Exploring the Effect of Annealing on PLA/Carbon Nanotube Nanocomposites: In Search of Efficient PLA/MWCNT Nanocomposites for Electromagnetic Shielding

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

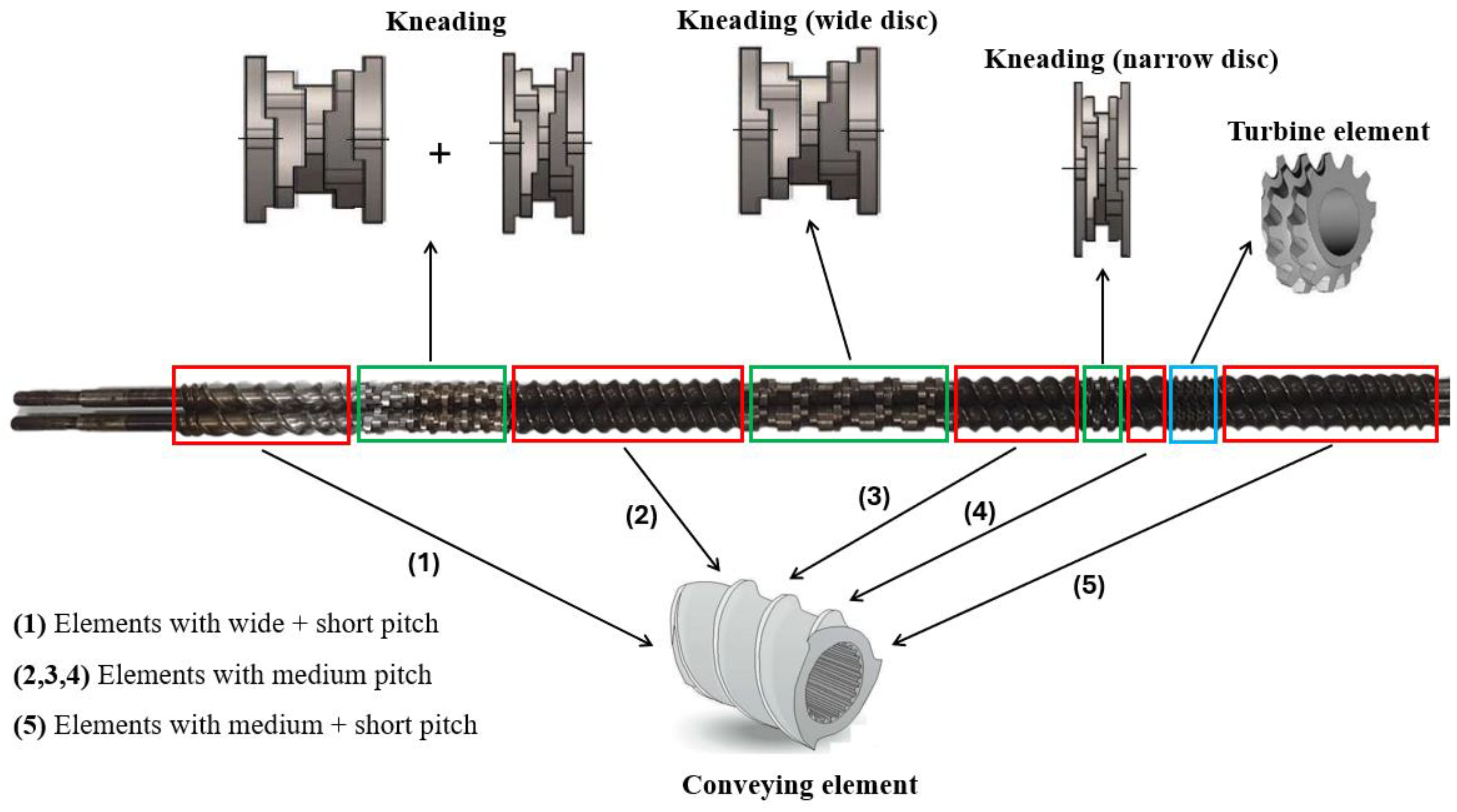

2.2. Extruder Processing

- Temperature profile: 160 °C–170 °C–170 °C–175 °C–180 °C–180 °C–190 °C;

- Screw rotation speed: 250 rpm;

- Feed rate in extruder: 3 kg/h.

2.3. Injection and Compression Molding

- Temperature profile: 160 °C–170 °C–175 °C–180 °C–190 °C;

- Mold temperature: 20 °C;

- Cooling time: 25 s;

- Injection pressure: 1200 bar;

- Holding pressure: 800 bar.

- Preload of 2 tons for 2 min;

- Final load of 8 tons for 3 min;

- Cooling at room temperature for 10 min, under a load of 50 N.

