Optimizing Tannin-NaCMC Compositions via DOE for Enhanced Carbon Yield and Strength in 3D-Printed Porous Carbon

Abstract

1. Introduction

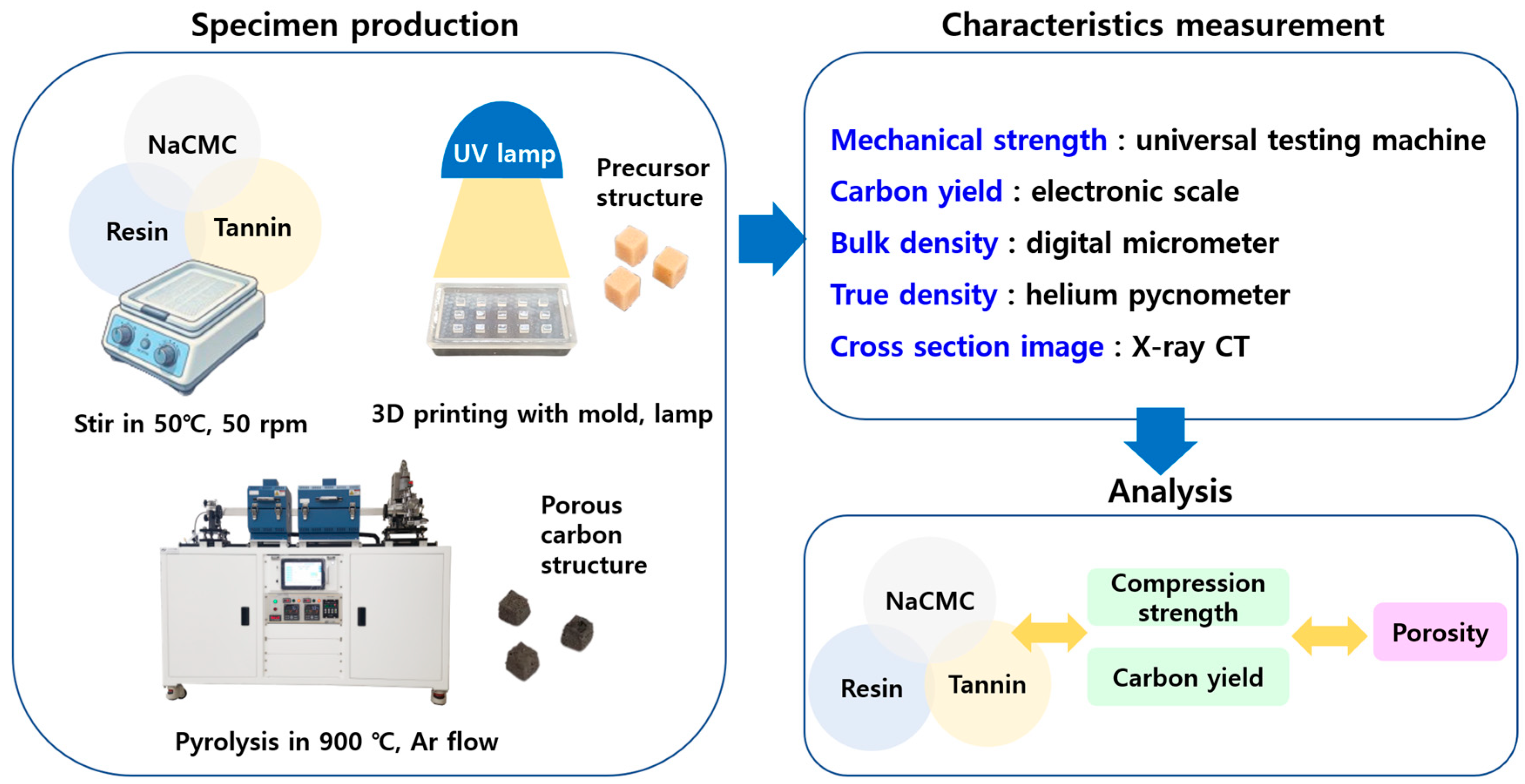

2. Materials and Methods

2.1. Materials

2.2. Manufacturing Process of 3D-Printed Carbon Precursor

2.3. Experimental Design

