque, M.J.; Fernández-López, E.; Artigas, J.M. Spectral Transmission of the Human Corneal Layers. J. Clin. Med. 2021, 10, 4490. [Google Scholar] [CrossRef] [PubMed]

- Patel, S.; Tutchenko, L. The refractive index of the human cornea: A review. Cont Lens Anterior Eye 2019, 42, 575–580. [Google Scholar] [CrossRef] [PubMed]

- Salles, T.H.C.; Lombello, C.B.; d’Ávila, M.A. Electrospinning of Gelatin/Poly (Vinyl Pyrrolidone) Blends from Water/Acetic Acid Solutions. Mater. Res. 2015, 18, 509–518. [Google Scholar] [CrossRef]

- Chiriac, R.; Toche, F.; Boyron, O. Chapter 8—Calorimetry and thermal analysis for the study of polymer properties. In Thermal Analysis and Calorimetry; Aline, A., Ljiljana, D.-V., Eds.; De Gruyter: Berlin, Germany, 2023. [Google Scholar]

- Gutiérrez-Gutiérrez, M.I.; Morales-Mendivelso, D.F.; Muvdi-Nova, C.-J.; Chaves-Guerrero, A. Síntesis y caracterización de membranas híbridas a partir de quitosan, polivinil alcohol y sílice para su aplicación en deshidratación de gases. Iteckne 2015, 12, 33–43. [Google Scholar] [CrossRef][Green Version]

- Martin, J.R.; Gupta, M.K.; Page, J.M.; Yu, F.; Davidson, J.M.; Guelcher, S.A.; Duvall, C.L. A porous tissue engineering scaffold selectively degraded by cell-generated reactive oxygen species. Biomaterials 2014, 35, 3766–3776. [Google Scholar] [CrossRef] [PubMed]

- Hynes, C.G.; Morra, E.; Walsh, P.; Buchanan, F. Chapter 7—Degradation of biomaterials. In Tissue Engineering, 3rd ed.; De Boer, J., Blitterswijk, C.A.V., Uquillas, J.A., Malik, N., Eds.; Academic Press: Cambridge, MA, USA, 2023. [Google Scholar]

- Abelson, M.B.; Udell, I.J.; Weston, J.H. Normal Human Tear pH by Direct Measurement. Arch. Ophthalmol. 1981, 99, 301. [Google Scholar] [CrossRef] [PubMed]

- Quade, B.N.; Marshall, A.; Parker, M.D. Loss of vision caused by an alkaline shift in the pH-dependence of the corneal H+/OH−-conducting membrane protein Slc4a11. Biophys. J. 2023, 122, 519a. [Google Scholar] [CrossRef]

- Doughty, M.J.; Bergmanson, J.P.G. Use of a Corneal Stroma Perfusion Technique and Transmission Electron Microscopy to Assess Ultrastructural Changes Associated with Exposure to Slightly Acidic pH 5.75 Solutions. Curr. Eye Res. 2008, 33, 45–57. [Google Scholar] [CrossRef]

- Loukovitis, E.; Kozeis, N.; Gatzioufas, Z.; Kozei, A.; Tsotridou, E.; Stoila, M.; Koronis, S.; Sfakianakis, K.; Tranos, P.; Balidis, M.; et al. The Proteins of Keratoconus: A Literature Review Exploring Their Contribution to the Pathophysiology of the Disease. Adv. Ther. 2019, 36, 2205–2222. [Google Scholar] [CrossRef] [PubMed]

- Girard, M.T.; Matsubara, M.; Fini, M.E. Transforming growth factor-beta and interleukin-1 modulate metalloproteinase expression by corneal stromal cells. Investig. Ophthalmol. Vis. Sci. 1991, 32, 2441–2454. [Google Scholar]

- Tanaka, I.; Nishinomiya, R.; Goto, R.; Shimazaki, S.; Chatake, T. Recent structural insights into the mechanism of lysozyme hydrolysis. Acta Crystallogr. Sect. D Struct. Biol. 2021, 77, 288–292. [Google Scholar] [CrossRef]

- Roman, D.L.; Ostafe, V.; Isvoran, A. Deeper inside the specificity of lysozyme when degrading chitosan. A structural bioinformatics study. J. Mol. Graph. Model. 2020, 100, 107676. [Google Scholar] [CrossRef] [PubMed]

- Andrea, L.; Marica, I.; Anamarija, R. Lysozyme-Induced Degradation of Chitosan: The Characterisation of Degraded Chitosan Scaffolds. J. Tissue Repair Regen. 2017, 1, 12–22. [Google Scholar]

- Rennie, I.G.; Parsons, M.A. Lysozyme distribution in human lacrimal glands and other ocular adnexa. Arch. Ophthalmol. 1981, 99, 1850–1853. [Google Scholar] [CrossRef] [PubMed]

- Romo-Valera, C.; Guerrero, P.; Arluzea, J.; Etxebarria, J.; de la Caba, K.; Andollo, N. Cytocompatibility and Suitability of Protein-Based Biomaterials as Potential Candidates for Corneal Tissue Engineering. Int. J. Mol. Sci. 2021, 22, 3648. [Google Scholar] [CrossRef]