2.4. Annealing Heat Treatment

2.5. Nanocomposite Characterization

3. Results and Discussion

3.1. Melt Flow Index (MFI)

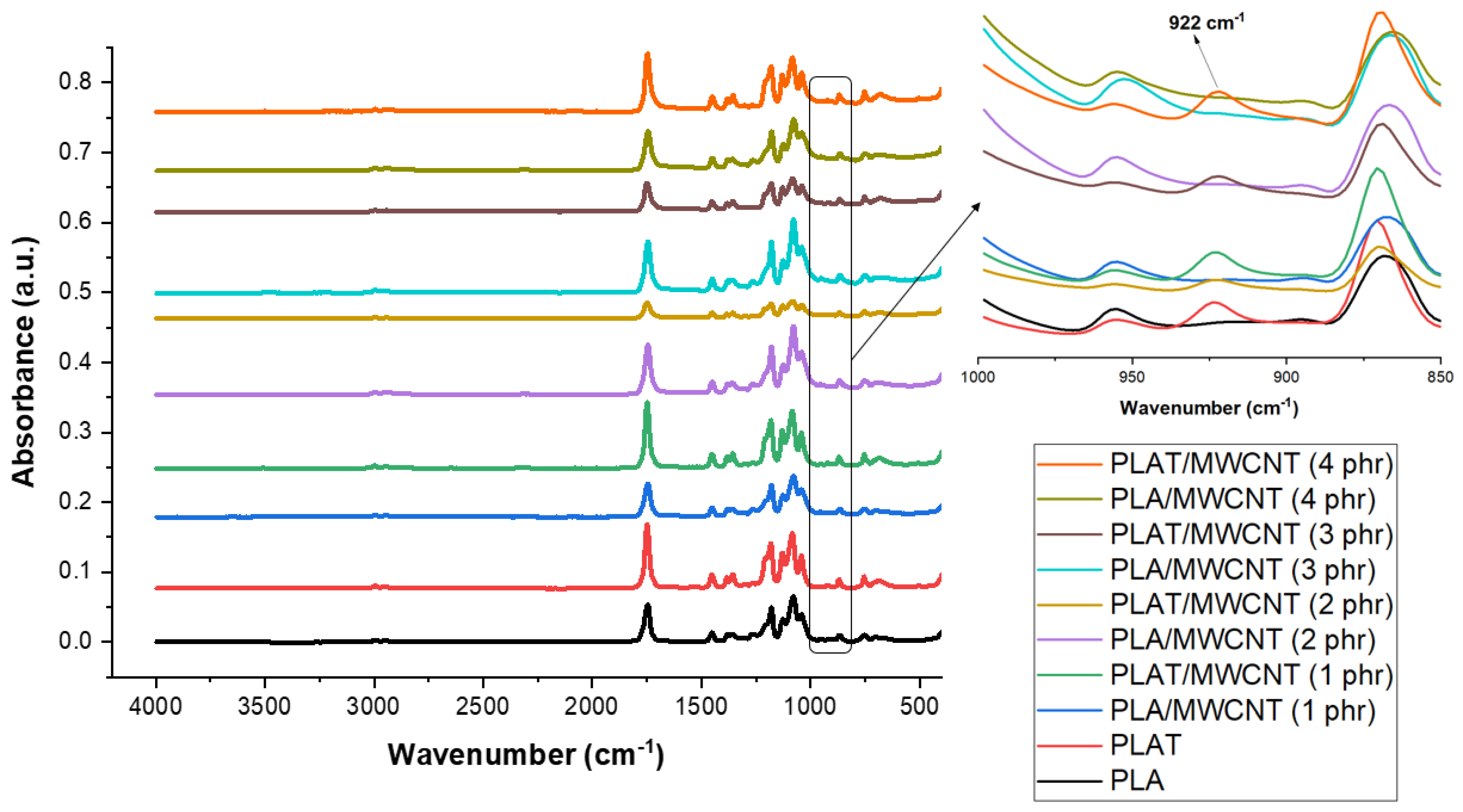

3.2. Fourier Transform Infrared Spectroscopy (FTIR)

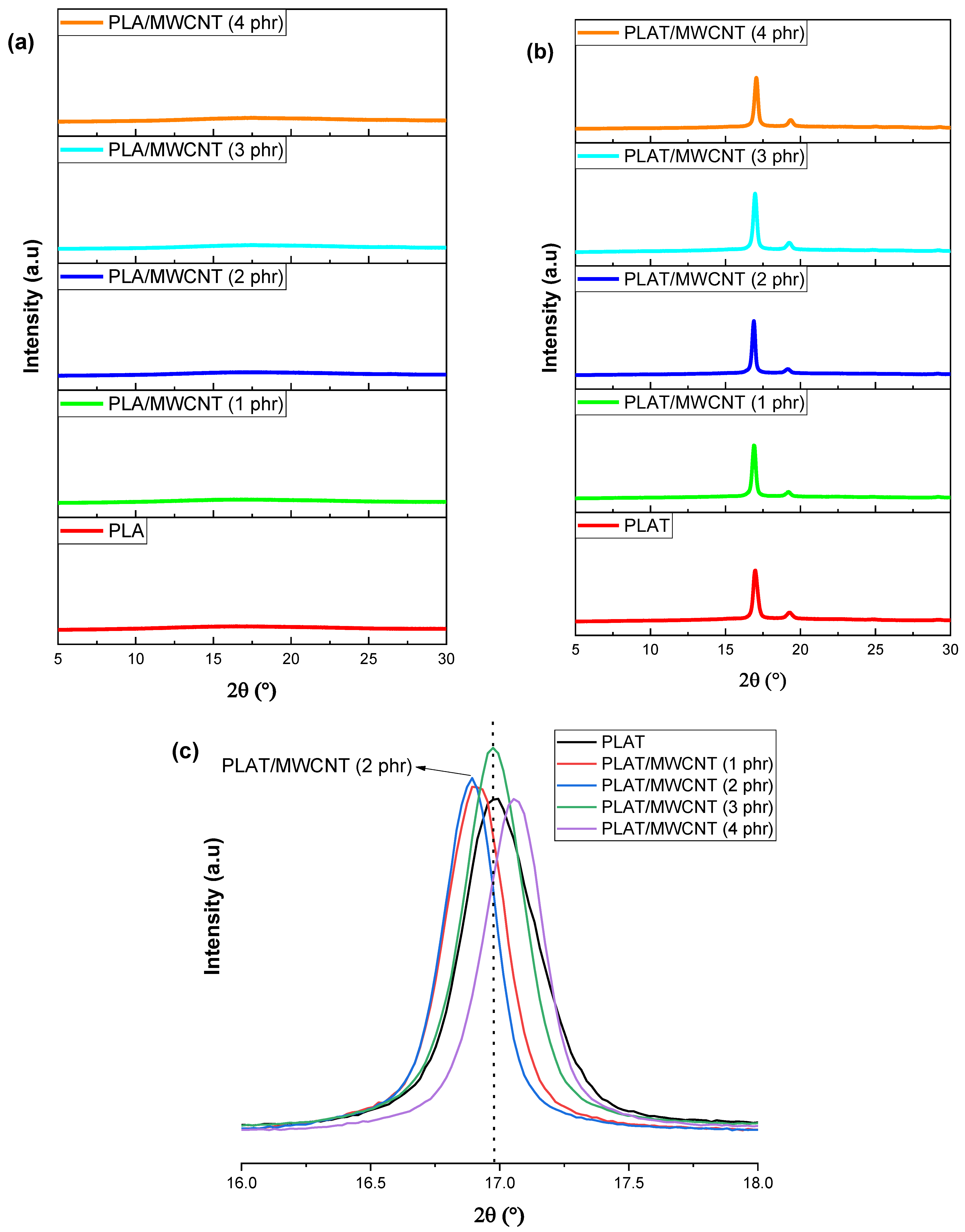

3.3. X-Ray Diffraction (XRD)

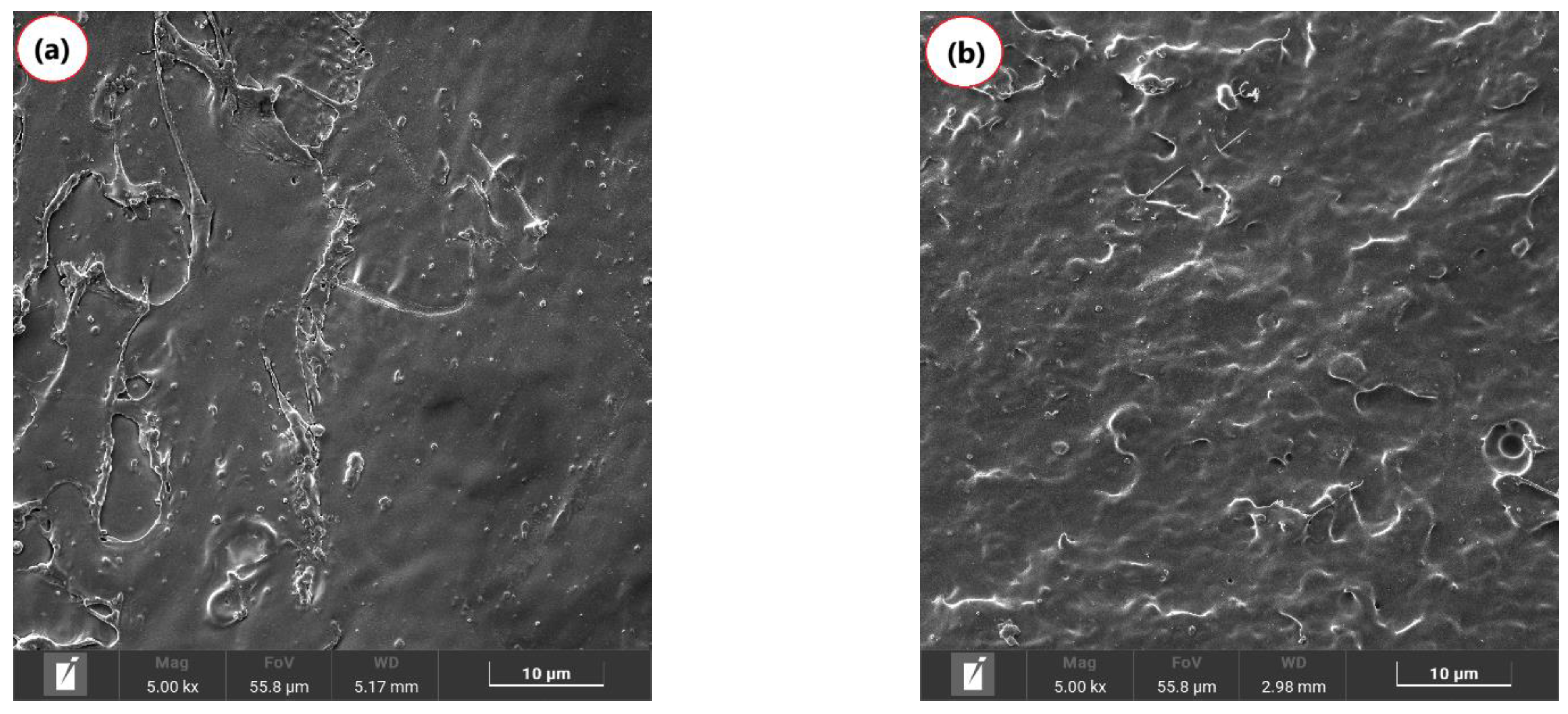

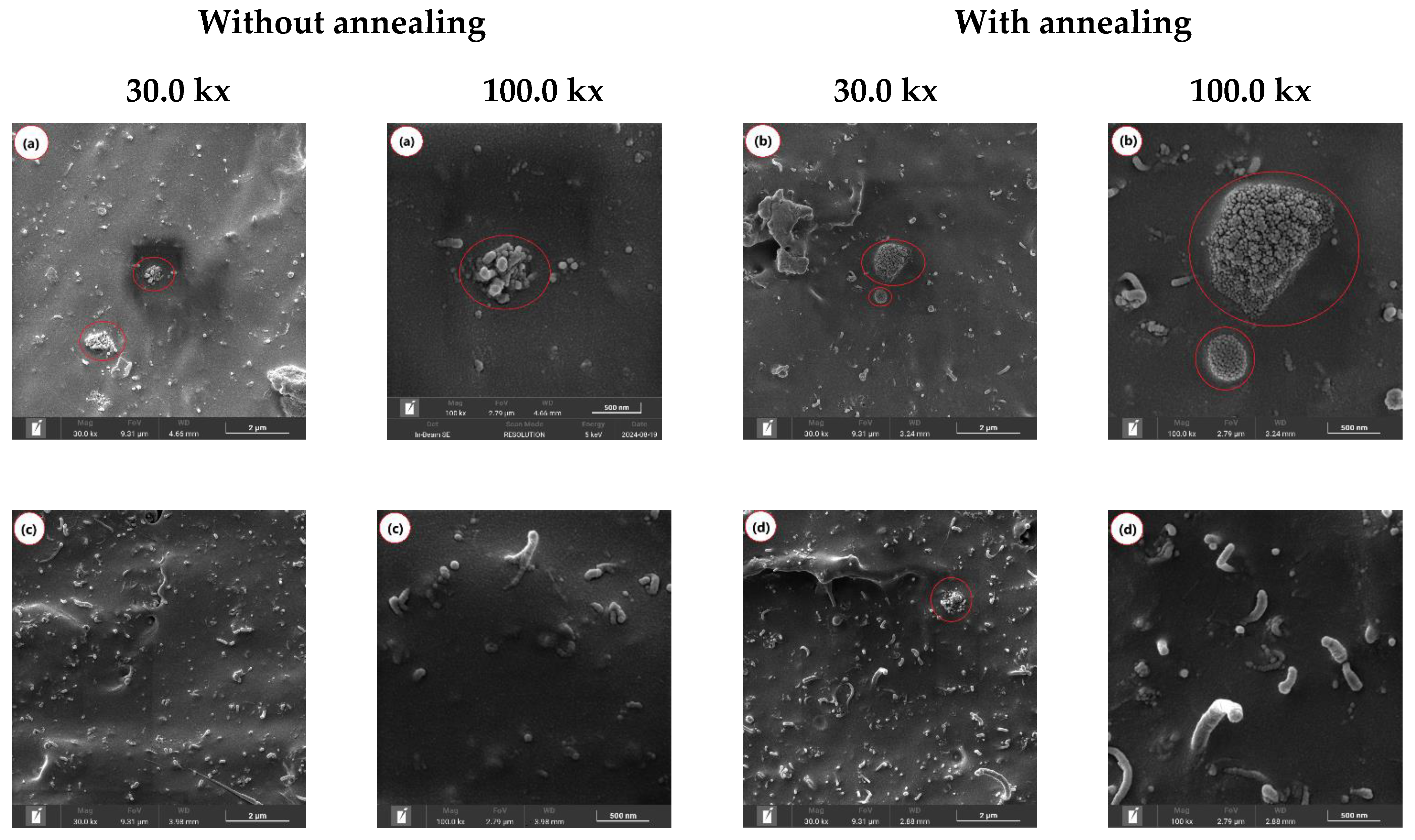

3.4. Scanning Electron Microscopy (SEM)

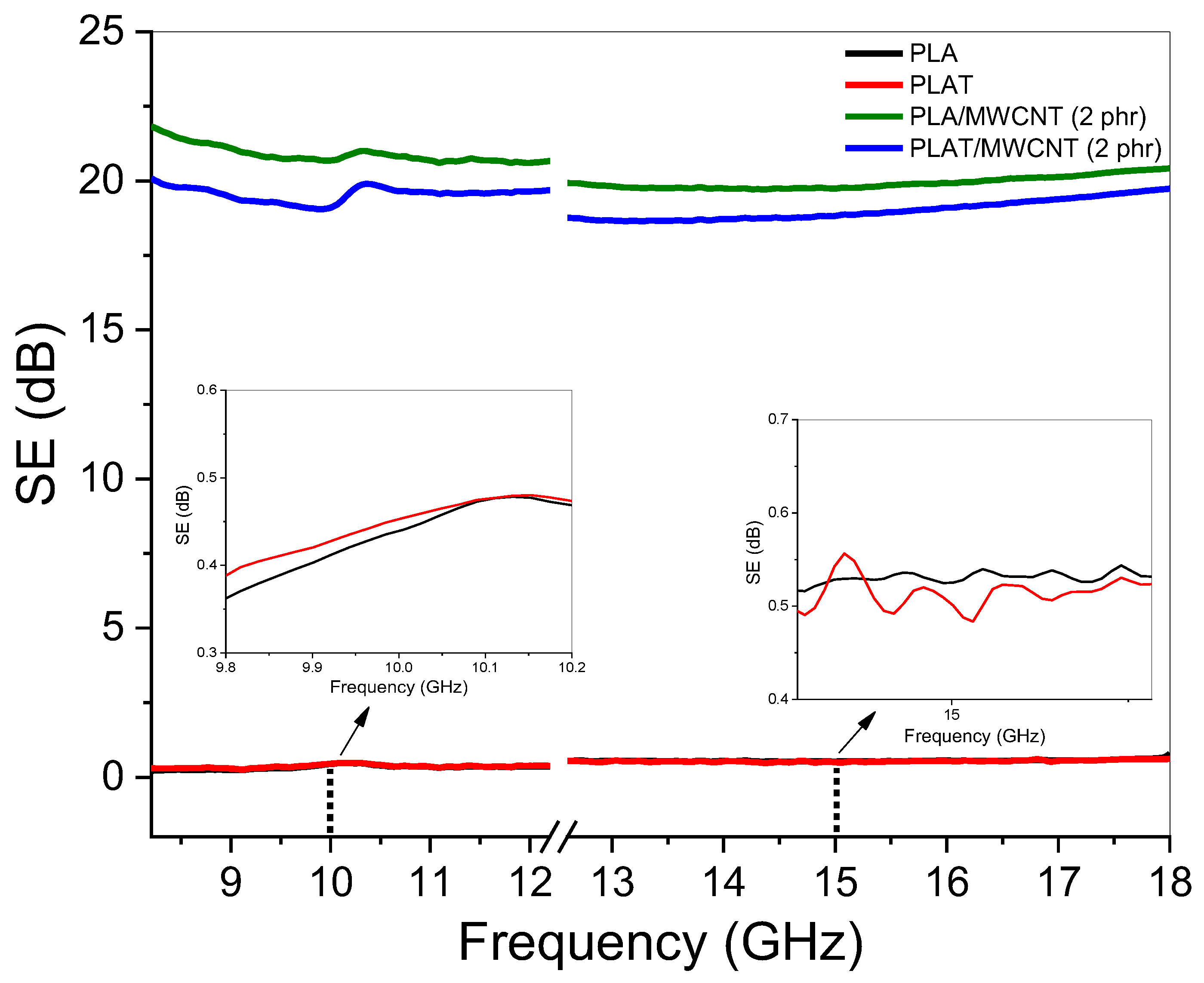

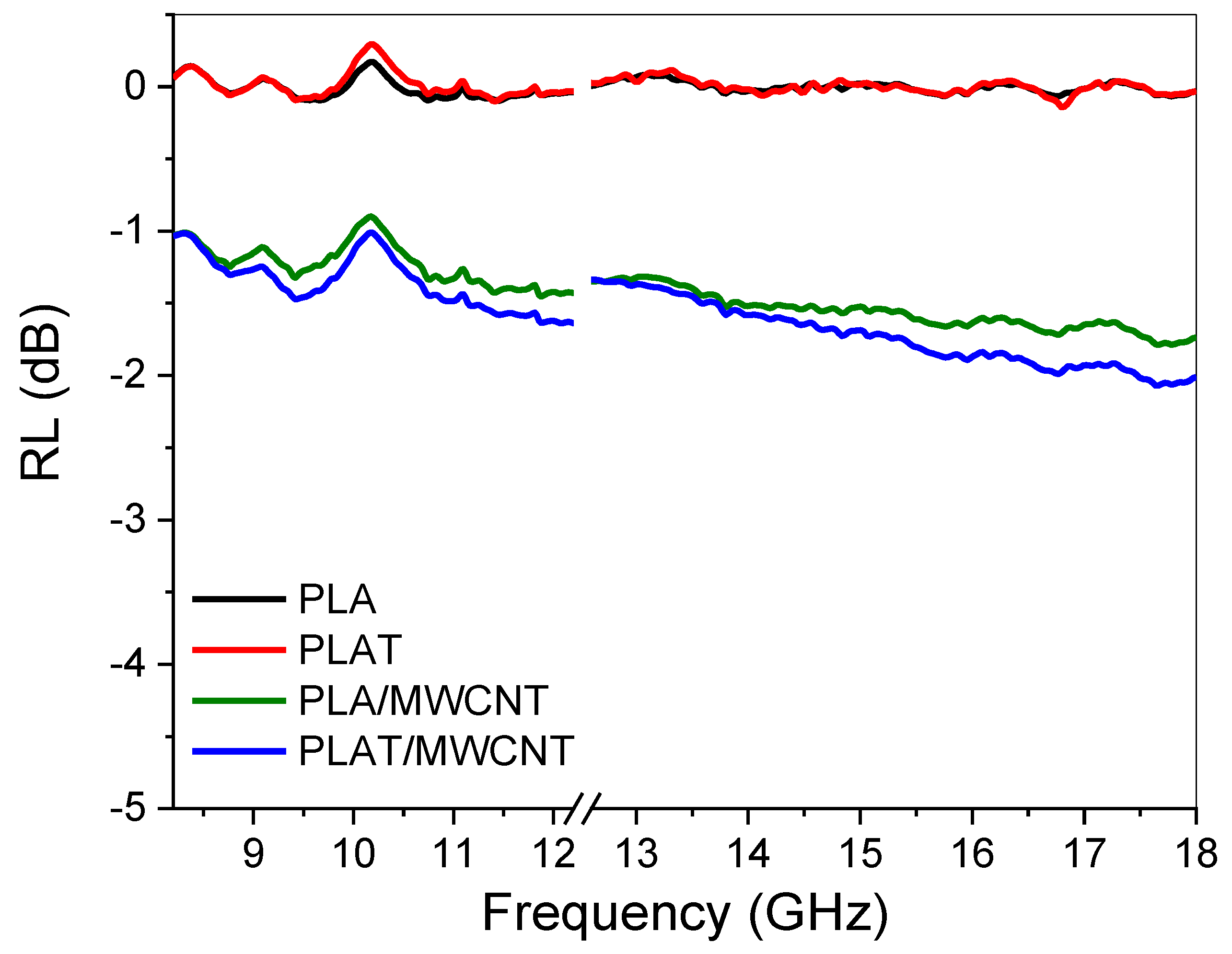

3.5. Electrical and Electromagnetic Properties

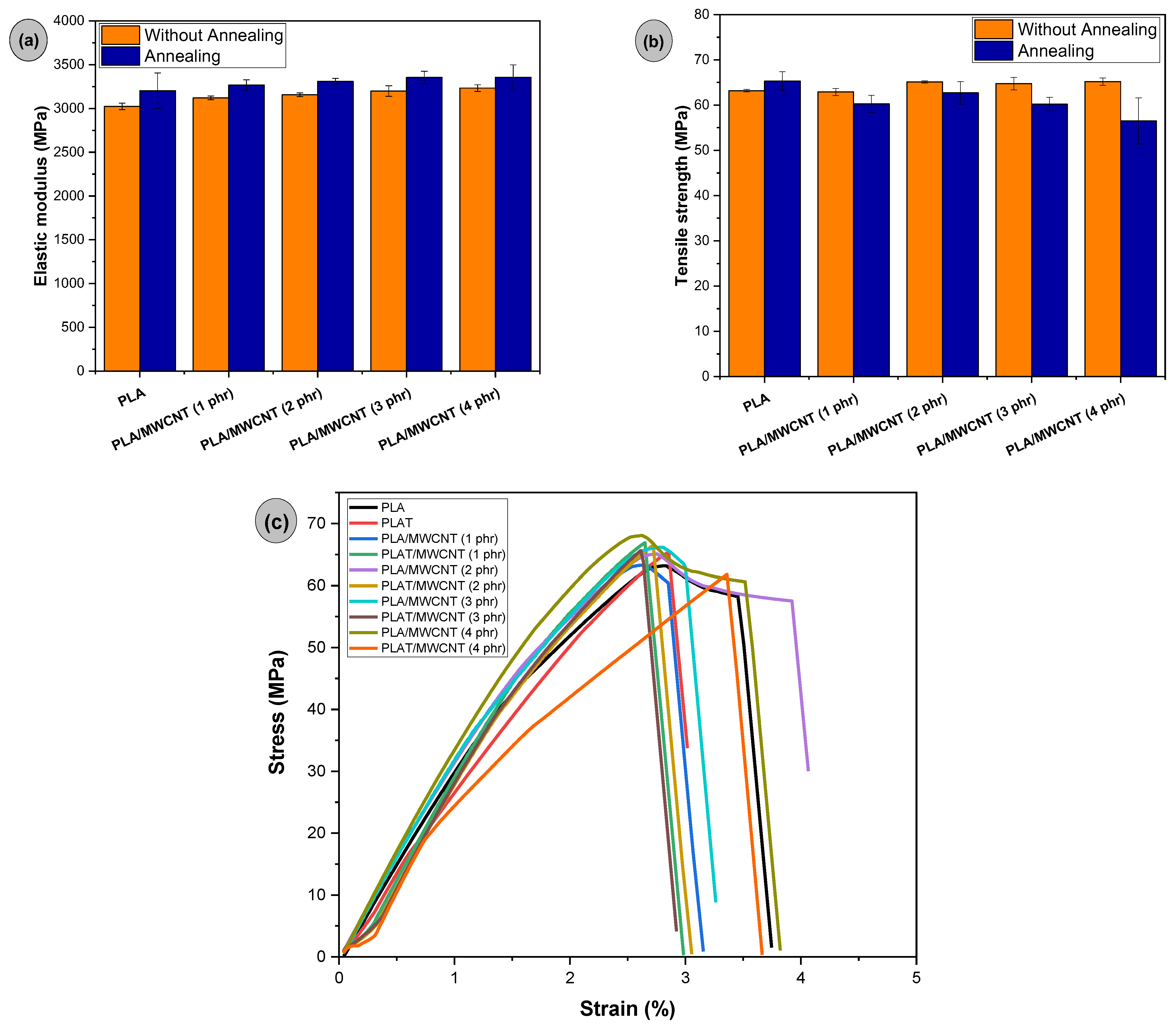

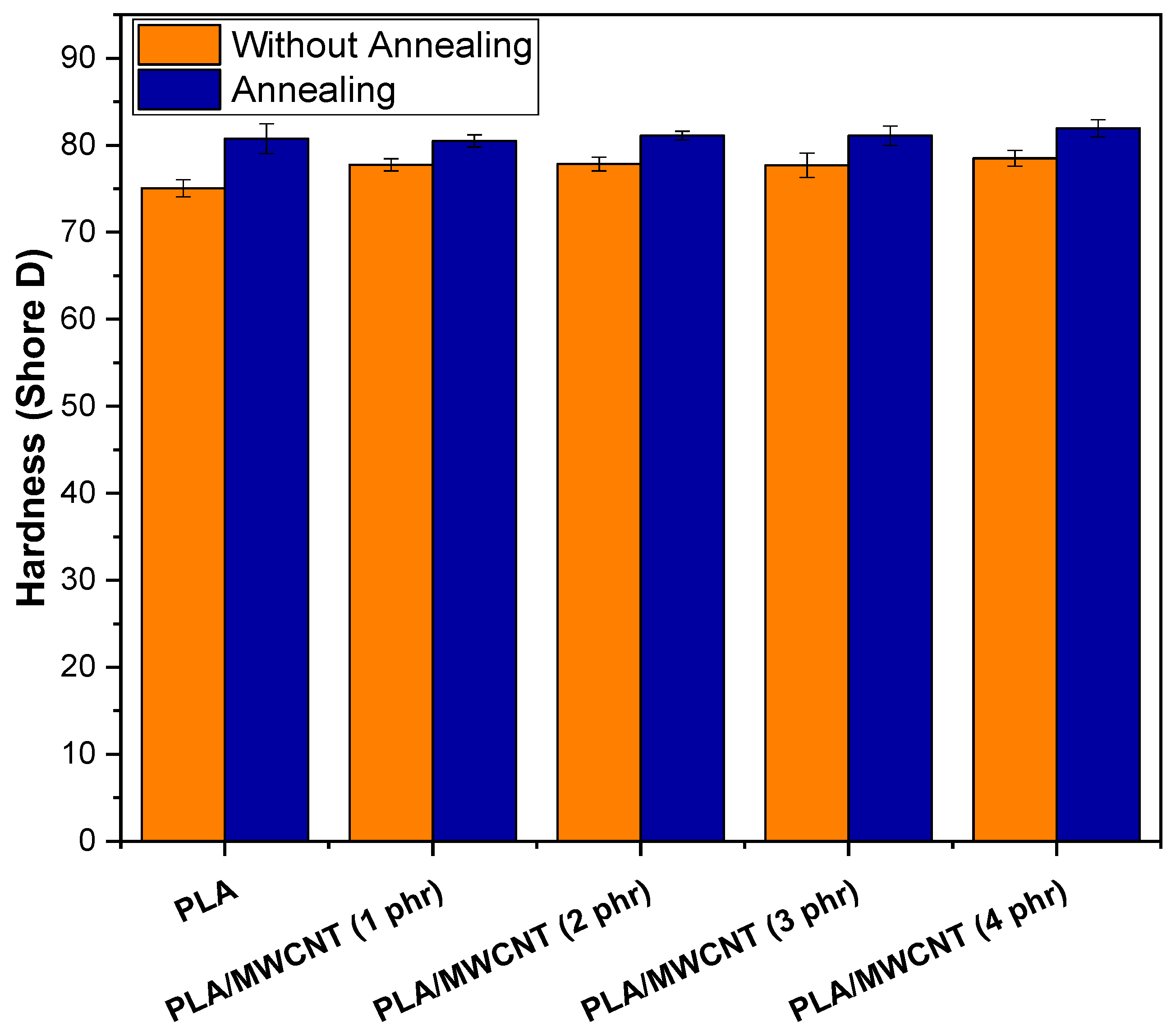

3.6. Mechanical Properties

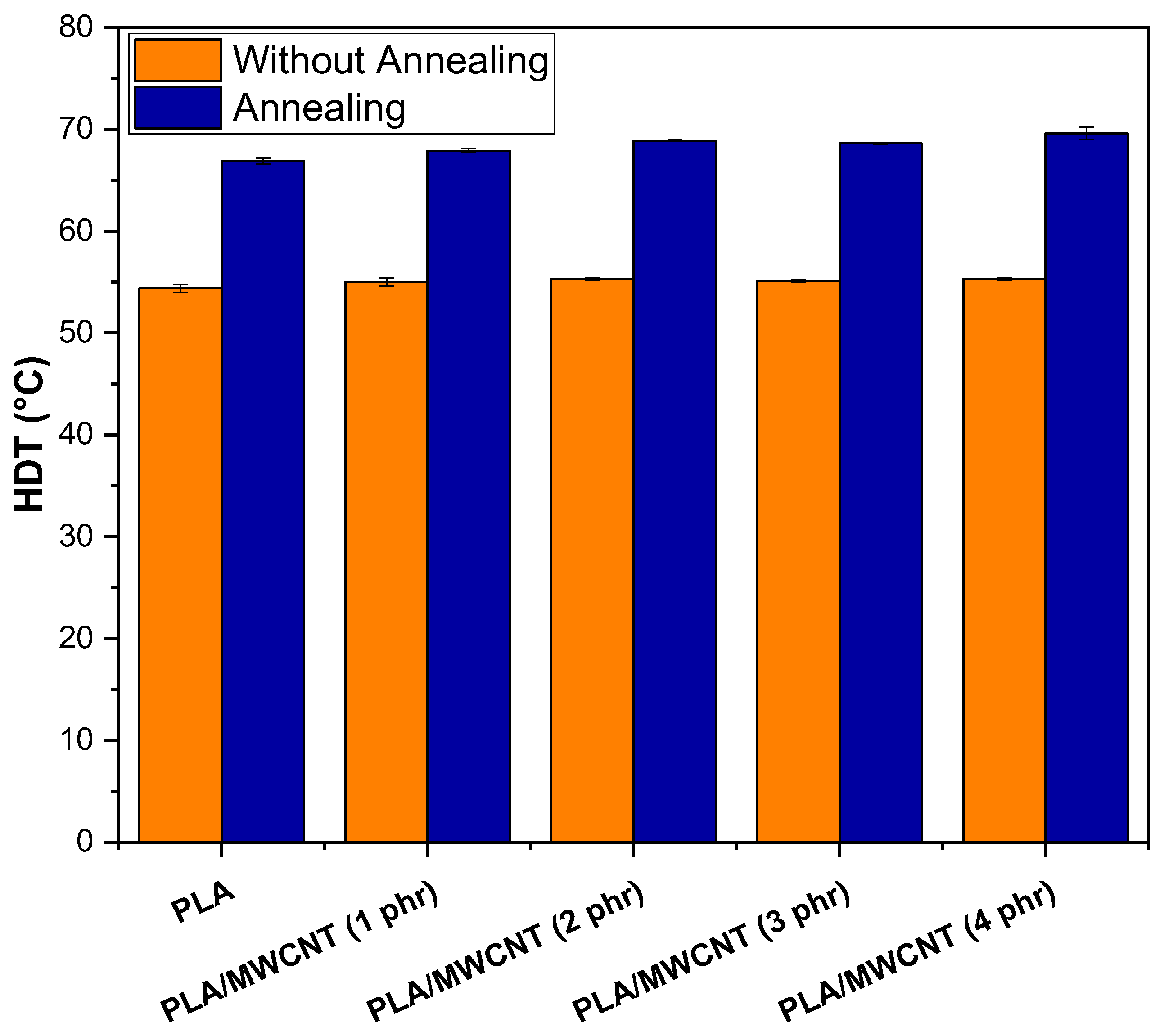

3.7. Heat Deflection Temperature (HDT)

3.8. Differential Scanning Calorimetry (DSC)

3.9. Perspectives of PLA/MWCNT Nanocomposites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Adaval, A.; Khurana, V.; Bhart, B.B.; Singh, S.; Gupta, D.; Maji, P.K.; Aslam, M.; Turney, T.W.; Simon, G.P.; Bhattacharyya, A.R. Piezoelectric properties of noncovalently functionalized 2D nanomaterials incorporated poly(vinylidene fluoride) nanocomposites. J. Appl. Polym. Sci. 2024, 141, e54814. [Google Scholar] [CrossRef]

- Shubhadarshinee, L.; Mohapatra, P.; Behera, S.; Jali, B.R.; Barick, A.K.; Mohapatra, P. Synergistic effect of gold nanoparticles decorated functionalized carbon nanotubes nanohybrids on the thermal, dielectric, and sensing properties of polyaniline ternary nanocomposites. J. Appl. Polym. Sci. 2024, 141, e55611. [Google Scholar] [CrossRef]