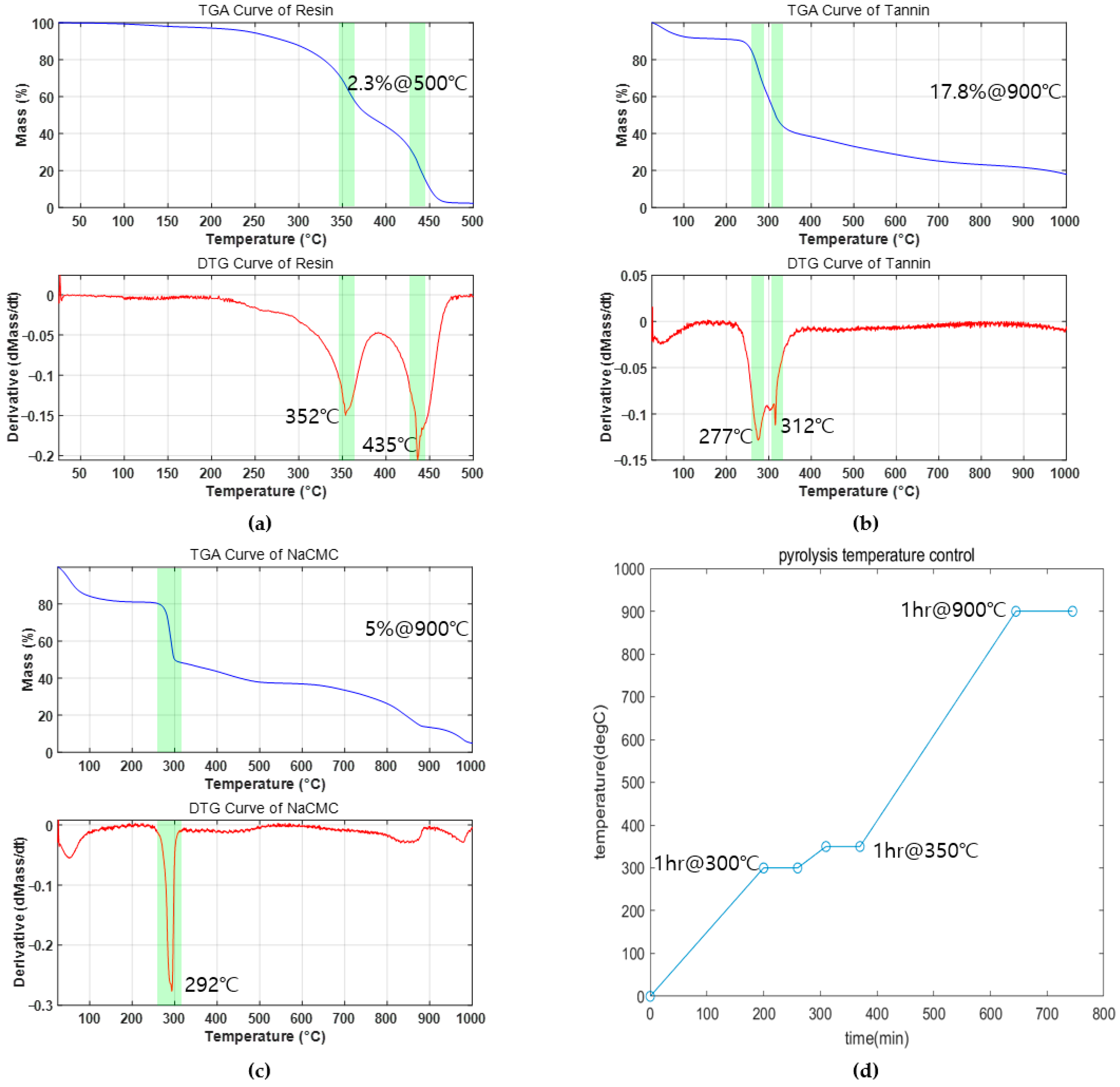

3. Results and Discussion

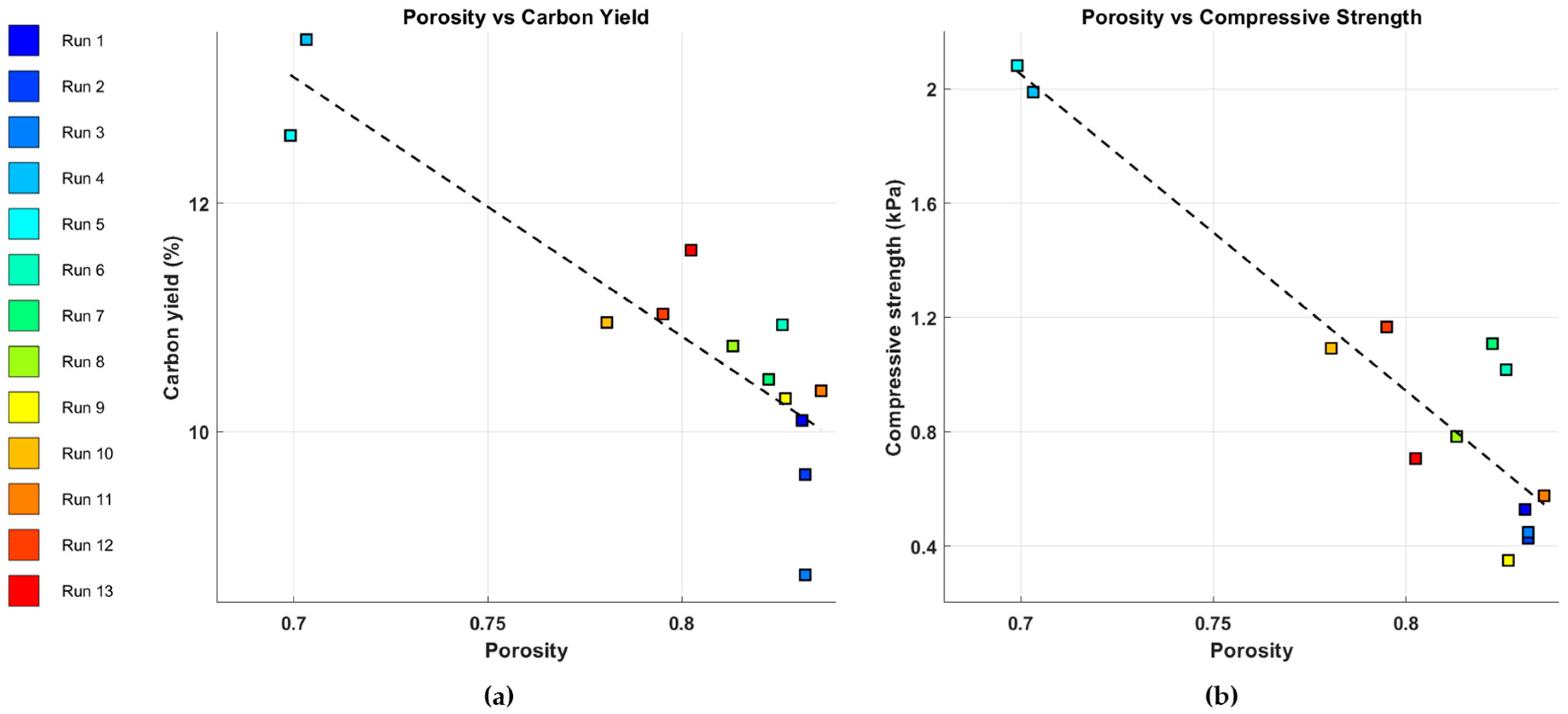

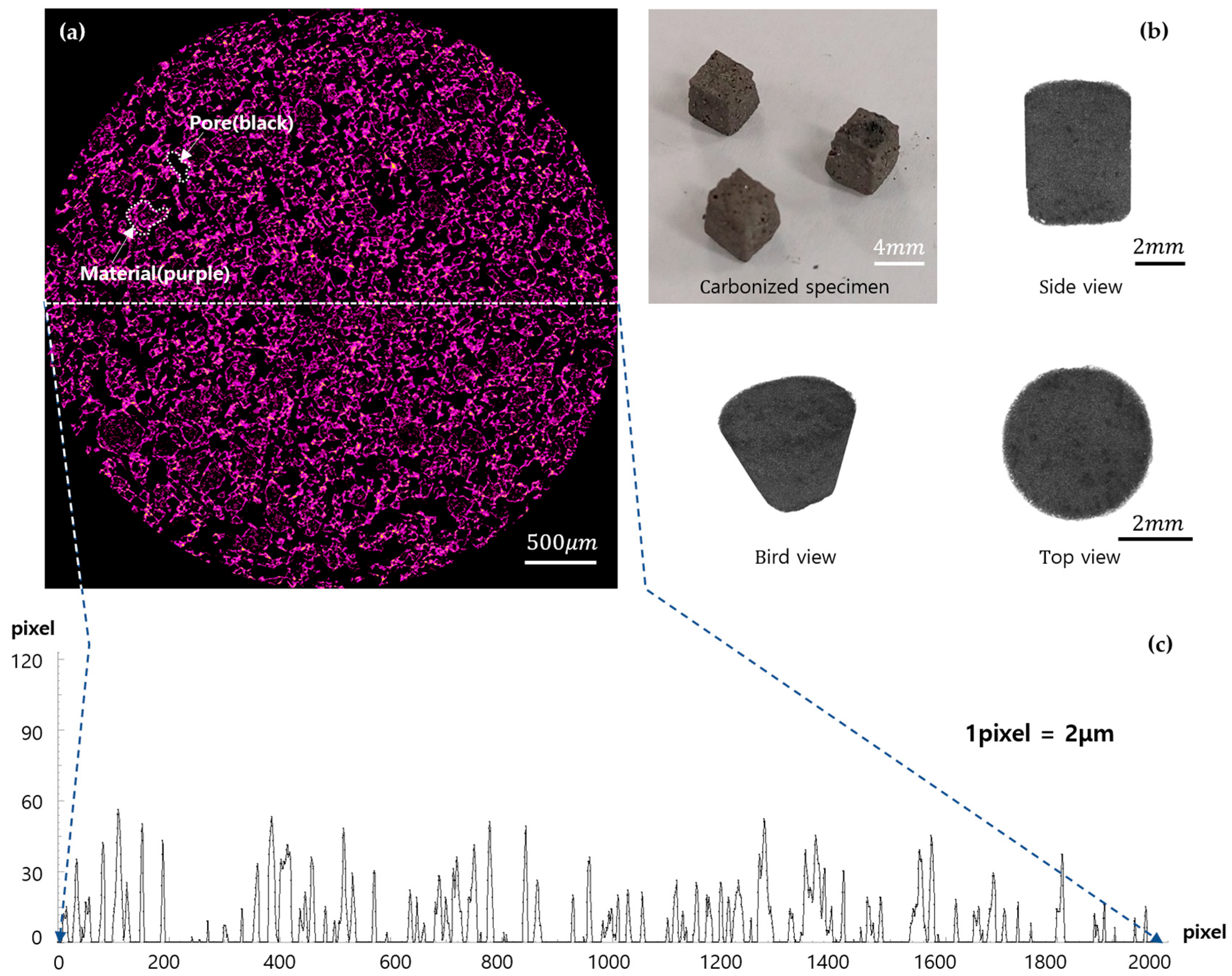

3.1. Porosity Analysis of the Carbon Structure

3.2. Properties of the Porous Carbon Structure

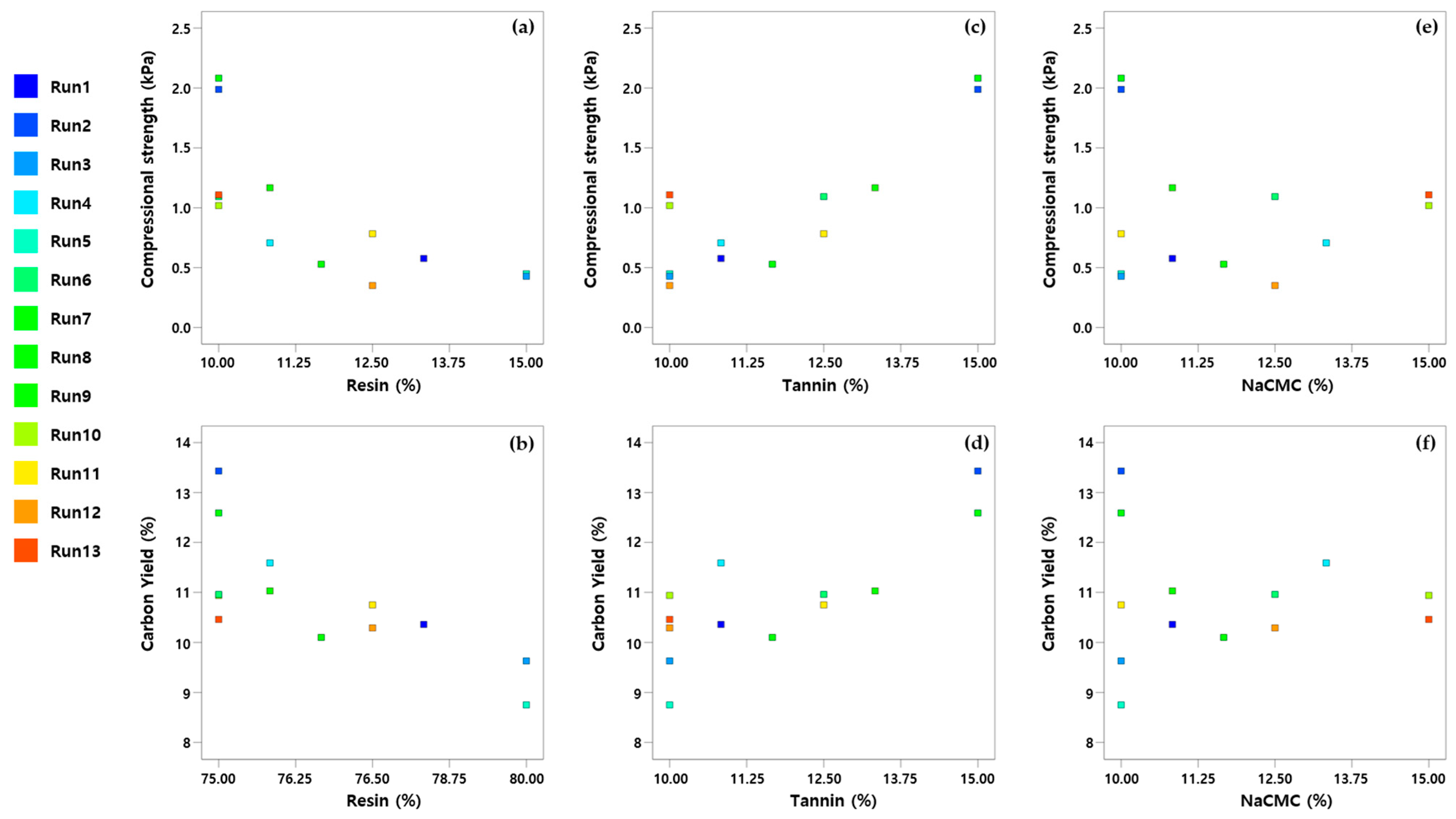

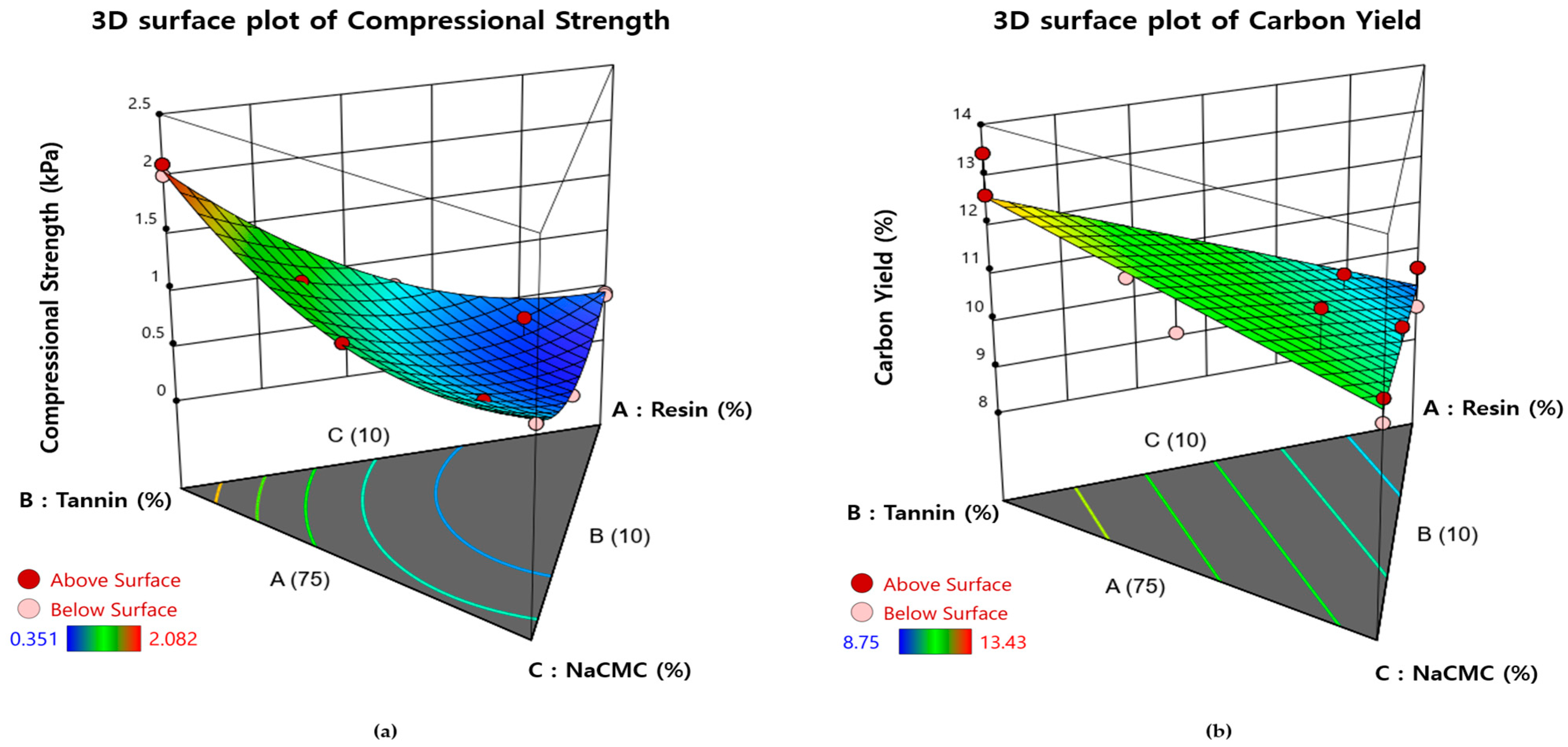

3.3. Results of the Experimental Design and Statistical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- ISO/ASTM 52900-15; Terminology for Additive Manufacturing—General Principles—Terminology. ASTM International: West Conshohocken, PA, USA, 2015.

- Tumbleston, J.R.; Shirvanyants, D.; Ermoshkin, N.; Janusziewicz, R.; Johnson, A.R.; Kelly, D.; Chen, K.; Pinschmidt, R.; Rolland, J.P.; Ermoshkin, A.; et al. Continuous Liquid Interface Production of 3D Objects. Science 2015, 347, 1349–1352. [Google Scholar] [CrossRef] [PubMed]

- Campbell, T.; Williams, C.; Ivanova, O.; Garrett, B. Could 3D Printing Change the World? Technologies, Potential, and Implications of Additive Manufacturing; Strategic Foresight Initiative, Atlantic Council: Washington, DC, USA, 2011; Available online: https://www.atlanticcouncil.org/in-depth-research-reports/issue-brief/could-3d-printing-change-the-world (accessed on 25 June 2025).