- Deshpande, P.; McKean, R.; Blackwood, K.A.; Senior, R.A.; Ogunbanjo, A.; Ryan, A.J.; MacNeil, S. Using poly(lactide-co-glycolide) electrospun scaffolds to deliver cultured epithelial cells to the cornea. Regen. Med. 2010, 5, 395–401. [Google Scholar] [CrossRef]

- Braccini, S.; Pecorini, G.; Chiellini, F.; Bakos, D.; Miertus, S.; Frecer, V. Adhesion of fibroblast cells on thin films representing surfaces of polymeric scaffolds of human urethra rationalized by molecular models of integrin binding: Cell adhesion on polymeric scaffolds for regenerative medicine. J. Biotechnol. 2020, 324, 233–238. [Google Scholar] [CrossRef]

- Wilson, S.E. Corneal wound healing. Exp. Eye Res. 2020, 197, 108089. [Google Scholar] [CrossRef]

- Bogdanov, M.; Pyrshev, K.; Yesylevskyy, S.; Ryabichko, S.; Boiko, V.; Ivanchenko, P.; Kiyamova, R.; Guan, Z.; Ramseyer, C.; Dowhan, W. Phospholipid distribution in the cytoplasmic membrane of Gram-negative bacteria is highly asymmetric, dynamic, and cell shape-dependent. Sci. Adv. 2020, 6, eaaz6333. [Google Scholar] [CrossRef] [PubMed]

- Stil, A.; Liberelle, B.; Guadarrama Bello, D.; Lacomme, L.; Arpin, L.; Parent, P.; Nanci, A.; Dumont, É.C.; Ould-Bachir, T.; Vanni, M.P.; et al. A simple method for poly-D-lysine coating to enhance adhesion and maturation of primary cortical neuron cultures in vitro. Front. Cell. Neurosci. 2023, 17, 1212097. [Google Scholar] [CrossRef] [PubMed]

- Faussner, A.; Deininger, M.M.; Weber, C.; Steffens, S. Direct addition of poly-lysine or poly-ethylenimine to the medium: A simple alternative to plate pre-coating. PLoS ONE 2022, 17, e0260173. [Google Scholar] [CrossRef] [PubMed]

- Ratanavaraporn, J.; Damrongsakkul, S.; Sanchavanakit, N.; Banaprasert, T.; Kanokpanont, S. Comparison of gelatin and collagen scaffolds for fibroblast cell culture. J. Met. Mater. Miner. 2017, 16, 31–36. [Google Scholar]

- Matei, A.; Puscas, C.; Patrascu, I.; Lehene, M.; Ziebro, J.; Scurtu, F.; Baia, M.; Porumb, D.; Totos, R.; Silaghi-Dumitrescu, R. Stability of Glutaraldehyde in Biocide Compositions. Int. J. Mol. Sci. 2020, 21, 3372. [Google Scholar] [CrossRef] [PubMed]

- Smith, D.R.; Wang, R.-S. Glutaraldehyde exposure and its occupational impact in the health care environment. Environ. Health Prev. Med. 2006, 11, 3–10. [Google Scholar] [CrossRef]

- Ballantyne, B.; Jordan, S.L. Toxicological, medical and industrial hygiene aspects of glutaraldehyde with particular reference to its biocidal use in cold sterilization procedures. J. Appl. Toxicol. 2001, 21, 131–151. [Google Scholar] [CrossRef]

- McLaughlin, S.; Ahumada, M.; Franco, W.; Mah, T.-F.; Seymour, R.; Suuronen, E.J.; Alarcon, E.I. Sprayable peptide-modified silver nanoparticles as a barrier against bacterial colonization. Nanoscale 2016, 8, 19200–19203. [Google Scholar] [CrossRef]

| Formulation | Refractive Index (SD) |

|---|---|

| G1C1 | 1.33759 (0.00029) |

| G1P1 | 1.33610 (0.00133) |

| G1Q1P1 | 1.33751 (0.00070 |

| G2C1P1 | 1.33900 (0.00065) |

| Cornea a | 1.335–1.432 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernández, J.; Panadero-Medianero, C.; Arrázola, M.S.; Ahumada, M. Mimicking the Physicochemical Properties of the Cornea: A Low-Cost Approximation Using Highly Available Biopolymers. Polymers 2024, 16, 1118. https://doi.org/10.3390/polym16081118

Hernández J, Panadero-Medianero C, Arrázola MS, Ahumada M. Mimicking the Physicochemical Properties of the Cornea: A Low-Cost Approximation Using Highly Available Biopolymers. Polymers. 2024; 16(8):1118. https://doi.org/10.3390/polym16081118

Chicago/Turabian StyleHernández, Juan, Concepción Panadero-Medianero, Macarena S. Arrázola, and Manuel Ahumada. 2024. "Mimicking the Physicochemical Properties of the Cornea: A Low-Cost Approximation Using Highly Available Biopolymers" Polymers 16, no. 8: 1118. https://doi.org/10.3390/polym16081118

APA StyleHernández, J., Panadero-Medianero, C., Arrázola, M. S., & Ahumada, M. (2024). Mimicking the Physicochemical Properties of the Cornea: A Low-Cost Approximation Using Highly Available Biopolymers. Polymers, 16(8), 1118. https://doi.org/10.3390/polym16081118