- Shameem, M.M.; Sasikanth, S.M.; Annamalai, R.; Raman, R.G. A brief review on polymer nanocomposites and its applications. Mater. Proc. 2021, 45, 2536–2539. [Google Scholar] [CrossRef]

- Luna, C.B.B.; Silva, F.S.; Filho, E.A.S.; Dantas, L.V.M.; Schmitz, D.P.; Soares, B.G.; Wellen, R.M.R.; Araújo, E.M. Tuning multifunctional behavior of PLA/POE-g-GMA/MWCNT nanocomposites: Mechanical, rheological, thermal, thermomechanical, and electromagnetic Properties. J. Appl. Polym. Sci. 2024, 141, e55931. [Google Scholar] [CrossRef]

- Oliveira, A.D.; Castro, L.D.C.; Jung, M.K.; Pessan, L.A. Influence of nanoclay modification on the mechanical, thermo-mechanical and morphological properties of polyamide 6/Acrylonitrile-EPDM-Styrene blend-based nanocomposites. Polímeros 2015, 25, 219–228. [Google Scholar] [CrossRef]

- Sharma, S.; Verma, A.; Rangappa, S.M.; Siengchin, S.; Ogata, S. Recent progressive developments in conductive-fillers based polymer nanocomposites (CFPNC’s) and conducting polymeric nanocomposites (CPNC’s) for multifaceted sensing applications. J. Mater. Res. Technol. 2023, 26, 5921–5974. [Google Scholar] [CrossRef]

- Lee, S.J.; Yoon, S.J.; Jeon, I.Y. Graphene/Polymer Nanocomposites: Preparation, Mechanical Properties, and Application. Polymers 2022, 14, 4733. [Google Scholar] [CrossRef]

- Darwish, M.S.A.; Mostafa, M.H.; Harbi, L.M.A. Polymeric Nanocomposites for Environmental and Industrial Applications. Int. J. Mol. Sci. 2022, 23, 1023. [Google Scholar] [CrossRef]