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies, 2nd ed.; Springer: New York, NY, USA, 2015. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Tappa, K.; Jammalamadaka, U. Novel Biomaterials Used in Medical 3D Printing Techniques. J. Forensic Biomech. 2018, 9, 17. [Google Scholar] [CrossRef] [PubMed]

- Hassan, M.; Dave, K.; Chandrawati, R.; Dehghani, F.; Gomes, V.G. 3D Printing of Biopolymer Nanocomposites for Tissue Engineering: Nanomaterials, Processing and Structure–Function Relation. Eur. Polym. J. 2019, 121, 109340. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D Printing of Polymer Matrix Composites: A Review and Prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Wu, H.; Fahy, W.P.; Kim, S.; Kim, H.; Zhao, N.; Pilato, L.; Kafi, A.; Bateman, S.; Koo, J.H. Recent Developments in Polymers/Polymer Nanocomposites for Additive Manufacturing. Prog. Mater. Sci. 2020, 111, 100638. [Google Scholar] [CrossRef]

- Zhou, L.; Fu, J.; He, Y. A Review of 3D Printing Technologies for Soft Polymer Materials. Adv. Funct. Mater. 2020, 30, 2000187. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Lü, J.; Li, C.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; et al. 3D Printing of Ceramics: A Review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Das, S.; Bourell, D.L.; Babu, S.S. Metallic Materials for 3D Printing. MRS Bull. 2016, 41, 729–741. [Google Scholar] [CrossRef]

- Davoodi, P.; Lee, L.Y.; Xu, Q.; Sunil, V.; Sun, Y.; Soh, S.; Wang, C.-H. Drug Delivery Systems for Programmed and On-Demand Release. Adv. Drug Deliv. Rev. 2018, 132, 104–138. [Google Scholar] [CrossRef]

- Sevilla, M.; Mokaya, R. Energy Storage Applications of Activated Carbons: Supercapacitors and Hydrogen Storage. Energy Environ. Sci. 2014, 7, 1250–1280. [Google Scholar] [CrossRef]

- Yu, F.; Wang, Y.; Wu, Y.; Liu, J.; Li, X.; Zhang, P.; Chen, S. Biomass-Derived Porous Carbon Materials: Synthesis, Designing, and Applications for Supercapacitors. Green Chem. 2019, 21, 1379–1411. [Google Scholar] [CrossRef]

- Tondi, G.; Petutschnigg, A. Tannin-Based Rigid Foams: Characterization and Modification. BioResources 2015, 10, 7892–7902. [Google Scholar] [CrossRef]

- Blyweert, P.; Nicolas, V.; Macutkevic, J.; Fierro, V.; Celzard, A. Tannin-Based Resins for 3D Printing of Porous Carbon Architectures. ACS Sustain. Chem. Eng. 2022, 10, 12432–12444. [Google Scholar] [CrossRef]

- Pizzi, A. Tannin-Based Adhesives. J. Macromol. Sci. Part C Polym. Rev. 1980, 18, 247–315. [Google Scholar] [CrossRef]

- Romero, C.; Liu, Z.; Wei, Z.; Fei, L. A review of hierarchical porous carbon derived from various 3D printing techniques. Nanoscale 2024, 16, 12274–12286. [Google Scholar] [CrossRef]

- Blyweert, P.; Nicolas, V.; Fierro, V.; Celzard, A. 3D-Printed Carbons with Improved Properties and Oxidation Resistance. ACS Sustain. Chem. Eng. 2023, 11, 153–164. [Google Scholar] [CrossRef]

- Blyweert, P.; Nicolas, V.; Fierro, V.; Celzard, A. Experimental Design Optimization of Acrylate–Tannin Photocurable Resins for 3D Printing of Bio-Based Porous Carbon Architectures. Molecules 2022, 27, 2091. [Google Scholar] [CrossRef]

- Blyweert, P.; Nicolas, V.; Fierro, V.; Celzard, A. Modeling the Pyrolysis of 3D-Printed Tannin Composites—A First Approach. Int. J. Therm. Sci. 2024, 5, 247–251. [Google Scholar] [CrossRef]

- Bergoglio, M.; Rossegger, E.; Schlögl, S.; Griesser, T.; Waly, C.; Arbeiter, F.; Sangermano, M. Multi-Material 3D Printing of Biobased Epoxy Resins. Polymers 2024, 16, 1510. [Google Scholar] [CrossRef]

- Kaczmarek, B.; Owczarek, A.; Kapuśniak, J. Natural Tannins and Their Use in Polymer Composites—A Review. Materials 2020, 13, 3771. [Google Scholar] [CrossRef]

- Hercules Inc. Aqualon Sodium Carboxymethylcellulose—Physical and Chemical Properties; Hercules Incorporated: Wilmington, DE, USA, 2002; Available online: https://www.researchgate.net/file.PostFileLoader.html?id=551d8944f15bc717108b467d&assetKey=AS%3A273748727402502%401442278190421 (accessed on 25 June 2025).