- Adrar, S.; Ajji, A. Interactions between PLA, organo-montmorillonite and plasticizer: Synergistic effect on the barrier and mechanical properties of PLA nanocomposites blown films. J. Appl. Polym. Sci. 2024, 141, e54867. [Google Scholar] [CrossRef]

- Kahraman, Y.; Gursu, H.; Arvas, M.B.; Ersozoglu, M.G.; Nofar, M.; Sarac, A.S.; Sahin, Y. Preparation of sulfur-doped graphenes by Yucel’s method and their corresponding polylactide-based nanocomposites. J. Appl. Polym. Sci. 2022, 139, e52828. [Google Scholar] [CrossRef]

- Kangalli, E.; Bayraktar, E. Preparation and characterization of poly(lactic acid)/boron oxide nanocomposites: Thermal, mechanical, crystallization, and flammability properties. J. Appl. Polym. Sci. 2022, 139, e52521. [Google Scholar] [CrossRef]

- Huang, A.; Song, X.; Liu, F.; Wang, H.; Geng, L.; Chen, B.; Peng, X.; Wang, Z.; Tian, G. Facile preparation of anisotropic PLA/CNT nanocomposites by hot and cold rolling processes for improving mechanical and conductive properties. J. Appl. Polym. Sci. 2022, 139, e52789. [Google Scholar] [CrossRef]

- Tian, G.; He, H.; Xu, M.; Liu, Y.; Gao, Q.; Zhu, Z. Ultralow percolation threshold biodegradable PLA/PBS/MWCNTs with segregated conductive networks for high-performance electromagnetic interference shielding applications. J. Appl. Polym. Sci. 2023, 140, e53558. [Google Scholar] [CrossRef]

- Rajabifar, N.; Arani, A.J. A new nanocomposite based on polylactic acid/butadiene rubber/clay: Morphology development and mechanical properties. J. Appl. Polym. Sci. 2024, 141, e54961. [Google Scholar] [CrossRef]