- Yu, M.; Han, Y.; Li, J.; Wang, L. One-Step Synthesis of Sodium Carboxymethyl Cellulose-Derived Carbon Aerogel/Nickel Oxide Composites for Energy Storage. Chem. Eng. J. 2017, 324, 287–295. [Google Scholar] [CrossRef]

- İstek, A.; Biçer, A.; Özlüsoylu, İ. Effect of sodium carboxymethyl cellulose (Na-CMC) added to urea-formaldehyde resin on particleboard properties. Turk. J. Agric. For. 2020, 44, 526–532. [Google Scholar] [CrossRef]

- Melilli, G.; Carmagnola, I.; Tonda-Turo, C.; Pirri, F.; Ciardelli, G.; Sangermano, M.; Hakkarainen, M.; Chiappone, A. DLP 3D Printing Meets Lignocellulosic Biopolymers: Carboxymethyl Cellulose Inks for 3D Biocompatible Hydrogels. Polymers 2020, 12, 1655. [Google Scholar] [CrossRef]

- Trendewicz, A.; Evans, R.; Dutta, A.; Sykes, R.; Carpenter, D.; Braun, R. Evaluating the Effect of Potassium on Cellulose Pyrolysis Reaction Kinetics. Biomass Bioenergy 2015, 74, 15–25. [Google Scholar] [CrossRef]

- Lee, J.; Kim, S.; Park, Y.; Choi, J.; Lee, S. Thermal Decomposition Behavior of UV-Curable Resins. Thermochim. Acta 2022, 710, 179105. [Google Scholar] [CrossRef]

- Ahmad, N.; Wahab, R.; Al-Omar, S.Y. Thermal Decomposition Kinetics of Sodium Carboxymethyl Cellulose: Model-Free Methods. Eur. J. Chem. 2014, 5, 247–251. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Q.; Zhang, Z.; Wu, Y.; Wang, S. Review on the Catalytic Effects of Alkali and Alkaline Earth Metals (AAEMs) Including Sodium, Potassium, Calcium and Magnesium on the Pyrolysis of Lignocellulosic Biomass and on the Co-Pyrolysis of Coal with Biomass. J. Anal. Appl. Pyrolysis 2022, 163, 105479. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties, 2nd ed.; Cambridge University Press: Cambridge, UK, 1999; Available online: https://www.cambridge.org/core/journals/mrs-bulletin/article/cellular-solids/D75AD0A311E503438FAC908AA45550B4 (accessed on 25 June 2025).

- El-Sakhawy, M.; Tohamy, H.A.S.; Salama, A.; Kamel, S. Thermal Properties of Carboxymethyl Cellulose Acetate Butyrate. Cellulose Chem. Technol. 2019, 53, 255–263. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, L.; Fuh, J.Y.H.; Lee, H.P. Effect of Porosity on Mechanical Properties of 3D Printed Polymers: Experiments and Micromechanical Modeling Based on X-ray Computed Tomography Analysis. Polymers 2019, 11, 1154. [Google Scholar] [CrossRef] [PubMed]

- Stepacheva, A.A.; Artyushkova, K.A.; Ismagilov, Z.R. Plant-biomass-derived carbon materials as catalyst support: A brief review. Catalysts 2023, 13, 655. [Google Scholar] [CrossRef]

| Exp. No. | Space Type | Resin (%) | Tannin (%) | NaCMC (%) |

|---|---|---|---|---|

| 1 | Center | 76.6667 | 11.6667 | 11.6667 |

| 2 | Vertex | 80 | 10 | 10 |

| 3 | Vertex | 80 | 10 | 10 |

| 4 | Vertex | 75 | 15 | 10 |

| 5 | Vertex | 75 | 15 | 10 |

| 6 | Vertex | 75 | 10 | 15 |

| 7 | Vertex | 75 | 10 | 15 |

| 8 | CenterEdge | 77.5 | 12.5 | 10 |

| 9 | CenterEdge | 77.5 | 10 | 12.5 |

| 10 | CenterEdge | 75 | 12.5 | 12.5 |

| 11 | AxialCB | 78.3333 | 10.8333 | 10.8333 |

| 12 | AxialCB | 75.8333 | 13.3333 | 10.8333 |

| 13 | AxialCB | 75.8333 | 10.8333 | 13.3333 |

| Exp. No. | Carbon Yield (%) | Bulk Density (g/cm3) | True Density (g/cm3) | Porosity | Compressive Strength (kPa) |