- Taib, N.A.A.B.; Rahman, M.R.; Huda, D.; Kuok, K.K.; Hamdan, S.; Bakri, M.K.B.; Julaihi, M.R.M.B.; Khan, A. A review on poly lactic acid (PLA) as a biodegradable polymer. Polym. Bull. 2023, 80, 1179–1213. [Google Scholar] [CrossRef]

- Li, X.; Lin, Y.; Liu, M.; Meng, L.; Li, C. A review of research and application of polylactic acid composites. J. Appl. Polym. Sci. 2023, 140, e53477. [Google Scholar] [CrossRef]

- Wu, Y.; Gao, X.; Wu, J.; Zhou, T.; Nguyen, T.T.; Wang, Y. Biodegradable Polylactic Acid and Its Composites: Characteristics, Processing, and Sustainable Applications in Sports. Polymers 2023, 15, 3096. [Google Scholar] [CrossRef]

- Oliveira, A.C.S.; Borges, S.V. Poli (Ácido Lático) Aplicado para Embalagens de Alimentos: Uma Revisão. REMAP 2020, 15, 1–10. [Google Scholar]

- Velghe, I.; Buffel, B.; Vandegisnste, V.; Thielemans, W.; Desplentere, F. Review on the Degradation of Poly(lactic acid) during Melt Processing. Polymers 2023, 15, 2047. [Google Scholar] [CrossRef]

- Luna, C.B.B.; Ferreira, E.S.B.; Nascimento, E.P.; Silva, A.L.; Albuquerque, A.K.C.; Wellen, R.M.R.; Araújo, E.M. Tuning the mechanical and thermomechanical properties through the combined effect of crosslinking and annealing in poly(lactic acid)/acrylonitrile-EPDM-styrene blends. J. Appl. Polym. Sci. 2024, 141, e55446. [Google Scholar] [CrossRef]

- Rosli, N.A.; Chen, R.S.; Dufresne, A.; Ahmad, I.; Ahmad, S.; Shahdan, D.; Shamene, B. Biobased rubber toughened poly(lactic acid) blend for sustainable packaging films: The role of optical purity of poly(lactic acid). J. Appl. Polym. Sci. 2024, 141, e56113. [Google Scholar] [CrossRef]