|---|---|---|---|---|---|

| 1 | 10.10 | 0.1568 | 0.9280 | 0.8310 | 0.529 |

| 2 | 9.63 | 0.1698 | 1.0100 | 0.8319 | 0.428 |

| 3 | 8.75 | 0.1683 | 1.0100 | 0.8319 | 0.449 |

| 4 | 13.43 | 0.3532 | 1.1900 | 0.7032 | 1.988 |

| 5 | 12.59 | 0.3521 | 1.1700 | 0.6991 | 2.082 |

| 6 | 10.94 | 0.2019 | 1.1600 | 0.8260 | 1.018 |

| 7 | 10.46 | 0.2023 | 1.1400 | 0.8225 | 1.108 |

| 8 | 10.75 | 0.1979 | 1.0600 | 0.8133 | 0.783 |

| 9 | 10.29 | 0.1598 | 0.9220 | 0.8267 | 0.351 |

| 10 | 10.96 | 0.2216 | 1.0100 | 0.7806 | 1.093 |

| 11 | 10.36 | 0.1886 | 1.1500 | 0.8360 | 0.577 |

| 12 | 11.03 | 0.2480 | 1.2100 | 0.7951 | 1.167 |

| 13 | 11.59 | 0.2054 | 1.0400 | 0.8025 | 0.707 |

| Exp. No. | Tannin (%) | NaCMC (%) | Carbon Yield (%) | Carbon Yield/Weighted Tannin | Carbon Yield/Tannin |

|---|---|---|---|---|---|

| 1 | 11.6667 | 11.6667 | 10.10 | 0.68 | 0.87 |

| 2 | 10 | 10 | 9.63 | 0.75 | 0.96 |

| 3 | 10 | 10 | 8.75 | 0.68 | 0.88 |

| 4 | 15 | 10 | 13.43 | 0.70 | 0.90 |

| 5 | 15 | 10 | 12.59 | 0.66 | 0.84 |

| 6 | 10 | 15 | 10.94 | 0.85 | 1.09 |

| 7 | 10 | 15 | 10.46 | 0.82 | 1.05 |

| 8 | 12.5 | 10 | 10.75 | 0.67 | 0.86 |

| 9 | 10 | 12.5 | 10.29 | 0.80 | 1.03 |

| 10 | 12.5 | 12.5 | 10.96 | 0.68 | 0.88 |

| 11 | 10.8333 | 10.8333 | 10.36 | 0.75 | 0.96 |

| 12 | 13.3333 | 10.8333 | 11.03 | 0.65 | 0.83 |

| 13 | 10.8333 | 13.3333 | 11.59 | 0.84 | 1.07 |

| Source | Sum of Squares | Degree of Freedom | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| ANOVA Compressive Strength | |||||

| Model | 3.69 | 5 | 0.7388 | 109.42 | <0.0001 |

| Linear mixture | 3.03 | 2 | 1.52 | 224.75 | <0.0001 |

| AB | 0.1860 | 1 | 0.1860 | 27.55 | 0.0012 |

| AC | 0.1408 | 1 | 0.1408 | 20.85 | 0.0026 |

| BC | 0.2234 | 1 | 0.2234 | 33.09 | 0.0007 |

| Residual | 0.0473 | 7 | 0.0068 | ||

| Lack of fit | 0.0386 | 4 | 0.0096 | 3.33 | 0.1753 |

| Pure error | 0.0087 | 3 | 0.0029 | ||

| Corrected Total | 3.74 | 12 | |||

| ANOVA Carbon Yield | |||||

| Model | 13.86 | 2 | 6.93 | 19.24 | 0.0004 |

| Linear mixture | 13.86 | 2 | 6.93 | 19.24 | 0.0004 |

| Residual | 3.60 | 10 | 0.3602 | ||

| Lack of fit | 2.75 | 7 | 0.3923 | 1.38 | 0.4323 |

| Pure error | 0.8552 | 3 | 0.2851 | ||

| Corrected Total | 17.46 | 12 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tae, W.; Cheng, H.; Kim, S.; Lee, Y.; Jung, W. Optimizing Tannin-NaCMC Compositions via DOE for Enhanced Carbon Yield and Strength in 3D-Printed Porous Carbon. Polymers 2025, 17, 1859. https://doi.org/10.3390/polym17131859

Tae W, Cheng H, Kim S, Lee Y, Jung W. Optimizing Tannin-NaCMC Compositions via DOE for Enhanced Carbon Yield and Strength in 3D-Printed Porous Carbon. Polymers. 2025; 17(13):1859. https://doi.org/10.3390/polym17131859

Chicago/Turabian StyleTae, Wonseok, Hao Cheng, Sangyou Kim, Yeongjun Lee, and Wonsuk Jung. 2025. "Optimizing Tannin-NaCMC Compositions via DOE for Enhanced Carbon Yield and Strength in 3D-Printed Porous Carbon" Polymers 17, no. 13: 1859. https://doi.org/10.3390/polym17131859

APA StyleTae, W., Cheng, H., Kim, S., Lee, Y., & Jung, W. (2025). Optimizing Tannin-NaCMC Compositions via DOE for Enhanced Carbon Yield and Strength in 3D-Printed Porous Carbon. Polymers, 17(13), 1859. https://doi.org/10.3390/polym17131859