- Long, Y.; Li, R.; LI, H.; Dong, X.; Xing, Q. Enhancing mechanical and shape memory properties of polylactide/polyamide elastomer blends via reactive blending with a chain extender. J. Appl. Polym. Sci. 2024, 141, e55229. [Google Scholar] [CrossRef]

- Li, T.; Li, T.X.; Zhao, D.F.; Xie, Y.H.; Feng, D.; Wu, F.; Xie, D.; Wang, C.; Liu, Y.; Mei, Y. Toughness enhancement of polylactide with low amounts of poly (butylene adipate-co-terephthalate) through in situ reactive compatibilization. J. Appl. Polym. Sci. 2024, 141, e55310. [Google Scholar] [CrossRef]

- Bruna, J.E.; Castillo, M.; Discatillo, C.L.; Shugulí, C.M.; Lira, M.; Guarda, A.; Mercado, F.J.R.; Galotto, M.J. Development of active biocomposite films based on poly(lactic acid) and wine by-product: Effect of grape pomace content and extrusion temperature. J. Appl. Polym. Sci. 2023, 140, e54425. [Google Scholar] [CrossRef]

- Sasaki, S.; Naito, K.; Uchidate, M. Development of polylactic acid-untreated bamboo filler composite and its chemical and mechanical Properties. J. Appl. Polym. Sci. 2024, 141, e55461. [Google Scholar] [CrossRef]

- Chaochanchaikul, K.; Nawarat, P.; Thongsang, S. Toughening Polylactic Acid with Epoxidized Natural Rubber via Altering the Dicumyl Peroxide Mixing Sequence. J. Polym. Environ. 2024, 33, 230–242. [Google Scholar] [CrossRef]

- Hao, Y.; Tian, H.; Chen, J.; Chen, Q.; Zhang, W.; Liu, W.; Liu, Y.; Chen, W.; Chen, W.; Zuo, Z.; et al. Roles of physical filling and chemical crosslinking on the physico-mechanical properties of polylactic acid. J. Appl. Polym. Sci. 2022, 139, e52808. [Google Scholar] [CrossRef]

- Zisopol, D.G.; Portoaca, A.I.; Tanase, M. Improving the Impact Resistance through Annealing in PLA 3D Printed Parts. Eng. Technol. Appl. Sci. Res. 2023, 13, 11768–11772. [Google Scholar] [CrossRef]

- Zennaki, A.; Zair, L.; Arabeche, K.; Benkraled, L.; Maschke, U.; Berrayah, A. Effect of annealing on thermal and dynamic mechanical properties of poly(lactic acid). J. Appl. Polym. Sci. 2022, 139, e53095. [Google Scholar] [CrossRef]

- Spineli, G.; Kotsilkova, R.; Ivanov, E.; Doycheva, I.P.; Menseidov, D.; Georgiev, V.; MAIO, R.D.; Silvestre, C. Effects of Filament Extrusion, 3D Printing and Hot-Pressing on Electrical and Tensile Properties of Poly(Lactic) Acid Composites Filled with Carbon Nanotubes and Graphene. Nanomaterials 2020, 10, 35. [Google Scholar] [CrossRef]

- Li, S.; Liao, X.; Xiao, W.; Jiang, Q.; Li, G. The improved foaming behavior of PLA caused by the enhanced rheology properties and crystallization behavior via synergistic effect of carbon nanotubes and graphene. J. Appl. Polym. Sci. 2022, 139, 51874. [Google Scholar] [CrossRef]

- Chakraborty, G.; Bhattacharjee, S.; Katiyar, V.; Pugazhenthi, G. Melt rheology analysis through experimental and constitutional mechanical models of exfoliated graphene based polylactic acid (PLA) nanocomposites. J. Polym. Res. 2023, 30, 10. [Google Scholar] [CrossRef]

- Silva, T.F.; Menezes, F.; Montagna, L.S.; Lemes, A.P.; Passador, F.R. Preparation and characterization of antistatic packaging for electronic components based on poly(lactic acid)/carbon black composites. J. Appl. Polym. Sci. 2019, 136, 47273. [Google Scholar] [CrossRef]

- Masiuchok, O.; Lurzhenko, M.; Kolisnyk, R.; Mamunya, Y.; Godzierz, M.; Demcenko, V.; Yermolenko, D.; Shadrin, A. Polylactide/Carbon Black Segregated Composites for 3D Printing of Conductive Products. Polymers 2022, 14, 4022. [Google Scholar] [CrossRef]

- Maheswaran, R.; Shanmugavel, B.P. A Critical Review of the Role of Carbon Nanotubes in the Progress of Next-Generation Electronic Applications. J. Electron. Mater. 2022, 51, 2786–2800. [Google Scholar] [CrossRef]

- Lopes, M.C.; Trigueiro, J.P.C.; Castro, V.G.; Lavall, R.S.; Silva, G.G. Optimization of carbon nanotubes dispersion process in thermoset polyurethane. Polímeros 2016, 26, 81–91. [Google Scholar] [CrossRef]

- Shang, M.; Gao, Z.; Cheng, H.; Wu, C.; Shentu, B. Relationship between microstructure evolution and properties enhancement of carbon nanotubes-filled polybutylene terephthalate/polypropylene blends induced by thermal annealing. J. Appl. Polym. Sci. 2022, 139, 51689. [Google Scholar] [CrossRef]

- Bortoli, L.S.; Farias, R.; Mezalira, D.Z.; Schabbach, L.M.; Fredel, M.C. Functionalized carbon nanotubes for 3D-printed PLA-nanocomposites: Effects on thermal and mechanical properties. Mater. Commun. 2022, 31, 103402. [Google Scholar] [CrossRef]

- Yakdoumi, F.Z.; Hamou, A.S.H.; Rahoui, N.; Rahman, M.M.; Abetz, V. Polylactic acid nanocomposites containing functionalized multiwalled carbon nanotubes as antimicrobial packaging materials. Int. J. Biol. Macromol. 2022, 213, 55–69. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, C.; Xin, Z.; Luo, Y.; Wang, B.; Feng, X.; Mao, Z.; Sui, X. Poly(lactic acid)/carbon nanotube composites with enhanced electrical conductivity via a two-step dispersion strategy. Compos. Commun. 2022, 30, 101087. [Google Scholar] [CrossRef]

- Younus, M.M.; Naguib, H.M.; Fekry, M.; Elsawy, M.A. Pushing the limits of PLA by exploring the power of MWCNTs in enhancing thermal, mechanical properties, and weathering resistance. Sci. Rep. 2023, 13, 16588. [Google Scholar] [CrossRef] [PubMed]

- Rivera, S.L.; Pernas, A.A.; Permuy, J.C.B.; Gosset, A.; Abad, M.J. Enhancement of 3D Printability by FDM and Electrical Conductivity of PLA/MWCNT Filaments Using Lignin as Bio-Dispersant. Polymers 2023, 15, 999. [Google Scholar] [CrossRef] [PubMed]

- Taweel, S.H.E.; Fathy, R. Synergistic Effects of Multi-Wall Carbon Nanotubes and Polycaprolactone on the Thermal and Mechanical Properties of Polylactic Acid. J. Macromol. Sci. Part B 2022, 61, 719–740. [Google Scholar] [CrossRef]

- Kaczor, D.; Bajer, K.; Kaczor, A.R.; Domek, G.; Madajski, P.; Szroeder, P. The Influence of Multiple Extrusions on the Properties of High Filled Polylactide/Multiwall Carbon Nanotube Composites. Materials 2022, 15, 8958. [Google Scholar] [CrossRef] [PubMed]

- Liesenfeld, J.; Jablonski, J.J.; Silva, J.R.F.; Buenos, A.A.; Scheuer, C.J. Impact of annealing on the characteristics of 3D-printed graphene-reinforced PLA composite. J. Manuf. Process. 2024, 128, 133–157. [Google Scholar] [CrossRef]

- Mi, D.; Zhao, Z.; Bai, H. Improved Yield and Electrical Properties of Poly(Lactic Acid)/Carbon Nanotube Composites by Shear and Anneal. Materials 2023, 16, 4012. [Google Scholar] [CrossRef]

- Hui, I.; Pasquier, E.; Solberg, A.; Agrenius, K.; Hakansson, J.; Carrasco, G.C. Biocomposites containing poly(lactic acid) and chitosan for 3D printing—Assessment of mechanical, antibacterial and in vitro biodegradability properties. J. Mech. Behav. Biomed. Mater. 2023, 147, 106136. [Google Scholar] [CrossRef]

- Silva, P.T.V.; Luna, C.B.B.; Filho, E.A.S.; Nascimento, E.P.; Araújo, E.M. Tailoring polyamide 6 to exhibit super-tough behavior and high thermomechanical stability: The role of AES and EPDM-MA hybridization. J. Appl. Polym. Sci. 2023, 140, e54470. [Google Scholar] [CrossRef]

- Soares, E.P. Determinação Experimental e Simulação das Curvas de Distribuição de Tempo de Residência no Processo de Extrusão de Polímeros. Ph.D. Thesis, Universidade Federal de Campina Grande, Campina Grande, Brazil, 2016; pp. 1–164. Available online: http://dspace.sti.ufcg.edu.br:8080/jspui/handle/riufcg/1045 (accessed on 3 January 2025).

- Ferreira, E.S.B.; Luna, C.B.B.; Siqueira, D.D.; Araújo, E.M.; França, D.C.; Wellen, R.M.R. Annealing Effect on Pla/Eva Blends Performance. J. Polym. Environ. 2022, 30, 541–554. [Google Scholar] [CrossRef]

- Wang, S.; Capoen, L.; D’hooge, D.R.; Cardon, L. Can the melt flow index be used to predict the success of fused deposition modelling of commercial poly(lactic acid) filaments into 3D printed materials? Plast. Rubber Compos. Macromol. Eng. 2017, 47, 9–16. [Google Scholar] [CrossRef]

- Correia, C.; Gomes, T.E.P.; Gonçalves, I.; Neto, V. Reprocessability of PLA through Chain Extension for Fused Filament Fabrication. J. Manuf. Mater. Process. 2022, 6, 26. [Google Scholar] [CrossRef]

- Hernández, T.R.; Ortíz, J.R.R.; López, M.E.G.; Campo, A.S.M.D.; Núnez, R.G.; Rodrigue, D.; Fonseca, A.A.P. Mechanical recycling of PLA: Effect of weathering, extrusion cycles, and chain extender. J. Appl. Polym. Sci. 2023, 140, e53759. [Google Scholar] [CrossRef]

- Lee, S.H.; Kim, M.W.; Kim, S.H.; Youn, J.R. Rheological and electrical properties of polypropylene/MWCNT composites prepared with MWCNT masterbatch chips. Eur. Polym. J. 2008, 44, 1620–1630. [Google Scholar] [CrossRef]

- Stanciu, N.V.; Stan, F.; Sandu, I.L.; Fetecau, C.; Turcanu, A.M. Thermal, Rheological, Mechanical, and Electrical Properties of Polypropylene/Multi-Walled Carbon Nanotube Nanocomposites. Polymers 2021, 13, 187. [Google Scholar] [CrossRef]

- Barbosa, V.C.S.; Sousa, A.M.F.; Silva, A.L.N. Influence of processing parameters on mechanical and thermal behavior of PLA/PBAT blend. Polímeros 2022, 32, e2022033. [Google Scholar] [CrossRef]

- Morales, Y.V.; Ballesteros, L.D.C.M.; Ozuna, L.E.R.; Nunez, Y.Y.M.; Hernández, J.F.; Encinas, J.C.E.; Santana, T.J.M. Processing and characterization of biocomposites based on polylactic acid and coconut by-products. Polímeros 2024, 34, e20240020. [Google Scholar] [CrossRef]

- Carrasco, F.; Pages, P.; Pérez, J.G.; Santana, O.O.; Maspoch, M.L. Processing of poly(lactic acid): Characterization of chemical structure, thermal stability and mechanical properties. Polym. Degrad. Stab. 2010, 95, 116–125. [Google Scholar] [CrossRef]

- Adrzejewski, J.; Das, S.; Lipik, V.; Mohanty, A.K.; Misra, M.; You, X.; Tan, L.P.; Chang, B.P. The Development of Poly(lactic acid) (PLA)-Based Blends and Modification Strategies: Methods of Improving Key Properties towards Technical Applications—Review. Materials 2024, 17, 4556. [Google Scholar] [CrossRef]

- Choi, K.M.; Choi, M.C.; Han, D.H.; Park, T.S.; Ha, C.S. Plasticization of poly(lactic acid) (PLA) through chemical grafting of poly(ethylene glycol) (PEG) via in situ reactive blending. Eur. Polym. J. 2013, 49, 2356–2364. [Google Scholar] [CrossRef]

- Guo, X.; Luo, C.; Fang, M.; Sun, J.; Chen, M. Effects of self-assembled nucleating agent on the crystallization behavior, thermal properties, and mechanical properties of polylactic acid. J. Appl. Polym. Sci. 2023, 140, e54222. [Google Scholar] [CrossRef]

- Lima, J.C.C. Blends of Poly(Lactic Acid) with Styrene/Ethylene-Butylene/Styrene Triblock Copolymer. Master’s Dissertation, Federal University of Campina Grande, Campina Grande, Brazil, 2016; pp. 1–125. Available online: http://dspace.sti.ufcg.edu.br:8080/jspui/handle/riufcg/1030 (accessed on 3 January 2025).

- Brito, G.F.; Agrawal, P.; Araújo, E.M.; Mélo, T.J.A. Toughening of Polylactide by Melt Blending with an (Ethylene/Methyl Acrylate/Glycidyl Methacrylate) Terpolymer. Polímeros 2012, 22, 164–169. [Google Scholar] [CrossRef]

- Novais, R.M.; Simon, F.; Potschke, P.; Villmow, T.; Covas, J.A.; Paiva, M.C. Poly(lactic acid) composites with poly(lactic acid)-modified carbon nanotubes. J. Polym. Sci. Part A Polym. Chem. 2013, 51, 3740–3750. [Google Scholar] [CrossRef]

- Gong, S.; Zhu, Z.H.; Li, J.; Meguid, S.A. Modeling and characterization of carbon nanotube agglomeration effect on electrical conductivity of carbon nanotube polymer composites. J. Appl. Phys. 2014, 116, 194306. [Google Scholar] [CrossRef]

- Yoon, J.T.; Jeong, Y.G.; Lee, S.C.; Min, B.G. Influences of poly(lactic acid)-grafted carbon nanotube on thermal, mechanical, and electrical properties of poly(lactic acid). Polym. Adv. Technol. 2009, 20, 631–638. [Google Scholar] [CrossRef]

- Ni, J.; Yu, K.; Zhou, H.; Mi, J.; Chen, S.; Wang, V. Morphological evolution of PLA foam from microcellular to nanocellular induced by cold crystallization assisted by supercritical CO2. J. Supercrit. Fluids 2020, 158, 104719. [Google Scholar] [CrossRef]

- Yadav, R.; Tirumali, M.; Wang, X.; Naebe, M.; Kandasubramanian, B. Polymer composite for antistatic application in aerospace. Def. Technol. 2020, 16, 107–118. [Google Scholar] [CrossRef]

- Silva, T.F.; Menezes, F.; Montagna, L.S.; Lemes, A.P.; Passador, F.R. Synergistic effect of adding lignin and carbon black in poly(lactic acid). Polímeros 2020, 30, e2020002. [Google Scholar] [CrossRef]

- Vieira, L.S.; Anjos, E.G.R.; Verginio, G.E.A.; Oyama, I.C.; Braga, N.F.; Silva, T.F.; Montagna, L.S.; Passador, F.R. A review concerning the main factors that interfere in the electrical percolation threshold content of polymeric antistatic packaging with carbon fillers as antistatic agente. Nanoselect 2022, 3, 248–260. [Google Scholar] [CrossRef]

- Weindenfellr, B.; Rode, H.; Weindenfellr, L.; Weindenfellr, K. Crystallinity, thermal diffusivity, and electrical conductivity of carbon black filled polyamide 46. J. Appl. Polym. Sci. 2020, 137, 48882. [Google Scholar] [CrossRef]

- Allahverdiyeva, K.V.; Kakhramanov, N.T.; Martynova, G.S.; Mustafayeva, F.A.; Gahramanli, Y.N.; Habibova, A.G.; Bafadarova, H.K.; Suleymanova, E.I.; Gurbanova, R.V. Structural features and mechanism of crystallization of nanocomposites based on maleinated high density polyethylene and carbon black. Heliyon 2023, 9, e14829. [Google Scholar] [CrossRef]

- Wang, J.; Kazemi, Y.; Wang, S.; Hamidinejad, M.; Mahmud, M.B.; Potschke, P.; Park, C.B. Enhancing the electrical conductivity of PP/CNT nanocomposites through crystal-induced volume exclusion effect with a slow cooling rate. Compos. Part B Eng. 2020, 183, 107663. [Google Scholar] [CrossRef]

- Ribeiro, B.; Botelho, E.C.; Costa, M.L. Electrical and Thermal study of carbon nanotubes reinforced poly (phenylene sulfide) nanostructured composites. Polímeros 2015, 25, 94–100. [Google Scholar] [CrossRef]

- Pascual, A.M.D.; Naffakh, M.; Marco, C.; Ellis, G. Mechanical and electrical properties of carbon nanotube/poly(phenylene sulphide) composites incorporating polyetherimide and inorganic fullerene-like nanoparticles. Compos. Part A Appl. Sci. Manuf. 2012, 43, 603–612. [Google Scholar] [CrossRef]

- Moniruzzaman, M.; Winey, K.I. Polymer Nanocomposites Containing Carbon Nanotubes. Macromolecules 2006, 39, 5194–5205. [Google Scholar] [CrossRef]

- Yang, Y.; Gupta, M.C.; Dudley, K.L.; Lawrence, R.W. Novel Carbon Nanotube−Polystyrene Foam Composites for Electromagnetic Interference Shielding. Nano Lett. 2005, 5, 2131–2134. [Google Scholar] [CrossRef]

- Ghamdi, A.A.A.; Ghamdi, A.A.A.; Turki, Y.A.; Yakuphanoglu, F.; Tantawy, F.E. Electromagnetic shielding properties of graphene/acrylonitrile butadiene rubber nanocomposites for portable and flexible electronic devices. Compos. Part B Eng. 2016, 88, 212–219. [Google Scholar] [CrossRef]

- Chung, D.D.L. Electromagnetic interference shielding effectiveness of carbon materials. Carbon 2001, 39, 279–285. [Google Scholar] [CrossRef]

- Zhao, T.; Yu, J.; Zhang, X.; Han, W.; Zhang, S.; Pan, H.; Zhang, Q.; Yu, X.; Bian, J.; Zhang, H. Thermal, crystallization, and mechanical properties of polylactic acid (PLA)/poly(butylene succinate) (PBS) blends. Polym. Bull. 2024, 81, 2481–2504. [Google Scholar] [CrossRef]

- Rajabifar, N.; Rostami, A. Investigation of the Effect of Hybrid Nanofiller on the Mechanical Performance and Surface Properties of Bio-Based Polylactic Acid/Polyolefin Elastomer (PLA/POE) Blend. Polymers 2023, 15, 2708. [Google Scholar] [CrossRef]

- Park, S.D.; Todo, M.; Arakawa, K. Effect of annealing on the fracture toughness of poly(lactic acid). J. Mater. Sci. 2004, 39, 1113–1116. [Google Scholar] [CrossRef]

- Oyama, H.T. Super-tough poly(lactic acid) materials: Reactive blending with ethylene copolymer. Polymer 2009, 50, 747–751. [Google Scholar] [CrossRef]

- Yu, L.; Liu, H.; Xie, F.; Chen, L.; Li, X. Effect of annealing and orientation on microstructures and mechanical properties of polylactic acid. Polym. Eng. Sci. 2008, 48, 634–641. [Google Scholar] [CrossRef]

- Nascimento, L.; Perez, J.G.; Santana, O.O.; Velasco, J.L.; Maspoch, M.L.; Urquiza, E.F. Effect of the Recycling and Annealing on the Mechanical and Fracture Properties of Poly(Lactic Acid). J. Polym. Environ. 2010, 18, 654–660. [Google Scholar] [CrossRef]

- Wang, L.; Gramlich, W.M.; Gardner, D.J. Improving the impact strength of Poly(lactic acid) (PLA) in fused layer modeling (FLM). Polymer 2017, 114, 242–248. [Google Scholar] [CrossRef]

- Yang, G.; Su, J.; Su, R.; Zhang, Q.; Fu, Q.; Na, B. Toughening of Poly(L-Lactic Acid) by Annealing: The Effect of Crystal Morphologies and Modifications. J. Macromol. Sci. Part B 2010, 51, 184–196. [Google Scholar] [CrossRef]

- Aurrekoetxea, J.; Sarrionandia, M.A.; Urrutibeascoa, I.; Maspoch, M.L. Effects of recycling on the microstructure and the mechanical properties of isotactic polypropylene. J. Mater. Sci. 2001, 36, 2607–2613. [Google Scholar] [CrossRef]

- Ferri, J.M.; Aldas, M.; Rayon, E.; Samper, M.D.; Pérez, A.A.L. The Influence of Different Sustainable Silk-Based Fillers on the Thermal and Mechanical Properties of Polylactic Acid Composites. Polymers 2022, 14, 5016. [Google Scholar] [CrossRef]

- Norazlina, H.; Kamal, Y. Elucidating the plasticizing effect on mechanical and thermal properties of poly(lactic acid)/carbon nanotubes nanocomposites. Polym. Bull. 2021, 78, 6911–6933. [Google Scholar] [CrossRef]

- Péter, T.; Litauski, K.; Kmetty, A. Improving the heat deflection temperature of poly(lactic acid) foams by annealing. Polym. Degrad. Stab. 2021, 190, 109646. [Google Scholar] [CrossRef]

- Perego, G.; Cella, G.D. Mechanical Properties. In Poly(Lactic Acid): Synthesis, Structures, Properties, Processing, and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar] [CrossRef]

- Pereira, R.B.; Moarles, A.R. Study of Mechanical and Thermal Behavior of PLA Modified with Nucleating Additive and Impact Modifier. Polímeros 2014, 24, 198–202. [Google Scholar] [CrossRef]

- Koca, N.; Aversa, C.; Barletta, M. Recycling of poly(lactic acid)/poly(butylene succinate) (PLA/PBS) blends with high amounts of secondary raw material. J. Appl. Polym. Sci. 2023, 140, e54659. [Google Scholar] [CrossRef]

- Zhou, S.; Guo, M.; Jin, Y.; Sun, J.; Tian, H.; Hu, J. Synergistic toughening and reinforcement of poly(lactic acid) with epoxy-terminated hyperbranched polymers. J. Appl. Polym. Sci. 2024, 141, e54740. [Google Scholar] [CrossRef]

- Issabayeva, Z.; Shishkovsky, I. Prediction of The Mechanical Behavior of Polylactic Acid Parts with Shape Memory Effect Fabricated by FDM. Polymers 2023, 15, 1162. [Google Scholar] [CrossRef] [PubMed]

| Samples | Xc (%) | 2θ (°) | d (Å) 1 | L (nm) 2 |

|---|---|---|---|---|

| PLAT | 46.0 | 16.98 | 5.24 | 20.9 |

| PLAT/MWCNT (1 phr) | 53.9 | 16.90 | 5.26 | 25.8 |

| PLAT/MWCNT (2 phr) | 63.7 | 16.88 | 5.27 | 26.1 |

| PLAT/MWCNT (3 phr) | 51.0 | 16.98 | 5.24 | 29.4 |

| PLAT/MWCNT (4 phr) | 47.2 | 17.06 | 5.21 | 26.9 |

| Electrical Conductivity (S/cm) | ||

|---|---|---|

| Samples | Without Annealing | With Annealing |

| PLA | (8.13 ± 0.05) × 10−11 | (8.54 ± 0.04) × 10−11 |

| PLA/MWCNT (1 phr) | (2.85 ± 0.02) × 10−7 | (2.17 ± 0.02) × 10−7 |

| PLA/MWCNT (2 phr) | (3.07 ± 0.03) × 10−6 | (2.65 ± 0.04) × 10−6 |

| PLA/MWCNT (3 phr) | (7.46 ± 0.03) × 10−6 | (8.20 ± 0.07) × 10−6 |

| PLA/MWCNT (4 phr) | (7.14 ± 0.06) × 10−6 | (8.26 ± 0.06) × 10−6 |

| Samples | Tg (°C) | Tm (°C) | Xc (%) |

|---|---|---|---|

| PLA | 62.1 | 175.4 | 9.7 |

| PLAT | 65.1 | 175.2 | 50.8 |

| PLA/MWCNT (1 phr) | 60.9 | 176.2 | 8.6 |

| PLAT/MWCNT (1 phr) | 66.4 | 175.3 | 54.5 |

| PLA/MWCNT (2 phr) | 58.5 | 175.8 | 8.4 |

| PLAT/MWCNT (2 phr) | 66.7 | 175.1 | 55.2 |

| PLA/MWCNT (3 phr) | 58.6 | 176.2 | 8.9 |

| PLAT/MWCNT (3 phr) | 66.8 | 175.3 | 54.1 |

| PLA/MWCNT (4 phr) | 58.4 | 174.9 | 8.7 |

| PLAT/MWCNT (4 phr) | 65.8 | 175.0 | 53.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

da Silva, F.U.; Luna, C.B.B.; da Silva, F.S.; Barreto, J.V.M.; Schmitz, D.P.; Soares, B.G.; Wellen, R.M.R.; Araújo, E.M. Exploring the Effect of Annealing on PLA/Carbon Nanotube Nanocomposites: In Search of Efficient PLA/MWCNT Nanocomposites for Electromagnetic Shielding. Polymers 2025, 17, 246. https://doi.org/10.3390/polym17020246

da Silva FU, Luna CBB, da Silva FS, Barreto JVM, Schmitz DP, Soares BG, Wellen RMR, Araújo EM. Exploring the Effect of Annealing on PLA/Carbon Nanotube Nanocomposites: In Search of Efficient PLA/MWCNT Nanocomposites for Electromagnetic Shielding. Polymers. 2025; 17(2):246. https://doi.org/10.3390/polym17020246

Chicago/Turabian Styleda Silva, Flávio Urbano, Carlos Bruno Barreto Luna, Fabiano Santana da Silva, José Vinícius Melo Barreto, Debora Pereira Schmitz, Bluma Guenther Soares, Renate Maria Ramos Wellen, and Edcleide Maria Araújo. 2025. "Exploring the Effect of Annealing on PLA/Carbon Nanotube Nanocomposites: In Search of Efficient PLA/MWCNT Nanocomposites for Electromagnetic Shielding" Polymers 17, no. 2: 246. https://doi.org/10.3390/polym17020246

APA Styleda Silva, F. U., Luna, C. B. B., da Silva, F. S., Barreto, J. V. M., Schmitz, D. P., Soares, B. G., Wellen, R. M. R., & Araújo, E. M. (2025). Exploring the Effect of Annealing on PLA/Carbon Nanotube Nanocomposites: In Search of Efficient PLA/MWCNT Nanocomposites for Electromagnetic Shielding. Polymers, 17(2), 246. https://doi.org/10.3390/polym17020246